Page 1

Signet 2839 to 2842 Conductivity Sensors

/

m

()

/

4

3-2850.090

3-2850.090 Rev F 06/03 English

SAFETY INSTRUCTIONS

WARNING

1. Specifi cations

Dimensions

1. Depressurize and vent system prior to installation or removal.

2. Confi rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifi cations.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. When using chemicals or solvents care should be taken and

appropriate eye, face, hand, body, and/or respiratory protection should be used.

2839: 0.01 cell 2841: 1.0 cell2840: 0.1 cell 2842: 10.0 cell

38.9 mm/

1.530 in.

38.9 mm/

1.53 in.

English

Table of Contents

1. Specifi cations

2. Cell constant

selection

3. In-line Installation

4. Submersible or Tank

installation

5. Wiring

6. Maintenance

7. Ordering information

38.9 mm/

1.53 in.

73.7 mm/

2.90 in.

15.9 mm/

0.625 in.

144 mm

5.66 in.

2850

5800CR

5900

102.7 mm/

4.05 in.

35.8 mm/

8850-X

1.41 in.

3-2840-1

3-2840-1D

8860

0.625 in.

15.9 mm/

8900

21.5 mm/

0.85 in.

9050CR

0.625 in.

15.9 mm/

3-2840-2

3-2840-2D

105.9 m

4.17 in.

35.8 mm/

1.41 in.

09 mm/

.29 in.

41.9 mm/

1.65 in.

0.625 in.

15.9 mm/

3-2841-1

3-2841-1D

3-2842-1

3-2842-1D

26.8 mm/

1.13 in.

15.9 mm/

3-2841-2

3-2841-2D

3-2842-2

3-2842-2D

41.9 mm/

1.65 in.

0.625 in.

112 mm

4.41 in.

PSIBAR

100

7

75

5

50

3

140.7 mm/

5.54 in.

73.7 mm/

2.90 in.

3-2839-1

3-2839-1D

General

Compatibility:

59.3 mm/

15.9 mm/

0.625 in.

CR Electrodes

with Cable (-1X)

CR Electrodes

with DryLoc™ (-2X)

2.33 in.

3-2839-2

3-2839-2D

Quality Standard:

• Manufactured under ISO 9001, ISO 14001

• CE

Shipping Weight:

2

25

°C

°F

-20-40

20

32 68

All -2X versions

60

100 140

212

140

284

2839: 0.34 kg (0.74 lb)

2840, 2841, 2842: 0.30 kg (0.66 lb)

Process connection:

-1 and -2 versions:

-1D and -2D versions: ISO 7/1-R3/

3

/4 in. NPT

4

Operating temperature/pressure:

(with thread engagement per ANSI B1.20.1)

-1X versions:

-10ºC to 100ºC @ 6.9 bar (14ºF to 212ºF @ 100 psi)

Cable (28XX-1X only):

4.6 m (15 ft.) std., 3 cond w/shld 22 AWG,

max length 30 m (100 ft.)

-10ºC to 131ºC @ 2.76 bar (14ºF to 268ºF @ 40 psi)

-2X versions:

-10ºC to 85ºC @ 6.9 bar (14ºF to 185ºF @ 100 psi)

(For resistivity measurements above 10 MΩ or

below 20°C, maximum cable length is 25 ft. (7.6 m)

Performance:

Accuracy: ±2% of cell value

Temperature measurement: PT1000

Temperature response time (τ):

2839: 5 s 2840: 10 s

2841: 20 s 2842: 30 s

Storage temperature: -20ºC to 131ºC (-4ºF to 268ºF)

Wetted materials:

DryLoc connector (-2 versions only): CPVC

Threaded fi tting: PEEK™

Insulator: PEEK™

Insulator O-ring (2841, 2842): FPM

Electrode contacts: 316L stainless steel

PEEK™ is a trademark of Victrex plc

Page 2

2. Cell constant selection

The nominal process value should be near the center of

the range. Ranges below are for use with +GF+ SIGNET

Conductivity instruments:

• 2839 (0.01 cell): 0.010 to 100 µS (10 kΩ /to 100 MΩ)

• 2840 (0.1 cell): 1 to 1000 µS (1 MΩ to 1 kΩ)

• 2841 (1.0 cell): 10 to 10,000 µS

• 2842 (10.0 cell): 100 to 200,000 µS

+GF+ SIGNET Conductivity/Resistivity Electrode Ranges

2842 10.0 cell

2841 1.0 cell

2840 0.1 cell

2839 0.01 cell

Electrode Models

0.010µs 1µs 10µs 100µs 200µs 1000µs 10 000µs 200 000µs 400,000µs

(100 MΩ)

(10 kΩ)

Conductivity Range (µS)

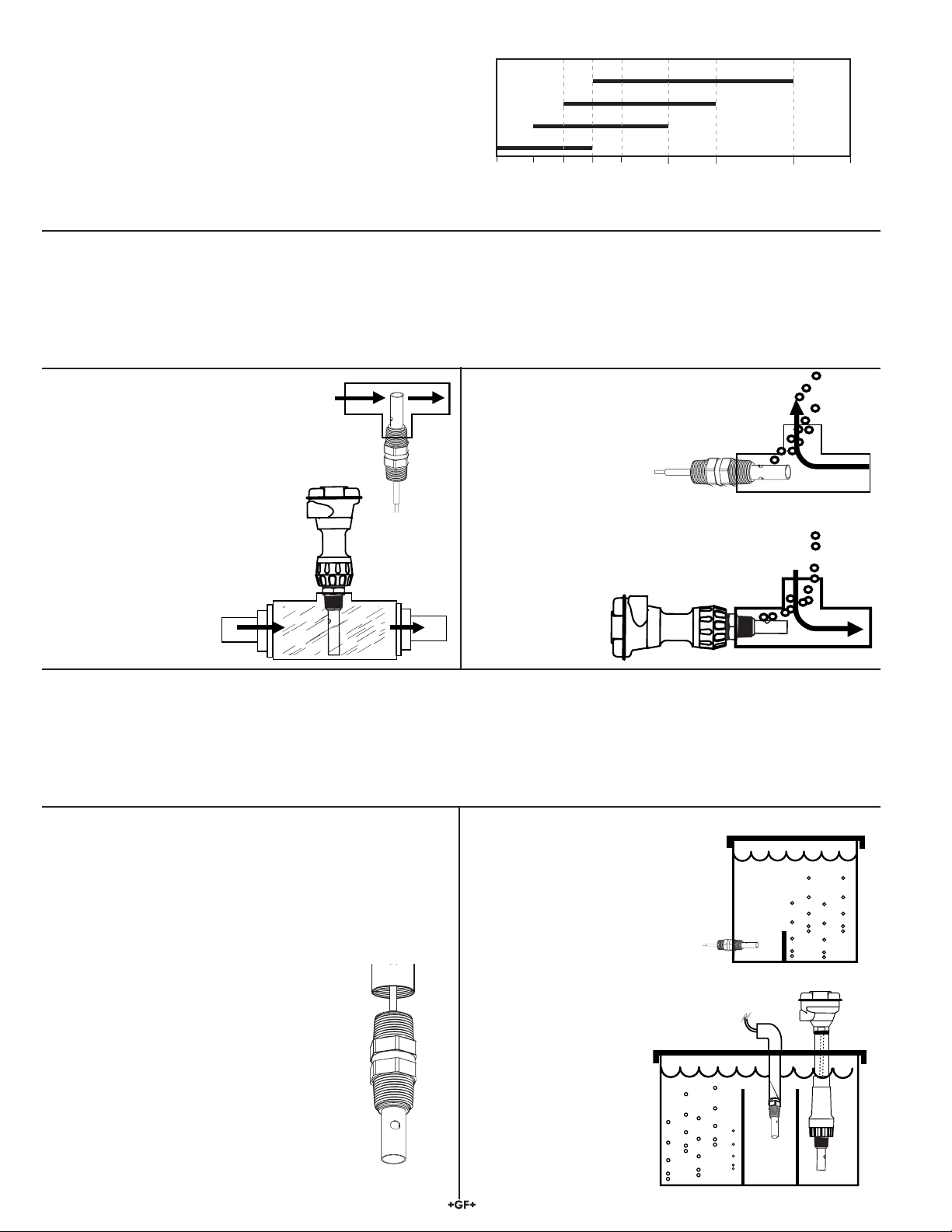

3. In-line installation for all -1X electrodes

• Inspect threads to ensure integrity. Do not install an electrode with damaged threads.

• Apply sealant or PTFE tape to threads.

• Wetted materials include 316L stainless steel, PEEK™ and FPM (FPM O-ring inside 2841, 2842).

Check for chemical compatibility before installing electrode.

• The -1X electrodes are supplied with 5 m (15 ft.) of cable. It may be extended to a maximum 30 m (100 ft.)

• For resistivity measurements above 10 MΩ or below 20°C, maximum cable length is 25 ft. (7.6 m)

If the electrode is mounted

vertically in a tee, do not recess

the openings inside the tee.

Mounting upside down may help

prevent air entrapment.

An oversized tee may also be

helpful for inline installations.

The preferred installation for in-line

applications directs fl ow straight into the

At least 4 threads (ANSI B1.20.1)

must be engaged to provide

pressure capacity per published

electrode. This confi guration dislodges

entrapped air bubbles, and provides the best

continuous sampling of the fl uid content.

specifi cations.

4. Submersible installation for all -1X electrodes

• Wetted materials include 316L stainless steel, PEEK™ (FPM O-ring inside 2841, 2842).

• Check for chemical compatibility before installing electrode.

• The -1X electrodes are supplied with 15 ft. of cable. It may be extended to a maximum 30 m (100 ft.)

• For resistivity measurements above 10 MΩ or below 20°C, maximum cable length is 25 ft. (7.6 m)

1. Feed cable into watertight conduit.

2. Apply thread sealant to the electrode before threading

conduit onto electrode. Avoid twisting the cable.

3. Secure cable with conduit or cable gland.

4. For additional defense against possible accumulation of

condensation at the back seal area of the electrode, fi ll the

lower 3-4 inches (75-100 mm) of conduit or extension pipe

with a fl exible sealant such as silicone.

In aerated vessels install the electrode

in a stillwell to prevent air from being

trapped inside the electrode.

3/4 in. NPT or

ISO 7/1-R3/4

2 Product name

Page 3

5. Wiring for all -1X electrodes

• Do not route electrode cable in conduit containing AC power wiring. Electrical noise may interfere with electrode signal.

• Routing electrode cable in grounded metal conduit will help prevent electrical noise and mechanical damage.

• Seal cable entry points to prevent moisture damage.

• For resistivity measurements above 10 MΩ or below 20°C, maximum cable length is 25 ft. (7.6 m)

Integral installation detail for all -1X electrodes

• 3-8052 Integral Kit and 3-9000.392-X Liquid Tight Connector

kit are required. (See Parts and Accessories on back page)

• Cut the cable to approx. 15 cm (6 in.)

• Strip outer cable cover back 5 cm (2 in.)

• Strip each conductor to expose 1 cm (3/8 in.) of bare wire.

• Tin each conductor with solder for best results.

All -2X DryLoc electrodes connect directly to the 2850

Conductivity Sensor with no interconnecting wiring.

Consult the 2850 Instruction manual for details.

ProcessPro

To 8850-1

Sensr Gnd

10

(SHIELD)

Iso. Gnd

9

(BLACK)

Temp. IN

8

(WHITE)

Signal IN

7

(RED)

locking ring

conduit base

integral

adapter

electrode

ProPoint

Conductivity Transmitter

SILVER (SHLD)

BLACK

WHITE

RED

8850

To 8850-2 and 8850-3

Sensr Gnd

14

(SHIELD)

Iso. Gnd

13

(BLACK)

Temp. IN

12

(WHITE)

Signal IN

(RED)

11

To 8860

SHIELD (Gnd)

BLACK

WHITE

RED

SHIELD (Gnd)

BLACK

WHITE

RED

SHLD

ISO GND

TEMP 1

SGNL 1

SHLD

ISO GND

TEMP 1

SGNL 1

Ch 1

Ch 2

To 5800CR

Intelek-Pro

To 9050CR

RLY3

C NO Tx GND Rx

1 2 3 4 5 6 7 8 9 10 11 12 13 14

RLY4

CH 2

CH 1

R+ R-

RED

WHITE

BLACK

CLEAR (SHLD)

RED

WHITE

BLACK

CLEAR (SHLD)

Shld

Temp. IN

Signal IN

Iso. Gnd

SERIALANL2

CH2

S2 T2

CH1

S1 T1 SG CNO

Installation for -2X DryLoc electrodes

Installation instructions for the -2 DryLoc version of these electrodes is located in the associated instrument manual.

3product name

Page 4

6. Maintenance

Conductivity electrodes require little maintenance except for periodic cleaning in installations where contaminants are present.

• Keep metal surfaces clean and free of coatings.

6.1 Replacement Insulator, 2842 electrode only

• 2842 electrodes have a removable insulator so the internal

cavity can be cleaned.

• After the insulator snaps into position it cannot be removed

without damage.

• Order insulator replacement kit 3-2842.390 before attempting

maintenance.

9 mm

0.34 in.

11 mm

0.44 in.

25.4 mm/1.0 in.

41 mm/1.6 in.

3-2842.390 Insulator replacement kit

14 mm

0.55 in.

8-32 thread for removal

7. Ordering Information

Insulator removal and replacement

A. Thread the screw into the insulator (8-32 thread)

B. Pull to remove the old insulator.

C. Clean any coating or deposits inside the electrode.

D. Insert the new insulator and press into place.

Electrode tip

(end view)

A

C

Internal contact

D

electrode tip

(side view)

Electrode tip

(side view)

Electrode

¥ Clean internal and external surfaces

New Insulator

Insulator

B

Cotton swab

Mfr. Part No. Code Description

3-2839-1 159 000 921 Cell 0.01, 15 ft cable, NPT

3-2839-1D 159 000 923 Cell 0.01, 15 ft cable, ISO

3-2840-1 159 000 786 Cell 0.1, 15 ft cable, NPT

3-2840-1D 159 000 788 Cell 0.1, 15 ft cable, ISO

3-2841-1 159 000 790 Cell 1.0, 15 ft cable, NPT

3-2841-1D 159 000 792 Cell 1.0, 15 ft cable, ISO

3-2842-1 159 000 794 Cell 10.0, 15 ft cable, NPT

3-2842-1D 159 000796 Cell 10.0, 15 ft cable, ISO

3-2839-2 159 000 922 Cell 0.01, DryLoc, NPT

3-2839-2D 159 000 924 Cell 0.01, DryLoc, ISO

3-2840-2 159 000 787 Cell 0.1, DryLoc, NPT

3-2840-2D 159 000 789 Cell 0.1, DryLoc, ISO

3-2841-2 159 000 791 Cell 1.0, DryLoc, NPT

3-2841-2D 159 000 793 Cell 1.0, DryLoc, ISO

3-2842-2 159 000 795 Cell 10.0, DryLoc, NPT

3-2842-2D 159 000 797 Cell 10.0, DryLoc, ISO

Parts and Accessories

3-8052 159 000 188

3

/4 in. Integral mounting kit

3-9000.392-1 159 000 839 Liquid-tight connector kit, 1 set, 1/2 in. NPT

3-9000.392-2 159 000 841 Liquid-tight connector kit, 1 set, PG 13.5

3-2842.390 159 000 925 2842 replacement insulator, PEEK™ with FPM O-ring

3-2850-1 159 000 783 Conductivity Sensor, In-line

3-2850-2 159 000 784 Conductivity Sensor, In-line w/EasyCal

3-2850-3 159 000 785 Conductivity Sensor, Submersible

3-2850-4 159 000 857 Conductivity Sensor, Submersible

George Fischer Signet Inc., 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

3-2840.090 Rev. F 06/03 English © George Fischer Signet, Inc. 2003 Printed in U.S.A. on recycled paper

Loading...

Loading...