Page 1

Signet 2724-2726 pH/ORP Electrodes

General Purpose

Compatible with ALL Signet pH/ORP instruments

and SmartPro transmitters

Flat

Glass

The Signet 2724-2726 pH and ORP electrodes are general

purpose sensors ideal for a wide range of applications.

These feature a patented reference design and uses the

unique foul-proof patented DryLoc® connector. The large

area PE reference junction and pathway is constructed

to increase the total reference e ectiveness and ensures

long service life.

The DryLoc

plated contacts readily connects the sensor to the

mating 2751 pH/ORP Smart Sensor Electronics or

the 2760 Preamplifi er. The robust Ryton® threaded

sensor body and choice of fl at pH, bulb pH, or fl at ORP

sensing elements allows a broad range of chemical

and mechanical compatibility for a wide variety of

applications.

® connector with corrosion resistant gold

Protected

Bulb

Features

• Patented reference design for exceptional

performance and prolonged life in harsh

environments*

• Memory chip enabled for access to a wide

range of unique features when connected to the

Signet 2751 pH/ORP Smart Sensor Electronics

• Ryton® (PPS) body for broad range of chemical

compatibility

• Patented DryLoc® connector with gold plated

contacts

• Special design allows for installation at any

angle, even inverted or horizontal

• ¾” NPT or ISO 7/1-R 3/4 threaded sensors

for use with reducing tees DN15 to DN100

(½ to 4 in.)

• Mounts in Signet standard fi ttings from

DN15 to DN100 (½ to 4 in.)

• Quick temperature response

• Bulb and fl at HF resistant glass available

for trace HF, in less than 2% concentration

applications

• Low conductivity sensor available for liquids down

to 20 μS/cm

There are two optional pH sensing versions available, HF

and LC. The HF version is for applications where traces

of hydrofl uoric acid (2% or less) will attack standard pH

glass. The LC version can be used for low conductivity

fl uids 20 - 100 µS/cm nominal and below 20 µS when

mounted under controlled conditions.

The quick temperature response is available in either

a Pt1000 or 3 K temperature sensor and allows

compatibility with all Signet pH/ORP instruments. The

2724-2726 electrodes incorporate ¾ inch NPT or ISO

7/1-R 3/4 threads for installing into standard pipe-tees.

They can also be mounted directly into Signet standard

fi ttings, DN15 to DN100 (½ to 4 inch).

Applications

• Water & Wastewater Treatment

• Neutralization Systems

• E uent Monitoring

• Sanitization Systems

• Pool & Spa Control

• Aquatic Animal Life Support Systems

• Process Control

• Cooling Towers

*U.S. Patent Nos.: 6,666,701, 7,799,193 B2,

7,867,371 B2 and 8,211,282 B2

Page 2

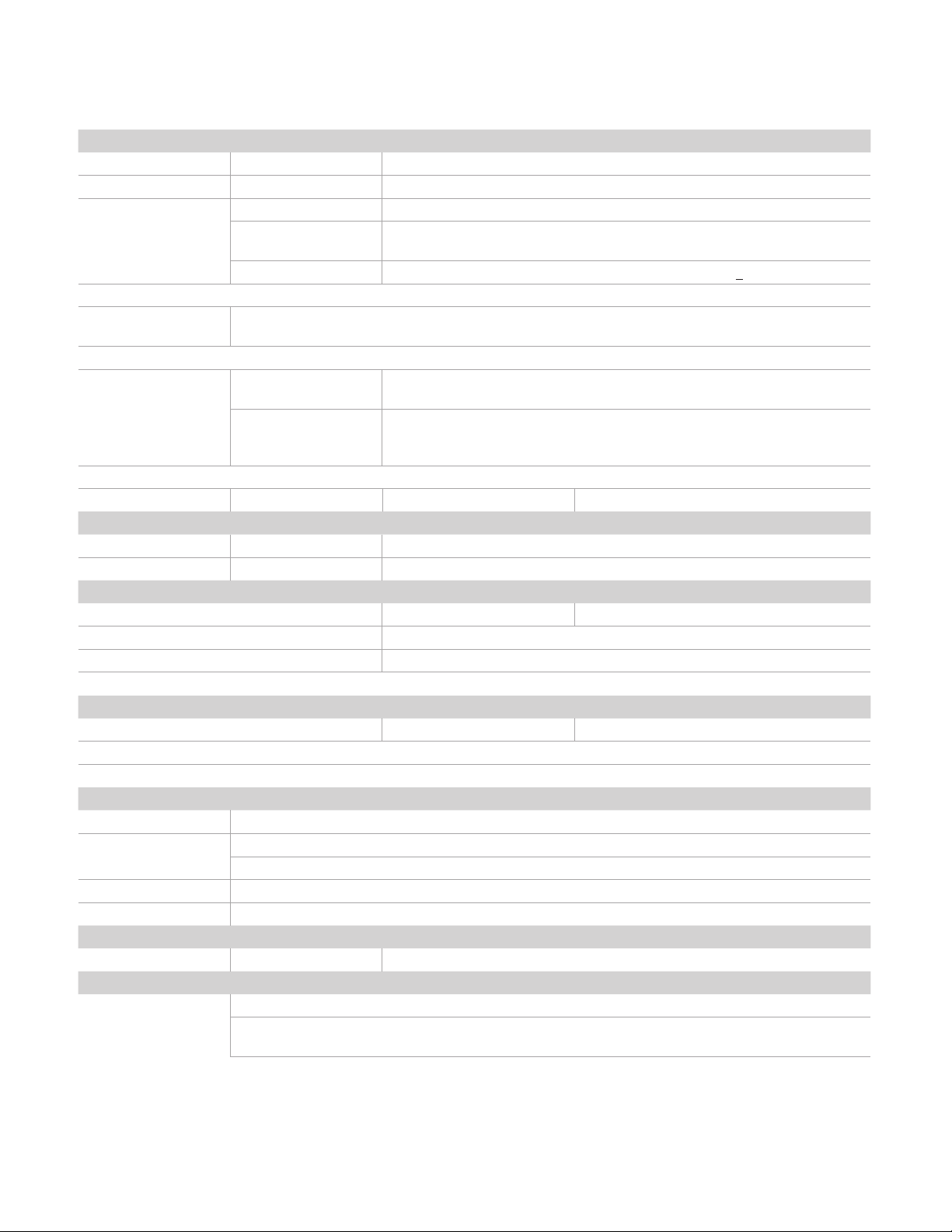

Specifi cations

General

Performance E ciency >97% @ 25 °C (77 ° F)

Operating Range pH 0 to 14 pH

ORP ±2000 mV

3-2726-LC Low conductivity fl uids; 20 - 100 µS/cm nominal < 20 µS; fl ow must

be less than 150 ml/min in a properly grounded system

3-2724-HF, 3-2726-HF Hydrofl uoric acid resistant glass, pH 6 or below; trace HF <2%

Compatibility

2751 Smart Sensor Electronics (for 8900, 9900, 9950, 4 to 20 mA or Profi bus Concentrator),

2760 Preamplifi er

Temperature Sensor

Pt1000 versions Compatible with Signet 2751 pH/ORP Smart Sensor Electronics for

connection to a PLC or to the Signet 8900, 9900 or 9950 instruments

3 KΩ Balco versions Compatible with Signet 2751 pH/ORP Smart Sensor Electronics or with

Signet 2760 pH/ORP Preamplifi er for connection to the

Signet 8750 pH/ORP Transmitter

Process Connection

¾ in. NPT ISO 7/1-R 3/4 Mounts into Signet fi ttings

Wetted Materials

®

pH Ryton

ORP Ryton

Max. Temperature/Pressure Rating

Operating Temperature Range*

Operating Pressure Range 6.8 bar @ -10 to 65 °C (100 psi @ 14 to 150 °F)

*Best performance for 2724-HF, 2726-HF sensors is above 10

Recommended Storage Temperature

The electrode glass will shatter if shipped or stored at temperature below 0 °C (32 °F)

The performance life of the electrode will shorten if stored at temperatures above 50 °C (122 °F)

Mounting

In-line Mounting Use the sensor threads

Use a Signet standard fi tting up to 4 in.

Sensor can be mounted at any angle

Submersible Mounting Use threads on models 2751 or 2760

Requires ¾ inch NPT or ISO 7/1-R 3/4 male threaded liquid tight extension conduit.

Shipping Weight

0.25 kg 0.55 lb

Standards and Approvals

RoHS compliant, China RoHS

Manufactured under ISO 9001 for Quality, ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety

(PPS), glass, UHMW PE, FKM

®

(PPS), glass, UHMW PE, FKM, Platinum

-10 °C to 85 °C 14 °F to 185 °F

4 bar @ 65 to 85 °C (58 psi @ 150 to 185 °F)

°C (50 °F)

0 °C to 50 °C 32 °F to 122 °F

See Temperature and Pressure graphs for more information

www.gfsignet.com

Page 3

Dimensions

*Yes

0.64 mm

(0.25 in.)

44.45 mm

(1.75 in.)

18.3 mm

(0.72 in.)

109 mm

(4.3 in.)

Threads:

¾ in. NPT

ISO 7/1 R-3/4

25.4 mm

(1.0 in.)

or

9.3 mm

(0.37 in.)

53.34 mm

(2.1 in.)

Yes

Yes

0°

Horizontal

Yes

Yes

*Yes

Mounting Angle

Models 2724-2726 may be mounted at any angle without

a ecting the performance.

*Avoid locations with air pockets and sediment.

When mounting in standard threaded fi ttings the electrode

must be mounted horizontally to 60 degrees below horizontal

position only.

Panel Mount 4 to 20 mA Output

Signet Instruments

8900 9900 or 9950

with 2751 Smart Sensor Electronics

ENTER

Signet 2724-2726

DryLoc® pH/ORP Electrodes

OR

Pipe, Tank, Wall Mount

Signet Instruments

9900 with 2751 Smart Sensor

Electronics and Rear Enclosure

+

NO NO

180°

240°

2751 Smart Sensor Electronics

and Customer Supplied Chart Recorder

or Programmable Logic Controller or

Programmable Automation Controller

+

PLC

90°

NO

0°

YESYES

NO

270°

300°

Automation System

2751 Smart Sensor Electronics with 0486 Profibus

Concentrator and Customer Supplied

Programmable Logic Controller or

Programmable Automation Controller

L IN+

L IN-

N/C

L OUT+

L OUT-

N/C

L IN+

L IN-

+5V OUT

DATA

GND

L IN+

L IN-

+5V OUT

DATA

GND

Out

In

S3L Loop

S3LLoop

USB

Profibus

Channel 5

Channel 6

Channel 7

+

Valve

Signet 3-0486 Profibus Concentrator

Address

Power

Channel 1

Channel 2

Channel 3

24 VDC

0.40A Max

S3LFreq

S3LFreq

S3LFreq

+5V OUT

+5V OUT

+5V OUT

Freq IN

Freq IN

Freq IN

PWR+

PWR+

PWR+

PWR-

PWR-

PWR-

DATA

DATA

DATA

GND

GND

GND

PLC

+

Channel 4

S3LFreq

+5V OUT

Freq IN

DATA

GND

System Overview

In-Line Installation Signet and threaded fittings only

Submersible Installation -

Customer supplied pipe extension

or conduit with 3/4 in. NPT or

ISO 7/1-R 3/4 threads

All sold separately

www.gfsignet.com

Page 4

Electrode Key Features and Benefi ts:

5

3

1. Ryton® body for chemical compatibility with most

harsh chemicals.

2. Porous UHMW PE (ultra high molecular weight

polyethylene) junction resists fouling and build-up.

3. Memory chip enabled for convenient data storage

and access (calibration data, operational data, and

manufacturing data), electrode health monitoring

via glass impedance measurement when used in

connection with the 2751 pH/ORP Smart Sensor

Electronics.

4. Internal temperature sensor located in the glass

stem for a quick temperature response.

5. DryLoc® connector with corrosion resistant gold

plated pins for quick and easy sensor removal.

Resists moisture and dirt intrusion.

6. Dual-patented reference design with a 406 mm

(16 in.) reference pathway for prolonged life in

harsh environments. This enables the sensor to last

signifi cantly longer than other standard pH/ORP

electrodes in most applications.

6a. With the patented reference design, the

Signet 2726-LC version performs better in low

conductivity water between 20 - 100 µS and lasts

longer than previous “DI” electrodes.

6b. The 2726-LC sensor also performs in

applications with extremely low (less than 20 µS)

conductivity. Special precautions must be taken to

avoid measurement complications.

Please note the following.

• Electrostatic charges (streaming potentials)

can cause dramatic o sets in a system with

very low conductivity water. To minimize this,

sensors should be placed in a well grounded

system.

• To enhance performance, a low fl ow cell is

recommended to provide a steady fl ow rate

(150 ml/minute). Sensors placed in high fl ow

applications will experience noisier readings

due to streaming potential.

7. Threads for NPT or ISO process connection into

reducing tees

• Use o -the-shelf GF reducing tees

DN20 to DN100 (¾ to 4 in.).

8. Mounts directly into Signet fi ttings (½ to 4 in.)

for easy sensor retrofi tting.

9. Mount submersed into a tank via the 2751 or

2760 back threads.

1

4

Dual-patented reference design

for long life in conductivity or

2

Sensor in threaded reducing tee

7

chemicals.

6

7

www.gfsignet.com

8

Sensor submersible installation

9

Sensor in Signet fi tting

Page 5

Temperature/Pressure Graph

Note:

The pressure/temperature graphs are specifically

for the Signet sensor. During system design the

specifications of all components must be considered.

In the case of a metal piping system, a plastic sensor

will reduce the system specification.

(psi)

150

125

100

75

50

25

(bar)

10.3

8.6

6.9

5.2

3.4

1.7

0

-40

°F°C-40

-20

-4

0

32 68

40

20

104

140

60 80 100

176

212

120

248

Application Tips

• Use the fl at glass electrodes when a self-cleaning

feature is desired; especially useful in applications

with abrasive chemicals for in-line installations.

• Use bulb protected electrodes for low temperature

applications or where fast response is required.

• ORP electrodes are generally used for chemical

reaction monitoring, not control.

• Ensure that sensor materials are chemically

compatible with the process liquid.

• Keep electrode tip wet, avoid air pockets and

sediment.

Bu er Solutions

3822-7004

3822-7007

3822-7010

Quinhydrone

3822-7115

Model 2724-2726 Ordering Notes

1) pH and ORP electrodes require connection to

model 2751 pH/ORP Smart Sensor Electronics or

2760 Preamplifi er.

2) The 2751 “EasyCal” feature recognizes common

pH and ORP bu er values of 4, 7 and 10 pH and

+87, +264 and +469 mV for ORP.

The Signet pH bu ers are ideal for calibration. The

liquid solutions are conveniently packaged in one pint

(473 ml) bottles. pH bu er kits in powder pillows are

available for mixing fresh solutions with water at the

time of use.

All pH bu ers are color coded for easy identifi cation;

4.01 pH is red, 7.00 pH is yellow, and 10.00 pH is blue.

All pH bu ers are traceable to NIST standards.

The 4.01 and 7.00 pH bu er solutions can be used

to calibrate ORP sensors when saturated with

quinhydrone.

www.gfsignet.com

Page 6

Ordering Information

Mfr. Part No. Code Tip Design Process Connection Thread Options

pH Electrodes

Temperature element Pt1000; use with 2751 pH/ORP Smart Sensor Electronics* and Profi bus Concentrator

3-2724-00 159 001 545 Flat ¾ in. MNPT, Thread

3-2724-01 159 001 546 Flat ISO 7/1-R 3/4 Thread

3-2726-00 159 001 553 Bulb ¾ in. MNPT, Thread

3-2726-01 159 001 554 Bulb ISO 7/1-R 3/4 Thread

3-2726-HF-00 159 001 549 Bulb, HF Resistant¹ ¾ in. MNPT, Thread

3-2726-HF-01 159 001 550 Bulb, HF Resistant¹ ISO 7/1-R 3/4 Thread

3-2726-LC-00 159 001 557 Bulb, Low Conductivity² ¾ in. MNPT, Thread

3-2726-LC-01 159 001 558 Bulb, Low Conductivity² ISO 7/1-R 3/4 Thread

Temperature element 3 K Balco; Compatible with both the 2751 pH/ORP Smart Sensor Electronics* and the

2760 Preamplifi er**

3-2724-10 159 001 547 Flat ¾ in. MNPT, Thread

3-2724-11 159 001 548 Flat ISO 7/1-R 3/4 Thread

3-2724-HF-10 159 001 771 Flat, HF Resistant¹ 3/4 in. NPT, Thread

3-2724-HF-11 159 001 772 Flat, pH Resistant¹ ISO 7/1-R 3/4 Thread

3-2726-10 159 001 555 Bulb ¾ in. MNPT, Thread

3-2726-11 159 001 556 Bulb ISO 7/1-R 3/4 Thread

3-2726-HF-10 159 001 551 Bulb HF Resistant

3-2726-HF-11 159 001 552 Bulb HF Resistant

3-2726-LC-10 159 001 559 Bulb, Low Conductivity

3-2726-LC-11 159 001 560 Bulb, Low Conductivity

ORP Electrodes; Compatible with both the 2751 pH/ORP Smart Sensor Electronics* and the 2760 Preamplifi er**

3-2725-60 159 001 561 Flat ¾ in. MNPT, Thread

3-2725-61 159 001 562 Flat ISO 7/1-R 3/4 Thread

1

1

¾ in. MNPT, Thread

ISO 7/1-R 3/4 Thread

2

¾ in. MNPT, Thread

2

ISO 7/1-R 3/4 Thread

*The 2751 pH/ORP Smart Sensor Electronics has a digital (S

3

L) output which is used with 8900, 9900 or 9950

instruments, and the Profi bus Concentrator.

It also has a 4 to 20 mA output for connections to PLC’s, data recorders, etc.

**The 2760 Preamplifi er is used for connection directly to 8750 transmitter or other analog transmitters.

1

HF resistant ‹2%HF

²Low conductivity applications, 20 - 100 µS/cm recommended

Note:

The 3 K Balco temperature element electrodes are compatible with the 2751

pH/ORP Smart Sensor Electronics, 8900, 9900 and 9950 instruments.

Accessories and Replacement Parts

Mfr. Part No. Code Description

1220-0021 198 801 000 O-ring, FKM (2 required per sensor)

3-2700.395 159 001 605 Calibration kit: includes 3 polypropylene cups, box used as cup stand,

1 pint pH 4.01, 1 pint pH 7.00

3822-7115 159 001 606 20 gm bottle quinhydrone for ORP calibration (must use pH 4.01 and/or

pH 7.00 bu er solutions)

3-2759 159 000 762 pH/ORP System Tester (adapter cable sold separately)

3-2759.391 159 000 764 2759 DryLoc adapter cable (for use with 2750 and 2760)

3-0700.390 198 864 403 pH Bu er Kit (1 each 4, 7, 10 pH bu er in powder form, makes 50 ml of each)

3822-7004 159 001 581 pH 4.01 bu er solution, 1 pint (473 ml) bottle

3822-7007 159 001 582 pH 7.00 bu er solution, 1 pint (473 ml) bottle

3822-7010 159 001 583 pH 10.00 bu er solution, 1 pint (473 ml) bottle

3800-5000 159 838 107 3.0M KCl storage solution for pH and ORP, 1 pint (473 ml) bottle

3-2700.397 159 001 870 Protective cap for pH/ORP electrodes, 5 pieces

3-2700.398 159 001 886 O-ring lubricant kit (5 packs of Super Lube, 1cc each)

3-2724.099 Rev J (06/19)

© Georg Fischer Signet LLC

3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057 • www.gfsignet.com • e-mail: signet.ps@georgfi scher.com

Specifi cations subject to change without notice. All rights reserved. All corporate names and trademarks stated herein are the property of their respective companies.

Loading...

Loading...