Page 1

Signet 2507 Mini Flow Sensor

r

*3-2707.090*

3-2507.090 Rev. K 11/05 English

SAFETY INSTRUCTIONS

1. Do not remove from pressurized lines.

2. Confirm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifications.

4. Wear safety goggles or faceshield during installation/service.

5. Do not alter product construction.

6. Failure to follow safety instructions could result in severe personal injury.

English

1. Description

The Signet 2507 Mini Flow Sensor contains a free-running rotor

which is driven by the fl uid fl ow. Within the given measurement

range, the rotational speed of the rotor is proportional to the fl uid

fl ow rate. Permanent magnets built into the rotor actuate an

electronic switch in the top of the sensor generating a squarewave output signal proportional to fl ow rate. Both opaque and

transparent fl uids can be measured from 0.2 to 20.0 centistokes.

Wetted sensor parts are constructed of PVDF and FPM, making

the sensor suitable for use with most process fl uids, including

most acids, bases, light oils, and solvents.

WARNING!

2. Specifi cations

General

Compatibility:

Flow Sensor

2507

3-5075

Flow Range:

• -2V sensor: 400 to 2800 mL/m (0.105 to 0.740 U.S. gpm)

• -3V sensor: 700 to 4200 mL/m (0.185 to 1.123 U.S. gpm)

• -4V sensor: 1300 to 6000 mL/m (0.343 to 1.585 U.S. gpm)

• -6V sensor: 3200 to 12000 mL/m (0.845 to 3.170 U.S. gpm)

Linearity: ±0.25% of full range

Repeatability: ±0.25% of full range

Viscosity range: 0.2 to 20.0 centistokes

Pipe connections: G

1

/4 in. ports, 1/4 in. NPT (male) pipe adapters

(2 included)

Cable length: Std: 7.6m (25 ft.), max.: 300 m (1000 ft.)

Cable type: 2-conductor shielded, twisted-pair, 22 AWG

Shipping Weight: 0.4 kg (0.8 lb.)

Instrument Options

3-8150-1

3-5500

3-5090

3-5600

3-8550

3-8900

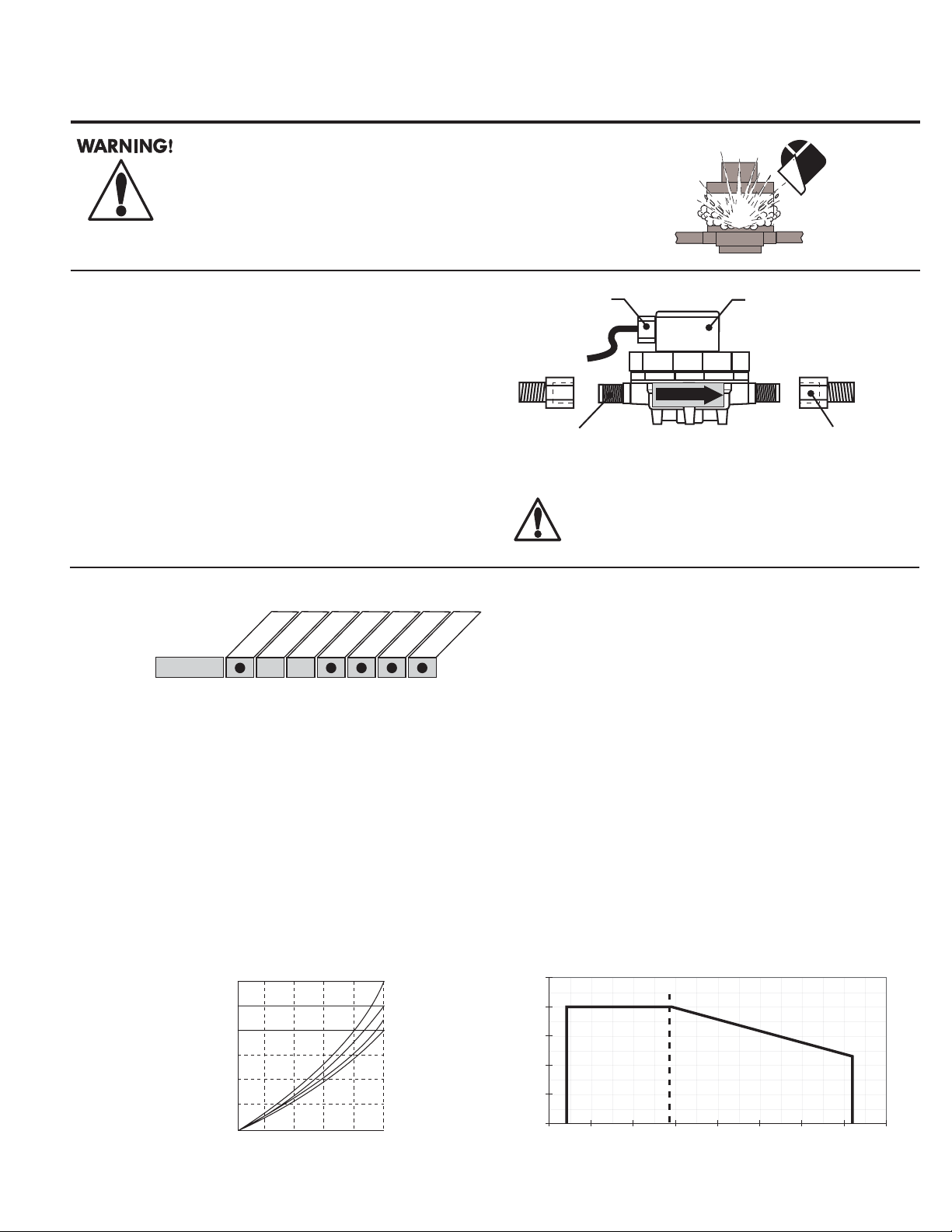

Cable plug

Upper body with

electronic switch

25 ft. cable

FLOW

1

G

/4 in.

port threads

Lower body with

built-in rotor

Pipe fitting adapte

G 1/4 x 1/4 in. NPT

(2 included)

Polar organic solvents (i.e., ketones and chlorinated

hydrocarbons) and aromatic hydrocarbons are not

compatible with this sensor.

Wetted Materials

• Housing: PVDF

• Flow insert: PTFE

• Quad ring seal: FPM

• Rotor: PVDF

• Pipe thread adapters: PVDF

• Suitable for clean fl uids only

Electrical

Power: 5 to 24 VDC @ 10 mA max.

Output type: Open-collector transistor, 10 mA max.

sink

Max. pressure/temperature:

• 5.5 bar @ -30°C (80 psi @ -22°F)

• 5.5 bar @ 24°C (80 psi @ 75°F)

• 3 bar @ 120°C (45 psi @ 248°F)

Pressure Drop:

Pressure Drop Across Sensor vs. Flow Rate

PSI

BAR

1.50

21.76

18.13

14.50

10.88

7.25

3.63

1.25

1.00

0.75

0.50

0.25

02040607080

Flow rate (%) of full scale

-2V

-3V

-4V

-6V

psi

bar

100

6.9

80

5.5

60

4.

1

40

2.8

20

1.4

0

-40 0 40 80 120 160 200 240 280

-40 -18 4 27 49 71 93 116 138

°F

°C

Page 2

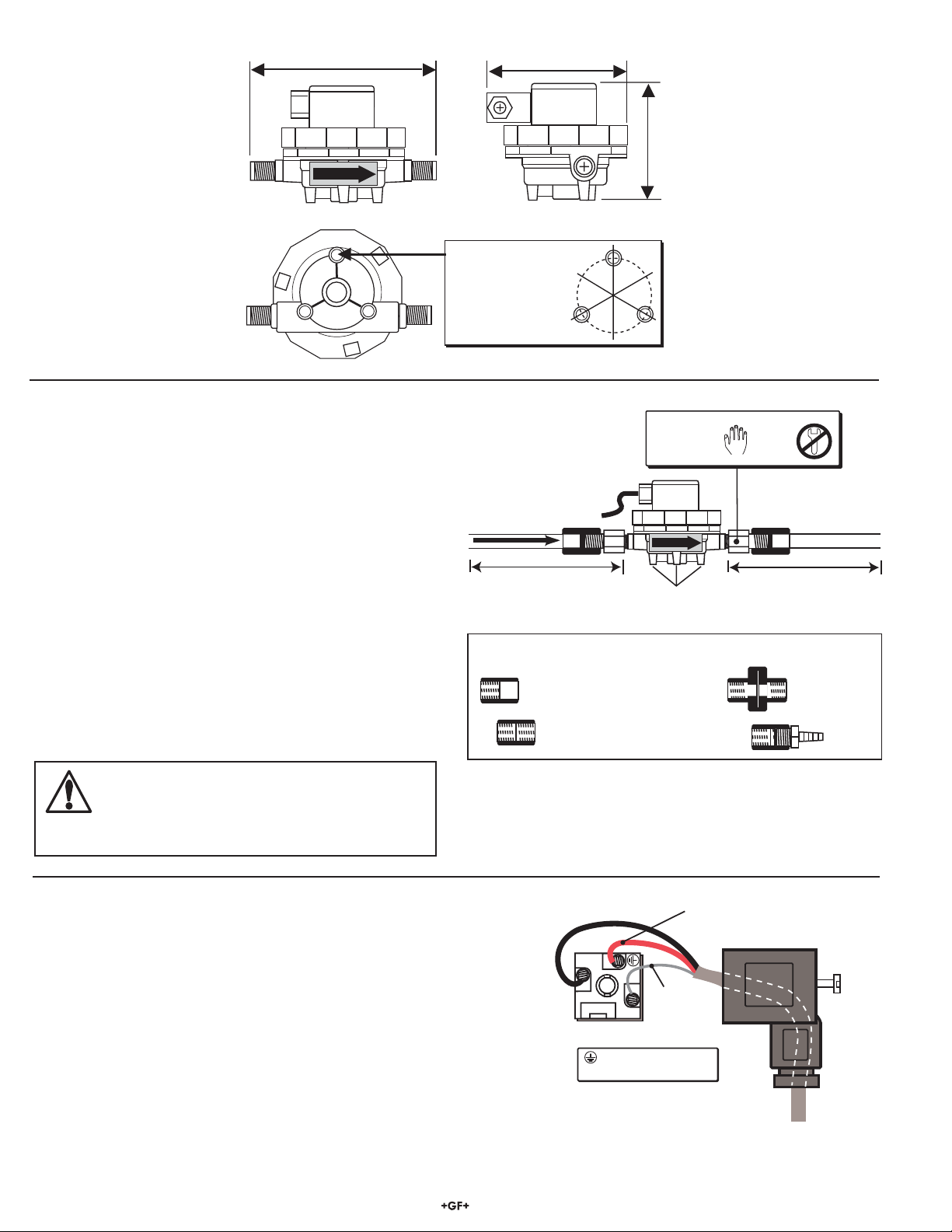

Dimensions:

95 mm (3.74 in.)

FLOW

68 mm (2.7 in.)

Mounting tabs (3),

#8 or M4 self-tapping

screws required

(customer supplied)

32.5 mm (1.28 in.)

bolt circle

65 mm

(2.6 in.)

3. Installation

• The sensor may be installed in any position, although

horizontal fl ow is recommended (the sensor mounted upright).

If the sensor is not installed upright, the linearity error may be

greater in the lower part of the sensor's measurement range.

• Mounting tabs are provided using #8 or M4 self-tapping

screws (customer supplied). See Dimensions illustration for

mounting tab hole pattern specifi cations.

• Install sensor with the arrow pointing in the direction of fl ow.

• Always maximize distance between the sensor and pump

source. Never install immediately downstream of valves,

fi ttings, etc. For optimum performance, a straight fl ow run of at

least 100 to 150 mm (4 to 6 in.) should be provided before and

after the sensor.

• Two pipe fi tting adapters (included) convert the G

1

/4 in. straight

threads to 1/4 in. NPT pipe threads. Hand tighten only! Apply

1-2 turns of sealing tape to all threaded connections to prevent

leaks.

CAUTION!

Use an adjustable wrench to prevent the fi tting

adapters from overtightning while installing

mating pipe connectors. Sensor damage will

occur if the ports are overtightened.

Pipe Fitting

Adapters

(included)

FLOW

FLOW

100-150 mm (4-6 in.)

Mounting

tabs (3)

Hand

tighten

only!

Coupling

100-150 mm (4-6 in.)

Compatible pipe/tubing connections (customer supplied):

Female SxT

coupling

Female TxT

coupling

Female TxT

coupling

Female TxT

union

Installation Hints

• Avoid vibrations and shocks

• Avoid solids in the fl uid

• Install a fi lter or line strainer upstream to protect sensor

Pipe or

tubing

Hose

adapter

4. Wiring Details

4.1 Cable Extensions

The standard 25 foot sensor cable can be extended to 300 m

(1000 ft.) using 2-conductor shielded twisted-pair cable.

• Always maintain cable shield through cable splice.

• For splice-free cable replacement up to 300 m (1000 ft.), refer

to the sensor plug connection diagram (below) for connection

details.

2

Sensor Power:

5 to 24 VDC

(Black wire)

1

Sensor

ground

2

(Silver wire)

Disregard ground

symbol on connector

Sensor Signal Output

(Red wire)

Sensor

Plug (side)

Max cable length:

300 m (1000 ft.)

Signet 2507 Mini Flow Sensor

Page 3

4.2 Instrument Connections

A

2507

C

2507

FLOW

FLOW

Shield

Black

Red

Std. Sensor

Black

Red

Shield

Signet

5500/5600

Freq. IN

Freq. IN

Sen. Pwr.

Open Collector

Sensor

Signet

9010

SENSOR

BLK RED SHLD

12 13 14

Iso. Gnd

B

OPEN

COLLECTOR

SENSOR

STANDARD

SENSOR

D

Signet

8550

Frequency In

Sensor Power

Gnd

Frequency In

2507

FLOW

Red

Black

Shield

Black

Shield

Red

2507

Other Brands

External Power supply

10 kΩ

FLOW

+

-

Gnd.

Input

5 to 24

VDC

Other

instrument

• Pull-up resistor required (10 kΩ recommended). Consult your instrument manual for

• Configure instrument input card for 2507 sensor input

additional information.

5. Calibration

The K-Factors listed below represent the number of pulses the sensor will generate for each measured engineering unit. They are listed

in U.S. gallons, liters, and mL by sensor model.

Sensor

Model

Flow

Insert

Pulses per

U.S.GAL

K-FACTORS

Pulses per

LITER

Pulses per

mL

3-2507.100-2v 2mm 5685 1502 1.502

3-2507.100-3v 3mm 3308 874 0.874

3-2507.100-4v 4mm 2316 612 0.612

3-2507.100-6v NONE 1249 330 0.33

6. Replacement Parts

Upper

body

Cable plug,

#3-2507.080-5

Signet 2507 Mini Flow Sensor

Rotor,

#3-2507.080-2

Flow inserts:

2 mm: #3-2507.081-2

3 mm: #3-2507.081-3

4 mm: #3-2507.081-4

Quad ring seal,

3-2507.080-3

FLOW

Lower body,

#3-2507.080-4V

3

Page 4

7. Replacing The Flow Insert

Sensor range can be modifi ed by changing the fl ow insert. The

sensor must be removed from service and disassembled prior to

installing the new fl ow insert. See section 2 specifi cations for fl ow

range data.

Flow Insert Replacement Procedure:

1. Depressurize system and remove sensor.

2. Rotate the upper sensor body clockwise until it releases from

the lower half, then lift off.

3. Remove rotor and quad ring seal from lower body.

4. Push the fl ow insert outward using a small screwdriver.

5. Install the new fl ow insert (small diameter inward) with the

eraser end of a pencil. Apply light pressure until insert seats

against the step in the lower body. Do not force!

6. Install rotor into lower body. Spin rotor with fi nger and check

for free rotation. If rotor hits fl ow insert, remove rotor and

push insert back until free rotor rotation is established. Use a

rounded object like a pen or pencil body to adjust fl ow insert

depth.

7. Install rotor, quad ring, and upper body. Hand tighten only!

Do not overtighten upper body or the lower body assembly

tabs will break.

8. Troubleshooting

8. Reprogram instrument with new K-Factor, see calibration

section 5.

WARNING!

Do not use tools of any kind on the sensor body or port

connections. Hand tighten only! Excessive force will

damage sensor.

Upper body

Assemble

(counterclockwise)

flow

insert

Inlet port

Rotor

FLOW

Lower Body

Disassemble

(clockwise)

Quad ring seal

Assembly

Tabs (3)

Outlet port

Condition Recommendation

Erratic or missing

sensor signal

A) Verify ALL cable and instrument connections (section 4).

B) Verify proper sensor installation (section 3).

C) Remove power from instrument and disconnect sensor inputs. Power up instrument and check across

Black and Shield terminals with a digital voltage meter for 5 VDC.

If 5 VDC is not present, the problem is in the instrument or the wiring.

D) Verify the 2507 paddlewheel is spinning freely by blowing into the fl ow chamber. If the paddlewheel

Perform steps A-E

If sensor problems

persist, contact your

local Signet dealer

doesn’t spin freely, the following conditions may exist:

• The sensor may be dirty or clogged. Disassemble and clean with hot tap water and soft brush

(see section 7).

• The rotor may be hitting the fl ow insert. Disassemble and adjust fl ow insert depth (see section 7).

E) Test sensor with fl ow system active and sensor powered. Use an oscilloscope to check the sensor input

signal across the Red (Signal IN) and Shield terminals. A square wave signal should appear at these

terminals. If no signal is present replace sensor.

9. Ordering Information

Mfr. Part No. Code Description

3-2507.100-2V 198 801 732 Mini-Flow Sensor, 2mm insert

3-2507.100-3V 198 801 733 Mini-Flow Sensor, 3mm insert

3-2507.100-4V 198 801 734 Mini-Flow Sensor, 4mm insert

3-2507.100-6V 198 801 736 Mini-Flow Sensor, 6mm inlet, no insert

Accessories

Mfr. Part No. Code Description

3-2507.080-2 159 000 254 Rotor, 2507

3-2507.080-3 159 000 255 Quad Ring, 2507

3-2507.080-5 159 000 256 DIN Connector, 2507

3-2507.081-2 198 801 502 2 mm Insert

3-2507.081-3 198 801 503 3 mm Insert

3-2507.081-4 198 801 558 4 mm Insert

5523-0222 159 000 392 Cable, per foot

George Fischer Signet, Inc. 3401 Aerojet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057

For Worldwide Sales and Service, visit our website: www.gfsignet.com • Or call (in the U.S.): (800) 854-4090

3-2507.090 Rev. K 11/05 English © George Fischer Signet, Inc. 2002 Printed in U.S.A. on recycled paper

Loading...

Loading...