Description

Technical data

Code

Positioner

Inputs with galvanic isolation

199 190 603

The inputs are galvanically isolated, so the power supply does not have to

be galvanically separated.

Disconnect the actuator from the supply voltage.

Do not touch the board itself. Electrostatic discharge can damage the

components.

Ensure that the board sits in the lateral guides and snaps.

BCD

Input

Output

0 (factory setting)

4-20 mA

4-20 mA

1

0-10 V

4-20 mA

2

4-20 mA (inverted)

4-20 mA

3

0-10 V (inverted)

4-20 mA

4

4-20 mA

4-20 mA (inverted)

5

0-10 V

4-20 mA (inverted)

6

-

-

7 (only as feedback)

-

4-20 mA

8 (only as feedback)

-

4-20 mA (inverted)

9

-

-

1 2 3 4 5

6

Ground

4-20

mA

Ground

0-10 V

Ground

4-20

mA

OUT

IN

GF Piping Systems

Instruction Manual

Electric actuators type EA25-250: Positioner

Georg Fischer Piping Systems Ltd CH-8201 Schaffhausen

Phone +41 (0)52 631 30 26 / info.ps@georgfischer.com / www.gfps.com

700 278 095

GFDO_6429_4 (01.16)

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2016

The technical data are not binding and not expressly

warranted characteristics of the goods. They are

subject to change. Our General Conditions of Sale apply.

Using the positioner, the instruction manual of the electric

actuator type EA25-250 must be observed.

Intended use

Accessory board Positioner

The positioner can be used with the electric actuators type EA25, EA45, EA120

and EA250, both with the 24V AC/DC as well as the 100-230V AC version. The

board is to be plugged into the housing of the actuator in the provided slots.

3. Insert the board vertical on the backside of the main board onto the red plug.

4. Stick scheme label into the housing cover.

5. Set signal configuration and if necessary, motor current monitoring (see

chapter 4 „Signal configuration“ and 6 „Settings motor current monitoring“).

3 Connecting the positioner and test functioning

Connect set point 4 – 20 mA (or 0 – 10 V) to terminals of the positioner, see 5

„Terminal assignment“. Move actuator in positions OPEN and CLOSE, adjust

positions if necessary: set 4 mA (0 V) for CLOSE and 20 mA (10 V) for OPEN.

6. Put the cover back in place and fasten it with the 4 screws.

4 Signal configuration

The signal configuration is performed via the right BCD-switch „Mode“,

depending on switch position, the following signal configuration can be

achieved:

1 Function

The positioner controls a user-defined valve position proportional to a given

setpoint value. This can be 0 – 10 V or 4 – 20 mA. Feedback on the valve

position (actual value) is done via the integrated 4 – 20 mA position detection.

All signals can be inverted in any desired combination.

The monitoring card module „Motor current monitoring“ is located on the

positioner (left BCD switch). See chapter 6 „Settings motor current

monitoring“ for further settings.

2 Assembly of the positioner board

1. Remove housing cover of the electric actuator (loosen the 4 screws, open

cover).

2. Take the positioner board out of the packaging and check for damages.

5 Terminal assignment

The cables are applied as follows via a plug (according to signal configuration):

6 Settings motor current monitoring

Motor Current Monitoring

BCD

EA25

EA45

EA120

EA250

0

25

25

50

50 1 100

300

300

400 2 150

350

400

500 3 200

400

500

600 4 250

450

600

700 5 300

500

700

800 6 400

600

800

1000 7 500

700

900

1200 8 600

900

1000

1500

9 (factory setting)

700

1100

1200

1800

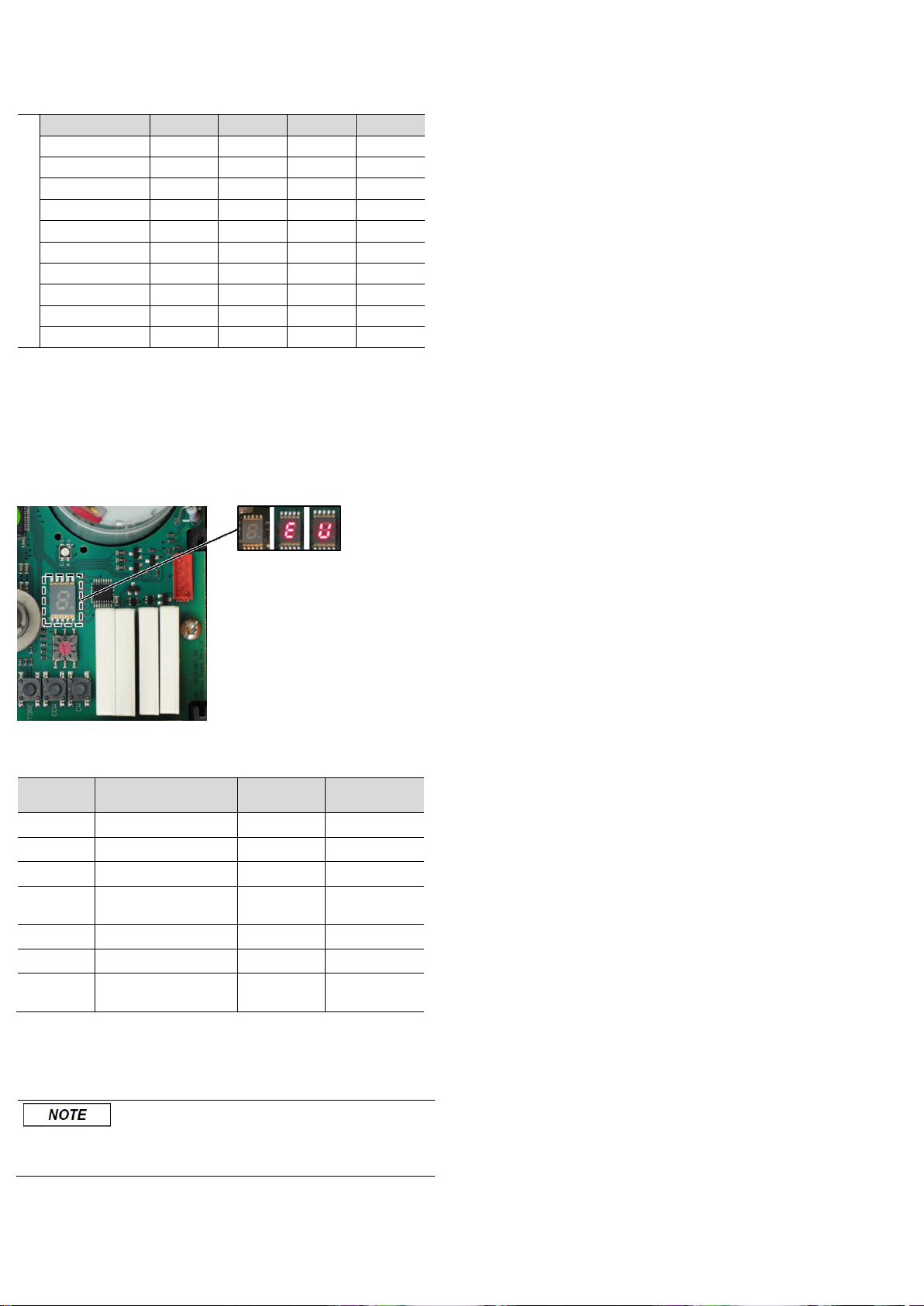

Error code

Description

Signal „Readyto-operate“

EA response

Setpoint error

None Actual value error

None

Setpoint reversed polarity

None

Actual value reversed

polarity

None

Setpoint short circuit

None Actual value short circuit

None

Actuator has run into

engine current limit

No

Stops

The message can be eliminated while the supply voltage is still connected

or the actuator is briefly disconnected from the mains voltage (does not

work with cycle monitoring).

The current monitoring function monitors the motor current. If the motor

current is higher than the preset value, an error is reported and the actuator

will remain in place.

7 Error message

An error message triggers the following signals:

The 7-segment display on the main board illuminates; see illustration

below. If the positioner PCB is installed, the respective LED lights up red on

the BCD switch, if its set value is exceeded.

The ready-to-operate signal will be off (terminals 5,6 NO contact)

LED flashes yellow (except in case of power outage)

Assignment of error codes for error messages

If the positioner PCB is installed, the following error codes can be displayed:

For further error codes of the main board, see instruction manual of the electric actuator

type EA 25-250.

Acknowledge error message

Check the cause of fault, if necessary, carry out relevant maintenance.

Error can be acknowledged via the „SET“ button on the main board.

Loading...

Loading...