Page 1

Signet 5500 Flow Monitor

d

r

English

*3-5500.090-1*

3-5500.090-1 Rev. K 3/06 English

Contents

1. Power Connections

2. Compatible Sensor Wiring

3. Sensor Pulse Output Connections

4. Auxiliary Pulse Output Connections

5. Totalizer Reset Connections

6. 4 - 20 mA Current Output Connections

7. Relay Connections

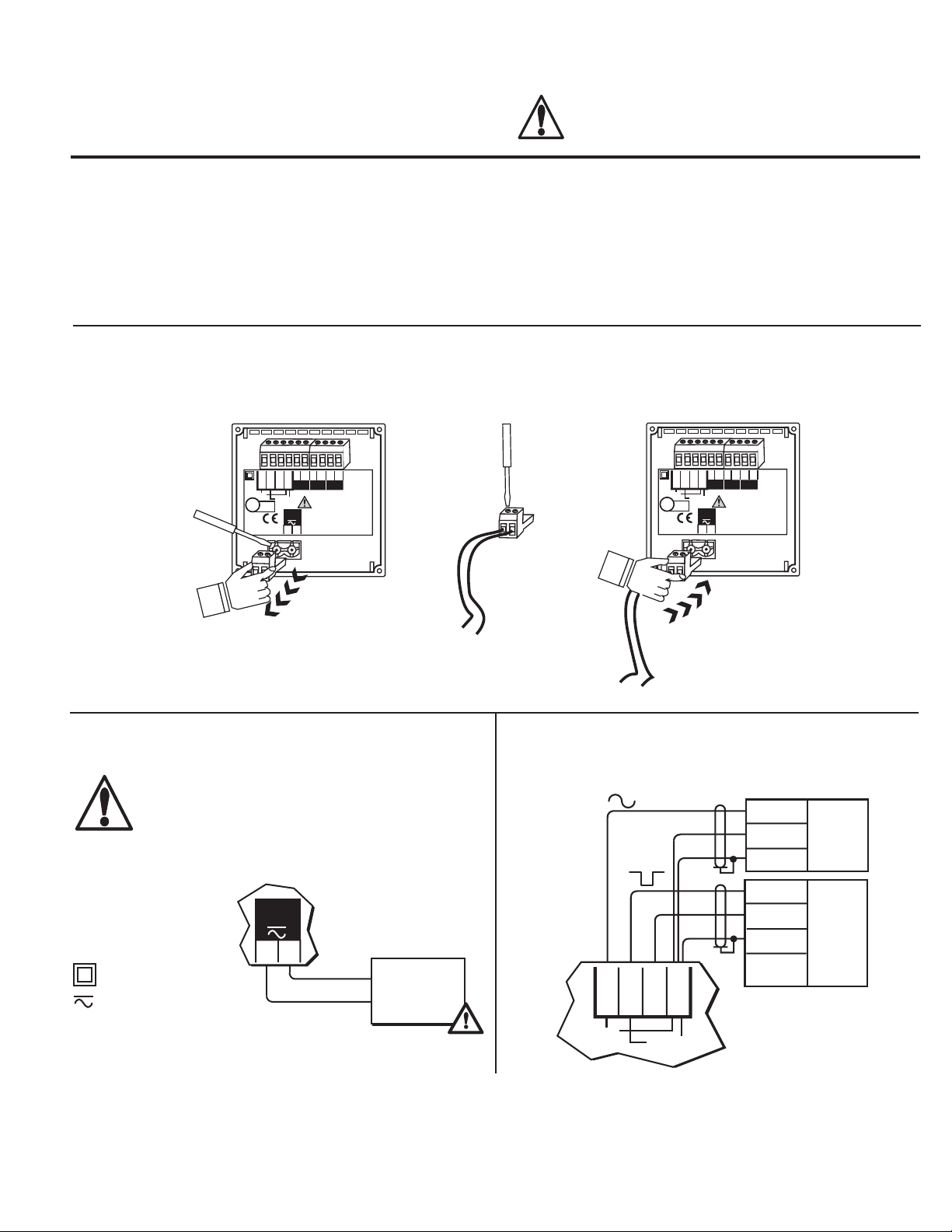

Remove terminal blocks for easy wiring

1.

2

+

1

Gnd

+

Gnd

Total

AUX

Std. Sensor

U

L

LISTED

77CJ

Freq. IN

Freq. IN

Sen. Pwr.

Open Collector

Sensor

12-24 V

10 W

+

Iso. Gnd

output

PLS

output

-

Flow

reset

Patent No. D376,328

CAUTION!

• Remove power to unit before wiring input and output

connections.

• Follow instructions carefully to avoid personal injury.

8. Output Functions

9. Menu Functions

10. Parts and Accessories

11. Specifi cations

12. Quick Reference Menu Parameters

13. Troubleshooting

14. Maintenance

2.

3.

Std. Sensor

U

L

LISTED

77CJ

Freq. IN

Freq. IN

Open Collector

Sensor

2

+

1

Gnd

+

Gnd

Total

AUX

PLS

Iso. Gnd

Sen. Pwr.

output

output

12-24 V

10 W

+

-

Flow

reset

Patent No. D376,328

1. Power Connections

2. Compatible Sensor Wiring

CAUTION!

Never connect 115 VAC or 230 VAC to rear power

terminals. High voltage AC will damage instrument

and void warranty.

5500

12-24 V

10 W

Terminals

External power

supply

-

+

12 - 24 VDC

OR

12 - 24 VAC

Std. Sensor

= Double Insulate

= DC or AC powe

+

-

Technical Notes:

• To reduce the possibility of noise interference, isolate AC power lines from signal lines.

• Maximum 4-20 mA loop impedance (sec. 6) is affected by the supply voltage.

Freq. IN

Freq. IN

Iso. Gnd

Sen. Pwr.

Open Collector

Sensor

Signet Sensors:

Red

Black

Shld.

Red

Black

Shld.

5500

Terminals

515

525

2517

2000

2507

2536

2540

2550

Vortex*

Page 2

t

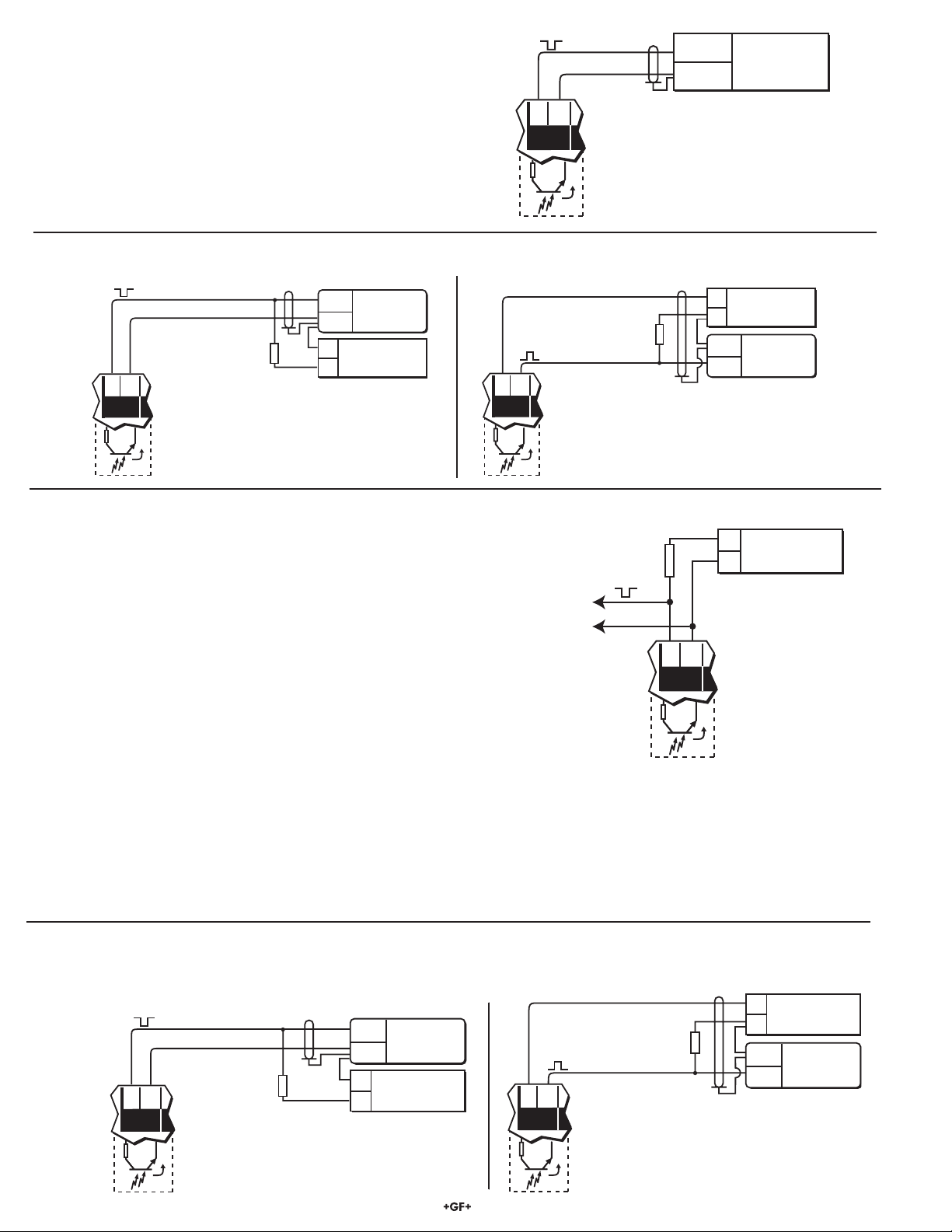

3. Sensor Pulse Output Connections (sec. 8.1)

3.1 Signet instrument with internal open-collector

excitation voltage and pull-up resistor.

Technical Notes:

• Use 2-conductor shielded twisted-pair cable for output lines up

to 30 m (100 ft.) max.

• Pull-up resistor NOT REQUIRED when connected to

+

100Ω

PLS

output

Gnd

5500

Terminals

Freq. IN*

Red

Shld

Iso. Gnd

Red

Shld

Signet

Instrument

*(Open-collector sensor

terminals)

Signet instruments.

3.2 Pulse output connection options for instruments without internal open-collector excitation voltage and pull-up resistor shown below.

NPN sink input

+

28 VDC

max.

-

Gnd

Input

Other

instrument

PNP source input

100Ω

+

PLS

output

Gnd

5500

Terminals

10 kΩ

Input

Gnd

-

+

External power supply

Other

instrument

28 VDC

max.

100Ω

+

PLS

output

10 kΩ

Gnd

5500

Terminals

4. Auxiliary Pulse Output Connections

4.1 Pulse mode (sec. 8.2) - External device control

• The auxiliary output can be confi gured for either TTL, CMOS,

or open-collector compatible inputs using the proper pull-up

resistor and an external power supply.

• TTL inputs: An external 5 VDC power supply and 10 kΩ pullup resistor is recommended.

• CMOS inputs:

An external 3 to 15 VDC power supply and 10 kΩ pull-up

resistor is recommended.

• 12 VDC Open-collector inputs:

An external 12 VDC power supply and 10 kΩ pull-up resistor is

recommended.

• 24 VDC Open-collector inputs:

An external 24 VDC power supply and 10 kΩ pull-up resistor is

recommended.

4.2 Totalizer pulse mode (sec. 8.2)

• External counter or accumulator inputs without internal opencollector excitation voltage and pull-up resistor.

NPN sink input

Counter

100Ω

+

AUX

output

Gnd

5500

Terminals

10 kΩ

Input

Gnd

-

+

External power supply

or

Accumulator

28 VDC

max.

External power supply

10 Ω

+

-

3 - 28

VDC

Signal output

Signal ground

100Ω

+

AUX

output

Gnd

5500

Terminals

Technical Notes:

• Open-collector transistor, optically isolated, 5 mA max. sink,

28 VDC max. pull-up voltage.

• Programmable pulse width, 0.10 - 999. seconds (sec. 9.2 M)

• Selectable Active high or active low pulse logic (sec. 9.3 J).

• Use 2-conductor shielded twisted pair cable for AUX output

lines to 30 m (100 ft) max.

External power supply

+

28 VDC

max.

Counter

or

Accumulator

PNP source inpu

100Ω

+

AUX

output

Gnd

5500

Terminals

10 kΩ

-

Gnd

Input

2

Signet 5500 Flow Monitor

Page 3

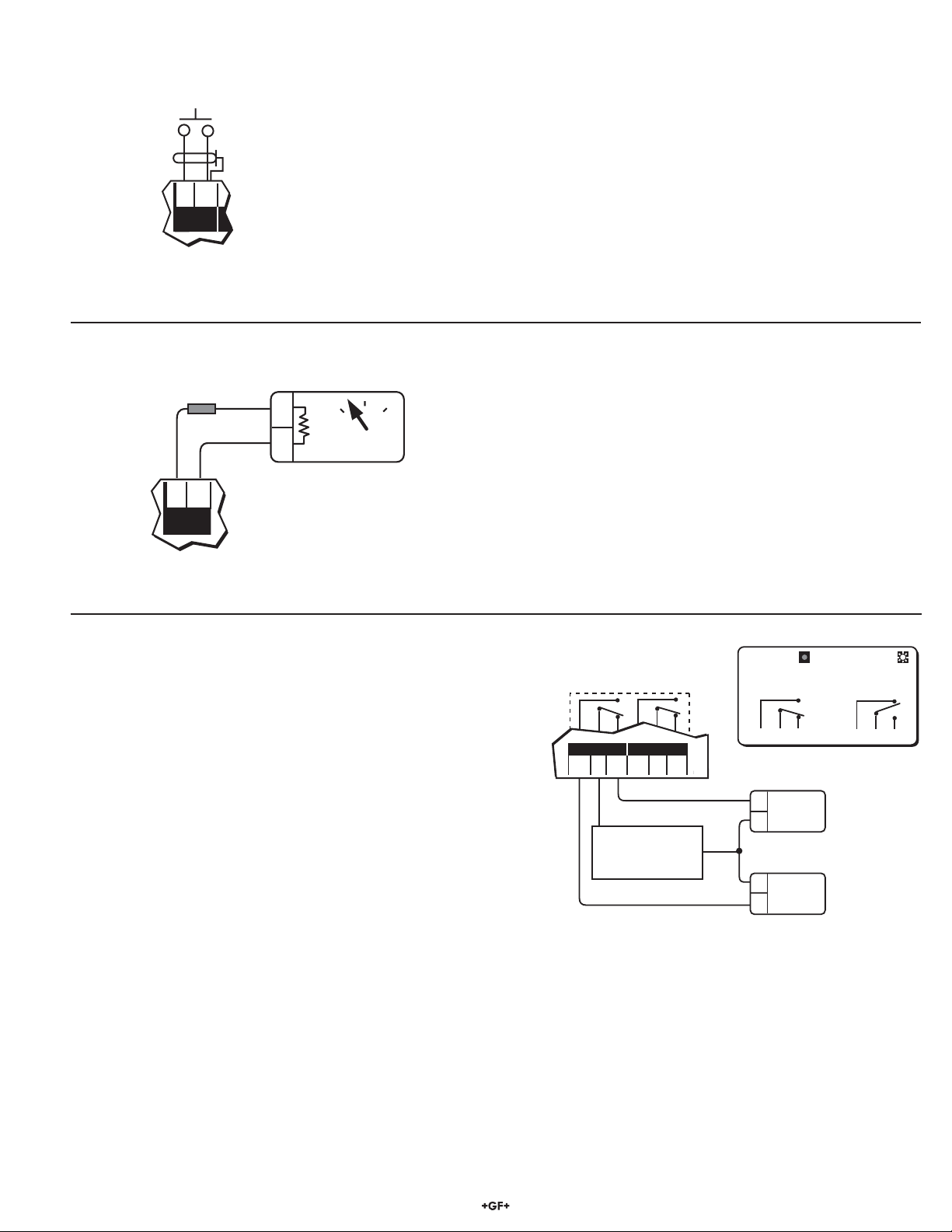

5. Totalizer Reset Connections (sec. 8.3)

Momentary pushbutton switch

2

1

To ta l

reset

5500

Terminals

6. 4-20 mA Current Output Connections (sec. 8.4)

Technical Notes:

• Use 2-conductor shielded twisted pair cable for reset lines up to

30 m (100 ft) max. External reset switch overrides software

security feature (section 9.3 I).

• To reduce the possibility of AC noise interference, isolate AC

power lines from reset lines.

Fuse**

1/8A

+

*

4

20

-

-

+

4-20

mA

7. Relay Connections

Two internal relay contact sets (COM, NO, and NC) may be used

for external device control. Front panel LED annunciators indicate

the activation status of each relay. Each relay can control up to

two devices simultaneously, as shown. Relay operation modes

include Low alarm, High alarm, Pulse, and Totalizer (sec. 8.5).

Common device connections include:

• Pulse mode - metering pump control

• Pulse mode - solenoid valve control

• Low or High mode - warning lamps

• Low or High mode - bells or sirens

• Low or High mode - external heavy-duty relay

5500

Terminals

mA

Technical Notes:

**1/8A fuse recommended (customer supplied)

* 4-20 mA output is internally powered (non-isolated), maximum

loop impedance 350 Ω with a 12 V instrument supply voltage,

950 Ω with a 24 V instrument supply voltage.

To isolate output and prevent ground loop problems:

1. Use monitor device with isolated inputs, or

2. Use separate DC supply for 5500 and monitor device, or

3. Power 5500 with12 - 24 VAC step down transformer

Relay

Energized

NO

5500

Terminals

NO

C

NC

+

External AC/DC

Relay 1Relay 2

NO

power

Relay

De-energized

C

NO

NC

C

NC

Device

+

A

-

-

-

Device

B

+

C

NC

Wiring Example Right

Device A IS powered when relay 2 is de-energized (front panel

LED "off"). Power is discontinued when the relay 2 setpoint is

reached (front panel LED "on"). Device B IS NOT powered when

the relay 2 is de-energized. Power is applied after the relay 2

setpoint is reached.

Signet 5500 Flow Monitor

Technical Notes:

• Maximum relay contact ratings: 5 A @ 30 VDC, 5 A @ 125 VAC,

or 3 A @ 250 VAC

• An external heavy-duty relay must be used for devices with

surge currents or operating currents that exceed the above

specifi cations.

3

Page 4

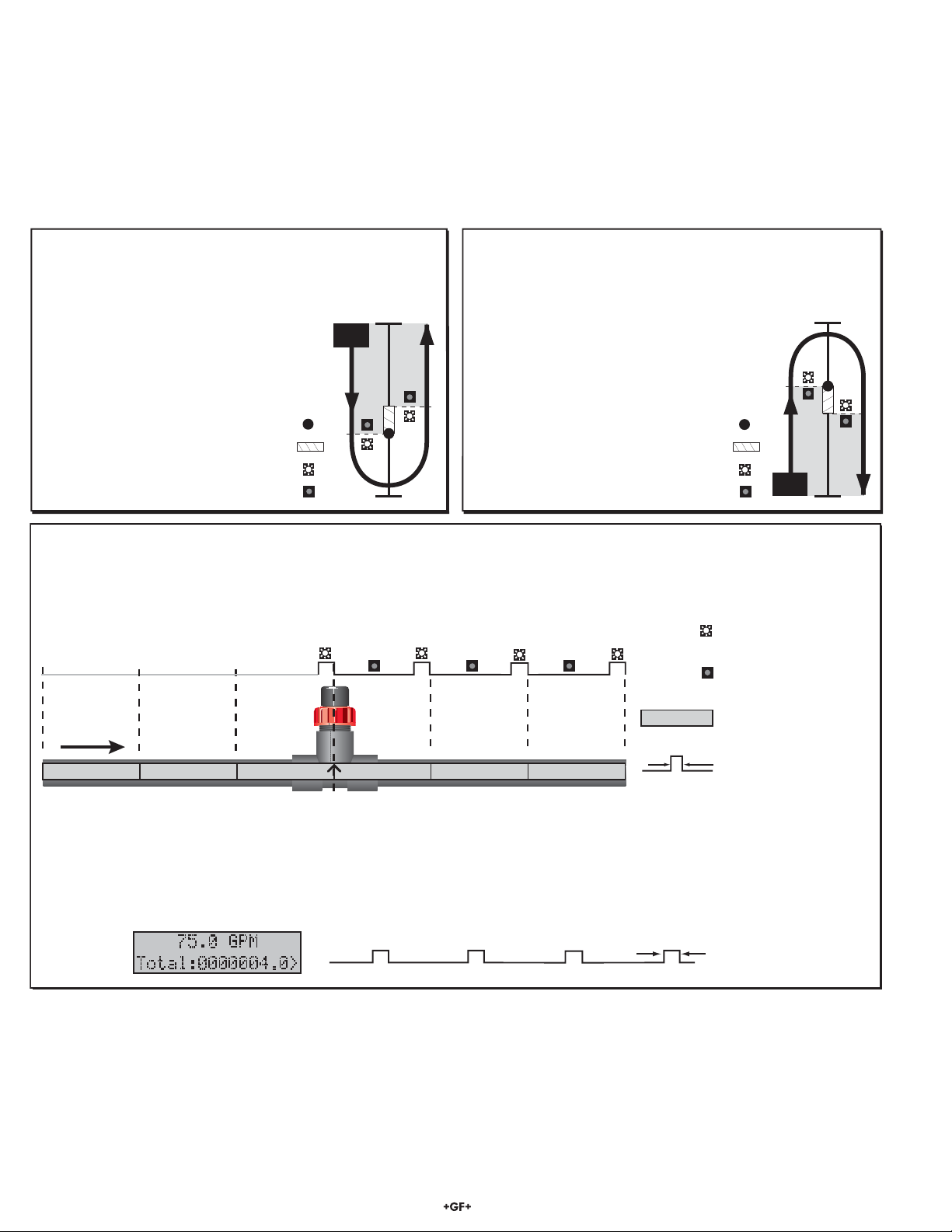

8. Output Functions

This section gives a detailed description of all 5500 output functions.

8.1 Sensor pulse output (sec. 3): This output emits an open-collector frequency equal to the sensor input. The output connects directly

to a second Signet instrument for expanded process control with a single sensor input (sec. 3.1). The output is an open-collector type

that requires an external pull up resistor and power supply for other instrument inputs (sec. 3.2).

8.2 Auxiliary pulse output (sec. 4): The auxiliary output can be confi gured as Low alarm, High alarm, Pulse or Totalizer output. Output

logic can be selected for either active low (factory default) or active high operation (sec. 9.3 J). The auxiliary output is an open-collector

type that requires an external pull-up resistor and power supply to operate. Refer to diagrams A - C below for operation details.

A. LOW alarm mode

The output is active (relay energized) when the flow drops below the

setpoint, and is inactive (relay de-energized) when the flow rises

above the setpoint plus hysteresis (sec. 9.2 F-G, 9.2 J-K).

• Auxiliary output: ideal for external device

inputs (sec. 4)

Flow

• Relay outputs: ideal for external warning

lamps, sirens, etc. (sec. 7)

Low setpoint=

Adjustable hysteresis=

Output active (relay energized)=

Output inactive (relay de-energized)=

B. HIGH alarm mode

The output is active (relay energized) when the flow rises above the

setpoint and is inactive (relay de-engergized) when the flow falls

below the setpoint plus hysteresis (sec. 9.2 F-G, 9.2 J-K).

• Auxiliary output: ideal for external device

inputs (sec. 4)

• Relay outputs: ideal for external warning

lamps, sirens, etc. (sec. 7)

High setpoint=

Adjustable hysteresis=

Output active (relay energized)=

Output inactive (relay de-energized)=

Flow

C. PULSE mode

The output is active (relay energized) for the programmed pulse width each time the programmed pulse volume is measured by the flow

sensor (sec 9.2 H-I, 9.2 L-M).

• Auxiliary output: ideal for external device control (sec. 4)

• Relay outputs: ideal for metering pump or solenoid valve control (sec. 7)

Flow

Sensor

FLOW

volume 2volume 3volume 4volume 5volume 6

volume

volume 1

= Output active

(relay energized)

= Output inactive

(relay de-energized)

= Programmed pulse

volume (e.g. 12.5 Gal.)

= Programmed pulse

width (relay energize time)

Totalizer function

The output emits an adjustable signal pulse width for each whole engineeing unit measured by the flow sensor (also displayed on totalizer).

To enable the totalizer function, the operator must set the relay or auxiliary pulse volume setpoint to 1.0000 (sec. 9.2 H, 9.2 L).

• Totalizer function: ideal for external counter or accumulator use (sec 4.2)

adjustable

pulse width

VIEW menu

totalizer display

=

1234

8.3 Totalizer reset (sec. 5): This feature allows the operator to reset the totalizer with a dry switch contact closure at any time.

The external reset switch overrides software security feature (sec. 5).

8.4 4-20 mA output (sec. 6): The 4-20 mA output is internally powered by the instrument. 4 mA and 20 mA setpoints are fully adjustable

within the programmed fl ow range (sec. 11 B). The output can also be reverse spanned.

8.5 Relay 1 and 2 outputs (sec 7): Relay outputs 1 and 2 can be independently confi gured as Low alarm, High alarm, Pulse or Totalizer

output. Refer to diagrams A - C above for operation details.

4

Signet 5500 Flow Monitor

Page 5

9. Menu Functions

To access either CALIBRATE or OPTIONS menus, press and hold

the ENTER key as illustrated below:

Press & hold ENTER key

for menu

access:

ENTER

VIEW

(sec. 9.1)

2

seconds

5

seconds

CALIBRATE

(sec. 9.2)

OPTIONS

(sec. 9.3)

9.1 VIEW Menu

Menus:

• VIEW menu (sec. 9.1): The VIEW menu is displayed during

standard operation. The operator can navigate freely through

the menu by pressing either UP or DOWN arrow keys. The

VIEW menu also offers a resettable totalizer feature that allows

the operator to reset the displayed total at the press of a button.

• CALIBRATE Menu (sec. 9.2): The CALIBRATE menu contains

all critical display setup and output parameters. A simple security code feature prevents unauthorized tampering. The operator is required to enter a simple access code for menu access.

The same code also unlocks OPTIONS menus.

• OPTIONS Menu (sec. 9.3): The OPTIONS menu contains setup

and display features that are seldom accessed for minor display

or output adjustments.

1

H↓

A.

B.

C.

D.

E.

F.

G.

H.

Choose: Change: Save:

Flow & resettable total

Permanent total

Loop output

Range

Relay 1

Relay 2

Aux output

Last calibration

2

3

Menu Displays A - H:

(Factory default displays shown in menu column 1)

A. Flowrate and resettable total display: can be reset

OPTIONS = OPTIONS =

(sec. 9.3I) (sec. 9.3I)

by the front panel keypad or by remote reset switch

(sec. 5). A simple access code feature prevents

A.

A.

accidental total reset, when enabled (sec. 9.3

I). External reset switch inputs override security

To reset

total press:

ENTER

Press keys in sequence,

(display shows: )

feature, when enabled.

B. Permanent total display: records volumetric fl ow

total for the life of the product and is non-resettable.

C. Loop output display: shows the current output level

B.

To exit without changes:

OR

quick

press

B.

C.

To reset

total press:

ENTER

at the rear terminals.

D. Flow Range display: shows the programmed min

and max meter range (sec. 9.2 B)

E. Relay 1 display: this display shows the pro-

grammed operation mode and setpoint for relay

1 (sec. 9.2 F-I)

F. Relay 2 display: this display shows the programmed

operation mode and setpoint for relay 2 (sec. 9.2

F-I).

G. Aux output display: this display shows the

programmed operation mode and setpoint for the

auxiliary output (sec. 9.2 J-M).

H. Last calibration: this display shows a user defi ned

setup date for maintenance records. This feature is

not an internal timer or calender.

A↑

Signet 5500 Flow Monitor

5

Page 6

9.2 CALIBRATE Menu

Press keys in sequence

will appear during code entry.

1

N↓

A.

B.

C.

D.

E.

F.

G.

H.

Choose:

Flow units

Flow range

Flow K-Factor

Total units

Total K-Factor

Relay Low or High Mode Selected

Relay

Relay

Relay Pulse Mode Selected, step F

Relay

Change:

Unit + timebase: h,m,s,d

Meter Min→Max

K-Factor

- Display label only -

K-Factor

Mode & setpoint

Hysteresis setting

Mode & setpoint

to enter menu,

Menu Settings A - N:

(Factory default displays shown in menu column 1)

A. Sets fl ow units label (gpm) and timebase (gpm).

2

3

Save:

Flow units label: Aa - Zz, 0 - 9, /

Timebase options: h=hours, m=minutes,

s=seconds, d=days (timebase entry affects fl ow

rate display and 4 to 20 mA output)

B. Sets Min→Max meter and dial range, 00.000 to

99999. (does not affect 4 to 20 mA output)

C. Sets fl ow K-Factor: 0.0001 to 99999.

(see technical notes below)

D. Sets 8-digit totalizer units label: Aa - Zz, 0 - 9, /

(does not affect totalizer display or outputs)

E. Sets totalizer K-Factor: 0.0001 to 99999.

(see techical notes below)

Menu items F - I repeat for relay 2 setup.

F. Sets relay operation mode Low or High, and fl ow

rate setpoint, 0.0000 - 99999. (sec. 8.5)

G. Sets relay hysteresis, 0.0000 - 99999. (sec. 8.5)

(Set to zero to disable hysteresis feature)

ENTER

"SAVING"

briefly

displays

H. Sets relay pulse volume setpoint, 0.0001 - 99999.

(sec. 8.5). Set to 1.0000 to enable totalizer

function (sec. 8.5).

I. Sets relay pulse width, 0.10 - 999. seconds

(sec. 8.5)

I.

J.

K.

L.

M.

N.

Last calibration

To return to

VIEW menu:

6

Relay

Aux output

Aux output

Aux output

Aux output

Pulse width

Aux Output Low or High Mode Selected

Mode & setpoint

Hysteresis

Aux Output Pulse mode selected, step J

Mode & setpoint

Pulse width

Setup date

A↑

To restore original value:

quick

press

quick

press

J. Sets auxiliary output mode Low or High, and fl ow

rate setpoint, 0.0000 - 99999. (sec. 8.2).

K. Sets auxiliary output hysteresis, 0.0000 - 99999.

(Set to zero to disable hysteresis feature)

L. Sets auxiliary output pulse volume setpoint,

0.0001 - 99999. (sec. 8.2). Set to 1.0000 (factory

default) to enable totalizer function (sec. 8.2).

M. Sets auxiliary output pulse width, 0.10 - 999.

seconds

N. Sets user defi ned setup date for maintenance

records. This feature is not an internal timer or

calender

Technical Notes:

The fl ow and total K-Factors are independent of each

other. The K-Factor settings represent the number of

pulses generated by the Signet fl ow sensor for each

engineering unit of fl uid measured (published in fl ow

sensor manual).

Signet 5500 Flow Monitor

Page 7

9.3 OPTIONS Menu

Press keys in sequence

will appear during code entry.

1

J↓

A.

B.

C.

D.

E.

F.

G.

H.

I.

Choose:

Display contrast Low -- -- -- -- -- High

Flow display Decimal

Total display Total decimal

Display averaging

Loop output

Loop output

Loop output

Loop output

Totalalizer reset

4 mA setpoint

20 mA setpoint

4 mA adjust

20 mA adjust

VIEW menu=

to enter menu,

Menu Settings A - J:

(Factory default displays shown in menu column 1)

A. Selects LCD display contrast: 5 levels

2

Change:

3

Save:

B. Selects fl ow display decimal:

*****

. to

** . ***

C. Selects totalizer display decimal:

. to

********

****** . **

D. Selects LCD display averaging:

Off = 0 seconds, Low= 4 seconds, High= 8 seconds

(also effects 4 - 20 mA output)

E. Sets 4 mA output setpoint. 4 mA and 20 mA

setpoints are reversible.

4s 8s0s

ENTER

F. Sets 20 mA output setpoint. 20 mA and 4 mA

setpoints are reversible.

"SAVING"

briefly

displays

G. Sets 4 mA current output: 3.0 to 5.0 mA

(overrides 4.00 mA factory calibration)

H. Sets 20 mA current output: 19 to 21 mA

(overrides 20.00 mA factory calibration)

I. Selects totalizer reset options: Lock "Off" disables

the VIEW menu access code feature; Lock "On"

enables the feature (sec. 9.1 A). When enabled,

the operator must enter an access code for totalizer

reset privileges. The totalizer will be reset in either

case if a contact closure is detected at rear reset

VIEW menu=

terminals (sec. 5).

J.

Auxiliary out logic

To return to

VIEW menu:

quick

press

Active Low or High

A↑

To restore original value:

quick

press

J. Selects Auxiliary output logic:

• Active Low logic (factory default): Output changes

from high to low when active, see diagram below.

• Active high logic: Output changes from low to high

when active, see diagram below.

Active Low Logic (factory default)

Inactive (Off)

Active (On)

Active High Logic

Active (On)

Inactive (Off)

Signet 5500 Flow Monitor

7

Page 8

10. Parts and Accessories

Splashproof rear cover

#3-5000.395

(code 198 840 227)

5 x 5 inch adapter plate

for Signet retrofi t

#3-5000.399

(code 198 840 224)

• Power supply, 115 VAC - 24 VAC, #3-5000.075

• Front snap-on bezel, #3-5000.525 (code 198 840 226)

• Assorted fl ow unit/multiplier decals, #3-5500.611 (code 198 840 230)

• 5500 instruction sheet #3-5500.090-1 (code 198 869 914)

11. Specifi cations

General

Sensor compatibility: All Signet fl ow sensors

Accuracy: ±0.5% of reading

Input: Optically isolated

Enclosure:

• Rating: NEMA 4X/IP65 front

• Dimensions: 1/4 DIN, 96 x 96 x 88 mm (3.8 x 3.8 x 3.5 in.)

• Case materials: ABS plastic

• Keypad material: Sealed 4-key silicone rubber

• Weight: Approximately 500 g (18 oz.)

Optional surface mount

bracket #3-5000.598

(code 198 840 225)

Electrical

Power:

• 12 to 24 VDC or 12 to 24 VAC, unregulated, 50-60 Hz,

10 W max.

Relay contacts (2 sets):

• Mechanical SPDT contacts

• Maximum voltage rating: 5 A @ 30 VDC, 5 A @ 125 VAC, or

3 A @ 250 VAC, (power factor = 1.0)

• Hysteresis: User adjustable

Display:

• Type: Microprocessor controlled air-core meter movement and

backlit alphanumeric 2 x 16 LCD

• Update rate: Flow = 1s, totalizer = <200 ms

• Contrast: User selected, 5 levels

• Relay annunciators: 2 LEDs

Totalizers:

• 8-digit resettable with security option

• 8-digit non-resettable

Environmental

Operating temp.: -10 to 55°C (14 to 131°F),

50°C (122°F) max. with optional rear

cover

Storage temp.: -15 to 80°C (5 to 176°F)

Relative humidity: 0 to 95%, non-condensing

Altitude: 4000 m max.

Pollution degree: 2

Agency Approvals

• CE, UL listed

• Manufactured under ISO 9001

Current output:

• 4 to 20 mA, non-isolated, internally powered, fully adjustable and

reversible

• Update rate: < 200 ms

• Max loop impedance: 350 Ω max with a 12 V instrument supply

voltage, 950 Ω max with a 24 V instrument supply voltage

• Accuracy: ±0.1% of max range

Sensor (PLS) Auxiliary (AUX) pulse outputs:

• Open-collector transistor, optically isolated, 5 mA max. sink,

28 VDC max. pull-up voltage, programmable (AUX) pulse width

100Ω

+

5500 rear PLS/AUX

output terminals

GND

Internal

PLS/AUX

circuits

Totalizer reset:

• Front keypad or external contact closure, 30 m (100 ft) max

cable length

• External contact closure overrides security feature (sec. 5)

Noise immunity: EN50082-2

Noise emissions: EN55011

Safety: EN61010-1

8

Signet 5500 Flow Monitor

Page 9

Dimensions

96 mm (3.8 in.)

Panel

Gasket

Optional Splashproof Rear Cover

Front

View

Rear

View

RELAY 1

Freq. IN

Std. Sensor

LISTED

U

L

®

77CJ

Signet

Model #3-5500

3

2

1

0

Signet Monitor

88 mm (3.5 in.)

+

Gnd

PLS

Freq. IN

Iso. Gnd

Sen. Pwr.

output

Open Collector

Sensor

12-24 V

10 W

+

-

4

GPM

Gnd

+

AUX

output

NO

5

6

RELAY 2

7

8

Mounting Panel

Mounting Clamp (2 ea.)

9

10

96 mm

(3.8 in.)

91 mm

(3.6 in.)

88 mm

(3.5 in.)

SIDE VIEW

ENTE

76 mm (3 in.)

96 mm (3.8 in.)

88 mm (3.5 in.)

2

+

1

-

4-20

Tot a l

reset

Relay 1Relay 2

C

NC

NO

mA

C

NC

Flow

88 mm

(3.5 in.)

Patent No. D376,328

92 x 92 mm

(3.62 x 3.62 in.)

12. Quick Reference Menu Parameters

VIEW Menu Setup Parameters (sec. 9.1)

Menu

Parameters

A.

• Resettable total

B.

C.

D.

E.

F.

Display

Description

• Flow rate and units

Permanent

total

Current loop

output

Min → Max meter

and dial range

• Relay 1 mode

• Relay 1 setpoint

• Relay 2 mode

• Relay 2 setpoint

Panel cutout

Range

00.000 - 99999. GPM

000000.00 - 99999999.

000000.00 - 99999999.

3 - 21 mA

00.000 - 99999.

Low or High, 0.0000 - 99999.

Pulse, 0.0001 - 99999.

Low or High, 0.0000 - 99999.

Pulse, 0.0001 - 99999.

Factory

Default

0000.0

0000000.0

0000000.0

n/a

0.000 - 100.00

Low

10.000 GPM

High

90.000 GPM

G.

H.

Signet 5500 Flow Monitor

• Aux output mode

• Aux output setpoint

Last calibration

date

Low or High, 0.0000 - 99999.

Pulse, 0.0001 - 99999.

00 - 00 - 00 to

39 - 39 - 99

Pulse

1.0000 Gallons

01 - 01 - 98

9

Page 10

CALIBRATE Menu Setup Parameters (sec. 9.2)

A.

B.

C.

D.

E.

F.

G.

H.

Menu

Parameters

Display

Description

flow unit= digits 1-3

flow timebase= digits 4

Range

Aa - Zz, 0 - 9, /, _;

Mm, Ss, Hh, Dd

Factory

Default

_GPM

_ = blank

display digit

option

Min → max

range

Flow K-Factor

Total units

Total K-Factor

• Relay 1 mode

• Relay 1 setpoint

00.000 - 99999.

0.0001 - 99999.

Aa - Zz, 0 - 9, /, _

(8-digits max.)

0.0001 - 99999.

Low or High

0.0000 - 99999.

00.000 - 100.00

GPM

60.000

_Gallons

60.000

Low

10.000 GPM

_ = blank

display digit

option

Relay mode

and setpoint

• Relay 1 Hysteresis

• Hysteresis volume

• Relay 1 mode

• Relay 1 pulse volume

I.

Relay 1 pulse width

0.0000 - 99999.

Pulse

0.0001 - 99999.

0.10 - 999. seconds

2.0000

GPM

10.000

Gallons

10.0

seconds

displays repeat

for relay 2

setup

J.

K.

L.

M.

N.

• Aux output mode

• Aux output setpoint

Aux output hysteresis

volume

• Aux output mode

• Aux output setpoint

Aux output pulse

width

Last calibration

date

OPTIONS Menu Setup Parameters (sec. 9.3)

Menu

Parameters

A.

Display

Description

Display contrast

Low or High

0.0000 - 99999.

0.0000 - 99999.

Pulse

0.0001 - 99999.

0.10 - 999. seconds

00 - 00 - 00 to

39 - 39 - 99

Range

0 to 5

Low

1.0000

0.0000

1.000

Gallons

0.10

seconds

01 - 01 - 98

Factory

Default

3

10

B.

C.

D.

E.

Flow decimal

Totalizer decimal

Display averaging

4 mA setpoint

**.*** to *****.

******.** to ********.

Off= 0 sec., Low= 4sec.,

High= 8 sec.

Unlimited

****.*

*******.*

Off

0.0000 GPM

Signet 5500 Flow Monitor

Page 11

OPTIONS Menu Setup Parameters Continued...

F.

G.

H.

J.

Menu

Parameters

I.

Auxiliary (AUX) output

Display

Description

20 mA setpoint

4 mA adjust

20 mA adjust

VIEW menu total

reset access code

pulse logic

Range

Unlimited

3.0 to 5.0 mA

19 to 21 mA

On or Off

Active Low or

Active High

Factory

Default

100.00 GPM

4.00 mA

20.00 mA

Off

Low

13. Troubleshooting

Display Problem Solution

-- -- -- -- Display timebase too large Change fl ow timebase (S=Seconds, M=Minutes, H=Hours, D=Days)

in CALIBRATE menu to a smaller value (e.g. GPD to GPM)

Check settings

for Relay 1

Check settings

for Relay 2

Check settings

for AUX output

Must be between

0.0001 - 99999

Must be between

0.10 - 999

Flow K-Factor

can not be zero

Total K-Factor

can not be zero

SETUP READ

ERROR

Press any Key

Relay 1 pulse width too large

for frequency input or pulse

volume too small

Relay 2 pulse width too large

for frequency input or pulse

volume too small

Auxiliary output pulse width too

large for frequency input or pulse

volume too small

Relay 1, Relay 2, or Auxiliary output

(AUX) pulse volume setpoint must

be within 0.0001 - 99999.

Relay 1, Relay 2, or Auxiliary output

(AUX) pulse width must be within

0.10 - 999 seconds

Flow display K-Factor cannot be

zero

Totalizer K-Factor cannot be

zero

Power fault occurred while saving

setup menu entry

Reduce Relay 1 pulse width setting (sec. 9.2 I) or increase pulse

volume setting (sec. 9.2 H)

Reduce Relay 2 pulse width setting (sec. 9.2 I) or increase pulse

volume setting (sec. 9.2 H)

Reduce auxiliary output pulse width setting (sec. 9.2 M) or increase

pulse volume setting (sec. 9.2 L).

Enter volumetric setpoint within 0.0001 - 99999. engineering units

(sec. 9.2 H or 9.2 L)

Enter pulse width within 0.10 - 999 seconds

(sec. 9.2 I or 9.2 M)

Enter K-Factor greater than zero (sec. 9.2 C)

Enter K-Factor greater than zero (sec. 9.2 E)

Press any key to reload factory defaults then reprogram fl ow system

setup parameters. Note: totalizer displays remain undistrubed and

will resume after instrument reset.

14. Maintenance

Clean the instrument case and front panel with a soft cloth and mild liquid soap solution.

Signet 5500 Flow Monitor

11

Page 12

George Fischer Signet, Inc. 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

3-5500.090-1 Rev. K 3/06 English © George Fischer Signet, Inc. 2001 Printed in U.S.A. on recycled paper

Loading...

Loading...