Page 1

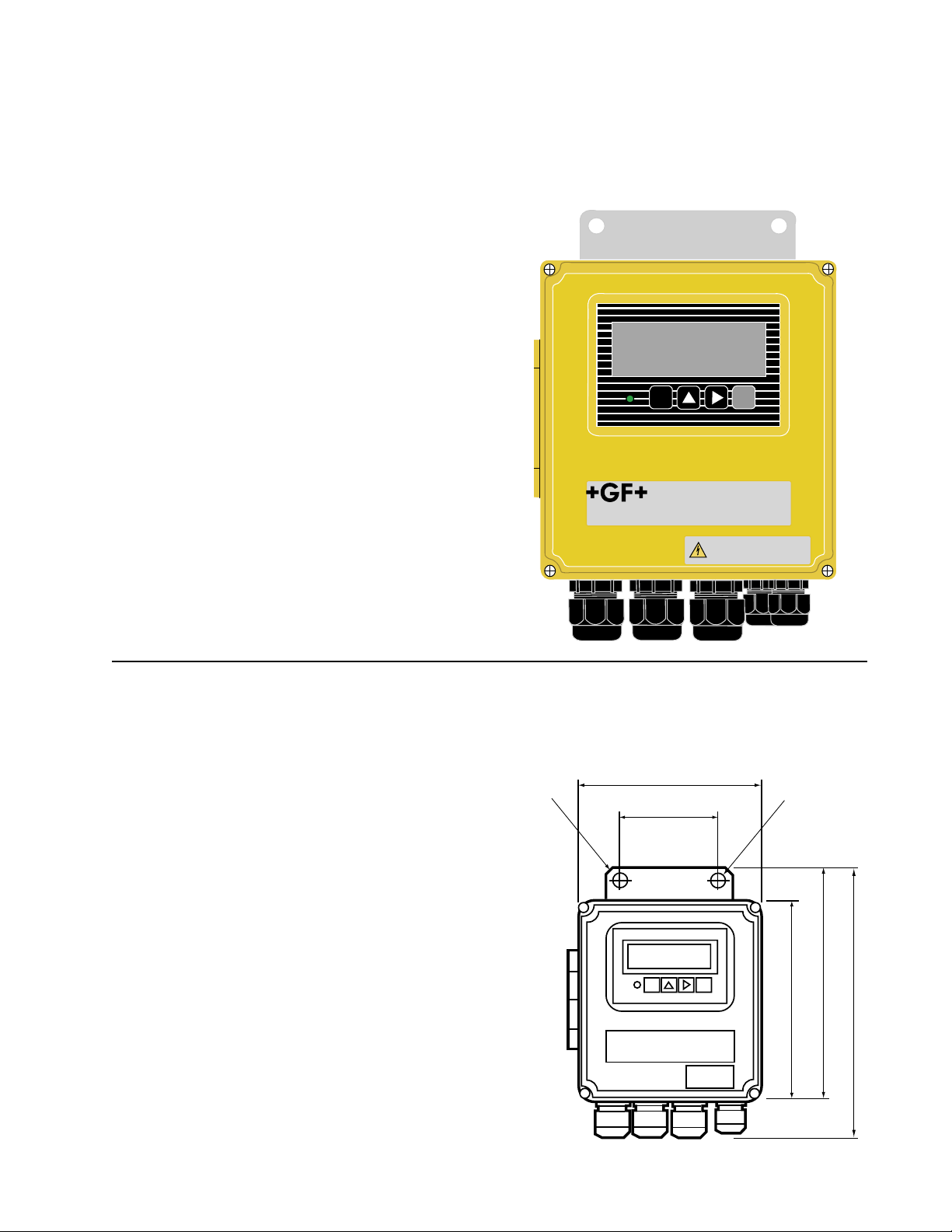

Signet 3350/3550 Ultrasonic Flowmeter

Mounting hole

130

70

140

170

(197)

Mounting

plat

e

ENT

ESC

Signet Ultrasonic Flowmeter

123.456 GPM

12345678 Gal

Caution: High Voltage

Turn off power before opening unit

Quick-Start Guide

3-3350.091

3-3350.091 A 11/05 English

This document contains the basic information required

to install the 3550 Ultrasonic Flowmeter and to begin the

measurement. Complete information and instructions can

be found in the 3-3350.090 Instruction manual.

This guide does not include information related to the setup

and use of the output features of the flowmeter.

The installation and startup of this flowmeter is divided into

seven steps. They are organized in the sequence they

should be completed:

1. Select a mounting location and method for the 3350

electronics.

2. Select a location and mount the 3550 strap-on sensor

assembly onto the pipe.

3. Connect the sensor cables and 24 VDC power to the

electronics terminals.

4. Navigate to the MEASURE SETUP menu and enter

the information for your pipe and fluid.

5. Record the PIPE PARAMETER number that is

displayed after the pipe and fluid information is

entered.

6. Position the two ultrasonic transducers at the spacing

indicated by the PIPE PARAMETER and secure them

in the frame.

7. Program the 3350 flowmeter electronics to reflect the

remaining application requirements.

Select a mounting location and method for the 3350 electronics.

The converter may be mounted on a wall or on a pipe

stand.

• For wall mounting, use two M8 bolts. Drill holes based

on the dimensions illustrated here.

• For pipe mounting, use the two U-bolts supplied with

the unit.

1.

Page 2

A

ir tends to accumulate

May not completely be filled with liqui

d

May not

completely be

filled with liquid

Good

Good

Pump

2A.

Pipe

Horizontal

45°

45°

Weldment Weldment

We

lding is included

Off the Welding.

Av

oid Welding.Welding is partly involved.

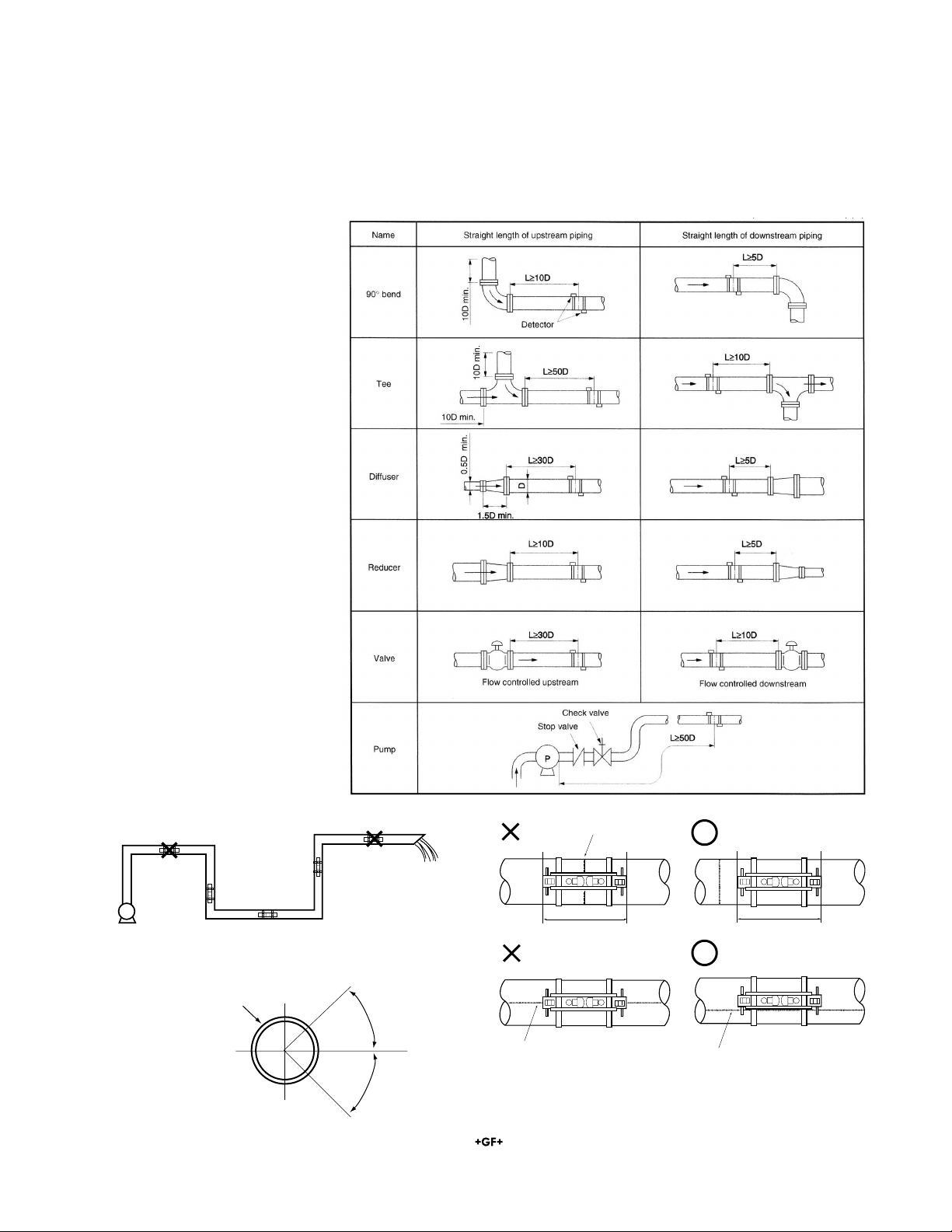

Select a location for the 3550 strap-on sensor assembly.

The length of upstream and downstream straight pipe of the ultrasonic detector should be long enough to ensure accurate

measurements.

• The sensor can be installed

vertical, horizontal or at any

posture provided that attention

is paid to the following things.

• The piping must completely be

filled with fluid when it flows.

• In case of horizontal piping,

mount the detector within ±45°

from the horizontal plane.

Otherwise, the measurement

could be impossible if bubbles

stay in the upper part of piping

or if deposits are accumulated

in the lower part of piping.

• Use thinner, sandpaper,

etc., to remove and surface

corrosive, rust, etc, and to

make the surface. rust, pitch,

convex and concave from the

pipe surface free of pits and

distortions

• Do not mount the detector on

a distorted section of pipe, or

straddling a flange or weld

seam.

2

Signet 3350/3550 Ultrasonic Flowmeter

Page 3

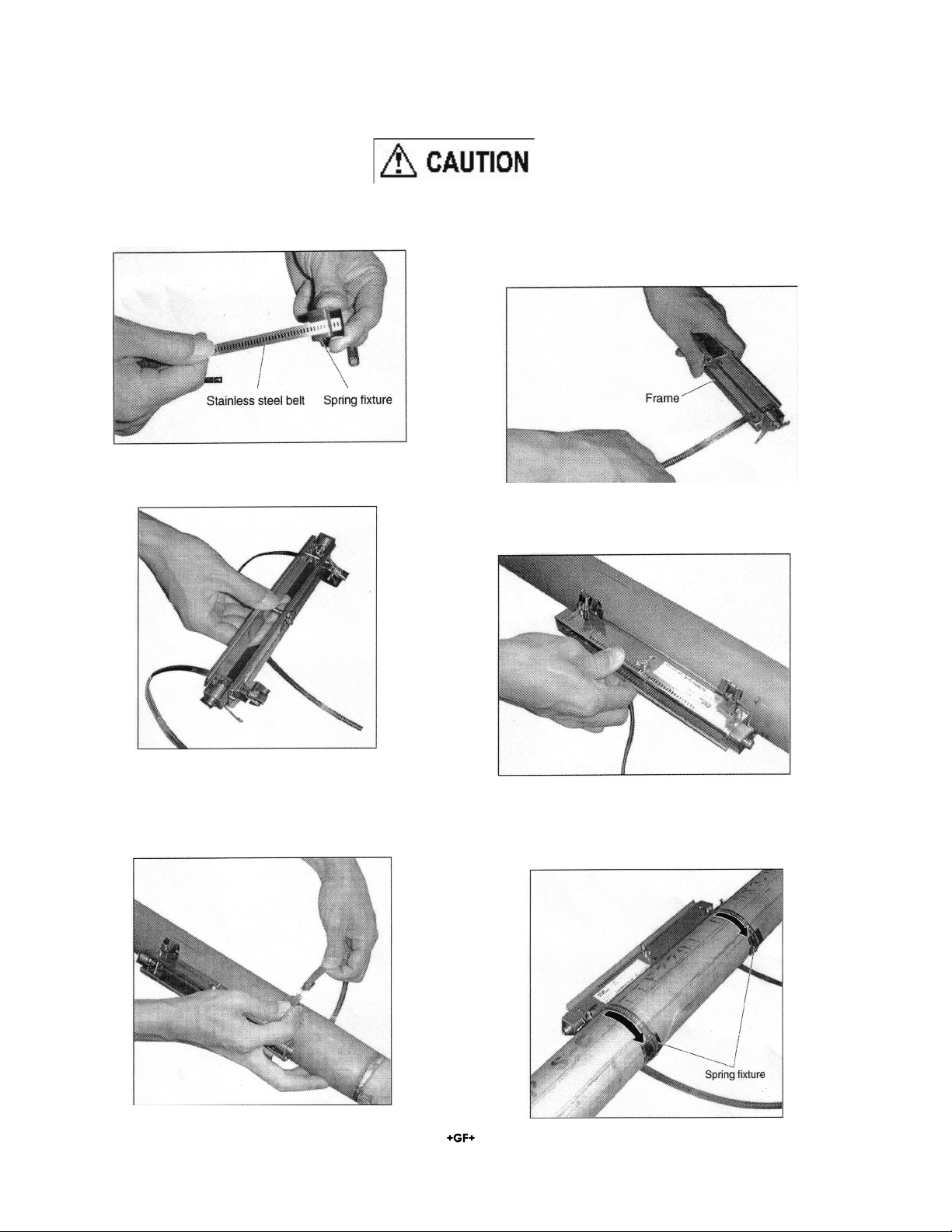

Mount the 3550 strap-on sensor assembly onto the pipe

• Handle the steel mounting belts carefully to avoid injury.

2B.

(1) Slide the spring fixture onto the stainless steel belt.

(3) Place the frame on a pipe smooth, clean section sub-

jected to a surface treatment (see fig. 3-4).

(2) Pass the stainless steel belt through 2 belt holes on the

frame.

(4) Temporarily tighten the first stainless steel belt on the

pipe (see fig. 3-5).

(5) Adjust the frame so it is parallel with the pipe, put the

spring fixture to the side of the frame and tighten the

stainless steel belt so that the frame will tightly be fitted.

Mounting on pipe whose diameter is 150A or larger,

connect 2 stainless steel belts (see fig. 3-6 and 3-7).

Signet 3350/3550 Ultrasonic Flowmeter

(6) After tightening both stainless steel belts, slide the

spring fixture to the opposite to the frame.

Note: Frame must be relocated, use new stainless steel

belts (see fig. 3-8).

3

Page 4

Mount the 3550 strap-on sensor assembly onto the pipe (continued)

Before mounting the sensor unit into the frame, Apply

silicone (or silicone-free grease Note) over the entire

transmission surface of the sensor unit, taking care not to

introduce bubbles.

Note) When using silicon-free grease, pay attention to the

fluid temperature range. The fluid temperature range is

shown below.

Silicon rubber: 20 to 100°C

Silicon-free grease: 0 to 60°C

Silicon-free grease should be reapplied approximately once

every 6 months. (Silicon rubber need not be reapplied.)

Insert the sensor unit into the frame, align the slit provided

on the pressing fixture of the sensor unit with graduations

located on the frame top surface and press the sensor

unit until the fixture claws are engaged with the frame side

square holes. Mount both sensor units so as to be roughly

symmetrical with respect to the frame.

2B.

Position of the slit and the graduation

(Magnified view of section A)

After connecting the signal line, make sure the red LED on

the flow transmitter has turned green. It takes about

10 seconds until the color changes to green.

The green color indicates the received signal is normal.

The red color indicates the received signal is abnormal. If

the LED remains red and does not turn green, examine

the sensor installation status (sensor spacing, sensor

orientation, claw engagement, etc.) and parameter

settings, and check whether the piping is filled with fluid.

4

(4) Connect the signal line with BNC connectors to the sen-

sor units. Engage the red BNC connector upstream, and

the black BNC connector downstream (see fig.3-16).

Signet 3350/3550 Ultrasonic Flowmeter

Page 5

3.

Main Board Terminal Block

Power Board Terminal Block

Upstream

sensor cable

Downstrea

m

sensor cable

Power cable

Output signal cabl

e

(analog output, DO1, DO2,

communication synchronization)

AC power source: 100 to 120 or 200 to

240 V AC, 50/60 Hz

Notes:

1.All screws are M3 on the terminal block. Use crimp-style terminals for M3 and whose outer diameter is Ø5.8 or smaller.

2. Be sure to connect to grounf the power board terminal block or external ground terminal (class D ground).

3. For output signal, use multiple core cable as required

.

Red (upstream sensor

)

Black (upstream sensor)

Coaxial signal cabl

e

DC power source: 20 to 30V DC

L N

GND GND

+ - GND GND

Communication Board

Terminal Block (Option

)

External Ground Termina

l

RS-232C

NC GND RXD TXD

RS-485 and synchronization

SYNC SHILD

TXCR2 TXDR1

Synchronization

RS-485

Ground terminal

Iout(+) DO1(+) DO2(+) GND HF1

Iout(-) DO1(-) DO2(-) GND

Upstream sensor

Downstream sensor

HF2

Connect Power and Signal cables

Signet 3350/3550 Ultrasonic Flowmeter

5

Page 6

4.

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

Navigate to the MEASURE SETUP menu and enter the necessary pipe information

The PIPE PARAMETER section of the Measure Setup menu calculates the correct spacing between the two Ultrasonic

electrodes. The following pages will guide the user through each step.

The operating procedure is as follows (from measurement mode).

If the parameter protection is set at “PROTECTION ON”, change it to “PROTECTION OFF”.

If ID NO. is set at this time, ID NO. must be inputted.

Press: Display shows:

3x. 1st line: [MEASURE SETUP]

1st line: [SYSTEM UNIT].

3x. 1st line: [PIPE PARAMETER].

1st line: [OUTER DIAMETER]. 2nd line: [60.00 mm]

Cursor blinks on 2nd line.

and Input the outer diameter of a measurement pipe.

piping data is located in section 3.2.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [PIPE MATERIAL]. 2nd line: [PVC] * As selected currently.

Cursor blinks on 2nd line.

Select the pipe material from menus. If there is no corresponding menu,

input the sound velocity of the pipe material at the end of its, See piping data

in section 3.2.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [WALL THICKNESS]. 2nd line: [4.50mm] * As selected currently.

Cursor blinks on 2nd line.

and Input the wall thickness of a measurement pipe.

As necessary, check the piping data in section 3.2.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

6

Signet 3350/3550 Ultrasonic Flowmeter

Page 7

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ESC

ESC

4.

Navigate to the MEASURE SETUP menu and enter the necessary pipe information (continued)

Press: Display shows:

1st line: [LINING MATERIAL]. 2nd line: [NO LINING].

* As selected currently. If pipe is not lined, press key to go to selection of

next fluid to be measured.

Cursor blinks on 2nd line.

Select the lining material from menus. If there is no corresponding menu, in

put the sound velocity of lining material on sound velocity input screen whose

menu is located at the last. As necessary, see lining data in section 6.6.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [LINING THICKNESS]. 2nd line: [2.00 mm]. * As selected currently.

Note: This setting only appears if a lining material is selected above.

Cursor blinks on 2nd line.

and Input the lining thickness.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [KIND OF FLUID]. 2nd line: [WATER]. * As selected currently.

Cursor blinks on 2nd line.

Select [WATER] or [SEA WATER]. If the fluid is other than these selections,

fluid, input the sound velocity of fluid on sound velocity input screen whose

menu is located at the last. As necessary, see piping data in section 6.6.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [KINEMATIC VISCO]. 2nd line: [1.0038E-6m2/s].

Kinematic viscosity of water is factory set. If fluid to be measured is other

than water, input the kinematic viscosity referring to piping data in section 6.6.

Cursor blinks on 2nd line.

and Input the kinematic viscosity.

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

2X 1st line: [SENSOR TYPE]. 2nd line: [3-3350]. * As selected currently.

Cursor blinks on 2nd line.

Select [3-3350.100] or [3-3350.200].

Registered after [**COMPLETE**] is indicated about 1 second on 2nd line.

1st line: [PIPE PARAMETER]. 2nd line: [S= 16 (48mm)

Use this value to secure the two sensors at the correct spacing.

1st line: [MEASURE SETUP]

2x. Measurement mode is resumed.

Signet 3350/3550 Ultrasonic Flowmeter

7

Page 8

6.

Spacing illustrated: 34

Position the two ultrasonic transducers at the spacing indicated by the PIPE PARAMETER

and secure them in the frame.

7.

Program the 3350 flowmeter electronics to reflect the remaining application requirements.

The 3350 is now ready to begin providing flow information, with the flow rate in units of meters per second and the

totalizer in cubic meters. These settings and many additional settings and features in the 3350 are not addressed in this

document. Please refer to the complete 3350 Operating manual for instructions on how to program these features.

George Fischer Signet Inc., 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

GEORGE FISCHER +GF+ Piping Systems

3-3350.091 (A-11/05) English © George Fischer Signet Inc. 2005 Printed in U.S.A. on Recycled Paper

Loading...

Loading...