Page 1

GF Piping Systems

Bedienungsanleitung

Instruction Manual

Elektrische Antriebe Typ EA25-250

Electric Actuators Type EA25-250

Page 2

Original instruction manual

Observe instruction manual

The instruction manual is part of the product and is an important element of the safety

concept.

Read and follow the instruction manual.

Always keep the instruction manual available at the product.

Pass on the instruction manual to all subsequent users of the product.

39

Page 3

Contents

Original instruction manual ...........................................................................................................39

Contents ..........................................................................................................................................40

1 Intended use .........................................................................................................................42

2 About this document ............................................................................................................42

2.1 Warnings ...............................................................................................................................42

2.2 Other related documents .....................................................................................................43

2.3 Product variants and types described .................................................................................43

2.4 Abbreviations ........................................................................................................................43

3 Safety and responsibility ......................................................................................................44

4 Transport and storage ..........................................................................................................44

5 Design and function ..............................................................................................................45

5.1 Design ...................................................................................................................................45

5.2 Identification .........................................................................................................................46

5.3 Principle of operation ...........................................................................................................46

5.3.1 Position indicator ..................................................................................................................47

5.3.2 LED status feedback.............................................................................................................48

5.3.3 Buttons for setting the end positions ..................................................................................49

5.3.4 Overload protection ..............................................................................................................50

5.3.5 Safety position .......................................................................................................................50

5.3.6 Heating element ...................................................................................................................50

5.3.7 Emergency manual override ................................................................................................50

5.4 Wiring diagram EA25/45/120/250 ........................................................................................51

5.5 Dimensional drawing of interfaces ......................................................................................52

6 Technical specifications .......................................................................................................53

7 Installation ............................................................................................................................53

7.1 Installing the actuator with valve .........................................................................................54

7.1.1 Preparation and assembly ...................................................................................................56

7.1.2 Connecting the actuator .......................................................................................................56

8 Commissioning .....................................................................................................................58

8.1 Putting the actuator into operation .....................................................................................58

9 Operation ...............................................................................................................................59

9.1 Insert the emergency manual override hand crank ...........................................................59

9.1.1 Preparation ...........................................................................................................................60

9.1.2 Procedure .............................................................................................................................60

9.2 Adjusting end positions ........................................................................................................61

40

Page 4

9.3 Inverting LED color assignment ..........................................................................................61

9.4 Adjusting the heating element .............................................................................................62

9.5 Performing a factory reset ...................................................................................................63

9.6 Teaching in the position sensor (learning run) ...................................................................63

10 Help in case of faults ............................................................................................................64

10.1 Fault message indicator.......................................................................................................64

10.2 Assignment of error codes ...................................................................................................65

10.3 Troubleshooting ....................................................................................................................66

11 Maintenance..........................................................................................................................67

12 Spare parts list .....................................................................................................................68

13 Accessories ...........................................................................................................................69

14 EC declaration of incorporation ...........................................................................................70

15 Disposal .................................................................................................................................71

41

Page 5

Intended use Operating manual

Risk of serious physical injury!

Non-observance will lead to a possible risk of fatal or serious physical injury!

Risk of minor physical injury!

Non-observance will lead to a risk of physical injury!

Risk of damage to property!

Non-observance will lead to a risk of damage to property (loss of time, loss of data, machine

damage, etc.)!

ATTENTION

1 Intended use

The electric actuators EA 25/45/120/250 are designed for assembly on a valve and for

connection to a system controller.

The electric actuators EA 25/45/120/250 are intended to activate valves with rotating

movements up to 180° (e. g. ball valves and butterfly valves).

The product is not intended for any types of use other than those described here. Nonobservance of the instructions contained in this manual will void the manufacturer's warranty

for the products mentioned above.

2 About this document

This document contains all the information necessary for installation, operation and

maintenance of the product.

2.1 Warnings

This instruction manual contains warnings that indicate a risk of death, injury, or material

damage. Always read and observe to these warnings!

42

Page 6

Operating manual About this document

Symbol

Meaning

1.

Call for action in a certain order: Here, you have to do something.

Call for action without fixed order.

Remarks: Contain especially important information for better understanding.

Abbreviation

Description

EA

Electric actuator

AC/DC

Alternating Current/Direct Current

SELV

Safety Extra Low Voltage

CW

Clockwise

CCW

Counter Clockwise

NO

Normally open contact

NC

Normally closed contact

BCD

Binary coded decimals

SMD

Surface Mounted Device

Other symbols

2.2 Other related documents

Georg Fischer industrial planning fundamentals

Assembly instructions accessories

Assembly instructions of the respective manual valve

These documents can be obtained via the agency of GF Piping Systems or under www.gfps.com.

2.3 Product variants and types described

Type EA25 24V AC/ DC and 100 – 230V AC

Type EA45 24V AC/ DC and 100 – 230V AC

Type EA120 24V AC/ DC and 100 – 230V AC

Type EA250 24V AC/ DC and 100 – 230V AC

2.4 Abbreviations

43

Page 7

Safety and responsibility Operating manual

3 Safety and responsibility

Only use the product for the intended purpose, see Intended Use.

Do not use the product if it is damaged or faulty. Sort out the product immediately or

obtain service if damaged.

Product and accessories only to be operated by persons, who have the necessary training,

knowledge or experience.

The following target groups are addressed in this instruction manual:

Operators: Operators are instructed in the operation of the actuator and observe the

safety guidelines.

Service staff: The service staff have been professionally trained and carry out

maintenance work.

Electrically qualified person: Persons who work on the electrical equipment must be

technically trained and qualified.

Regularly instruct personnel on all questions regarding the local regulations applying to

occupational safety and environmental protection, especially for pressurized pipelines.

Make sure that personnel know, understand and follow the instruction manual and the

instructions contained therein.

Observe the instruction manual for the manual valve. They are an integral component of

this manual.

Take precautions against electrostatic hazards.

4 Transport and storage

Protect the product against external forces during transport (impacts, knocks, vibrations,

etc.).

Transport and/or store the product in its unopened original packaging.

Protect the product from dust, dirt, moisture as well as heat and ultraviolet radiation.

Ensure that the product is not damaged either by mechanical or thermal influences.

Before assembly, check the product for damage during transport.

44

Page 8

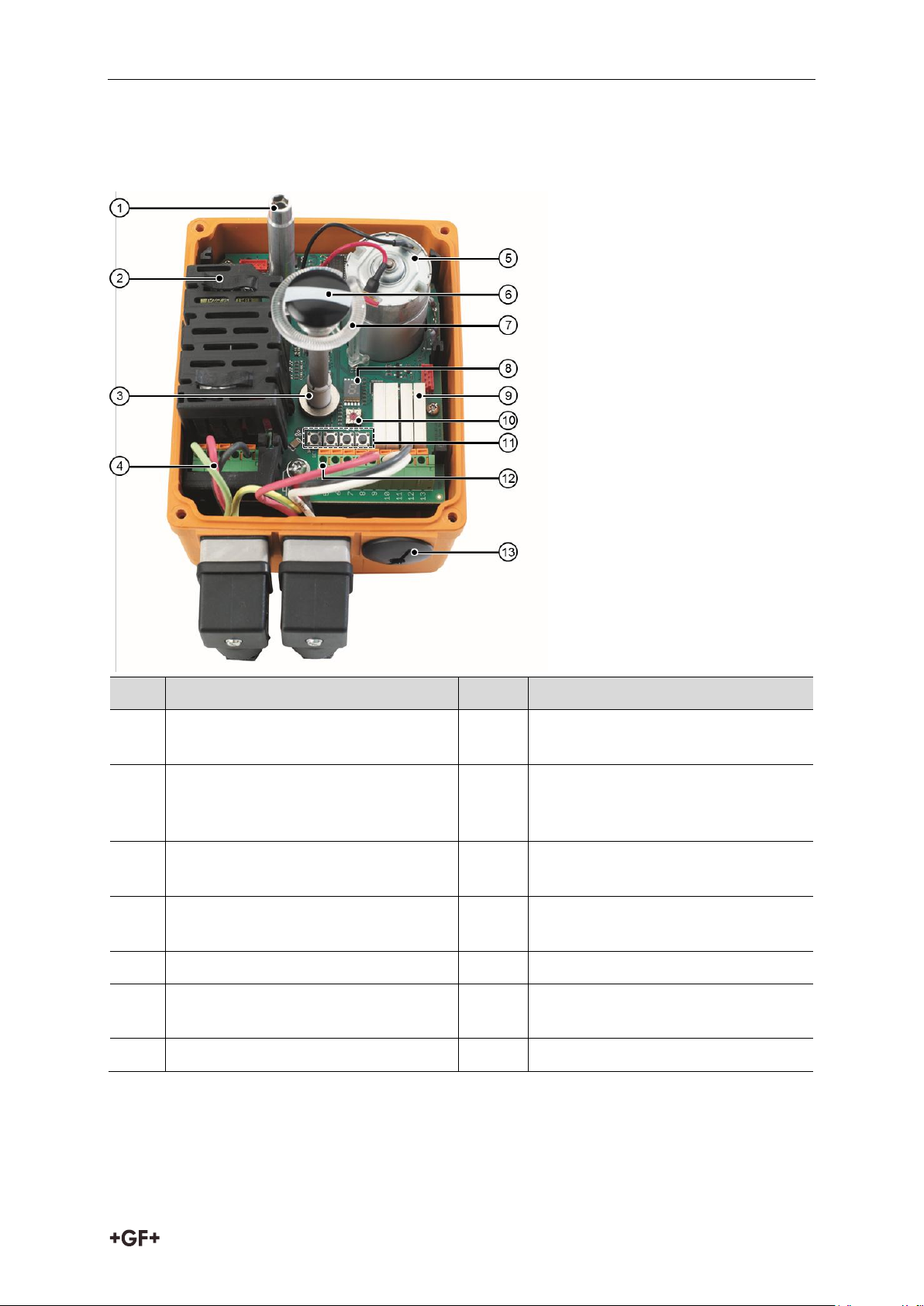

Operating manual Design and function

Item

Name

Item

Name

1

Shaft for emergency manual

override hand crank

8

7 segment error display

2

Power supply with cover (100 – 230 V

version shown)

9

Position feedback via relay for

OPEN/CLOSE/MIDDLE/ready-tooperate

3

Digital position detection

10

Heating element (temperature

threshold control)

4

Control power for

OPEN/CLOSE/MIDDLE position

11

Button for end position adjustment

5

DC motor

12

Signal output “Ready-to-operate”

6

Optical position indicator

13

Connections for DIN plug or cable

gland

7

Light tube for LED status feedback

5 Design and function

5.1 Design

45

Page 9

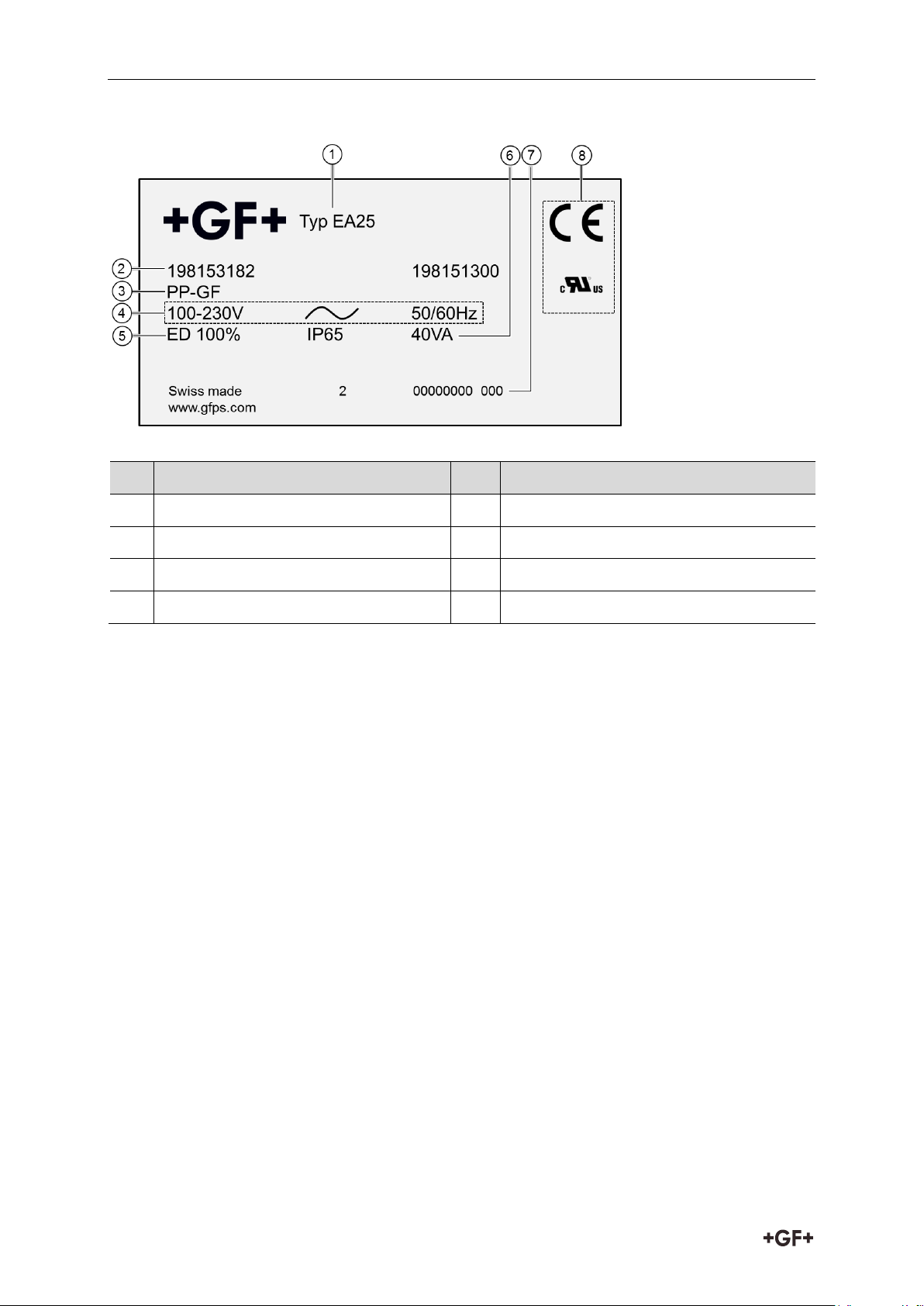

Design and function Operating manual

No.

Designation

No.

Designation

1

Type plate (e. g. EA25)

5

Duty cycle/protection rating

2

Assembly number

6

Nominal power

3

Housing material

7

Serial number

4

Voltage type

8

Approvals & CE-mark

5.2 Identification

5.3 Principle of operation

The actuator runs by switching the voltage from the OPEN position to the CLOSE position.

By switching the voltage to the other input, the actuator runs from the CLOSE position

to the OPEN position.

The end positions are factory set to 0 and 90°. Additionally, any 3rd position (MIDDLE position)

can be adjusted, which is located between the OPEN position and the CLOSE position.

This position is not assigned at the factory.

End positions and Middle position can later be changed via the end position buttons, see

Chapter 9.2 “Adjusting end positions”, Page 61.

46

Page 10

Operating manual Design and function

GF actuators are always delivered in the OPEN position.

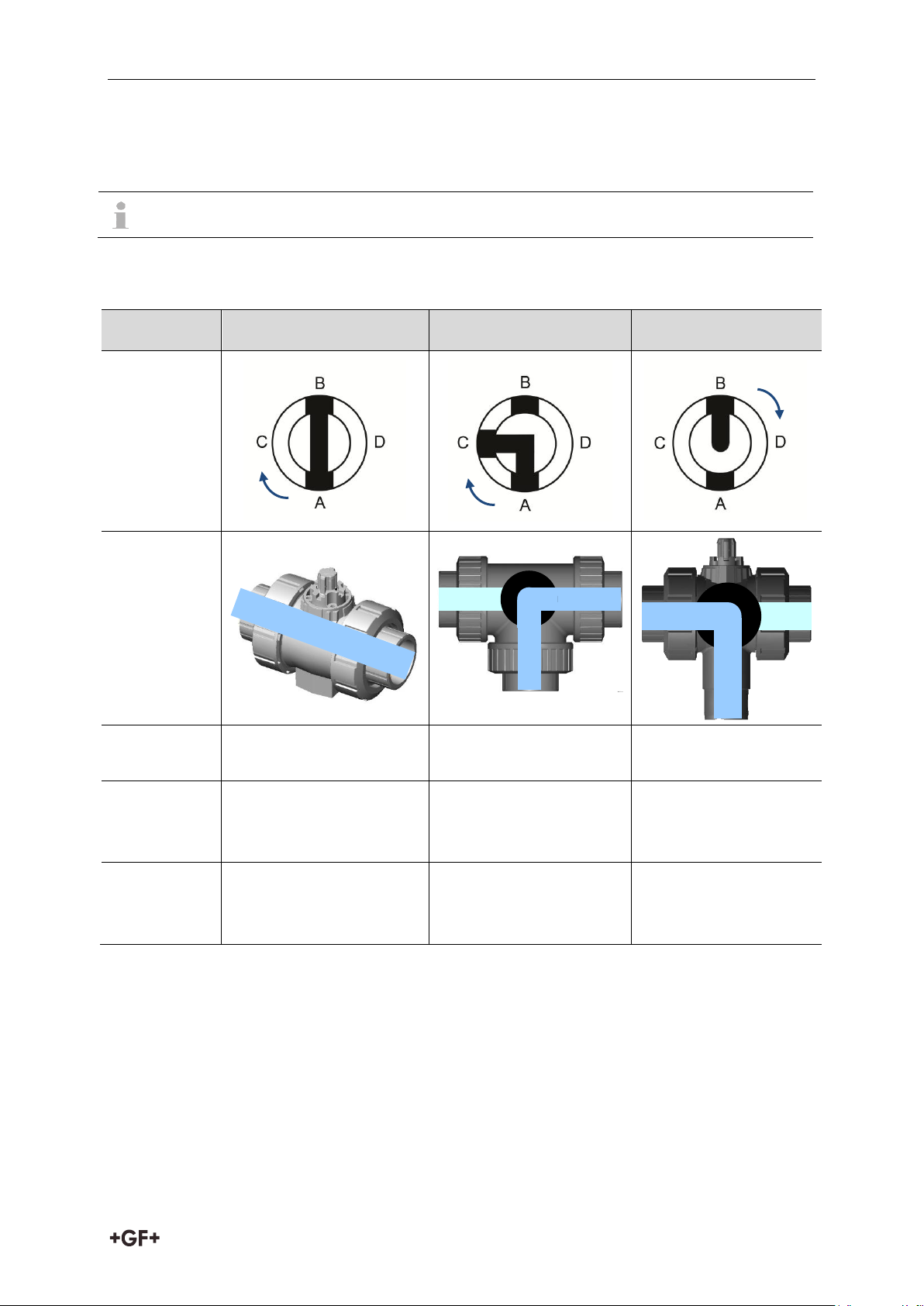

2-way

3-way horizontal (L)

3-way vertical (L)

Image of

position

indicator

in valveposition 1

Valve

function

Actuating

angle

0° - 90°

0° - 90°

0° - 180°

Valveposition 1

A-B (OPEN)

A–C

(Flow right side, outlet

to the front)

B-C

(Flow left side, bottom

outlet)

Valveposition 2

C-D (CLOSE)

B–C

(Flow left side, outlet to

the front)

A-C

(Flow right side,

bottom outlet)

A B C D B C A

5.3.1 Position indicator

The position indicator shows the valve position. The valve positions can be read on the

installed cover.

When the cover is installed, the following image can be seen (Example ball valve):

47

Page 11

Design and function Operating manual

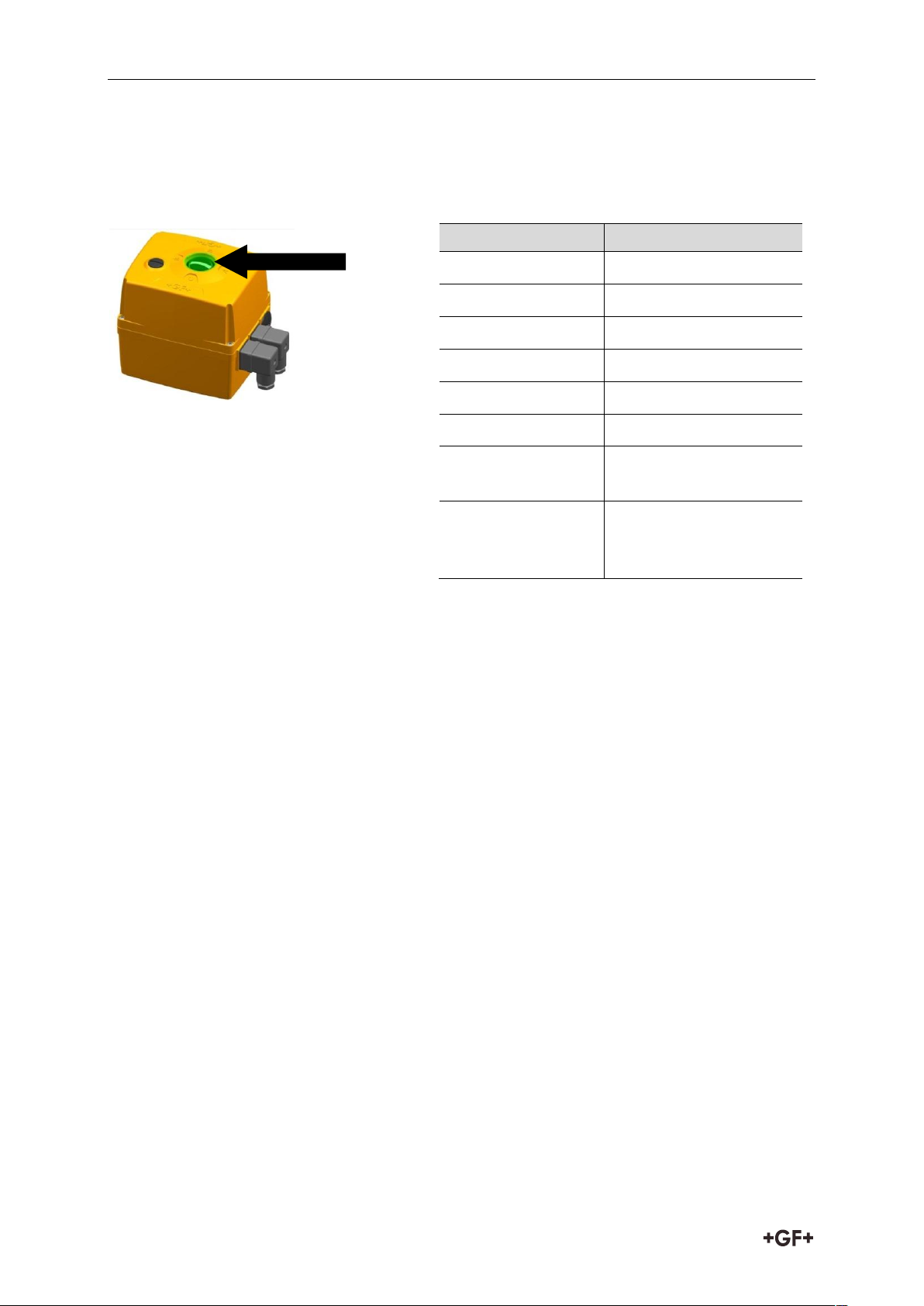

LED status feedback on the actuator

Color

Meaning

Red

OPEN position

Green

CLOSE position

White

MIDDLE position

Flashes white

Actuator moves

Flashes yellow

Fault

Flashes blue

Learning mode

Green/yellow

Setpoint value reached

(at positioner)

Turquoise

Adjustment run /

operation of color

inversion

5.3.2 LED status feedback

The LED status feedback shows the valve positions and the current status of the actuator.

The following table shows the color assignment of the LED:

If the plant standard requires an inversion of the color assignment, the customer can adjust

this afterwards, see Chapter 9.3 “Inverting LED color assignment”, Page 61.

48

Page 12

Operating manual Design and function

Button

Adjustment mode

(“SET” button pressed for 3 s)

Standard mode

(terminal 4

permanently

energized)

Error mode

SET

Press the button, until the color of

the LED of which the assigned

position is to be changed lights up

(e. g. green – CLOSE)

Acknowledge

the error (instead

of disconnecting

the power supply)

STORE

Saving the position moved to

Moving to

position CLOSE

CCW

Moving counterclockwise

Moving to

position MIDDLE

CW

Moving clockwise

Moving to

position OPEN

Button

combination

(press ~3s)

Function

Action

SET + CCW

LED color assignment

Inverting colors

SET + CW

Factory reset

Actuator will be set to the values

predefined at the factory

SET +

STORE

Learning run / new adjustment of

the position sensor (if magnet

position has been twisted or after

exchanging boards)

Deleting the taught in positions

5.3.3 Buttons for setting the end positions

Buttons for setting the end positions inside the actuator

The following table describes the functions of buttons shown above:

The following table describes the functions of button combinations:

49

Page 13

Design and function Operating manual

5.3.4 Overload protection

The supply unit of the EA 25/45/120/250 has an overload protection that protects the DC motor

and the power supply from overheating. The overload protection is activated as soon as the

load exceeds the torque range. The actuator motor resumes as soon as the load is in the

torque range and the temperature/current has gone down.

5.3.5 Safety position

During a power outage, the actuator remains in its current position. If the actuator is fitted

with the “fail-safe return unit” accessory, it can automatically move to a predefined safety

position (OPEN or CLOSE), in case of a power outage.

5.3.6 Heating element

The integrated heating element prevents condensation or icing inside the housing. It starts

heating from a preset value. The value depends on the ambient temperature, at which the

actuator is operated, and can be set manually. The default setting is <0 °C / <32 °F. When

the heating element is active, the dot on the 7 segment display is illuminated.

5.3.7 Emergency manual override

The integrated emergency manual override is used to run the actuator manually into another

position. The integrated emergency manual override allows the operation of the actuator to be

maintained for a short time if there is no current applied, e. g. during putting into operation or

during a power outage.

50

Page 14

Operating manual Design and function

Ex factory, the position feedback is wired as a normally closed contact (NC). On site,

this might also be implemented as a normally open contact (NO), subsequently.

Standard delivery is with a unit plug for position feedback OPEN/CLOSE. A unit plug

with additional pin for MIDDLE feedback can be ordered as an accessory or special

configuration. Each actuator is provided with this functionality. Connection via cable

gland is also possible.

5.4 Wiring diagram EA25/45/120/250

Connection of the voltage supply for positions OPEN, CLOSE and MIDDLE

Connection of position feedback for positions OPEN, CLOSE and MIDDLE (optional)

51

Page 15

Design and function Operating manual

deep

deep

deep

deep

5.5 Dimensional drawing of interfaces

EA 25/45 Flange fitting F05

EA 120 Flange fitting F07

EA 250 Flange fitting F07

52

Page 16

Operating manual Technical specifications

EA 25

EA 45

EA 120

EA 250

Nominal power

AC: 35 VA at

100 – 230 V

AC: 55 VA at

100 – 230 V

AC: 50 VA at

100 – 230 V

AC: 60 VA at

100 – 230 V

AC/DC:

40 VA at 24 V

AC/DC:

60 VA at 24 V

AC/DC:

55 VA at 24 V

AC/DC:

65 VA at 24 V

Nominal torque Mdn

(peak)

10 (25) Nm

20 (45) Nm

60 (120) Nm

100 (250) Nm

Duty cycle

100 %

50 %

50 %

35 %

Cycle time s/90°

at Mdn

5 s

6 s

15 s

20 s

Flange fitting

F05

F05

F07

F07

Tested cycles

(at 20 °C and Mdn)

250 000

100 000

100 000

75 000

Weight

2.1 kg

2.2 kg

3.6 kg

5.0 kg

Actuating angle

Max. 355°, set to 90°

Nominal voltage

AC: 100 – 230 V, 50/60 Hz

AC/DC: 24 V, 50/60 Hz

Nominal voltage

tolerance

± 15 %

Protection class

IP 65 (IP67)

1)

according to EN 60529

Pollution degree

2 according to EN 61010-1

Overload protection

Current/time dependent, resetting

Overvoltage category

II

Fuse

SMD fuse 2 A, not replaceable

Ambient

temperature

-10 °C to +50 °C

Allowable humidity

Max. 90 % relative humidity, non condensing

Housing material

PP-GF for very good chemical resistance

6 Technical specifications

1)

When used with cable glands and vertical installation

7 Installation

If a complete valve is supplied, no mounting activities and adjustments are required. The actuator

can directly be put into operation, see Chapter 8 “Commissioning” Page 58. When assembled by

the customer, the actuator must be assembled, connected, and, if necessary, adjusted.

53

Page 17

Installation Operating manual

EA 25

EA 45

EA 120

EA 250

2-way ball valve

to DN 50

e. g. ball valve

type 546

DN10-DN50 /

3/8 – 2 inch

- - -

2-way ball valve

to DN 100

e. g. ball valve

type 546

DN65-DN100 / 2

½ - 4 inch

-

-

3-way ball valve

to DN 50

e. g. ball valve

type 543

- - -

Butterfly valves

e. g. butterfly

valve type

567/578

-

7.1 Installing the actuator with valve

The actuators have a standard ISO 5211 interface, and can therefore be mounted on all valves

that are provided with this interface and the appropriate torques. The assembly using valves

from GF Piping Systems with suitable coupling piece and adapter is possible in accordance

with the following table:

54

Page 18

Operating manual Installation

Valve

2-way ball valve

3-way ball valve

Butterfly valve

Type

546

543

567

578

+

Actuator

EA

11

25 DN10 – DN50 / 3/8 – 2 inch

45 DN65 / 2 ½ inch

120 DN80 - DN100 / 3 – 4 inch

25

45 to DN65 / 2 ½

inch

120 to DN150 / 6

inch

250 from DN200 / 8

inch

= Type

107

179

180

181

182

183

184

167

168

169

170

145

146

147

Remark

metric

metric

metric

metric

ANSI

BS

JIS

horizontal

horizontal

horizontal

vertical

Wafer

Lug

Lug ANSI

Lug JIS

PVC-U

x x x x x x x x x x x

PVC-C

x x x x x x x x x x

ABS

x x x x x x x x x x

PP-H

x x x x x x x x x x

PVDF

x x x x x x x x x x

Installation and assembly of the actuator may only be carried out by electrically

qualified persons, see Chapter 3 “Safety and responsibility”, Page 44.

55

Page 19

Installation Operating manual

Voltage too high!

Danger of injury and/or damage to property.

Make sure that 24 V devices are only connected to voltages that meet the requirements

of a safety extra low voltage circuit (SELV).

Damage to the actuator by short circuit or corrosion!

Moisture and/or dirt in the actuator.

Make sure that no water enters the actuator.

Mount the cable routing, so it does not point upwards.

7.1.1 Preparation and assembly

In addition to this manual, please also follow the specifications of the valve manufacturer.

Before installation, compare the technical data of the actuator with those of the control

and the valve. Only install the actuator if the data match.

Before installation, check plugs and terminals for possible damage.

Make sure that no damaged parts are used.

Mount the actuator on the valve, see assembly instructions of the respective manual valve.

If the actuator for the system requires protection class IP67, implement the following

measures:

- Use cable glands.

- Fit the actuator vertically.

If the device is directly controlled, implement the following measures:

- Fit a circuit breaker on site.

- Do not connect earth ground conductor.

7.1.2 Connecting the actuator

Requirements

Wire gauge max. 1.5 mm²

Wire gauge min. 0.75 mm2

Sizing of the fuse: > 6 A

56

Page 20

Operating manual Installation

Premature component wear, error signals and false fail safe return signals due

to faulty control!

If the voltage is removed when reaching the end position, the status signal of the

end position is omitted and the actuator controls again the now energized position.

This causes the LED to flash red or green, as well as premature relay wear.

During normal operation avoid switching off the control power to the actuator.

E.g. connect the inputs OPEN/CLOSE as a changeover contact

Upon delivery, the heating element is set as follows:

T < 0 °C heating element is heating

T > 5 °C heating element switches off again

If required, the switch-on threshold can be set up to 40 °C.

1. Connect the unit plug for the power supply and the unit plug for position feedback

according to wiring diagram, see Chapter 5.4 “Wiring diagram EA25/45/120/250”,

Page 51. Make sure that the cable routing does not point upwards.

2. If necessary, connect the ready for operation monitoring (terminal 5.6 NO), see

Chapter 5.4 “Wiring diagram EA25/45/120/250”, Page 51.

3. If necessary, adjust the end positions, see Chapter 9.2 “Adjusting end positions”,

Page 61.

4. If necessary, adjust the heating element, see Chapter 9.4 “Adjusting the heating

element”, Page 62.

57

Page 21

Commissioning Operating manual

Using the emergency manual override hand crank, the valve can also be opened or

closed without power, see Chapter 9.1 “Insert the emergency manual override hand

crank”, Page 59.

Too high current peaks during the actuator is switched on due to charging of the mains

capacitor!

Danger of injury and/or malfunction.

Connect and operate the actuator as per wiring diagram, see Chapter 5.4 “Wiring

diagram EA25/45/120/250”, Page 51.

In case of a malfunction, the “ready-to-operate” signal goes out (normally contact)

and a fault message is indicated at the 7 segment display, see Chapter 10.1 “Fault

message indicator”, Page 64.

8 Commissioning

Before putting the system into operation, a functional test of the actuator must be carried out.

Requirements

The actuator is not connected to power.

Make sure that the supply voltage matches the details on the type plate.

Make sure that the actuator is connected properly.

Check fuse: > 6 A.

Check that the valve position matches the position indicator of the actuator.

Make sure that actuator and valve are connected correctly and tightly with each other.

8.1 Putting the actuator into operation

1. Connect the actuator to appropriate power.

The ready for operation signal appears.

2. If necessary, make further settings, e. g. invert the LED color assignment, adjust the

end positions and set the heating element, see Chapter 9 “Operation”, Page 59.

58

Page 22

Operating manual Operation

Working with removed cover on the actuator!

Danger of injury and/or damage to property.

Disconnect connections of the feed and control voltage.

Only carry out adjustments on live parts with specially insulated tools.

Direction of rotation

Function

Clockwise (CW)

close

Counter clockwise (CCW)

open

Type

Number of rotations

Angle

EA 25

9

90°

EA 45

9

90°

EA 120

27

90°

EA 250

41

90°

Unintentional restarting of the actuator!

Danger of injury due to rotation of the actuator if powered while emergency manual override

hand crank is installed.

If possible, disconnect the unit plug during manual operation or disconnect the actuator

in another way.

9 Operation

9.1 Insert the emergency manual override hand crank

The emergency manual override hand crank can be turned clockwise or counterclockwise.

The direction depends on whether the valve is to be opened or closed.

Depending on the type of actuator a different number of rotations at the crank handle is

necessary, in order to open or close the valve. The following table shows how many rotations

are necessary for the respective type:

59

Page 23

Operation Operating manual

Step 1

Step 2

Step 3

Pull the crank handle (1) out

of the holder.

Remove cover screw (2) with

crank handle (1). The magnet

centers the position. The

cover screw sticks

magnetically at the crank

handle.

Insert crank handle into the

hexagon under the opening.

Damage to the actuator by short circuit or corrosion!

Moisture and/or dirt in the actuator.

Make sure that no water has entered the actuator.

9.1.1 Preparation

9.1.2 Procedure

1. Remove power to actuator by disconnecting DIN plug.

2. Press hand crank to the stop. The crank engages.

If the actuator is still energized, the “ready-to-operate” signal will go out.

3. To open or close the valve, turn the crank handle according to the above tables.

4. In order to put the actuator back into normal operation, remove the crank handle (1).

Apply power by reinstalling DIN plug. After 3 seconds, the actuator will start up.

5. Screw on cover screw (2) again.

6. Put crank handle (1) back into the holder.

60

Page 24

Operating manual Operation

If an end position is not reached, the actuator automatically switches off after 2 min.

and displays a fault message.

Color

combination

End position

Blue/red

OPEN

Blue/green

CLOSE

Blue/white

MIDDLE

9.2 Adjusting end positions

The two end positions in the actuator have been factory set to 90°. A readjustment may be

required after assembly by the customer or after repair work.

The end positions can be set via the 4 buttons on the base board.

1. Open cover. To do so, loosen the 4 screws (torx size 20).

2. Connect the actuator to the appropriate power and let it rotate, until an end position

is reached.

3. Press the SET button and hold it for 3 seconds. The LED status feedback starts

flashing blue (adjustment mode).

4. Press the SET button again. With each pressing, the LED goes through the following

color combinations:

5. Press the SET button, until the desired color combination of the end position to be set

is displayed.

6. Move the actuator to the desired position by using the CCW and CW buttons.

7. Save the position by using the STORE button.

8. Repeat this process, until all positions are adjusted.

9. Reinstall the cover and fasten it with the 4 screws.

9.3 Inverting LED color assignment

The LED color assignment has been set at the factory to red = OPEN, and green = CLOSE.

This assignment can be inverted by the customer, if desired.

1. Open cover. To do so, loosen the 4 screws (torx size 20).

2. Make sure that the actuator is connected to appropriate power.

3. Press the SET + CCW buttons and hold them for 5 seconds.

The LED lights up turquoise. The colors red and green are inverted.

4. Reinstall the cover and fasten it with the 4 screws.

61

Page 25

Operation Operating manual

Position heating adjustment

Heating on (°C)

Heating off (°C)

0 (default)

< 0

< 5 1 5

10

2

10

15

3

15

20 4 20

25

5

25

30

6

30

35

7

35

40

8

40

45

9

40

45

When the heating element is active, the dot on the 7 segment display is illuminated.

9.4 Adjusting the heating element

Heating adjustment inside the actuator

The heating element has been set at the factory, so it starts heating from an internal device

temperature of 0 °C. For environments with higher temperatures and high humidity,

the heating threshold must be increased, in order to prevent moisture condensation inside

the housing. The heating threshold can be set via the heating adjustment.

The following table shows the positions of the heating adjustment and in which corresponding

temperature ranges the heating element will heat.

In order to change the heating threshold, turn the heating adjustment with a suitable

screwdriver to the desired position.

62

Page 26

Operating manual Operation

Damage of actuator, valve or intermediate element!

During the learning run of the position sensor, make sure that there are no structures

blocking the several 360° rotations of the actuator. If necessary, dismount the actuator

from the valve.

9.5 Performing a factory reset

When performing a factory reset, all previously saved positions will be deleted, and

a possible color inversion will be cancelled.

1. Open cover. To do so, loosen the 4 screws (torx size 20).

2. Press the SET + CW buttons.

The factory reset is performed.

9.6 Teaching in the position sensor (learning run)

1. Open the cover. To do so, loosen the 4 screws (torx size 20).

2. Press the SET + STORE buttons and hold them for 3 seconds.

The actuator does several rotations.

After completion of the learning run, the LED status feedback lights up yellow, if there

were no end positions saved before.

3. Readjusting the end positions, see Chapter 9.2 “Adjusting end positions”, Page 61.

4. Reinstall the cover and fasten it with the 4 screws.

63

Page 27

Help in case of faults Operating manual

10 Help in case of faults

10.1 Fault message indicator

7 segment display on the base board

In case of a fault message, the following events occur:

The LED flashes yellow (except during a power outage).

The “ready-to-operate” signal (terminal 5.6 NO) drops.

The 7 segment display is illuminated on the base board, see Chapter 10.2 “Assignment of

error codes”, Page 65.

If the monitoring accessories are installed, the LED on the BCD switch, of which the set

value has been exceeded, will also light up.

64

Page 28

Operating manual Help in case of faults

Error code

Description

“Ready-to-operate”

signal

EA response

No voltage

No

None

Voltage below specification

No

None

Housing internal

temperature too high (>80 °C)

No

Stops

Time from end position

to end position too long (>

120s)

No

Stops

Voltage above specification

No

Stops

Heating defective and T =

< 0 °C

No

Normal

operation

e

Error in position detection

No

None

Invalid position

No

Normal

operation

Emergency manual override

active

No

None

No communication with

accessories

No

None

Battery voltage < 50 %

(with installed fail-safe

return unit)

No

Normal

operation

Actuator was run in motor

current limit

No

Stops

10.2 Assignment of error codes

In case of a fault, the error codes will be displayed on the 7 segment display on the base board.

65

Page 29

Help in case of faults Operating manual

Repair the fault either while the supply voltage is still applied or when the actuator

is briefly disconnected from the main power (not effective in cycle monitoring).

Fault

Possible cause

Remedy

Actuator does not

react

No power available

Check voltage source.

Internal wiring error

Correct the wiring of the actuator,

see Chapter 7 “Installation”, Page 53.

End positions not correctly set

Adjust the end positions,

see Chapter 9.2 “Adjusting end

positions”, Page 61.

Motor blocked

Use emergency manual override,

see Chapter 9.1 “Insert the

emergency manual override hand

crank”, Page 59.

Actuator only

runs in one

direction

Position sensor defective

Use emergency manual override,

see Chapter 9.1 “Insert the

emergency manual override hand

crank”, Page 59.

Overload

protection is

activated

Valve dirty/jammed

Clean the valve, see valve manual.

Duty cycle too high

Extend cycle time with accessories

“Cycle time extension”.

Ambient temperature too high

If possible, reduce ambient

temperature.

Valve does not

fully close or

open

End positions not adjusted

Adjust the end positions,

see Chapter 9.2 “Adjusting end

positions”, Page 61.

Valve does not

close or open

correctly

Valve stem twisted

Replace valve stem

If an end position is not reached, the actuator automatically switches off after 2 min.

and displays a fault message.

10.3 Troubleshooting

1. Check the cause of fault. To do so, open the cover of the actuator, if necessary.

2. In order to remove the fault, press the SET button on the base board, in order

to acknowledge the error, or disconnect the actuator from the mains.

3. Perform troubleshooting in accordance with the table.

66

Page 30

Operating manual Maintenance

Lack of product quality through use of spare parts not provided by GF Piping Systems!

Danger of injury.

Only use the listed spare parts, see Chapter 12 “Spare parts list”, Page 68.

Maintenance

interval

Maintenance task

Regularly

Check that the cover of the emergency manual override is correctly

installed. If necessary, install cover.

Check that the housing cover of the actuator is secured with 4

screws.

If necessary, tighten screws.

Regularly

Check if grating noises are coming from the actuator.

Replace actuator, see assembly instructions for building valve with

actuator.

Regularly

Check that position indicator matches signal of the control.

If necessary, adjust the end positions, see Chapter 9.2 “Adjusting

end positions”, Page 61.

11 Maintenance

Set maintenance intervals as per the conditions of use (e. g. actuating cycles, fluid,

ambient temperature).

As part of the regular system inspection, carry out the following maintenance activities:

For questions regarding maintenance of the product, please contact your national GF Piping

Systems representative.

67

Page 31

Spare parts list Operating manual

Designation

Code No.

Actuator EA25 100 – 230 V AC

198 153 182

Actuator EA25 24 V AC/DC

198 153 183

Actuator EA45 100 – 230 V AC

198 153 184

Actuator EA45 24 V AC/DC

198 153 185

Actuator EA120 100 – 230 V AC

198 153 186

Actuator EA120 24 V AC/DC

198 153 187

Actuator EA250 100 – 230 V AC

198 153 188

Actuator EA250 24 V AC/DC

198 153 189

Crank for emergency manual override

198 151 307

Manual emergency cover (lock screw)

198 000 503

12 Spare parts list

68

Page 32

Operating manual Accessories

Designation

Function

Code No.

Fail-safe return unit with

integrated battery pack

In case of a power outage, the fail-safe return

unit can be used to move to a preset safe

position (OPEN/CLOSE). Assembly in the

housing actuator

199 190 601

External fail-safe return

unit

In case of a power outage, the fail-safe return

unit can be used to move to a preset safe

position (OPEN/CLOSE). Voltage supply (24 V

DC) implemented externally

199 190 604

Positioner

For continuous control operation (4-20 mA / 010 V)

199 190 603

Monitoring

For monitoring control time and motor current,

as well as for extending the control times and

counting the control cycles (even without bus

system) via a collective alarm

199 190 602

Profibus

For integrating the actuator into a Profibus DP

network

199 190 605

Diagnostic tool

For reading various data for a first error

diagnosis via USB

199 190 600

AS-Interface module

ASEV 2400

Connection to an AS-i network (supply in

combination with limit switch kit)

199 190 562

Adapter SW 11 for F04

Modification for valves with F04 interface

198 000 587

Adapter SW 14 for F05

Modification for valves with F05 interface

198 204 057

Reducer bushing WS 11

for F05

Adjustment for valves with F05 interface and

wrench size 11

198 803 145

Standard plug set

For the connection of accessories

198 000 502

Plug set 4 pin

For connection of MIDDLE position feedback

199 190 606

13 Accessories

69

Page 33

EC declaration of incorporation Operating manual

14 EC declaration of incorporation

EC Declaration of incorporation for incomplete machines (Machinery Directive 2006/42/

EC Annex II B) and EC declaration of conformity as per EMV and low voltage directive

(2004/108/EG), (2006/95/EG)

Manufacturer:

Georg Fischer Piping Systems Ltd., Ebnatstrasse 111, 8201 Schaffhausen / Switzerland

Person authorized to compile technical documentation:

Georg Fischer Piping Systems Ltd., R&D Manager, Ebnatstrasse 111, 8201 Schaffhausen /

Switzerland

We hereby confirm that the following incomplete machine

Electrical actuator

Type: EA25, EA45, EA120, EA250

Variants: 24V AC/DC, 100-230V AC

Article numbers: 198 153 182, 198 153 183, 198 153 184, 198 153 185, 198 153 186, 198 153

187, 198 153 188, 198 153 189

fulfils all the basic requirements of the machine directive 2006/42/EC, as far as the scope

of delivery allows. We further declare that the special technical documentation has been

compiled in accordance with Annex VII, Section B of this directive. We shall forward this,

if requested, to the competent authorities via the aforementioned authorized person.

Commissioning is prohibited until it has been established that the entire machine, into which

the aforementioned incomplete machine is to be incorporated, meets the provisions of

the machine directive 2006/42/EC.

The incomplete machine also meets the requirements of the following European directives,

implementing national legal provisions, and relevant harmonized standards:

Electromagnetic compatibility – Directive EMV (2004/108/EG)

Low voltage directive (2006/95/EG)

EN 15714-2 (Electrical actuators for industrial valves)

ISO 5211 (actuator interface)

EN 60068-2-6 (vibration tests)

VDE 0843 section 20 (EMV requirements)

Georg Fischer Piping Systems Ltd

Name: Antonio De Agostini

Position: R&D Manager

Georg Fischer Piping Systems Ltd

Date: 2016-01-11

70

Page 34

Operating manual Disposal

Parts of the product may be contaminated with media that are harmful to health and

the environment, so it is not enough just to clean them!

These media represent a risk of physical injury or damage to the environment.

Before disposing of the product:

Collect leaking media and dispose of them according to local regulations. Refer to

the safety data sheet.

Neutralize any media residues remaining in the product.

Separate the materials (plastics, metals etc.) and dispose of them according to local

regulations.

Products marked with this symbol must be taken to a separate collection point

for electrical and electronic devices.

If you have questions regarding the disposal of your product, please contact

your national GF Piping Systems representative.

15 Disposal

Before disposal, separate the different materials into recyclable materials, normal waste,

and special waste.

Comply with the local regulations and legislation when recycling or disposing of the

product, individual components, and packaging.

Comply with national regulations, standards and guidelines.

71

Page 35

GF Piping Systems

Worldwide at home

Our sales companies and representatives

ensure local customer support in over 100 countries

www.gfps.com

Argentina / Southern South America

Georg Fischer Central Plastics

Sudamérica S.R.L.

Buenos Aires, Argentina

Phone +54 11 4512 02 90

gfcentral.ps.ar@georgfischer.com

www.gfps.com/ar

Australia

George Fischer Pty Ltd

Riverwood NSW 2210 Australia

Phone +61 (0) 2 9502 8000

australia.ps@georgfischer.com

www.gfps.com/au

Austria

Georg Fischer

Rohrleitungssysteme GmbH

3130 Herzogenburg

Phone +43 (0) 2782 856 43-0

austria.ps@georgfischer.com

www.gfps.com/at

Belgium / Luxembourg

Georg Fischer NV/SA

1070 Bruxelles/Brüssel

Phone +32 (0) 2 556 40 20

be.ps@georgfischer.com

www.gfps.com/be

Brazil

Georg Fischer Sist. de Tub. Ltda.

04571-020 São Paulo/SP

Phone +55 (0)11 5525 1311

br.ps@georgfischer.com

www.gfps.com/br

Canada

Georg Fischer Piping Systems Ltd

Mississauga, ON L5T 2B2

Phone +1 (905) 670 8005

Fax +1 (905) 670 8513

ca.ps@georgfischer.com

www.gfps.com/ca

China

Georg Fischer Piping Systems Ltd

Shanghai 201319

Phone +86 21 3899 3899

china.ps@georgfischer.com

www.gfps.com/cn

Denmark / Iceland

Georg Fischer A/S

2630 Taastrup

Phone +45 (0) 70 22 19 75

info.dk.ps@georgfischer.com

www.gfps.com/dk

Finland

Georg Fischer AB

01510 VANTAA

Phone +358 (0) 9 586 58 25

Fax +358 (0) 9 586 58 29

info.fi.ps@georgfischer.com

www.gfps.com/fi

France

Georg Fischer SAS

95932 Roissy Charles de Gaulle Cedex

Phone +33 (0) 1 41 84 68 84

fr.ps@georgfischer.com

www.gfps.com/fr

Germany

Georg Fischer GmbH

73095 Albershausen

Phone +49 (0) 7161 302-0

info.de.ps@georgfischer.com

www.gfps.com/de

India

Georg Fischer Piping Systems Ltd

400 083 Mumbai

Phone +91 224007 2001

branchoce@georgfischer.com

www.gfps.com/in

Indonesia

George Fischer Pte Ltd –

Representative Oce

Phone +62 21 2900 8564

Fax +62 21 2900 8566

sgp.ps@georgfischer.com

www.gfps.com/sg

Italy

Georg Fischer S.p.A.

20063 Cernusco S/N (MI)

Phone +39 02 921 861

it.ps@georgfischer.com

www.gfps.com/it

Japan

Georg Fischer Ltd

556-0011 Osaka,

Phone +81 (0) 6 6635 2691

jp.ps@georgfischer.com

www.gfps.com/jp

Korea

GF Piping Systems

Georg Fischer Korea Co., Ltd.

Unit 2501, U-Tower

120 HeungdeokJungang-ro (Yeongdeok-dong)

Giheung-gu, Yongin-si, Gyeonggi-do, Korea

Phone: +82 31 8017 1450

Fax : +82 31 217 1454

kor.ps@georgfischer.com

www.gfps.com/kr

Malaysia

George Fischer (M) Sdn. Bhd.

40460 Shah Alam, Selangor Darul Ehsan

Phone +60 (0) 3 5122 5585

Fax +603 5122 5575

my.ps@georgfischer.com

www.gfps.com/my

Mexico / Northern Latin America

Georg Fischer S.A. de C.V.

Apodaca, Nuevo Leon

CP66636 Mexico

Phone +52 (81) 1340 8586

Fax +52 (81) 1522 8906

mx.ps@georgfischer.com

www.gfps.com/mx

Middle East

Georg Fischer

Piping Systems (Switzerland) Ltd

Dubai, United Arab Emirates

Phone +971 4 289 49 60

gcc.ps@georgfischer.com

www.gfps.com/int

Netherlands

Georg Fischer N.V.

8161 PA Epe

Phone +31 (0) 578 678 222

nl.ps@georgfischer.com

www.gfps.com/nl

Norway

Georg Fischer AS

1351 Rud

Phone +47 67 18 29 00

no.ps@georgfischer.com

www.gfps.com/no

Philippines

George Fischer Pte Ltd

Representative Oce

Phone +632 571 2365

Fax +632 571 2368

sgp.ps@georgfischer.com

www.gfps.com/sg

Poland

Georg Fischer Sp. z o.o.

05-090 Sekocin Nowy

Phone +48 (0) 22 31 31 0 50

poland.ps@georgfischer.com

www.gfps.com/pl

Romania

Georg Fischer

Piping Systems (Switzerland) Ltd

020257 Bucharest - Sector 2

Phone +40 (0) 21 230 53 80

ro.ps@georgfischer.com

www.gfps.com/int

Russia

Georg Fischer

Piping Systems (Switzerland) Ltd

Moscow 125040

Phone +7 495 748 11 44

ru.ps@georgfischer.com

www.gfps.com/ru

Singapore

George Fischer Pte Ltd

11 Tampines Street 92, #04-01/07

528 872 Singapore

Phone +65 6747 0611

Fax +65 6747 0577

sgp.ps@georgfischer.com

www.gfps.com/sg

Spain / Portugal

Georg Fischer S.A.

28046 Madrid

Phone +34 (0) 91 781 98 90

es.ps@georgfischer.com

www.gfps.com/es

Sweden

Georg Fischer AB

117 43 Stockholm

Phone +46 (0) 8 506 775 00

info.se.ps@georgfischer.com

www.gfps.com/se

Switzerland

Georg Fischer

Rohrleitungssysteme (Schweiz) AG

8201 Schahausen

Phone +41 (0) 52 631 30 26

ch.ps@georgfischer.com

www.gfps.com/ch

Taiwan

Georg Fischer Co., Ltd

San Chung Dist., New Taipei City

Phone +886 2 8512 2822

Fax +886 2 8512 2823

www.gfps.com/tw

United Kingdom / Ireland

George Fischer Sales Limited

Coventry, CV2 2ST

Phone +44 (0) 2476 535 535

uk.ps@georgfischer.com

www.gfps.com/uk

USA / Caribbean

Georg Fischer LLC

9271 Jeronimo Road

92618 Irvine, CA

Phone +1 714 731 88 00

Fax +1 714 731 62 01

us.ps@georgfischer.com

www.gfps.com/us

International

Georg Fischer

Piping Systems (Switzerland) Ltd

8201 Schahausen/Switzerland

Phone +41 (0) 52 631 30 03

Fax +41 (0) 52 631 28 93

info.export@georgfischer.com

www.gfps.com/int

The technical data are not binding. They neither constitute expressly

warranted characteristics nor guaranteed properties nor a guaranteed durability.

They are subject to modification. Our General Terms of Sale apply.

700.278.091

GFDO_6414_1_4 (01.16)

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2016

Loading...

Loading...