Page 1

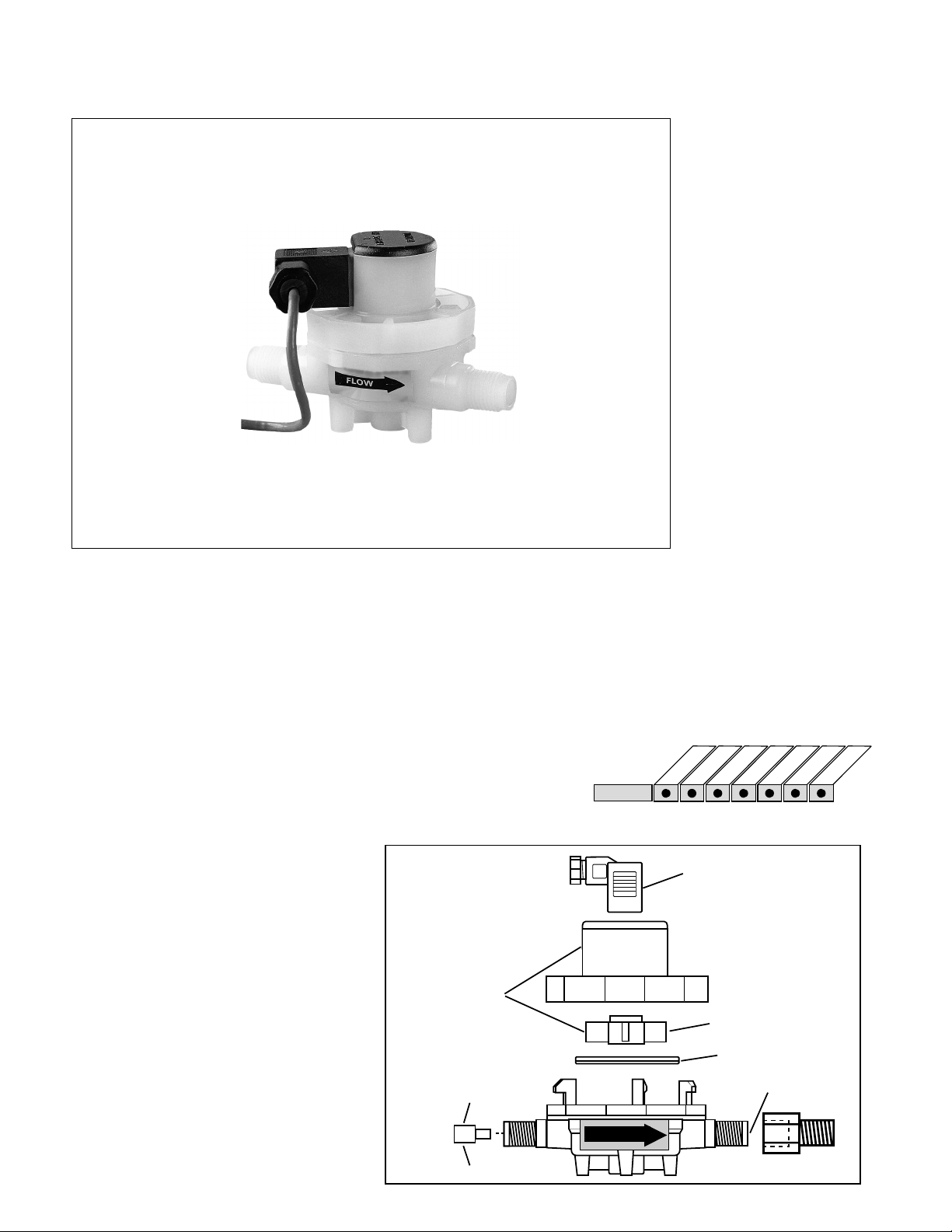

‡ SIGNET 2507 Mini Flow Sensor

2507

Flow Sensor

Instrument Options

3-5075

3-5500

3-5600

3-8550-1

3-8550-2

3-8550-3

3-9010

Description

The +GF+ SIGNET 2507 Mini Flow

Sensor contains a free-running rotor that

is driven by the fluid flow. Within the

given measurement range, the rotational

speed of the rotor is proportional to the

fluid flow rate. Permanent magnets built

into the rotor trigger an electronic switch

in the top of the sensor creating a

square-wave output frequency proportional to flow rate. Both opaque and

transparent fluids can be measured from

0.2 to 20.0 centistokes.

Features

• Compact Assembly

• Simple Installation

• 1/4 in. Threaded

Connection

• Detachable Signal

Connector

• PVDF Construction

• Four Flow Ranges

• Between 0.5 to 12

lpm (0.1 to 3.2 gpm)

Application

• Fluid Dispensing

• Laboratory and

Clinical Wet Benches

• Chemical Dosing

• Batch Processes

Options

Technical Features

a) Removable, sealed electrical connection

b) PVDF body and rotor

c) 4-magnet rotor (fully encapsulated)

d) Viton quad-ring seal

e) Inserts for different flow ranges

f) G 1/4 or 1/4” NPT tubing or pipe con-

nection adapters included

28

b

Flow Inserts:

2 mm

3 mm

4 mm

e

a

c

d

f

FLOW

www.gfsignet.com

Page 2

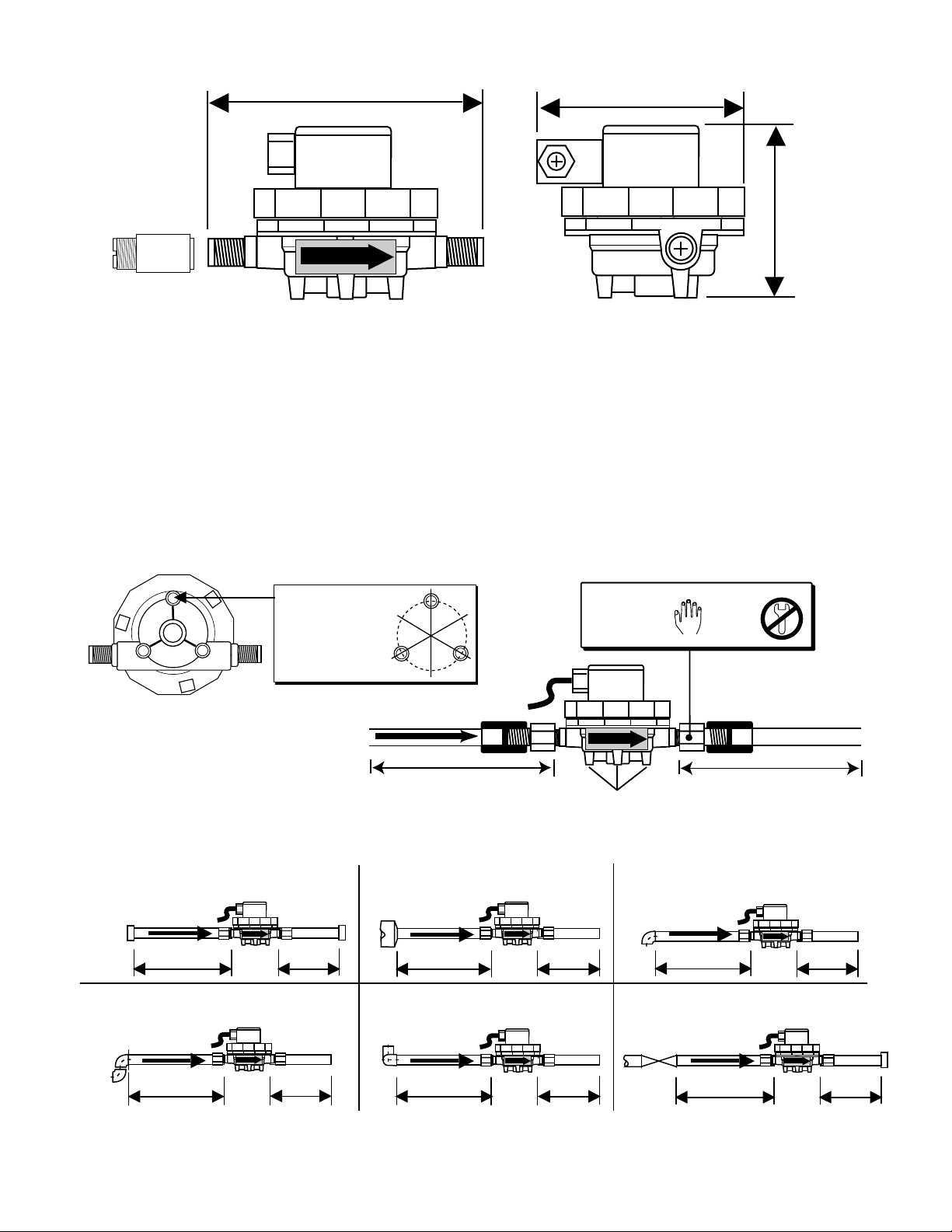

Dimensions

FLOW

100-150 mm (4-6 in.)

100-150 mm (4-6 in.)

FLOW

Pipe Fitting

Adapters

(included)

Hand

tighten

only!

Coupling

Pipe or

tubing

Mounting

tabs (3)

1-1/4 in.G 1/4

Adapter (2 included)

95 mm/3.74 in.

FLOW

68 mm/2.7 in.

65 mm/

2.6 in.

Installation

• The sensor may be installed in any position, although

horizontal flow is recommended with the top of the sensor

pointing upward. If the sensor is not installed horizontally, the linearity error may be greater in the lower part

of the sensor's measurement range. Mounting tabs are

provided for surface mounting using #8 or M4 selftapping screws (customer supplied). See drawings below

for mounting tab hole pattern specifications.

• Install sensor with the arrow pointing in the direction of

flow.

Mounting tabs (3),

#8 or M4 self-tapping

screws required

(customer supplied)

32.5 mm (1.28 in.)

bolt circle

• Always maximize distance between the sensor

and pump source. Never install immediately

downstream of valves, fittings etc. For optimum

performance, a straight flow run of at least 100 to

150 mm (4 to 6 in.) should be provided before

and after the sensor.

• Two pipe fitting adapters (included) convert the

sensor's G1/4 in. straight threads to 1/4 in. NPT

pipe threads for use with common pipe fittings.

Flange

2 x 90° Elbow

www.gfsignet.com

Inlet

Outlet

FLOW

10x I.D. 5x I.D.

FLOW

25x I.D. 5x I.D.

Reducer

15x I.D. 5x I.D.

2 x 90° Elbow

3 dimensions

40x I.D. 5x I.D.

FLOW

90° Elbow

FLOW

20x I.D. 5x I.D.

Valve/Gate

FLOW

FLOW

50x I.D. 5x I.D.

29

Page 3

Wiring

‡ SIGNET

• Use 2-conductor shielded cable for

cable extensions up to

300 m (1000 ft).

• Cable shield must be maintained

through cable splice.

• +GF+ SIGNET Intelek-Pro, use 2536

input card setting

• Refer to your instrument manual for

specific wiring details.

Other Brands

• Pull-up resistor required (10 kΩ

recommended).

• Use 2-conductor shielded cable for

cable extensions up to

300 m (1000 ft).

• Cable shield must be maintained

through cable splice.

2507

Sensor Power:

5 to 24 VDC

(Black wire)

Sensor Signal Output

(Red wire)

1

Wiring to +GF+ SIGNET Instrument

Sensor

ground

2

(Silver wire)

Disregard ground

symbol on connector

Max cable length:

Black

Power

Red

Frequency Input

Shield

Ground

300 m (1000 ft.)

Detachable

connector (side view)

Technical Data

FLOW

General

Flow Range:

-2V sensor: 400 to 2800 mL/m (0.105 to 0.740 U.S. gpm)

-3V sensor: 700 to 4200 mL/m (0.185 to 1.123 U.S. gpm)

-4V sensor: 1300 to 6000 mL/m (0.343 to 1.585 U.S. gpm)

-6V sensor: 3200 to 12000 mL/m (0.845 to 3.170 U.S. gpm)

Linearity: ±0.25% of full range

Repeatability: ±0.25% of full range

Viscosity range: 0.2 to 20.0 centistokes

Pipe connections: G 1/4 in. ports, 1/4 in. NPT (male)

pipe adapters (2 included)

Cable length: 7.6m (25 ft.), can splice up to

300 m (1000 ft.) max.

Sensor

Model

-2V

-3V

-4V

-6V

Cable type: 2-conductor shielded twisted-

pair (22 AWG) (SIGNET 5523-0222)

Shipping Weight: 0.59 kg (1 .3 lbs.)

Wetted Materials

• Housing: PVDF

• Flow insert: PTFE

• Quad ring seal: Viton

®

Max. pressure/temperature:

• 5.5 bar @ -30°C (80 psi @ -22°F)

• 5.5 bar @ 24°C (80 psi @ 75°F)

• 3 bar @ 120°C (45 psi @ 248°F)

• Rotor: PVDF

• Pipe thread adapters: PVDF

• Suitable for clean fluids only

Electrical

Power: 5 to 24 VDC @ 10 mA max from +GF+ SIGNET

instrument or external supply

Output type: Open-collector transistor, 10 mA max. sink

Pressure Drop Across Sensor vs. Flow Rate

PSI

BAR

1.50

21.76

18.13

14.50

10.88

7.25

3.63

1.25

1.00

0.75

0.50

0.25

-2V

-3V

-4V

-6V

K-Factors

Flow

Insert

2 mm

3 mm

4 mm

None

psibar

100

6.9

80

5.5

60

4.

1

40

2.8

20

1.4

0

-40 0 40 80 120 160 200 240 280

-40 -18 4 27 49 71 93 116 138

Pulses Per

U.S. Gallon

5685

3308

2316

1249

Pulses Per

Liter

1502

874

612

330

Pulses Per

mL

1.502

0.874

0.612

0.330

°F

°C

30

02040607080

Flow rate (%) of full scale

www.gfsignet.com

Page 4

Ordering Information

Mfr. Part No. Code Description

3-2507.100-2V 198 801 732 Mini-Flow Sensor, 2mm insert

3-2507.100-3V 198 801 733 Mini-Flow Sensor, 3mm insert

3-2507.100-4V 198 801 734 Mini-Flow Sensor, 4mm insert

3-2507.100-6V 159 000 264 Mini-Flow Sensor, 6mm inlet, no insert

Accessories

Mfr. Part No. Code Description

3-2507.080-2 159 000 254 Rotor, 2507

3-2507.080-3 159 000 255 Quad Ring, 2507

3-2507.080-5 159 000 256 DIN Connector, 2507

3-2507.081-2 198 801 502 2 mm Insert

3-2507.081-3 198 801 503 3 mm Insert

3-2507.081-4 198 801 558 4 mm Insert

5523-0222 159 000 392 Cable, per foot

Engineering Specifications

• The sensor shall operate with a power input of 4.5 to 24 VDC @ 13 mA maximum.

• The sensor shall provide an output signal via an open-collector transistor sinking a maximum of 10 mA.

• Output shall be via a twisted pair, foil-shielded cable with drain wire.

Supplied cable shall be at least 7.6 m (25 ft) long, with a maximum allowable length of 300 m (1000 ft).

• Measurement accuracy and repeatability shall be ±0.25% of full range.

• The sensor shall be available in versions that accommodate nominal flow rates from:

-2V sensor: 400 to 2800 mL/m (0.105 to 0.740 U.S. gpm)

-3V sensor: 700 to 4200 mL/m (0.185 to 1 .123 U.S. gpm)

-4V sensor: 1300 to 6000 mL/m (0.343 to 1.585 U.S. gpm)

-6V sensor: 3200 to 12000 mL/m (0.845 to 3.170 U.S. gpm)

• The sensor body and rotor shall be made of polyvinylidene fluoride (PVDF) that shall accommodate up to 80

psi @ -30°C (-22°F) and 45 psi @ 120°C (248°F).

• The sensor body shall be constructed to allow easy access for inspecting and cleaning internal mechanical

parts without exposing electronic components.

• The sensor shall provide 0.25 in. NPT male fittings for attachment to rigid pipe or tubing.

• The flow sensor shall be

+GF+

SIGNET 2507 Mini Flow.

Viton® is a registered trademark of DuPont Dow Elastomers.

www.gfsignet.com

31

Loading...

Loading...