Page 1

Signet 2536 Rotor-X Paddlewheel Flow Sensors

Features

• Operating range 0.1 to 6 m/s (0.3 to 20 ft/s)

• Wide turndown ratio of 66:1

• Open-collector output

• Highly repeatable output

• Simple, economical design

• Installs into pipe sizes DN15 to DN900

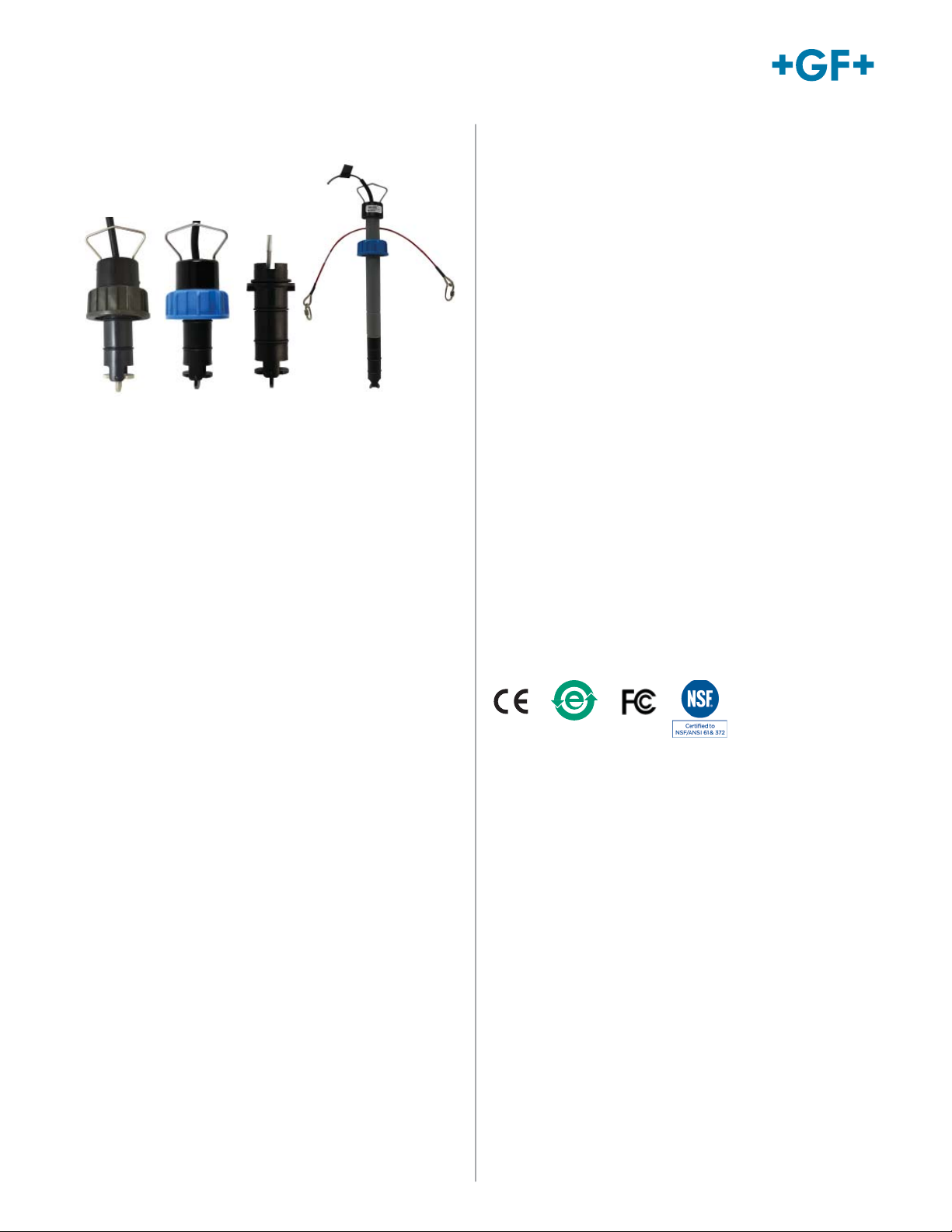

PVC

Sensor

(gray body

and cap)

Standard

Sensor

(blue cap)

Integral

Sensor

Wet-Tap

Sensor

(½ to 36 in.)

• PVC 2536 version DN15 to DN100 (½ to 4 in.) for

concentrated Sodium Hypochlorite 12.5% applications

• High resolution and noise immunity

Simple to install with time-honored reliable

performance, Signet 2536 Rotor-X Paddlewheel Flow

Sensors are highly repeatable, rugged sensors that

o er exceptional value with little or no maintenance.

The Model 2536 has a process-ready open collector

signal with a wide dynamic fl ow range of 0.1 to 6 m/s

(0.3 to 20 ft/s). The sensor measures liquid fl ow rates in

full pipes and can be used in low pressure systems.

The Signet 2536 sensors are o ered in a variety of

materials for a wide range of pipe sizes and insertion

confi gurations. The many material choices including

PP and PVDF make this model highly versatile and

chemically compatible to many liquid process solutions.

Sensors can be installed in DN15 to DN900 (½ to 36 in.)

pipes (except the 2536 PVC versions, which can be

installed in DN15 to DN100 (½ to 4 in.) pipes), using

Signet’s comprehensive line of custom fi ttings. These

custom fi ttings, which include tees, saddles, and

weldolets, seat the sensor to the proper insertion depth

into the process fl ow. The sensors are also o ered in

confi gurations for wet-tap installation requirements.

• Test certifi cate included for -X0, -X1

• Chemically resistant materials

(3-2536-PX

version only)

Applications

• Pure Water Production

• Filtration Systems

• Chemical Production

• Liquid Delivery Systems

• Pump Protection

• Scrubber/Gas Stacks

• Gravity Feed Lines

• Not suitable for gas

• Sodium Hypochlorite transfer/

injection/batching (3-2536-U0)

www.gfsignet.com

Page 2

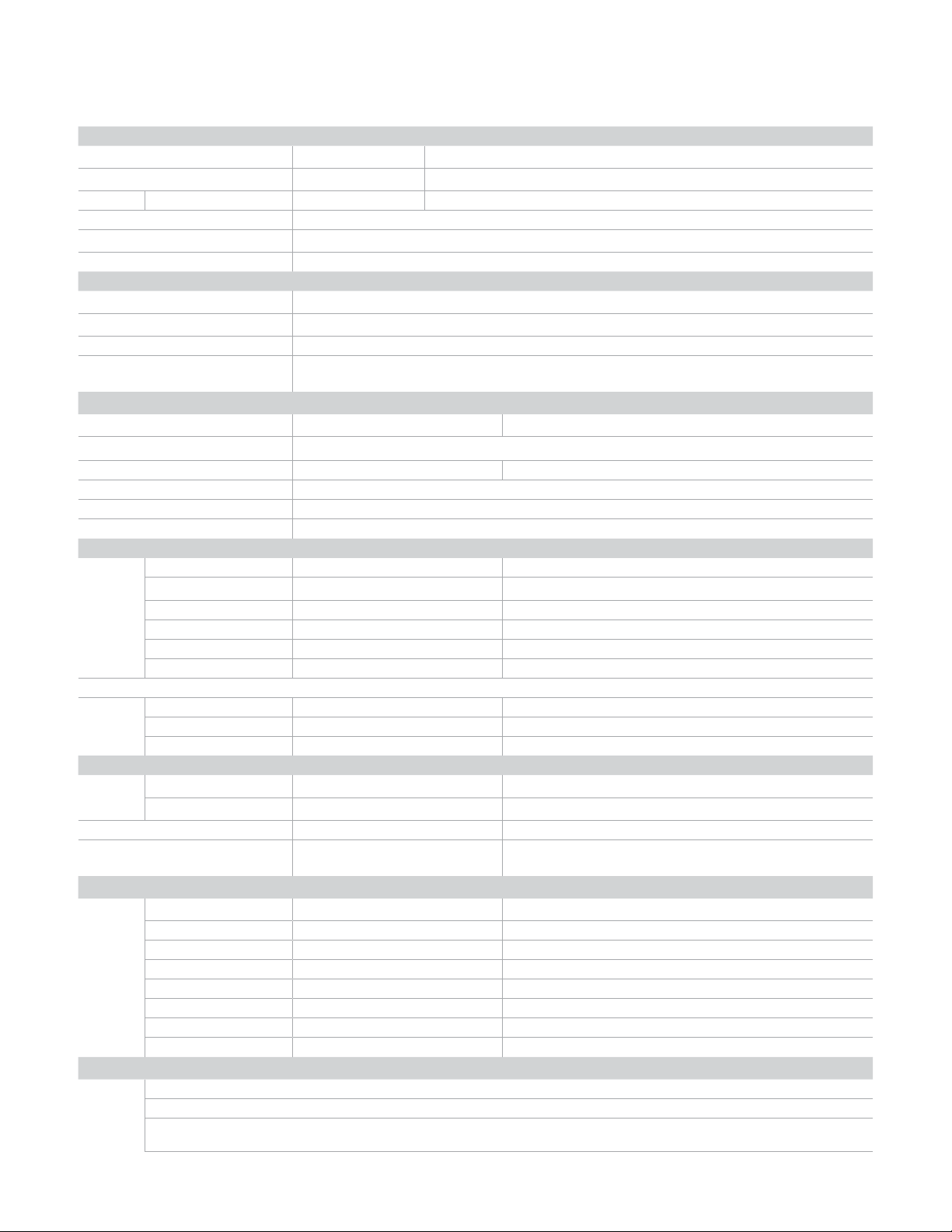

Specifi cations

General

Operating Range 0.1 to 6 m/s 0.3 to 20 ft/s

Pipe Size Range DN15 to DN900 ½ to 36 in.

PVC DN15 to DN100 ½ to 4 in.

Linearity ±1% of max. range @ 25 °C (77 °F)

Repeatability ±0.5% of max. range @ 25 °C (77 °F)

Min. Reynolds Number Required 4500

Wetted Materials

Sensor Body Glass-fi lled PP (black), PVDF (natural) or PVC (gray)

O-rings

Rotor Pin Titanium, Hastelloy-C or PVDF; optional Ceramic, Tantalum or Stainless Steel

Rotor Black PVDF or Natural PVDF; optional ETFE, with or w/o carbon fi ber reinforced PTFE

Electrical

Frequency 49 Hz per m/s nominal 15 Hz per ft/s nominal

Supply Voltage 5 to 24 VDC ±10%, regulated

Supply Current <1.5 mA @ 3.3 to 6 VDC <20 mA @ 6 to 24 VDC

Output Type Open collector, sinking 10 mA max.

Cable Type 2-conductor twisted pair with shield, 22 AWG

Cable Length 7.6 m (25 ft) can be extended up to 305 m (1000 ft) maximum

Max. Temperature/Pressure Rating - Standard and Integral Sensor

PP 12.5 bar @ 20 °C 180 psi @ 68 °F

PVDF 14 bar @ 20 °C 200 psi @ 68 °F

PVC 12.5 bar @ 20 °C 180 psi @ 68 °F

Operating Temperature

PP -18 °C to 85 °C 0 °F to 185 °F

PVDF -18 °C to 85 °C 0 °F to 185 °F

PVC 0 °C to 50 °C 32 °F to 122 °F

Max. Temperature/Pressure Rating - Wet-Tap Sensor

PP 7 bar @ 20 °C 100 psi @ 68 °F

Operating Temperature -18 °C to 60 °C 0 °F to 140 °F

Max. Wet-Tap Sensor Removal

Rating

Shipping Weight

3-2536-X0 0.454 kg 1.00 lb

3-2536-X1 0.476 kg 1.05 lb

3-2536-X2 0.680 kg 1.50 lb

3-2536-X3 0.780 kg 1.72 lb

3-2536-X4 0.800 kg 1.76 lb

3-2536-X5 0.880 kg 1.94 lb

3-8512-X0 0.35 kg 0.77 lb

3-8512-X1 0.37 kg 0.81 lb

Standards and Approvals

CE, FCC, NSF (3-2536-PX only)

RoHS compliant, China RoHS

Manufactured under ISO 9001 for Quality and ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety

FPM (std) optional EPR (EPDM) or FFPM

sleeve for rotor pin

1.7 bar @ 85 °C 25 psi @185°F

1.7 bar @ 85 °C 25 psi @ 185 °F

6.9 bar @ 60 °C 100 psi @ 140 °F

1.4 bar @ 60 °C 20 psi @ 140 °F

1.7 bar @ 22 °C 25 psi @ 72 °F

See Temperature and Pressure Graphs for more information

www.gfsignet.com

Page 3

26.7 mm

(1.05 in.)

-P3

thru

-P5

Dimensions

Standard Mount

PVC Mount

(0.5 to 4 in. pipe range only)

53.3 mm

(2.1 in.)

26.7 mm

(1.05 in.)

Pipe range

0.5 to 4 in. -X0 = 104 mm (4.1 in.)

5 to 8 in. -X1 = 137 mm (5.4 in.)

10 in. and up -X2 = 213 mm (8.4 in.)

Signet Instruments

8550 8900

9900 9900-1BC

Signet 2536

PVC, Standard, Wet-Tap or

8512 Integral Mount

Flow Sensors

-X0

thru

-X2

Signet Instruments

8550 with 3-8050 Universal Mount Kit

9900-1P 9900-1BC with Rear Enclosure

OR

ENTER

102 mm

(4.0 in.)

26.7 mm

(1.05 in.)

Pipe, Tank, Wall Mount

+

Integral Mount

(shown with Transmitter

sold separately)

96 mm

(3.8 in.)

+

-Y0 or -Y1

Signet Instruments

8550 9900

with 3-8051-X Integral Mount Kit

-Y0 or -Y1

Pipe range

0.5 to 4 in. -Y0 = 152 mm (6.0 in.)

5 to 8 in. -Y1 = 185 mm (7.3 in.)

OR

99.06 mm

(3.90 in.)

Field (Integral) MountPanel Mount

OR

ENTER

106 mm

(4.16 in.)

26.7 mm

(1.05 in.)

Wet-Tap Mount Sensor

with 3519 Wet-Tap Valve

(See 3519 product page for

more information).

Pipe range

0.5 to 4 in. -P3 = 297 mm (11.7 in.)

5 to 8 in. -P4 = 333 mm (13.1 in.)

10 in. and up -P5 = 409 mm (16.1 in.)

Automation System

0486 Profibus Concentrator

and Customer Supplied

Programmable Logic Controller or

Programmable Automation Controller

L IN+

L IN-

N/C

L OUT+

L OUT-

N/C

L IN+

L IN-

+5V OUT

DATA

GND

L IN+

L IN-

+5V OUT

DATA

GND

Out

In

S3LLoop

S3L Loop

USB

Profibus

Channel 5

Channel 6Channel 7

+

Valve

Signet 3-0486 Profibus Concentrator

Address

Power

Channel 1

Channel 2

Channel 3

24 VDC

0.40A Max

S3LFreq

S3LFreq

S3LFreq

+5V OUT

+5V OUT

+5V OUT

Freq IN

Freq IN

Freq IN

PWR+

PWR+

PWR+

PWR-

PWR-

PWR-

DATA

DATA

DATA

GND

GND

GND

PLC

+

Channel 4

S3LFreq

+5V OUT

Freq IN

DATA

GND

System Overview

Signet Fittings

For overview of Wet-Tap System, see 3519 product page

Application Tips

• Use the Conduit Adapter Kit to protect the

cable-to-sensor connection when used in outdoor

environments. See Accessories section for more

information.

• Use a sleeved rotor in abrasive liquids to

reduce wear.

All sold separately

• Sensor plug can be used to plug installation fi tting

after extraction of sensor from pipe.

• For liquids containing ferrous particles, use Signet

Magmeters.

• For systems with components of more than one

material, the maximum temperature/pressure

specifi cation must always be referenced to the

component with the lowest rating.

www.gfsignet.com

Page 4

Temperature/Pressure Graphs

Note:

The pressure/temperature graphs are specifically

for the Signet sensor. During system design the

specifications of all components must be considered. In

the case of a metal piping system, a plastic sensor will

reduce the system specification. When using a PVDF

sensor in a PVC piping system, the fitting will reduce the

system specification.

(bar)(psi)

14.5

210

13.8

200

13.1

190

12.4

180

11.7

170

11.0

160

10.3

150

9.7

140

9.0

130

8.3

120

7.6

110

6.9

100

6.2

90

5.5

80

4.8

70

4.1

60

3.4

50

2.8

40

2.1

30

1.4

20

.7

10

0

-20 0 20 40 60 80 100

°F°C-4 32 68 104 140 176 212

Polypropylene

PVDF

PVC

Ordering Notes

1) Most common part number combinations shown. For

all other combinations contact factory.

2) Other rotor and pin materials are available for

purchase from the factory and can be easily replaced

in the fi eld. See Accessories section.

Ordering Information

Model 2536 Standard Mount Paddlewheel

When choosing this style of sensor, the instrument can be mounted nearby on a pipe or wall or in a remote location up

to 305 m (1000 ft) by connecting the sensor through a standard 3-8050-1 universal junction box. Standard cable length

is 7.6 m (25 ft). Use Signet fi ttings for proper seating of the sensor into the process fl ow.

Mfr. Part No. Code Body Rotor Pin Material

Flow Sensor for use with remote mount instrument

DN15 to DN100 - ½ to 4 in.

3-2536-P0 198 840 143 Polypropylene Black PVDF Titanium

3-2536-T0 198 840 149 Natural PVDF Natural PVDF Natural PVDF

3-2536-U0 159 001 843 PVC Sleeved ETFE Titanium

3-2536-V0 198 840 146 Natural PVDF Natural PVDF Hastelloy-C

DN125 to DN 200 - 5 to 8 in

3-2536-P1 198 840 144 Polypropylene Black PVDF Titanium

3-2536-V1 198 840 147 Natural PVDF Natural PVDF Hastelloy-C

DN250 - DN900 - 10 to 36 in.

3-2536-P2 198 840 145 Polypropylene Black PVDF Titanium

www.gfsignet.com

Page 5

Ordering Information (continued)

Model 2536 Integral Mount Paddlewheel

When choosing this style of sensor, the instrument is mounted directly onto the sensor for a local display.

See guidelines below for instructions.

Mfr. Part No. Code Body Rotor Pin Material

Flow sensor for integral mounting on the 8150 or 8550 instrument using the 3-8051-X Flow Sensor Integral

Mount Kit (sold separately)

DN15 to DN100 - ½ to 4 in.

3-8512-P0 198 864 513 Polypropylene Black PVDF Titanium

3-8512-T0 198 864 518 Natural PVDF** Natural PVDF Natural PVDF

3-8512-V0 198 864 516 Natural PVDF** Natural PVDF Hastelloy-C

DN125 to DN200 - 5 to 8 in. (PP only)

3-8512-P1 198 864 514 Polypropylene Black PVDF Titanium

**Natural PVDF available ½ in. to 4 in. only

Guidelines: Combining a 2536 integral mount fl ow sensor with an integrally mounted instrument

Option 1

Once an integral mount sensor is chosen, it can be

mounted directly to a fi eld mount transmitter by

following these guidelines:

a) Order the 3-8051-X fl ow sensor integral mounting kit

(sold separately) to connect the sensor to

an instrument.

b) Order a fi eld mount transmitter (sold separately). The

following part numbers are compatible:

3-8550-3, 3-9900-1.

c) Assembling the sensor with the integral adapter and

instrument is quick and simple.

Model 2536 Wet-Tap Mount Paddlewheel Flow Sensor

When choosing this style of sensor, the instrument can be mounted nearby on a pipe or wall or in a remote location

up to 305 m (1000 ft) by connecting the sensor through a standard 3-8050-1 universal junction box. Standard

cable length is 7.6 m (25 ft). This style of sensor uses the 3519 Wet-Tap valve only (see individual product page

for more information).

Mfr. Part No. Code Body Rotor Pin Material

Flow Sensor for wet-tap mounting with the 3519 Wet-Tap Valve (sold separately)

DN15 to DN100 - ½ to 4 in.

3-2536-P3 159 000 758 Polypropylene Black PVDF Titanium

DN125 to DN200 - 5 to 8 in.

3-2536-P4 159 000 759 Polypropylene Black PVDF Titanium

DN250 to DN900 - 10 to 36 in.

3-2536-P5 159 000 760 Polypropylene Black PVDF Titanium

Guideline: Combining a 2536 Wet-Tap Sensor with a 3519 Wet-Tap Valve

a) Once a sensor is chosen, it can be mounted in a 3519 Wet-Tap Valve (sold separately)

b) Assembling a sensor with a 3519 Wet-Tap valve is quick and simple. These parts can also be ordered as complete

assemblies. See 3519 product page.

Model 2536 Ordering Notes

1) Other rotor and pin materials are available for

purchase from the factory and can be easily replaced

in the fi eld. See Accessories section.

Please refer to Wiring, Installation, Accessories and Fittings sections for more information.

www.gfsignet.com

Page 6

Accessories and Replacement Parts

Mfr. Part No. Code Description

Rotors

3-2536.320-1 198 820 052 Rotor, PVDF Black

3-2536.320-2 159 000 272 Rotor, PVDF Natural

3-2536.320-3 159 000 273 Rotor, ETFE

3-2536.322-1 198 820 056 Sleeved rotor, PVDF Black

3-2536.322-2 198 820 057 Sleeved rotor, PVDF Natural

3-2536.322-3 198 820 058 Sleeved rotor, ETFE

Rotor Pins

M1546-1 198 801 182 Pin, Titanium

M1546-2 198 801 183 Pin, Hastelloy-C

M1546-3 198 820 014 Pin, Tantalum

M1546-4 198 820 015 Pin, Stainless Steel

P51545 198 820 016 Pin, Ceramic

O-Rings

1220-0021 198 801 000 O-ring, FPM (2 required per sensor)

1224-0021 198 820 006 O-ring, EPR (EPDM) (2 required per sensor)

1228-0021 198 820 007 O-ring, FFPM (2 required per sensor)

Miscellaneous

P31536 198 840 201 Sensor plug, Polypropylene

P31542-3 159 000 464 Sensor cap, Blue

3-2536.555 159 500 532 Sensor cap, Gray

P31934 159 000 466 Conduit cap

P51589 159 000 476 Conduit adapter kit

5523-0222 159 000 392 Cable (per foot), 2 cond. w/shield, 22 AWG

3-2536.321 198 820 054 PVDF Natural, Rotor kit (rotor and pin)

3-8050 159 000 184 Universal mount kit

3-8050-1 159 000 753 Universal junction box

3-8050.390-1 159 001 702 Retaining nut replacement kit, NPT, Valox (for use with 8510 and 8512)

3-8050.390-3 159 310 116 Retaining nut replacement kit, NPT, PP (for use with 8510 and 8512)

3-8050.390-4 159 310 117 Retaining nut replacement kit, NPT, PVDF (for use with 8510 and 8512)

3-8051 159 000 187 Transmitter integral adapter (for use with 8510 and 8512)

3-8051-1 159 001 755 Transmitter integral mounting kit, NPT, PP (for use with 8510 and 8512)

3-8051-2 159 001 756 Transmitter integral mounting kit, NPT, PVDF (for use with 8510 and 8512)

3-2536.099 Rev L (07/16)

© Georg Fischer Signet LLC

3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057 • www.gfsignet.com • e-mail: signet.ps@georgfi scher.com

Specifi cations subject to change without notice. All rights reserved. All corporate names and trademarks stated herein are the property of their respective companies.

www.gfsignet.com

Loading...

Loading...