Page 1

Signet 2744-2747 Di erential DryLoc®

pH/ORP Electrodes

High Performance

Protected

Bulb

The Signet 2744-2747 Differential pH and ORP

electrodes are high performance sensors built with the

DryLoc® connector, a Ryton® body, and PTFE reference

junction to handle the most extreme and harshest of

chemical applications.

These differential electrodes use a field-proven

3-electrode differential technique: the pH and reference

electrodes are measured against a ground electrode,

ensuring a steady and stable signal.

Flat

Glass

Features

• Di erential design for stable measurements in

the most aggressive applications

• Long service life even in severe or di cult

chemical applications

• Memory chip enabled for access to a wide range

of unique features when connected to the Signet

2751 pH/ORP Smart Sensor Electronics

• High performance glass that can withstand

high pH caustic media as well as elevated

temperature applications

• Ryton (PPS) body for broad range of chemical

compatibility

• Watertight DryLoc® connector with foul-proof

gold plated contacts*

• Porous PTFE reference junction resists fouling

and chemical attack

• Rebuildable reference electrode

• Solution ground

• Temperature sensor (pH)

A key feature is the reference electrode, which is housed

in a glass half-cell embedded in the reference chamber

and is protected from compounds that may contain

sulfides (S2-) and metals. To ensure long service life,

the reference features a refillable electrolyte chamber

and a replaceable equitransferant salt bridge, both

easily serviced in the field. The patented porous PTFE

reference junction resists fouling, clogging and chemical

attack.

Other elements of the design are the solution ground,

the pH/ORP electrodes, and the temperature element.

The solution ground eliminates noisy measurements

by draining electrical current away from the reference

electrode. The pH/ORP electrodes are designed with a

flat or bulb surface, and a temperature device positioned

at the tip of the measurement surface for a quick

temperature response. Various temperature devices

offered include 3 KΩ or Pt1000 RTD.

The electrodes are used with the Signet 2751 Smart

Sensor Electronics, which provide a blind 4 to 20 mA

output or use the digital (S3L) output to connect the

Signet 8900, 9900 or 9950 instruments, and the

0486 Profibus Concentrator. The electrodes can also be

used with the 2760 Preamplifier to connect to ProPoint®

and ProcessPro® series of pH/ORP instrumentation.

• Easy sensor replacement using DryLoc

electrode connector

• Quick temperature response

• Compatible with all Signet instruments

Applications

• Plating Baths

• Surface Finishing

• Plant E uent

• Water and Wastewater Treatment

• Scrubbers

• Textile Dye Process

• Harsh Chemical Applications

• Heavy Metal Removal and Recovery

• Toxic Destruction

• Coagulation and Flocculation

See Technical Reference section for assistance in choosing

the correct sensor.

*U.S. Patent No.: 6,666,701

Page 2

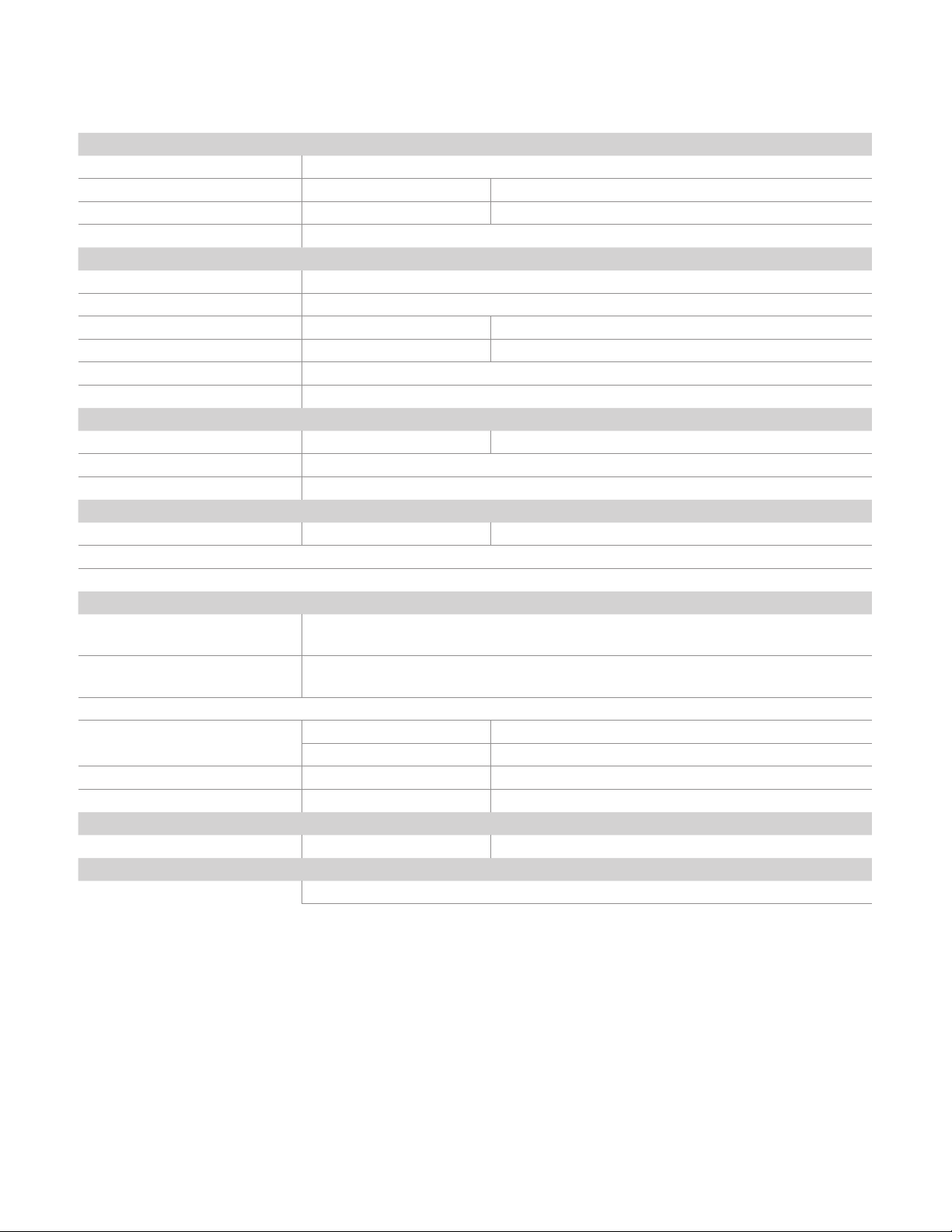

Specifi cations

General

Compatibility Signet 2751 and 2760

Operating Range 2744/2746 0 to 14 pH

2745/2747 ±1500 mV (ORP)

Process Connection 1 in., for use in reducing tees up to 4 in.

Wetted Materials

Body Ryton®

Reference Junctions PTFE

Sensing Surface pH Glass membrane

ORP Platinum

O-rings EPDM

Solution Ground Carbon graphite

Max. Temperature/Pressure Rating

Operating Temperature Range 10 °C to 100 °C 50 °F to 212 °F

Operating Pressure Range 0 to 6.9 bar (0 to 100 psi) @ 10 °C to 65 °C (50 °F to 149 °F)

Linearity Derated 6.9 to 4.0 bar (100 to 58 psi) @ 65 °C to 100 °C (149 °F to 212 °F)

Recommended Storage Temperature

0 °C to 50 °C 32 °F to 122 °F

The electrode glass will shatter if shipped or stored at temperatures below 0 °C (32 °F).

The performance life of the electrode will shorten if stored at temperatures above 50 °C (122 °F).

Mounting

In-line/Vertical Mounting Use sensor 1 in. threads. Sensor must be mounted at least 15 degrees above

the horizontal axis.

Submersible Mounting Use threads on Model 2751 or 2760; requires ¾ in. NPT or ISO 7/1-R 3/4 male

threaded extension.

Reference

Electrolyte Bu ered equi-transferant salt solution gel

Element pH half-cell

Temperature Sensor pH 3 KΩ, Pt1000 RTD

ORP 10K ID Resistor

Shipping Weight

0.25 kg 0.55 lb

Standards & Approvals

Manufactured under ISO 9001, 14001 and OHSAS 18001 for Quality

www.gfsignet.com

Page 3

Dimensions

38.6 mm

(1.52 in.)

35.6mm

(1.4 in.)

32.5 mm

(1.28 in.)

133.8 mm

(5.27 in.)

1 in.

NPT

25.4 mm

(1.0 in.)

Flat and Bulb versions

have the same dimensions

28.7 mm

(1.13 in.)

0.63 mm

(0.25 in.)

insertion

depth,

typical

System Overview

Panel Mount Pipe, Tank, Wall 4 to 20 mA Output Automation System

Signet Instruments

with 2751 Smart Sensor

Electronics

- 8900

- 9900

- 9950

ENTER

Signet 2744-2747

DryLoc® pH/ORP

Electrodes

In-Line Installation threaded fi ttings only

Signet Instruments

with 2751 Smart Sensor Electronics

- 9900 and Rear Enclosure

+

2751 Smart Sensor Electronics with

- Customer Supplied Chart Recorder

Programmable Logic Controller, or

- Programmable Automation Controller

+

Submersible Installation Customer supplied pipe extension

or conduit with 3/4 in. NPT or ISO 7/1-R 3/4

threads*

PLC

2751 Smart Sensor Electronics with

- 0486 Profi bus Concentrator and

Customer Supplied Programmable Logic

Controller or

- Programmable Automation Controller

L IN+

L IN-

N/C

L OUT+

L OUT-

N/C

L IN+

L IN-

+5V OUT

DATA

GND

L IN+

L IN-

+5V OUT

DATA

GND

Out

In

S3LLoop

S3LLoop

USB

Profibus

Channel 5

Channel 6Channel 7

Valve

Signet 3-0486 Profibus Concentrator

+

Address

Power

Channel 1

24 VDC

0.40A Max

S3LFreq

+5V OUT

Freq IN

PWR+

PWR+

PWR+

PWR-

PWR-

PWR-

+

Channel 2

Channel 3

Channel 4

S3LFreq

S3LFreq

S3LFreq

+5V OUT

+5V OUT

+5V OUT

Freq IN

Freq IN

Freq IN

DATA

DATA

DATA

DATA

GND

GND

GND

GND

All sold separately

PLC

*Refer to the Signet Submersion Kit brochure (3-0000.707) located on our website for installation suggestions and options.

www.gfsignet.com

Page 4

Electrode Key Features and Benefi ts

1. Glass encased reference electrode protects the Ag/AgCl (silver/silver

chloride) element from reacting with certain chemical compounds that

typically leach into the reference chambers. Keeps the pH/ORP reading

stable.

2. Large volume reference electrolyte chamber resists dilution over time for

a long service life. Chamber is refi llable. Holds approximately 30 ml of

electrolyte.

3. Salt Bridge serves as a double reference junction and is the fi rst line of

defense to keep out process chemicals from the reference electrolyte

chamber. It is built with a double porous PTFE reference junction which is

highly compatible to chemicals, resists fouling and build-up of dirt.

4. Memory chip enabled for convenient data storage and access (calibration

data, operational data, and manufacturing data), electrode health

monitoring via glass impedance measurement when used in connection

with the 2751 pH/ORP Smart Sensor Electronics.

5. Ryton® body for chemical compatibility to most harsh chemicals. Also able

to withstand high temperatures.

6. DryLoc connector with corrosion resistant gold plated pins for quick and

easy sensor removal.

7. Capillary TC (temperature sensor) embedded in tip of pH/ORP electrode for

quick temperature response.

8. Measuring pH/ORP electrode.

6

4

1

5

2

3

7

8

9. Solution Ground electrode eliminates noisy measurements by draining

electrical current away from the reference electrode.

9

Electrode Cut-Away View

A di erential electrode solves many common problems typically experienced by standard pH/ORP electrodes at troublesome

measuring points. See the table below to fi nd the common problem, cause and e ect, and the di erential pH/ORP electrode

solution.

If the (Signet Models 272X,

273X or 277X) pH/ORP

electrode experiences

The cause and e ect of the

problem may be:

Use a Di erential Electrode to solve

the problem because:

the following:

-

• Salt bridge will slow or stop attack. If attacking

or

4

ions penetrate the salt bridge and a ect the

reference, simply refi ll reference solution.

• Readings do not drift due to stable di erential

reference design, however may require

cleaning or replacement of the salt bridge if

• Reading slowly drifts

over time

• Sensor responds slowly

• Chemical attack from Hg

2+

, Cu+, Pb2+, ClO

other compounds which react with or dilute

the KCl reference electrolyte.

• Reference junction gets clogged from oils,

grease, or dirt from the process.

electrode gets too dirty.

• Reading slowly drifts

over time

• Sensor reading becomes

erratic

• Chemical attack of the Ag

-

, CN-, and S

I

-

compounds.

2

+

reference from Br-,

• Clogged reference and slowed reading from

silver compounds forming on the inside of

the reference electrode from Ag

element reacting and precipitating Ag

AgBr, AgI, AgCN, or other silver compounds.

+

of reference

S,

2

• Will not a ect electrode due to Ag

protected in glass encased reference electrode.

• Will not a ect electrode due to Ag

protected in glass encased reference electrode.

+

element

+

element

• Reading suddenly jumps

to a new value

• Reading unexpectedly

changes

www.gfsignet.com

• Stray electrical currents in the process liquid;

+

reference element picks up current and

Ag

shifts reference reading, resulting in shifted

pH reading. The Ag

+

element will eventually

become totally stripped. Process must be

properly grounded or place metal rod close to

electrode.

• Will not a ect electrode due to Ag

+

element

protected in glass encased reference electrode;

also, electrode has a built in solution ground, so

if there is a stray current, it will not be seen by

the electrode.

Page 5

Temperature/Pressure Graph

Note:

The pressure/temperature graphs are specifically

for the Signet sensor. During system design the

specifications of all components must be considered.

In the case of a metal piping system, a plastic sensor

will reduce the system specification.

Ion Ion name Ion Ion name Compound Compound name

Br-Bromide Hg2+Mercury KCI Potassium chloride

Cu+Copper iron CIO

-

Cyanide Ag+Silver AgBr Silver bromide

CN

I-Iodide S2-Sulfi de AgI Silver iodide

++

Pb

Lead AgCN Silver cyanide

-

Perchlorate Ag2S Silver sulfi de

4

Model 2744-2747

Ordering Notes

1) pH and ORP electrodes require connection to model

2751 or 2760.

2) Conduit and mounting brackets for submersible

installations must always be used (customer

supplied).

3) Adapters from 1 - 1½ in. are available.

4) Use sensor threads for in-line mounting; Model

2751 or 2760 threads for submersible mounting.

5) Reference electrode can be rebuilt with

replacement electrolyte and salt bridge.

(psi)

(bar)

10.3

150

8.6

125

6.9

100

5.2

75

3.4

50

1.7

25

0

-40

°F°C-40

-20

-4

0

32 68

20

40

60 80 100

104

140

176

212

Application Tips

• Use the fl at glass electrodes when a self-cleaning

feature is desired; especially useful in applications

with abrasive chemicals for in-line installations.

• Use bulb protected electrodes for low temperature

applications where a fast response is required.

• ORP electrodes are generally used for chemical

reaction monitoring, not control.

• Ensure sensor materials are chemically compatible

with the process liquid.

• Keep electrode tip wet, avoid air pockets and

sediment.

120

248

Bu er Solutions

3822-7004

3822-7007

3822-7010

Quinhydrone

3822-7115

The Signet pH bu ers are ideal for calibration. The

liquid solutions are conveniently packaged in one pint

(473 ml) bottles. pH bu er kits in powder pillows are

available for mixing fresh solutions with water at the

time of use.

All pH bu ers are color coded for easy identifi cation;

4.01 pH is red, 7.00 pH is yellow, and 10.00 pH is blue.

All pH bu ers are traceable to NIST standards.

The 4.01 and 7.00 pH bu er solutions can be used

to calibrate ORP sensors when saturated with

quinhydrone.

Please refer to Wiring, Installation, and Accessories sections for more information.

www.gfsignet.com

Page 6

Ordering Information

Mfr. Part No. Code Tip Design Temperature Element

pH Di erential Electrode

3-2744-1 159 001 944 Flat 3 K Balco

3-2744-2 159 001 910 Flat Pt1000

3-2746-1 159 001 911 Bulb with protection 3 K Balco

3-2746-2 159 001 912 Bulb with protection Pt1000 RTD

ORP Di erential Electrode

3-2745-1 159 001 913 Flat 10 K ID

3-2747-1 159 001 914 Bulb with protection 10 K ID

1

For use with the Multi-Parameter instruments, and Profi bus Concentrator when used with the 2751 Smart Sensor Electronics.

The 2751 Smart Sensor Electronics has a digital (S3L) output which is used with the Multi-Parameter instruments. It also has a

4 to 20 mA output for connections to PLC’s, data recorders, etc.

2

The 2760 preamplifi er is used for connection directly to ProPoint® and ProcessPro® series pH/ORP instrumentation.

1, 2

1

1, 2

1

1, 2

1, 2

Accessories and Replacement Parts

Mfr. Part No. Code Description

1224-0205 159 000 836 O-ring, EPDM

3-2700.395 159 001 605 Calibration kit: includes 3 polypropylene cups, box used as cup stand, 1 pint pH

4.01, 1 pint pH 7.00

3822-7115 159 001 606 20 gm bottle quinhydrone for ORP calibration (must use pH 4.01 and/or

pH 7.00 bu er solutions)

3800-4340 159 001 948 Replacement salt bridge in black

3864-0001 159 001 007 Replacement salt bridge in gray

3864-0002 159 001 008 Replacement reference electrolyte solution, 500 ml

2120-0015 159 001 009 CPVC adapter: 1.5 in. MNPT to 1 in. FNPT

2122-0015 159 001 010 PVDF adapter: 1.5 in. MNPT to 1 in. FNPT

3-0700.390 198 864 403 pH bu er kit (1 each 4, 7, 10 pH bu er in powder form, makes 50 ml of each)

3822-7004 159 001 581 pH 4 bu er solution, 1 pint (473 ml) bottle

3822-7007 159 001 582 pH 7 bu er solution, 1 pint (473 ml) bottle

3822-7010 159 001 583 pH 10 bu er solution, 1 pint (473 ml) bottle

3-2759 159 000 762 pH/ORP system tester kit for all pH instruments

3-2759.391 159 000 764 Adapter cable for use with 2751/2760

3800-5000 159 838 107 3.0M KCl storage solution for pH and ORP, 1 pint (473 ml) bottle

3-2700.398 159 001 886 O-ring lubricant kit (5 packs of Super Lube, 1cc each)

3-2744.099 Rev A (12/19)

© Georg Fischer Signet LLC

3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057 • www.gfsignet.com • e-mail: signet.ps@georgfi scher.com

Specifi cations subject to change without notice. All rights reserved. All corporate names and trademarks stated herein are the property of their respective companies.

Loading...

Loading...