Page 1

CSA is cross sectional area.

*

www.gfsignet.com

Technical Reference Section: Conductivity/

Resistivity

Principle of operation

AC

+

Half Cells

Voltage

+

z

+

+

+

+

+

+

+

+

+

+

+

+

+

+

1cm

1cm

+

+

2

-1

Graphs

221

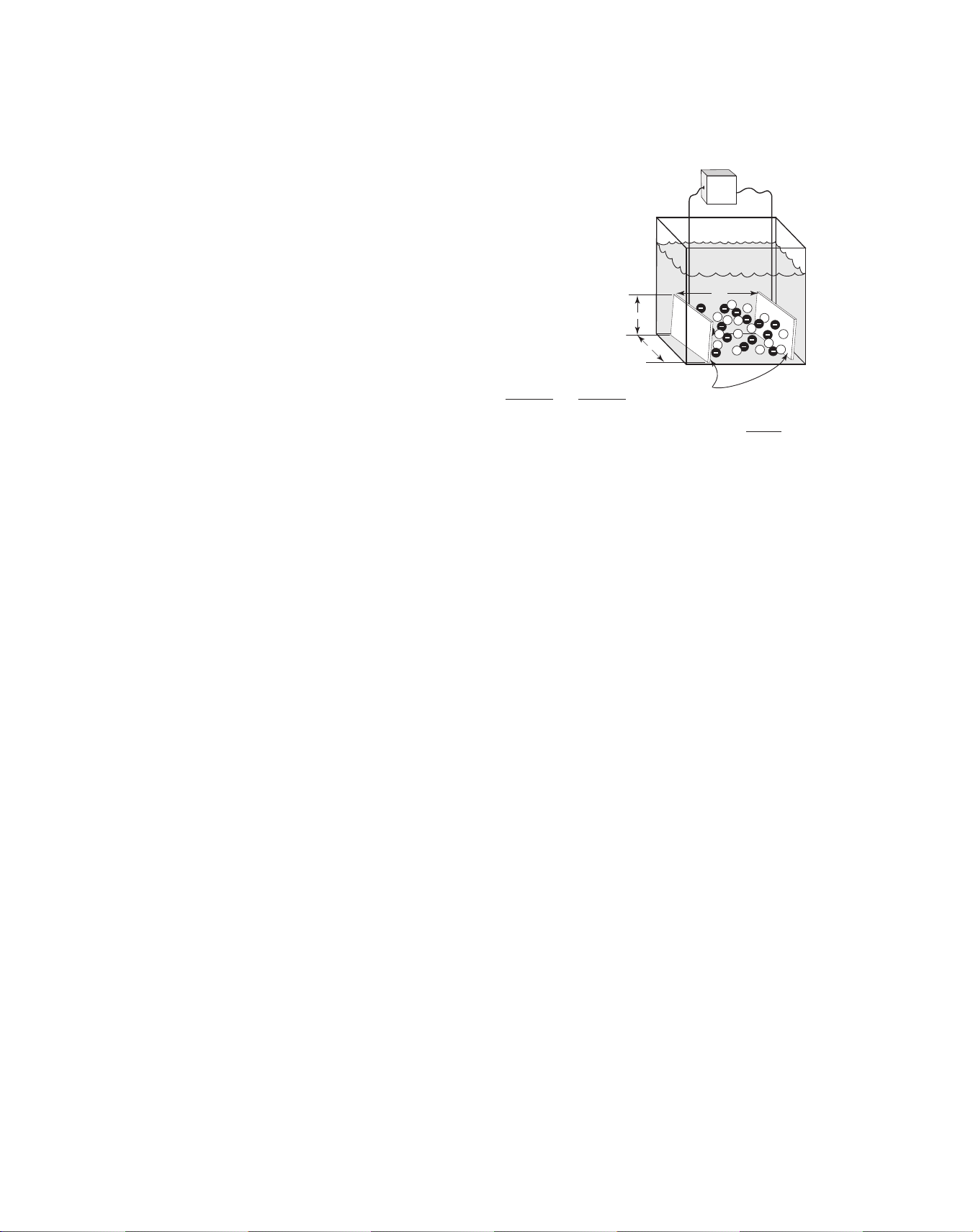

Most conductivity electrodes consist

of two measuring half-cells. The

geometry of the half-cells can be tailored to provide highly accurate measurements over a specific conductivity range. Cell constants

help to

describe electrode geometry for the

purpose of selecting the appropriate

x

electrode for a given application. A

cell constant is defined as the length

y

between the two half-cells divided by

the area of the cells.

Conductivity Cell Constant = =

Length

CSA*

z

xy

As an example, When x = y = z = 1cm the cell constant becomes = 1cm

Solutions of very low conductivity (high resistivity) such as ultra-pure water are

best measured with half-cells that are very close together (i.e., cell constant =

-1

0.01cm

). Highly conductive solutions should be measured with half-cells that

are farther apart and that have relatively little cross sectional area between

-1

them (i.e., cell constant = 20.0cm

Temperature Compensation

The conductivity of a solution is

highly dependent upon temperature.

Therefore, conductivity measurements are almost always converted

to an equivalent conductivity at the

common reference temperature of

25°C (77°F). This is accomplished by

means of temperature compensation algorithms in the instruments,

which require temperature as well as

conductivity measurement input. To

simplify and facilitate this requirement all Signet conductivity electrodes contain high-quality temperature sensing elements intelligently

positioned for quick and accurate

response.

).

siderably with the ionic composition

of the solution and can range from

less than 1% to more than 3% per °C.

This is true of regional ground water

sources as well as for other solutions

such as brackish water, acids and

bases. Signet instruments allow the

entry of custom linear compensation

coefficients for these applications.

See the instruction manual of any

Signet conductivity instrument for

details.

The conductivity or resistivity of pure

water is not a linear function with

respect to temperature. In fact, the

latest Signet conductivity instruments utilize a sophisticated polynomial to compensate for the peculiar

effects. For seamless measurement

Temperature effects on conductivity

are more or less linear for normal

water-based solutions, hovering

around 2% per °C. However, the

actual linear relationship varies con-

accuracy all current Signet conduc-

tivity instruments switch automati-

cally between linear and pure-water

compensation as certain measure-

ment thresholds are crossed.

Temperature Compensation Exception

One exception to the requirement for temperature compensation has been established by USP (United States Pharmacopeia), which prescribes limits of acceptability for ultra-pure water quality based upon non-compensated measurements.

This methodology is used to eliminate measurement variances that may result

from differences in the pure-water temperature compensation algorithms used by

different manufacturers of conductivity measurement equipment. A more thorough treatment of the USP standard and instrument functionality can be found in

the instruction manuals of the following Signet conductivity instruments: Model

8900 Multi-Channel, Multi-Parameter Controller (Appendix D), model 8860 Dual

Channel Conductivity/Resistivity Controller.

Choosing

Products

Instrument

Multi-Pa-

rameter

Flow

pH/ORP

Conductivity/

Resistivity

Pressure, Level

Temperature,

Products

Other

Installation

Wiring &

Reference

Technical

Temperature/

Pressure

of Terms

Glossary

Reference

Part No.

Index

Page 2

p

p

Relay Information

The two most common methods of controlling a process are “on/off” and “proportional” control. In on/off control, relay setpoints are defined as either high

or low limits on the process variable. When the measurement value reaches a

limit the relay is energized, typically for the purpose of opening a valve or starting a pump to introduce a chemical reagent to the process. This should cause

the measurement value to change in the direction of the setpoint as shown in

these on/off control diagrams:

High limit on/off relay control

= HI setpoint

= Hysteresis

= Relay energized

= Relay de-energized

pH

Notice the relay will not de-energize

until the setpoint is exceeded by the

hysteresis value. This is a programmable value and is primarily used to

prevent ”relay chatter”, which occurs

if a relay is set to energize and deenergize at the same value. Because

of hysteresis, and because reagent

delivery is fairly constant while the

relay is energized, a condition known

as “overshoot” is inherent to the on/

off control method. Overshoot refers

to the introduction of more chemical

reagent than is absolutely necessary

for achieving a desired adjustment to

the process value, and can be expensive over time.

Proportional control is a popular

alternative to the on/off control

method. This method typically makes

use of variable-rate metering pumps

to reduce overshoot and improve

precision. Establishing a proportional control scenario requires the

selection of setpoint(s), deviation

Low limit on/off control

pH

= LO setpoint

= Hysteresis

= Relay energized

= Relay de-energized

range(s) and maximum pulse rates.

The example shown here illustrates

how two relays in ”pulse mode” can

be used to proportionally control pH

within a desired range, or to a single

setpoint. This is called “Dual Proportional Control”. Of course, a single

relay in proportional pulse mode can

be used to establish a high or low

limit and will also reduce overshoot.

Metering pumps are idle at and between setpoints. When a setpoint is

exceeded, the pump begins delivering

reagent at a rate proportional to the

difference between the measurement

value and the setpoint. The larger

the difference, the faster the delivery. The programmed deviation value

defines how quickly the maximum

pulse rate is reached. Depending on

the input requirements of the metering pump, proportional control can

also be accomplished with scaleable

4 to 20 mA outputs instead of pulsing

relays or open collectors.

Dual proportional pulse relay control

Maximum Pulse Rate

0

pH

Deviation=

5.30 pH

LO

5.30

H

HI

7.50

H

Deviation=

3.50 pH

11.00

pH

222

14

pH

pH

Maximum Pulse Rate

Deviation=

5.20 pH

0

2.10

pH

LO and HI

7.30 pH

Deviation=

4.90 pH

12.20

pH

14

pH

www.gfsignet.com

Page 3

Open Collector Output

Many Signet instruments and sensors feature “Open Collector Outputs” for

purposes of signal transmission, alarming, control signal output, etc. Although

such outputs allow for a lot of wiring flexibility, care must be taken not to

destroy the circuits via incorrect polarity, over-voltage, transients or current

overload. Below is an explanation of proper wiring and dimensioning of related

circuit components. Please note that the following recommendations may or

may not apply to other manufacturer’s equipment.

1. Function

Open Collector (“OC”) outputs are low powered, solid state switches.

Although the term “Open Collector” stipulates the use of bipolar transistors

(NPN-type or PNP-type) as a switch, nowadays Field Effect Transistors (FET

or MOSFET) are used. Unlike electromechnical switches (e.g. pushbuttons

or dry contact relays) these OC switches are very fast, use little power, are

inexpensive, do not bounce and do not wear. However, OC’s are also more

limited in terms of voltage and current rating as well as being polarized

(i.e. they have a “plus” and “minus” terminal and thus DC only switching

capability). They are less tolerant to overload abuse than electromechanical

devices. Usually these switches have higher resistance and voltage drop.

2. Sensor Wiring

A typical example of the need for high speed switching capability is the

OC frequency output of Signet flow sensors like 3-2536 or 3-2540. Signal

frequencies can reach several hundred pulses per second while voltage and

current requirements are small enough, allowing the use of a transistor

switch. For each output pulse this switch connects the signal output to the

negative supply or ground terminal of the sensor and is therefore an “NPN”

style output. Signet does not produce sensors with PNP style outputs (which

connect the signal output internally to the positive supply terminal).

Choosing

Products

Instrument

Multi-Pa-

rameter

Flow

pH/ORP

Conductivity/

Resistivity

Pressure, Level

Temperature,

Products

Other

Do not exceed the absolute

maximum voltage rating of

the OC output as listed in

the sensor specifications,

normally 27 or 30 Volt, DC

only. This includes changes

to power line fluctuations,

transients or power supply

instability, otherwise damage to the OC will occur.

Most indicating instruments or control system inputs require a signal

voltage of 0 to 5V (TTL or CMOS logic levels) or 0 to 24V. Therefore, Open

Collector output circuits must be complemented with a “Pull-Up-Resistor”

to function properly. Please see the following example diagram for wiring

with a PLC input:

+5V to

Gnd

+24V

Power

Supply

V+

Signet

Sensor/Instrument

Signal

OCSwitch

Gnd

Pull-UpResistor

Input

Gnd

PLC

Please note that the voltage connected to the positive sensor supply (V+)

must correspond to the required high-level PLC input voltage (i.e. if the

high-input voltage of the PLC is 24V, then the pull-up must be supplied with

24V). If the input is “TTL-Level” or “CMOS-Level”, that means 5V for high

level, then the pull-up should not be connected with a supply higher than 5V.

Signet instruments already have the pull-up-resistor and the sensor power

supply built into the instrument. No external pull-up-resistors are required.

Installation

Wiring &

Reference

Technical

Temperature/

Pressure

Graphs

of Terms

Glossary

Reference

Part No.

Index

www.gfsignet.com

223

Page 4

Open Collector Output (continued)

3. Instrument Output Wiring

Open collector control and alarm outputs on Signet instruments (i.e.

ProcessPro

instrument’s power supply. That means these can be used in the above

mentioned NPN configuration as well as in PNP configuration, if required.

Below are a few sample circuits:

• PLC Wiring “NPN” style

Signet

Instrument/Sensor

OCSwitch

• Alarm circuit or alarm lamp wiring to a single Signet instrument

®

or ProPoint™ series) are electrically isolated from the

+5V to

+24V

OC+

OC-

Pull-UpResistor

Input

Gnd

PLC

Gnd

Power

Supply

Signet

Instrument

OCSwitch

OC+

Alarm

Circuit

V+

Gnd

Power

Supply

• Alarm circuit or alarm lamp wiring to serve multiple Signet instruments

- Triggers the alarm if any one of the instruments open collector outputs are on.

Signet

Instrument

OCSwitch

OC+

Signet

Instrument

OCSwitch

OC+

Signet

Instrument

OCSwitch

OC+

Alarm

Circuit

V+

Gnd

Power

Supply

224

www.gfsignet.com

Page 5

Open Collector Output (continued)

4. Voltage and Current Limitation

As mentioned before, the supply voltage in the OC output circuit MUST

be limited to the specified maximum OC voltage (see operating manual

for specific instrument). The use of a quality regulated 5V, 12V or 24V

(depending on the application) power supply is recommended.

The current through the Open Collector switch must be limited. Typical OC

outputs allow only for 10 to 50mA switch current (please consult manual).

Exceeding this current limit can burn out the OC output components

immediately. Please see the following section on how to dimension the

loads.

5. Load and Pull-Up/Down Resistor Considerations

By utilizing basic arithmetic and Ohm’s law, one can determine the safe

limits of load resistance. When the OC switch is closed, almost the entire

supply voltage is applied to the load, (i.e. the pull-up or pull-down resistor,

the alarm horn input, a potential power relay coil or annunciator lamp). The

resulting current through the load and through the OC switch, as well, can

be calculated as:

(Current) = (Supply Voltage)/(Load Resistance)

Choosing

Products

Instrument

Multi-Pa-

rameter

Flow

pH/ORP

Conductivity/

Resistivity

Pressure, Level

Temperature,

• Example 1:

The supply voltage is 24V and a

pull-up-resistor of 10kΩ is used.

Current is 24/10,000 = 2.4mA

(If the OC current rating is 10mA, then in this

example, it would be considered safe.)

• Example 2:

The supply voltage is 12V and a horn

with a resistance of 100Ω is used

Current is 12/100 = 120mA

(Even if the OC current rating is 50mA, this load

will damage the instrument)

6. Transient Protection

There are several “difficult” load cases that must be considered:

• Inductive loads:

These can be power relay

or other solenoids, motors,

alarm horn coils, etc. Such

loads generate very high

voltage spikes everytime

the load switches. If such a

load is unavoidable, the use

of transient suppression

• Capacitive loads:

This type of load should be

rare but can occur if the load

contains an internal power

supply/regulator that is fed

from the output circuit. In such

a case, it must be assured that

the in-rush current does not

exceed the OC current rating.

components, or Signet RCFilters (3-8050.396), or

snubbers, wired parallel to

the load is required. This is

critical, as a single transient

pulse may destroy the output.

• Incandescent lamps:

Such lamps have a very high

start-up current until the

filament glows and the current

settles to the specified value.

The use of incandescent

lamps on an OC output is not

recommended. An LED type

annunciator should be used

instead.

Products

Other

Installation

Wiring &

Reference

Technical

Temperature/

Pressure

Graphs

of Terms

Glossary

Reference

Part No.

www.gfsignet.com

Index

225

Page 6

Open Collector Output (continued)

7. “Active High” and “Active Low” Setting

Depending on the desired function of the circuit attached to the OC output, it

may be necessary to have the OC output switch turned “on” or “off” when the

criteria for the activation of this output are met.

By default, Signet instruments are set to operate in “active low” mode.

This means when the user-defined condition for the activation is met (e.g.

exceeding of an alarm limit) the OC switch is turned “on”. If wired as standard

“NPN-style” output (see previous page) the logic level of the attached control

system or PLC input consequently becomes “low” logic level.

If a high input logic level is required for activation, it can be accomplished by

changing the OC output function to “active high” in the menu system of the

instrument. Most Signet instruments allow for this option.

8. Fail-Safe Behavior

No matter what the setting, most OC outputs of Signet instruments turn off

when the instrument loses power. This must be taken into account when

evaluating system failure consequences. If the system layout requires a

“closed” or “on” condition for the output in case of power loss, a mechanical

dry contact relay (NC contacts) must be used instead of the OC output.

226

www.gfsignet.com

Loading...

Loading...