Page 1

2291 Guided Wave Radar Level Transmitter

Features

• Measuring range up to 6 m (19.6 ft)

• Accuracy: ± 5 mm (0.2 in)

• PP / PFA coated probes available on request

• Rod & cable versions available

• Minimum εr 1.9

• 2-wire version

• Graphic LCD display

• 4 to 20 mA + HART output

• Medium temperature range: -30 °C to +90°C

(-22 °F to +194 °F)

The 2291 Guided Wave Radar level transmitter is

designed for continuous level measuring of conductive

or non-conductive liquids, pulps and solids. The 2291

level gauge operates based on the well-known TDR

(Time Domain Reflectometry) principle. Micropulses are

sent along a probe guide at the speed of light. As soon

as the impulse reaches the surface of the medium, it is

reflected back to the electronic module. Level distance

is directly proportional to the flight time of the impulse.

The reflected signal is dependent on the dielectric

constant of the material; the feasibility of the

measurement is ε

unaffected by the properties of the medium as well

as that of the space above it. Measurement is also

unaffected by the change in the physical properties of

the materials such as temperature, pressure, dielectric

constant.

≥ 1.9. The TDR technology is

r

• Maximum process pressure: 40 bar (580 psi)

• IP67 protection

Applications

• Inventory Tanks

• Day Tanks

• Process Vessels for Mixing & Batching

• Bypass Applications (requires calibration)

• Stilling-wells

• Powders

• Slightly Conductive Foams

• Low Dielectric Constant Liquids

Page 2

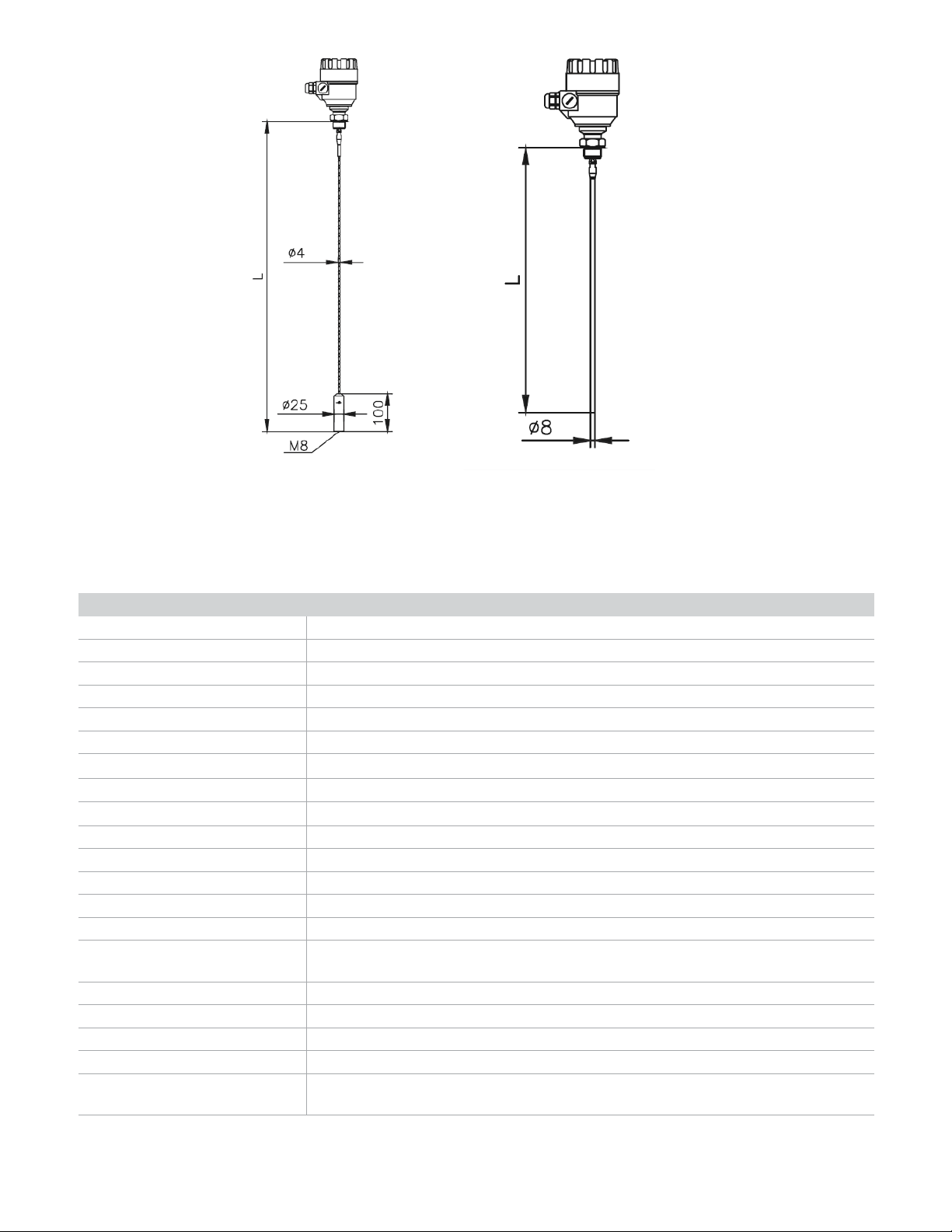

Dimensions

Type 2291 Cable Version

L = 6 m (19.69 ft)

Type 2291 Rod Version

L = 2 m (6.56 ft)

Specifi cations

General

Measured Values Level, Distance; Calculated values: Volume, Mass

Measuring Range Depends on the probe type and dielectric constant (ε

Probe Types Mono cable, mono rod

Accuracy: Linearity Error

1

For liquids: ± 5 mm (0.2 inch), if probe length ± 10 m (32 feet): ± 0.05 % of the probe length

Accuracy: Resolution ± 3 μA

Minimal ε

of the Medium 1.9

r

Power Supply 18 V… 35 V DC

Output: Digital Communication 4-20 mA + HART

Output: Display Graphical LCD display unit

Medium Temperature -30 °C… +90 °C (-22 °F… +194 °F),

Maximum Medium Pressure 4 MPa (40 bar g/ 580 psi g); with plastic lined fl ange: max. 2.5 MPa (25 bar g/ 363 psi g)

Ambient Temperature -20 °C… +60 °C (-4 °F… +140 °F)

Process Connection 1” BSP, 1” NPT Thread

Ingress Protection IP 67

Electrical Connection 2x M20x1.5 cable glands + internal thread for 2x ½”NPT cable protective pipe, cable outer

diameter: Ø 7 … Ø 13 mm (0.3 … 0.5 inch), wire cross section: max. 1.5 mm2 (AWG 15)

Electrical Protection Class III

Housing Material Plastic (PBT)

Sealing FPM, On request: FFKM, EPDM

Mass (head unit) 1.5 kg (3.3 lb)

EX-Approvals ATEX (ia): II 1/2 G Ex ia IIB T6…T5 Ga/Gb

ICEX (ia): EX ia IIB T6…T5 Ga/Gb

) of the measured medium

r

1

Under reference conditions and stabilized temperature

www.gfsignet.com

Page 3

Probe specifi cations*

Probe Type Max. Measuring

Dead-zone

2

Process Connection εr min.

Range

Upper (t)

/lower (b)

ε

= 80

r

Mono cable Ø 4 mm

(0.15 inch)

Mono rod Ø 8 mm

(0.3 inch)

*The unmeasurable upper and lower part of the tank. The lower dead zone is extended by the length of the counterweight (cable versions only).

6 m (19.6 feet) 300 /20 mm

(12 / 0.75 inch)

2 m (6.56 feet) 300 /20 mm

(12 / 0.75 inch)

Upper (t)

/lower (b)

ε

= 2.4

r

400 / 100 mm

(16 / 4 inch)

400 / 100 mm

(16 / 4 inch)

1” 1.9

1” 1.9

Technical data of the probes

Cable Rod

Max. meas. dist. 24 m (80 feet) 3 m (10 feet)

Min. meas. Dist. (ε

Minimal medium ε

= 80 / εr = 2.4) 0.3 m / 0.4 m (1 feet / 1.3 feet)

r

r

1.9

Sensing space around the probe Ø 600 mm (2 feet)

Process connection 1” BSP, 1” NPT

Probe material 1.4401 (316) 1.4571 (316 Ti)

Probe nominal Ø 4 mm (0.15 inch) 8 mm (0.3 inch)

Mass 0.12 kg/m (0.08 lb/ft) 0.4 kg/m (0.25 lb/ft)

Counterweight dimensions Ø 25x100 mm (1x4 inch) -

Counterweight material 1.4571 (316 Ti) -

2

The unmeasurable upper and lower part of the tank, the lower dead-zone is extended with the length of the counterweight (cable version)

Installation

The probes can be removed from the head unit by the user.

s = minimum distance from the internal disturbing objects.

Objects that are parallel to the probe do not disturb the

measurement. s > 300 mm (12 in.), h ≤ d, t

www.gfsignet.com

Page 4

Wiring

Display unit

connector

To Power Supply / HART Modem

Standard wiring & connection of HART-Modem

V

200mV

Loop current

measuring connector

U

1/2” NPT

M20x1,5

234561

GND

4...20 mA

1/2” NPT

M20x1,5

and supply

loop curren

(HART)

2312

-

+

To i-Go Converter - S3L / 4 to 20 mA

9900 Transmitter

8058-3

Signal

S3L/Freq

Converter

Black

Red

White

Black

SHLD

DATA

GND

V+

9900 S3L

Terminal

9900

Power

Input

Jump

PWR+

PWR–

LOOP+

LOOP–

Red

+

12 to 24 VDC

Black

Power Supply

–

Jumper from

PWR+ to LOOP+

2291 Radar

Level Sensor

E

250 Ohm

24V

A

HART

t

Wiring in an EX-environment

3

2

Ex Non Ex

Ex power

supply

3

2

Pin No. Assignment

1 Not Assigned

2 (+) Voltage measuring connector (200 mV)

3 (-) 4-20 mA loop current + supply (HART)

4 (+) 4-20 mA loop current + supply (HART)

5 (-) Voltage measuring connector (200 mV)

6 Not Assigned

Black

Red

Ordering Information

Mfr. Part No Code Description

2291-S-1DB1-6-R 159 300 190 LCD, PBT housing, 1" BSP, 6m cable Ø 4mm, SS316 Ti

2291-S-1DN1-6-R 159 300 191 LCD, PBT housing, 1" NPT, 6m cable Ø 4mm, SS316 Ti

2291-S-1DB1-2-D 159 300 192 LCD, PBT housing, 1" BSP, 2m rod Ø 8mm, SS316 Ti

2291-S-1DN1-2-D 159 300 193 LCD, PBT housing, 1" NPT, 2m rod Ø 8mm, SS316 Ti

Accessories

Mfr. Part No Code Description

3-8058-3 Special Order Wire-mount Signet i-Go signal (4 to 20 mA /S

3-8058-2 159 000 967 DIN rail mount Signet i-Go (4 to 20 mA/S

3-9900-1P 159 001 695 9900 Transmitter - Panel Mount

3-9900-1 159 001 696 9900 Transmitter - Field Mount

3-9950-1 159 001 841 9950 Base Unit – Two Channel Multi-Parameter Inputs, Two 4 to 20 mA Outputs,

3-9950-2 159 001 842 9950 Base Unit – Two Channel Multi-Parameter Inputs, Two 4 to 20 mA Outputs,

Rev B (03/18)

123456

159 300 181 HART - USB Modem

9900 Smart Pro, 8900 Multi-Parameter Controller. Single input.

9900 SmartPro, 8900 Multi-Parameter Controller. Two inputs.

Panel Mount, DC Power

Panel Mount, AC or DC Power

3

L) converter to connect 2290 to

3

L) converter to connect 2290 to

Loading...

Loading...