Page 1

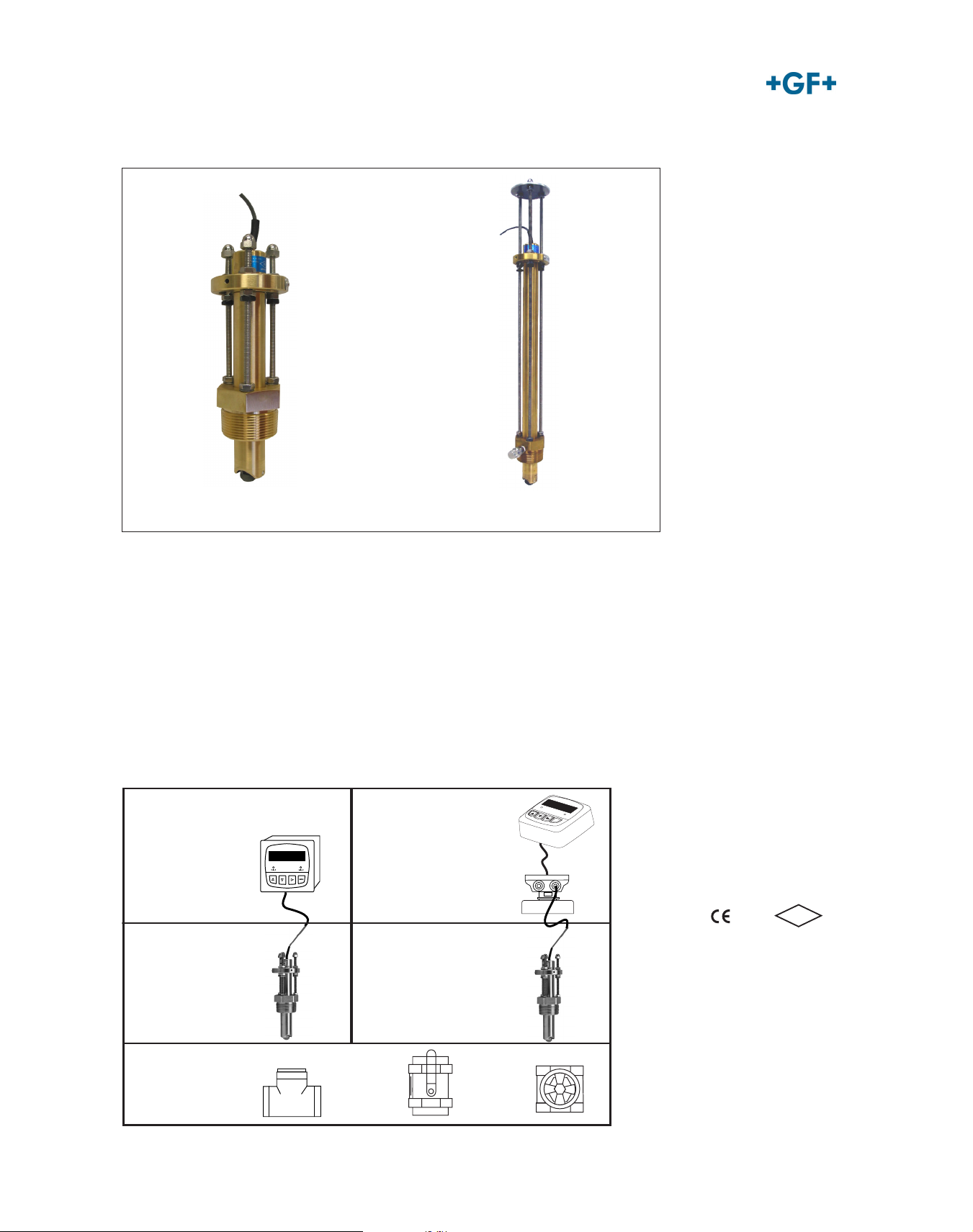

Signet 2517 Brass Paddlewheel Flow Sensor

Standard Sensor

Hot-Tap Sensor

Features

• Flow rate range

0.5 to 6 m/s

(1.6 to 20 ft/s)

• Standard NPT or ISO

process connections

• Usable in pipe sizes

up to DN 900 (36 in.)

• Hot-tap versions

for installation/service without system

shutdown

• No external power

required

Description

The Signet 2517 Paddlewheel Flow

Sensors offer added strength and

durability of brass construction for a

variety of applications. The wide flow

range of 0.5 to 6 m/s (1.6 to 20 ft/s)

allows the sensor to measure liquid

flow rates in full pipes and can be

used in low pressure systems. Fluo-

®

roloy B

/PTFE bearings and a Tungsten Carbide pin provide exceptional

wear resistance. The 2517 brass

System Overview

Pipe, Tank, Wall MountPanel Mount

Signet Flow Instrument

(sold separately)

8150 8900

5075 8550

5500 5600

Signet

Model 2517

Standard or

Hot-Tap (not shown)

Flow Sensor

sensor signal allows for remote totalization when coupled with the 8150

battery operated Flow Totalizer. Sensors can be installed in DN 40 to DN

600 (1.5 to 24 in.) pipes using the 1.5

inch (or ISO 7/1-R 1.5) threaded process connection. The sensors are also

offered in a hot-tap configuration with

a bleed valve for installation in pipes

up to DN 900 (36 in.) and allows for

servicing without process shutdown.

Signet Flow Instrument

(sold separately)

8150 8550

Signet Universal

Adapter Kit

(sold separately)

Signet

Standard or

Hot-Tap (not shown)

Flow Sensor

(3-8050)

Model 2517

• Adjustable sensor

- one size for entire

pipe range

• 7.6m (25 ft.) cable

Application

• HVAC

• Turf Irrigation

• Cooling Systems

• Filtration Systems

• Water Distribution

• Leak Detection

• Pump Protection

• Clarified Effluent

Totalization

• Ground Water

Remediation

FM

APPROVED

Customer Supplied

Fittings

34

www.gfsignet.com

Page 2

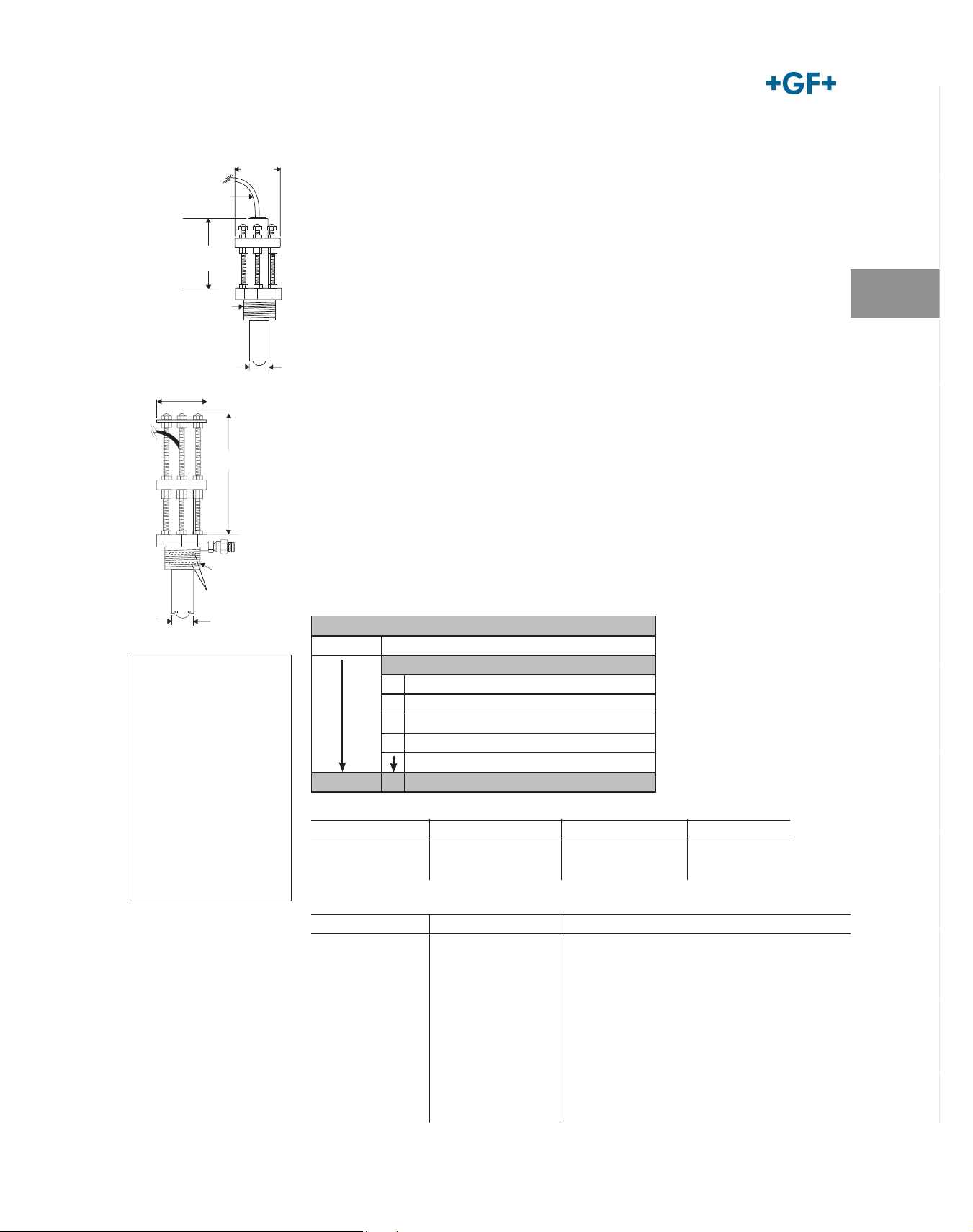

Dimensions

2517

Standard Sensor

1.5 to 24 in. pipes

7.6 m (25 ft.)

integral cable

194.31 mm

(6.0 in.)

1-1/2 in. NPT

or ISO 7/1-Rc

1.5 Thread

26.95 mm

(1.06 in.) dia.

64 mm (2.5 in.) dia.

7.6 m

(25 ft.)

cable

Application Tips:

• For systems with components of more than

one material, the maximum temperature/pressure specification must

always be referenced to

the component with the

lowest rating.

• Use the Conduit Adapter

Kit when used in outdoor

environments.

• The 2517 can be used in

intrinsically safe areas

using an approved barrier between the sensor

and instrument.

63.5 mm

(2.5 in.)

2517

Hot-Tap

Sensor

1.5 to 36

in. pipes

457 mm

(18 in.)

Bleed

valve

Sensor fitting:

1.5 in. NPT or

ISO 7/1-R 1.5

thread

O-ring

seals (2)

24 mm (0.94 in.) dia.

Specifications

General

Flow Rate Range:

0.5 to 6 m/s (1.6 to 20 ft/s)

Linearity: ±1% of full range

Repeatability: ±0.5% of full range

Min. Reynolds Number Required: 4500

Pipe size range:

• Standard version:

DN40 to DN600 (1.5 to 24 in.)

• Hot-Tap version:

DN40 to DN900 (1.5 to 36 in.)

Sensor fitting options:

• 1.5in NPT threads

• ISO 7/1-R 1.5 threads

Wetted materials

• Sensor body:

C36000 Free cutting brass

• Sensor fitting:

C36000 Free cutting brass

• Sensor fitting O-rings:

Standard Viton

®

, optional EPR

• Rotor:

CB7cU-1

• Rotor pin: Tungsten Carbide GRP 1

• Retainers (2):

316 stainless steel (1.4401)

• Rotor bearings (2): Fluoroloy B

®

Electrical

Frequency: 20 Hz per ft/s nominal,

5 to 8 mV p-p per Hz

Source Impedance: 11.6 KΩ

Cable length: 7.6 m (25 ft.), can be

extended up to 60m (200 ft.)

Cable type:

2-conductor twisted-pair with shield,

22AWG

Max. Pressure/Temperature Rating

• Sensor with optional EPDM sensor

fitting O-rings:

17 bar @ 82°C (250 psi @ 180°F)

• Sensor with standard FPM sensor

fitting O-rings:

17 bar @ 100°C (250 psi @ 212°F)

See Temperature and Pressure graphs for

more information.

Shipping Weight:

• 3-2517.100, .101: 2.04 kg (4.5 lbs.)

• 3-2517.102, .103: 2.63 kg (5.8 lbs.)

Standards and Approvals

• Manufactured under ISO 9001:2000

for Quality and ISO 14001:2004 for

Environmental Management

• FM approved, CE

Ordering Information

Sensor Part Number

3-2517.10 Brass High Performance flow sensor

Mounting option - choose one

0 1.5 inch NPT thread

1 1.5 inch ISO thread

2 1.5 inch NPT thread, hot tap design*

3 1.5 inch ISO thread, hot tap design*

3-2517.10 1 Example Part Number

*Must use 3-1500.663 Hot-Tap installation tool (sold separately)

Mfr. Part No. Code

3-2517.100 198 840 003

3-2517.101 198 840 007

Mfr. Part No. Code

3-2517.102 159 000 267

3-2517.103 159 000 268

Accessories and Replacement Parts

Model 2517 Ordering Notes:

Installation fitting, Wet-Tap

valves and accessories are

customer supplied

Choosing

Products

Instrument

Multi-Pa-

rameter

Flow

pH/ORP

Conductivity/

Resistivity

Pressure, Level

Temperature,

Products

Other

Installation

Wiring &

Reference

Technical

Temperature/

Pressure

Graphs

Please refer to Wiring,

Installation, and

Accessories sections

for more information.

www.gfsignet.com

Mfr. Part No. Code Description

3-1500.663 198 820 008 Hot-Tap Installation Tool

1220-0121 159 000 852 O-ring, FPM

1224-0021 198 820 006 O-ring, EPDM

P52509-1 159 000 479 Rotor Kit, 316SS Pin (1.4401)

P52509-3 159 001 068 Rotor Kit, Tungsten Carbide Pin

P52504-1 198 801 500 Pin, 316SS (1.4401)

P52504-2 198 820 023 Pin, Tungsten Carbide

P52503 198 820 013 Bearing, Fluoroloy B

®

/PTFE

3-2517.567 159 000 269 Shaft Retainer

P51589 159 000 476 Conduit Adapter Kit

P31934 159 000 466 Conduit Cap

6400-9001 159 001 466 Intrinsic Safety Barrier (2 required)

35

of Terms

Glossary

Reference

Part No.

Index

Loading...

Loading...