Page 1

Signet 3300/3500 Ultrasonic Flow Monitor System

Features

3-3500.31X-X

• Bi-directional flow

• Measures debris

laden flow

• Open channel or full

pipe measurements

• Self-diagnostics

3-3300 (-1)

Description

The Signet 3300 Ultrasonic Flow Monitoring System advances the use of Doppler

ultrasonic technology in flow measurement by utilising proprietary “Advanced

Spectrum” signal processing to measure

the entire flow stream. The result is reliable, power-efficient, low cost liquid flow

monitoring in open or closed channels.

The Signet 3300 includes features tailored

to meet common requirements in a variety

of applications like municipal water/

wastewater, industrial waste, etc.

3-3500.320-X

3-3500.330-X

The Signet 3300 system can be equipped

with a 4 to 20mA output for interfacing to

loggers, telemetry systems or PLC’s for

long-term monitoring or an RS232 local

connection to laptops. This vandal-resistant unit is dual password protected, one

for viewing data and one for programming. These sensors have no moving

parts and lend minimal obstruction in the

flow stream.

• Local display of flow

rate and total

• Minimal straight run

requirements

• No moving parts

• Battery powered

(optional solar panel)

• High-intensity proportional flashing rate

indicator

• Weatherproof stainless steel enclosure

• Vandal-resistant

• PC access

and downloads

• Data logger

System Overview

Strap-in Sensor Mount Insertion Sensor Mount

Signet Flow Instrument

3-3300 (-1)

Mounting Kit included

Signet Flow

Sensor

3-3500.312

3-3500.313

(Pipe sold separately)

Strap mount kit required.

See Ordering Info.

66

Signet Flow Sensor

3-3500.320

3-3500.330

Pipe fitting (customer supplied)

• 4 to 20mA output

(dependant on user

defined rate)

• Wet-Tap capability

Applications

• Industrial/Municipal

Wastewater

• Pump Station

Monitoring

• Environmental

Monitoring

• Billing Networks

• Sewer and Stormwater Flow Monitoring

• Open channels,

Flumes, and weirs

www.gfsignet.com

Page 2

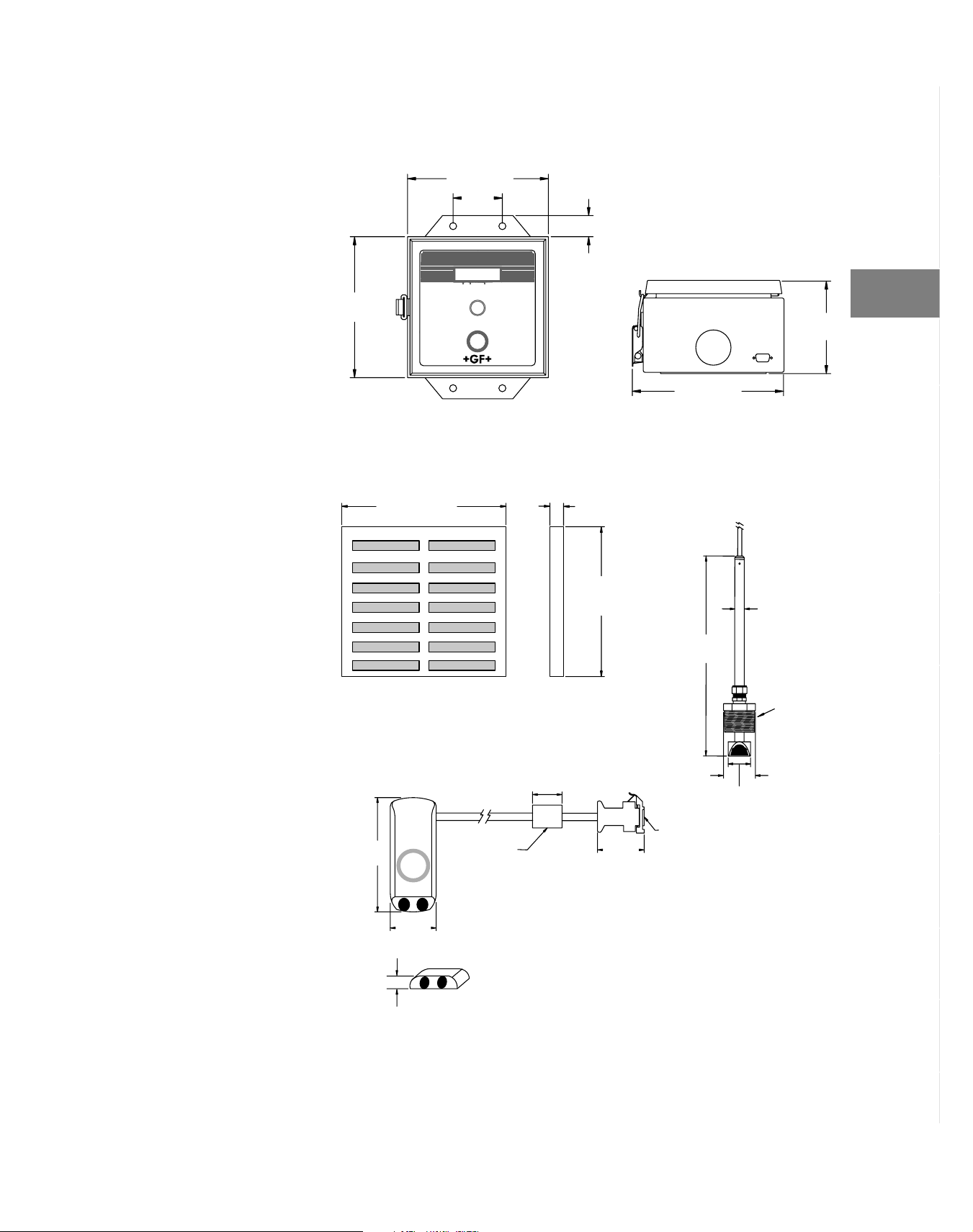

Dimensions

2

m

.

3300 Monitor Logger

Choosing

Products

200mm

(7.87 in.)

Solar Panel (optional)

270mm (10.63 in.)

200mm (7.87 in.)

30mm

(1.18 in.)

3200/

Front View

30mm (1.18 in.)

22.6mm

(0.89 in.)

245mm

(9.65 in.)

216mm (8.5 in.)

Bottom View

Insert Transducer

3500.320-X

3500.330-X

20mm

(0.78 in.)

134m

(5.28 in

Instrument

Multi-Pa-

rameter

Flow

pH/ORP

Conductivity/

Resistivity

Pressure, Level

Temperature,

Products

Other

Front View

Strap Mount Transducer

3500.31X-X

125mm

(4.92 in.)

50mm

(1.97 in.)

16mm (0.63 in.)

Top View

Clip-on

ferrite bead

Cable length:

10m or 20m

(30 ft. or 60 ft.)

Face View

13.7mm

(0.54 in.)

Side View

50mm

(1.97 in.)

(13.87 in.)

DB9 Male

Connector

352mm

45mm

(1.77 in.)

2 in. NPT

or ISO 7/1-R

73.6mm

(2.9 in.)

Installation

Wiring &

Reference

Technical

Temperature/

Pressure

Graphs

of Terms

Glossary

Reference

Part No.

www.gfsignet.com

Index

67

Page 3

Specifications

3300 Flowmeter

General

User Interface:

• Flow display is an internal 6-digit, 0.5 in.

(12mm) LCD of constant status, flow rate

and flow volume total

• High-intensity LED light flashes proportionately to flow rate (user configurable)

• RS232 serial cable for local connection to

PC, laptops and pocket PC

Flow Volume Logging Capacity:

• Configuration dependent to maximum of

250,000 records at 15 min. intervals. Includes independent logging of depth . Over

120 days data logging.

Material:

316 Stainless Steel

Electrical

Power:

• 9VDC- 1 amp, regulated power converter

required for 110 VAC/240 VAC operation.

Internal battery.

• Internal 6V 12 Ah battery , rechargeable

(charger is customer supplied) Solar panel

available*

Outputs:

•

Pulse Output: open-collector flow volume

pulse, which shorts pulse pin to system

ground

• 4 to 20 mA output

Alarm:

Short Message Service Protocol (SMS)

Program Memory:

Battery backed NVRAM

Units of Measure:

User definable for rate and total (in metric

Application Software (required)

• CD-ROM included with required FloCom™

Environmental

Enclosure Rating: IP66

Operating Temperature:

23°F to 122°F (-5°C to 50°C)

**

or English units)

for PCs with help files, user manual, installation instructions, system configuration,

data downloading & velocity profile testing.

Minimum PC requirements - Windows

98 or newer, 10MB hard drive disk space,

one serial comms port (must be COM1 or

COM2), at least 640 x 480 resolution std.

VGA screen

(1.4401) enclosure

®

3500 Series Sensors

General

Velocity Performance - all sensors

• Velocity Measurement Method:

Wetted Doppler

• Bi-directional flow display (fully accountable), reverse flow indication and net flow

calculation

• Velocity Range (strap mount and insertion

type sensors):

0.03m/s to 4m/s (0.1 ft/sec to 13 ft/sec)

• Velocity Accuracy:

±1% of value up to 3.0m/sec (9.8 ft/sec)

±1.5% of value at velocities greater than

3.0m/sec (9.8 ft/sec)

• Repeatability: 0.5% @ 1m/s (3.2 ft/s)

• Velocity Resolution:

1mm (0.04 in.) @ 1m/sec (3.3 ft/sec)

• Max. operating temp./pressure:

10 bar @ 25°C (147 psi @ 77°F)

Depth Measurement Performance

(3-3500.312, 3-3500.313)

Depth Sensor Ranges:

• 4m (13.1 ft.)

• 10m (32.8 ft.)

• Max. depth (over range): 60m (197 ft.)

without damage

Depth Sensor Accuracy:

0.2% of full scale at constant temperature in

a static stream (depth measurement only).

1% of full scale over a flow stream (5°C to

55°C)

Repeatability: 0.5% at 1m/s (3.2 ft/s)

Depth Sensor Resolution: 1mm (0.04 in.)

• Max. operating temp./pressure:

10 bar @ 25°C (147 psi @ 77°F)

Mounting

• Installation Distance:

6x diameter and 2x diameter (reversible up or down stream)

• Insertion sensor fitting: 2 in. NPT threads

or ISO 7/1-R2 threads

• Insertion Installation Limits:

DN100 to DN1800 (4 in. to 72 in.)

Wetted Materials

• Strap Mount: Epoxy and PVC

• Pressure transducer: Alumina ceramic

• Insertion Mount: Epoxy and nickel plated

brass or 316 stainless steel

• Cable: PVC 9 mm diameter from 10m

(33 ft.) to 50m (165 ft.)

Shipping Weight (Flowmeter and Sensor):

9 kg (21 lbs.)

Standards and Approvals:

• CE

* Optional battery-solar

panel for trickle charge

stand-alone power system.

Approximate life expectancy is 7 years, depending

on application conditions.

* * One pulse/volume unit

independent of integration

time period.

68

www.gfsignet.com

Page 4

Ordering Information

Electronics Package (required) - Used with any of the sensors listed below

3-3300

3-3300-1

Sensor Part Number (required) - Choose one

3-3500 Ultrasonic Doppler Flow Sensor - must be used with 3-3300 Electronics package - Choose one

3-3500 .312 -2 Example Part Number

Sensor Strap Styles - Choose one (required)

3-3500.390 Adjustable strap poly - 300mm to 450mm pipe

3-3500.392

3-3500.393 Adjustable strap poly - 225mm to 300mm pipe

Mfr. Part No. Code

Electronics

3-3300 159 000 989

3-3300-1 159 001 499

Sensors

3-3500.312-1 159 000 994

3-3500.312-2 159 000 995

3-3500.313-1 159 000 996

3-3500.313-2 159 000 997

3-3500.320-1 159 000 998

3-3500.320-2 159 000 999

Ultrasonic Doppler flow meter electronics package; includes electronics, mounting

hardware, battery, communication serial cable, set-up CD and software

Ultrasonic Doppler flow meter electronics package; includes electronics, mounting

hardware, battery, communication serial cable, set-up CD and software, with one 4 to 20mA

output.

.312 Strap-in sensor, 0 - 4 m (0 - 13.1 ft) depth measurement above transducer face

.313 Strap-in sensor, 0 - 10 m (0 - 32.8 ft) depth measurement above transducer face

Cable length for strap-in sensor

-1 10m (33 ft) cable

-2 20m (66 ft) cable

.320 Insertion sensor, nickel plated brass

.330 Insertion sensor, 316 stainless steel (1.4401)

Cable length and thread size for insertion sensor - choose one

-1 10 m (33 ft.) cable for both styles; 2 inch NPT threads

-2 20 m (66 ft.) cable for both styles; 2 inch NPT threads

-3 10 m (33 ft.) cable for both styles; ISO 7/1 R-2 threads

-4 20 m (66 ft.) cable for both styles; ISO 7/1 R-2 threads

Strap-in sensor mounting plate - polypropylene; used for pipes > 450mm

Mfr. Part No. Code

Sensors

3-3500.320-3 159 001 001

3-3500.320-4 159 001 002

3-3500.330-1 159 001 003

3-3500.330-2 159 001 004

3-3500.330-3 159 001 005

3-3500.330-4 159 001 006

Sensor Straps*

3-3500.390 159 000 986

3-3500.392 159 000 984

3-3500.393 159 000 987

Accessories and Replacement Parts

Mfr. Part No. Code Description

3-3200.075 159 000 973

(Panasonic LC-R0612P)

3-3200.076 159 000 975 Solar panel - Solarex 6V 5W MSX5V6

3-3200.395 159 000 976 Solar panel mounting kit

3-3200.090 159 000 977 Signet FloCom™ CD Doppler operating

3-3200.391

159 000 979

Battery - sealed lead acid 6V 12 Ah

system and instructions (Win32)

Communication cable 3300 to PC - DB9

serial cable

Model 3300/3500

Ordering Notes:

1) Select a Doppler Flow

meter with or without a 4

to 20mA output

2) Select a sensor: strap-in

or insertion

*Select strap: mounting

3)

plate or adjustable strap

4) Optional 30 m (100 ft.)

and 50 m (165 ft.) cable

lengths available. Call

factory for details.

5) All strap-in sensors

measure depth and

velocity, and are the

perfect choice for open

channels.

6) Insertion sensors do not

measure depth. They are

for full pipe applications

only.

7) Select a 4 to 20mA output

for interfacing to loggers,

telemetry, or PLCs.

8) For 110VAC/240VAC operation, a power supply to

9VDC/1 amp is required

(customer supplied). It

will trickle charge the

internal battery. In the

event of a power failure,

the battery will ensure

continuous data logging.

9) Minimum pipe size for installation of strap-in and

insertion sensors is DN

100 (4 in.). Maximum pipe

size for insertion sensors

is DN 1800 (72 in.)

Choosing

Products

Instrument

Multi-Pa-

rameter

Flow

pH/ORP

Conductivity/

Resistivity

Pressure, Level

Temperature,

Products

Other

Installation

Wiring &

Reference

Technical

Temperature/

Pressure

Graphs

of Terms

Glossary

www.gfsignet.com

Reference

Part No.

* All hardware is included.

Index

69

Loading...

Loading...