Page 1

Signet 2760 DryLoc® pH/ORP Preamplier

*3-2760.090*

3-2760.090 Rev. 9 01/18

Description

The Signet 2760 pH/ORP Preampliers with DryLoc® connectors are part of

Signet's growing line of sensors for industrial uid measurement and control.

There are two styles of preampliers, and each is available with NPT or ISO

threads at the cable outlet. They all connect to four different families of pH and

ORP electrodes to supply an amplied mV (analog) signal to Signet instruments.

English

Product Manual

• English

• Deutsch

• Français

• Español

Table of Contents

Warranty Statement .............................................................................. 2

Product Registration ............................................................................. 2

Safety Information................................................................................. 2

Chemical Compatibility ......................................................................... 2

Specications........................................................................................ 2

Dimensions ........................................................................................... 3

In-Line Assembly and Installation ...................................................... 3-4

Wet-Tap Assembly and Installation ....................................................... 4

Submersible Sensor assembly and Installation .................................... 5

Wiring to Signet Instruments................................................................. 6

Wiring from DryLoc Preamplier to Others Equipment ......................... 7

Ordering Information ............................................................................. 8

Page 2

Hand tighten only!

Chemical CompatibilityWarranty Information

Refer to your local Georg Fischer Sales ofce for the most

current warranty statement.

All warranty and non-warranty repairs being returned must

include a fully completed Service Form and goods must be

returned to your local GF Sales ofce or distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

Signet products with limited shelf-life (e.g. pH, ORP, chlorine

electrodes, calibration solutions; e.g. pH buffers, turbidity

standards or other solutions) are warranted out of box but not

warranted against any damage, due to process or application

failures (e.g. high temperature,

mishandling (e.g. broken glass,

chemical poisoning, dry-out) or

damaged membrane, freezing

and/or extreme temperatures).

Product Registration

Thank you for purchasing the Signet line of Georg Fischer

measurement products.

If you would like to register your product(s), you can now

register online in one of the following ways:

• Visit our website www.gfsignet.com.

Under Service and Support click on

Product Registration Form

• If this is a pdf manual (digital copy), click here

Safety Information

1. Depressurize and vent system prior to installation or removal.

2. Conrm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specications.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. When using chemicals or solvents care should be taken and

appropriate eye, face, hand, body, and/or respiratory protection

should be used.

WARNING

The retaining nuts of certain pH and ORP sensors and

preampliers are not designed for prolonged contact

with aggressive substances. Strong acids, caustic

substances and solvents or their vapor may lead to failure of

the retaining nut, ejection of the sensor and loss of the process

uid with possibly serious consequences, such as damage to

equipment and serious personal injury. Retaining nuts that may

have been in contact with such substances, e.g. due to leakage

or spilling, must be replaced.

Specications

General

Compatible Electrodes

Signet DryLoc Electrodes ..... 2724-2726, 2756-WTP- 2757-WTP,

2764-2767, 2774-2777

Compatible Instruments

Preamplier models to

Signet 5700, 8750 ............. 2760-1, -2, -11, -21

Response Time (includes response time of electrodes):

pH ..................................... < 6 sec. for 95% of change

ORP .................................. application dependent

Temperature, τ .................. 20 sec.

Electrical (2760-1, -2,-11, -21 Preampliers)

Maximum Offset ................... ± 7 mV

Input Impedance, Z............... > 1011 Ω

Supply Voltage (V+ to V–) .... 6 to 12 VDC

Current consumption ............ < 1 mA

Environmental

Enclosure Rating .................. 2760-1, -2, NEMA 6P/IP68

2760-11, -21, NEMA 4

with electrode and watertight

conduit and/or extension pipe

connected

Materials

Submersible versions........ CPVC (Gray)

In-Line versions................. PBT (Yellow)

Caution / Warning / Danger

Indicates a potential hazard. Failure to follow all warnings

may lead to equipment damage, injury, or death

Electrostatic Discharge (ESD) / Electrocution Danger

Alerts user to risk of potential damage to product by ESD,

and/or risk of potential of injury or death via electrocution.

Personal Protective Equipment (PPE)

Always utilize the most appropriate PPE during

installation and service of Signet products.

Pressurized System Warning

Sensor may be under pressure, take caution to vent

system prior to installation or removal. Failure to do so

may result in equipment damage and/or serious injury.

Hand Tighten Only

Overtightening may permanently damage product threads

and lead to failure of the retaining nut.

Do Not Use Tools

Use of tool(s) may damage product beyond repair and

potentially void product warranty.

2

Signet 2760 DryLoc pH/ORP Preamplier

Cable .................................... 4.6 m (15 ft) 6-conductor

w/shield, 22 AWG

Maximum cable: ................... 122 m (400 ft)

Shipping Weight: .................. 0.64 kg (1.41 lb)

Operating Temperature ......... 0 °C to 85 °C (32 °F to 185 °F)

Storage Temperature ............ –20 °C to 85 °C (–4 °F to 185 °F)

Relative Humidity.................. 0 to 95%, non-condensing

(without electrode connected)

Standards and Approvals

Manufactured under ISO 9001 and ISO 14001

China RoHS (Go to www.gfsignet.com for details)

Page 3

35.0 mm

(1.38 in.)

89.4 mm

(3.52 in.)

101 mm

(4.0 in.)

35.0 mm

(2.40 in.)

Dimensions

Lock

Lock

Unlock

100 mm

(4 in.)

3-2760-1 Preamplier, Sub, NPT

3-2760-2 Preamplier, Sub, ISO

31.75 mm

(1.25 in.)

70.1 mm

(2.76 in.)

56.6 mm

(2.23 in.)

3-2760-11 Preamplier, In-line, NPT

3-2760-21 Preamplier, In-line, ISO

101 mm

(4.0 in.)

(1.38 in.)

61.0 mm

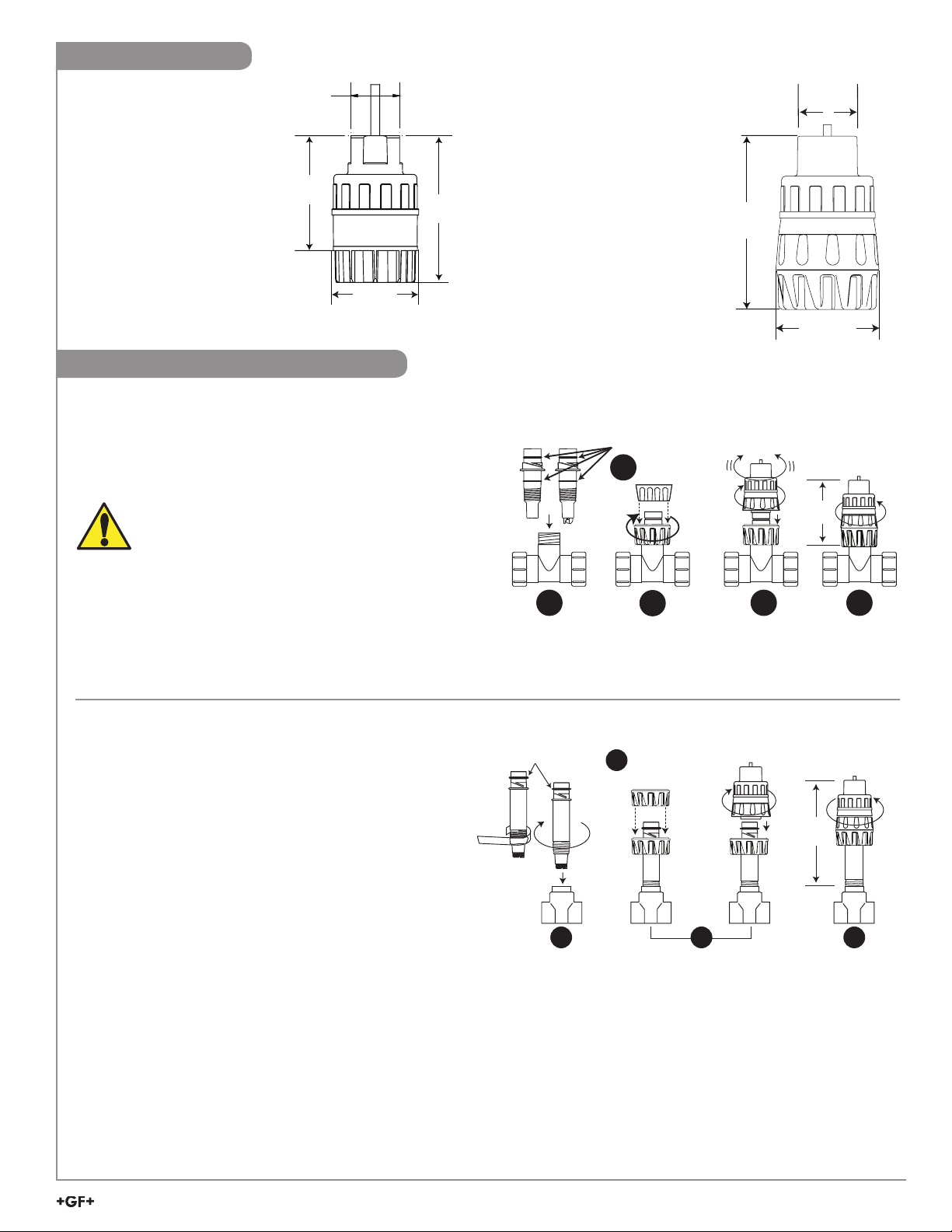

In-line Assembly and Installation

2760 In-Line models used with 2724-2726 series electrodes:

1. The 2724-2726 can use a Signet installation tting. Electrodes are sealed by the O-ring when it is installed into a Signet

installation tting.

2. The lower threaded nut is required to attach the electrode to the

installation tting when using a Signet tting.

HAND-TIGHTEN THE THREADED NUT ONTO THE

INSTALLATION FITTING. DO NOT USE TOOLS!

DO NOT USE THREAD SEALANT OR LUBRICANTS

ON THE FITTING THREADS OR THE SENSOR CAP.

Lubricate O-rings

3

Unlock

100 mm

(4 in.)

3. Lubricate O-rings with a non-petroleum based, viscous lubricant

(grease) compatible with the system.

1

2

4 5

4. Seat the 2760 DryLoc connector onto the top of the electrode.

Open the DryLoc connector by turning the upper locking ring ¼-turn clockwise.

5. Turn the locking ring ¼-turn counter-clockwise to lock the preamplier in place. The mechanism will “click” when it is locked.

When fully assembled the 2760 will stand about 100 mm (4 in.) above the installation tting.

2760 In-Line models used with 2764-2767 or 2774-2777 series electrodes:

BEFORE YOU START:

2764-2767: Install a 1 in. NPT pipe tee into the process line.

Lubricate O-rings

2

2774-2777: Install a ¾-in. reducing tee into the process line.

1. Wrap the process threads on the electrode with an

appropriate sealant (example: PTFE tape ) to create a

water-tight connection. HAND-TIGHTEN the electrode into

Unlock

178 mm

(7 in.)

the installation tting. DO NOT USE TOOLS!

NOTE: The lower threaded nut may be dropped onto the top

of the electrode or it may be discarded. It is not used with

these electrodes.

2. Lubricate O-rings with a non-petroleum based, viscous

lubricant (grease) compatible with the system.

1

3

3. Seat the 2760 DryLoc connector onto the top of the

electrode.

Open the DryLoc connector by turning the upper locking ring ¼-turn clockwise.

4. Turn the locking ring ¼-turn counter-clockwise to lock the preamplier in place. The mechanism will “click” when it is locked.

When the 2760 Preamplier is fully assembled with one of the threaded electrodes (276X and 277X models) it will stand

approximately 178mm (7 in.) from the process threads to the top of the preamplier.

Lock

4

Signet 2760 DryLoc pH/ORP Preamplier

3

Page 4

In-Line Assembly

with Submersible 2760 Preamplifier

2764-2767 Electrodes

2774-2777 Electrodes

and standard installation fitting

178 mm

(7 in.)

2760 Preamplifier

Electrode

Threaded nut

Lubricate O-ring

2

1

3

4

5 6

In-line Assembly and Installation

2760 Submersible models used as in-line system:

The Submersible 2760 design can also be used in-line when

using the 2724-2764, 2764-2767 series or the 2774-2777

series electrodes.

BEFORE YOU START:

2764-2767: Install a 1 in. NPT pipe tee in the process line.

2774-2777 and 2724-2726: Install a ¾-in. reducing tee in

the process line. DO NOT install in a ¾-inch tee or probe

will be damaged.

1. Wrap the process threads on the electrode with an

appropriate sealant (example: PTFE tape) to create a

water-tight connection.

2. Lubricate O-rings with a non-petroleum based, viscous lubricant (grease) compatible with the system.

3. Remove the threaded nut from the preamplier and place it around the electrode from the bottom as illustrated.

4. HAND-TIGHTEN the electrode into the installation tting. DO NOT USE TOOLS!

5. Seat the 2760 DryLoc connector onto the top of the electrode.

6. Lift the threaded nut up and thread it hand-tight onto the preamplier.

When the 2760 Preamplier is fully assembled with one of the threaded electrodes (276X and 277X models) it will stand

approximately 178 mm (7 in.) from the process threads to the top of the preamplier.

• The 2760 Preamplier signal can be routed to a Signet 5700 ProPoint pH Monitor, or to any model of the 3-8750 pH Transmitter.

• If the preamplier cable must be extended beyond the standard 4.6m (15 ft) that is supplied with the 2760, use a junction box to

terminate the wires.

Note: Do not extend the 2760 cable more than 120 m (400 ft).

Wet-Tap Assembly and Installation

The 2760 DryLoc Preamplier can be used to connect Signet 275X Wet-Tap electrodes to a pH or ORP instrument.

1. Select the process tting.

• Select a low prole installation saddle (customer-supplied) with a 1½ in. or 2 in. outlet (depending on 3719 model ordered).

• The 3719 is available with NPT or ISO thread options.

• The 3719 can also be adapted to t into tee ttings. Refer to the 3719 pH Wet-Tap instructions for detailed information.

2. Install the Wet-Tap and the electrode.

• Install the 3719 into the tting, then insert the electrode into the assembly.

3. Attach the preamplier to the electrode.

• Attach the 3-2760-11 or -21 Preamplier to the DryLoc tting at the top of the electrode.

4. Connect the 2760 Preamplier to the instrument.

• The 2760 Preamplier signal can be routed to any 5700 or 8750 pH/ORP instrument (see Pg. 5).

1. 2. 3. 4.

Lubricate O-rings

4

RELAY 1

2

4

Signet 2760 DryLoc pH/ORP Preamplier

Lubricate O-rings

Page 5

Fill with

75-100 mm

(3 to 4 in.)

of sealant

55 mm

(2.16 in.)

55 mm

(2.16 in.)

Fill with

75-100 mm

(3 to 4 in.)

of sealant

Submersible Sensor Assembly and Installation

The submersible 2760 can be installed in a tank or vessel if conditions are within pressure and temperature specications.

The 2760 is able to withstand uid temperatures up to 85 °C (185° F), but the electrode tolerances vary. Check the specications of

each component before installation.

1. Insert any DryLoc electrode into base of the 2760. Lubricate O-rings with a non-petroleum based, viscous lubricant (grease)

compatible with the system.

2. Thread retaining cap over electrode and hand-tighten onto 2760.

• Keep the DryLoc electrical interconnection between electrode and preamplier dry and clean at all times.

3. Attach 3/4 in. watertight pipe to the top of the 2760. Secure the threaded connection to prevent any leakage.

• Fill the lower 75-100 mm (3 to 4 in.) of conduit or extension pipe with a exible sealant such as silicone to prevent liquid

accumulation on the back seal of the 2760.

3

1

2

Lubricate O-ring

Use standard installation hardware to

connect the submersible 2760 directly

to external equipment.

Fill with

75-100 mm

(3 to 4 in.)

of sealant

The 8052-1 NPT Mount Junction

box connects to

3

/4 in. pipe or

conduit and provides convenient

wiring termination.

Fill with

75-100 mm

(3 to 4 in.)

of sealant

The 8050-1 Universal Mount

OROR

junction box mounts at onto a

wall or can be strapped to a post

or pipe.

½ in. NPT threads

Fill with

75-100 mm

(3 to 4 in.)

of sealant

Signet 2760 DryLoc pH/ORP Preamplier

5

Page 6

Standard output,

¾ in. process connector.

3-2774

3-2775

3-2776

3-2777

Differential output,

1 in. process connector.

3-2764-1

3-2765-1

3-2766-1

3-2767-1

Standard output,

Signet installation fittings

3-2724-10, -11

3-2725-60, -61

3-2726-10, -11

3-2726-HF-10, -11

3-2726-LC-10, -11

3-2756-WTP-1

3-2757-WTP

3-2760-1

3-2760-2

3-2760-1

3-2760-2

3-2760-11

3-2760-21

3-5700 pH/ORP Monitor

V +

Red Wire

V -

Black wire

-

+

T -

White wire

T +

Green wire

Iso. Gnd

Blue wire

Blue Iso. Gnd

mV Input

Brown wire

Brown mV

4-20

mA

Red V+

Black V-

White T-

Green T+

Connect this terminal to Earth GND to reduce electrical interference.

White (Temp)

Green (Temp)

Blue (Iso. Gnd)

Brown (mV input)

Shield

Black (V-)

Red (V+)

12

11

10

9

8

7

6

5

18

17

16

15

14

13

12

11

16

15

14

13

12

11

10

9

3-8750-13-8750-23-8750-3

ProcessPro pH/ORP Transmitter

3-2760-11

3-2760-21

Wiring to Signet Instruments

Any of these electrodes can be connected to the Signet ProPoint and ProcessPro pH instruments using the 3-2760-1(X) or -2(X)

Preampliers.

Wiring diagrams illustrate the actual terminals on these products for convenience.

Signet 8750-X

ProcessPro pH/ORP Transmitter

4

RELAY 1

2

Signet 5700

ProPoint pH/ORP Monitor

6

Signet 2760 DryLoc pH/ORP Preamplier

Page 7

Wiring from 2760 DryLoc Preamplier to Other Manufacturer's Equipment

DryLoc Preamplifier, Submersible

3-2760-1

3-2760-2

DryLoc Preamplifier, In-Line

3-2760-11

3-2760-21

White (Temperature)

Green (Temperature)

Blue (mV Reference)

Shield (Earth Ground)

Black (V-)

Red (V+)

Brown (Active mV, pH/ORP)

White (Temperature)

Green (Temperature)

Blue (mV Reference)

Shield (Earth Ground)

Black (V-)

Red (V+)

Brown (Active mV, pH/ORP)

Standard output,

¾ in. process connector.

3-2774

3-2775

3-2776

3-2777

Differential output,

1 in. process connector.

3-2764-1

3-2765-1

3-2766-1

3-2767-1

The 2760-1/-2 Preamplier and electrode options may be used with third party equipment if the equipment can process the AMPLIFIED mV

signal for pH and is compatible with one of the temperature compensation options. (3 KΩ or PT1000).

Refer to the manufacturer's manual for wiring details. Other products may use different terms to identify the function of each conductor.

Signet Combination pH Electrodes

3-2724-10 (3 KΩ, NPT)

3-2724-11 (3 KΩ, ISO)

3-2726-10 (3 KΩ, NPT)

3-2726-11 (3 KΩ, ISO)

3-2726-HF-10 (HF Resist, 3 KΩ, NPT)

3-2726-HF-11 (HF Resist, 3 KΩ, ISO)

3-2726-LC-10 (Low Cond, 3 KΩ, NPT)

3-2726-LC-11 (Low Cond, 3 KΩ, ISO)

3-2774 (3 KΩ TC)

3-2776 (3 KΩ TC)

Combination ORP (Redox) Electrodes

3-2725-60 (10 KΩ ID, NPT)

3-2725-61 (10 KΩ ID, ISO)

3-2757-WTP (10 KΩ ID)

3-2775 (10 KΩ ID)

3-2777 (10 KΩ ID)

Differential pH Electrodes

3-2764-1 (3 KΩ RTD)

3-2766-1 (3 KΩ RTD)

Differential ORP (Redox)

Electrodes

3-2765-1 (10 KΩ ID)

3-2767-1 (10 KΩ ID)

Signet 2760 DryLoc pH/ORP Preamplier

7

Page 8

Ordering Information

Mfr. Part No. Code Description

3-2760-1 159 000 939 Submersible Preamplier with ¾ in. NPT threads and 4.6 m (15 ft) cable

3-2760-2 159 000 940 Submersible Preamplier with ¾ in. ISO 7/1R threads and 4.6 m (15 ft) cable

3-2760-11 159 001 367 In-line Preamplier with ¾ in. NPT threads and 4.6 m (15 ft) cable

3-2760-21 159 001 368 In-line Preamplier with ¾ in. ISO 7/1R threads and 4.6 m (15 ft) cable

Accessories and Replacement Parts

Calibration Tools

3-2759 159 000 762 pH/ORP System Tester (adapter cable sold separately)

3-2759.391 159 000 764 2759 Adapter Cable for use w/2760 DryLoc Preamplier

3-0700.390 198 864 403 pH Buffer Kit (1 each 4, 7, 10 pH buffer in powder form, makes 50 mL)

5523-0624 159 000 636 Cable, 6 conductor, 24 AWG shielded

3822-7004 159 001 581 pH 4.01 buffer solution, 1 pint (473 ml) bottle

3822-7007 159 001 582 pH 7.00 buffer solution, 1 pint (473 ml) bottle

3822-7010 159 001 583 pH 10.00 buffer solution, 1 pint (473 ml) bottle

3822-7115 159 001 606 20 gram bottle Quinhydrone for ORP calibration

3-2700.395 159 001 605 Calibration kit: included 3 Polypropylene cups, box as cup stand, 1 pint pH 4.01, 1 pint pH 7.00

Special Request NIST Traceable Certicate

Electrodes

DryLoc pH Electrodes

3-2724-10 159 001 547 Flat glass pH Electrode, 3 KΩ RTD, ¾ in. NPT or Signet ttings

3-2724-11 159 001 548 Flat glass pH Electrode, 3 KΩ RTD, ISO 7/1 R¾ or Signet ttings

3-2726-10 159 001 555 Bulb glass pH Electrode, 3 KΩ RTD, ¾ in. NPT or Signet ttings

3-2726-11 159 001 556 Bulb glass pH Electrode, 3 KΩ RTD, ISO 7/1 R¾ or Signet ttings

3-2726-HF-10 159 001 551 Bulb glass pH Electrode, 3 KΩ RTD, HF resistant, ¾ in. NPT or Signet ttings

3-2726-HF-11 159 001 552 Bulb glass pH Electrode, 3 KΩ RTD, HF resistant, ISO 7/1 R¾ or Signet ttings

3-2726-LC-10 159 001 559 Bulb glass pH Electrode, 3 KΩ RTD, Low conductivity, ¾ in. NPT or Signet ttings

3-2726-LC-11 159 001 560 Bulb glass pH Electrode, 3 KΩ RTD, Low conduct., ISO 7/1 R¾ or Signet ttings

3-2764-1 159 000 943 Differential pH Electrode, 3 KΩ RTD, 1 in. NPT process connection

3-2766-1 159 000 949 Differential pH Electrode, 3 KΩ RTD, 1 in. NPT process connection

3-2774 159 000 955 Flat glass pH Electrode, 3 KΩ RTD, ¾ in. NPT process connection

3-2776 159 000 959 Flat glass pH Electrode, 3 KΩ RTD, ¾ in. NPT process connection

DryLoc ORP (Redox) Electrodes

3-2725-60 159 001 561 Flat ORP Electrode, 10KΩ ID, ¾ in. NPT or Signet installation ttings

3-2725-61 159 001 562 Flat ORP Electrode, 10KΩ ID, ¾ in. ISO 7/1 R¾ or Signet installation ttings

3-2765-1 159 000 946 Differential ORP (Redox) Electrode, 10 KΩ ID, 1 in. NPT process connection

3-2767-1 159 000 952 Differential ORP (Redox) Electrode, 10 KΩ ID, 1 in. NPT process connection

3-2775 159 000 957 Flat ORP (Redox) Electrode, 10 KΩ ID, ¾ in. NPT process connection

3-2777 159 000 961 Bulb ORP (Redox) Electrode, 10 KΩ ID, ¾ in. NPT process connection

3-2757-WTP 159 001 391

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to date information, please refer to our website at www.gfsignet.com

3-2760.090 Rev. 9 01/18 English © Georg Fischer Signet LLC 2018

Flat, Wet-Tap ORP electrode, 10 KΩ ID

8

Signet 2760 DryLoc pH/ORP Preamplier

Loading...

Loading...