Georg Fischer 3719 Specifications

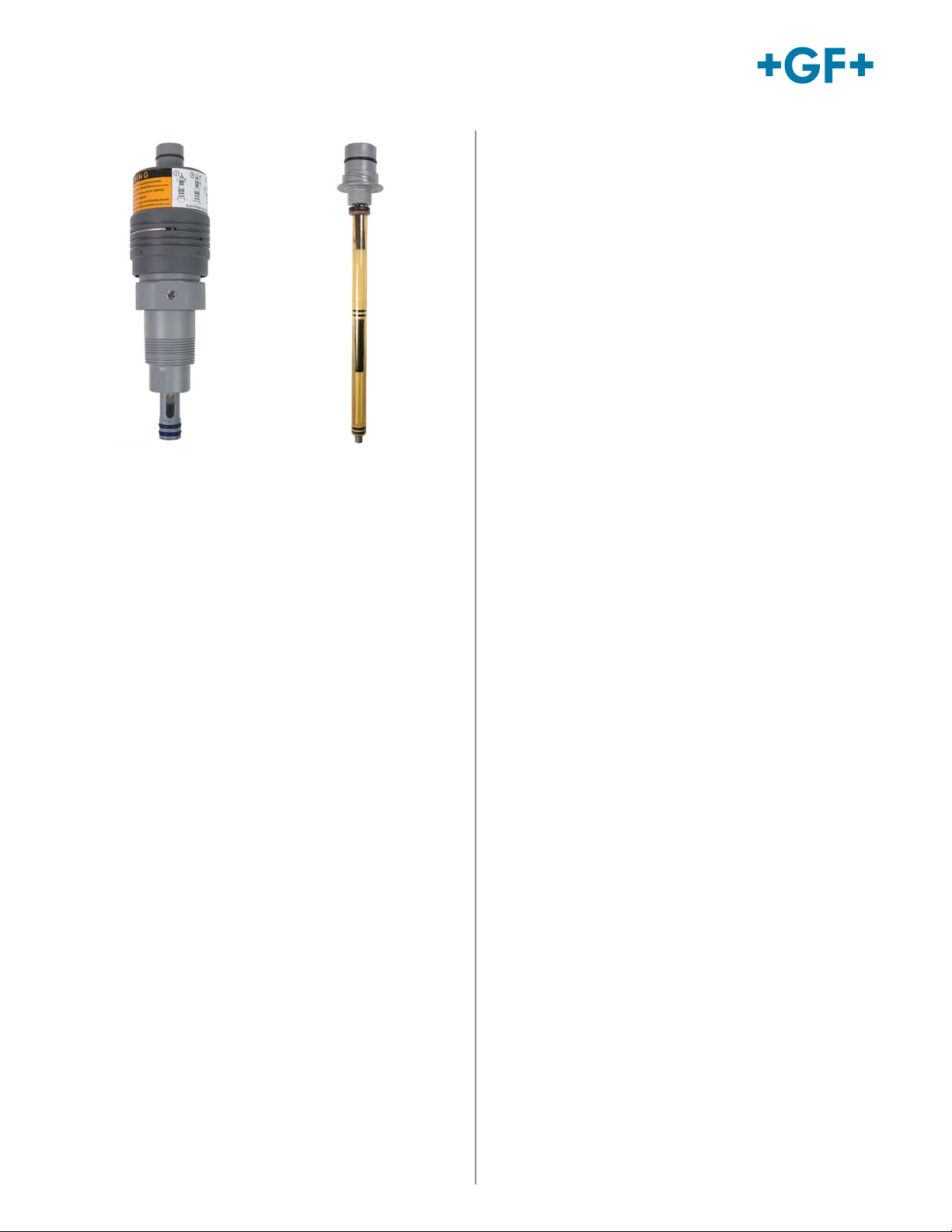

Signet 3719 pH/ORP Wet-Tap Assembly

Features

• Electrode removal without process shutdown

• Space saving 45 mm (1.75 in.) short-stroke design

• Sealed pneumatic dampening for smooth and safe

operation

• SafeLoc™: Cam-activated automatic locking

mechanism

• Protects electrode sensing surface from breakage

• Suitable for mounting in any orientation

3719

Assembly

The Signet 3719 pH/ORP Wet-Tap allows installation and

removal of pH or ORP electrodes, even under process

pressure, without the need for process shutdown during

routine electrode maintenance and calibration.

Process isolation is achieved during electrode

retraction with two sets of double O-ring seals on a

unique and compact retraction assembly; no separate

valve is required.

The Wet -Tap body design allows full access to the

plunger and internal O-rings, to easily perform

maintenance such as lubrication/replacement of O-rings

and the cleaning of the internal plunger/housing to

remove material build up in di cult applications.

A patented cam-activated automatic locking mechanism,

SafeLoc™, and the short stroke design help to assure

operator safety. The wet-tap unit can be mounted at any

angle and can be used with the Signet DryLoc®

Wet-Tap electrodes.

2756, 2757 Wet-Tap

Electrodes

(Sold Separately)

• Process threaded connection NPT or ISO

• Fully serviceable internal O-rings

Applications

• Aquatic Animal Life Support Systems

• Recreational Water Monitoring

• Water & Wastewater Treatment

• E uent Monitoring

• Neutralization Systems

• Sanitization Systems

• Pool and Spa Control

NOTE:

This product is assembled using Synthetic grease

with PTFE.

Specifi cations

General

®

Compatible DryLoc

Process Connection 3719-11 NPT 1½

Maximum Flow Velocity 3 m/s 10 ft/s

Materials

Retraction Housing (Wetted) CPVC

O-rings (Wetted) FKM (O-Rings are lubricated with Super Lube multi-purpose grease with PTFE)

Locking Shroud PVC

Hardware 316 stainless steel

Max. Temperature/Pressure Rating

Operating Pressure 100 psi (6.9 bar) maximum @ 25 °C

Shipping Weight

Standards/Approvals

Electrodes 2756-WTP, 2756-WTP-1 plastic

2757-WTP plastic

3719-21 NPT 2 in.

3719-12 ISO 7/1 - R 1.5

3719-22 ISO 7/1 - R 2

1.2 kg 2.7 lb

Manufactured under ISO 9001 for Quality, ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety

in.

See Temperature and Pressure graphs for more information

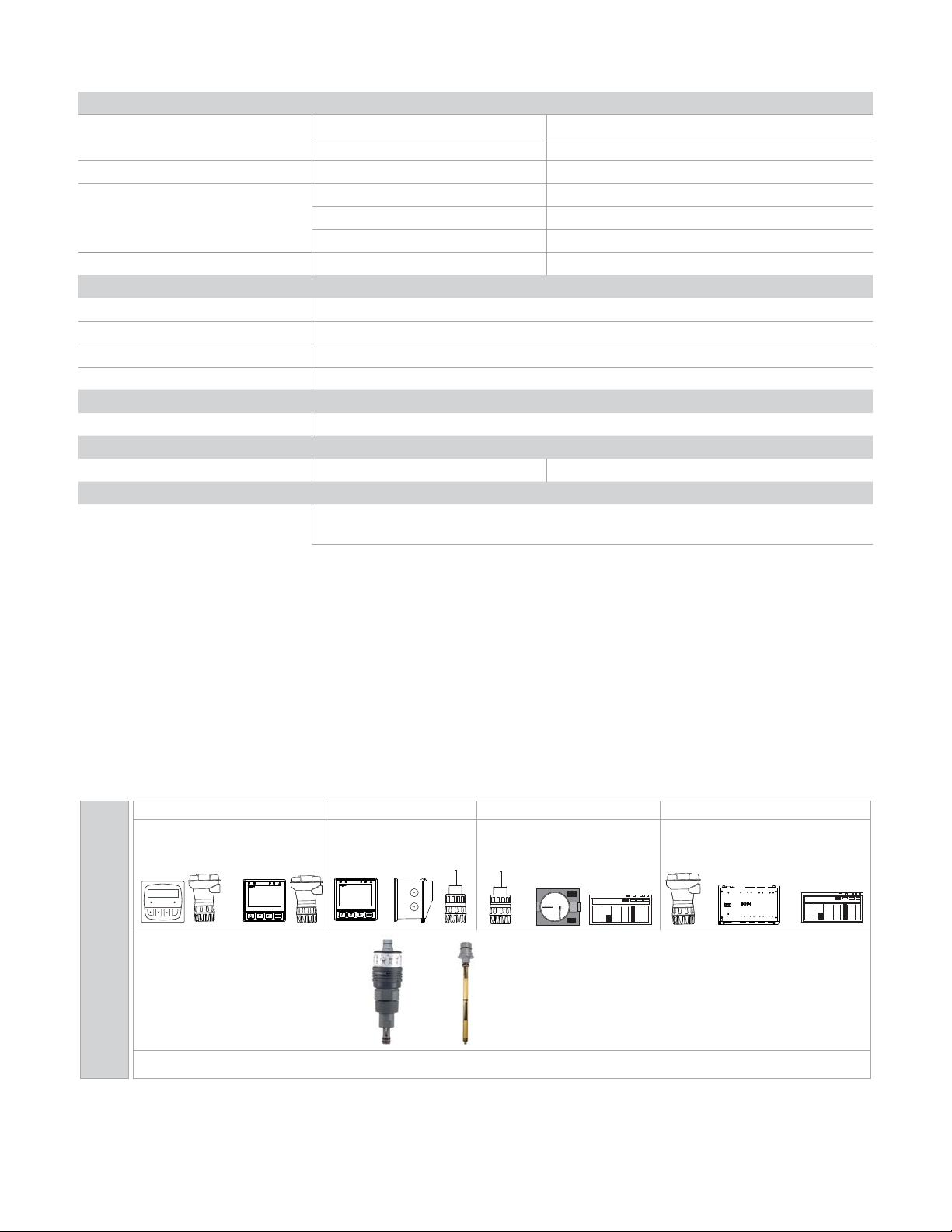

Wet-Tap Installation

Pipe, Tank, Wall Mount

Signet Instrument

8900 9900 9950

with 2751 Sensor Electronics

ENTER

Signet Model 3719 Wet-Tap Assembly

with Wet-Tap Electrode 3-2756-WTP

or 3-2757-WTP

OR

Signet Instruments

9900 with 2751 Electronics

and Rear Enclosure

+

+

System Overview

Customer supplied tees and fittings

4 to 20 mA InputPanel Mount

2751 Sensor Electronics

and Customer Supplied Chart Recorder,

Programmable Logic Controller, or

Programmable Automation Controller

+

PLC

Automation System

2751 Sensor Electronics with 0486 Profibus

Concentrator and Customer Supplied

Programmable Logic Controller or

Programmable Automation Controller

L IN+

L IN-

N/C

L OUT+

L OUT-

N/C

L IN+

L IN-

+5V OUT

DATA

GND

L IN+

L IN-

+5V OUT

DATA

GND

Out

In

S3L Loop

S3L Loop

USB

Profibus

Channel 5

Channel 6

Channel 7

+

Valve

Signet 3-0486 Profibus Concentrator

Address

Power

Channel 1

Channel 2

Channel 3

24 VDC

0.40A Max

S3LFreq

S3LFreq

S3LFreq

+5V OUT

+5V OUT

+5V OUT

Freq IN

Freq IN

PWR+

PWR+

PWR+

PWR-

PWR-

PWR-

DATA

DATA

GND

GND

PLC

+

Channel 4

S3LFreq

+5V OUT

Freq IN

Freq IN

DATA

DATA

GND

GND

All sold separately

www.gfsignet.com

Loading...

Loading...