Page 1

Signet 2000 Micro Flow Rotor Sensor

Features

• Operating range 0.11 to 12.11 lpm

(0.03 to 3.2 U.S. gpm)

• Simple mounting

• ¼ in. NPT or ISO threads for simple pipe or

tubing connection

• Measures opaque and transparent liquids

• Low pressure drop

• Standard cable 7.6 m (25 ft)

The Signet 2000 Micro Flow Rotor Sensor is constructed

of Polyphenylene Sulfide (PPS) which provides high

material strength. The 2000 offers two flow ranges

starting at 0.11 or 1.13 lpm (0.03 or 0.3 gpm), for clean

process liquids, regardless of fluid color or opacity.

This sensor can be connected to flexible tubing or

rigid pipe, and uses standard hardware for mounting.

Only one moving part and a low pressure drop across

the sensor reduces operating costs and maintenance

requirements.

Applications

• Coolant Flow

• Dosing

• Batch Dispensing

• Not recommended for Strong Oxidizers

www.gfsignet.com

Page 2

Specifications

General

Operating Range -11 & -12 version 0.11 to 2.6 lpm 0.03 to 0.7 U.S. gpm

-21 & -22 version 1.13 to 12.11 lpm 0.3 to 3.2 U.S. gpm

Linearity ±1.2% of full range

Repeatability ±0.5% of full range

Connections ¼ in. NPT (male) or ISO 7/1 - R1/4 (male)

Wetted Materials

Sensor Body and Cover 40% glass filled Polyphenylene Sulfide (PPS)

Rotor PEEK™, natural, unfilled

Cover O-ring FPM

Electrical

Power 5 to 24 VDC ±10%, regulated, 10 mA max.

Output Type Open-collector, sinking, 20 mA max.

Cable Length 7.6 m (25 ft), can be extended up to 300 m (1000 ft)

Cable Type 2-conductor twisted pair w/shield, 22 AWG

Max. Temperature/Pressure Rating

0 °C to 80 °C @ 5.5 bar max. 32 °F to 176 °F @ 80 psi max.

Shipping Weight

0.03 kg 0.7 lb

Standards and Approvals

Manufactured under ISO 9001 for Quality and ISO 14001 for Environmental Management and

OHSAS 18001 for Occupational Health and Safety

See Temperature and Pressure graphs for more information.

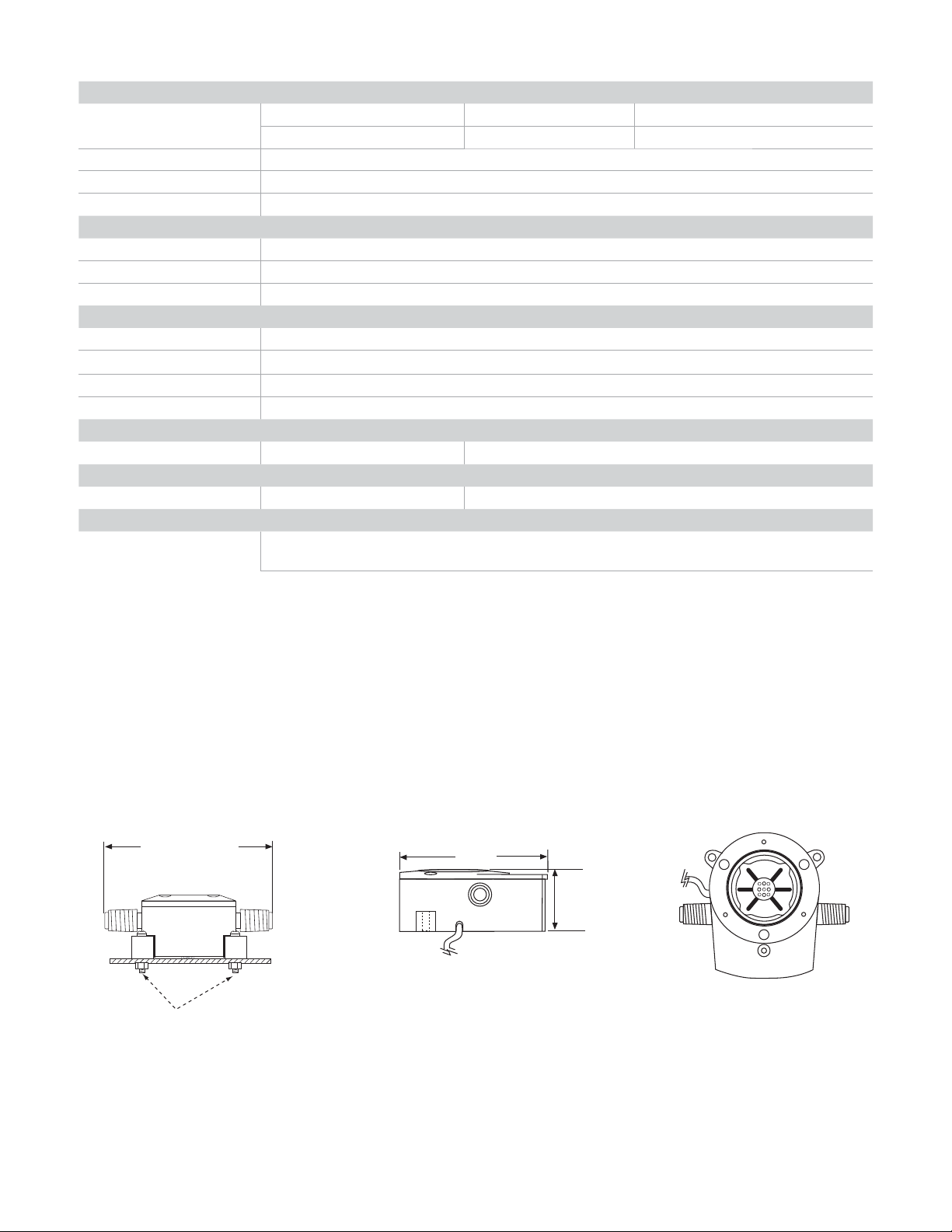

Dimensions

Top View

100 mm (3.94 in.)

Mounting tabs for metric M3 or

standard #6 screws on 68 mm

(2.68 in.) bolt circle

Side View

81 mm

(3.2 in.)

Cover Removed

36 mm

(1.42 in.)

www.gfsignet.com

Page 3

Panel Mount

Signet Instruments

8550 9900

8900 9900-1BC

Field Mount - Pipe, Tank, Wall

Signet Instruments

8550 9900

with 3-8050 Universal Mount Kit

ENTER

Signet 2000 Flow

Sensor

System Overview

Flexible tubing or rigid pipe

(customer supplied)

Application Tips

•

For use in clean fluids - no suspended solids.

• Use the mounting tabs to secure the sensor to a

flat surface, ±30°.

• Verify chemical compatibility before installation.

ENTER

+

All sold separately

Operating Temperature/Pressure Graphs

Note:

The pressure/temperature graphs are specifically for the Signet sensor. During system design the specifications

of all components must be considered. In the case of a metal piping system, a plastic sensor will reduce the

system specification.

Low Flow High Flow

Pressure Drop

(bar)(psi)

30 2.1

20 1.4

10 .7

LPM

GPM

2100 - Pressure Drop-Low Flow

Low Flow

0

0 0.8

0

0.2

1.5 2.3

0.4

0.6

Flow

3.0

0.8

3.8

1.0

(bar)(psi)

30 2.1

20 1.4

10 .7

Pressure Drop

LPM

GPM

2000 - Pressure Drop-High Flow

0

0

0

3.0

1.5 3.8 5.3

0.4

0.8

1.0

1.4

Flow

High Flow

6.8 7.6 9.1 10.6

1.8

2.0 2.4 2.8

11.5

3.0

Please refer to Wiring, Installation, and Accessories sections for more information.

www.gfsignet.com

Page 4

Ordering Information

Mfr. Part No. Code Flow Range End Fittings

Micro Flow Rotor Flow Sensor

3-2000-11 198 822 000 Low flow, 0.11 to 2.61 lpm (0.03 to 0.7 gpm) ¼ NPT threads

3-2000-12 198 822 001 Low flow, 0.11 to 2.61 lpm (0.03 to 0.7 gpm) ISO 7/1-R1/4 threads

3-2000-21 198 822 002 High flow, 1.13 to 12.11 lpm (0.3 to 3.2 gpm) ¼ NPT threads

3-2000-22 198 822 003 High flow, 1.13 to 12.11 lpm (0.3 to 3.2 gpm) ISO 7/1-R1/4 threads

Accessories and Replacement Parts

Mfr. Part No. Code Description

3-2000.390 159 000 248 Replacement rotor kit

1220-0029 198 820 049 Cover O-ring

2450-0620 198 820 051 Cover screw, each

5523-0222 159 000 392 Cable (per foot), 2 cond. w/shield, 22 AWG

3-8050-1 159 000 753 Universal junction box

3-2000.099 Rev F (4/13)

© Georg Fischer Signet LLC

3401 Aero Jet Avenue, El Monte, CA 91731-2882 U.S.A. • Tel. (626) 571-2770 • Fax (626) 573-2057 • www.gfsignet.com • e-mail: signet.ps@georgfischer.com

Specifications subject to change without notice. All rights reserved. All corporate names and trademarks stated herein are the property of their respective companies.

www.gfsignet.com

Loading...

Loading...