Page 1

GERBER MAXX 2™

Owner’s Guide

Page 2

Page 3

Copyright Notice

COPYRIGHT 2002 Gerber Scientific Products, Inc. All Rights Reserved.

This document may not be reproduced by any means, in whole or in part, without written

permission of the copyright owner.

This document is furnished to support the GERBER MAXX 2 wide-format thermal printer. In

consideration of the furnishing of the information contained in this document, the party to

whom it is given assumes its custody and control and agrees to the following:

1 The information herein contained is given in confidence, and any part thereof shall not be

copied or reproduced without written consent of Gerber Scientific Products, Inc.

2 This document or the contents herein under no circumstances shall be used in the

manufacture or reproduction of the article shown and the delivery of this document shall not

constitute any right or license to do so.

Printed in USA

GSP and EDGE are registered trademarks of Gerber Scientific Products, Inc. GERBER MAXX, MAXX 2,

MAXX READY, OMEGA, ThermApprove, GerberTone, GerberColor Spectratone, ODYSSEY, FasTrack,

Gerber FastFacts, and Support First are trademarks of Gerber Scientific Products, Inc. Adobe PhotoShop

is a registered trademark of Adobe Systems Incorporated. Chemtronics and Ultrajet are registered

trademarks of Chemtronics, Inc. 3-IN-ONE and WD-40 are a registered trademarks of the WD-40

Company. CorelDRAW is a registered trademark of Corel Corporation. HPGL is a trademark of HewlettPackard Company. Microsoft is a registered trademark of Microsoft Corp. PANTONE and other

Pantone, Inc. trademarks are the property of Pantone, Inc. Windows is a registered trademark of

Microsoft Corp. in the U.S. and other countries.

Page 4

FCC Notice

Warning: Changes or modifications to this unit not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference

at his own expense.

1284-1994 Compliant cables must be used with this unit to ensure compliance with the Class A

FCC limits.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la class A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Page 5

Contents

Chapter 1: Introduction............................................................................................................. 1

In this manual .......................................................................................................................................... 1

Conventions ............................................................................................................................................. 1

Customer support ...................................................................................................................................2

Chapter 2: Getting to Know the GERBER MAXX 2............................................................... 3

Basic requirements .................................................................................................................................. 3

Environment and temperature importance...................................................................................... 3

Using MAXX READY material.............................................................................................................. 3

Vinyl care .............................................................................................................................................. 3

Vinyl storage......................................................................................................................................... 4

Overview of the MAXX 2....................................................................................................................... 5

The printer table ...................................................................................................................................... 6

The printhead carriage assembly.......................................................................................................... 6

Loading the material............................................................................................................................... 7

The foil cassettes...................................................................................................................................... 9

Loading the foil cassette......................................................................................................................... 9

Straightening wrinkles in foil ........................................................................................................... 11

Loading the cassettes in the MAXX 2................................................................................................. 11

Chapter 3: Understanding the MAXX 2 Control Panel ..................................................... 12

Control panel keys ................................................................................................................................12

MAXX 2 power up sequence ............................................................................................................... 14

Entering menu selections ..................................................................................................................... 14

Starting jobs............................................................................................................................................ 14

Run single mode................................................................................................................................. 14

Run continuous mode .......................................................................................................................15

Quick Start operation............................................................................................................................ 15

Stopping and restarting jobs................................................................................................................ 15

Pausing jobs and restarting a job ..................................................................................................... 16

Reprinting the last job........................................................................................................................... 16

Queuing jobs at the MAXX 2 control panel....................................................................................... 16

Displaying a list of jobs in the View Job Details ............................................................................ 16

Displaying detailed information about each queued job .............................................................17

Re-positioning a job in the queue..................................................................................................... 18

Deleting jobs from the queue............................................................................................................ 18

Adjusting the pull distance when slewing material......................................................................... 19

Updating the MAXX 2 firmware......................................................................................................... 19

Chapter 4: MAXX 2 Care and Cleaning.................................................................................21

Recommended MAXX 2 cleaning materials...................................................................................... 21

Daily cleaning procedures ................................................................................................................... 21

Cleaning the vinyl squeegees and magnet bars............................................................................. 22

Cleaning the edge sensor strip ......................................................................................................... 23

Cleaning the platen............................................................................................................................ 23

Inspecting and refilling the wiper box ............................................................................................ 24

Cleaning the ways, lead screw, and ball screws............................................................................ 24

Cleaning the material catching baskets........................................................................................... 24

The importance of cleaning the printhead......................................................................................... 25

Page 6

Automatic head cleaning .................................................................................................................. 27

Manually cleaning the printhead..................................................................................................... 27

Cleaning foil cassettes........................................................................................................................ 31

Chapter 5: Printing Jobs .......................................................................................................... 33

Setting up and sending the job............................................................................................................ 33

Determining the status of each bay..................................................................................................... 33

Reducing the recorded amount of foil in a cassette.......................................................................34

Printing the job ......................................................................................................................................34

Viewing foil and material information for the job......................................................................... 35

Printing test jobs.................................................................................................................................... 37

Chapter 6: Modifying MAXX 2 Print Settings......................................................................39

Printing the Pull Out or Pull Back Check prints ............................................................................... 39

Modifying the Darkness Adjust setting ............................................................................................. 40

Modifying the Seam Adjust setting .................................................................................................... 41

Chapter 7: Understanding Messages ................................................................................... 43

Status messages ..................................................................................................................................... 43

Error Messages ......................................................................................................................................46

Index ............................................................................................................................................50

Page 7

Chapter 1:

Introduction

Congratulations on your purchase of the GERBER MAXX 2 thermal printer. This wide-format

printer combines the reliability and superior printing ability of the revolutionary GERBER

EDGE with the utility of printing on 36" wide material.

In this manual

The following chapters introduce you to the MAXX 2, describe the printing process and

procedures, and show you how to maintain your printer for maximum quality output.

Getting to Know the GERBER MAXX 2 contains photographs and descriptions of the major

parts of the printer and provides instructions for loading vinyl and foil cassettes.

Understanding the MAXX 2 Control Panel describes the control panel, run modes, starting and

stopping jobs, the Job Queue, and updating the MAXX firmware.

MAXX 2 Care and Cleaning includes information on the proper cleaning of the MAXX 2, foil

cartridges, and materials. Extensive in-house and field-testing reveals cleanliness is an

important factor impacting printing quality.

Printing Jobs describes in a step-by-step sequence how to print jobs on the MAXX 2. This

chapter also includes a list of test jobs and their purpose.

Modifying MAXX 2 Print Settings explains Pull Check prints and details how to modify the

Print Darkness and Seam Adjust settings to achieve optimal print quality.

Understanding Messages lists display messages that may appear, describes what the messages

mean, and suggests actions in response.

Conventions

The following conventions are used in this addendum:

Tip: A tip contains valuable information that could make the task faster or easier.

Note: A note contains important information that could affect the successful completion of a

task.

CAUTION: A caution statement contains information which, if not observed, could

result in equipment damage.

WARNING: A warning statement contains information which, if not observed,

could result in personal injury.

Page 8

CHAPTER 1

2

Introduction

Customer support

If you have questions regarding using, maintaining, or troubleshooting the MAXX 2, please

contact your Gerber distributor, GSP Field Service for hardware questions, or Technical

Systems Support for software questions.

phone: 800-828-5406 for hardware, 860-644-6971 for software

fax: 860-648-8376

Additional sources of information are:

♦ Gerber FastFacts provides answers to technical and service questions. The telephone

♦ If you are a Support First member, use your toll-free assistance number (for more

e-mail: gspservice@gspinc.com (hardware) or gsptech@gspinc.com (software)

www.gspinc.com

number is 860-648-8040. FastFacts are also available on the web site under “Support.”

information about Support First, call 860-644-6971).

Page 9

Chapter 2:

Getting to Know the GERBER MAXX 2

The GERBER MAXX 2 is a sophisticated machine but is very easy to use. The following pages

introduce the printer and describe basic operation.

Basic requirements

The MAXX 2 is a network device. Your computer must have an Ethernet network card installed

to communicate with the printer. Gerber provides the proper network cables to connect your

computer with the MAXX 2 so that you are up and running without delay.

You must have OMEGA 1.56 or higher to print to a MAXX 2. However, you do not have to

specifically design a job for the MAXX 2.

3

We currently support the Gerber ODYSSEY plotter and the Gerber FasTrack 1300 plotter for

cutting MAXX 2 graphics.

Environment and temperature importance

The room temperature where the MAXX 2 is located should be 68°F to 78°F (20°C to 25.6°C)

with a relative humidity of 20% to 85%. Be sure to allow the equipment and materials to reach

and remain at room temperature for 24 hours before printing.

Using MAXX READY material

The MAXX prints only on GERBER MAXX READY materials. Gerber specially developed

GERBER MAXX READY materials for thermal printing and are the only materials

recommended for use with the MAXX. Gerber continues to qualify more substrates and foils on

an on-going basis. For a list of currently qualified MAXX READY materials see www.gspinc.com.

Gerber recommends printing on only 36" MAXX READY material. Do not use punched vinyl,

material less than 36" in width, or any other material that is not MAXX-qualified. Residue from

the punched vinyl adhesive can cause serious problems that will require service.

Vinyl care

CAUTION: Never clean vinyl with isopropyl alcohol, only clean the vinyl with

distilled water.

The best way to keep the vinyl clean is to always use the material catching baskets. If the vinyl

gets dirty (often the static charge on the vinyl attracts dirt from the rug or floor), the printed job

may show imperfections such as voids, hair lines, or small unprinted areas. Wipe the vinyl with

a clean, lint-free cloth moistened with distilled water. Allow the vinyl to dry completely before

Page 10

CHAPTER 2

g

4

Getting to Know the GERBER MAXX 2

printing as water or moisture can damage the printhead. Before loading vinyl into the MAXX 2,

wipe the ends of the roll with a tack cloth to remove any dirt or dust.

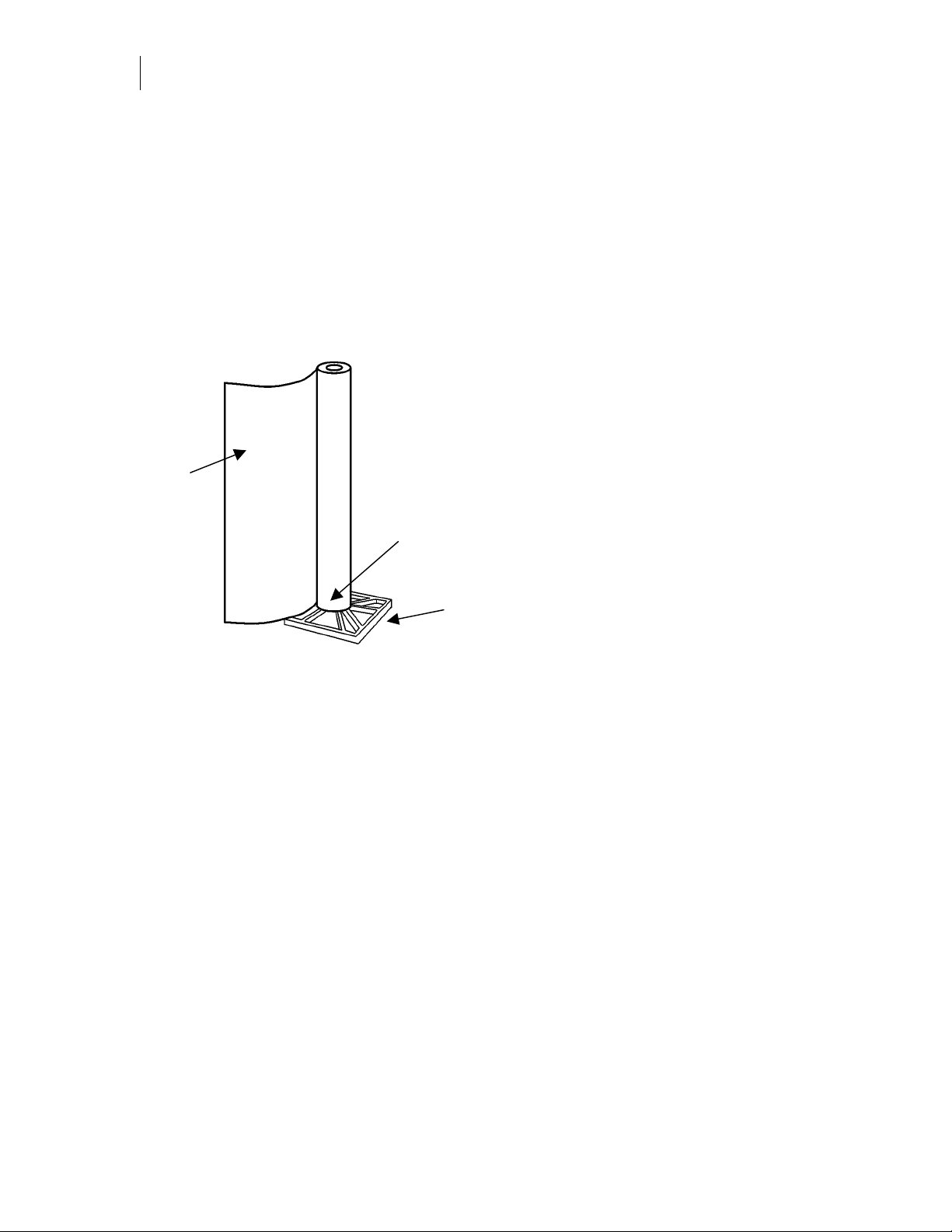

Vinyl storage

When not in use, vinyl should be stored in the original plastic bag to protect it from dust and

dirt. Save the original box for long-term storage of vinyl rolls. Never store the vinyl lying down

or in the MAXX 2 material catching baskets, which can leave impressions on the surface of the

vinyl. Store the vinyl standing on the end of the roll that will be opposite the edge sensors at the

left side of the MAXX 2. Standing the roll on the end that will be used to align the vinyl can

cause print quality problems. To protect the material from the floor, stand the roll on the plastic

plug included with the original packaging.

Backing

sheet side

of vinyl

Stand the roll on this end to avoid

damaging the end of the roll that the

MAXX sensor uses to ali

Stand the roll on the plastic plug

included with the original packaging.

n the vinyl.

Page 11

Overview of the MAXX 2

Rack cover

Control

panel

Base

5

Cassettes in rack

Supply roll

The MAXX 2 base houses the control circuitry for the printer. In addition to these electronic

components, a vacuum pump is mounted in the base. The pump comes on automatically at the

start of the printing sequence to hold the material firmly against the platen.

The material supply roll is mounted on the front of the base. A loop of material is automatically

unrolled into the material catching basket to reduce drag on the material advance system

(magnet bars) during printing.

Up to six foil cassettes can be mounted in the cassette rack. The foil can be loaded and unloaded

in the cassettes as required.

The control panel is the interface between the operator and the printer. A message display

provides information and prompts, and the keypad controls the printer functions.

Page 12

CHAPTER 2

6

Getting to Know the GERBER MAXX 2

The printer table

Foil in

cassette

Magnet bars

Platen

Material is pulled through the printer by the magnet bars. The vacuum draws through the holes

in the platen and holds the material flat during printing. The cassette rack stores up to six foil

cassettes. Each cassette is stored in an individual cassette bay.

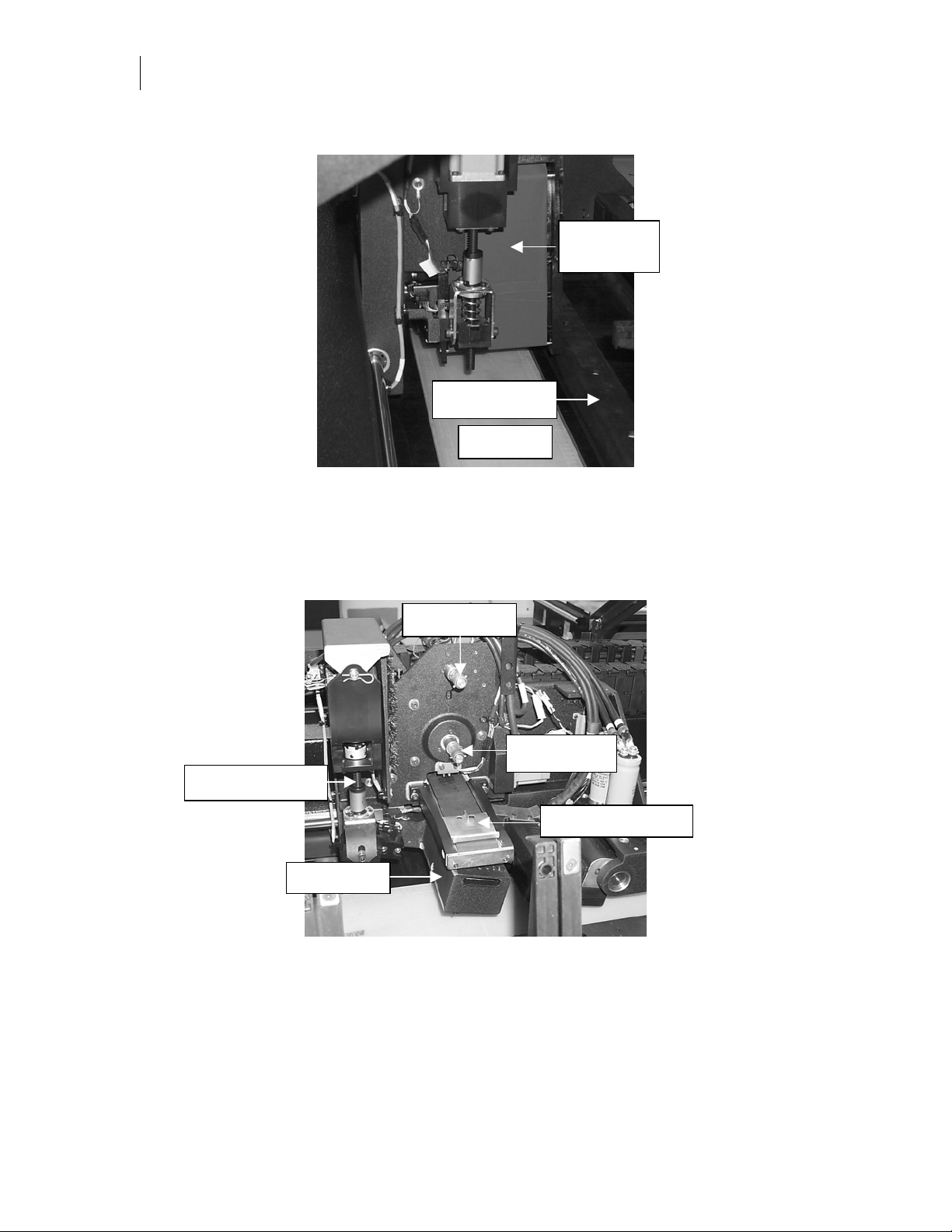

The printhead carriage assembly

Take-up pin

Supply pin

Z axis lead screw

Cassette changer

Printhead

During printing, the supply and take-up cassette pins pull the foil across the printhead. The

printhead is lowered by the Z axis lead screw and motor to press the printhead against the foil

and material when printing. The automatic cassette changer loads and unloads foil cassettes as

required by the job design.

Page 13

Loading the material

Alignment

line

Material tray

7

Front vinyl

squeegee

Left roll hub

and motor

Right roll hub

The rolls of MAXX READY material are mounted on the roll hubs at the front of the printer.

There is a material loading path illustration on the left material roll hub for guidance in loading

material. Under the roll hubs are roll rests to aid in loading heavy rolls of material.

The left roll hub is stationary, while the right roll hub slides across the front of the base to

accommodate the slight variations in width of the supply roll. The left roll hub is motor-driven

to provide a loop of material, which reduces drag while the material advances through the

printer. When the loop is the correct size, the motor is off.

Before loading the material, lift the material tray up and lock it in the horizontal position. On

the left side of the tray is an alignment line. There is another alignment line on the back of the

table where the vinyl exits. When you load the material, align the left side of the material with

both of these lines before clamping the material with the magnet bars.

Page 14

CHAPTER 2

8

Getting to Know the GERBER MAXX 2

To load the material

1

Raise the material tray.

2

Move the material catching basket away from the front of the base.

3

Slide the right roll hub so that it is the same approximate distance from the left roll

hub as the material width.

4

Unroll some material, then put the roll of material on the left and right roll rests so that

the unrolled material is near the front of the base and the substrate or carrier side is

facing away from the base and toward you.

5

Put the left end of the material core tube on the left roll hub, then raise the right end of

the roll and slide the right roll hub into the right end of the material core tube. Use the

thumbscrew on the right roll hub to lock it into position.

6

Roll the material catching basket so that it locks in place in the basket clips in front of

the base.

7

Unroll several feet of material behind the vinyl flag and into the material catching

basket.

8

Turn on the printer. The message display is

initializing sequence is complete and the display is

Initializing

Ready for Print job

. Do not touch any keys until the

, then press LOAD

VINYL on the control panel.

CAUTION: When performing the next step, be certain that the vinyl slides between

the magnet bars and on top of each bar’s keeper plate. If the vinyl goes under the

keeper plate, it will get damaged. In order to keep the mag bars clean, make certain

that the leading edge of the vinyl is clean cut and that there is no residual adhesive.

9

Feed the material across the material tray, under the front vinyl squeegee, through the

two magnet bars, under the rear vinyl squeegee, and out of the back of the table. The

material should extend approximately 4" beyond the rear vinyl squeegee.

Tip: When sliding the material on the material tray, it may help to tilt the material slightly to

get one corner under the front vinyl squeegee and magnet bar as you push the material into

the printer.

10

Align the material with the alignment lines on the front material tray and on the back

of the table. Careful alignment of the vinyl at the front and back of the MAXX shortens

the automatic alignment sequence.

11

Press LOAD VINYL on the control panel to clamp the material with the vinyl

squeegees and magnet bars.

12

Lower the material tray.

Page 15

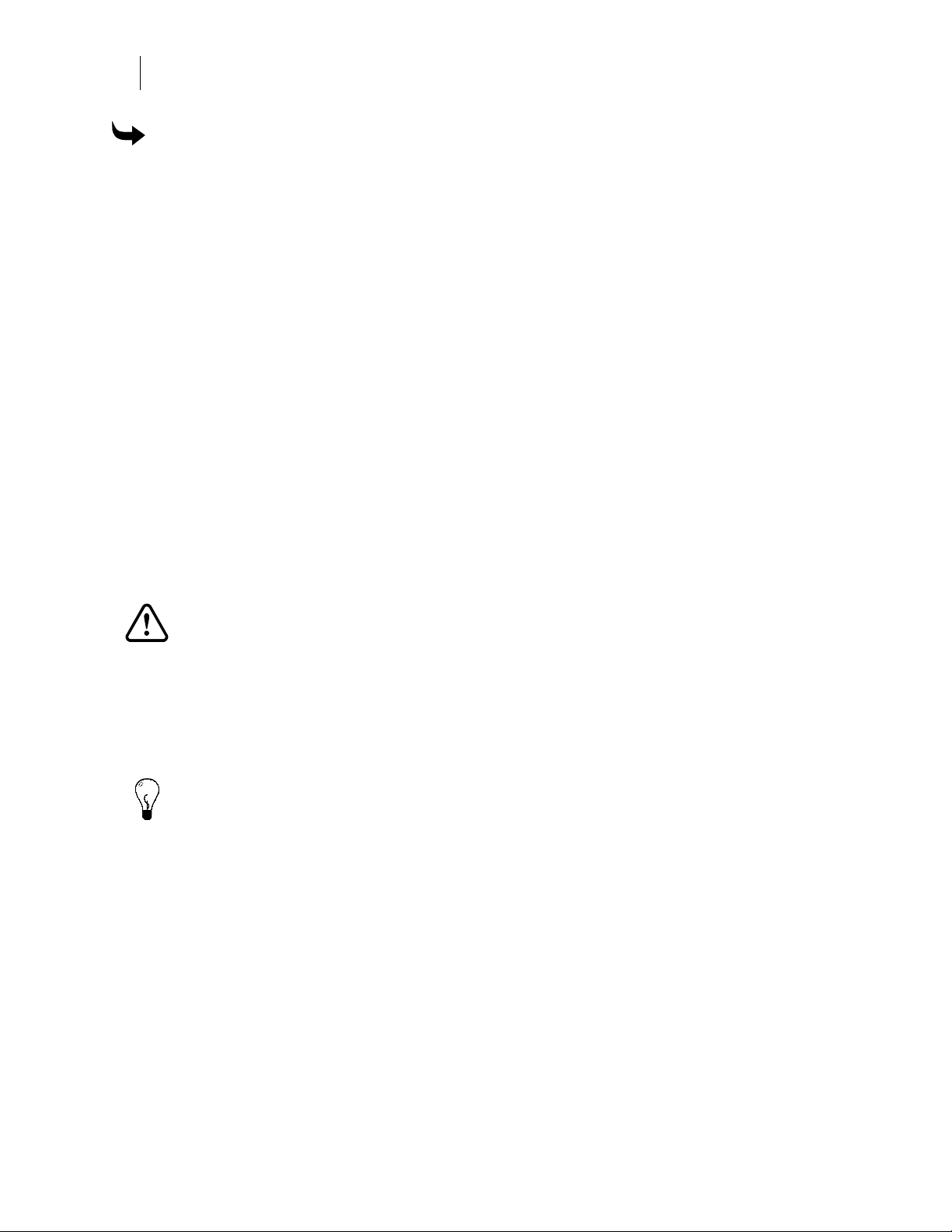

The foil cassettes

y

p

Bay sto

Cassette ba

9

Cassette

Each foil cassette contains a continuous ribbon of foil. When the supply roll is low or empty, the

control panel display prompts you to load more foil in the cassette. The cassettes are “smart”

cassettes. A cassette reader button inside the supply roll core monitors the amount of foil used,

the amount remaining on the supply roll, and the color of the foil. Metal contact strips on the

bottom of the cassette touch contact strips on the bay stops to transmit this information to the

MAXX 2. The control panel also displays which foil cassette is loaded in each bay. The

printhead carriage assembly automatically loads the foil cassettes and lowers the printhead to

the material for printing.

Loading the foil cassette

The foil in the package is on two rolls − a supply roll (the larger roll) and a take-up roll (the

smaller roll). There is a clear stiff leader at the start of the supply roll to make loading the foil

easier. The supply roll also contains a cassette reader button that monitors the amount of foil

used, the amount remaining on the roll, and the foil color. This information is sent to the control

panel for display and is also used to identify which cassette bay contains the proper foil color

for the job.

CAUTION: The foil is fragile. When you handle the supply roll, be very careful

that it does not “telescope” (the inside part of the roll sliding out of the outer part of

the roll). If this happens, the foil may be damaged, it will be difficult to load, and it

may cause wrinkling or other printing problems. Do not touch the unused foil.

Fingerprints on the foil will create areas on the foil that will not print on the

material.

Page 16

CHAPTER 2

10

Getting to Know the GERBER MAXX 2

When loading the cassette, load the supply roll first. The memory reader button goes on the

front end of the roll (nearest the outside of the cassette). The cover has a label showing you the

foil path.

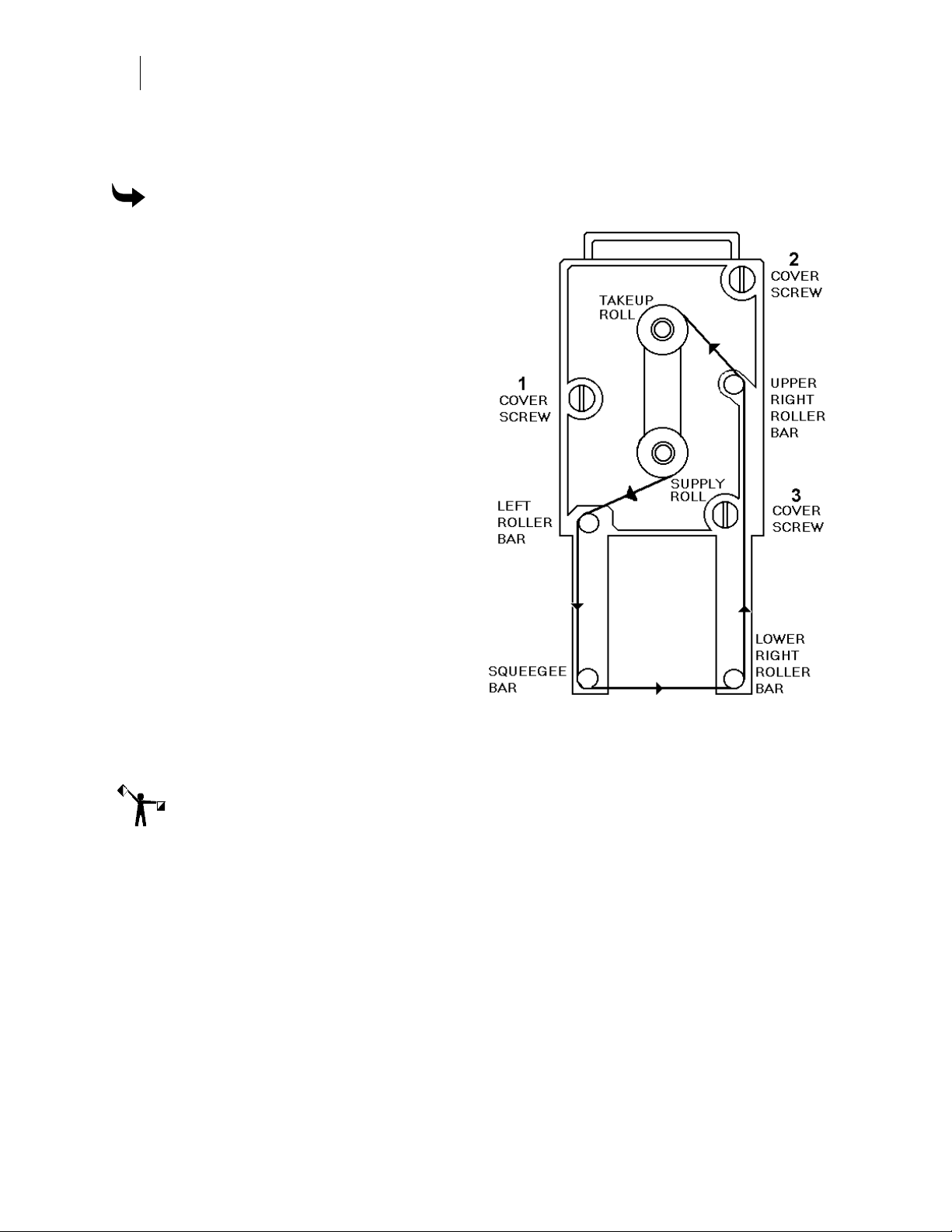

To load the foil in the cassette

1

Use a screwdriver to turn the three

cover screws 1/4 turn counterclockwise to loosen them, then lift off the

cassette cover.

2

Unwrap the new foil.

3

Slide the supply roll on the lower

cassette shaft.

4

Feed the leader and take-up roll

through the side of the cassette,

around the left roller, squeegee bar,

and lower right roller bar as shown

in the illustration. The dull side of the

foil will be facing away from the

cassette body.

5

Feed the take-up roll through the

trapezoidal window on the right side

of the cassette and over the upper

right roller bar.

6

Slide the take-up roll on the upper

cassette shaft.

7

Put the cover on the cassette and

tighten the three screws in the order

shown in the illustration. Turn the

screws 1/4 turn clockwise.

Note: If the foil folds over on itself, it will cause wrinkles on the print. To unfold the foil, push

the foil with your fingernail while rotating the take-up roll counterclockwise.

8

Before loading the cassette into the MAXX, ensure that the foil in the cassette is tight

and wrinkle-free from the supply roll to the lower right roller bar, and that the clear

plastic leader is not in or near the print area.

Page 17

11

p

p

Straightening wrinkles in foil

After loading the foil cassettes, inspect them to ensure that the foil is not folded over on itself (as

shown below). If the foil folds over on itself, it will cause wrinkles on the print. To unfold the

foil, push the foil with your fingernail while rotating the take-up roll (the top roll)

counterclockwise.

Take-up roll

Put fingernail under

fold, to straighten foil,

and wind foil onto

take-u

roll

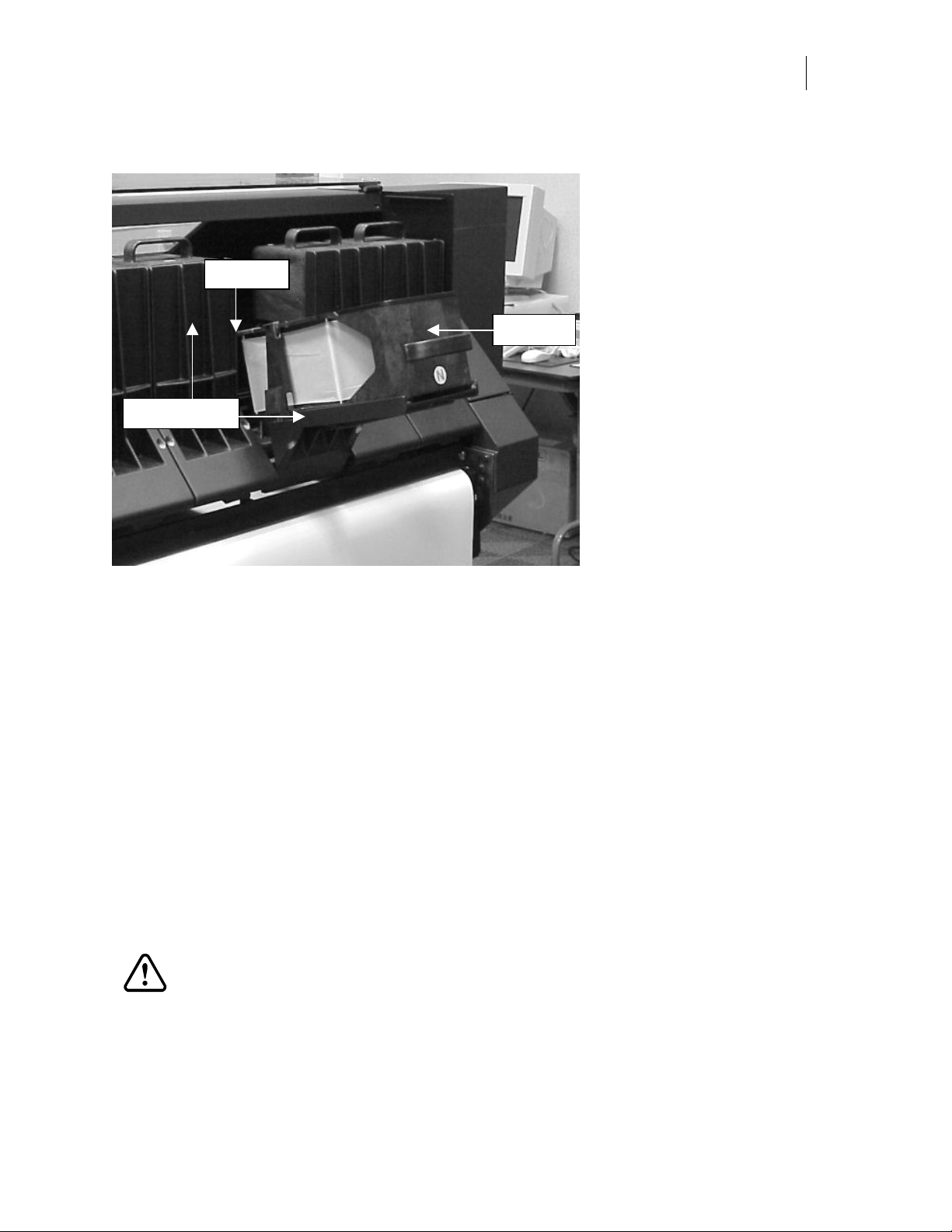

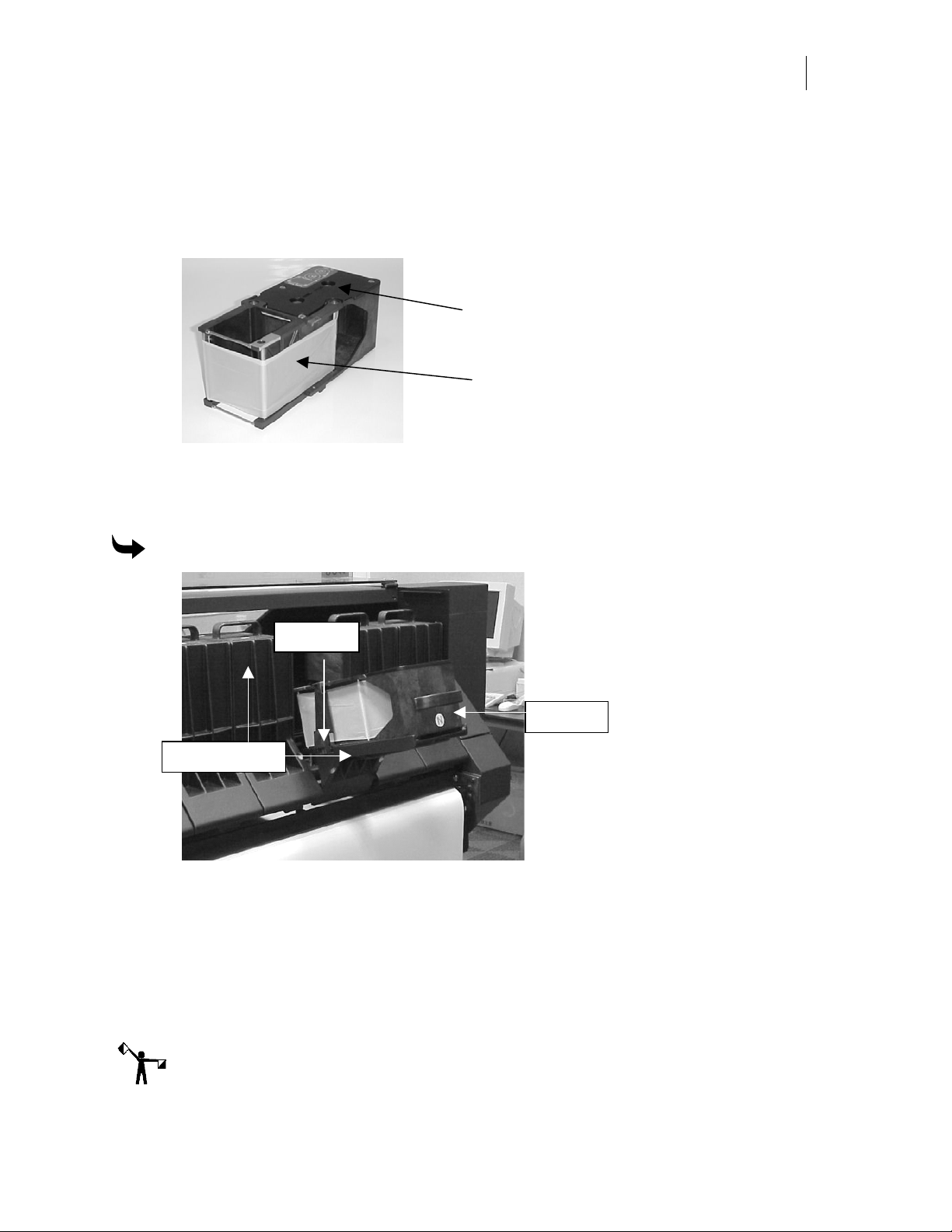

Loading the cassettes in the MAXX 2

Once the foil is loaded into the cassettes you can load up to six cassettes into the cassette rack.

To load the cassette in the cassette rack

Bay sto

Cassette

Cassette bays

1

Raise the transparent cassette rack cover.

2

Tilt one of the cassette bays out and away from the front of the table.

3

Lay the cassette in the bay as shown in the photo, then push it toward the inside of the

table until it touches the bay stops.

4

Carefully lift the cassette bay so that it is vertical and the cassette is in the table area.

5

Close the cassette rack cover.

Note: All the cassette bays in the rack must be vertical and the cassette rack cover must be

closed or the printer will not operate.

Page 18

CHAPTER 3

12

Understanding the MAXX 2 Control Panel

Chapter 3:

Understanding the MAXX 2 Control Panel

Before you start printing jobs become familiar with the commands, features, and messages of

the MAXX 2. This chapter details the following topics:

♦ Control panel keys

♦ MAXX 2 power up sequence

♦ Entering menu selections

♦ Starting jobs

♦ Quick Start operation

♦ Stopping and restarting jobs

♦ Reprinting the last job

♦ Queuing jobs at the MAXX 2 control panel

Control panel keys

The illustration below shows the MAXX 2 control panel. The keys and their functions are

discussed in this chapter.

4 Function keys

The control panel is the interface between the user and the printer. The message display

provides information and prompts, while keys provide the ability to control the printer

functions.

The control panel displays up to four lines of a message at one time. The UP and DOWN

buttons scroll messages that are longer than 4 lines. Message lines preceded by the “<” symbol

Page 19

indicate that pressing the key will result in action or display submenus. The lines from the

function keys to the message lines indicate which key to press on the display.

The following chart briefly describes the purpose of the keys.

Name Purpose

Function keys These four keys have functions that change depending on the

menu or message display.

MENU Press this key to display the Main menu.

ENTER Press this key to confirm a selection you make in the menu

mode.

CANCEL Press this key to exit the current menu without making any

menu changes.

UP Press this key to slew vinyl through the printer. It is also used

to scroll through message displays greater than four lines and

to change numeric values.

13

DOWN Press this key to slew vinyl out of the printer. It is also used to

scroll through message displays greater than four lines and to

change numeric values.

RUN CONT In the RUN CONTINUOUS mode, the printer stays online when

a printing job is complete. If more than one job is sent to the

printer, the next job starts automatically if a material change is

not required. Press this key when the RUN CONT indicator light

is on to put the printer into the pause mode (the light blinks).

RUN SINGLE In the RUN SINGLE mode, the printer goes offline when a

printing job is complete. Press this key when the RUN SINGLE

indicator light is on to put the printer into the pause mode (the

light blinks).

STOP Press this key once to pause a job. Press this key twice to

immediately halt printing, terminate the job, and put the

printer offline.

CLEAN HEAD Press this key to initiate the automatic head cleaning

sequence.

QUICK START Press this key to eliminate the automatic substrate alignment

and straightening procedure between jobs. Press and hold this

key for 5 seconds to move the printhead to the left from the

park position and allow you to refill the wiper box.

LOAD VINYL Press this key to raise the vinyl squeegees and open the

magnet bars so you can load material. Press the key again to

lower the vinyl squeegees and close the magnet bars.

Page 20

CHAPTER 3

14

Understanding the MAXX 2 Control Panel

MAXX 2 power up sequence

When the MAXX 2 is turned on it initializes the axes and then displays the firmware version

number followed by the Ready message. Do not press any of the control panel keys when you

first turn on the MAXX 2. Wait until the

Ready to Print Job

message or a prompt is displayed.

Entering menu selections

When the display is showing printer status, such as

Ready to Print Job

, press MENU on the

control panel to open the Main menu. The display is:

< Bay Status

< Job Queue

< Setup

< Service

Message lines preceded by the “<” symbol indicate that pressing the key results in an action or

displays submenus. For example, if you press the function key corresponding to the

< Setup

message line, the display changes to:

< About Printer

< Language

< Units

< Connection

Pressing the function key corresponding to

< Set English Units

< Set Metric Units

< Units

changes the display to:

Pressing the function key for one of the choices activates it.

Starting jobs

Starting jobs is controlled by the RUN CONT and RUN SINGLE keys. When you send a job to

the printer from the GSPPlot program, the lights over the two keys blink alternately. Pressing

either one of the keys starts the printing sequence and the light is on over the pressed key to

indicate the active printing mode.

Run single mode

In the run single mode, the MAXX prints one job and stops (even if more than one job was sent

to the printer). When you press RUN SINGLE, the light over the key is on and the light over the

RUN CONT key is off. When the job is complete, the light goes off if only one job was sent to

the printer. If more than one job was sent, when the job is complete the lights over the two keys

blink alternately to alert you that another job is in the queue for printing. To start the next job,

press either the RUN CONT or the RUN SINGLE key.

Page 21

15

Run continuous mode

In the run continuous mode, the MAXX prints continuously as jobs are sent to it. When you

press RUN CONT, the light over the key is on and the light over the RUN SINGLE key is off.

When all jobs are complete, the light remains on, indicating that when another job is sent, it will

start to print without operator intervention. The printer remains in the run continuous mode

until you pause the printer or change to the run single mode.

Note: You can change the mode while a job is printing. For example, if you start printing in the

run continuous mode and press RUN SINGLE while printing a job, the printer changes to the

run single mode and stops when the job is complete.

Quick Start operation

Note: Be aware that when printing a job longer than 4 feet (1.22 meters), the MAXX 2

performs a precise material straightening sequence. This sequence can take up to three minutes

before printing starts.

Quick Start is a convenient feature when printing multiple jobs that are less than 5 feet (152.4

cm) in length on the same substrate. After aligning the vinyl for the initial job, the Quick Start

feature saves time by eliminating the substrate alignment and straightening procedure on

subsequent jobs. The operator must be present to ensure that the vinyl is properly loaded. Take

care when using Quick Start.

Do not use Quick Start if:

♦ a job is longer than 5 feet (152.4 cm)

♦ the operator is leaving the MAXX 2 unattended while printing multiple jobs of any

length

The QUICK START key enables Quick Start operation. When you press this key so that the

indicator light is on, the following occurs:

♦ the MAXX 2 assumes that the correct vinyl type is loaded and that it is parallel to the

loading alignment line

♦ straightening and alignment is not performed after the initial sequence

♦ the vinyl width and positioning checks are performed

♦ there is no gap between jobs when printing multiple jobs

To deselect Quick Start mode, press the QUICK START key again. Quick Start is also deselected

at start-up or by pressing the RUN SINGLE, RUN CONT, or STOP key when no job is running.

Stopping and restarting jobs

Terminating jobs is a multi-step process. After a job starts printing, press STOP on the control

panel to pause the printing. If you press STOP again, the following display appears:

< Cancel This Job

< Cancel This Job and Advance Substrate

< Continue This Job

Page 22

CHAPTER 3

16

Understanding the MAXX 2 Control Panel

Press the function key adjacent to the action you want to take. When you choose

the job is aborted and the remaining data is cleared from the printer buffer. If you press

This Job

the job is restarted.

Cancel This Job

Continue

Note: If you cancel a job in GQMgr, the substrate will always be advanced. If you cancel a job

using the MAXX keypad, the canceled job will be pulled off the platen only if you choose

This Job and Advance Substrate

.

Cancel

Pausing jobs and restarting a job

Printing may be temporarily stopped at any time while a job is printing. To pause a job, press

the RUN key that is lit to enter the paused mode. The printer completes the swipe it is currently

printing, then unloads the cassette. The RUN CONT and RUN SINGLE lights alternately blink.

The display is

Paused by Operator

Job Name

Foil:

name of foil

Vinyl:

name of vinyl

To restart a job from the paused mode (as indicated by the alternately blinking lights), press

either the RUN CONT or RUN SINGLE key. The job resumes in the mode selected by the key.

Reprinting the last job

When you are in the run single mode, you can reprint (also called replay) the last job you

printed. You can also use this feature to restart a job you aborted. The display message is

< R Job waiting to print

. If you press the function key next to the

< R

symbol, the job automatically

reprints. In the run continuous mode, only the last job in a sequence can be replayed.

Queuing jobs at the MAXX 2 control panel

The Main menu item, <

♦ display a list of all jobs currently in the queue (excluding jobs marked for abort)

♦ determine if a job is available for reprinting (called the replay job)

♦ display detailed information about each queued job

♦ re-position jobs in the queue

♦ delete jobs from the queue

Displaying a list of jobs in the View Job Details

When the Job Queue function key is selected, a list of all the jobs in the queue (not marked for

abort) displays. The queue can hold up to 32 jobs and includes the queue position and job

description (or file name if it is a test or calibration job) for each job. Use the UP and DOWN

keys to scroll through the list.

The most recent job that is started (the job does not have to finish printing) is held in MAXX

memory as a replay job. When in run single mode you can examine a job and if required,

reprint the replay job without resending it from GQ Manager. When a replay job is available, it

displays at the top of the Job Queue, but with the letter

Job Queue

, allows you to:

R

in place of the queue position number.

Page 23

As a new job is printed, it replaces the previous replay job in memory. You can not delete a

replay (

R

) job from the Job Queue.

When in run continuous mode, the replay job is automatically replaced when a new job is

started. At the end of a RUN CONTINUOUS sequence, the last job printed is the replay job.

Note: Any incompletely printed or unprinted jobs in the queue are retained at power-down.

This feature ensures that you will not lose work in the event of a power loss. For partially

printed jobs, the entire job can be reprinted.

To display the job queue

1

Press MENU on the control panel. The display is:

< Bay Status

< Job Queue

< Setup

< Service

17

2

Press the function key for

< Job Queue

. The display for a Job Queue with five jobs is

shown below. Your display will vary based the number of jobs in the queue.

Job Queue (5)

< R Replay Job Description

< Job A Description

< Job B Description

3 Press DOWN or UP to scroll through the queue.

Displaying detailed information about each queued job

Press the function key adjacent to any job listed in the queue and choose View Job Details to

display the job information. This display shows the queue position, the job identification

number (which is assigned by GQMgr), the job (file) name, the first foil that prints, and the

substrate name. If you press the function key for the foil, you get a list of all foils in the job.

To display detailed job information

1

Press the function key next to a job. This display is:

< View Job Details

< Change Queue Position

< Remove Job From Queue

2

Press the function key for

Queue #: 2 Job Id: 17

Job B Description

< Process – Black GCP-712

< Vinyl: White 225 Custom

(not displayed for a replay job or when there is only one job in the queue)

(not displayed for a replay job)

< View Job Details

(if you press this function key, you get a list of all the foils in the job)

. The display is:

3

Press CANCEL to return to the Job Queue.

Page 24

CHAPTER 3

18

Understanding the MAXX 2 Control Panel

Re-positioning a job in the queue

When you change the position of a job in the queue, other jobs are shifted up or down in the

queue as needed. Re-positioning is not available for the replay job or when there are less than

two jobs are in the queue. It is not possible to change the queue position when the job at the

original or new queue position has already begun to print.

To change the position of a job in the queue

1

Press the function key next to a job. This display is:

< View Job Details

< Change Queue Position

< Remove Job From Queue

(not displayed for a replay job or when there is only one job in the queue)

(not displayed for a replay job)

2

Press the function key for

Job B Description

Move From Entry 2 to: 3

Press UP/DN To Adjust

ENTER to save, CANCEL to quit

3

Press UP or DOWN to move the job to a new queue position.

4

Press ENTER to save the new position.

< Change Queue Position

. The display is:

Deleting jobs from the queue

You can delete a job from the queue by using the Remove Job From Queue command. Deleting

a job is not available for the replay job or if a job has already begun to print.

When you select Remove Job From Queue, you must respond to a confirmation message before

the job is marked for deletion. (When viewing the Job Queue from GQ Manager, jobs removed

from the queue are marked as aborted.) Even though a deleted job no longer appears in the

queue on the MAXX 2 display, the job is not removed from the queue until it reaches the first

queue position. Deleted jobs that still reside in the MAXX queue occupy one of the 32 available

queue positions. To immediately remove a job from the queue, move the job to the first queue

position and then delete it.

To delete a job from the queue

1

Press the function key next to a job. This display is:

< View Job Details

< Change Queue Position

< Remove Job From Queue

(not displayed for a replay job or when there is only one job in the queue)

(not displayed for a replay job)

2

Press the function key for

Queue #: 2 Job Id: 17

Job B Description

Remove this job from queue?

Press ENTER if “yes”, CANCEL if “no”

3

Press ENTER to delete the job.

< Remove Job From Queue

. The display is:

Page 25

19

Adjusting the pull distance when slewing material

When pressing the UP or DOWN key, the MAXX 2 slews the material a designated amount. The

default value is 16 inches (40.64 cm). You can temporarily adjust the amount of material that is

pulled across the platen when slewing.

To temporarily adjust the pull distance amount

1

Press and hold the UP or DOWN key on the MAXX 2 control panel. When pressing the

UP key the display is:

Enter Pull Distance

16

When pressing the DOWN key the display is:

Enter Pull Distance

-16

2

Press UP to increase the pull distance or DOWN to decrease the pull distance. Press

ENTER to accept the new value or CANCEL to exit.

3

Press the UP or DOWN key to slew the material the distance entered. The pull

distance then resets to the default value of 16 inches and –16 inches (40.64 cm to

–40.64 cm).

Updating the MAXX 2 firmware

Occasionally GSP will update the firmware in your GERBER MAXX 2 to a new revision level.

Before updating the firmware using GQ Manager, you must set the MAXX 2 to accept a system

update.

Note: Before installing the MAXX 2 firmware, it is important to clean out the

c:\Windows\temp directory so that there is space to enable you to back up files before

installing the new firmware.

To update the MAXX 2 firmware

1

On the MAXX 2 keypad press

System ready for update…

Press CANCEL or MENU to exit:

2

On the computer attached to the MAXX 2 click Start > Programs > OMEGA > GQMgr

to open the GQ Mgr dialog box.

3

Right click on the MAXX icon to access Properties.

4

Click Properties to open the Properties for Gerber MAXX dialog box.

Menu > Service > System Update

. The display shows:

Page 26

CHAPTER 3

20

Understanding the MAXX 2 Control Panel

5

Click Batch to open the Open GSP MAXX Batch File dialog box.

6

Browse the Look in drop down list to find your CD drive, then open it.

7

Click Firmware > MAXX > Backup XX.mxb. The current system files backup to the

temp directory.

8

Click Build XX.mxb. The firmware installs. As the firmware is installing, messages will

automatically scroll through the Properties for Gerber MAXX dialog box. When

finished the following message is displayed:

MAXX FILES TRANSFERRED

CYCLE POWER ON MAXX TO

COMPLETE FIRMWARE UPDATE

9

After installing the new firmware and before sending a job to the MAXX 2, turn the

MAXX 2 off for at least 10 seconds before restarting the machine.

Page 27

Chapter 4:

MAXX 2 Care and Cleaning

Extensive in-house and field testing reveal that proper cleaning of the MAXX 2 and the

substrates are essential to maintaining good print quality. The following sections provide

comprehensive inspection, cleaning, and foil care instructions.

CAUTION: When cleaning the MAXX 2 (or any time you have the cover of the

MAXX 2 open), you increase the chance of contaminates such as sand or dirt

adhering to the head cleaning pad or platen. Inspect these areas carefully after

cleaning to guard against possible damage.

Recommended MAXX 2 cleaning materials

21

The recommended cleaning materials are:

♦ rubber gloves (strongly recommended)

♦ pink ThermApprove printhead cleaning film, Gerber part number P72966C

♦ ThermApprove printhead cleaning kit, Gerber part number P66530B

♦ a clean, lint-free cloth

♦ 99 percent isopropyl alcohol

♦ tack cloth (commercially available from most hardware stores)

♦ glass cleaner

♦ 3-IN-ONE machine oil

♦ Chemtronics Ultrajet 2000 (or equivalent) compressed air, ultra-filtered,

non-residue dust remover

Daily cleaning procedures

Daily cleaning of the MAXX 2 is strongly recommended. Everyday you should:

♦ Vacuum the exterior of the MAXX 2.

♦ Clean the magnet bars and squeegees.

♦ Clean the edge sensor strip.

♦ Clean the platen.

♦ Inspect and if necessary, refill the wiper box.

♦ Clean the ways, lead screw, and ball screws.

♦ Clean the material catching baskets.

Page 28

CHAPTER 4

22

MAXX 2 Care and Cleaning

Cleaning the vinyl squeegees and magnet bars

Turn on the printer and press LOAD VINYL on the control panel to raise the front and rear

vinyl squeegees. Remove any material loaded in the printer. Use a wet alcohol printhead

cleaning pad to clean the squeegees. Fold it in half and wrap it around the squeegee, then wipe

the entire length of the squeegee. The squeegee is clean when you re-wipe the squeegee and the

pad still looks clean. You may refresh the pad with 99 percent isopropyl alcohol if it becomes

dry during cleaning.

Note: Isopropyl alcohol may discolor the squeegees over time. Discoloring does not affect the

operation of the squeegee.

Platen

Magnet bar

Tilt the cassette rack out of the front of the printer to allow access to the magnet bars and wipe

them clean with a lint-free cloth moistened with glass cleaner. Pay special attention to the small

slot between the top and bottom of the magnet bar. Be careful to not get the cleaning cloth

trapped under the magnet bar. Check the magnet bars for pieces of vinyl that may have gotten

stuck to them.

An additional way to clean the magnet bar and keeper plate is tilt the foil cassettes out to gain

access to the magnet bar. Remove the pins at each end of the magnet bar and slide the keeper

plate out. This also allows more room to clean under the magnet bar. Be careful to not bend the

keeper plate. Reinstall the keeper plate in exactly the same orientation with the slightly rounded

edges facing up. Allow the area to air dry before loading material. If you are not loading

material at this time, press LOAD VINYL to lower the vinyl squeegees.

Tip: It is a good idea to wipe the material tray with the alcohol-moistened cloth while you are

cleaning the squeegees and magnet bars. Occasionally, adhesive may build up on the tray from

the material passing over it.

Page 29

Cleaning the edge sensor strip

The edge sensor strip is located behind the back cover panel above the table.

To clean the edge sensor strip

1

Unload any material from the printer.

2

Move the rear material catching basket away from the back of the printer.

3

Remove the three screws across the top of the back cover panel so that the cover can be

lowered on its hinges.

4

Locate the edge sensor strip. It is a very dark strip (much darker than the surrounding

black surface and has a matte finish) just inside of the rear squeegee.

5

Use a compressed air, ultra-filtered, non-residue dust remover (such as Chemtronics

Ultrajet 2000 or equivalent) to quickly spray the entire length of the edge sensor strip

from left to right.

6

Vacuum away any dislodged debris.

7

Secure the back cover panel to the printer with the three screws removed at step 3 and

replace the material catching baskets.

23

Cleaning the platen

CAUTION: When cleaning the platen as described in the next paragraphs, do not

wipe or clean the black edge sensor notch with alcohol or cleaning solvents that will

damage or change the paint color. It is important to keep this area free of dust, lint,

and dirt.

Moisten a clean, lint-free cloth with 99 percent isopropyl alcohol and wipe the platen to remove

any dirt, debris, or adhesive. Be sure to check the platen for pieces of vinyl that may have gotten

stuck to it. Allow to air dry. Wipe the platen with a tack cloth to remove any contaminates that

may interfere with printing and damage the printhead.

An edge sensor notch strip is located at the center of the platen on the left side. It is a notch

approximately 2" (50.8 mm) long and 1/2" (12.7 mm) wide cut into the platen and is painted

black. Clean the edge sensor notch strip by quickly spraying in the notch with a compressed air,

ultra-filtered, non-residue dust remover such as Chemtronics Ultrajet 2000.

Page 30

CHAPTER 4

24

MAXX 2 Care and Cleaning

Inspecting and refilling the wiper box

CAUTION: When inspecting the wiper box as described in the next paragraph,

verify that there is cleaning film in the wiper box and that all four corners of the

film strips are under the corners of the wiper box. If the film is not completely

seated and under the corners, equipment damage may result.

Inspect the cleaning film in the head wiper box and be certain to keep the head wiper box filled.

Do not over-fill the box; one full package (100) of ThermApprove printhead cleaning film is

sufficient. Load the package into the head wiper box with the dull (and slightly abrasive) side

facing up toward the printhead. If the wiper box is nearly empty, it may contain small metal

chips, which could damage the printhead during the head cleaning cycle. Refill the wiper box

before it is completely empty and inspect for any contaminates on the surface, which could

damage the printhead.

If you cannot easily fit your hand under the printhead to load the cleaning film in the head

wiper box, you can move the printhead out of the way and park it. On the MAXX 2 control

panel, press and hold the Quick Start key for five seconds. The printhead moves to the left and

stops and the display is

printhead automatically relocates to the proper position before printing the job

Ready for print job

. After you load more cleaning film, just send a job. The

Cleaning the ways, lead screw, and ball screws

Note: To clean the ways and ball screws, remove the left and back covers and open the right

cover.

The MAXX 2 has six ways: two X ways for moving the magnet bars; two Y ways for the

printhead carriage assembly; and two Z ways in the printhead carriage for raising and lowering

the printhead. There is a Z lead screw that raises and lowers the printhead and three ball screws

for the X and Y axis.

Smooth operation of moving parts depend on the ways and lead screws being clean and free of

debris. Use a clean, lint-free cloth to clean the ways, lead screw, and ball screws. Occasionally −

every two or three months − lightly oil the ways and ball screws with light machine oil such as

3-IN-ONE.

Cleaning the material catching baskets

Use a clean, dry, lint-free cloth to wipe the metal surfaces and the straps of the material catching

baskets.

Page 31

25

The importance of cleaning the printhead

Proper cleaning of the MAXX 2 printhead is extremely important for maintaining consistent

print quality. The following photographs show a print made before the printhead was cleaned.

Note the raggedness at the start of the print and the visible seaming in the print.

The dirty printhead contributes to a ragged application of the foil to the vinyl. Seaming is

evident and caused by dirt at the extreme ends of the printhead. In the close-up view below, the

ragged start and seaming are clearly visible.

Seaming Ragged start

Page 32

CHAPTER 4

26

MAXX 2 Care and Cleaning

The following photographs show the same areas after cleaning the printhead and reprinting the

job. The only change made to the MAXX 2 was the cleaning procedure performed according to

the instructions in this document. This should be ample evidence of the importance of cleaning

the printhead, especially the extreme ends.

The circles in these photographs show the exact same areas after cleaning the printhead and

reprinting the job. Note that the seams are now invisible and there is no ragged start to the

printing.

Page 33

27

Automatic head cleaning

The MAXX 2 performs an automatic head cleaning by wiping the printhead across the cleaning

film in the wiper box before printing each job. While the cleaning occurs, the light above the

CLEAN HEAD key flashes. You have the ability to manually initiate the sequence by pressing

the CLEAN HEAD key (even in the middle of printing a job).

The MAXX 2 counts the number of cleanings, and after a preset number, displays

detected message

change head cleaning pad.

. When you press the function key to view the error, the display is

Open the right side cover and remove the top cleaning pad (pink film)

Error(s)

Reminder to

in the head wiper box.

CAUTION: After you remove the top cleaning pad, verify that there are pads in the

wiper box and that all four corners of the fresh pad are under the corners of the

wiper box. If the cleaning film is not completely seated and under the corners,

equipment damage may result. Check that there are no small bits of dirt or metal

chips on the cleaning film. These small particles of dirt of metal chips can cause

serious damage to the printhead.

Even though the MAXX 2 automatically cleans the printhead, you should still manually clean

the printhead every day. See the following instructions.

Manually cleaning the printhead

NOTE: Because head cleaning is automatic, the frequency of manual cleaning with the pink

ThermApprove cleaning film is very low. Cleaning with an alcohol pad should be done more

often

procedures for cleaning with both the pink cleaning film and the alcohol pad. The use of heavily

pigmented foil such as white may require more frequent cleaning.

up to several times per day if the MAXX 2 is printing all day. Use the following

−

CAUTION: When cleaning the printhead (or any time you have the cover of the

MAXX 2 open), you increase the chance of contaminates such as sand or dirt

adhering to the cleaning pad or platen. Inspect these areas carefully after cleaning to

guard against possible printhead damage.

Before cleaning the printhead, the printhead carriage must be parked (stopped at the far right of

the MAXX 2). Open the right end cover to see the printhead carriage and printhead.

Page 34

CHAPTER 4

p

28

MAXX 2 Care and Cleaning

End of the

rinthead

The photographs below are close-up views of the printhead. The photograph on the left shows

the printhead mounted on the printhead carriage. The photograph on the right (printhead

removed from the MAXX 2 for identification purposes) shows the parts of the printhead.

Peel bar

Bead or print

element

Green strip

between bead

and insulation

Black insulation

Peel bar Bead or print

element area

Circuit card

Page 35

29

Cleaning the printhead is slightly awkward because it is difficult to see where you are cleaning.

You can get down on your knees so that you are looking up at the bottom of the printhead

carriage or you can reach under the bottom of the printhead from the top as shown. In this

photograph, note that the cleaning film is between the printhead elements and the fingers so

that the skin is not touching the elements. Gerber strongly recommends that you wear rubber

gloves when cleaning the printhead.

Printhead

Pink cleaning film

Cleaning the printhead is a two-step operation. The first step is to clean the peel bar and

printhead elements using the pink cleaning film. The second step is to remove dirt buildup on

the head using the pre-moistened alcohol pad from the cleaning kit. It is very important to

clean the entire width of the printhead. The worst buildup and contamination normally

occur at the ends of the peel bar and printhead element.

Note: If you are cleaning the printhead after a foil break, visually inspect the printhead and

elements very closely to make certain that foil has not fused to the printhead. Extra cleaning

may be required if fusing has taken place.

To manually clean the printhead

CAUTION: When cleaning the printhead, it is very important that your fingers do

not touch the printhead element. Oils and salt on your skin will damage the

printhead. Be certain to keep the printhead cleaning film and the pre-moistened

alcohol pad between your fingers and the printhead. We strongly suggest using

rubber gloves to prevent your skin from touching the printhead, although the

gloves are not a requirement as long as your skin does not contact the printhead.

1

Rub the front and bottom of the peel bar with the dull, abrasive side of the pink

cleaning film. Be certain to rub the entire width of the peel bar all the way out to each

edge. Use about one pound of pressure when rubbing and rub the width for

approximately 10 strokes.

Page 36

CHAPTER 4

30

MAXX 2 Care and Cleaning

2

Rub the printhead element strip or bead with the dull, abrasive side of the pink

cleaning film. Be certain to rub the entire width of the bead all the way out to each

edge. Use about one pound of pressure when rubbing and rub the width for

approximately 10 strokes.

Tip: Save the used pink cleaning film for cleaning the cassette. Do not use it again to clean the

printhead.

3

Using the pre-moistened alcohol pad from the cleaning kit, rub the peel bar, printhead

elements, the green strip area between the bead and the insulation. Do not clean the

circuit card. Rub the entire width all the way out to each edge approximately 10

strokes. You may refresh the alcohol pad with 99 percent isopropyl alcohol if the pad

becomes dry when cleaning.

Peel bar

Bead or print

element

Green strip

between bead

and insulation

Black insulation

Circuit card

Page 37

31

Cleaning foil cassettes

Clean the foil cassette each time before loading it with foil. The following photographs show the

major areas to clean.

Contact

strip

roller bar right bar right roller

bar roller bar roller bar bar

Left Squeegee Lower Squeegee Lower Right

Contact

strip

CAUTION: When cleaning the cassette with 99 percent isopropyl alcohol, be

certain that the cassette parts are completely dry before loading the cassette with

foil. Wet alcohol could damage the foil.

To clean the cassette

1

Rub the squeegee bar with the dull, abrasive side of new or used pink cleaning film. Be

certain to rub the entire width of the squeegee bar all the way out to each edge. As

shown in the following photograph, backcoat from the foil typically builds up at the

far edges of the squeegee bar. Use about one pound of pressure when rubbing and rub

the width for approximately 10 strokes.

Usual area of backcoat buildup

Squeegee bar

Usual area of backcoat buildup

Page 38

CHAPTER 4

32

MAXX 2 Care and Cleaning

2

Moisten a clean, lint-free cloth with 99 percent isopropyl alcohol and wipe the roller

bars, squeegee bar, and the contact strips. Use the moistened cloth to wipe the metal

parts of the removable cover.

3

If there is no foil in the cassette, quickly spray the interior of the cassette with a

compressed air, ultra-filtered, non-residue dust remover (such as Chemtronics Ultrajet

2000 or equivalent).

Tip: When cleaning the cassette with the alcohol, it is a good time to wipe the MAXX 2 foil bay

contact strips in the cassette rack and on the cassette to ensure good clean contact

between the contact strips on the bay stops and the cassettes.

Page 39

Chapter 5:

Printing Jobs

This chapter describes the process of printing jobs on the GERBER MAXX 2. It covers the

following topics.

♦ Setting up and sending the job

♦ Determining the status of each bay

♦ Printing the job

♦ Printing test jobs

Setting up and sending the job

33

Jobs are set up and sent to the MAXX 2 in the GSPPlot program. The MAXX 2 is capable of

printing any job file that can be opened in the GSPPlot program of OMEGA 1.56 or higher or

that has been rendered and saved as an SPL file. For a complete list of usable file types, click on

the down arrow beside the Files of type list box in the GSPPlot Open dialog box.

After you open a job in GSPPlot, you can use all the features of the program to set up the job

(such as rotate, panel, and repeat, for example). To use the GSPPlot program, refer to the

GSPPlot Help system.

After the job is set up, click on the print button to send the job to the MAXX 2.

Determining the status of each bay

The Bay Status display shows you the name of the foil and amount of foil in each bay.

To view the Bay Status

1

Press MENU to display the Main menu.

< Bay Status

< Job Queue

< Setup

< Service

2

Press the function key for

bays. Following is an example of a typical display.

< Bay Status

. The display shows the status of the first three

Bay Inches Description

1 empty

< 2 4759 PROCESS CYAN GCP-707

< 3 2590 PROCESS YELLOW GCP 705

Page 40

CHAPTER 5

34

Printing Jobs

3

Press DOWN key to view the status of the next three bays. Press UP to view previous

lines of information. To return to the Main menu, press CANCEL on the control panel.

Reducing the recorded amount of foil in a cassette

If you have manually advanced some foil, to move past dirt or a tear in the foil, you should

reduce the amount remaining on the roll so that the recorded and displayed amount is accurate.

To reduce the recorded amount of foil in a cassette

1

Press MENU to display the Main menu.

< Bay Status

< Job Queue

< Setup

< Service

2

Press the function key for

< Bay Status

. The display shows the status of the bays.

Following is a typical example.

Bay Inches Description

1 empty

< 2 4759 PROCESS CYAN GCP-707

< 3 2590 PROCESS YELLOW GCP 705

3

Press the function key for the foil you want to reduce. In this example, we want to

reduce the amount of Process Cyan. The display is:

Reduce Foil Remaining, Bay 2

4759 inches

4

Estimate the number of inches of foil you advanced, then press DOWN to reduce the

amount shown in the display. Press ENTER to accept the new value.

Note: If you accidentally decrease the value too much, the UP key allows you to increase the

amount back to the starting value, but no greater.

Printing the job

When the printer is ready for a job, the display is

RUN CONT and RUN SINGLE keys blink.

When you send a job, it automatically starts printing if the printer is in the RUN CONT or RUN

SINGLE mode. If it is not in a RUN mode, the display at the top level is:

Ready For Print Job

and the lights above the

Job Waiting To Print

job name

< Foil:

name of foil (press this key to get details of foils in the job)

< Vinyl:

name of vinyl (press this key to get details of the vinyl in the job)

The first thing that happens before each job, whether in RUN SINGLE or RUN CONT, is that

the printer aligns the printhead to the left edge of the material. The display is:

Adjusting Vinyl…

Note: If the MAXX 2 is in Quick Start mode, it only adjusts the vinyl for the first job sent to

the MAXX 2. You will not see the

Adjusting Vinyl…

message for subsequent jobs.

Page 41

When adjustment is complete, the display is:

Printing

job name

< Foil:

name of foil

< Vinyl:

name of vinyl

Printing continues until:

♦ the job is complete in the RUN SINGLE mode. If more jobs are waiting to be printed,

the RUN CONT and RUN SINGLE lights alternately blink.

♦ all jobs are complete in the RUN CONT mode. The light over the RUN CONT key

remains on to indicate that the printing sequence will start automatically when more

jobs are sent.

♦ a condition requiring operator intervention is encountered such as the printer runs out

of foil or vinyl or the vinyl required is different than the last job printed. In this case,

the printer pauses and displays a prompt message to tell you what to do.

Tip: Refer to the chapter “Understanding Messages” on page 43 for a list of messages, what

each means, and your response to the message.

35

Viewing foil and material information for the job

Before or after you start printing, you can check the foil and vinyl status by pressing the

function key opposite the

< Foil:

name of foil

When viewing foil details, the display shows the foils needed in the job, the amount of foil

loaded in the cassette, and the amount of foil that is required for the job. When viewing material

details, the display shows the design width of the job, and the actual width and length of

material required.

To view the foils information for the job

1

From the Main menu press

Job Queue (n)

< 1 Job name

< 2 Job name

< 4 Job name

< Job Queue

2 Press the function key next to a job. This display is:

< View Job Details

< Change Queue Position

< Remove Job From Queue

3

Press the function key for < View Job Details. The an example of a typical display is:

Queue #: 2 Job Id: 17

Job Description

< Process yellow GCP-706

< Vinyl: White 225 Custom

(not displayed for a replay job or when there is only one job in the queue)

(not displayed for a replay job)

(if you press this function key, you get a list of all the foils in the job)

< Vinyl:

or

. The display is:

name of vinyl

line in the display.

4

Press the function key for the foil. An example of a typical display is:

Foils needed this job (1 of 4)

Process yellow GCP-706

60 in. loaded, Bay 1

48 in. required

Page 42

CHAPTER 5

36

Printing Jobs

5

Press the DOWN arrow to scroll through the foils required for the job. An example of a

typical display is:

Foils needed this job: (2 of 4)

Process magenta GCP-773

40 in. loaded, Bay 2

48 in. required – load more

6

In this case, there is not enough Process Magenta foil to complete the job. You can

either pause the printer now and load the foil, or press RUN to continue the job. If you

let the job continue, when the process magenta foil color reaches the low foil threshold

value the MAXX 2 pauses and displays:

Foil Low, Bay 2

or

Foil Very Low, Bay 2

7

Press RUN to continue printing, or replace the foil in the cassette and then press RUN.

To view the material information for the job

1

From the Main menu press

Job Queue (n)

< 1 Job name

< 2 Job name

< 4 Job name

< Job Queue

. The display is:

2 Press the function key next to a job. This display is:

< View Job Details

< Change Queue Position

< Remove Job From Queue

3 Press the function key for

Queue #: 2 Job Id: 17

Job Description

< Process yellow GCP-706

< Vinyl: White 225 Custom

4

Press the function key for the vinyl. An example of the display is:

Job Vinyl Information

Expected Roll Size 36.0 inches

Job Width (y) 14.7 inches

Job Length (x) 155.7 inches

5

To exit any of these displays, press CANCEL.

(not displayed for a replay job or when there is only one job in the queue)

(not displayed for a replay job)

< View Job Details

(if you press this function key, you get a list of all the foils in the job)

. The display is:

Tip: When printing in the run continuous mode, try to group jobs by material and foil colors,

then make sure that the foil colors for all jobs are loaded in the cassette rack. This allows the

MAXX 2 to print all the jobs in an unattended mode without pausing. To check the list of foils

loaded in the cassette rack, check Bay Status as described in “Determining the status of

each bay” on page 33.

Page 43

Printing test jobs

The GERBER MAXX 2 includes a number of test jobs in the Service > Run Test Job menu. See

the descriptions below for detailed explanations of each job.

Test Job Foils Used Job Description

BLACK50.RAW Process Black Used by an installation technician to calibrate the

MAXX 2.

BLACK75.RAW Process Black Used by an installation technician to calibrate the

MAXX 2.

CYAN50.RAW Process Cyan Used by a technician for density calibration.

CYAN75.RAW Process Cyan Used by a technician to calibrate the MAXX 2.

MAGTA50.RAW Process Magenta Used by a technician to calibrate the MAXX 2.

MAGTA75.RAW Process Magenta Used by a technician to calibrate the MAXX 2.

EIFFEL.RAW 4-color Process Used by an installation technician to calibrate the

MAXX 2.

37

MAXXLOGO.RAW 4-color Process Used by an installation technician to verify MAXX 2

operation.

PREMIUM.RAW Ruby Red

Spot Black

RUBYPULL.RAW Ruby Red Used by an installation technician to check seam

STARTUP.RAW Process Yellow

Process Black

BREAK.RAW Process Black Used by a technician to check calibration of the MAXX

LPISHP.RAW Process Black Reference chart of available halftone types for shape

LPISHPO.RAW Process Black Reference chart of the resulting optimized halftone

Used by an installation technician to check seam

overlap on spot colors.

overlap on spot colors.

Used by a technician to check calibration of the MAXX

2 after installing a new printhead.

2 after installing a new printhead.

fills. Includes blocks filled with 10% to 100% black

tint in 10% increments in the following halftone types

GerberTone Fine, GerberTone Long, GerberTone,

Classical Dot 14, 18, 26, 42, 52, and 70 LPI.

for

100% black tint in 10% increments. Although labeled

Optimized GerberTone Fine, Optimized GerberTone

Long, or Optimized GerberTone, the halftones are

identical – Optimized GerberTone MAXX.

fills. Includes blocks filled with 10% to

shape

LPIBM.RAW Process Black

Reference chart of available halftone types for

fills. Includes blocks filled with 10% to 100% black

tint in 10% increments in the following halftone types

GerberTone Photo, GerberTone Artwork, Stochastic,

Classical Dot 14, 18, 26, 42, 52, and 70 LPI.

image

Page 44

CHAPTER 5

38

Printing Jobs

LPIPROC.RAW 4-color Process Reference chart of four images filled with the

following halftone types: GerberTone, Classical Dot

70, 42 and 26 LPI. Top section of each image is a

multicolor linear fill to illustrate color banding that

may occur with different halftone types. Bottom

section of the image is a four color photo to illustrate

image details and range of color.

LPIPROCO.RAW 4-color Process Example of the same four color image used in

LPIPROC.RAW after being optimized through GSPPlot.

The halftone type is Optimized GerberTone MAXX.

Top section of the image is a multicolor linear fill to

illustrate color banding. Bottom section of the image

is a four color photo to illustrate image details and

range of color. See

MAXX 2

for more detailed explanations on halftones.

OMEGA Tips for the GERBER

Page 45

39

Chapter 6:

Modifying MAXX 2 Print Settings

Your MAXX 2 is optimized at the factory to produce high quality prints. If you suspect that

your MAXX 2 is out of calibration, you can print several calibration check prints that are

resident in the MAXX 2. You can also fine tune printhead settings for individual materials by

modifying Print Darkness or Seam Adjust. Take care when adjusting factory default settings. If

you have questions about your MAXX 2 print settings, contact Gerber Field Service.

Printing the Pull Out or Pull Back Check prints

The Pull Out or Pull Back check prints are designed to assist a Gerber technician in determining

if your MAXX 2 requires adjustment. The Pull Out and Pull Back Check prints must be printed

on 225 white vinyl only. Using a different substrate may provide erroneous results. After

printing the check prints, contact Gerber Field Service for assistance.

To print the Pull Out or Pull Back Check prints

1