Page 1

GF Piping Systems

Instruction Manual

2291 Guided Radar Level Transmitter

Page 2

2

Page 3

Original instruction manual

Follow the instruction manual

The instruction manual is part of the product and is an important element of the safety

concept.

Read and follow the instruction manual.

Always keep the instruction manual available of the product.

Pass on the instruction manual to all subsequent users of the product.

3

Page 4

Contents

Original instruction manual ............................................................................................................ 3

Contents ........................................................................................................................................... 4

1 Intended use .......................................................................................................................... 5

2 About this document ............................................................................................................. 5

2.1 Warnings ................................................................................................................................ 5

3 Safety and responsibility ....................................................................................................... 5

4 Transport and storage ........................................................................................................... 6

5 Design and function ............................................................................................................... 6

5.1 Function ................................................................................................................................. 6

5.2 Principle of operation ............................................................................................................ 6

6 Technical data ........................................................................................................................ 7

6.1 Dimensions ............................................................................................................................ 8

7 Installation ............................................................................................................................. 9

7.1 Handling and Storage ............................................................................................................ 9

7.2 Mounting on the tank ...........................................................................................................10

7.2.1 Installation instructions: General notes ..............................................................................10

7.2.2 Specific installation instructions: Gauge – solid applications ...........................................13

7.3 Wiring ....................................................................................................................................14

7.4 Power on and start-up .........................................................................................................17

8 Programming type 2291 .......................................................................................................18

8.1 The display unit .....................................................................................................................18

8.1.1 Behavior in manuals programming mode ..........................................................................18

8.1.2 Manual programming...........................................................................................................19

8.2 Characteristics .....................................................................................................................20

8.2.1 Gauge operating logic when the reflection is lost ..............................................................21

8.2.2 Gain and voltage amplitude..................................................................................................22

8.2.3 Typical signal trends ............................................................................................................24

8.2.4 Automatic adjustment ..........................................................................................................25

8.2.5 Level measurement when more than one phase or layer in the tank ..............................25

9 Troubleshooting ....................................................................................................................27

10 Repair and Maintenance ......................................................................................................30

11 Accessories ...........................................................................................................................30

12 Set-up parameters ...............................................................................................................30

13 Disposal .................................................................................................................................30

4

Page 5

Instruction manual Intended use

Danger of personal injury!

Failure to comply leads to a risk of personal injury!

Risk of damage to property!

Failure to comply leads to a risk of damage to property (loss of time, loss of data, device

fault etc.)!

1 Intended use

The Level Transmitter uses the Time Domain Reflectometry (TDR) measuring principle and

two-wire technology for level measurement. It is designed for measuring the distance, level

and volume of liquids, pastes, slurries and powder products. The device is applicable in tank,

silo, rigid pipe, reaction vessel and level reference vessel.

The device is HART capable; it can be programmed using the GF Signet configuration

software Eview2 which is available on www.gfps.com/level

Please note: All display units also can be programmed directly without any additional

hardware.

2 About this document

2.1 Warnings

This instruction manual contains warning notices that alert you to the possibility of injuries or

damage to property. Always read and pay attention to these warnings!

3 Safety and responsibility

Only use the product for the intended purpose, see Intended Use.

Do not use any damaged or faulty product. Sort out any damaged product immediately.

Have the product and accessories installed only by persons who have the required

training, knowledge or experience.

Regularly train personnel on all questions regarding the locally regulations applying to

occupational safety and environmental protection, especially for pressurize tanks.

5

Page 6

Transport and storage Instruction manual

4 Transport and storage

Protect the product against external forces during transport (impacts, knocks, vibrations

etc.).

Transport and / or store the product unopened in its original packaging.

Protect the product from dust, dirt, moisture as well as heat and ultraviolet radiation.

Ensure that the product is not damaged either by mechanical or thermal influences.

Before assembling, check the product for damage during transport.

5 Design and function

5.1 Function

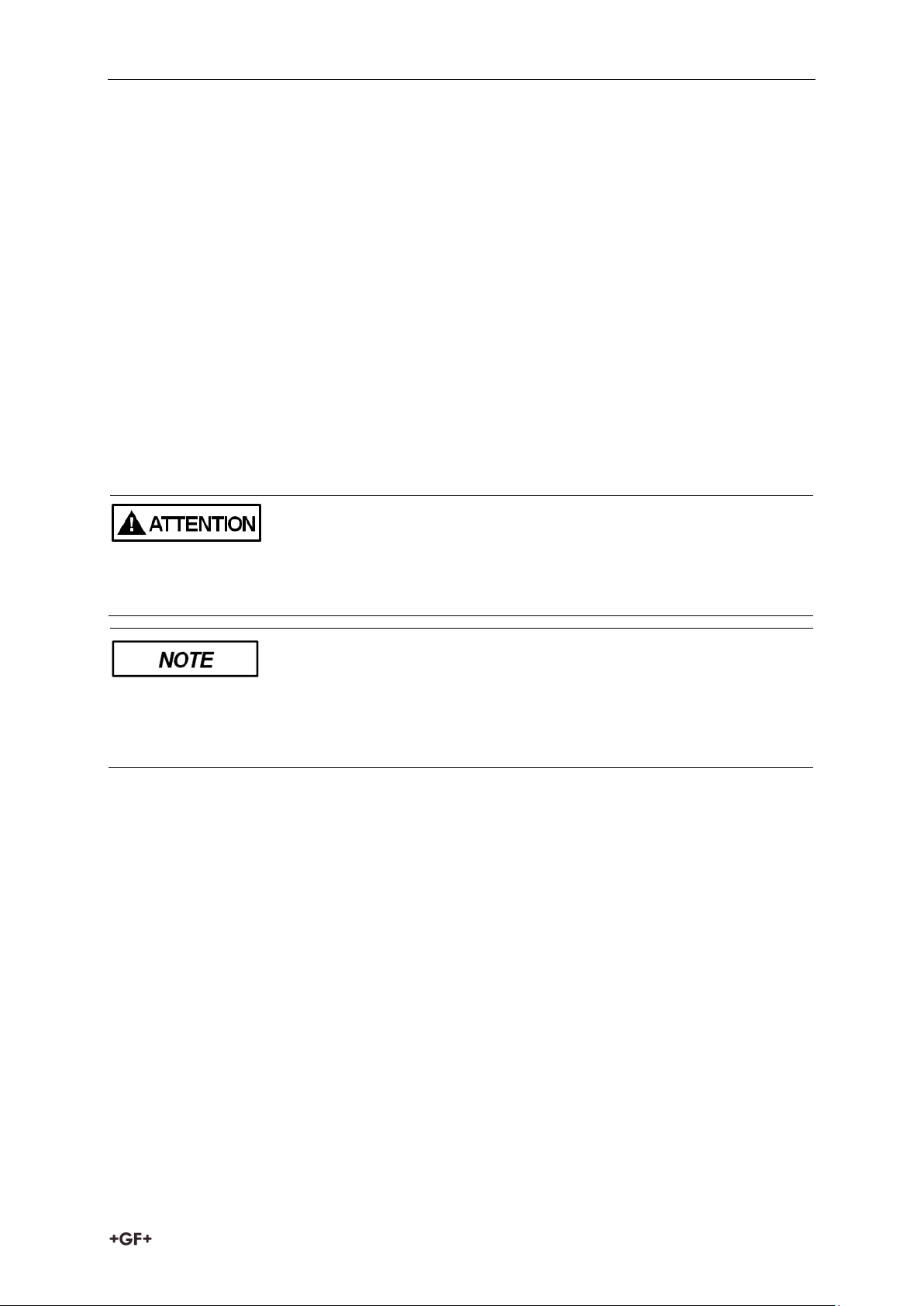

5.2 Principle of operation

The Type 2291 guided microwave level transmitter uses the TDR (Time Domain Reflectometry)

principle. The instrument sends low power ns wide pulses along an electrically conductive

rod, cable or coaxial probe with a known propagation speed (the speed of light). As the pulse

reaches the surface of the medium or phase of two liquids (altered dielectric constant r), a

part of it is reflected back to the electronic module. The efficiency of the reflected signal

depends on the dielectric constant r difference of the mediums or layers. (From the plain

surface of air-water phase the reflected signal's strength will be approx. 80% of the emitted

signal). The reflected pulse is detected as an electrical voltage signal and processed by the

electronics. Level distance is directly proportional to the flight time of the pulse. The

measured level data is converted into 4-20 mA current and HART signals and is displayed on

the LCD display. From the level data further derived measuring values can be calculated such

as volume and mass. The TDR technology is unaffected by the other properties of the medium

as well as that of the space above it.

6

Page 7

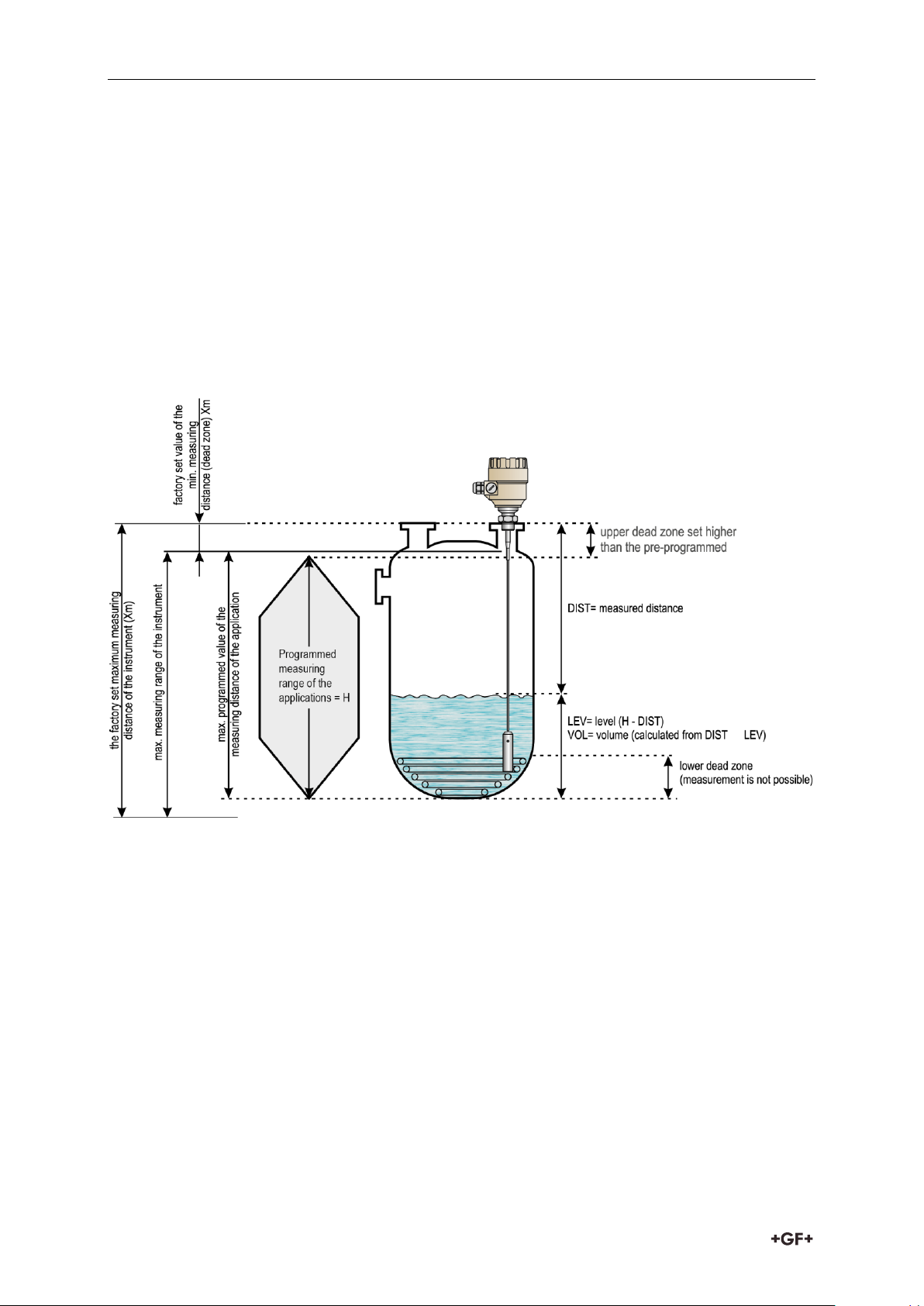

Instruction manual Technical data

Data

Kv value

Input data

Measured values

Between the reference point of the unit and reflection

plane (material surface), distance, level, and volume

Measuring range

Single cable 6 m (19,7 ft), single rod 2 m (6.6 ft)

Housing

Plastic BPT

Medium temperature

–30 °C ... +90 °C (–22 °F ... +194 °F

Minimal dielectric constant (r)

1.9

Medium pressure

- 0.1 … 1.6 MPa (- 1… 16 bar) max. allowed pressure

at 20 °C (68 °F)

Ambient temperature

With display: –20 °C … +60 °C (-4 °F… +140 °F)

Sealing

FPM

Ingress protection

IP 65 (NEMA 4 – 4X)

Power supply

18 … 35 V DC , nominal 24 V DC, Ex version 18 … 28V

Output

data

Output signals

Analogue: 4 … 20 mA, (3.9 … 20.5 mA) passive output,

error 22 mA

BUS: serial line, HART interface, terminal resistor max.

750 ohm

Display: LCD matrix

Accuracy

Liquids: 5mm. For probe

length L ≤10m 0.05% of the

range

Under ideal reflection

and stabilized

temperature conditions.

Resolution

3A

Electrical connection

2 x M20x1.5 metal cable glands Cable diameter: 7 … 13

mm (Ex), or M20x1.5 plastic cable glands, Cable

diameter: 6 … 12 mm

wire cross-section: 0.5 … 1.5 mm2 (shielded cable is

advised) + 2 x NPT ½” for cable gland

Electrical protection

Class III.

Mass (housing)

1.5 kg

6 Technical data

7

Page 8

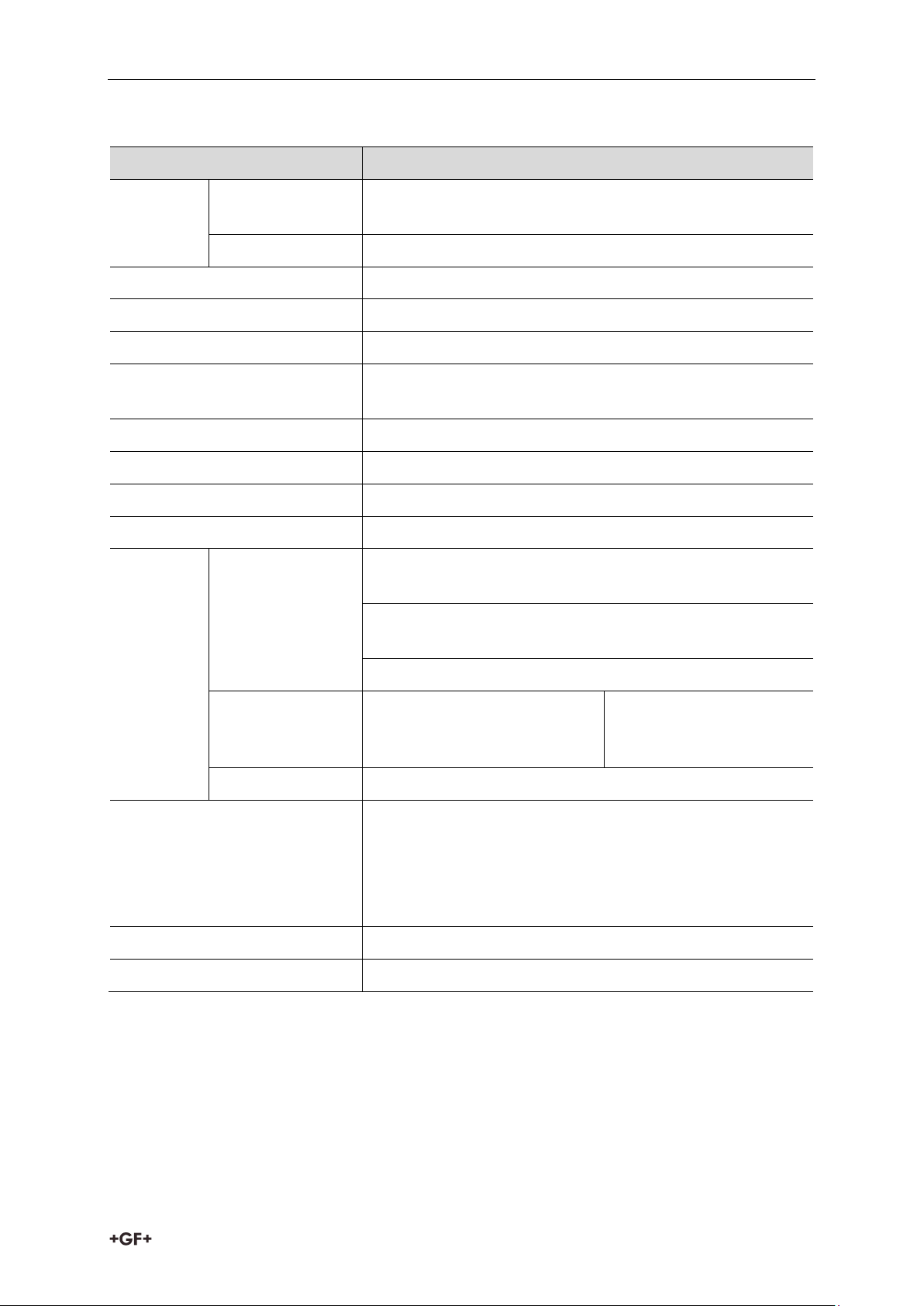

Technical data Instruction manual

Type

Ex marking

II 1 D iaD A20/21 IP 65 T100°C

Intrinsically safe data

Ci ≤ 10 nF, Li ≤ ≤ 30 V, Ii ≤ 150 mA, Pi ≤

1 W For Ex transmitter only EEx ia power supply

should be used

Ex power supply

Uo < 30 V, Io < 150 mA, Po < 1 W, Supply range 18

V … 30 V

Nr.

Description

1

Housing

2

Cable gland

3

Process connection

4

Mono cable probe

5

Weight

6

Mono rod probe

Explosion Protection, Ex markings, Ex limit data

6.1 Dimensions

8

Page 9

Instruction manual Installation

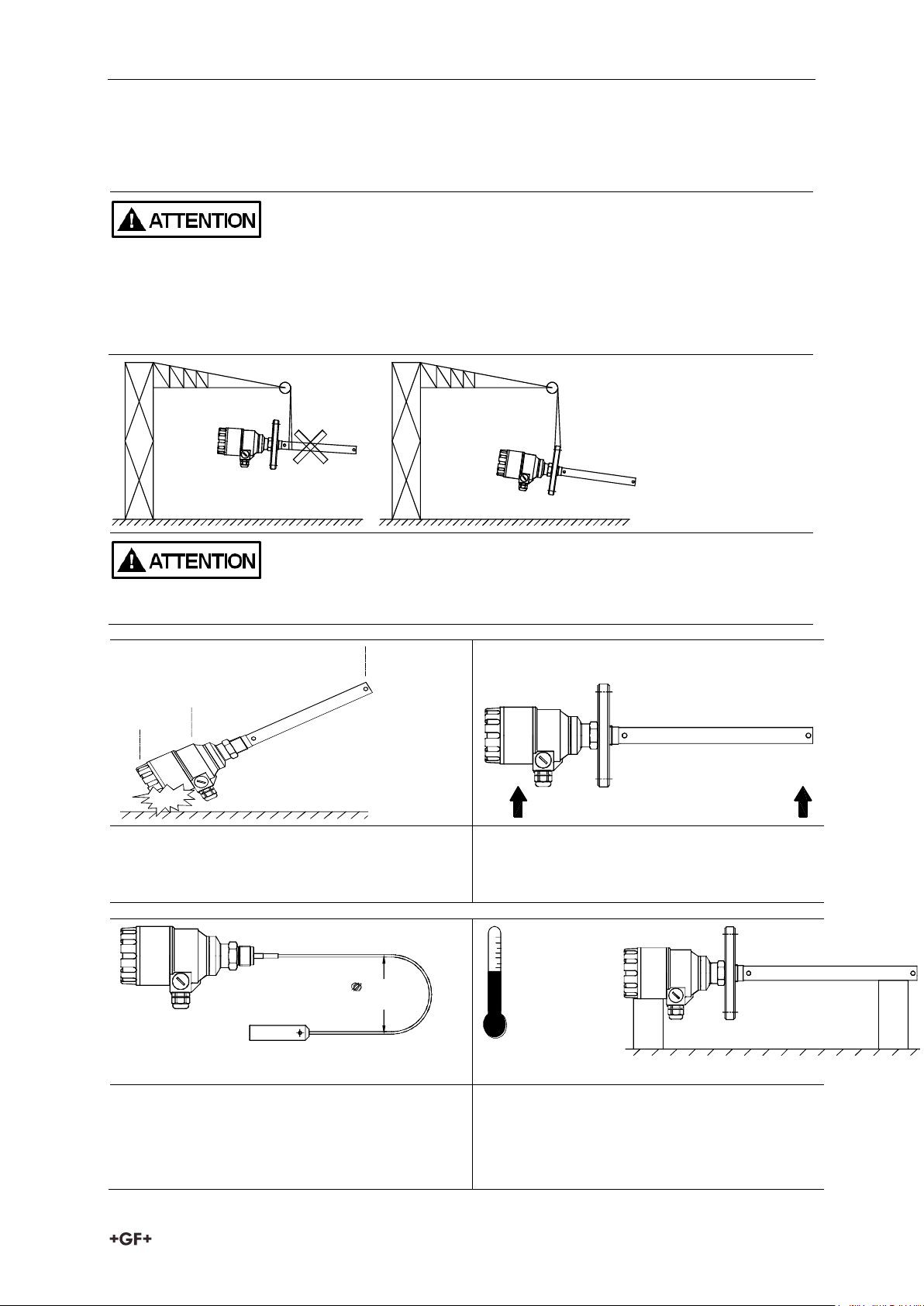

The device will weigh between approximately 1.5 kg or 3 lb, 12 kg or 25 lb.

Carry using both hands to lift the device carefully by the converter housing. If necessary, use

lifting gear. No attempt should be made to lift the instrument by its probe. Caution: The

probe is a critical gauge component. Do not damage - Handle with care!

Avoiding blows - avoid hard blows, jolts, impacts, etc. Caution: fragile electronics

Avoid bending (single rod and coaxial

probes) - Support the probe to avoid

bending.

400mm

minimum

+80°C

-40°C

Avoid cable kinks and fraying

Do not coil the cable less than 400 mm or 16 “

in diameter. Cable kinks or fraying will cause

measurement errors.

Storage temperature

7 Installation

7.1 Handling and Storage

9

Page 10

Installation Instruction manual

Threaded process connections

The simplest and most economical way is to

mount type 2291 directly on the tank with the

1” BSP or 1” NPT threaded connection.

Nozzle height

Do not fit a nozzle longer than its diameter,

especially for single probes and powder

applications.

h ≤ Ød

h = nozzle height and

d = nozzle diameter

Nozzles penetrating into tank

Caution: Do not use nozzles that penetrate

into the tank. This will disturb the emitted

pulse.

7.2 Mounting on the tank

7.2.1 Installation instructions: General notes

Prior the installation some consideration is to be made regarding tank fittings and tank shape.

Nozzle position in relation to the tank walls and other objects inside the tanks

(Warning: this free area will depend on the probe type selected: refer to later on in this

section) type of tank roof, i.e. floating, concrete, integral, etc; and base, i.e. conical, etc.

Whenever working on an installation, remember to: Disconnect the power supply before

starting work. However, the gauge may be installed when the tank contains product.

10

Page 11

Instruction manual Installation

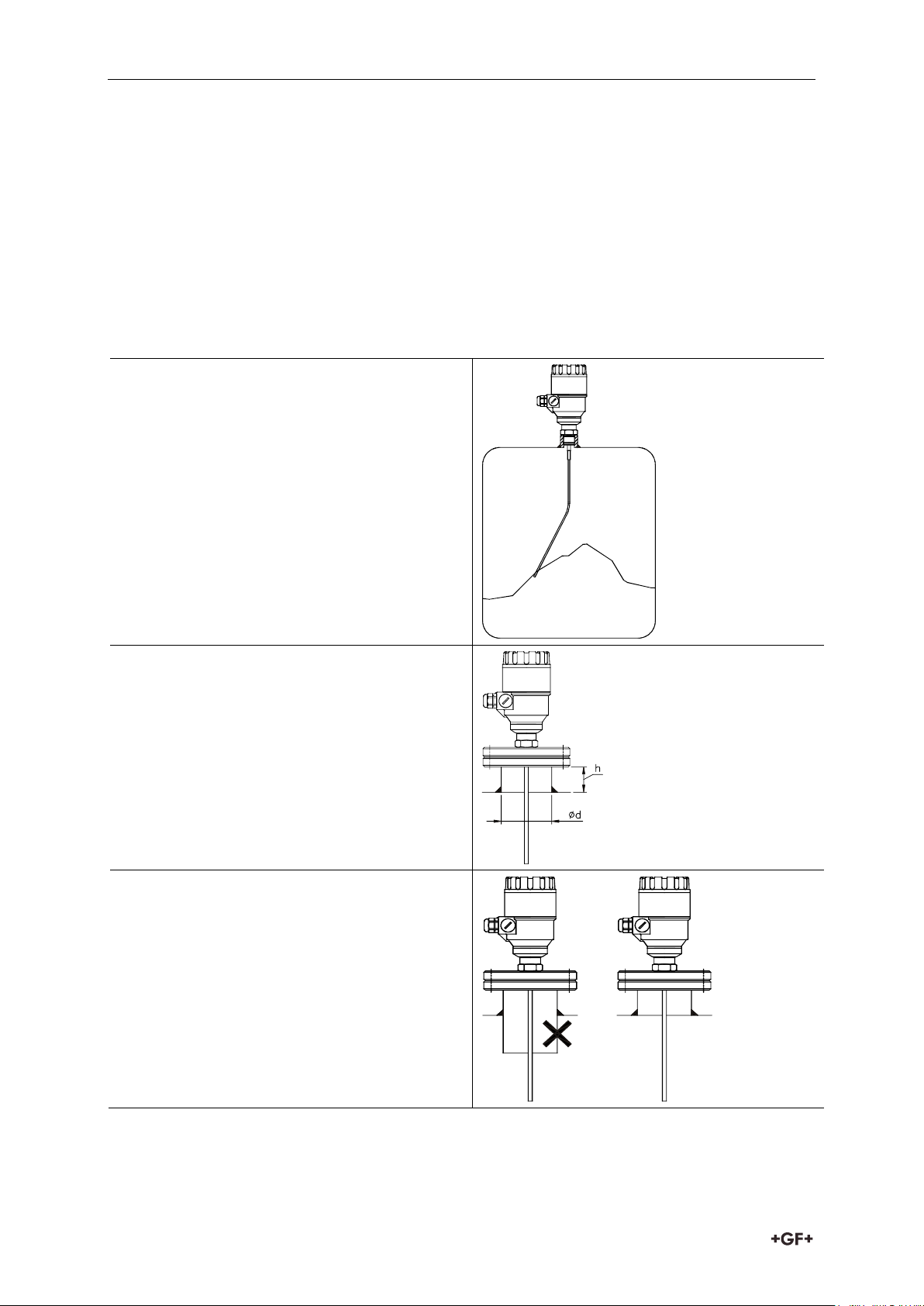

Installation of two devices

If two devices are to be used on the same

tank, these should be mounted at a distance

of at least 2 m or 6.5 ft away from each other.

If not, interferences from the electromagnetic

(EM) fields generated by both instruments

may cause measurement errors.

Coaxial probes: the outer shell of the probe

contains the EM field: no minimum distance

required.

Process connection and entry pipe

Caution: Do not put the nozzle close to the

entry pipe.

Pouring the product directly onto the probe

will give false readings.

Install deflector plate if impossible to

distance gauge from entry pipe.

Install far from

entry pipe

or use a

deflector

plate

medium

Stilling wells

Tanks with floating roofs for petrochemical

applications: Use a stilling well.

1 Stilling well

2 Tank

3 Floating roof

4 Product (petroleum applications)

5 Well fixed to tank base (no roof deformation)

6 Sediment

11

Page 12

Installation Instruction manual

Probes: entanglement, straightness and tank

bottom clearance

Cable probes must be straight once inserted

into the tank.

They must also be far from other objects (e.g.

mixers) to avoid entanglement.

In order to maintain the gauge’s operating

characteristics, it is recommended to avoid

touching the tank bottom with the

counterweights (for cable probes) or probe

end (other types).

Avoid mounting near objects (discontinuities)

inside the tank that influence the probe’s EM

(electromagnetic) field

Install the gauge far from protruding objects

such as: heating tubes, sudden changes in

tank cross-section, tank wall reinforcements

and beams, weld lines and dip-stick pipes,

etc.

1. Agitator

2. Support beam perpendicular to the pulse

direction

3. Abrupt changes in tank cross section

4. Heating tubes

5. Alternative solution: reference chamber

- electromagnetic field is within chamber

6. Gauge electromagnetic field:

Any intruding metallic object will be

detected in this zone if perpendicular to

the emitted pulse direction.

Do not fit the gauge near to these objects.

When measuring liquids the use of a stilling

well or reference chamber is favorable

because it ensures electromagnetic

protection for an accurate measuring.

Use a sunshade if the unit is exposed to

direct sunlight.

No electromagnetic field outside the

reference chamber.

12

Page 13

Instruction manual Installation

Fastening the probe to the tank bottom

Flexible probes can be fastened with a chuck (ring), turnbuckle or similar fastening device to

the tank bottom.

Shortening cable probes

If required, the cable probe can be shortened, but this applies only when used in liquids.

Procedure

1. Detach socket set screw M6x10 (ISO 4026)

with 5 mm Allen (hexagon) key (ISO 2936).

2. Pull cable out of counterweight and

shorten to required length using cable

cutters to prevent the cable wires and

strands from splaying out.

3. Insert cable back into counterweight and

tighten down screws

4. Change configuration parameters to new

probe length; the reference point is the

top edge of the weight.

False readings

1. Do not let the probe touch the side of the

nozzle.

7.2.2 Specific installation instructions: Gauge – solid applications

13

Page 14

Installation Instruction manual

Conical silo nozzles, false readings and

traction on the cable probes

2. High traction forces:

We recommend that the probe should not

be anchored to avoid excessive traction

loads on the cable.

3. Bending and traction:

Position the connection on the roof at ½

radiuses of the tank and with minimum

nozzle height. This will avoid damage due

to bending and traction during emptying.

Product build-up can occur under the nozzle:

this may weaken the pulse.

Avoid cavities that permit the build-up of

deposits.

No.

Description

1

Detach the cover of the unit

2

Guide the cable into the housing

through the cable gland

3

Remove a 4 mm length of isolation

from the wires and cut away the free

part of the shielding

4

Connect the wires of the current loop

to terminals 2 and 3 (any polarity).

5

Pull back the cable till a 10 mm cable

length remains in the housing behind

the cable gland.

Tighten the cable gland using two

spanners.

Check the connection of wires and the

tightness at the cable gland

6

Array the wires in the housing and

screw the cover on the housing.

The 500V AC insulation test should not

be performed on the instrument

because of the overvoltage protection

of the electronics.

7.3 Wiring

Wiring in non-Ex environment Wiring in non-Ex environment

14

Page 15

Instruction manual Installation

Electrostatic discharge (E.S.D.)

Type 2291 non-Ex and Ex gauge electronics

are shielded up to 4 kV against E.S.D.

Note: E.S.D. cannot be solved by Type 2291

E.S.D. protection.

It is the customer’s responsibility to avoid

E.S.D. by grounding the tank, product and

probe installation.

1. Danger of injury

The probe may receive an electrostatic

discharge during operation; earth the

probe by pushing it against tank wall with

a suitably isolated tool just before

touching it to avoid receiving a shock.

2. Earth the entry pipe and product.

Connection to the EP network (grounding).

Screw type terminal (EP) on the housing max. cable cross-section: 4 mm².

The housing of the Type 2291 must be grounded.

Grounding resistance R < 1 Ohm

The shielding of the signal cable should be grounded at the control room.

Avoid coupling of electromagnetic noises place the singnal cable away from power-current

cables.

15

Page 16

Installation Instruction manual

=

U

S

R

A

HART

4 ... 20mA

U

E

MikroTREK 2-wire

mA

L

Power supply

Nominal voltage

24 V DC

Maximum voltage (U

input

):

35 V DC

Minimum voltage (U

input

):

dependent on load impedance, see graph

below

Load impedance RA

Loop resistance, R

loop

R

HART

+ R

cable

+ R

ammeter

Ohm

Minimum load impedance RA

0 Ohm

Maximum load impedance RA

750 Ohm

RHART resistance for HART® communication

250 Ohm, recommended

2291 2-wire

Non-hazardous-duty version

Line A = minimum voltage at the Type 2291 wire terminals

Line B = minimum supply voltage (for voltage drop caused by a 250 Ohm loop resistance)

Example for calculating the power supply: The voltage drop is tested at 22 mA:

U

power minimum 22

U

power minimum 22

16

= 22 mA x load impedance + U

= 22 mA x 250 Ohm + 10 V = 5.5 V + 10 V = 15.5 V

input minimum 22

Page 17

Instruction manual Installation

An ’Ex’ repeater power supply unit must be

used

For calculation of the supply voltage the same

applies as for the standard non-’Ex’ version.

The connected Ex repeater must be HART®-

compatible so that it can be operated with the

GF Signet Eview 2 communication software.

The HART adapter should be connected to the

intrinsically safe input of the Ex repeater!

The units with plastic coating can only be

used in IIB gas class hazardous area.

R

A

=

non area Ex

Ex area

HA RT

Mi roTREK 2c -wire

mA

L

[Ex ia]

4-20mA

EEx ia

2291 2-wire

In order to cover the whole current range, the voltage drop must also be tested at 4 mA:

By analogy, the following applies:

U

power minimum 4

U

power minimum 4

= 4 mA x load impedance + U

input minimum 4

= 4 mA x 250 Ohm + 18 V = 1 V + 18 V = 19 V

At a load impedance of 250 Ohm a power supply voltage of 19 V is sufficient to energize the

current device range of 4 to 20 mA.

Hazardous-duty version

Connect the wires of the current loop to terminals 2 and 3 (any polarity).

The intrinsically safe certified device may only be used in conjunction with an other

intrinsically safe certified equipment.

All the allowed electrical safety data indicated on the nameplate must be observed.

7.4 Power on and start-up

The Type 2291 wire is pre-configured in accordance to customer order specifications and

measurements can be made immediately. A start-up time of less than 60 seconds should be

allowed once the unit is connected and the power is switched on.

If the probe length has been shortened since delivery, please refer to section.

17

Page 18

Programming type 2291 Instruction manual

E

The display based on LCD technology, do not expose to continuous

direct sunlight to avoid display damage.

If type 2291 is not equipped with a sunshade and ambient

temperature exceeds the operating temperature of LCD do not leave

the LCD in the instrument!

Display

64x128 Dot-matrix LCD, glyphs, units and bargraph

Ambient temperature

– 20°C…+60°C

Housing material

PBT fiberglass, plastic (DuPont)

E

8 Programming type 2291

The main parameters of the Type 2291 can be also set using the display unit.

The default display shows the primary measured value (which the output current is calculated

from).Besides the numerical display there is a bargraph on the right showing the value of the

current output.

Programming is helped by a text-based menu. Navigation in the menu can be done with

/

/ / buttons.

8.1 The display unit

The display unit is a 64x128 dot-matrix LCD display which can be plugged into the transmitter.

8.1.1 Behavior in manuals programming mode

After power-up Type 2291 shows the measured value on the LCD.

Remote mode:

If the instrument senses external HART communication it changes its display mode and

shows a "REMOTE MODE" message in the bottom of the display. In this mode the measured

values are refreshed according to the queries of the external HART master.

If the HART master does not refresh the display will show the last measured values.

In the absence of display unit the COM LED indicates the HART communication.

If HART communication stops the COM LED turns off after 120 sec.

Entering the menu can be done by pressing the

pressing and buttons.

Enter into selected menu point with E button. Exit to the previous menu with

The buttons work only in presence of display unit.

When leaving the Type 2291 in (programming) menu after 30 minutes the instrument

automatically returns to measuring mode.

button. Scrolling the menu can be done by

button.

If display unit is removed the instrument instantly returns to measuring mode.

18

Page 19

Instruction manual Programming type 2291

Main menu

BASIC SETUP

OUTPUT SETUP

APPLICATION

Sub-menu

TANK HEIGHT

CURRENT MODE

APPLICATION TYPE

DEAD ZONE

FAILURE CURRENT

CLOSE-END BLOCKING

CURRENT MIN

DAMPING TIME

CURRENT MAX

PROBE LENGTH

ERROR DELAY

E

E

Because manual programming (with display unit) and remote programming (with external

HART master, or GF Signet Eview 2 software) cannot be performed at the same time (as both

of them act like a HART master) only one programming mode has priority and this is manual

programming.

During manual programming the instrument sends the "BUSY" response to the external

HART master device. (HART response code 32 - Device is busy)

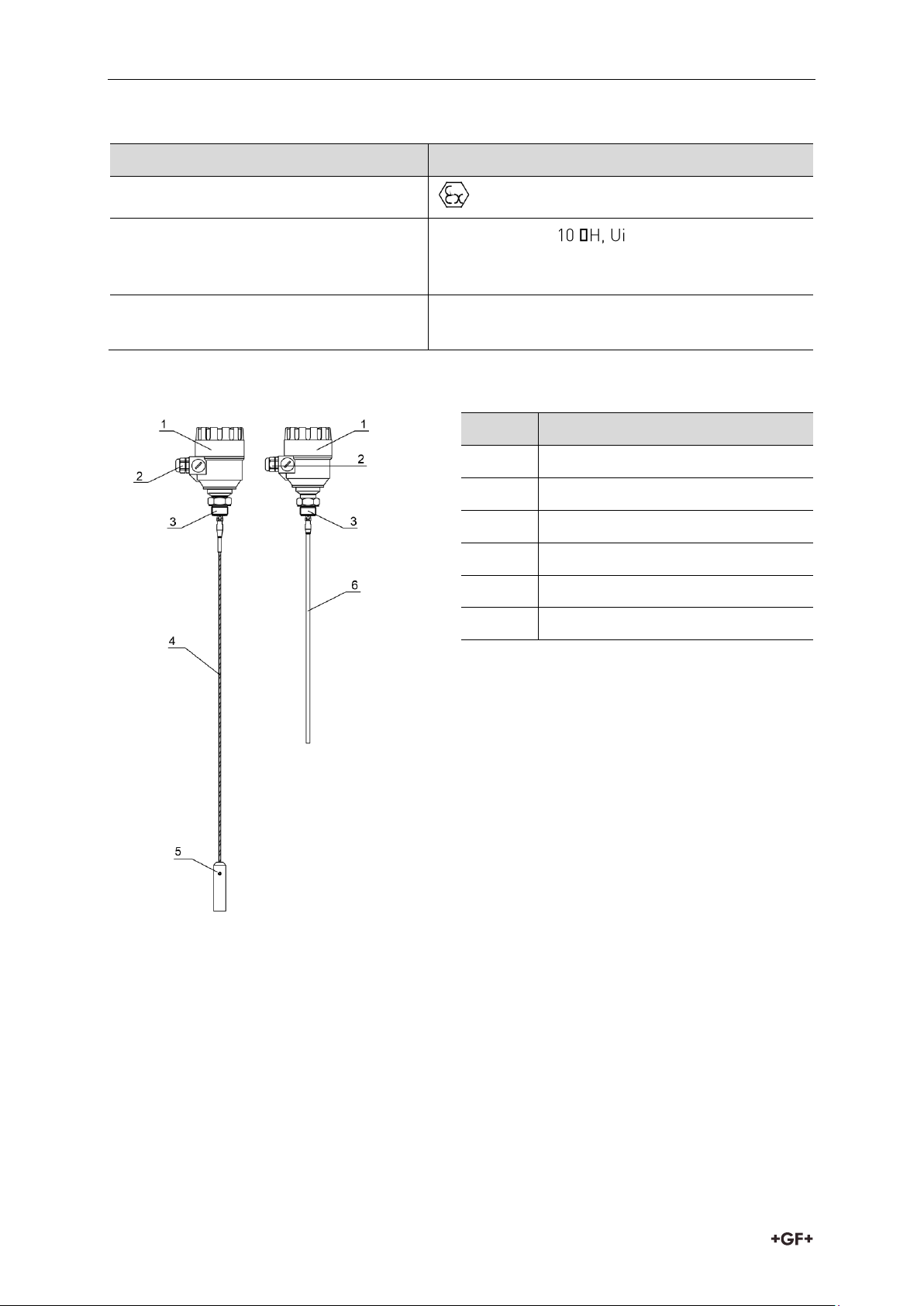

8.1.2 Manual programming

Manu structure

Changing parameters can be done by selecting a sub-menu and pressing E button in two

ways:

Text-based list:

Navigation is the same as in menu lists.

Accept changes with

button, cancel changes (and exit) with button.

Numerical field:

Serves for editing a numeric value.

Editing is helped by a cursor (inverted character).

Change the value of the selected digit with

/

buttons

(There is no under-, and overflow between the characters).

Selecting a digit can be done using the

Accept changes with

button.

button.

After accepting the parameter change the Type 2291 checks the parameter and

downloads it.

If parameter is incorrect the CHECK/WRITE FAILED! message appears.

19

Page 20

Programming type 2291 Instruction manual

Nr.

Description

A

Tank height

B

Probe length

C

Detection delay

D

Non-measurable zone

E

Minimum distance between

non-measurable zone and

dead zone

F

Upper dead zone

G

Measuring range

H

Reference point at tank

bottom

8.2 Characteristics

This subsection explains:

the four principle configurations for setting up a measurement scale and what the user

should be aware of in each case;

what happens when the tank is full or empty;

what is the level threshold and how to modify it

what happens when level is measured when more than one product in the tank;

The measurement scale:

Five possible configurations for analogue current output – with “Level” selected in the EView

2 configuration software.

The configurations described below are illustrated in the above diagram

1. The “current output” range is smaller than the max. possible measuring range

2. The “current output” range is equal to the measuring range:

Scale min.: 4 mA = tank height – probe length + H

Scale max.: 20 mA = tank height – dead zone

3. The “current output” range is greater than the measuring range:

Scale min.: 4 mA = 0.0

Scale max.: 20 mA = tank height – dead zone

4. The “current output” range is greater than the measuring range:

Scale min.: 4 mA = tank height – probe length + H

Scale max.: 20 mA = tank height

20

Page 21

Instruction manual Programming type 2291

Zone 1 : Dead and detection delay zones

Marker “Tank full” and “Level lost” is displayed when

the product enters the dead zone and no reflection is

found.

This will also occur once the level reflection is within the

detection delay zone.

The gauge assumes the tank is full and displays the

maximum level value.

The gauge searches for a reflection along the entire

length of the probe.

Zone 2 : Full zone (and dead zone)

Marker “Tank full” is displayed in this zone.

If the gauge loses the signal in this zone, it reacts as in

zone 1: the tank is assumed to be full.

The gauge searches for a reflection along the length of

the probe.

Zone 3 : Central measurement zone

The gauge searches along the length of the probe for the

largest pulse reflection.

If the pulse is lost the reading freezes at the last value.

Marker “Level lost” will be displayed.

Zone 4 : Empty zone

If the reflection is lost here then the gauge assumes the

tank is empty and marker “tank empty” is displayed.

The gauge searches for a reflection in this zone but

makes a search along the entire length of the probe once

every minute.

The reading will remain frozen during this time.

The short circuit reflection will become larger than

product reflection at this time.

5. The “current output” range is greater than the measuring range:

Scale min.: 4 mA = 0.0

Scale max.: 20 mA = tank height

NOTE: The reference point for distance measurements is the bottom of the flange face.

8.2.1 Gauge operating logic when the reflection is lost

The product reflection pulse is usually lost when the level is in the top dead zone or near the

bottom of the tank. The diagram below shows the action taken by the gauge depending on

where the last reflection was lost.

21

Page 22

Programming type 2291 Instruction manual

8.2.2 Gain and voltage amplitude

As explained in the measuring principle in the introduction, the level of a product is converted

from a return signal (the product reflection) received by the gauge: this signal has taken a

certain amount of time to return to the gauge and it has a certain strength / size measured

in milli-volts (dependant on the dielectric constant r of the product).

All pulse signals returning to the gauge electronics block (including flange, obstruction and

the product surface reflections) are converted to voltage amplitudes. The gauge’s

microprocessor looks for part of the largest signal that is over a set voltage amplitude, called

the “threshold”, and identifies this as the product being measured. For this signal to be

usable by the gauge, the microprocessor will amplify the signal by increasing the gain. Once

the signal is within a set “working” range, the gauge follows this signal. The gauge registers

any changes in time for this part of the signal to return to the converter and translate this into

a displayed level or volume.

Gain is a function of voltage amplitude.

This defines the default threshold value when the gauge is searching for the product level. A

strong return signal will be given a low gain (i.e. Gain 0 or a small amplification). However, if

the signal is very weak, then a Gain of 3 (i.e. high signal amplification) is given.

Example of signal amplification:

The level signal can be optimized by way of two factors:

22

Page 23

Instruction manual Programming type 2291

Gain

0 1 2 3 Amplification factor

1.05

2.10

4.37

8.93

Nr.

Description

1

Initial pulse

2

Flange reflection

3

Level signal

4

Interference signal

Nr.

Description

1

Initial pulse

2

Flange reflection

3

Level signal

4

Interference signal

5

Threshold

Amplification factor

The amplitude of the signals is proportional to the dielectric constant r of the product. At low

amplitudes the signal should be amplified.

The amplification factor is dependent on the dielectric constant r and on the probe type. The

device sets the gain automatically.

The following factors apply to the set gain:

Level threshold

The level threshold suppresses interference signals so that only the reflections from the

product surface (level signal) are shown. The factory setting of the level threshold is suitable

for standard applications.

The threshold will need to be adjusted in the case of very low dielectric constants r, multiple

interference reflections or unfavourable installation conditions.

The illustrations below show interference signals when the oscilloscope function is used.

These reflections can be due to various causes, e.g. tank internals or multiple reflections

within the measuring range.

Even though the interference signals are very weak, the threshold should nevertheless be set

to a value above these signals.

23

Page 24

Programming type 2291 Instruction manual

In the diagram above it can be seen that the level of the threshold is not constant:

400 mV at 1000 mm or 3.3 ft, and only 250 mV at 10000 mm or 33 ft. No attenuation is required

at a probe length ≤ 3000 mm or 10 ft. The form of the threshold is dependent on attenuation

and is automatically adjusted by the device over the measured length.

Setting the level threshold

If the level threshold is set too high, i.e. it is greater than the amplitude of the level reflection,

the device will not find any level even with maximum amplification.

If the level threshold is set too low, i.e. it is below the amplitude of some of the interference

signals, the device will identify and indicate one of these interference signals as a level

reflection only if the tank is empty.

Precise setting of the level threshold is especially important when the dielectric constant r is

low.

To set, the level (amplitude of the reflection) must be known. A level of 500 mm or 20” is ideal.

The level threshold should be half-way between the invalid interference signals and the level

reflection signal.

The reflection from the probe tip, which is clearly identifiable at a low r value, does not need

to lie below the level threshold.

8.2.3 Typical signal trends

The following diagrams show characteristic signals that have been recorded with the

oscilloscope function.

Rod or cable probe with gain 1 Rod or cable probe with gain 2

The signal from coaxial probes does not include the flange reflection, due to the mechanical

setup which does not produce any change in impedance at the flange.

The amplitude of reflection from the product surface increases as the level rises and

decreases as the level falls

24

Page 25

Instruction manual Programming type 2291

Nr.

Description

1

is located between a distance of

2000 and 4000 mm or 6.5 and 13

feet.

2

is the level threshold. This is shown

below:

Nr.

Description

1

is located over 4000 mm or 13 feet.

2

threshold

3

interference signals

8.2.4 Automatic adjustment

To maintain a sufficiently strong reflection signal, the gain is adjusted automatically.

When the amplitude of the level reflection decreases, the gain will increase to compensate for

the loss in signal amplitude. Gain and level threshold thus maintain the same proportion.

At gain 3, the level signal

The amplification factor is 3

The level has dropped, increasing the distance between level and flange.

The interference signals are now below the level threshold (2), whose lower limit is 50 mV.

As in the diagram above, the amplification factor is 3.

In both cases, the automatically adjusted gain of the threshold indicates all signals located

above one-half of the amplitude of the level signal.

In the event of operational or installation faults, you can frequently identify the cause of the

fault by means of this function and normally eliminate it yourself.

8.2.5 Level measurement when more than one phase or layer in the tank

Level can be measured with more than one phase in the tank.

This requires setting a parameter in the factory menu (Fct. 1.1.3: Application Type) to the

following measurement mode:

2 liquids, 1 level: For measuring level with two or more phases

1 liquid, 1 level: For measuring one phase or liquid

25

Page 26

Programming type 2291 Instruction manual

Nr.

Description

1

Level measurement signal

2

Threshold

Application Type set to 1 liquid, 1 level, the wire will

search for the return signal with the highest

amplitude (i.e. higher than the threshold). It will

measure the oil level.

Nr.

Description

1

Threshold

2

Level signal

3

Oil-water interface signal

Application Type set to 2 liquids, 1 level, the wire

will search for the first return signal higher than

the control threshold. It will correctly measure the

oil level (i.e. “level”).

Characteristics

The level of the top product can be detected

if it has a minimum layer of approximately 100 mm - when measuring a top product with a

dielectric constant of r =2.4.

The mode “2 liquids, 1 level” permits level to be measured even when more than 2 liquids are

present in the tank. The first return signal is identified as being level and the second is

ignored.

This mode may be used with all probe types

Example application 1:

Level measurement of oil (1 liquid in the tank)

Example application 2:

Level measurement when there are 2 liquids (oil/water) in the tank – using a correctly

configured gauge

26

Page 27

Instruction manual Troubleshooting

Event

Fault

Action

Error messages

“Tank full” status

marker on*, reading

frozen at max. or min.

value

No fault. The level has reached

(and possibly risen above) the top

configured measurement limit

and is either displaying the

maximum (when measuring level)

or minimum (when measuring

distance) output.

None.

Measurements should be

normal once the level is in the

configured measurement

range.

“Tank empty” status

marker on*, reading

frozen at max. or min.

value

No fault. The level has entered the

gauge’s bottom dead zone and

can no longer detect a return

signal. Either the maximum (when

measuring distance) or minimum

(when measuring level) output is

displayed.

None.

Measurements should be

normal once the level is in the

configured measurement

range.

“Tank full” and “Level

lost” status marker

on*, reading frozen at

max. or min. value

No fault. The level has entered the

gauge’s top dead zone and can no

longer detect a return signal.

Empty the tank below the top

measurement range limit and

check the measurement.

“Level lost” status

marker on*, reading is

frozen

The instrument has lost the level

signal, has searched but not yet

found the return pulse. This may

occur if the pulse has dropped

below the threshold. Parasite

signals from the flange or

obstructions in the tank may

render the gauge unable to

identify the correct signal.

Ensure that tank is emptied

below maximum level and

check the measurement.

“Reference not found”

status marker on*

Occurs when there is a problem

with the time base on the HF

board.

Please contact GF Piping

Systems.

“Level lost” and

“Reference not found”

status markers on*,

reading frozen

The probe has received an

electrostatic discharge.

The gauge will search for the

level again and resume

readings. If the reading

remains frozen then the signal

converter may have been

damaged by ESD and may need

replacing.

Please contact GF Piping

Systems

“Flange not found”

status marker on*

The signal converter has been

incorrectly configured to measure

with a cable or rod probe when it

is equipped with a coaxial probe.

Contact GF Piping Systems for

the corrective procedure.

9 Troubleshooting

27

Page 28

Troubleshooting Instruction manual

Event

Fault

Action

Error messages

This may be also due to

installation on a long nozzle which

has the effect of attenuating the

flange pulse.

“Delay out of limits”

status marker on*,

reading is frozen.

The emitted pulse has not been

detected.

The gauge will not work until it

has been found

Contact GF Piping Systems for

the corrective procedure.

“Delay out of limits”

status marker on*,

reading is frozen.

The emitted pulse has not been

detected.

The gauge will not work until it

has been found.

The signal converter may need

replacing. Please contact GF

Piping Systems.

“Negative voltage

error”*

Occurs when there is a problem

with the time base on the HF

board.

Please contact GF Piping

Systems.

“VC01 voltage error” *

“VC02 voltage error” *

“Reprogramming

FPGA” *

Event

Fault

Action

General operation

Instrument is not

accurate with a

product that has a

high dielectric

constant. A constant

offset is observed

when taking

measurements.

Tank height is not correct.

Check current output and tank

height parameters.

If the signal converter has been

replaced, verify that factory

calibration parameters are still

the same.

Ask GF Piping Systems for the

factory calibration sheet (if not

supplied) and the password for

access to the factory menu.

The Type 2291 2-wire

indicates an incorrect

level value.

The Type 2291 2-wire measures a

non-valid reflection.

Check the tank for

obstructions and verify that the

probe is clean.

In the case the indicated level

is close to the nozzle, increase

the detection delay and the

dead zone with the same ratio

or increase the threshold level

if the full measurement range

is essential.

The threshold level must be

adjusted so that it masks the

* Gauge connected to GF Signet EView2 software.

28

Page 29

Instruction manual Troubleshooting

Event

Fault

Action

General operation

disturbances. It also gives

enough margin for detection of

the level pulse.

Very large pulses along the

measurement signal

(same amplitude as the initial

pulse) can be caused by a

probe which is touching the

nozzle or the tank side (see

section 1.3.5). Ensure that no

contact is possible.

Instrument is not

accurate when there

are two or more

phases in the tank.

The instrument may be incorrectly

configured for this type of

application i.e. it is measuring the

interface instead of the level.

Contact GF Piping Systems for

the corrective procedure or

refer to the Service Manual.

Check if application type had

been set to: Application Type is

set to “2 liquids, 1 level”.

Check also that there is a layer

of more than 100 mm of top

product above the bottom

product.

Event

Fault

Action

Electrical Connections and Communication Output

Current Output value <

4 mA.

No power supply

Check the power supply

Connection of the device is

incorrect.

Check the connection between

the device and the power supply.

The calibration of the current

output is incorrect.

Execute the calibration if you have

authorized access or contact GF

Piping Systems Service centre.

Reads 22 mA.

An error has occurred.

This happens in case the range 420 mA / error 22 mA is selected.

Check the status of the device by

selecting the marker window (F8)

or enter the status (4.0) menu of

the HART® communicator.

The device is in its start-up

phase

Wait 50 seconds.

If the current value drops to a

value between

4 and 20 mA, and goes

immediately back to 22 mA,

contact your GF Piping Systems

Service Centre.

29

Page 30

Repair and Maintenance Instruction manual

Remote program 90

Basic setup

Output setup

Application

Service

Application 97

Treshold

Service 89

Service code

Application type

Epsilon R

Treshold 98

Ampl= 00345 mV

Dist.= 1.25 m

Pulse ampl.= 820mV

Gain= 3

Output setup 92

Current mode

Current min.

Current max.

Failure current

Error current

Length unit 120

m

cm

mm

ft

inch

Error delay 95

None

10 sec

20 sec

30 sec

1 min

2 min

5 min

15 min

Current mode 93

Level

Distance

Volume

Ullage volume

Failure current 94

Hold

22 mA

Application type 94

1 Liq. 1 Level

2 Liq. 1 Level

Basic setup 91

Length unit

Tank height

Dead zone

Close-end blocking

Damping time

Probe length

A product marked with this symbol must be taken to a separate collection point for

electrical and electronic devices. If you have any questions regarding disposal of

the product, please contact your national agent for GF Piping Systems.

10 Repair and Maintenance

Type 2291 does not require maintenance on a regular basis. In some very rare instances,

however, the probe may need a cleaning from deposited material. This must be carried out

gently, without damaging the probe. Repairs during or after the warranty period are carried

out exclusively at the Manufacturers. The equipment sent back for repairs should be cleaned

or neutralized (disinfected) by the User.

11 Accessories

The level transmitter must be operated in intrinsically safe circuit only.

The metal enclosure of the unit must be connected to the EP circuit.

12 Set-up parameters

Parameters in the Service Menu are read-only parameters. Changing of these parameters

require the service code of the instrument.

13 Disposal

Before disposing of the different materials, separate them into recyclable materials,

normal waste and special waste.

Comply with local legal regulations and provisions when recycling or disposing of the

product, individual components and packaging.

Comply with national regulations, standards and directives.

30

Page 31

31

Page 32

GF Piping Systems

Worldwide at home

Our sales companies and representatives

ensure local customer support in over 100 countries

www.gfps.com

Argentina / Southern South America

Georg Fischer Central Plastics

Sudamérica S.R.L.

Buenos Aires, Argentina

Phone +54 11 4512 02 90

gfcentral.ps.ar@georgfischer.com

www.gfps.com/ar

Australia

George Fischer Pty Ltd

Riverwood NSW 2210 Australia

Phone +61 (0) 2 9502 8000

australia.ps@georgfischer.com

www.gfps.com/au

Austria

Georg Fischer

Rohrleitungssysteme GmbH

3130 Herzogenburg

Phone +43 (0) 2782 856 43-0

austria.ps@georgfischer.com

www.gfps.com/at

Belgium / Luxembourg

Georg Fischer NV/SA

1070 Bruxelles/Brüssel

Phone +32 (0) 2 556 40 20

be.ps@georgfischer.com

www.gfps.com/be

Brazil

Georg Fischer Sist. de Tub. Ltda.

04571-020 São Paulo/SP

Phone +55 (0)11 5525 1311

br.ps@georgfischer.com

www.gfps.com/br

Canada

Georg Fischer Piping Systems Ltd

Mississauga, ON L5T 2B2

Phone +1 (905) 670 8005

Fax +1 (905) 670 8513

ca.ps@georgfischer.com

www.gfps.com/ca

China

Georg Fischer Piping Systems Ltd

Shanghai 201319

Phone +86 21 3899 3899

china.ps@georgfischer.com

www.gfps.com/cn

Denmark / Iceland

Georg Fischer A/S

2630 Taastrup

Phone +45 (0) 70 22 19 75

info.dk.ps@georgfischer.com

www.gfps.com/dk

Finland

Georg Fischer AB

01510 VANTAA

Phone +358 (0) 9 586 58 25

Fax +358 (0) 9 586 58 29

info.fi.ps@georgfischer.com

www.gfps.com/fi

France

Georg Fischer SAS

95932 Roissy Charles de Gaulle Cedex

Phone +33 (0) 1 41 84 68 84

fr.ps@georgfischer.com

www.gfps.com/fr

Germany

Georg Fischer GmbH

73095 Albershausen

Phone +49 (0) 7161 302-0

info.de.ps@georgfischer.com

www.gfps.com/de

India

Georg Fischer Piping Systems Ltd

400 083 Mumbai

Phone +91 224007 2001

branchoce@georgfischer.com

www.gfps.com/in

Indonesia

George Fischer Pte Ltd –

Representative Oce

Phone +62 21 2900 8564

Fax +62 21 2900 8566

sgp.ps@georgfischer.com

www.gfps.com/sg

Italy

Georg Fischer S.p.A.

20063 Cernusco S/N (MI)

Phone +39 02 921 861

it.ps@georgfischer.com

www.gfps.com/it

Japan

Georg Fischer Ltd

556-0011 Osaka,

Phone +81 (0) 6 6635 2691

jp.ps@georgfischer.com

www.gfps.com/jp

Korea

GF Piping Systems

Georg Fischer Korea Co., Ltd.

Unit 2501, U-Tower

120 HeungdeokJungang-ro (Yeongdeok-dong)

Giheung-gu, Yongin-si, Gyeonggi-do, Korea

Phone: +82 31 8017 1450

Fax : +82 31 217 1454

kor.ps@georgfischer.com

www.gfps.com/kr

Malaysia

George Fischer (M) Sdn. Bhd.

40460 Shah Alam, Selangor Darul Ehsan

Phone +60 (0) 3 5122 5585

Fax +603 5122 5575

my.ps@georgfischer.com

www.gfps.com/my

Mexico / Northern Latin America

Georg Fischer S.A. de C.V.

Apodaca, Nuevo Leon

CP66636 Mexico

Phone +52 (81) 1340 8586

Fax +52 (81) 1522 8906

mx.ps@georgfischer.com

www.gfps.com/mx

Middle East

Georg Fischer

Piping Systems (Switzerland) Ltd

Dubai, United Arab Emirates

Phone +971 4 289 49 60

gcc.ps@georgfischer.com

www.gfps.com/int

Netherlands

Georg Fischer N.V.

8161 PA Epe

Phone +31 (0) 578 678 222

nl.ps@georgfischer.com

www.gfps.com/nl

Norway

Georg Fischer AS

1351 Rud

Phone +47 67 18 29 00

no.ps@georgfischer.com

www.gfps.com/no

Philippines

George Fischer Pte Ltd

Representative Oce

Phone +632 571 2365

Fax +632 571 2368

sgp.ps@georgfischer.com

www.gfps.com/sg

Poland

Georg Fischer Sp. z o.o.

05-090 Sekocin Nowy

Phone +48 (0) 22 31 31 0 50

poland.ps@georgfischer.com

www.gfps.com/pl

Romania

Georg Fischer

Piping Systems (Switzerland) Ltd

020257 Bucharest - Sector 2

Phone +40 (0) 21 230 53 80

ro.ps@georgfischer.com

www.gfps.com/int

Russia

Georg Fischer

Piping Systems (Switzerland) Ltd

Moscow 125040

Phone +7 495 748 11 44

ru.ps@georgfischer.com

www.gfps.com/ru

Singapore

George Fischer Pte Ltd

11 Tampines Street 92, #04-01/07

528 872 Singapore

Phone +65 6747 0611

Fax +65 6747 0577

sgp.ps@georgfischer.com

www.gfps.com/sg

Spain / Portugal

Georg Fischer S.A.

28046 Madrid

Phone +34 (0) 91 781 98 90

es.ps@georgfischer.com

www.gfps.com/es

Sweden

Georg Fischer AB

117 43 Stockholm

Phone +46 (0) 8 506 775 00

info.se.ps@georgfischer.com

www.gfps.com/se

Switzerland

Georg Fischer

Rohrleitungssysteme (Schweiz) AG

8201 Schahausen

Phone +41 (0) 52 631 30 26

ch.ps@georgfischer.com

www.gfps.com/ch

Taiwan

Georg Fischer Co., Ltd

San Chung Dist., New Taipei City

Phone +886 2 8512 2822

Fax +886 2 8512 2823

www.gfps.com/tw

United Kingdom / Ireland

George Fischer Sales Limited

Coventry, CV2 2ST

Phone +44 (0) 2476 535 535

uk.ps@georgfischer.com

www.gfps.com/uk

USA / Caribbean

Georg Fischer LLC

9271 Jeronimo Road

92618 Irvine, CA

Phone +1 714 731 88 00

Fax +1 714 731 62 01

us.ps@georgfischer.com

www.gfps.com/us

International

Georg Fischer

Piping Systems (Switzerland) Ltd

8201 Schahausen/Switzerland

Phone +41 (0) 52 631 30 03

Fax +41 (0) 52 631 28 93

info.export@georgfischer.com

www.gfps.com/int

The technical data are not binding. They neither constitute expressly

warranted characteristics nor guaranteed properties nor a guaranteed durability.

They are subject to modification. Our General Terms of Sale apply.

GFDO_6447_4 (07.16)

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2016

Loading...

Loading...