Page 1

Signet 2724-2726 and 2734-2736 Series DryLoc pH and ORP Electrodes

*3-2724.090*

3-2724.090 Rev. 20 10/19

Operating Instructions

Description

English

2724 & 2725

2734 & 2735

Flat Style

Electrode

2726 & 2736

Protected

Bulb Style

Electrode

Signet General Purpose 2724-2726 and High Performance 2734-2736 series of pH and

ORP electrodes are designed to minimize maintenance time and maximize performance

longevity and value.

• The unique DryLoc® connector provides quick assembly and a secure connection

featuring gold-plated contacts and an O-ring seal.

• The patented design features a lengthened reference chamber pathway to extend

the operational life of the electrode.

• Wetted materials are selected to withstand a wide range of industrial applications.

• Multiple mounting features address the need for installation fl exibility.

These electrodes can be threaded into ¾ in. NPT or ISO 7/1 R¾ inch pipe fi ttings,

submerged in a tank, or mounted into familiar Signet installation fi ttings ranging

from 0.5" to 4" size.

• Combine the 2724-2726 or 2734-2736 electrodes with the Signet 2751 Smart

Sensor Electronics or the 2760 Preamplifi er to provide a 4 to 20 mA loop to a

Programmable Logic Controller (PLC), SCADA system, or datalogger.

• Memory chip enabled to store Manufacturing, Calibration and Operational Data.

- Manufacturing Information (Serial Number, Model Number, and Factory

Glass Impedance).

- Calibration Information (Factory Calibration pH/ORP, Factory Calibration

Temperature, User Calibration pH/ ORP, User Calibration Temperature,

Offset pH/ORP and Slope Effi ciency % pH/ORP).

- Operational Data (Sensor Runtime Hours, Minimum & Maximum Measured

pH/ ORP, and Minimum and Maximum Measured Temperature).

• English

• Deutsch

• Français

• Español

• Italiano

• Português

• 中文

• 뭨펯

California Prop. 65

WARNING:

Cancer and Reproductive Harm

www.p65warnings.ca.gov

• For more fl exibility and unique features, pair the 2724-2726 or 2734-2736 series

a 2751 Smart Sensor Electronics and the 9900 Transmitter, 9950 Dual Channel

Transmitter or the 0486 Profi bus Concentrator. Additional features include electrode

health monitoring and diagnostics through glass impedance measurement, broken

glass detection and reference impedance measurement. Convenient remote

calibration eliminates the hassle of fi eld calibration.

• Connect up to six 2724-2726 or 2734-2736 electrodes to one 8900 Multi-Parameter

Controller with six 2751 pH/ORP Sensor Electronics using digital (S3L) serial data

output.

• Connect up to two 2724-2726 or 2734-2736 electrodes to one 9950 Dual Channel

Transmitter with two 2751 pH/ORP Sensor Electronics using digital (S3L) output for a

truly amazing set of features, options and measurements.

• The 2724-2726 electrodes are recommended for general purpose applications.

• The High Performance 2734-2736 electrodes are recommended for harsh

applications.

• The 2734-2736 electrodes utilize advanced reference technology and special

formulation glass to extend electrode life in all applications.

with

Page 2

Warranty Information

Chemical Compatibility

Refer to your local Georg Fischer Sales offi ce for the most current

warranty statement.

All warranty and non-warranty repairs being returned must include

a fully completed Service Form and goods must be returned to your

local GF Sales offi ce or distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

Signet products with limited shelf-life (e.g. pH, ORP, chlorine

electrodes, calibration solutions; e.g. pH buffers, turbidity standards

or other solutions) are warranted out of box but not warranted

against any damage, due to process or application failures (e.g. high

temperature,

glass,

chemical poisoning, dry-out) or mishandling (e.g. broken

damaged membrane, freezing and/or extreme temperatures).

Product Registration

Thank you for purchasing the Signet line of Georg Fischer

measurement products.

If you would like to register your product(s), you can now register

online in one of the following ways:

• Visit our website www.gfsignet.com and

click on Product Registration Form.

• If this is a pdf manual (digital copy), click here.

Safety Information

1. Use appropriate eye, face, hand, body and/or respiratory protection

when using chemicals or solvents.

2. Prior to installation or removal:

• Depressurize and vent system

• Drain below sensor level.

3. Confi rm chemical compatibility before use.

4. Do not exceed the max. temperature/pressure specifi cations.

5. Do not alter product construction.

If installing into a threaded connection:

6. Inspect threads to ensure integrity. Do not install a sensor that has

damaged threads.

7. Apply PTFE tape to the 3/4" M-NPT or ISO 7/1-R 3/4 process

connection threads in accordance with industry practices.

8. HAND TIGHTEN the sensor into the process connection.

DO NOT USE TOOLS.

Caution / Warning / Danger

Indicates a potential hazard.

Failure to follow all warnings may lead to equipment

damage, injury, or death

Personal Protective Equipment (PPE)

Always utilize the most appropriate PPE during

installation and service of Signet products.

Pressurized System Warning

Sensor may be under pressure, take caution to vent

system prior to installation or removal.

Failure to do so may result in equipment damage and/or

serious injury.

Hand Tighten Only

Overtightening may permanently damage product

threads and lead to failure of the retaining nut.

Do Not Use Tools

Use of tool(s) may damage product beyond repair and

potentially void product warranty.

Note / Technical Notes

Highlights additional information or detailed procedure.

Do Not Freeze

Products are temperature sensitive and may contain

DO NOT

FREEZE

freezable liquids.

Freezing damage to pH, ORP, and Chlorine electrodes

voids product warranty.

The retaining nuts of pH and ORP sensors are not designed

for prolonged contact with aggressive substances.

Strong acids, caustic substances and solvents or their

vapor may lead to failure of the retaining nut, ejection of the

sensor and loss of the process fl uid with possibly serious

consequences, such as damage to equipment and serious

personal injury. Retaining nuts that may have been in

contact with such substances, e.g. due to leakage or spilling,

must be replaced.

• The use of this product assumes

operators are trained and familiar

with this type of device.

• Operators should be knowledgeable

of the potential risks associated with

pressurized piping systems.

• Operators MUST follow all

necessary safety procedures.

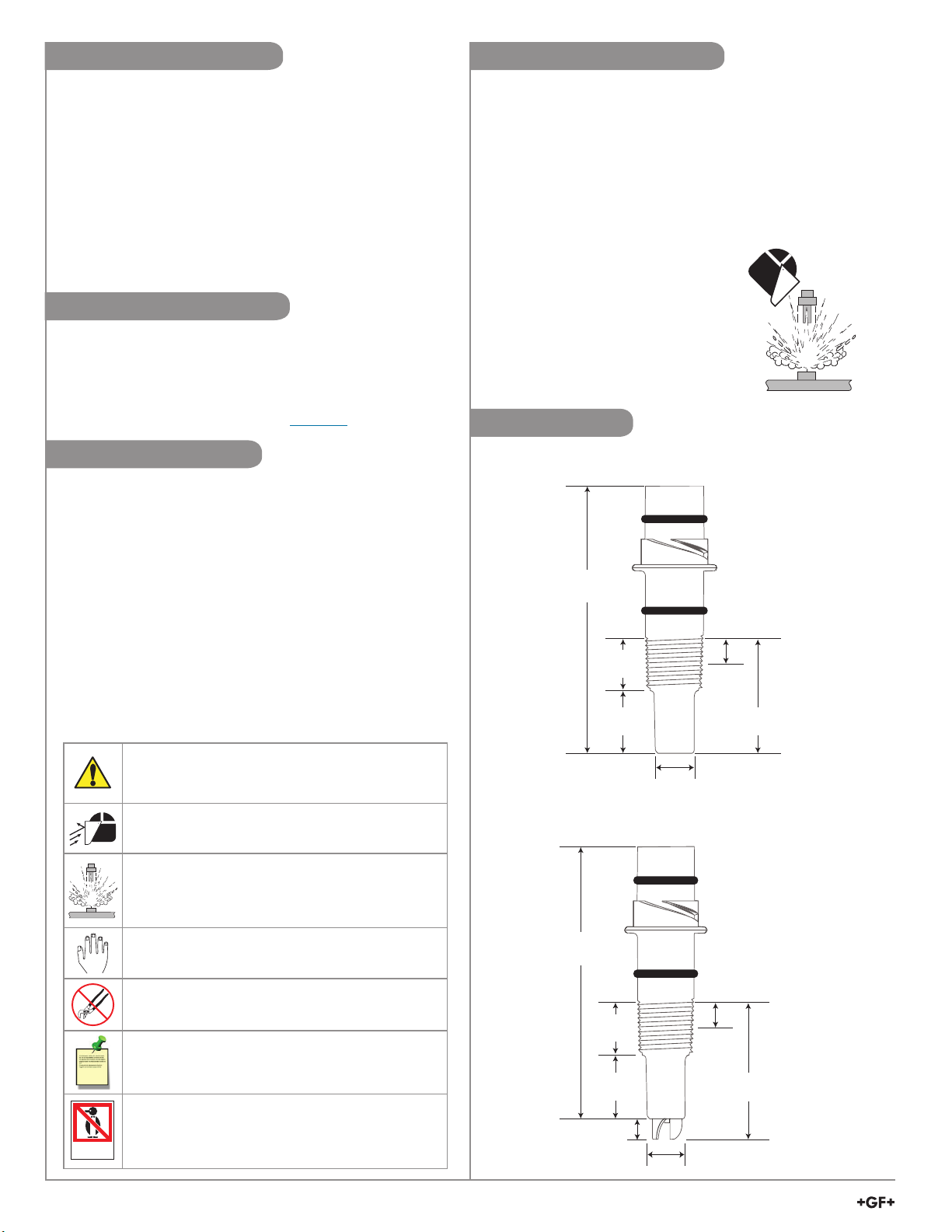

Dimensions

2724, 2725, 2734, & 2735 Flat Glass Electrode

Threads:

¾ in. NPT or

95.76 mm

(3.77 in.)

19.05 mm

(0.75 in.)

25.4 mm

(1.0 in.)

2726 & 2736 Protected Bulb Glass Electrode

95.76 mm

(3.77 in.)

19.05 mm

(0.75 in.)

25.4 mm

(1.0 in.)

8.89 mm

(0.35 in.)

ISO 7/1 R¾

6.35 mm

(0.25 in.)

44.45 mm

(1.75 in.)

18.3 mm

(0.72 in.)

Threads:

¾ in. NPT or

ISO 7/1 R¾

6.35 mm

(0.25 in.)

53.34 mm

(2.1 in.)

18.3 mm

(0.72 in.)

2

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

Page 3

Specifi cations

General

Compatibility ................... 2751 pH/ORP Smart Sensor Electronics,

2760 pH/ORP Preamplifi er

(2724-2726 3K Balco only)

pH Temp. Sensor:

Pt1000 ............................ Compatible with 2751 pH/ORP Smart

Sensor Electronics

Connection to ............. PLC, 9900 Transmitter,

8900 Multi-Parameter Controller

9950 Dual Channel Transmitter

3 K Balco ..................... Compatible with 2760 Preamplifi er

Connection to ............. 8750 pH/ORP Transmitter

Process Connection ....... ¾ in. NPT, ISO 7/1 R¾ threads,

or Signet Installation Fittings 0.5" to 4" sizes

Wetted Materials

pH (2724 & 2726) ........... Ryton (PPS), glass, UHMW PE, FKM

ORP (2725) .................... Ryton (PPS), glass, UHMW PE, FKM,

Platinum

pH (2734 & 2736) ........... Ryton (PPS), glass, PTFE, FKM

ORP (2735) .................... Ryton (PPS), glass, PTFE, FKM, Platinum

Shipping Weight ........... 0.25 kg (0.55 lb)

Performance

Effi ciency

2724-2726 ...................... > 97% @ 25 °C (77 °F)

2734-2736 ...................... > 95% @ 25 °C (77 °F)

• Effi ciency indicates the "wellness" of a new electrode.

• Effi ciency is measured by comparing the actual slope (mV/pH) at

25 °C to the theoretical output of 59.16 mV/pH.

• An effi ciency of 95% to 100% is equivalent to a slope of

56.20 to 59.16 mV/pH.

Measuring Range

pH ................................... 0 to 14

ORP ................................ ±2000 mV

3-2726-LC ......................

Low Conductivity fl uids (20 to 100 S/cm)

20 S/cm ................. Flow must be less than 150 ml/min. in a

properly grounded system

3-2724-HF, 3-2726-HF, 3-2734-HF, 3-2736-HF:

Hydrofl uric acid resistant glass, pH 6 or below; trace HF 2%

For applications where hydrofl uoric acid, in concentrations of 2%

or less, will attack standard pH glass in situations where process

upsets may temporarily drop to these pH levels.

Environmental Requirements

Operating Temperature

2724-2726* .............................. -10 °C to 85 °C (14 °F to 185 °F)

2734-2736* .............................. 10 °C to 100 °C (50 °F to 212 °F)

*Best performance for 3-2724-HF, 3-2726-HF, 3-2734-HF,

3-2736-HF is above 10 °C (50 °F)

Note: The Sensor Electronics must be remotely mounted when

the temperature exceeds 85 °C (185 °F)

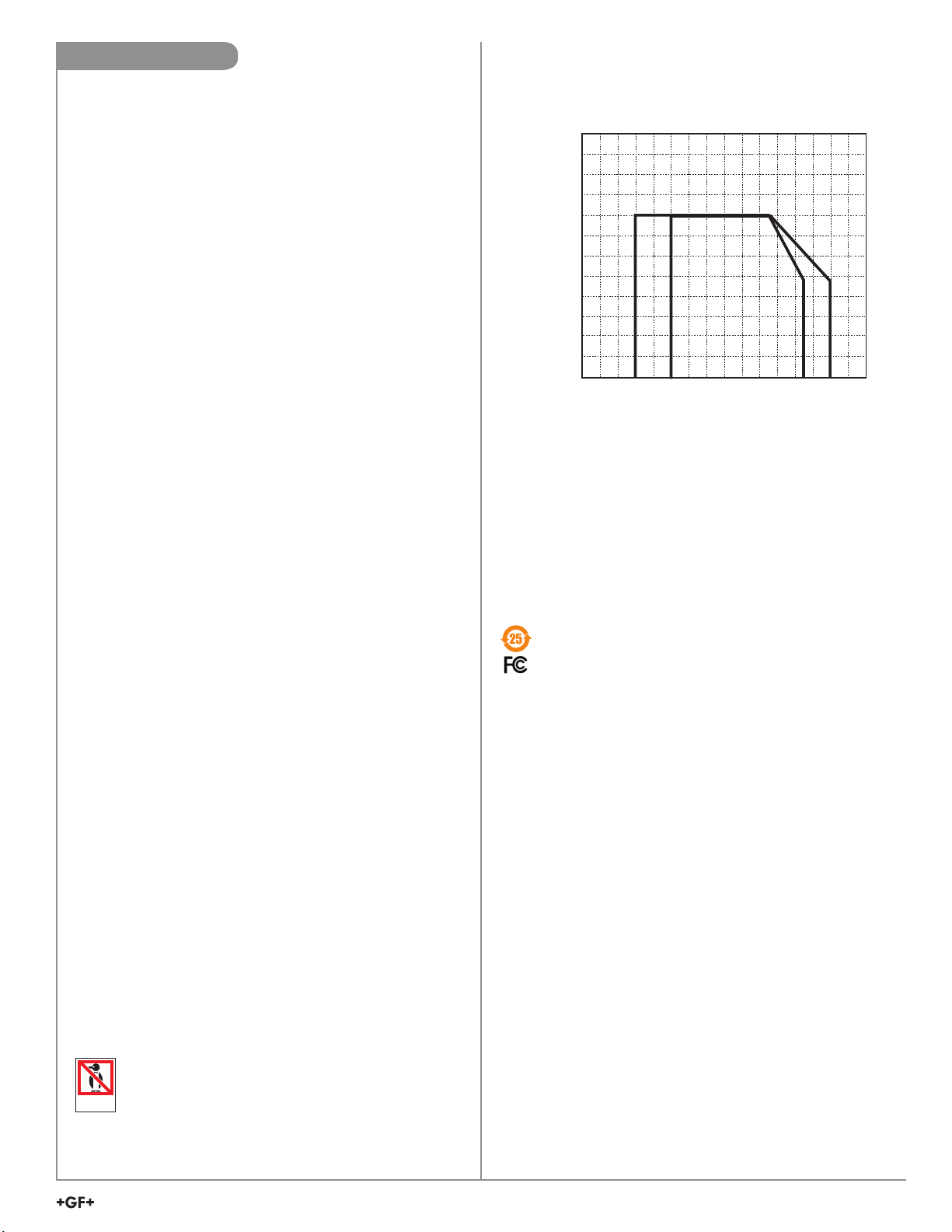

Maximum Temperature and Pressure Rating

10.3

150

8.6

125

6.9

100

273X

272X

5.2

75

3.4

50

1.7

25

(bar)(psi)

0

°C

-40

°F

-40 -4 32

Standards and Approvals

• CE, WEEE, RoHS Compliant

• Manufactured under ISO 9001 for Quality,

ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety.

China RoHS (Go to www.gfsignet.com for details)

Declaration of Conformity according to FCC Part 15

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

REACH Information Obligation: in accordance with

Article 33 of the European REACh Regulation (EC)

No. 1907/2006, the substances Lead and Acrylamide

are present in the glass matrix and as a polymerized gel

respectively; in a concentration >0.1% (w/w). During normal

use, the articles do not pose any risks and no additional

information is required for safe use.

-20

272X

0

273X

20

68

40

60

104

140 176 212

80

100

120

248

Operating Pressure Range

2724-2726:

• 0 to 6.9 bar (0 to 100 psi) @ -10 °C to 65 °C (14 °F to 149 °F)

• Linearity Derated 6.9 to 4.0 bar (100 to 58 psi) @

65 °C to 85 °C (149 °F to 185 °F)

2734-2736:

• 0 to 6.9 bar (0 to 100 psi) @ 10 °C to 65 °C (50 °F to 149 °F)

• Linearity Derated 6.9 to 4.0 bar (100 to 58 psi) @

65 °C to 100 °C (149 °F to 212 °F)

Recommended storage temperature

pH/ORP electrodes ................. 0 °C to 50 °C (32 °F to 122 °F)

• The electrode glass will shatter if shipped or stored at

temperatures below 0 °C (32 °F).

• The performance life of the electrode will be shortened

DO NOT

FREEZE

if stored at temperatures above 50 °C (122 °F).

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

3

Page 4

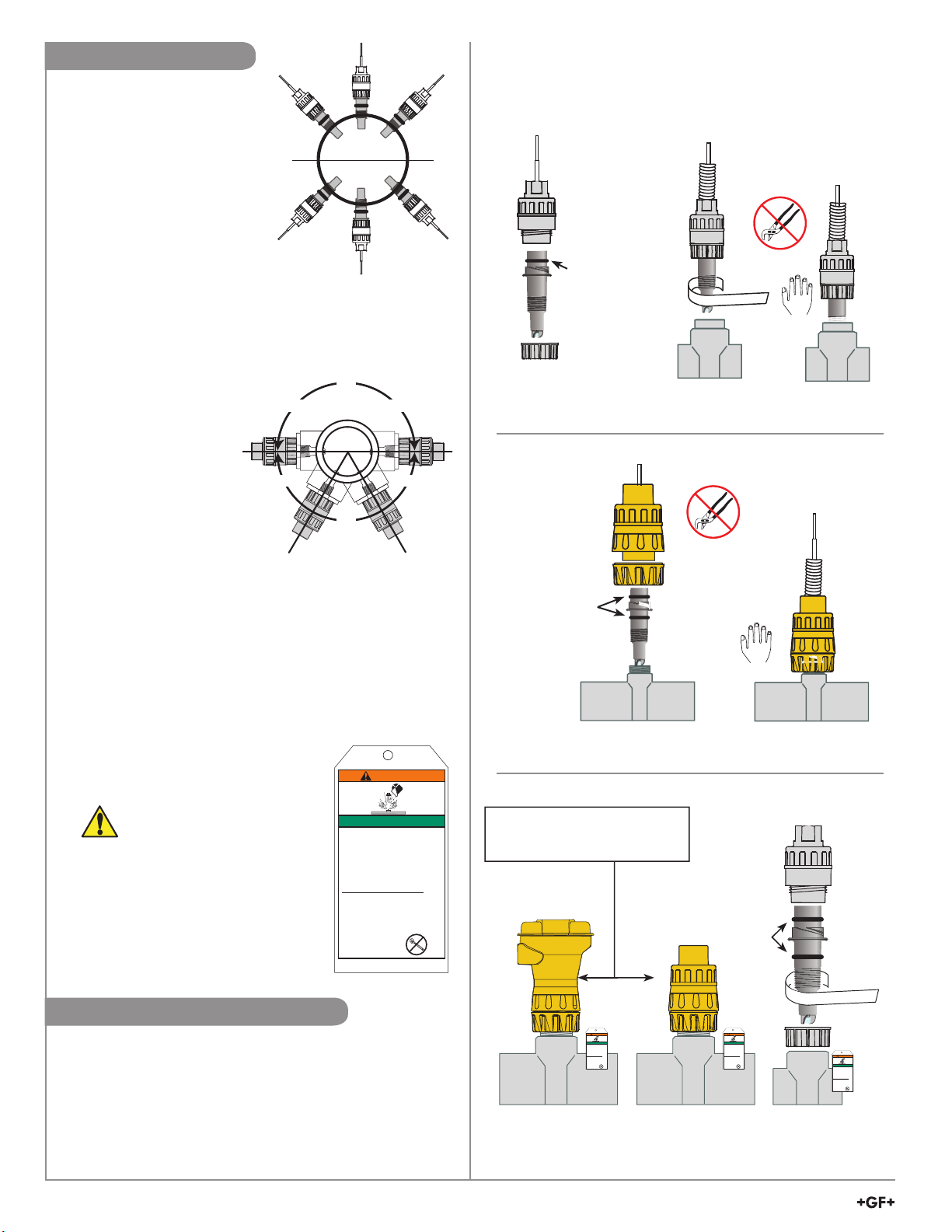

In-Line Installation

1. The electrode can be

mounted at any angle.

Yes

Yes

2. Avoid air pockets and sediment.

3. The fi tting must place the

electrode in the fl ow but

0°

Horizontal

must not bottom out in the pipe.

4. Select a Signet installation

fi tting (0.5" to 4" size range) for

convenience. Lightly lubricate

Yes

Yes

Yes

O-ring with a non-petroleum

based lubricate (grease)

compatible with the system.

NOTE:

When mounting in a standard threaded fi tting,

the electrode must be mounted horizontal to 60 degrees

below horizontal position only:

5. Use the ¾ in. M-NPT or

ISO 7/1-R ¾ threads on

NO NO

NO

the electrode body to

install the electrode into

reducing tee fi ttings.

6. Inspect threads to ensure

YESYES

integrity. Do not install an

electrode with damaged

threads.

NO

270°

7. Apply PTFE tape to

the M-NPT or ISO 7/1-R ¾ process connection threads, in

accordance with industry standards.

8. Use piping installation hardware with smooth,

well-fi nished threads to facilitate the installation.

9. If necessary, the pipe should be plumbed with a depression

(trap) so liquid is maintained around the electrode tip.

10. Hand-tighten the electrode into the process connection.

Do not use any tools to install the electrode.

The use of wrenches, pliers or similar may over-stress the

sensor body and lead to breakage and

subsequent spillage of the process liquid.

3-2700.615 (B-04/08)

WARNING

CAUTION:

A broken sensor may be

ejected forcefully from the fi tting

and can cause severe injury.

11. The safety instructions have an

adhesive label and should be

placed near the sensor.

SAFETY INSTRUCTIONS

1. Use appropriate eye, face, hand, body

and/or respiratory protection when using

chemicals or solvents

2. Prior to installation or removal:

a. Depressurize and vent system

b. Drain below sensor level

3. Confirm chemical compatibility before use

4. Do not exceed the maximum

temperature/pressure specifications

5. Do not alter product construction

If installing into a threaded connection:

6. Inspect threads to ensure integrity. Do not

install a sensor that has damaged threads

7. Apply PTFE tape to the process connection

threads in accordance with industry

practices

8. Hand tighten the sensor into the process

connection. DO NOT USE TOOLS

Failure to follow

these instructions may

result in personal injury

See peel & stick warning label on back!

Attach near sensor

Yes

3-2751-X

3-2760-X

Submersible

Preamplifi er

Lightly lubricate

O-ring with a

non-petroleum

based lubricate

(grease)

compatible with

the system.

Flexible conduit

PTFE tape

Fitting (customer supplied)Electrode

3-2751-X,

3-2760-X1

In-Line

Preamplifi er

Lightly lubricate

O-ring with a

non-petroleum

based lubricate

(grease)

compatible with

the system.

Electrode

Flexible

conduit

Signet Installation Fitting DN15 to DN100 (½ in. to 4 in.)

Do not use as a handle!

• Do not use tools or lubricant

to install yellow retaining cap.

• Do not overtighten.

Lightly lubricate O-ring

with a non-petroleum

based lubricate

(grease) compatible

with the system.

Low Conductivity Installation

• The 3-2726-LC pH electrodes can be used in

low conductivity water of less than 100 S.

• When used in the range of 20 to 100 S,

the fl ow range must not exceed 1 m/s (3 ft/s) velocity.

• When used in liquids of less than 20 S,

the fl ow range must not exceed 150 ml/min;

the sensor should also be mounted in a well grounded cell.

4

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

3-2700.615 (B-04/08)

WARNING

SAFETY INSTRUCTIONS

1. Use appropriate eye, face, hand, body

and/or respiratory protection when using

chemicals or solvents

2. Prior to installation or removal:

a. Depressurize and vent system

b. Drain below sensor level

3. Confirm chemical compatibility before use

4. Do not exceed the maximum

temperature/pressure specifications

5. Do not alter product construction

If installing into a threaded connection:

6. Inspect threads to ensure integrity. Do not

install a sensor that has damaged threads

7. Apply PTFE tape to the process connection

threads in accordance with industry

practices

8. Hand tighten the sensor into the process

connection. DO NOT USE TOOLS

Failure to follow

these instructions may

result in personal injury

SAFETY INSTRUCTIONS

1. Use appropriate eye, face, hand, body

and/or respiratory protection when using

chemicals or solvents

2. Prior to installation or removal:

a. Depressurize and vent system

b. Drain below sensor level

3. Confirm chemical compatibility before use

4. Do not exceed the maximum

temperature/pressure specifications

5. Do not alter product construction

If installing into a threaded connection:

6. Inspect threads to ensure integrity. Do not

install a sensor that has damaged threads

7. Apply PTFE tape to the process connection

threads in accordance with industry

practices

8. Hand tighten the sensor into the process

connection. DO NOT USE TOOLS

these instructions may

result in personal injury

GF Signet Installation Fittings 0.5" to 4"

3-2700.615 (B-04/08)

WARNING

Failure to follow

Customer supplied Tee,

or Reducing Tee

PTFE tape

3-2700.615 (B-04/08)

WARNING

SAFETY INSTRUCTIONS

1. Use appropriate eye, face, hand, body

and/or respiratory protection when using

chemicals or solvents

2. Prior to installation or removal:

a. Depressurize and vent system

b. Drain below sensor level

3. Confirm chemical compatibility before use

4. Do not exceed the maximum

temperature/pressure specifications

5. Do not alter product construction

If installing into a threaded connection:

6. Inspect threads to ensure integrity. Do not

install a sensor that has damaged threads

7. Apply PTFE tape to the process connection

threads in accordance with industry

practices

8. Hand tighten the sensor into the process

connection. DO NOT USE TOOLS

Failure to follow

these instructions may

result in personal injury

Page 5

Signet Installation Fittings

Type Description Type Description

Plastic tees

PVC saddles

• Available in ½ in. to 4 in. sizes

• PVC, CPVC w/solvent cement socket

• PVDF or PP w/union end fittings

• Available in 2 in. to 4 in. sizes

• Requires 1-7/16 in. hole in pipe

Carbon steel

weldolets

Carbon steel

threaded tees

• Available in 2 in. to 4 in. sizes

• Requires 1-7/16 in. hole in pipe

• Install by certified welder only

• Available in ½ in. to 2 in. sizes

• Female NPT ends

Iron

strap-on

saddles

• Available in 2 in. to 4 in. sizes

• Requires 1-7/16 in. hole in pipe

Universal

pipe adapters

Removing from In-Line Installation

In-line removal Instructions:

• The use of this product assumes

that operators are trained and are

familiar with this type of device.

• They should be knowledgeable of

1. Depressurize and vent the piping system.

2. Drain the system to below sensor level.

3. Wear safety goggles or face shield during removal.

the potential risks associated with

pressurized piping systems.

• Operators MUST follow all

4. Practice proper Lock Out/ Tag Out procedures when the sensor

necessary safety procedures.

Submersible Installations

The user must supply the following hardware

to complete a submersible installation:

• ¾ in. Pipe, ¾ in. (DN 20) Male Adapter, Liquid Tight

Connection at top of pipe assembly

• Wiring junction box

• Pipe clamps (quick-release type recommended)

• Tank fl ange for closed tanks

• Silicone Caulking Sealant & PTFE Tape

2724-2726 / 2734-2736 with 2751/2760 pH/ORP Sensor Electronics

• Use for installation in pipes >4 in. (1¼ in. NPT)

• PVC, CPVC, or PVDF versions

• Specify socket or 1¼ inch NPT male threads

• Contact factory for support

Use all appropriate eye, face, hand, body and/or respiratory

protection when working with chemicals or solvents.

is removed for maintenance to prevent accidental opening and

exposure to potentially hazardous chemicals.

Technical Note:

• Mount the electrode near tank outlets, away from reagent

addition areas.

• Use the ¾ in. (

ISO 7/1-R ¾

) threads at the top of the

preamplifi er to run the cable inside pipe or conduit.

• Place the electrode tip in pH 4 Buffer for temporary storage

during system maintenance to avoid dehydration. For

long term storage place the electrode tip in 3.0 mol/L KCl

solution.

1

2

3

3

4

Fill with

Lubricate

O-ring

The Signet pH/ORP electrodes are designed to install in tanks by attaching conduit to the ¾ in. (

3 to 4 in.

caulking

of

sealant

Open

tanks

ISO 7/1-R ¾ )

Closed

tanks

threads at

the top of the accompanying preamplifi er or sensor electronics:

1. The O-ring at the top of the electrode fi ts very tightly into the preamplifi er. Use a small amount of non-petroleum based

lubricant to assist the assembly.

2. To prevent moisture from migrating into the preamplifi er, backfi ll the conduit with 3 in. to 4 in. of sealant.

3. Mount electrodes in a location with ample clearance to remove them for periodic cleaning and recalibration.

4. Choose a location that keeps the electrode glass completely submersed at all times.

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

5

Page 6

K2

K2

Electrode Date Code

• The electrode date code indicates the

manufacturing date of the electrode.

• Electrodes should be put into service as

soon as possible and should not remain in

the box for more than two years.

• Over time, the storage solution (found in

the "boot" covering the electrode tip) will

evaporate or leak, allowing the delicate

sensing tip and reference junction to dry.

• To rehydrate a dry electrode, soak the tip in

3.0 mol/L KCl solution for 24 to 48 hours.

Preheating the KCl solution to <140 °F may

speed up the re-hydration process.

• Electrodes more than 2 years old may still be

functional, but will take longer to rehydrate.

• Restoration may not be effective for severely

dehydrated electrodes.

Letter = Month

N = January

M = February

L = March

K = April

J = May

H = June

G = July

F = August

E = September

D = October

C = November

B = December

K2

K2

Example: K2 = manufactured in April 2017

Numeral = Year

5 = 2010

6 = 2011

7 = 2012

8 = 2013

9 = 2014

0 = 2015

1 = 2016

2 = 2017

3 = 2018

4 = 2019

5 = 2020

6 = 2021

Electrode Care

Depending on the type of application and the accuracy needed, pH and ORP electrodes will require routine maintenance.

Contaminated/dirty electrodes should be swapped with properly cleaned conditioned and calibrated electrodes.

The solution used to clean an electrode varies depending on the type of coating:

Caution: Always wear appropriate safety gear and exercise proper safety practices when working with or near chemicals

• General Cleaning – Soak the electrode for 5 minutes in a mixture of warm tap water (< 140° F), and mild detergent such as

liquid dish detergent. A soft brush, like a toothbrush may also be used to clean off particulates.

• Biofi lm and bacterial growth – Soak the electrode in a diluted household laundry bleach solution (pH electrodes only), 1part

bleach to 10 parts water for 10 minutes.

• Alkaline or Scale – Lime/calcium and mineral buildup deposits may be removed by soaking the electrode in a solution of 2% to

5% hydrochloric acid (HCl) or vinegar for no more than 5 minutes.

• Acidic contaminants – May be removed by soaking the electrode in a weak caustic (less than 2% to 5% NaOH) for a few

minutes only. Use the least harsh chemical which will remove the contaminant within 2-5 minutes of soaking without attacking

the materials of construction.

• Oily or organic coatings – Soak the probe for 5 to 10 minutes in a solution of warm tap water < 140° F, and dish detergent.

Alternatively, use an appropriate solvent (isopropyl alcohol or similar) that will not attack the materials of construction. If

required gently clean junction and/or glass with a very soft tooth brush, and follow up with brief soaking (2-5 minutes) in 2% to

5% NaOH (sodium hydroxide). In the case of pH (not ORP) a diffi cult organic fouling can be treated with household bleach (4-

6%) as a substitute for the dish detergent.

• ORP Platinum Coating – Gently wipe the electrode surface with a soft lint-free paper towel. If the various forms of chemical

cleaning are not suffi cient to achieve an accurate measurement and response time, a last resort would be to polish the platinum

surface with a 0.3-1.0 micron alumina polishing slurry to remove any stubborn coatings.

• After cleaning, rinse pH/ORP electrode in distilled or tap water, then re-examine the electrode for damage that may have been

hidden from view. Sensor may not initially behave properly; and have a temporary offset due to the cleaning chemistry. Proper

conditioning is always recommended.

Electrode Conditioning

Soak sensor tip (pH or ORP) in 3 mol/L KCl (potassium chloride), for at least 45 minutes to regenerate/condition.

The more aggressive the cleaning, the longer the soak in potassium chloride.

Failure to soak the electrode will cause the electrode to drift for a time after the cleaning procedure, and could adversely affect the

calibration process/results.

If the cleaning and conditioning yield results within operational tolerance, the pH/ORP sensor is once again suitable for use.

However, if the results do not bring the readings of the pH/ORP sensor within tolerance, it is time to replace the sensor.

6

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

Page 7

pH System Calibration

There are two functions in a pH electrode that require the system to be calibrated:

Temperature Calibration

• The temperature output of the electrode (measured by a 3K Balco or Pt1000 RTD) must be calibrated only once. When a new electrode

is installed, it does not need to be repeated.

• Because the temperature measurement has a signifi cant infl uence on the electrochemical measurement, the temperature output in new

pH electrodes should always be calibrated before the pH/mV calibration.

NOTE: All Signet transmitters and controllers incorporate automatic temperature compensation.

pH error due to temperature changes in fl uid

°C pH 2 pH 3 pH 4 pH 5 pH 6 pH 7 pH 8 pH 9 pH 10 pH 11 pH 12

0.15 0.12 0.09 **0.06 0.03 0 0.03 0.06 0.09 0.12 0.15

15

25

35

45

Table 1

As the pH value moves away from neutral (7 pH) or the temperature moves away from 25 ºC, the electrochemical output is affected.

* Example: At pH 5 the mV output of the electrode is not affected if the temperature is at 25 °C.

** The electrode output will be shifted by 0.06 pH units if the temperature is reduced to 15 °C.

55

Offset and Slope Calibration

The pH electrode calibration is an important function that must be done routinely to standardize the electrode due to its ever-changing

characteristics. The electrode contains a gel that depleates over time, so the instrument must be readjusted periodically to maintain

system accuracy. There are many infl uences, including aging, temperature, coatings and chemicals used that will affect the probe

characteristics. After cleaning and conditioning, Signet pH electrodes may be calibrated in two pH buffer solutions of different pH

values (a two point calibration).

000* 0 0000000

0.15 0.12 0.09 0.06 0.03 0 0.03 0.06 0.09 0.12 0.15

0.3 0.24 0.18 0.12 0.06 0 0.06 0.12 0.18 0.24 0.3

0.45 0.36 0.27 0.18 0.09 0 0.09 0.18 0.27 0.36 0.45

The pH electrode is calibrated by placing it in a buffer solution of known pH and measuring the cell potential.

This is a linear function of pH in the range of pH 2-11, therefore two calibration points are needed. Most

common calibration buffers are pH 4.01 and pH 7.00 (@ 25 °C). If the pH measurements are made in an acid

to neutral range, we recommend using buffer pH 4.01 and buffer pH 7.00 for calibration. If an alkaline sample

is measured, we recommend using buffer 7.00 and buffer 10.01 for calibration.

The response of the glass electrode is characterized by two parameters, offset and slope. The theoretical

output of a pH electrode at pH 7 is 0 mV. The offset, or zero pH is the deviation of the pH from the nominal

value. In the Signet transmitters, the offset calibration is performed under STANDARD.

The glass electrode slope is the mV developed per each pH unit (mV/pH). At 25 °C, the theoretical slope is

59.16 mV/pH. So, at pH 4.01, +177 mV will be generated, while at pH 10.01 (with a lower H+ concentration),

a potential of -177 mV will be generated, (see Table 2). A new electrode however, will generate 0 ±± 15 mV

in pH 7.00 and will have a slope effi ciency between 93.2 and 103%. In the Signet transmitters, manual slope

calibration is performed under SLOPE.

Theoretical mV

Values @ 25 °C

pH mV

2 +295.8

3 +236.64

4 +177.48

5 +118.32

6 +59.16

70

8 –59.16

9 –118.32

10 –177.48

11 –236.64

12 –295.8

Table 2

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

7

Page 8

pH System Calibration cont.

How to calculate a pH electrode slope effi ciency

Two pH buffers are selected to check the pH probe performance, pH 4.01 and pH 7.00. The ratio of the measured potentials (E2-E1) to

the difference of pH (7.00 – 4.01) gives the slope of the straight line.

1. Read the mV potential generated by the electrode in two calibration buffers

2. Determine the slope (the mV potential generated per pH unit)

3. Divide this number by the theoretical slope, 59.16 mV/pH @ 25 °C and multiply by 100.

Example 1

pH electrode generates -12 mV in pH 7.00 buffer

and +162 mV in pH 4.01 buffer.

160 mV - (-12 mV) = 172 mV

172 mV/ 3 = 57.33 mV/pH unit

57.33/59.16 x 100 = 96.9 % slope effi ciency

Example 2

pH electrode generates -45 mV in pH 7.00 buffer

and +115 mV in pH 4.01 buffer.

115 mV - (-45 mV) = 160 mV

160 mV/3 = 53.33 mV/pH unit

53.33/59.16 x 100 = 90.1%

In Example 2, slope effi ciency of 90.1% is acceptable but the offset of -45 mV is not.

An offset shift can be the result of the reference electrode being contaminated or poisoned.

A slope shift can be the result of the glass being etched or coated with a hard build-up.

As the electrode ages, the slope decreases gradually, generally a slope between 85% and 105% is acceptable. If the offset value

(pH 7.00) is > +/- 45 mV, electrode should be replaced. When a great accuracy is required from the electrode, the offset and the slope

values need to be as close as possible to the theoretical values.

Refer to the Calibration Procedure section of the instrument manual for a 2 point pH calibration. If the sensor is used in a 4 to 20 mA

‘blind application’ refer to the Calibration section of the 2751 Smart Sensor Electronics for a 2-point EasyCal pH calibration.

ORP System Calibration

ORP electrodes do not incorporate a temperature sensor, so the only system calibration required is the electrochemical adjustment.

ORP electrodes should need less frequent calibration than a typical pH sensor, the redox potential is a characteristic of the interaction

between the platinum measuring electrode and the redox species in solution.

ORP measurement is only an indicator of the process solution reducing or oxidizing potential. Always perform a single point calibration

(standardization). Using the 9900 or 9950 transmitter, this can be performed under STANDARD. Disregard the SLOPE calibration.

If calibrating the ORP electrode under EasyCal (9900 Transmitters, Gen IV or later), one point calibration will be your only option.

A new ORP electrode measures the listed value +/- 20 mV. A two-point calibration will not increase the accuracy of the measurement

given the +/- 20 mV repeatability of the sensor itself. On top of that, the ORP is not temperature compensated, so if the measurement

is not done at 25 °C, any benefi t gained will be lost. A true two-point calibration is possible in very few applications where only one

redox couple is present in solution and its chemistry is known.

Calibration should be done using ORP premade standard solutions such as Zobell's solution and Light's solution, or solutions made

using the standard pH 4.01 buffer and pH 7.00 buffer with quinhydrone powder mixed in until saturation is reached (Table 3). If all the

quinhydrone does dissolve, continue to add small amounts and stir until a small amount of quinhydrone remains un-dissolved after

mixing. Quinhydrone is the oxidizer that is measured by the ORP electrode. Please note that Zobell's solution is not compatible with

the AutoCal function in Signet ORP instrumentation.

Pre-packaged or mixed Quinhydrone solutions are strong and may have a long lasting effect on the electrode, therefore after

calibration it's recommended to properly condition the electrode before returning to the process. It is also possible to calibrate the ORP

electronics based upon a known grab sample confi rmed with a lab meter.

Pick a solution with a mV value closest to the process value and if possible adjust the temperature of the solution to the process

temperature to minimize the offset.

The ORP electrode is functional until the offset exceeds 50 mV.

When the offset measures greater than 50 mV, the electrode should

replaced.

Table 3:

ORP test solutions

*Saturate 50 mL of pH 4 or

pH 7 buffer with 1/8 g quinhydrone

Zobell's

solution

ORP at 20 °C 268 mV 92 mV

ORP at 25 °C 228 mV 469 mV 263 mV 86 mV

ORP at 30 °C 258 mV 79 mV

Light's

solution

4 pH buffer

w/quinhydrone*

7 pH buffer

w/quinhydrone*

8

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

Page 9

Buffer Solutions

Proper handling, storage and use of buffers is very important on the pH and ORP measurement accuracy. If the buffers are

contaminated or used improperly, the calibration will be inaccurate and all subsequent measurements will be wrong.

• When calibrating pH electrodes, always use pH buffers in the range of your sample.

• To achieve an accurate calibration make sure the electrode and the buffer are at the same temperature.

• Buffers have limited shelf life. Do not use a buffer if the expiration date has passed.

• Never return used buffers to the buffer bottle. Discard it.

• Do not leave the buffer bottle open (exposed to air).

The atmospheric carbon dioxide lowers the pH of the alkaline buffers (10.01 pH).

• To avoid contamination, rinse the electrode with distilled or tap water before placing it in the buffer. If necessary, the electrode

might be blotted dry using a lint-free paper towel (e.g. Kimwipes) to remove excess water. Be extra careful not to touch or rub

the surface of the glass. The wiping of the glass can produce a static charge that will interfere with the voltage reading of the

electrode. In addition to this, the hydration gel layer is interrupted.

• Store buffers at room temperature.

• Signet offers the following pH buffer solutions, pH 4.01, pH 7.00 and pH 10.01.

• Make fresh buffer solutions just before using. ORP solutions made with quinhydrone are very unstable and may not read

properly after being exposed to air for a prolonged time. These solutions must be discarded after a few hours.

• Dispose of all calibration solutions in accordance with local guidelines and regulations.

Electrode Storage

Proper electrode storage maximizes electrode performance and extends electrode life.

Prior to storage - add 3 mol/L KCl to the electrode storage cap (about half full), and carefully secure the cap onto the electrode tip.

• Store boxed electrodes wet, fl at or upright (electrode tip down) to maximize hydration of the glass surface.

• Store electrodes in stable temperature environment, avoiding freezing conditions (below 0 °C (<33° F) and heat above 100° F).

• Never store the electrode in deionized (DI) water. Use 3 mol/L KCl solution to keep the glass wet when out of the process.

Short term storage (up to 24 hours) - soak the electrode tip in either pH 4.01 buffer or 3 mol/L KCl solution.

• Drying out of the pH sensitive glass and the junction must be avoided (or damage to the electrode will occur).

• Prior to electrode installation, make sure there’s a light fi lm of synthetic grease (such as silicone-free grease) applied to the upper

electrode O-ring. If the electrode will be installed into a GF Signet Installation Fitting, then also apply a thin fi lm of synthetic

grease to the lower O-ring.

Long term storage (longer than 24 hrs) - add 3 mol/L KCl solution to the storage cap (about half full) and carefully secure the cap onto

the electrode tip. This will ensure probes are always ready to use.

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

9

Page 10

Notes

10

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

Page 11

Ordering Information

2724-2726 and 2734-2736 pH/ORP Electrodes

Mfr. Part No. Code Description

3-2724-00 159 001 545 pH Electrode, fl at, Pt1000, ¾ in. NPT

3-2724-01 159 001 546 pH Electrode, fl at, Pt1000, ISO 7/1 R¾

3-2724-10 159 001 547 pH Electrode, fl at, 3K Balco, ¾ in. NPT

3-2724-11 159 001 548 pH Electrode, fl at, 3K Balco, ISO 7/1 R¾

3-2724-HF-10 159 001 771 pH Electrode, HF resistant, fl at, 3K Balco, ¾ in. NPT

3-2724-HF-11 159 001 772 pH Electrode, HF resistant, fl at, 3K Balco, ISO 7/1 R¾

3-2726-00 159 001 553 pH Electrode, bulb, Pt1000, ¾ in. NPT

3-2726-01 159 001 554 pH Electrode, bulb, Pt1000, ISO 7/1 R¾

3-2726-10 159 001 555 pH Electrode, bulb, 3K Balco, ¾ in. NPT

3-2726-11 159 001 556 pH Electrode, bulb, 3K Balco, ISO 7/1 R¾

3-2726-HF-00 159 001 549 pH Electrode, HF resistant, bulb, Pt1000, ¾ in. NPT

3-2726-HF-01 159 001 550 pH Electrode, HF resistant, bulb, Pt1000, ISO 7/1 R¾

3-2726-HF-10 159 001 551 pH Electrode, HF resistant, bulb, 3K Balco, ¾ in. NPT

3-2726-HF-11 159 001 552 pH Electrode, HF resistant, bulb, 3K Balco, ISO 7/1 R¾

3-2726-LC-00 159 001 557 pH Electrode, bulb, Low Cond, Pt1000, ¾ in. NPT

3-2726-LC-01 159 001 558 pH Electrode, bulb, Low Cond, Pt1000, ISO 7/1 R¾

3-2726-LC-10 159 001 559 pH Electrode, bulb, Low Cond, 3K Balco, ¾ in. NPT

3-2726-LC-11 159 001 560 pH Electrode, bulb, Low Cond, 3K Balco, ISO 7/1 R¾

3-2725-60 159 001 561 ORP Electrode, platinum, fl at, 10 K ID, ¾ in. NPT

3-2725-61 159 001 562 ORP Electrode, platinum, fl at, 10 K ID, ISO 7/1 R¾

3-2734-00 159 001 774 pH Electrode, fl at, Pt1000, ¾ in. NPT

3-2734-01 159 001 775 pH Electrode, fl at, Pt1000, ISO 7/1 R¾

3-2734-HF-00 159 001 776 pH Electrode, HF resistant, fl at, Pt1000, ¾ in. NPT

3-2734-HF-01 159 001 777 pH Electrode, HF resistant, fl at, Pt1000, ISO 7/1 R¾

3-2736-00 159 001 778 pH Electrode, bulb, Pt1000, ¾ in. NPT

3-2736-01 159 001 779 pH Electrode, bulb, Pt1000, ISO 7/1 R¾

3-2736-HF-00 159 001 780 pH Electrode, HF resistant, bulb, Pt1000, ¾ in. NPT

3-2736-HF-01 159 001 781 pH Electrode, HF resistant, bulb, Pt1000, ISO 7/1 R¾

3-2735-60 159 001 782 ORP Electrode, platinum, fl at, 10 K ID, ¾ in. NPT

3-2735-61 159 001 783 ORP Electrode, platinum, fl at, 10 K ID, ISO 7/1 R¾

3-2735-G-60 159 001 844 ORP Electrode, graphite, fl at, 10 K ID, ¾ in. NPT

3-2735-G-61 159 001 845 ORP Electrode, graphite, fl at, 10 K ID, ISO 7/1-R¾

Signet 2724-2726 and 2734-2736 Series pH and ORP Electrodes

11

Page 12

Ordering Information cont.

Accessories and Replacement Parts

3-2751-1 159 001 804 In-line Smart Sensor Electronics with 4.6 m (15 ft) cable (recommended for use with 9900 or 9950)

3-2751-2 159 001 805 In-line Smart Sensor Electronics with Junction Box and EasyCal (recommended for current loop and 0486)

3-2751-3 159 001 806 Submersible Smart Sensor Electronics with 4.6 m (15 ft) cable, ¾ in. NPT threads

3-2751-4 159 001 807 Submersible Smart Sensor Electronics with 4.6 m (15 ft) cable, ISO 7/1-R¾ threads

3-2760-1 159 000 939 Submersible Preamplifi er with ¾ in. NPT threads and 4.6 m (15 ft) cable

3-2760-2 159 000 940 Submersible Preamplifi er with ¾ in. ISO threads and 4.6 m (15 ft) cable

3-2760-11 159 001 367 In-line Preamplifi er with ¾ in. NPT threads and 4.6 m (15 ft) cable

3-2760-21 159 001 368 In-line Preamplifi er with ¾ in. ISO threads and 4.6 m (15 ft) cable

3-2759 159 000 762 pH/ORP System Tester (adapter cable sold separately)

3-2759.391 159 000 764 2759 DryLoc Adapter Cable (for use with 2751 and 2760)

3-0700.390 198 864 403 pH Buffer Kit (1 each 4, 7, 10 pH buffer in powder form, makes 50 mL)

3822-7004 159 001 581 pH 4 buffer solution, pint (16 oz) (473 ml

3822-7007 159 001 582 pH 7 buffer solution, pint (16 oz) (473 ml)

3822-7010 159 001 583 pH 10 buffer solution, pint (16 oz) (473 ml)

3822-7115 159 001 606 20 gram bottle Quinhydrone for ORP calibration

3-2700.395 159 001 605 Calibration kit: 3 Polypropylene cups, box used as cup stand, 1 pint pH 4.01, 1 pint pH 7.00

3-8050.390-1 159 001 702 Retaining Nut, Replacement, NPT, Valox

3800-5000 159 838 107 3.0M KCl Storage Solution for pH and ORP, 1 pint (473 ml) bottle

3-2700.397 159 001 870 Protective cap for pH/ORP electrodes, 5 pieces

3-2700.398 159 001 886 O-ring lubricant kit (5 packs of Super Lube, 1cc each)

®

Georg Fischer Signet LLC, 3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

For the most up-to-date information, please refer to our website at www.gfsignet.com

3-2724.090 Rev. 20 10/19 English © Georg Fischer Signet LLC 2019

Loading...

Loading...