Page 1

Copyright Notice

COPYRIGHT 2006 Gerber Scientific International. All Rights Reserved.

This document may not be reproduced by any means, in whole or in part, without written permission of

the copyright owner.

This document is furnished to support the ART Path and Auto-CarveUser’s Guide. In consideration of

the furnishing of the information contained in this document, the party to whom it is given assumes its

custody and control and agrees to the following:

1. The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Gerber Scientific International.

2. This document or the contents herein under no circumstances shall be used in the manufacture or

reproduction of the article shown and the delivery of this document shall not constitute any right or

license to do so.

Information in this document is subject to change without notice.

PrintedinUSA

GSP is a registered trademark,and ART Path,Auto-Carve,Sabre, Dimension, and OMEGAare trademarksof GerberScientific

Products,Inc. HPGLis a trademark of Hewlett-PackardCompany. Rowmark is a registeredtrademarkof Rowmark,Inc. Microsoftand

Windows are registeredtrademarks of Microsoft Corporationin the US and other countries.

Page 2

FCC NOTICE

WARNING This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own risk.

This digital apparatus does not exceed the Class B limits for radio noise emissions from digital apparatus

set out in the Radio Interference Regulationsof the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux

appareils numeriques de la classe B prescrites dans les Reglements sur le brouillage radioelectrique edicte

par le Ministere des Communications du Canada.

Page 3

Book One: I ntroducti on to ART Path.................................................................................. 1

Chapter 1 : Setting up ART Pa th........................................................................................... 3

Unpacking/Installation.................................................................................................................... 3

Systemrequirements ........................................................................................................................ 3

Installing the ART Path software option......................................................................................... 4

Accessing ART Path.......................................................................................................................... 4

Customer Support.............................................................................................................................5

Chapter 2 : Reviewing t he AR T Pa th Toolbox..................................................................... 7

CancelSelect...................................................................................................................................... 7

Pointer................................................................................................................................................ 7

Zoom.................................................................................................................................................. 8

Unzoom............................................................................................................................................. 8

Male................................................................................................................................................... 9

Male Auto Inlay Parameters........................................................................................................ 10

Female.............................................................................................................................................. 12

Female Auto-Inlay Parameters.................................................................................................... 13

Engrave............................................................................................................................................ 15

Engraving Channel Cut Parameters........................................................................................... 15

Cleanout........................................................................................................................................... 16

Direction....................................................................................................................................... 18

Auto-Inlay Parameters................................................................................................................. 19

Use Diagonals............................................................................................................................... 19

Drill .................................................................................................................................................. 20

Nesting............................................................................................................................................. 21

HorizontalCutline.......................................................................................................................... 22

Move Cutline................................................................................................................................... 22

Auto-Carve 3D................................................................................................................................ 23

Prismatic ...................................................................................................................... .................... 23

Set Start Point.................................................................................................................................. 23

Book Two: Menus and Proc edures................................................................................... 25

Chapter 3 : File Menu........................................................................................................... 27

New.................................................................................................................................................. 27

Open................................................................................................................................................. 27

Close................................................................................................................................................. 27

Save.................................................................................................................................................. 28

Save As ............................................................................................................................................ 28

Save Plot File................................................................................................................................... 29

Save to Spool File............................................................................................................................ 29

Save Parameters.............................................................................................................................. 30

Place................................................................................................................................................. 30

Library............................................................................................................................................. 31

Print................................................................................................................................................. 31

Print Setup....................................................................................................................................... 31

Recently Used File list..................................................................................................................... 31

Exit................................................................................................................................................... 31

Page 4

Chapter 4 : Edit Menu...........................................................................................................33

Undo................................................................................................................................................ 33

Cut.................................................................................................................................................... 33

Copy and Paste................................................................................................................................ 33

Pastefrom Composer................................................................................................................... 34

PasteBack..................................................................................................................................... 35

Delete......................................................................................................................... ...................... 35

SelectAll.......................................................................................................................................... 35

Reverse Select.................................................................................................................................. 35

SelectOpen Shapes......................................................................................................................... 35

SelectUnused Shapes..................................................................................................................... 36

Chapter 5 : Shape Menu......................................................................................................37

Repeats............................................................................................................................................. 37

Repeats dialog box....................................................................................................................... 37

Sizing Shapes................................................................................................................................... 38

Percent Size dialogbox ........................................................................................................... ..... 39

Absolute Size dialogbox............................................................................................................. 40

Join................................................................................................................................................... 41

Group............................................................................................................................................... 42

Ungroup .......................................................................................................................................... 42

Layer................................................................................................................................................ 42

SmartEdit Layer........................................................................................................................... 43

Chapter 6 : Setup M e nu.......................................................................................................45

Tool Edit.......................................................................................................................................... 45

Tool InformationDialogBox....................................................................................................... 45

Tool Edit Dialog Box.................................................................................................................... 46

Start/End Position.......................................................................................................................... 48

RouterSelection.............................................................................................................................. 50

Use Material.................................................................................................................................... 50

Material Size.................................................................................................................................... 51

Nesting Setup.................................................................................................................................. 52

Join Tolerance.................................................................................................................................. 52

Show Tool ChangerPosition.......................................................................................................... 53

Chapter 7 : Tool Pa th Menu................................................................................................55

Tools Used....................................................................................................................................... 55

Organize Tool Order dialog box................................................................................................. 55

Engrave............................................................................................................................................ 56

Male................................................................................................................................................. 56

Female.............................................................................................................................................. 56

Cleanout........................................................................................................................................... 57

Drill .................................................................................................................................................. 57

Toolpath Dialog Boxes.................................................................................................................... 58

Understanding the Tool path...................................................................................................... 58

Setting Tool path parameters.......................................................................................................58

Applying additional features......................................................................................................... 61

Using tool path templates............................................................................................................ 61

Applying a finish cut ................................................................................................................... 63

Creating an inlay.......................................................................................................................... 63

Applying climb milling................................................................................................................ 64

Page 5

Selecting Lead In/Lead Out........................................................................................................ 65

Setting the spindle speed ........................................................................................................... 65

Using the Engrave command ......................................................................................................... 65

Additional information found in the Default Engrave Info Dialog Box................................... 67

Using theMale tool path................................................................................................................. 67

Applying a male basic cut...........................................................................................................67

Applying a male finish cut ..........................................................................................................68

Applying an inlay........................................................................................................................ 69

Cuttingstencils with the Femaletool ............................................................................................. 70

Applying a Female basic cut ....................................................................................................... 70

Adding a Female finishcut......................................................................................................... 72

Adding an inlay............................................................................................................................ 73

Using Cleanout................................................................................................................................ 73

Selecting Direction....................................................................................................................... 73

Applying Use Diagonals.............................................................................................................. 74

Selecting Cleanout shapes........................................................................................................... 75

UsingDrill....................................................................................................................................... 77

Retrieving Drill symbols.............................................................................................................. 77

Generating a Drill tool path......................................................................................................... 78

Chapter 8 : Outpu t Menu..................................................................................................... 81

Job Output Dialog Box.................................................................................................................... 81

Position....................................................................................................................... .................. 82

Material Used............................................................................................................................... 82

Preposition.................................................................................................................................... 82

RouterName................................................................................................................................ 83

Job Header Message..................................................................................................................... 83

In-Place Repeats........................................................................................................................... 84

Repeats.......................................................................................................................................... 85

Plotting Parameters...................................................................................................................... 87

Tool Parameters............................................................................................................................87

Chapter 9 : Panel Menu.......................................................................................................91

HorizontalCutline.......................................................................................................................... 91

Move Cutline................................................................................................................................... 91

Panel Setup...................................................................................................................................... 92

Chapter 1 0 : View Menu.......................................................................................................95

Redraw............................................................................................................................................. 95

Toolbars and StatusBar........................................................................................................... ....... 95

Animate........................................................................................................................................... 95

ShowDry Haul Moves................................................................................................................... 96

Show Path Start Point..................................................................................................................... 96

ColorAssignments..........................................................................................................................96

Chapter 11: W indow Menu................................................................................................99

New Window.................................................................................................................................. 99

Cascade............................................................................................................................................ 99

Tile ................................................................................................................................................... 99

Arrange Icons.................................................................................................................................. 99

CloseAll .......................................................................................................................................... 99

File List ............................................................................................................................................ 99

Page 6

Chapter 1 2 : Getti n g Help in ART Path............................................................................101

Finding a topic................................................................................................................................101

Finding additionaltopics in the Topic pane..............................................................................102

Finding previously-viewed topics.............................................................................................102

Finding frequently-viewed topics..............................................................................................103

Printing topics................................................................................................................................103

Copying topics...............................................................................................................................104

Personalizing Help topics..............................................................................................................104

Displaying the ART Path version..................................................................................................104

Book Three: Intr oduc t ion to Auto- Carve........................................................................105

Chapter 13: Installing Auto-Carve...................................................................................107

SystemRequirements....................................................................................................................107

Installing ARC Station Firmware..................................................................................................108

Installing the FACS-13 Control Board...........................................................................................109

Installing the Auto-Carve Option.................................................................................................111

Chapter 14: Three-Dimensional Carving T oo ls..............................................................113

Carving Tool Sharpness.................................................................................................................114

Selecting a 3-D Tool Path Auto-Carve.....................................................................................115

Using the Default Carve Info dialog box V-Bottom.............................................................115

Default Roughing Tool InformationDialogBox.......................................................................118

Generating a 3D V bottom tool path..........................................................................................120

Using the Default Carve Info Dialog Box Flat-bottom............................................................121

Default Flat-bottom Tool InformationDialog Box....................................................................124

Generating a Flat-bottom3D tool path.........................................................................................125

Setting V-Toolparameters..........................................................................................................125

Choosing basic carving parameters...........................................................................................125

Using a roughing tool............................................................................................................. ....126

Defining Depth Limitations........................................................................................................128

Selecting Flat Bottom..................................................................................................................129

Prismatic ...................................................................................................................... ...................133

Reviewing the Default Prismatic Info dialogbox.....................................................................133

Eliminating RoughEdges...........................................................................................................136

Generating a 3-D Tool Path ......................................................................................................... ..137

SmartEditinga Tool Path..............................................................................................................137

Masking the Sign Blank.................................................................................................................138

Routing the Design........................................................................................................................139

Initializing the Router (D200 or AR600)....................................................................................139

To initializea Sabrerouter to the table ......................................................................................140

To initializea Sabrerouter to the material surface......................................................................141

Finishing the Design......................................................................................................................141

Appendix A: ART Pa th Glossary.......................................................................................143

Appendix B: Material Flat n ess.........................................................................................147

Manufactured Material..................................................................................................................147

Wood...............................................................................................................................................147

GrainType and Sawing Techniques..........................................................................................147

Moisture Content and Humidity...............................................................................................148

Shipping.......................................................................................................................................148

Page 7

Storage.........................................................................................................................................148

Carving into a Warped Panel........................................................................................................148

Appendix C: Spe e ds and Feed s for Standard R outer Motor.......................................149

Index....................................................................................................................................151

Page 8

Page 9

1

Book One:

Introduction to ART Path

ART Path32 is an OMEGA output tool that is used to link a Gerber routing system to

OMEGA programs. The Gerber routing systems listed below can be used with the ART Path

program:

♦ Sabre series 404 and 408

♦ Dimension 200

♦ ADVANTAGE R outer 600

ART Path allows you to benefit from the OMEGA Composer's design capabilities while

offering routing features such as:

♦ Climb Milling

♦ Lead In/Lead Out

♦ User-defined Tool Table

♦ Nesting Placement

♦ Drill

ART Path automatically generates tool paths for male, female, engraved, or cleanout tool paths.

It also enables automatic cutting of inlay shapes with rounded edges, use of multiple cutters

and/or depths of cut within the same job, and operator messaging while the job is being cut on

the router.

Jobs created in Composer are brought into the ART Path program where the design may be

viewed closely and nested for better positioning to conserve material.

Page 10

Page 11

3

Chapter 1:

Setting up ART Path

Unpacking/Installation

♦ If you are adding the ART Path option to your existing OMEGA release, please

continue with the instructions below (starting with the “Package contents” paragraph)

in order to install ART Path on your system.

♦ If you are upgrading to or have just purchased OMEGA, you should already have

followed the instructions in the Getting Started guide for installing OMEGA as well as

any other fonts, libraries, and options acquired, including ART Path. Refer to

documentation for your particular router if necessary for instructions on physically

connecting the router to the OMEGA system.

System requirements

Before ART Path can be installed and used, your system should be set up with the following

releases:

♦ OMEGA 2.0/2.1 with Microsoft® Windows® version 98, 2000, ME, or XP

♦ OMEGA 2.5 and higher with Microsoft Windows version 2000 or XP

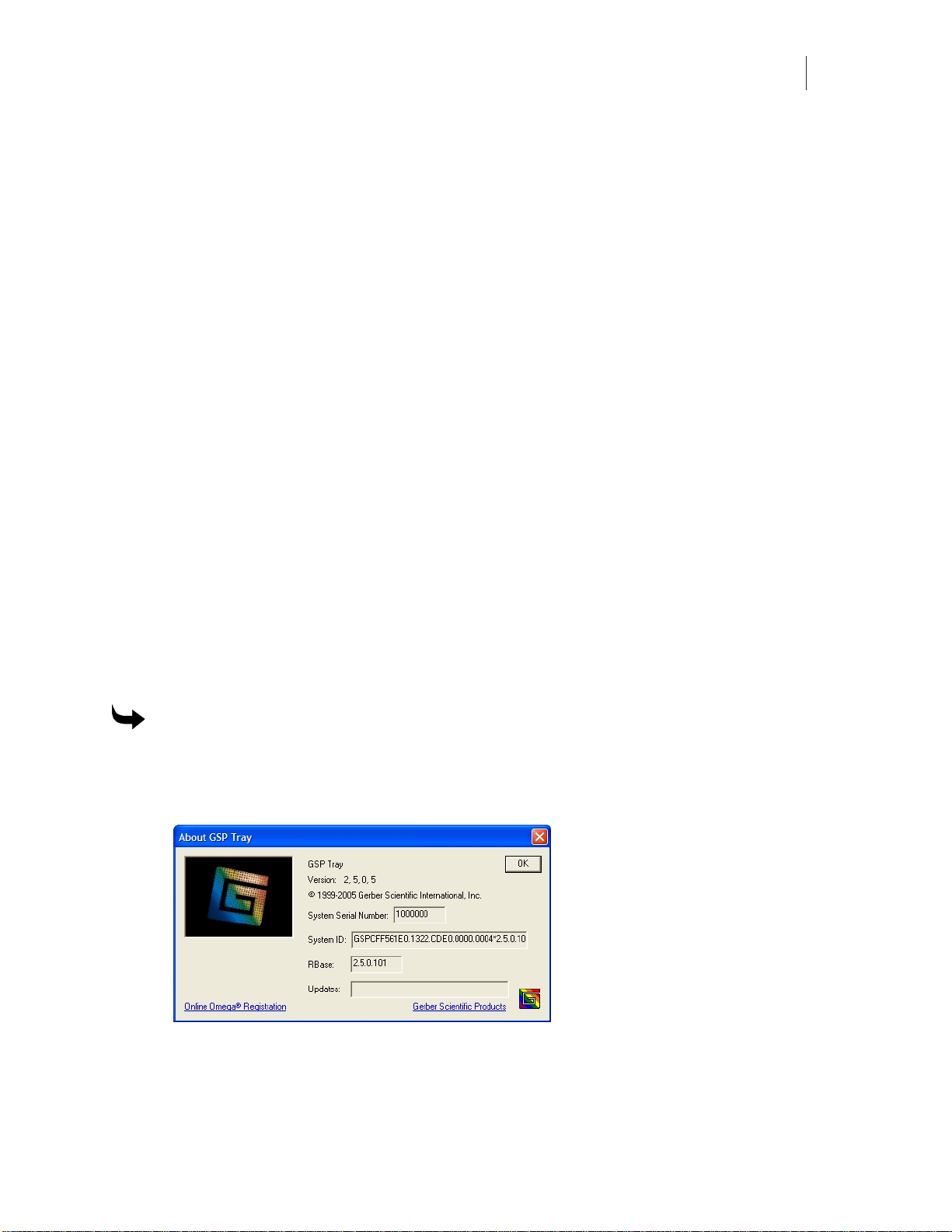

To verify your OMEGA release

1 Right-click the GSP Tray icon that appears on the right end of the Windows s tatus bar

to open the Gerber Tray menu.

2 Click About GSP Tray. The number in the Rbase field is your OMEGA version.

3 Verify that the version listed in the Rbase field matches the software that you are

installing.

4 Click OK to return to your desktop.

Page 12

Chapter 1

4

Setting up ART Path

Installing the ART Path software option

This procedure describes loading ART Path as an option after OMEGA has been installed.

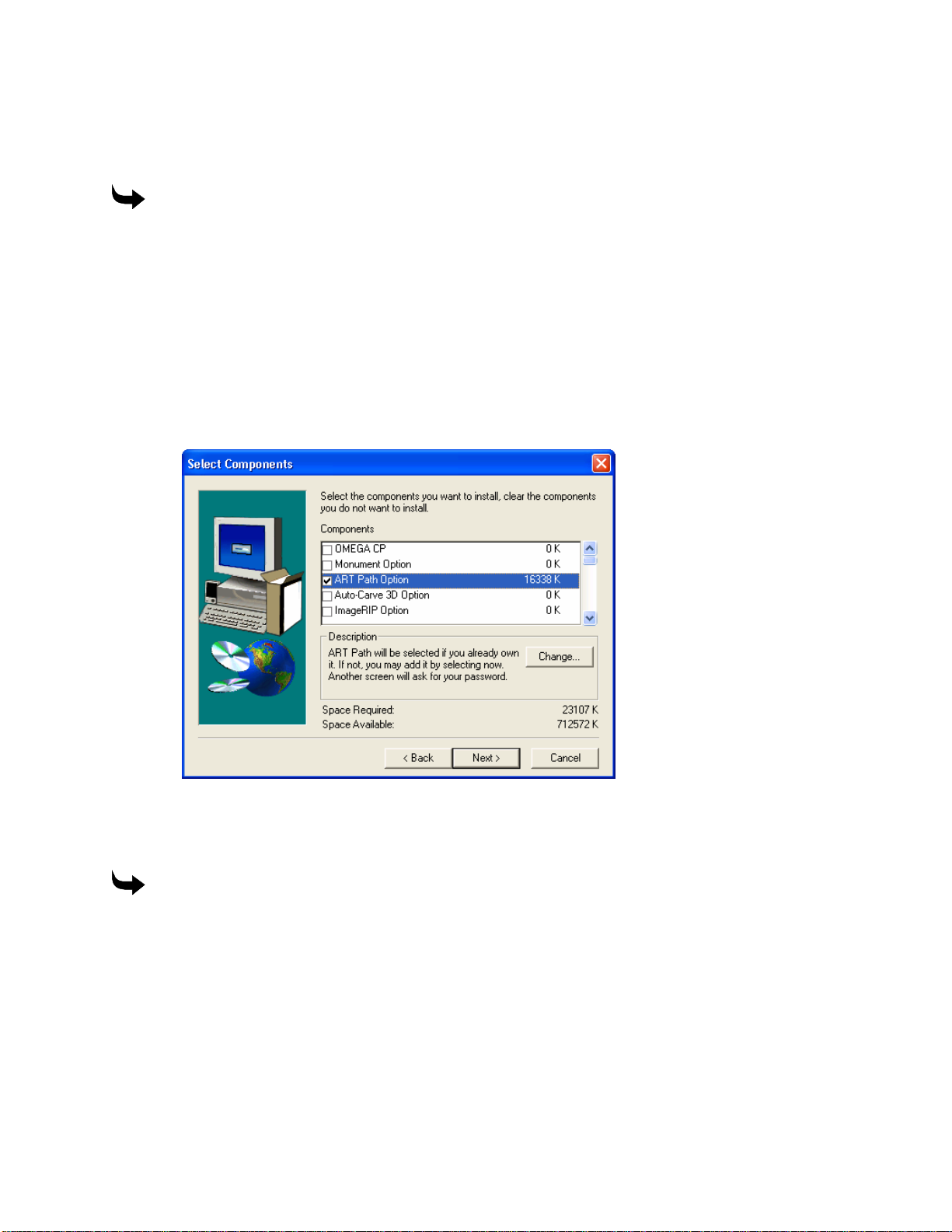

To install the ART Path software option

1 Insert the OMEGA installation CD disk into the disk drive. The OMEGA Setup Wizard

should automatically display. If it does not click Start > Run to display the Run dialog

box. Type D:\Setup.exe and click OK (Where D:\ is the drive containing the disk).

2 Click Install Products to display the Install Products menu.

3 Click Install OMEGA 2.5. Follow the instructions until the Installation Type dialog box

displays. Choose Add/Reload Individual components and click Next.

4 At the Select Components dialog box turn on ART Path Option. If you have purchased

the Auto-Carve Option turn on this option as well. Auto-Carve requires a password to

load. Click Next to load the software.

5 When the installation completes, click Finish and restart your computer.

Accessing ART Path

To access Art Path

Click Start > Programs > GSP OMEGA > ART Path32.

Page 13

5

Customer Support

If you require assistance installing or using ART Path, contact your Gerber

!

Please use a phone that is close to your system and have the following available before calling:

If you have an OMEGA system, please have the following information ready as well:

distributororGerberTechnicalSupportat:

Phone: 860-644-6971

Fax: 860-871-3862

e-mail: gsptech@gspinc.com

♦ Microsoft Windows version numbers

♦ Systemserial number

♦ Router serial number

♦ Router User Manual

♦ OMEGA, Windows, and hardware utility CD’s.

♦ OMEGA Reference Guide

♦ The names of any peripheral (output) devices, such as a printer.

Page 14

Page 15

7

Chapter 2:

Reviewing the ART Path Toolbox

The Toolbox is located on the left side of the ART Path window. The toolbox contains tools,

which allow the user to select, zoom in, and position the shapes in a design. You can also choose

a tool path from the Toolbox.

Cancel Select

Cancel Select makes all previously selected shapes unavailable. It is useful in correcting a

selection mistake.

To deselect a shape, click on the Cancel Select Tool. The selected shape becomes deselected.

Pointer

Pointer selects and deselects a shape.

When the Pointer Tool is clicked on in the toolbox, the mouse pointer changes to a pointing

finger. The selected shape is redrawn with a solid blue line.

The Pointer Tool is also used for Smart Editing. Smart Edit allows the user to change the tool

path settings. The user returns to the specific tool path dialog box for editing the desired

parameters. A shape or design does not have to be selected first before it may be Smart Edited.

A shape must be selected with the Pointer Tool first before choosing a tool path. When using the

rubber band method of selection, the rubber band box must surround the entire shape.

To select or deselect a shape

1 Click the Pointer Tool. The mouse pointer changes to a pointing finger when moved

into the working area.

2 Move the Pointer Tool until it touches the shape and click the left mouse button. The

shape is selected and redrawn in solid blue lines. If a shape is deselected, it is redrawn

in a contrasting color.

To select or deselect multiple shapes

1 Click the Pointer Tool. The mouse pointer changes to the Pointer Tool when moved

into the working area.

2 Move the Pointer Tool to a top corner above the shapes to be selected.

3 Click and drag the tool across the shapes to the opposite corner. As the Pointer Tool is

moved, a rubber band box will be drawn around it.

Page 16

Chapter 2

8

Reviewing t h e ART Path Toolbox

4 Release the mouse button. The shapes are selected and redrawn in solid blue lines. If

shapes are deselected, they are redrawn in a contrasting color.

Zoom

Zoom magnifies a piece of a design for a closer look. When the Zoom Tool is clicked on, the

mouse pointer changes to a cross hair with a small magnifying glass shown in the lower right

corner. The design is centered and fills as much of the working area as possible after each zoom.

All tools and menu commands work on a zoomed design as on an unzoomed design. Line

lengths remain the same at every magnification.

To magnify part of a design

1 Click the Zoom Tool. The tool is highlighted. The mouse pointer changes when moved

into the working area.

2 Move the Zoom Tool to a top corner above the shape to be magnified.

3 Click and drag the Zoom Tool across the shape to be magnified. A dotted box is drawn

around the shape.

4 Click the right m ouse button. The area within the box is magnified.

5 Repeat Steps 1-4 to magnify the shape again.

Unzoom

The Unzoom Tool returns a design to its original appearance or to the previous appearance in a

series of zooms.

Unzoom remembers the appearance of the previous five zooms performed on the same design.

Clicking the left mouse button on the Unzoom Tool backtracks the working area to the previous

zoom appearance. Clicking the right mouse button on the Unzoom tool returns the design to its

original appearance before the first zoom.

Unzoom is available only after using the Zoom Tool. Only the Unzoom Tool remembers the last

five zooms. Backtracking to a sixth zoom automatically returns the design to its original

appearance.

To return a design to the previous appearance in a series of zooms

1 Click the Unzoom Tool.

2 Click the left mouse button. The magnified design redraws to its last appearance.

3 Repeat steps 1 and 2 to backtrack through each previous appearance in the series of

zooms.

Note: The design automatically returns to its original appearance on the sixth backtrack.

Page 17

9

To return a design to full size after magnifying it

Click the Unzoom Tool with the right mouse button.

Male

Male allows the user to generate a tool path to create a solid shape from the material. Clicking

on the Male Tool opens the Default Male Info Dialog Box. Refer to the “Toolpath Dialog Boxes”

section for more information. The shape must be selected before the Male Tool is available for

use.

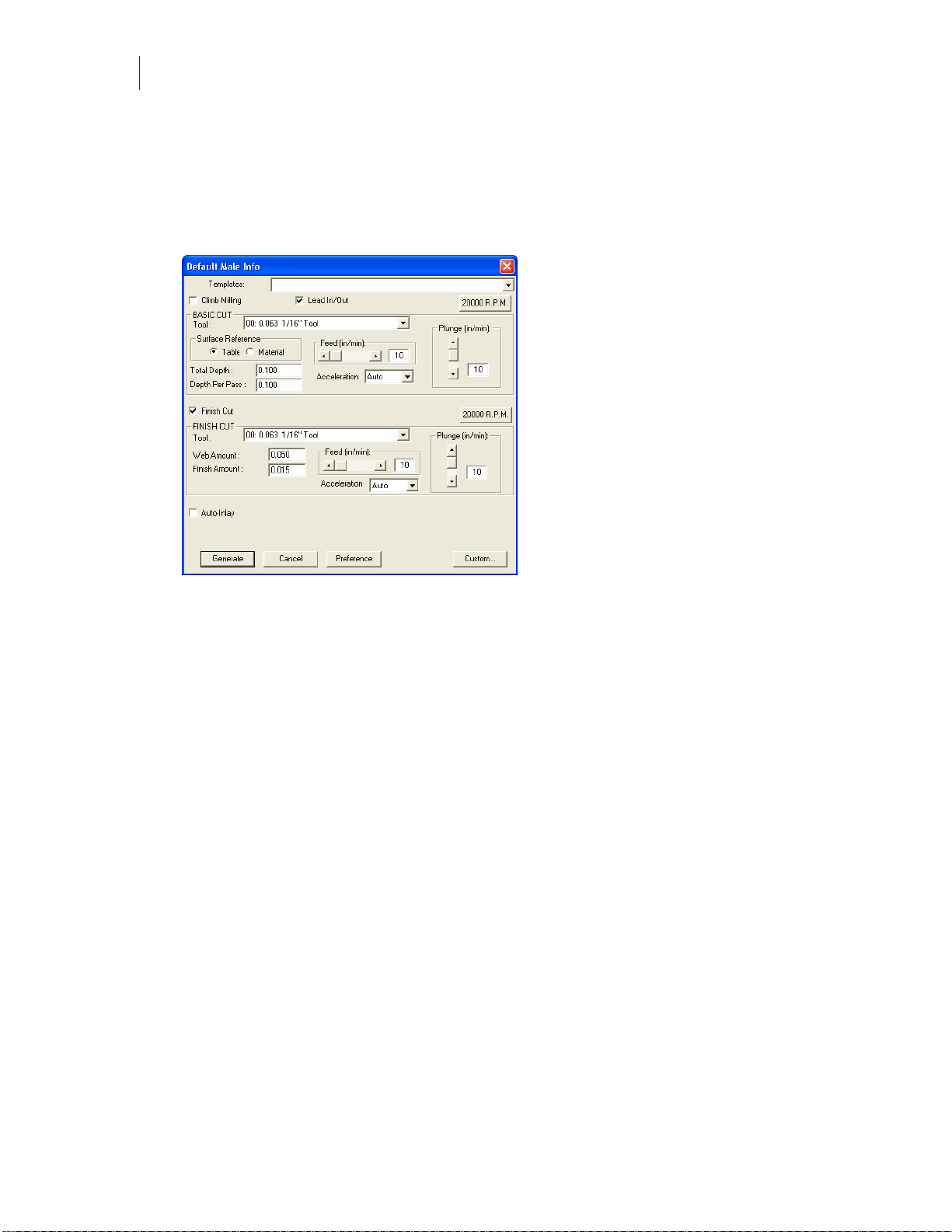

To set male basic cut parameters

1 Select the shape to be routed with the Pointer Tool. The selected shape changes in

color to show it is selected.

2 Click the Male Tool in the Toolbox. The Default Male Info dialog box appears on

screen.

3 In Basic Cut, click the down arrow on the right side of the Tool entry box. A drop

down list box appears.

4 Click the desired routing tool.

5 Enter the desired parameters for Total Depth, Depth Per Pass, Feed Rate, Plunge Rate,

RPM’s, Acceleration, and Surface Reference into the dialog box.

6 Click Generate, the tool path appears on screen in a contrasting color.

To set male and finish cut parameters

Note: It is important for Finish Cut to use the same tool used for Basic Cut.

1 Select the shape to be routed with the Pointer Tool. The selected shape changes in

color to show it is selected.

2 Click Male from the Tool Paths menu. The Default Male Info Dialog Box opens.

Page 18

Chapter 2

10

Reviewing t h e ART Path Toolbox

3 Click the down arrow on the right side of the Tool entry box. A drop-down list box

appears.

4 Click the desired routing tool.

5 Enter the desired Basic Cut parameters.

6 Turn on Finish Cut to display the Finish Cut parameters.

7 Click the down arrow on the right side of the Tool entry box. A drop down list box

appears.

8 Click the desired routing tool.

9 Enter the desired Finish Cut parameters for Web Amount, Finish Amount, Feed Rate

and Plunge Rate.

10 Click the 20000 R.P.M. button. The Enter Spindle Speed dialog box appears. Type the

desired speed (between 6,000 and 24,000 RPM) and click OK to close the dialog box.

11 Click Generate in the tool path information dialog box. The Basic Cut tool path and the

Finish Cut tool paths appear on screen in contrasting colors.

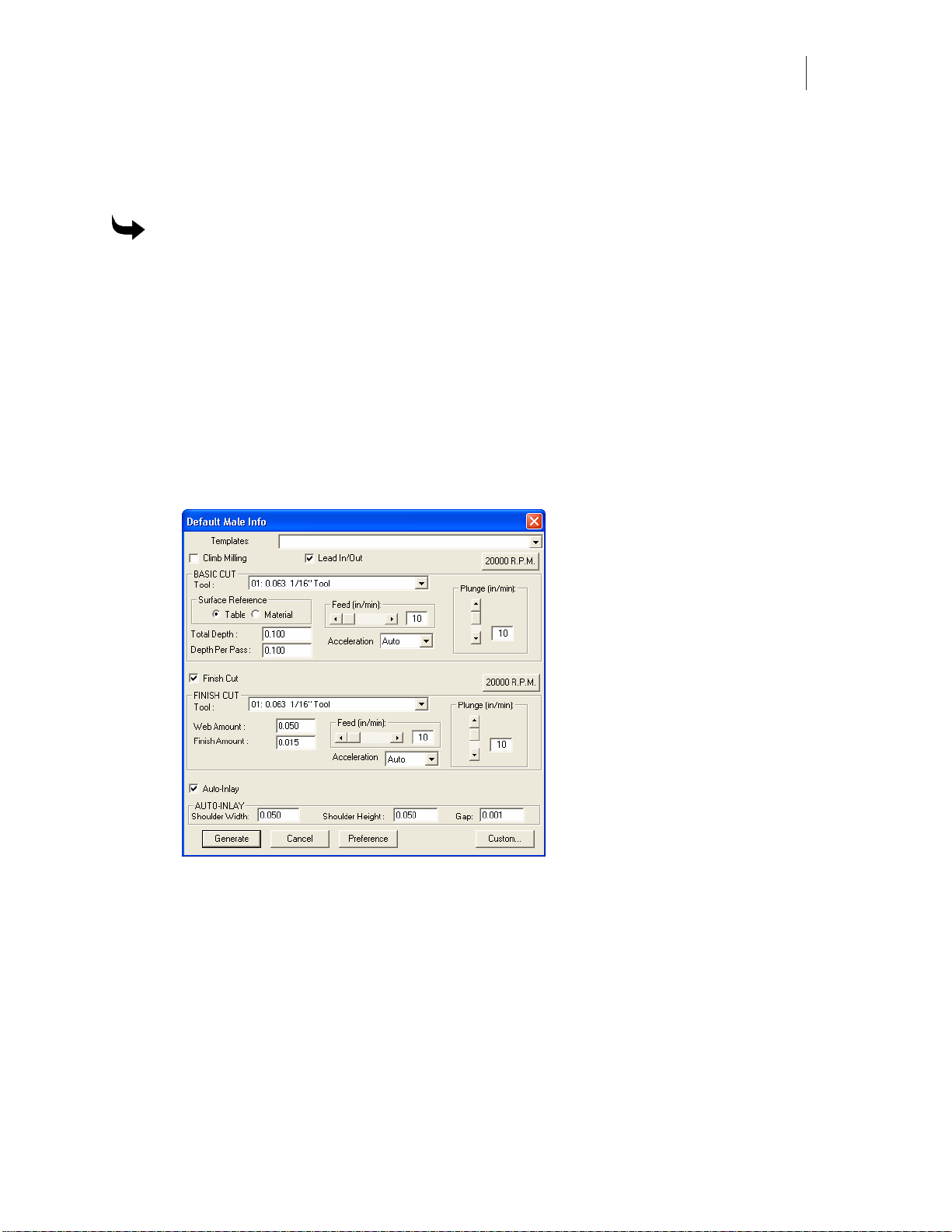

Male Auto Inlay Parameters

Auto-Inlay parameters provide information on how the two shapes (male and female) are

routed. The two auto-inlay shapes must be routed with the same tool. Auto-Inlay is an optional

parameter.

Auto-Inlay parameter values for shoulder width, shoulder height, and gap are entered when a

Shoulder is cut from the material. A Shoulder prevents light from showing through gaps

between the inlaid shapes. A Shoulder is also useful to hold letters in place. Click on the AutoInlay check box. An X appears in the check box and the Auto-Inlay parameters appear in the

dialog box.

♦ The Shoulder Width should be less than 2 or equal to the tool size. A typical shoulder

width is .125 inches (3.175mm).

Page 19

11

♦ AtypicalShoulder Height is .125 inches (3.175mm).

♦ The Gap is the amount of material that is cut between the male and female shapes. The

Gap enables the two shapes to fit together properly. A recommended gap is .005

inches (.127mm) wide.

To set male and auto-inlay paramet er s

1 Select the shape to be routed with the Pointer tool. The selected shape changes in color

to show it is selected.

2 Click Tool Path from the menu bar.

3 Click Male to display the Default Male Info Dialog Box.

4 Click the down arrow on the right side of the Tool entry box. A drop-down list box

appears.

5 Click the desired routing tool.

6 Enter the desired Basic Cut parameters.

7 Turn on Auto-Inlay to display the Auto-Inlay parameters.

8 Enter the desired parameters for Shoulder Width, Shoulder Height and Gap (see the

guidelines above for reference.) If no shoulder is desired, set shoulder width & height

to zero.

9 Click Generate in the tool path information dialog box. The Basic Cut tool path, the

Finish Cut tool path, and the Inlay Tool path appear on screen in contrasting colors.

Page 20

Chapter 2

12

Reviewing t h e ART Path Toolbox

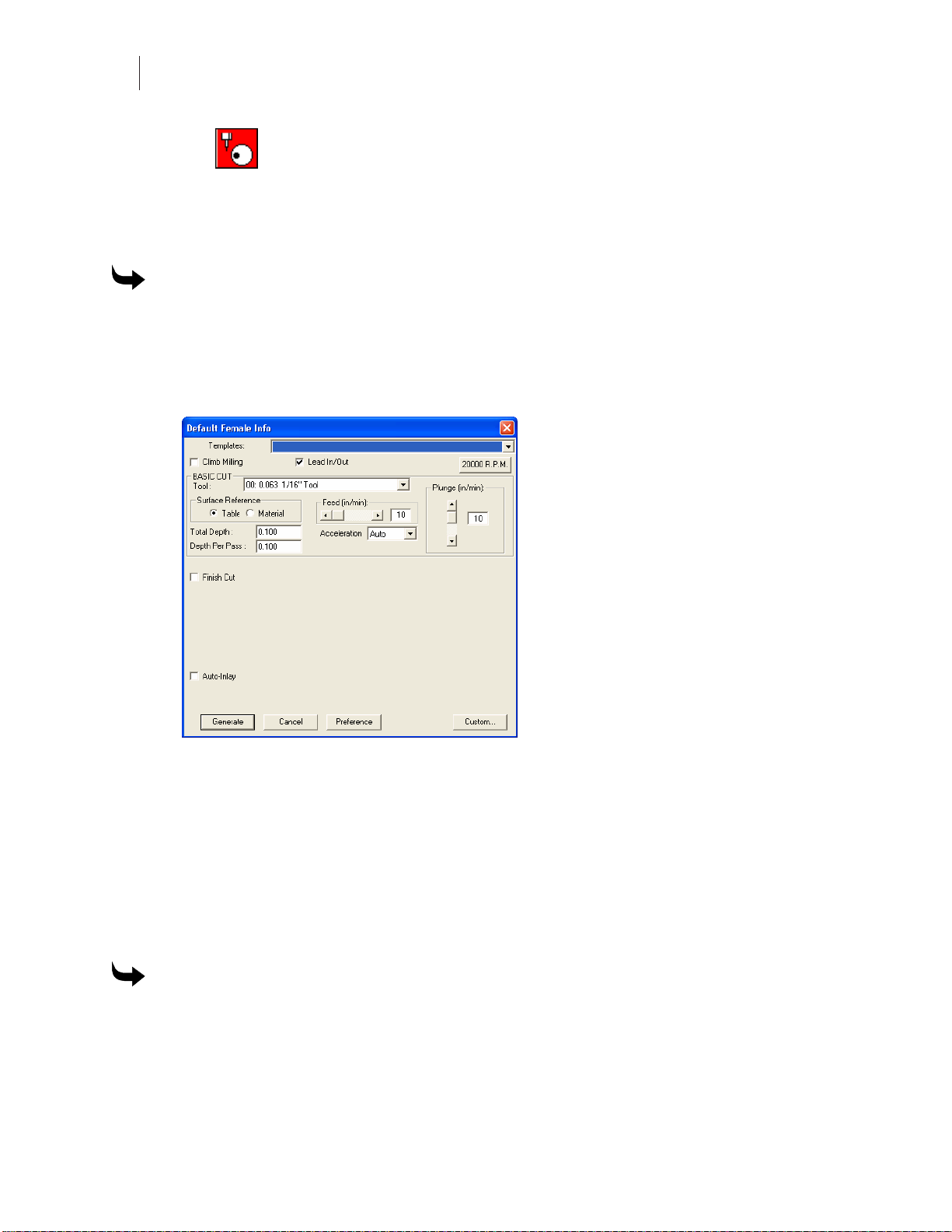

Female

Female allows the user to generate a tool path to create a stencil from the material. Clicking on

the Female Tool opens the Default Female Info Dialog Box. Refer to the “Toolpath Dialog

Boxes” section for more information. The shape must be selected before the Female Tool is

available for use.

To set female basic cut parameters

1 Select the shape to be routed with the Pointer tool. The selected shape changes in color

to show it is selected.

2 Click Tool Path from the menu bar.

3 Click Female to display the Default Female Info Dialog Box.

4 Click the down arrow on the right side of the Tool entry box. A drop down list box

appears.

5 Click the desired routing tool.

6 Enter the desired parameters for Total Depth, Depth Per Pass, Feed Rate, Surface

Reference, RPM’s, Acceleration and Plunge Rate into the dialog box.

7 Click the 20000 R.P.M. button. The Enter Spindle Speed dialog box appears. Type the

desired speed (between 6,000 and 24,000 RPM) and click on OK to close the dialog box.

8 Click Generate. The tool path appears in a contrasting color.

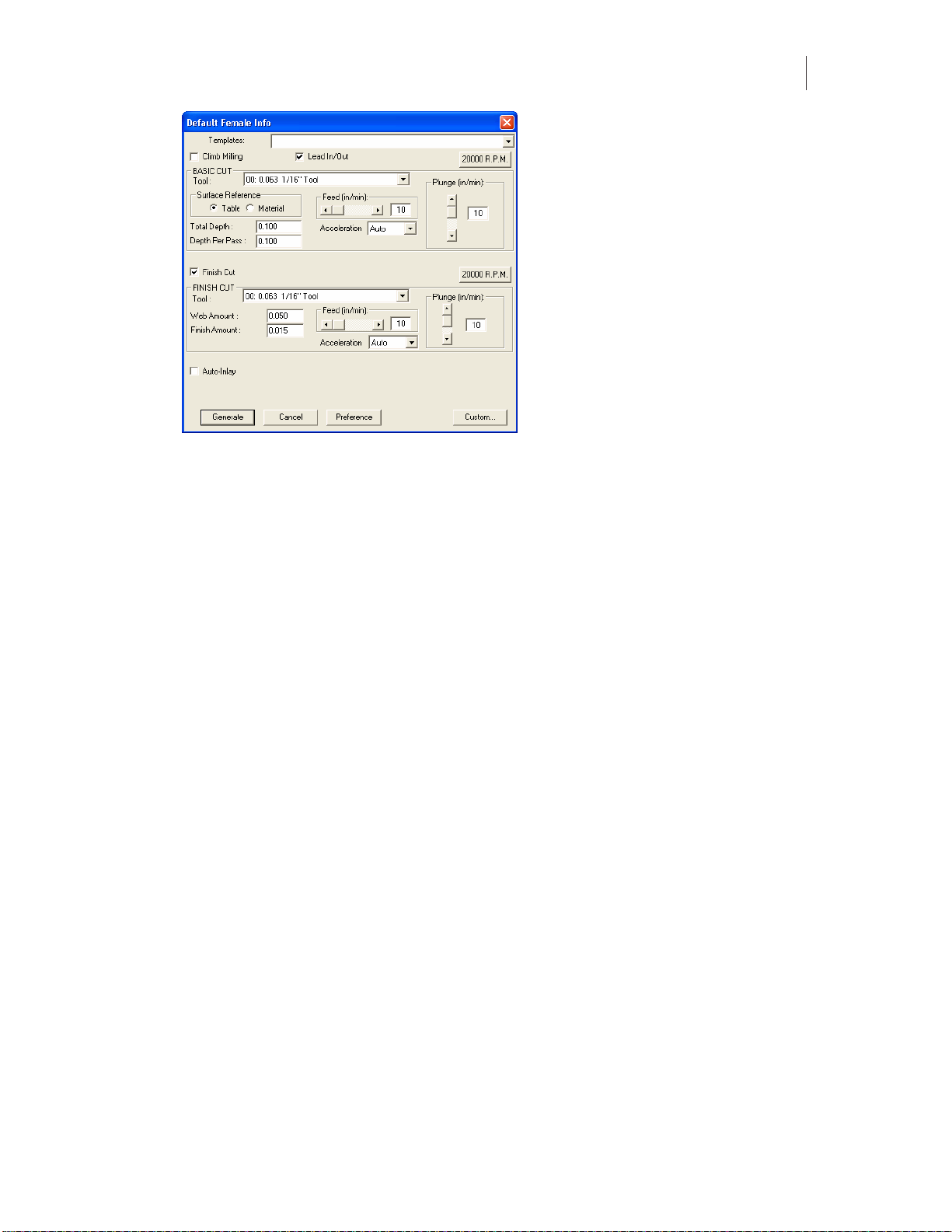

To set female and finish cut parameters

1 Select the shape to be routed with the Pointer Tool. The selected shape changes in

color to show it is selected.

2 Click Tool Path from the menu bar.

3 Click Female to display the Default Female Info Dialog Box.

Page 21

13

4 Click the down arrow on the right side of the Tool entry box. A drop-down list box

appears.

5 Click the desired routing tool.

6 Enter the desired Basic Cut parameters.

7 Click the Finish Cut check box, an X appears in the check box. The Finish Cut

parameters appear on screen.

8 Click the down arrow on the right side of the Tool entry box. A drop down list box

appears. Choose the same tool that was used for the Female Basic Cut.

9 Click the desired routing tool.

10 Enter the desired Finish Cut parameters for Web Amount, Finish Amount, Feed Rate

and Plunge Rate.

11 Click the 20000 R.P.M. button. The Enter Spindle Speed dialog box appears. Type the

desired speed (between 6,000 and 24,000 RPM) and click on OK to close the dialog box.

12 Click Generate in the tool path information dialog box. The Basic Cut tool path and the

Finish Cut tool paths appear on screen in contrasting colors.

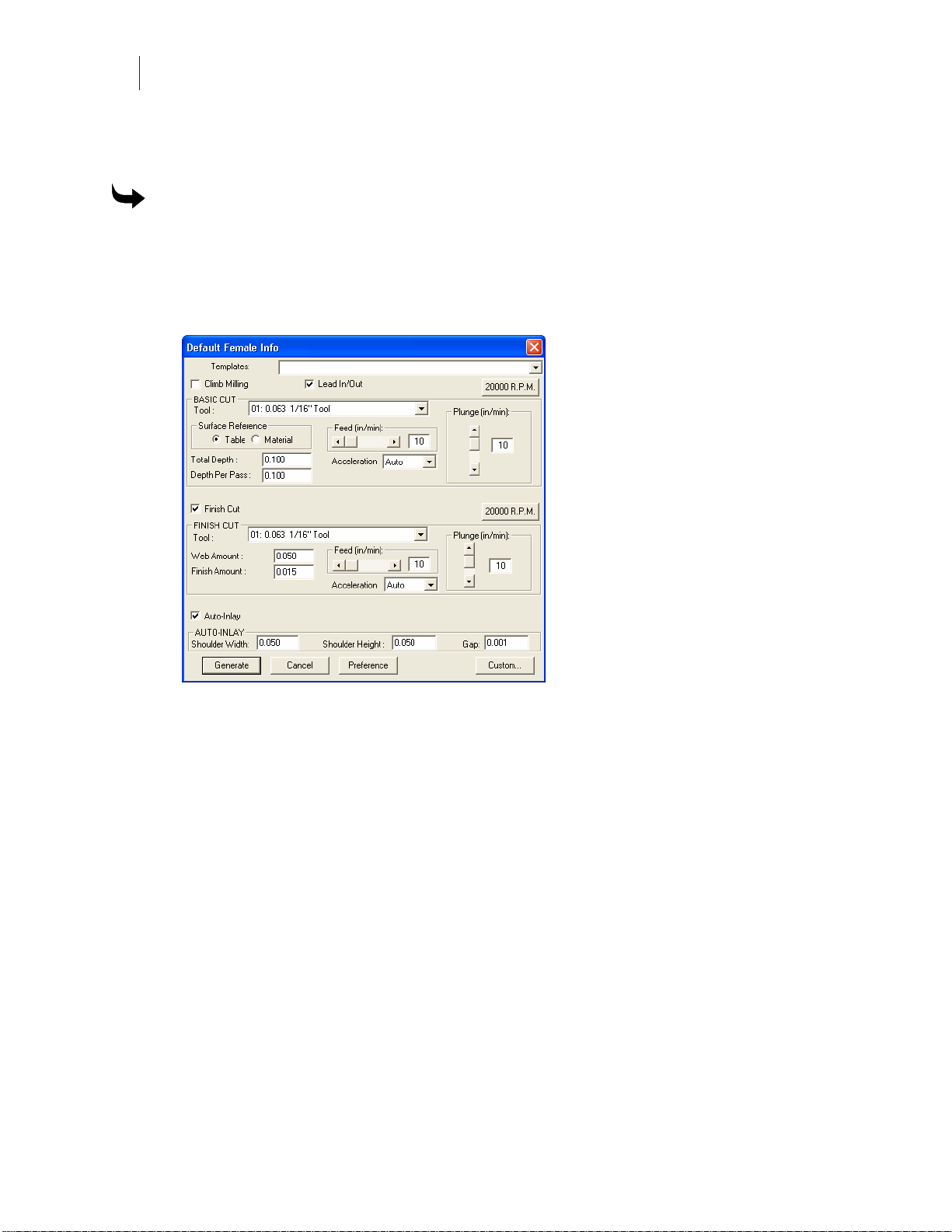

Female Auto-Inlay Parameters

The Auto-Inlay parameters are used when a Shoulder is cut from the material. The purpose of a

Shoulder is to prevent light from showing through gaps between the inlaid shapes. A Shoulder

is also useful to hold letters in place. Click on the Inlay check box. An X appears in the check

box. The Auto-Inlay parameters appear in the dialog box.

♦ The Shoulder Width should be less than the tool size. A typical shoulder width is .125

inches (3.175mm).

♦ Atypicalshoulder height is .125 inches (3.175mm).

Page 22

Chapter 2

14

Reviewing t h e ART Path Toolbox

♦ The Gap is the amount of material that is cut between the male and female shapes. The

Gap enables the two shapes to fit together properly. A recommended gap is .005

inches (.127mm) wide.

To set female auto-inlay parameters

1 Select the shape to be routed with the Pointer Tool. The selected shape changes in

color to show it is selected.

2 Click Tool Path from the menu bar.

3 Click Female to open the Default Female Info Dialog Box.

4 Click the down arrow on the right side of the Tool entry box. A drop-down list box

appears.

5 Click the desired routing tool.

6 Enter the desired Basic Cut parameters.

7 Click the Auto-Inlay check box an X appears in the check box. The Auto-Inlay

parameters can be entered.

8 Enter the desired Auto-Inlay parameters for the Shoulder Width, Shoulder Height and

Gap (see the guidelines above for reference.) If no shoulder is desired, set shoulder

width & height to zero.

9 Click Generate. Both the Auto-Inlay tool path and the Basic Cut tool path appear on

screen in contrasting colors.

Page 23

15

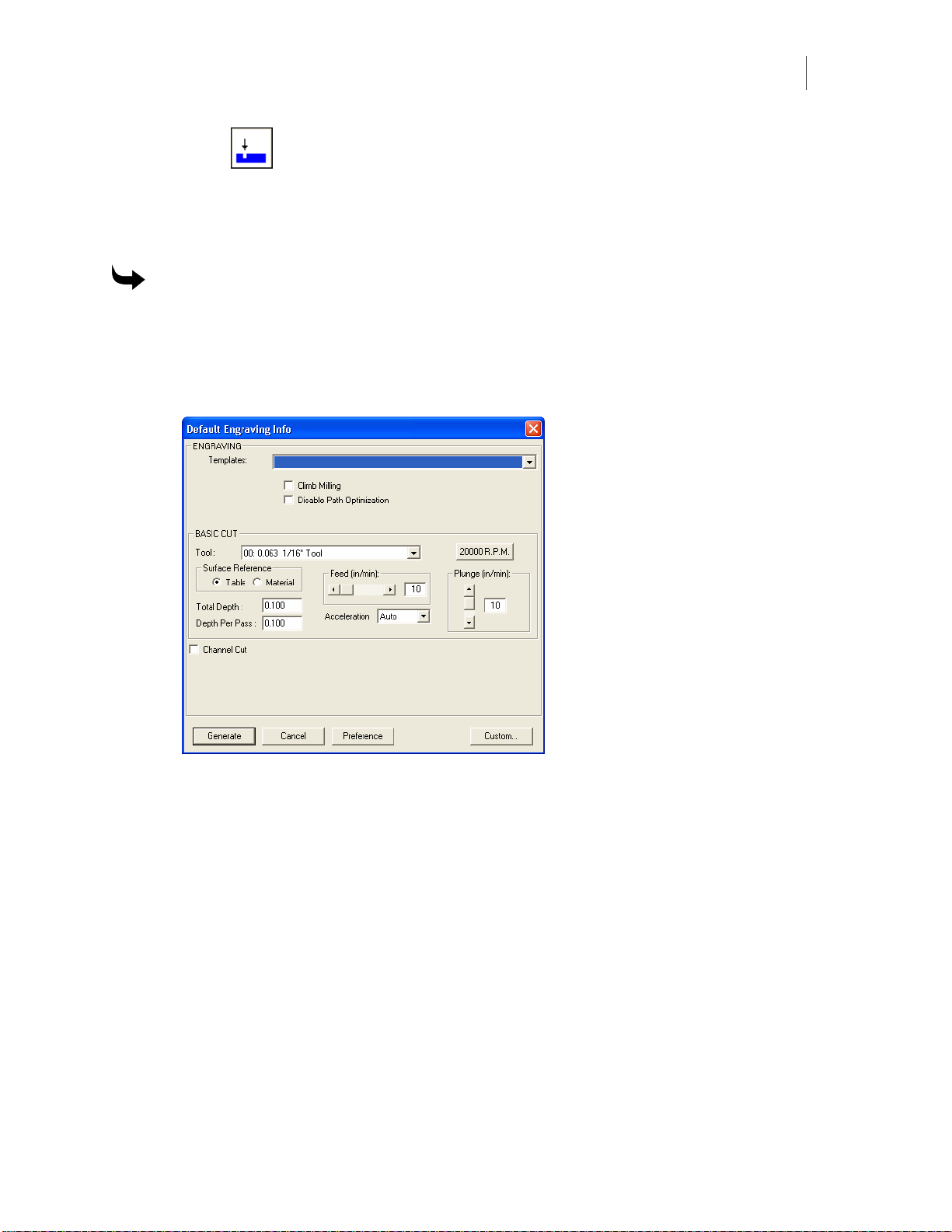

Engrave

The Engrave Tool etches a design into the material on the shape's contour without using an

offset. Clicking on the Engrave Tool opens the Default Engrave Info Dialog Box. Refer to the

section “Toolpath Dialog Boxes” for more information. The shape must be selected before the

Engrave Tool is available for use.

To set engraving parameters

1 Select the shape to be routed with the Pointer Tool. The selected shape changes color

to show it is selected.

2 Click Tool Path from the menu bar.

3 Click Engrave. The Default Engraving Info dialog box appears on screen.

4 Click the down arrow on the right side of the Tool entry box. A drop-down list box

appears.

5 Click the desired Engraving Tool.

6 Enter in the desired parameters for Total Depth, Depth Per Pass, Surface Reference,

Acceleration, RPM’s and Plunge Rate into the dialog box.

7 Click Generate to set the tool path. The tool path appears on screen in a contrasting

color.

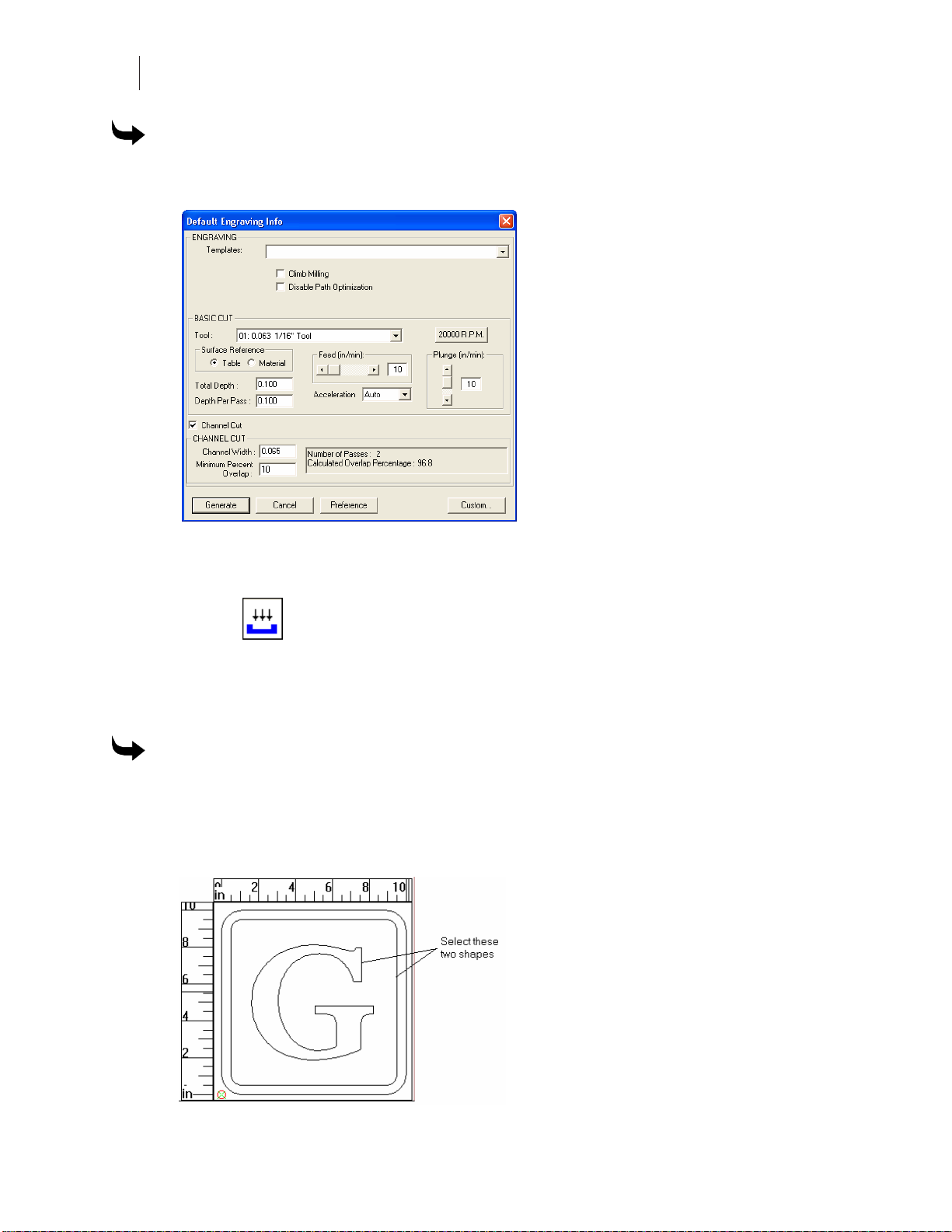

Engraving Channel Cut Parameters

The Channel Cut featuregenerates tool paths for channels whose width is larger than the

diameter of the available cutters. Turn on Channel Cut and set the stroke width. ART Path

automatically calculates the number of passes required and the percentage of overlap that

occurs.

Page 24

Chapter 2

16

Reviewing t h e ART Path Toolbox

To use Channel Cut

1 In the Default Engraving Info box, turn on Channel Cut to display the Channel Cut

dialog box.

2 Enter a value for the Stroke Width of the crease channel.

3 Click Generate to create a Channel Cut tool path for this job.

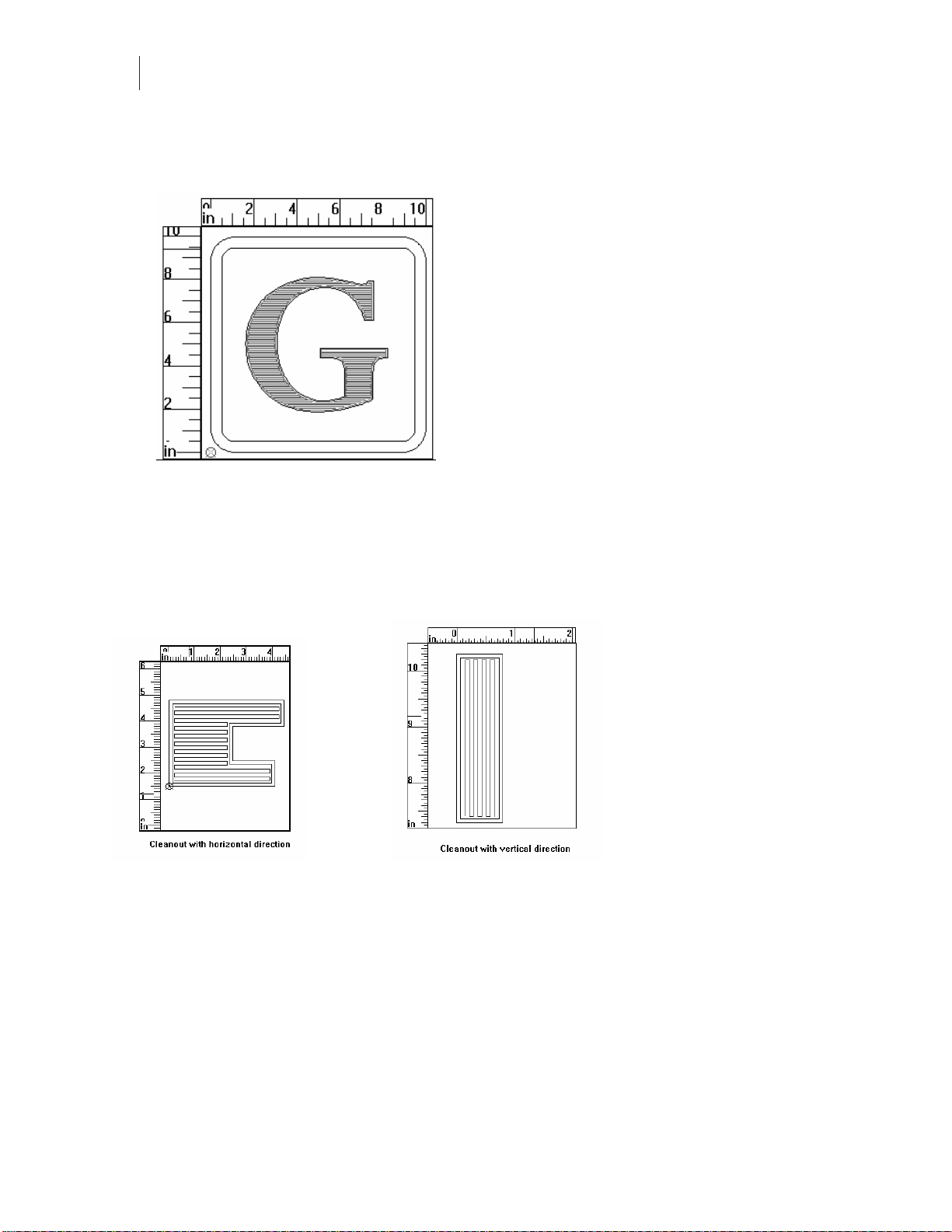

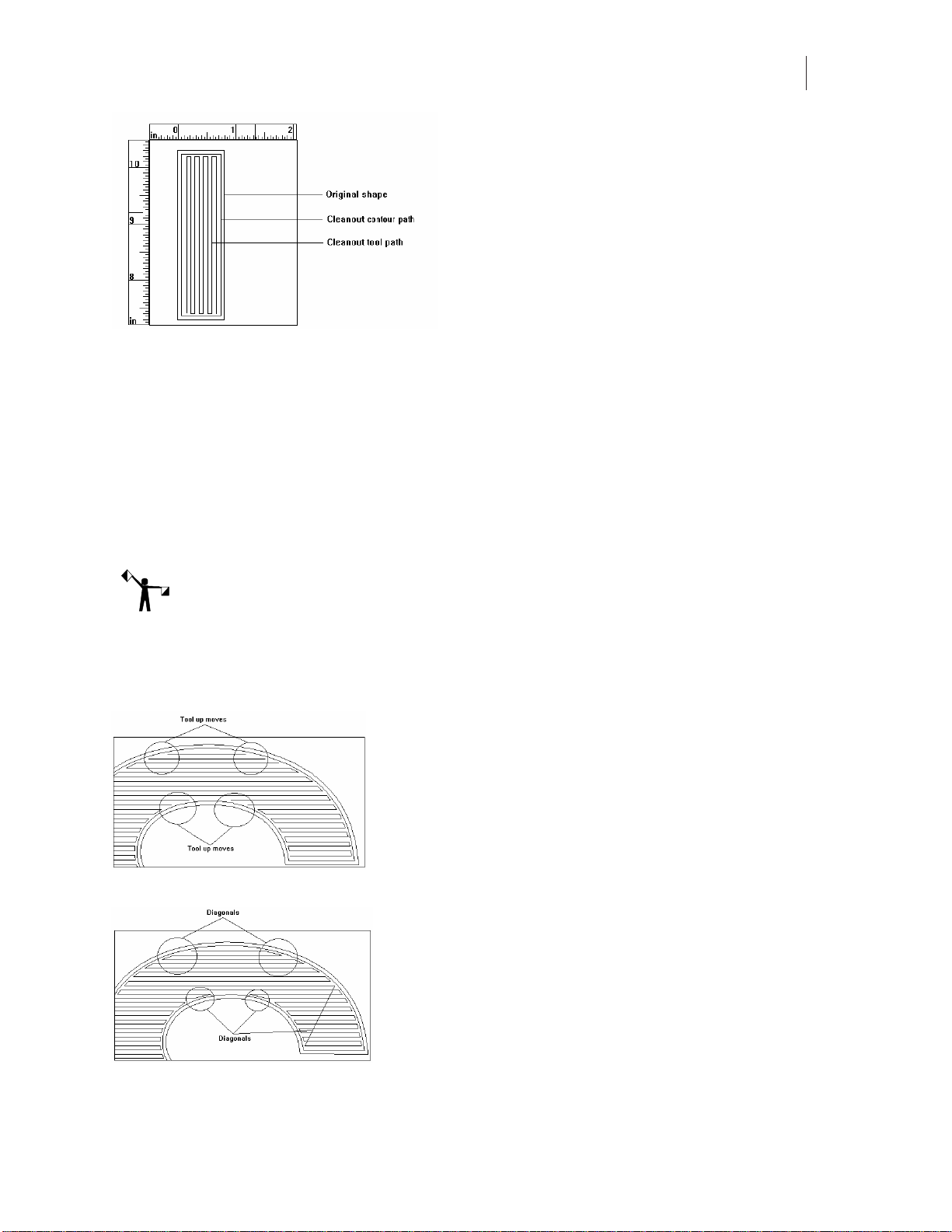

Cleanout

Cleanout routs an area of a shape without completely cutting through the material. C licking on

the Cleanout Tool opens the Default Cleanout Info Dialog Box. Refer to the section “Toolpath

Dialog Boxes” for more information. The sha pe must be selected before the Cleanout Tool is

available for use.

To set parameters to cleanout a backgr ound shape

To clean out a background around a shape, select the background and the shape it surrounds. If

needed nest the shapes before generating the Cleanout tool path.

1 Select the shapes to be routed with the Pointer Tool. The selected shape changes in

color to show it is selected.

Page 25

17

2 Click Tool Path from the menu bar.

3 Click Cleanout to open the Default Cleanout Info Dialog Box.

4 Click the down arrow on the right side of the Tool entry box. A drop down list box

appears.

5 Click the desired routing tool.

6 Enter the desired Cleanout parameters for the Total Depth, Depth Per Pass, Feed Rate,

Plunge Rate, Surface Reference, Acceleration, RPM’s and Direction.

7 Click Generate. The tool path appears in a contrasting color.

To set parameters to cleanout a for egr ound shape

1 Select the foreground shape to be routed with the Pointer Tool. The selected shape

changes in color to show it is selected.

2 Click Tool Path from the menu bar.

3 Click Cleanout. The Default Cleanout Info Dialog Box appears on screen.

4 Click the down arrow on the right side of the Tool entry box. A drop-down list box

appears.

5 Click the desired routing tool.

Page 26

Chapter 2

18

Reviewing t h e ART Path Toolbox

6 Enter the desired Cleanout parameters for the Total Depth, Depth Per Pass, Feed Rate,

Plunge Rate, Surface Reference, Acceleration, RPM’s and Direction.

7 Click Generate. The tool path appears in a contrasting color.

Direction

Cleanout Direction refers to the horizontal or vertical direction of the Cleanout tool path.

Selecting a Direction in Cleanout makes cutting cleanout shapes more efficient.

Use Horizontal when the design contains many horizontal elements. Use Vertical when the

design contains many vertical elements.

Cleanout tool path consists of two paths. The first is the cleanout path; the second path follows

the shape contour and smoothes the edge.

Page 27

19

Auto-Inlay Parameters

An inlay consists of a solid male shape that fits snugly into a stencil female shape or cleaned-out

area. A cleanout shape can be cut as an inlay shape. By applying Auto-Inlay to a Cleanout tool

path, the Cleanout shape is automatically cut with rounded corners. Auto-Inlay produces

shapes with matching corner radii, which do not require hand filing to ensure a good fit.

A typical use of Cleanout and Auto-Inlay is to clean out a foreground shape, and cut a mating

male shape for inlay.

To apply inlay to a Cleanout shape, click on the Auto-Inlay check box in the Cleanout dialog

box.

Note: A Cleanout Inlay shape and its mating shape must be cut with the same diameter tool.

Use Diagonals

The Use Diagonals feature allows certain shapes to be cut more efficiently by eliminating some

tool up moves by the router.

Shape with cleanout tool path without diagonals

Shape with cleanout tool path with diagonals

Page 28

Chapter 2

20

Reviewing t h e ART Path Toolbox

Drill

The Drill Tool allows the user to generate tool drilling positions designated on the design in

Composer. When the design is opened in the ART Path program, the drill symbol designates

the tool drilling position. Clicking on the Drill Tool opens the Default Drill Info Dialog Box.

Refer to the section “Toolpath Dialog Boxes” for more information. The shape must be selected

before the Drill Tool is available for use. The user must open a drill symbol from the Composer

Library before designating a drill tool path in the ART Path program.

If the drill symbol is larger than the tool chosen for the Drill tool path, no tool path is generated.

If the drill symbol is smaller than or equal to the tool, then the Drill tool path is generated.

To open and position a drill symbol from Composer

1 Create a design to be routed in Composer.

2 Click File. A drop down menu appears on screen.

3 Click Library. The File Open Dialog Box appears on screen.

4 From the Libraries List Box, click on Drill. The Drill.GCA’s appear in the Files List Box.

5 Click the desired drill symbol. Make sure the drill symbol chosen is not larger than the

routing tool.

6 Click Open. The chosen drill symbol appears in the working area.

7 Select the drill symbol with the Pointer Tool.

8 Use the Move Tool to position the drill symbol to the desired location in the design.

Repeat this process to add and position additional drill symbols to the design.

9 Save the design. The drill symbols appear on the design when the file is opened in the

ART Path program.

To set drill parameters to a f ile c ont ai ning drill symbols

1 Open a file containing drill symbols.

2 Select the drill symbol with the Pointer Tool. The selected shape changes in color to

show it is selected.

3 Click the Drill Tool from the Tool Box. The Default Drill Info Dialog Box appears on

screen.

4 Click the down arrow on the right side of the Tool entry box. A drop-down list box

appears.

5 Click the desired routing tool.

6 Enter the desired Drill parameter for the Total Depth, Depth Per Pass, Plunge Rate,

Surface Reference, Dwell Time, and Single Speed.

7 Click Generate to enter in the parameters. The tool path appears in a contrasting color.

Page 29

21

Nesting

Nesting allows the user to select, move, mirror, and rotate shapes for closer placement to

conserve material. When the Nesting Tool is clicked on in the toolbox, the mouse pointer

changes to a crosshair with a circle.

To move shapes using the nesting tool

1 Click left on the Nesting Tool. The Nesting Tool becomes available for use and the

mouse p ointer changes into a .

2 Set the cross hair on a shape (or draw a rubber band box around multiple shapes) and

click left on the mouse pointer to select the shapes.

3 Click right to "grab" the shape and move it to the desired location by moving the

mouse.

4 The keyboard can also be used to rotate, mirror, and position the shapes. All of the

Nesting methods may be used at the same time. Use the keys indicated to achieve the

moves desired.

♦ X - mirrors the shape in a horizontal direction

♦ Y - mirrors the shape in a vertical direction

♦ 1, 3, 5, or 9 - rotates the shape in a counterclockwise direction in 1, 30, 15, and 90

degree increments

♦ 2, 4, 6, or 0 - rotates the shape in a clockwise direction in 1, 30, 15, and 90 degree

increments

♦ The up and down arrow keys help position the shapes more closely together.

5 Click right to anchor the shapes in position.

6 Click the Nesting Tool to exit Nesting.

Page 30

Chapter 2

22

Reviewing t h e ART Path Toolbox

Horizontal Cutli ne

Horizontal Cutline inserts a horizontal cutline at a specified position into a design.

ART Path automatically inserts horizontal cutlines into a design that exceeds the height limits of

the router table. A cutline can also be placed in the design by the user to divide the design for

routing. A cutline may also be moved or removed to best suit the design needs using the Move

Cutline Tool.

Moving a horizontal cutline cannot result in creating a panel larger than the router will allow.

Any cutline the system requires for routing panels cannot be removed. It is recommended to

generate a tool path before inserting horizontal cutlines into a design. If the horizontal cutlines

are inserted before a tool path is generated the cutlines are deleted from the design and need to

be reinserted.

To create a horizontal cutline

1 Click Panels > Horizontal Cutline. The mouse pointer changes to a hand with a solid

red horizontal line across it that moves as the hand moves.

2 Move the horizontal cutline to the desired position.

3 Click the left mouse button to secure it.

4 Repeat steps 1 through 3 to insert another cutline. The cutlines are numbered in

sequence.

Move Cutline

Move Cutline allows the user to move a horizontal cutline to a different position in a design. A

Horizontal Cutline may be moved or removed to best suit the design needs using the Move

Cutline feature. Cutlines can also be dragged out of the rulers or created and moved using the

tools in the toolbox.

To move a horizontal cutline

1 Click Panels > Move Cutline. The mouse pointer changes to a hand.

2 Move the tool to the cutline to be moved.

3 Click and drag the cutline to the desired position.

4 Releasethemousebutton.

To remove a horizontal cutline

1 Click Panels > Move Cutline. The mouse pointer changes to a hand.

2 Movethetooltothecutlinetoberemoved.

3 Click and drag the cutline off the screen or until it meets another cutline.

4 Releasethemousebutton.

Page 31

23

To remove more than one horizontal cutline

1 Pull down the Panels menu and click on Move Cutline. The mouse pointer changes to

ahand.

2 Move the tool to a cutline.

3 Click and drag the cutline into the next one to be removed. The two horizontal cutlines

merge to create one cutline.

4 Repeat Steps 1 and 2 until all the desired cutlines are merged into one.

5 Click and drag the cutline off the working area. The cutline disappears.

6 Releasethemousebutton.

Auto-Carve 3D

The Auto-Carve 3D Tool lets you generate a three-dimensional tool path. For more information,

refer to the section “Auto-Carve 3D”.

Prismatic

The Prismatic Tool lets you generate a three-dimensional prismatic tool path. For more

information refer to the section “Prismatic”.

Set Start Point

The Set Start Point tool allows you to change the location at which the cutter begins routing.

To set a new start point

1 Create tool paths on the shapes to be routed.

2 Select the tool path with the Selection tool.

3 Click the Set Start Point tool and the cursor turns into an arrow. The default start point

is shown as a small square on the tool path.

Page 32

Chapter 2

24

Reviewing t h e ART Path Toolbox

4 Click and drag the Set Start Point arrow across the tool path at the location to set the

new start point. The new start point is designated by a small square and the original

start point is removed.

Page 33

25

Book Two:

Menus and Procedures

The ART Path programs are grouped by menu and procedures. The chapters in this book a

separated by menus and procedures within those menus.

♦ Chapter 3: File Menu

♦ Chapter 4: Edit Menu

♦ Chapter 5: Shape Menu

♦ Chapter 6: Setup Menu

♦ Chapter 7: ToolPaths Menu

♦ Chapter 8: Output Menu

♦ Chapter 9: Panels Menu

♦ Chapter 10: View Menu

♦ Chapter 11: Window Menu

♦ Chapter 12: Help Menu

Page 34

Page 35

27

Chapter 3:

File Menu

The Open command in the File Menu opens many different kinds of files including plot files

(PLT), job files (JOB), AutoCAD (DXF) files, router files (RTP), and many other files created by

popular graphics programs including Adobe Illustrator (AI) and Adobe Acrobat (PDF) files.

There are a variety of import filters that can be used when import the files. See OMEGA Help

for detailed explanation of each filter and its capabilities.

New

Choosing New in the File menu opens a new file or clean workspace in ART Path. To open a

new file in ART Path, choose New from the F ile menu. A new working area displays.

Open

Open loads a design saved as a plot, job, or router file into the working area. Open can also

open many other types of files listed in the Files of type drop-down list box.

Open is a command in the File menu. Open accesses the Open dialog box. The system defaults

to the Open dialog box each time the ART Path program is opened.

To open a file

1 Click File > Open. The Open dialog box appears.

2 In the Look In list box, click the down arrow to list the available drives. Click the

desired drive letter and folder.

3 In the Files of Type list box, click the down arrow to list the file types. Click the desired

file type.

4 To choose the file, click the name of the file in the File name list box. If needed, click on

the scroll arrows to show file names that are not currently visible in the list. The file

name is highlighted.

5 Click OK. The design will appear in the working area.

Close

Clicking Close in the File menu closes the open file but does not close the ART Path program.

Page 36

Chapter 3

28

File Menu

Save

Choosing Save in the File menu keeps all changes made to a design. The design is saved as a

router (RTP) file using the previously assigned name and directory.

A file is updated each time you save. If the design already has a file name, then the previous

version of the design is replaced.

Designs are automatically saved to the hard disk as a router file into the C:\Jobs directory. The

system adds an RTP extension to the end of the file name. If the file was opened from the floppy

or CD drive the file will be saved to that drive and not the hard drive.

The Save command is available only when a design has been opened and has changed in

appearance. Job and plot files are automatically saved as router files. A copy of the job or plot

file remains in its original form.

To save new changes to an already named file

1 Click File > Save.

2 The system automatically saves the changes in the design without leaving the working

area. The file will be saved as a router file with an .RTP file extension.

Save As

Choosing Save As in the File menu accesses the Save As dialog box. Here, you can keep all

changes made to a design and store the design as a router file using the same file name or a

different file name.

When Save As is clicked, the edited version of a file may be saved under a unique name. The

original file does not change and is not replaced. The file extension for router files (RTP) is

added at the end of the file name. If the same file name is given to two different designs, a

message box appears asking if the previously stored design is to be replaced by the new design

havingthesamename.SaveAscanalsobeusedtosaveafilewiththesamename.

Save As also allows the design to be saved in a different drive or directory. When no drive is

designated, the file is automatically saved to the hard disk as a router file into the C:\Jobs

directory.Adesignmayalsobesavedasarouterfileontoadiskette.SaveAsisusefulfor

changing an existing design and keeping an original version without any changes.

The system automatically adds an RTP extension to the file name. When using the Save As

command, job and plot files are automatically saved as router files. A copy of the job or plot file

remains in its original form.

Router files can be opened/imported into Composer or GSPPlot. If extensive editing of a router

file is necessary, the original plot or job file should be opened and edited in the Composer

program.

To save changes to a file and keep the original version

1 Click File > Save As. The Save As dialog box appears on screen.

2 Type in a file name in the File name text box.

3 Click OK to save the new file name. The new file name appears in the title bar.

Page 37

29

Save Plot File

Save Plot File in the File menu keeps all changes made to a design and stores the design as a

plot file using the same file name or a different file name.

When Save Plot File is clicked, the edited version of a file may be saved under a unique name.

The original job or router file does not change and is not replaced. The file extension for plot

files (PLT) is added at the end of the file name.

Save Plot File is useful for changing an existing design but keeping the original version of the

file unchanged. If the same file name is given to two different designs, a message box appears

asking if the previously stored design is to be replaced by the new design having the same

name.

Save Plot File also allows the design to be saved into a different drive or directory. When no

drive is designated, designs are automatically saved to the hard disk as a plot file into the

C:\Jobs directory. A design may also be saved as a plot file onto a diskette.

When using the Save Plot File command the original version of the plot file is overwritten with

the new plot file information.

The system automatically adds a .PLT extension to the file name. When using the Save Plot File

command, job and router files are automatically saved as plot files. A copy of the job or router

file remains in the system in its original form.

To save the file as a plot (PLT) file

1 Click File > Save Plot File to open the Save As dialog box. The file type to save as is

PLT.

2 Choose a folder to Save in. The default folder for plot files is C:\Jobs.

3 Type in a file name in the File name text box.

4 Click OK to save the file as a PLT file.

Save to Spool File

Organize your workflow when processing large files by saving to spool (SPL) files. An SPL file

allows you to rout the job at your convenience, without having to render the job at that time.

Creating an SPL file is particularly beneficial when working with large files.

You can create a SPL file and send it to the router at the same time by turning on the Send file to

router check box in the Save as dialog box. After creating the SPL file open it in GQ Manager

and send it directly to the router using the File > Open & Cut command.

To save a spool file

1 Click File > Open to open an existing file.

2 Click File > Save to Spool File to open the Save As dialog box.

3 Turn on Send file to router if you wish to output the job to the router while you save

the spool (SPL) file.

Page 38

Chapter 3

30

File Menu

4 Choose the folder to Save in.

5 Type the file name.

6 Click Save.

Note: You cannot edit an SPL file. If you change the original RTP file you must save it again as

an SPL file to reflect the changes.

Save Parameters

A parameter (PRM) file containing all of the job settings is created when a job is output. If you

set up a job with tool paths, repeats, or other job output settings and then choose not to rout the

job, you can save these parameters in a PRM file. When you later reopen the RTP file, the saved

PRM file resets the job parameters.

To save job paramets

1 Setup a job with tool paths, repeats, etc.

2 Save the file as an RTP file using File > Save As.

3 Click File > Save Parameters to save the settings in a PRM file.

Place

Choosing Place in the File menu merges the contents of a saved file with the currently displayed

design. The Place command is available only after a file has been opened. Place accesses the File

> Open dialog box. Place can be used repeatedly to merge additional files into the currently

displayed design. Previously selected shapes become deselected as the saved file appears on the

screen.

To place a design into an opened fil e

1 Click File > Open. The Open Dialog Box appears.

2 Choose the file you wish to have as the current design and click OK.

Page 39

31

3 Click File > Place. The Open dialog box appears.

4 Choose the file you wish to merge with the current design, then click OK. The merged

file appears selected in the center of the working area.

5 Use the Place command repeatedly to merge additional files into the current design.

Library

Clicking on Library in the File menu opens the Open dialog box so that you can choose a Gerber

library file (GCA) to add to a job. For example, if you design a job in Composer and later decide

that you need drill holes to mount the sign, you can go to the library, open a drill file, and add

holes to your design. Use the Nesting tool to move the drill holes to the proper location. This

feature saves you from having to go back to Composer to make design changes, then

reapplying tool paths to the changed design.

Print

Clicking Print in the File menu opens the Windows standard Print dialog box. Please refer to

your Microsoft Windows documentation for using this dialog box.

Print Setup

Clicking Print Setup in the File menu opens the Windows standard Print Setup dialog box.

Please refer to your Microsoft Windows documentation for using this dialog box.

Recently Used File list

The Recently Used File list in the File menu displays the last eight files that were accessed in

ART Path.

Exit

Clicking Exit in the File menu closes the ART Path program.

Page 40

Page 41

33

Chapter 4:

Edit Menu

Edit commands allow the user to change the condition of job, router, or plot files in the working

area. The following commands are available for editing purposes.

Undo

Choosing Undo from the menu bar cancels the previous editing operation. Undo must be

clicked on immediately after making an error. Undo will undo only the previous command. To

cancel the previous editing operation, choose Undo from the Edit menu before clicking

anywhere in the working area. The last edit is cancelled.

Cut

Choosing Cut from the Edit menu removes a selected shape from the working area and puts it

on the clipboard. A cut shape can be placed back into a working area using the Paste or Paste

Back command as many times as desired. Cutting is similar to cutting out a picture with a pair

of scissors.

Cut is available only when a shape is selected in the working area. The clipboard holds one Cut

at a time. When another Cut is made, any previously cut shape already on the clipboard is

deleted and replaced by the newly Cut shape.

To cut a shape for storage on the clipboard

1 Select the shape in the design. The shape is redrawn in a different color.

2 Click Edit > Cut. The selected shape is removed from the working area and sent to the

clipboard.

3 UsethePasteorPasteBackcommandtoaddthecutshapeintoanotherdesignor

place the design in its original position in the working area.

Copy and Paste

Choosing Copy from the Edit menu places a copy of a selected shape in the working area on the

clipboard. The original selected shape remains in the working area. A copied shape can be

placed back into a working area from the clipboard using the Paste command as many times as

desired.

Copy is available only when a shape is selected in the working area. The clipboard holds one

Copy at a time. When another Copy is made, any previously copied shape already on the

clipboard is deleted and replaced by the newly copied shape.

Page 42

Chapter 4

34

Edit Menu

To copy a shape from a design

1 Select the shape in the design. The shape is redrawn in a different color.

2 Click Edit > Copy. The original selected shape remains in the working area as a copy

of it is sent to the clipboard.

3 Use the Paste command to add the copied shape at the exact location it was copied

from in the design.

To create multiple copies of a shape

1 Select a shape in the design. The shape is redrawn in a different color.

2 ClickEdit>CutorCopy.

3 Click Edit > Paste. The selected shape appears in the working area.

4 The shape must be moved to the desired location using the Nesting Tool.

5 Repeat steps 3 and 4 to create as many copies as required.

To move a shape from one file to another

1 Select a shape in the design. The shape is redrawn in a different color.

2 Click Edit > Copy or Cut.

3 Click File > Open.

4 Open the desired file that will receive the new shape from the clipboard.

5 Click Edit > Paste. The selected shape appears at the exact location it was cut or copied

from the design.

6 The shape must be moved to the desired location us ing the Nesting tool.

Paste from Composer

Paste lets you insert objects from Composer directly into ART Path. Choosing Paste inserts the

contents from the Composer clipboard into the ART Path working area. You can paste the

Composer contents into the working area as many times as desired. Use the Nesting tool to

move the added shape to the proper location.

♦ Paste places a shape in the middle of the work area.

♦ Paste Back replaces the shape in its original location in the job.

♦ Paste Back does not place the copied shape in its original position if placed in a

different file

Note: You cannot paste objects from any application other than Composer, it is possible to

cut/copy an object in ART Path and Paste it into Composer.

Page 43

35

To paste a Composer object int o ART Pat h

1 In Composer, open the file that contains the object you want to paste into ART Path.

2 Select the object and choose Cut or Copy from the Composer Edit menu to place the

object onto the Composer clipboard.

3 In ART Path, open the desired plot, job or router file that will receive the pasted object.

4 Click Edit > Paste. The object stored in the clipboard is placed in the working area. The

pasted object is selected and all previously selected shapes in the current design are

deselected.

5 The object can be moved to the desired location in the working area using the Nesting

tool.

6 To paste in multiple copies of the object, repeat steps 4 and 5.

Paste Back

Paste Back inserts the contents from the clipboard into the ART Path working area. If you

copied the object in ART Path, Paste Back inserts the object back in the same location in the

same design.

Delete

Choosing Delete from the Edit menu permanently removes a selected shape from the working

area. The Undo command restores any shape or design deleted by mistake if it was the last

command accessed. To delete a shape, select the desired shape to be deleted and choose Delete

from the Edit menu. The shape is removed from the working area.

Select All

Choosing Select All in the Edit menu selects all shapes in a design. The design is selected and

redrawn in a different color.

Reverse Select

Choosing Reverse Select in the Edit menu changes the selection condition of a shape. Any

selected shapes become deselected. Any shapes not selected become selected.

To reverse select shapes

Click Edit > Reverse Select. The deselected shapes become selected, and the selected shapes

become deselected.

Select Open Shapes

Select Open Shapes determines if any shapes in the design are open. If Select Open Shapes is

gray, the design contains no open shapes. If SelectOpen Shapes is black, the design contains

open shapes.

Page 44

Chapter 4

36

Edit Menu

To select open shapes

1 Click Edit.

2 If Select Open Shapes is black, click on it to determine which shapes are open.

Note: All open shapes will be selected. It may be appropriate for some shapes to remain open,

such as shapes for engraving.

3 To close shapes, use the Join command in the Shape menu.

Select Unused Shapes

Clicking the Select Unused Shapes command selects (highlights) design shapes which do not

have a tool path assigned. This is useful for checking the design before routing to make sure

that all shapes have an assigned tool path. It can also be used to select and delete shapes which

you do not want to route (for example, when using clip art, you may not want all of the design).

Page 45

37

Chapter 5:

Shape Menu

The Shape menu provides commands that allow you to repeat, size and close shapes.

Repeats

Repeats creates multiple copies of a shape alongside and above the original in the working area.

Clicking on Repeats opens the Repeats Dialog Box. The spacing between repeated shapes may

be changed two ways using: Gap and Distance.