Page 1

Ball Valves

George Fischer 3-Way Horizontal Ball Valve Type 343

George Fischer plastic

ball valves have the

following outstanding

features:

• Corrosion resistance

• Ideal flow

characteristics

• Long working life,

maintenance-free

• Light weight

• Silicone free versions

available

• Ball valves Type 343

can be equiped with

George Fischer

electric or pneumatic

actuators (refer to

Type 101 and Type

201 in Section 11)

• Can be actuated

after installation

George Fischer offers a wide range of

manually operated ball valves. The

introduction of the new 3-way ball valve

further extends the industrial product

range. 3-way ball valves are usually

installed for diverting and mixing liquids

in piping systems. While the 3-way ball

valve with L-port is used for the distribution of liquids or the interruption of the

flow, the T-port ball valve is the ideal

solution for mixing of liquids.

The Type 343 is available in PVC, CPVC,

PP and PVDF and also in all the relevant

standards ISO/DIN, BS, ASTM/ANSI,

JIS.

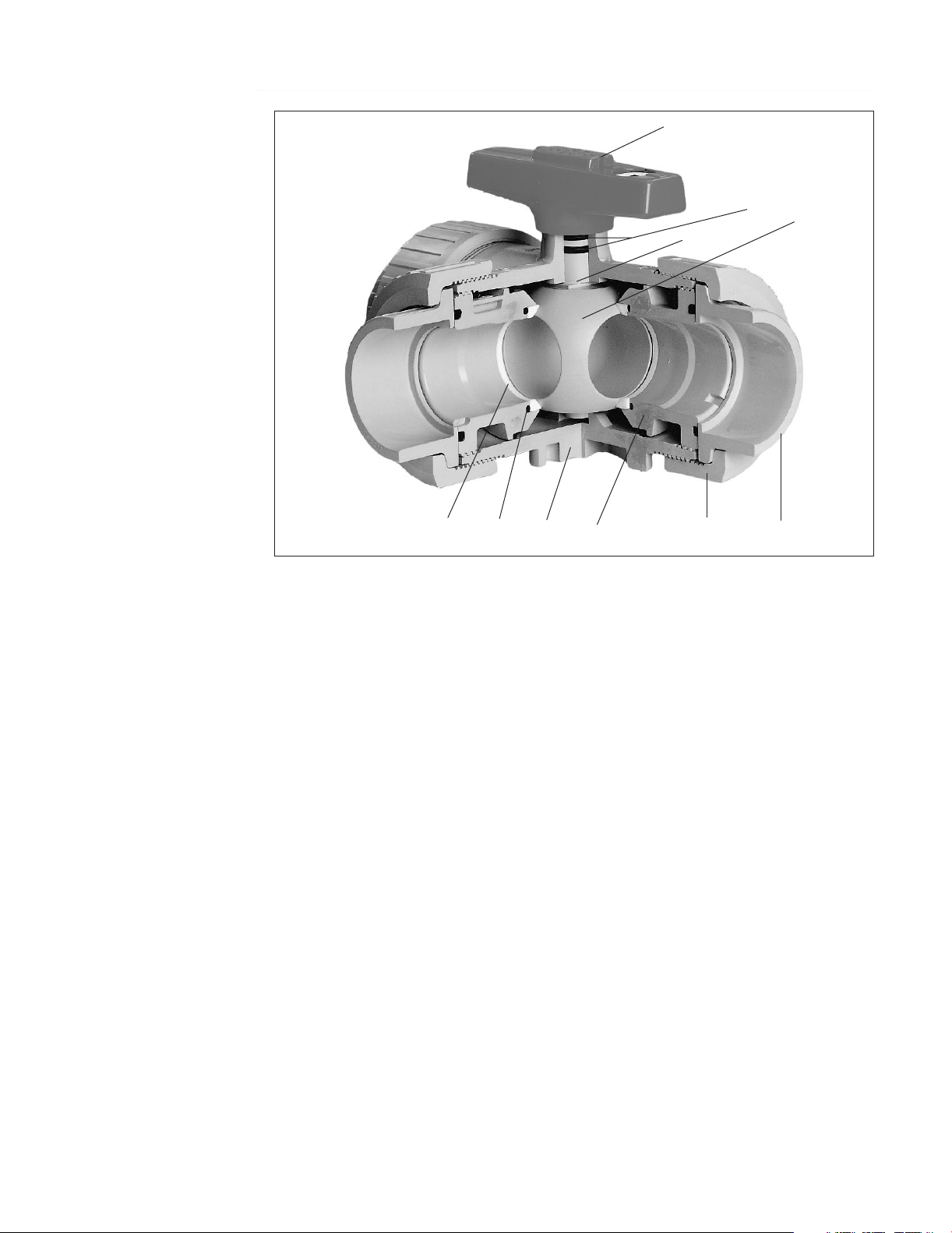

Technical Features

º Position indicator on handle and stem

for easy recognition of function

º Union ends for easy installation and

disassembly

º Handle with integrated tool for easy

maintenance

º High safety via 3 separately inte-

grated union bushings with left hand

threads

L-port ball:

Provides independent connection of

inlets with outlet.

T-port ball:

Provides straight through flow (left to

right), independent connection of inlets

with outlets or interconnection of all three

ports.

º High reliability and long life-span via

3 separate PTFE ball seals directly in

contact with the ball, supported by an

O-ring

º Integrated universal mounting system

for simple and efficient installation.

10

www.us.piping.georgefischer.com

10.45

Page 2

Technical Data

k

g

a) Connections

– sockets

– spigots

– threaded sockets

– IR/butt fusion ends

b) Union ends, allow installation or

removal of the connection parts for

easy inspection and maintenance.

The pipeline should be depressurised before dismantling.

c) Union bushing with left-hand thread

and molded end prevents ball from

being blown out by line fluid.

d) Balls with L- or T-port with diverting/

mixing function.

e) Double sealing on the stem for

maintenance free operation.

h

e

f

l

c

f) High strength stem.

g) PTFE ball seal is extremely abrasion

resistant and has good antifriction

properties, good chemical resistance

and a long service life.

h) Backing O-ring automatically com-

pensates for expansion and contraction in the valve and ball seal wear,

resulting in maintenance free operation with low friction ball movement.

k) Handle with integrated position indi-

cator and tool function: the position

of the ball is visible on the handle.

The integrated cams allow the

assembly and dismantling of the ball

valve without additional tooling.

l) Integrated fixing with insert screws.

b

d

a

10.46

¬ ‡

Page 3

Ball Valves

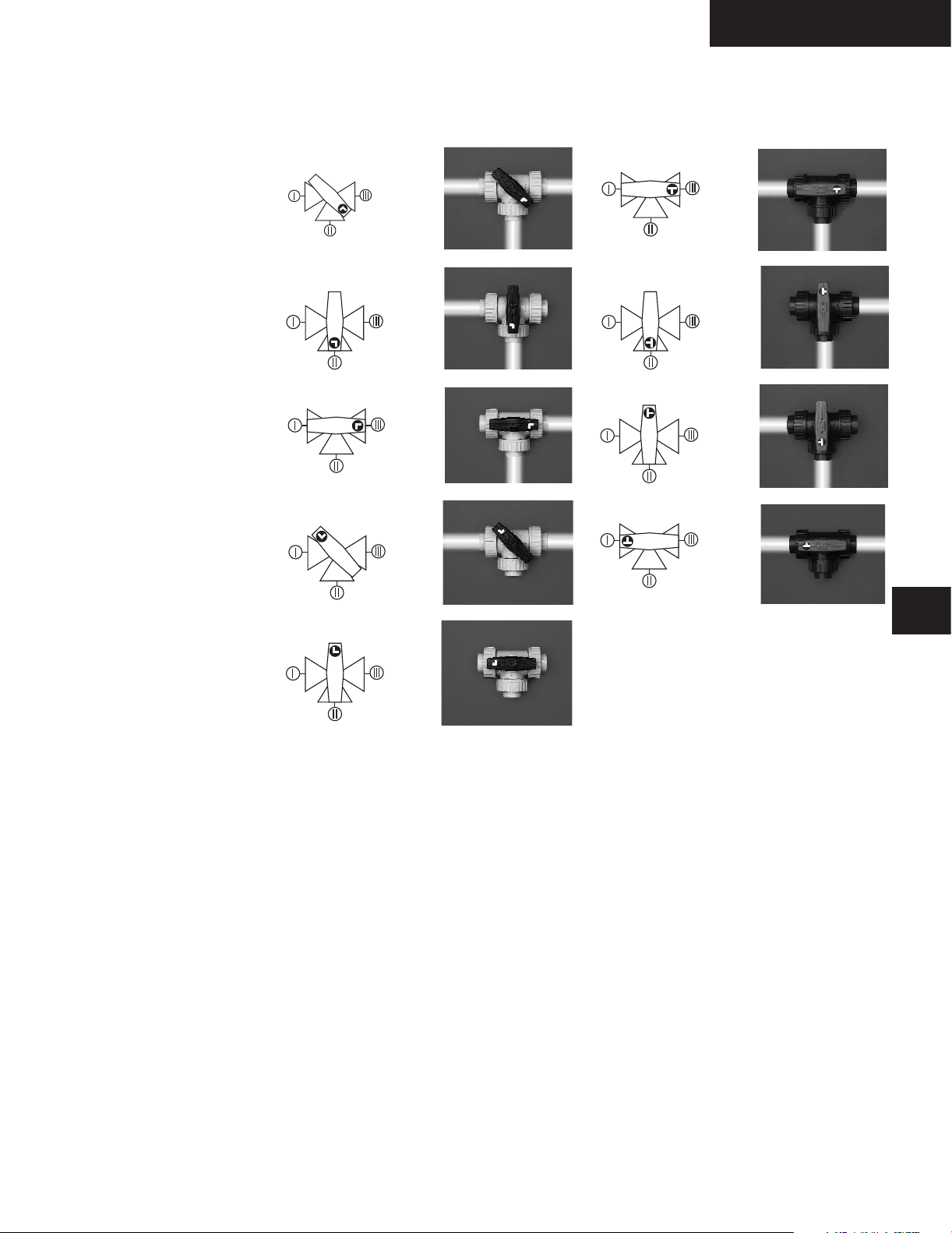

Functions

The following illustrations show the functions and the corresponding position of

the handle:

Mixing function

Diverting function

Diverting function

Branch closed/

passage open

L-port

T-port

*

*

Closed

10

Example 1 Example 2

* Cv/kv-value low

www.us.piping.georgefischer.com

10.47

Page 4

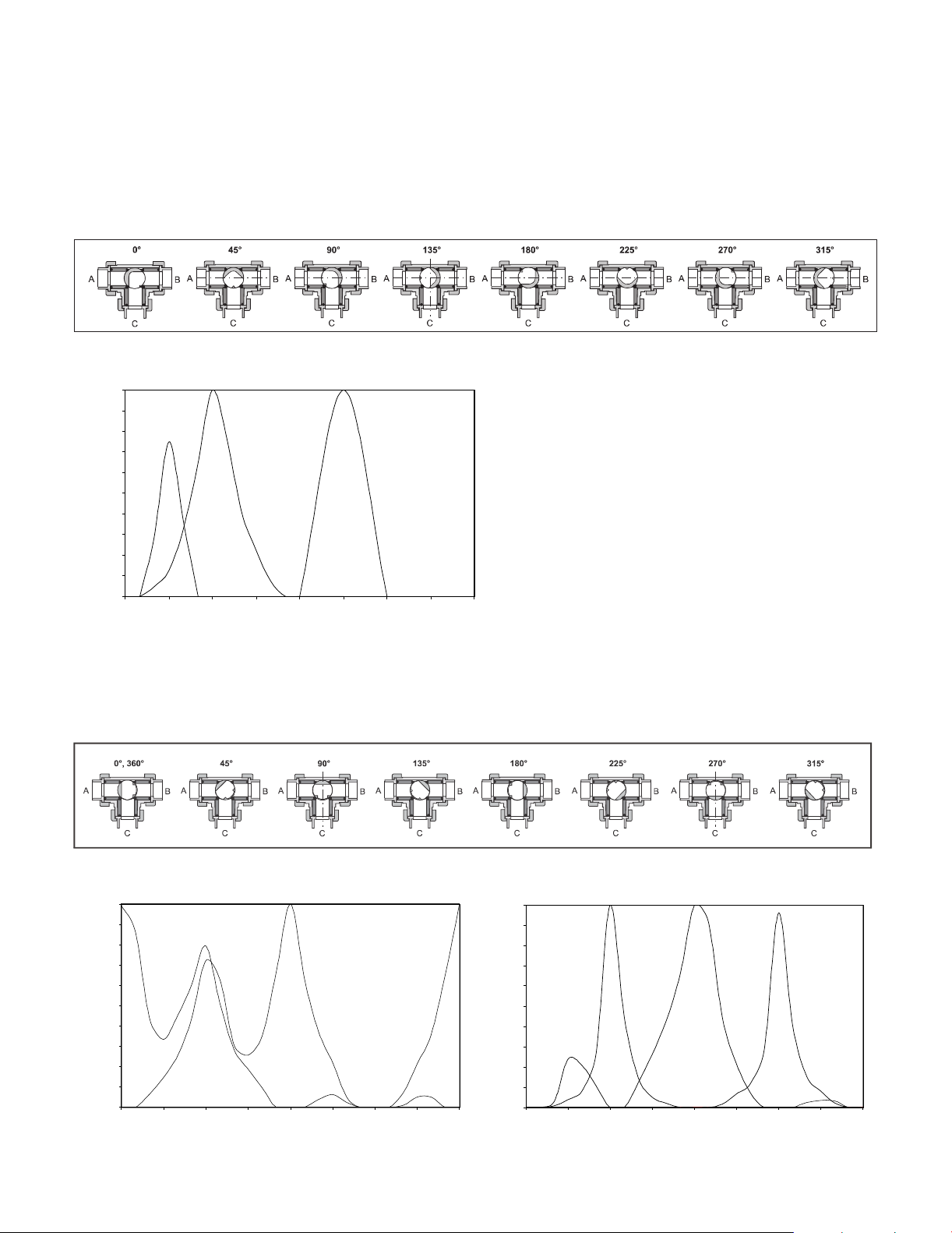

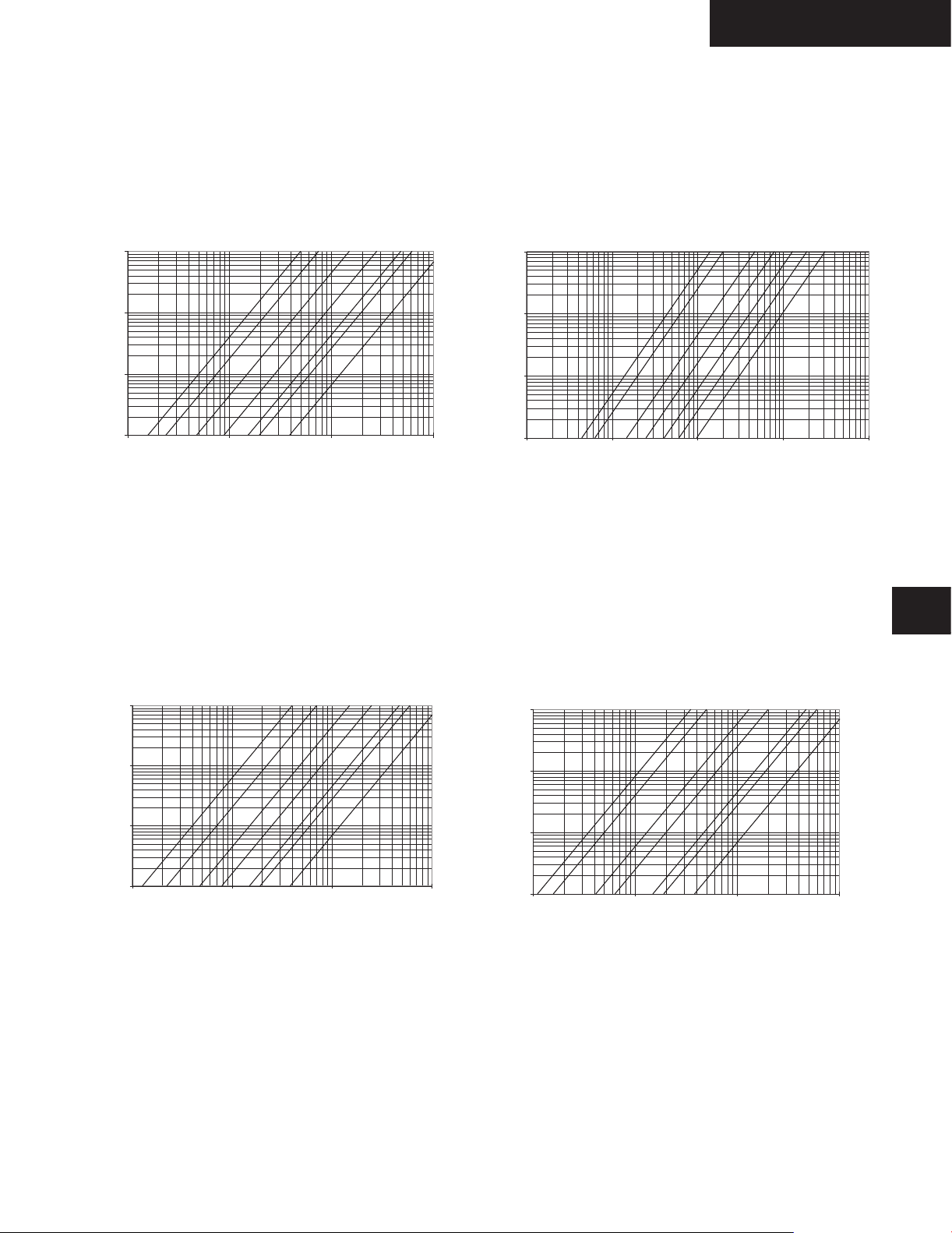

Flow Characteristics

The kv factor is defined as the flow rate of water in litres per minute with a pressure drop of 1 kg/cm2 across the

valve.

The shown k

v-values are in %, to calculate the absolute flow multiply these values with the corresponding values

from the tables.

L-port

Valve positions L-port:

Flow A . B and A . C

100%

90%

A - B

80%

70%

60%

50%

[%]

v

K

40%

30%

20%

10%

0%

0 45 90 135 180 225 270 315 360

a Angle of operation

K

v Kv-value

[°]

a

A - BA - C

F176.1

T-port

Valve positions T-port:

Flow C . A and C . B

100%

C - B

90%

80%

70%

60%

50%

[%]

v

K

40%

30%

20%

10%

0%

0 45 90 135 180 225 270 315 360

C - A

Flow A . B and A . C

100%

90%

80%

C - B

C - A

[°]

a

F200.1

70%

60%

50%

[%]

v

K

40%

30%

20%

10%

0%

0 45 90 135 180 225 270 315 360

A - B

A - C

A - C

A - B

[°]

a

F177.1

a Angle of operation

v Kv-value

K

10.48

a Angle of operation

v Kv-value

K

¬ ‡

Page 5

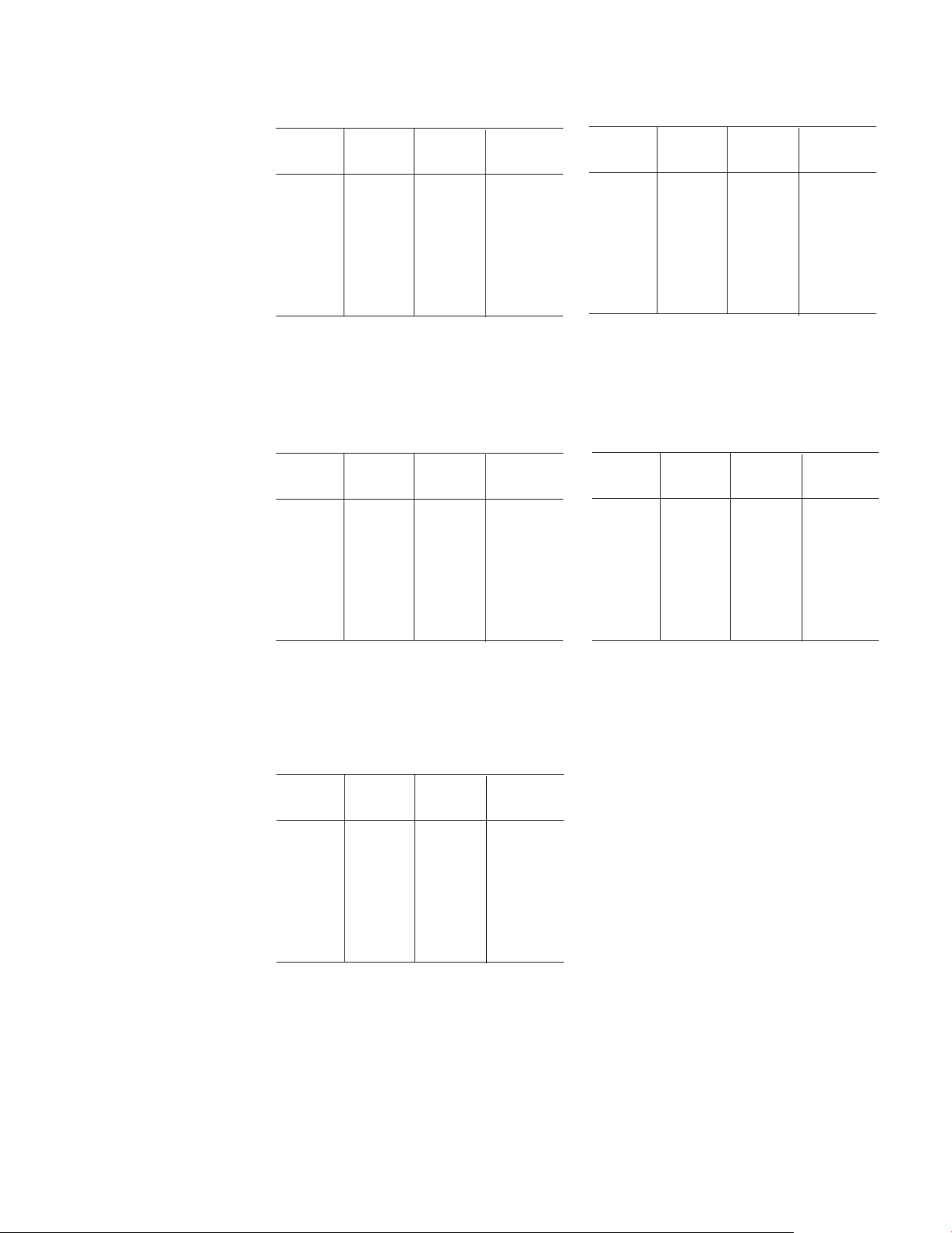

Pressure Loss Characteristics

Ball Valves

L-port

Flow C . A

Valve position: 90°

1

0.1

0.01

0.001

1 10 100 1000

Medium: water, 20°C

X Flow rate (l/min)

Y Pressure loss p (bar)

DN10 DN15 DN20 DN25 DN32 DN40

X

T-port

Flow A . C

Valve position: 180°

DN50

T-port

Flow A . B

Valve position: 90°

DN20

1

0.1

0.01

0.001

1 10 100 1000 10000

DN10 DN15

X

Medium: water, 20°C

X Flow rate (l/min)

Y Pressure loss p (bar)

DN25

DN32

T-port

Flow C . A and C . B

Valve position: 180°

DN40

DN50

10

1

0.1

0.01

0.001

1 10 100 1000

DN10 DN15 DN20 DN25 DN32 DN40

X

Medium: water, 20°C

X Flow rate (l/min)

Y Pressure loss p (bar)

DN50

1

0.1

0.01

0.001

1 10 100 1000

DN10 D N15 DN20 DN25 DN32 DN40

X

Medium: water, 20°C

X Flow rate (l/min)

Y Pressure loss p (bar)

DN50

www.us.piping.georgefischer.com

10.49

Page 6

L-port

Flow A . C, C . A, B . C, C . B

Valve position: 90°

L-port

Flow A . B

Valve position: 225°

Inch C

size gal/min l/min mm

3/8

1/2

3/4

1

1 1/4

1 1/2

2

v K

3.50 50 16

5.25 75 2o

10.50 150 25

19.60 280 32

33.61 480 40

43.42 620 50

86.13 1230 63

v

100 d

T-port

Flow A . B

Valve position: 90°

Inch Cv Kv 100 d

size gal/min l/min mm

3/8

1/2

3/4

1

1 1/4

1 1/2

2

9.80 140 16

14.01 200 20

32.91 470 25

55.53 793 32

90.34 1290 40

133.75 1910 50

217.09 3100 63

Inch Cv Kv 100 d

size gal/min l/min mm

3/8

1/2

3/4

1

1 1/4

1 1/2

2

0.70 10 16

1.05 15 20

2.10 30 25

3.50 50 32

6.30 90 40

7.70 110 50

15.41 220 63

T-port

Flow A . C

Valve position: 180°

Inch Cv Kv 100 d

size gal/min l/min mm

3/8

1/2

3/4

1

1 1/4

1 1/2

2

2.80 40 16

4.90 70 20

10.50 150 25

17.51 250 32

32.91 470 40

42.02 600 50

84.73 1210 63

T-port

Flow C . A and C . B

Valve position: 180°

Inch Cv Kv 100 d

size gal/min l/min mm

3/8

1/2

3/4

1

1 1/4

1 1/2

2

C

v = gal./min at 1 psi pressure drop

Kv = litres/min at 1 bar pressure drop

2.45 35 16

3.50 50 20

9.10 130 25

14.01 200 32

26.61 380 40

32.91 470 50

62.32 890 63

10.50

¬ ‡

Page 7

Dimensions

3-Way Ball Valve Type 343 Horizontal

with sockets

Ball Valves

L

3

PVC

CPVC

solvent cement sockets

PP

metric fusion sockets

PVDF

metric fusion sockets

d DNInchz z1DHH1H

mm mm size inch inch inch inch inch inch inch inch inch inch inch inch mm

16 10 13/8 3.15 1 .57 1 .69 1 .97 1.06 0.31 4.76 3.07 2.83 2.40 0.98 1.42 6

20 15 11/2 3.15 1 .57 1 .69 1 .97 1 .06 0.31 4.76 3.07 2.83 2.40 0.98 1.42 6

25 20 13/4 3.70 1 .85 2.05 2.36 1 .30 0.31 5.59 3.62 3.39 2.80 0.98 1 .69 6

32 25 1 4.09 2.05 2.56 2.68 1 .42 0.31 6.22 3.94 3.78 3.11 0.98 1 .89 6

40 32 11/4 4.96 2.48 3.07 3.11 1 .73 0.35 7.60 4.33 4.57 3.82 1 .77 2.28 8

50 40 11/2 5.67 2.83 3.62 3.54 1 .93 0.35 8.35 4.72 5.39 4.17 1 .77 2.72 8

63 50 2 7.32 3.66 4.57 4.29 2.40 0.35 10.43 5.75 7.05 5.24 1.77 3.54 8

d DN Inch z z

mm mm size inch inch inch inch inch inch inch inch inch inch inch inch mm

16 10 13/8 3.07 1 .54 1 .81 1 .97 1.06 0.31 4.25 3.07 2.76 2.13 0.98 1 .42 6

20 15 11/2 3.11 1 .57 1 .81 1 .97 1.06 0.31 4.37 3.07 2.76 2.20 0.98 1 .42 6

25 20 13/4 3.74 1 .89 2.20 2.36 1 .30 0.31 5.16 3.62 3.39 2.60 0.98 1 .69 6

32 25 1 4.25 2.13 2.64 2.68 1 .42 0.31 5.83 3.94 3.78 2.91 0.98 1 .89 6

40 32 11/4 5.24 2.64 3.23 3.11 1 .73 0.35 6.97 4.33 4.49 3.50 1 .77 2.28 8

50 40 11/2 6.10 3.07 3.86 3.54 1 .93 0.35 8.07 4.72 5.39 4.06 1 .77 2.72 8

63 50 2 7.99 4.02 4.76 4.29 2.40 0.35 10.28 5.75 7.05 5.16 1 .77 3.54 8

d DN Inch z z

mm mm size inch inch inch inch inch inch inch inch inch inch inch inch mm

16 10 13/8 3.07 1 .54 1 .81 1 .97 1.06 0.31 4.25 3.07 2.76 2.13 0.98 1 .42 6

20 15 11/2 3.11 1 .57 1 .81 1 .97 1 .06 0.31 4.37 3.07 2.76 2.20 0.98 1 .42 6

25 20 13/4 3.74 1 .89 2.20 2.36 1 .30 0.31 5.16 3.62 3.39 2.60 0.98 1 .69 6

32 25 1 4.25 2.13 2.64 2.68 1 .42 0.31 5.79 3.94 3.78 2.91 0.98 1 .89 6

40 32 11/4 5.24 2.64 3.19 3.11 1 .73 0.35 6.93 4.33 4.49 3.46 1.77 2.28 8

50 40 11/2 6.10 3.07 3.82 3.54 1 .93 0.35 8.03 4.72 5.39 4.02 1 .77 2.72 8

63 50 2 7.99 4.02 4.69 4.29 2.40 0.35 10.20 5.75 7.05 5.12 1 .77 3.54 8

DHH1H2LL1L

1

DHH1H2LL1L2L3L

1

LL1L2L3L4L

2

2

L3L4L

4

5

5

L5M

M

M

10

www.us.piping.georgefischer.com

10.51

Page 8

Dimensions

3-Way Ball Valve Type 343 Horizontal

with threaded sockets NPT

L

3

PVC

CPVC

PP

PVDF

Inch d z z1DH H1H

size mm inch inch inch inch inch inch inch inch inch inch inch inch mm

LL1L

2

L

L

L

2

4

3

M

5

13/8 16 2.99 1 .50 1 .69 1 .97 1 .06 0.31 4.49 3.07 2.83 2.24 0.98 1.42 6

11/2 20 2.99 1 .50 1 .69 1 .97 1 .06 0.31 4.53 3.07 2.83 2.28 0.98 1.42 6

13/4 25 3.54 1 .77 2.05 2.36 1 .30 0.31 5.20 3.62 3.39 2.60 0.98 1.69 6

1 32 3.94 1 .97 2.56 2.68 1 .42 0.31 5.98 3.94 3.78 2.99 0.98 1 .89 6

11/4 40 4.80 2.40 3.07 3.11 1.73 0.35 6.97 4.33 4.57 3.50 1 .77 2.32 8

11/2 50 5.98 2.99 3.62 6.54 1.93 0.35 8.07 4.72 5.39 4.06 1 .77 2.72 8

2 63 7.87 3.94 4.57 4.29 2.40 0.35 10.28 5.75 7.05 5.16 1.77 3.54 8

Inch d z z1DHH1H

size mm inch inch inch inch inch inch inch inch inch inch inch inch mm

LL1L

2

L

L

L

2

4

3

M

5

13/8 16 2.99 1 .50 1 .81 1.97 1 .06 0.31 4.49 3.07 2.76 2.24 0.98 1 .42 6

11/2 20 2.99 1 .50 1 .81 1 .97 1.06 0.31 4.53 3.07 2.76 2.28 0.98 1.42 6

13/4 25 3.54 1 .77 2.20 2.36 1 .30 0.31 5.20 3.62 3.39 2.60 0.98 1 .69 6

1 32 3.94 1 .97 2.64 2.68 1 .42 0.31 5.98 3.94 3.78 2.99 0.98 1 .89 6

11/4 40 4.80 2.40 3.19 3.11 1 .73 0.35 6.97 4.33 4.49 3.50 1 .77 2.32 8

11/2 50 5.98 2.99 3.82 6.54 1 .93 0.35 8.07 4.72 5.39 4.06 1.77 2.72 8

2 63 7.87 3.94 4.69 4.29 2.40 0.35 10.28 5.75 7.05 5.16 1 .77 3.54 8

10.52

¬ ‡

Page 9

Dimensions

3-Way Ball Valve Type 343 Horizontal

with IR/butt fusion ends

Ball Valves

PP

PVDF

d DN Inch D H H

mm mm size inch inch inch inch inch inch inch inch inch inch mm

H

1

LL1L

2

L

L

L

2

4

5

M

6

20 15 11/2 1 .81 1 .97 1 .06 0.31 5.51 3.07 2.76 0.98 1.42 2.76 6

25 20 13/4 2.20 2.36 1 .30 0.31 6.14 3.62 3.39 0.98 1 .69 3.07 6

32 25 1 2.64 2.68 1 .42 0.31 6.61 3.94 3.78 0.98 1.89 3.31 6

40 32 11/4 3.23 3.11 1 .73 0.35 7.80 4.33 4.40 1 .77 2.28 3.90 8

50 40 11/2 3.86 3.54 1 .93 0.35 9.17 4.72 5.39 1 .77 2.72 4.61 8

63 50 2 4.76 4.29 2.40 0.35 11 .18 5.75 7.05 1.77 3.54 5..59 8

d DN Inch D H H

mm mm size inch inch inch inch inch inch inch inch inch inch mm

H

1

LL1L

2

L

L

L

2

4

5

M

6

16 10 13/8 1.81 1 .97 1 .06 0.31 4.69 3.07 2.76 0.98 1.42 2.36 6

20 15 11/2 1 .81 1 .97 1 .06 0.31 5.51 3.07 2.76 0.98 1.42 2.76 6

25 20 13/4 2.20 2.36 1 .30 0.31 6.14 3.62 3.39 0.98 1 .69 3.07 6

32 25 1 2.64 2.68 1 .42 0.31 6.61 3.94 3.78 0.98 1.89 3.31 6

40 32 11/4 3.19 3.11 1 .73 0.35 7.80 4.33 4.40 1 .77 2.28 3.90 8

50 40 11/2 3.82 3.54 1 .93 0.35 9.17 4.72 5.39 1 .77 2.72 4.61 8

63 50 2 4.69 4.29 2.40 0.35 11 .22 5.75 7.05 1 .77 3.54 5.63 8

10

www.us.piping.georgefischer.com

10.53

Page 10

Integrated, Universal Mounting System

The 3-way ball valve Type 343 has an

integrated mounting unit (insert screws in

high-grade steel). The George Fischer

mounting blocks are designed to allow

ble with George Fischer’s pipe clips.

The mounting blocks can be used for

PVC, CPVC, PP, PVDF ball valves Type

343 horizontal, 3/8" - 2".

different size George Fischer Valves to

be aligned with the same pipe center

line by equalizing the different heights

from the base to the center line of the

Mounting blocks:

material PP-GF 15, black,

3 sizes

pipe. They are designed to be compati-

Mounting Blocks for

3-Way Horizontal Ball Valve Type 343

Types/Dimensions

H

L

10.54

2

L1L

D

Inch DN d Part Number H L

size mm mm inch inch inch inch inch inch inch lbs.

3

/8–1/21)16/20 10/15 167 480 423 0.14 0.98 0.67 1.65 1 .83 0.30 0.31 0.088

3

/4–1 25–32 20–25 167 482 238 0.59 0.98 0.67 1.65 1 .83 0.30 0.31 0.0352

11/4–2 40–63 32–50 167 482 239 0.43 1 .77 0.87 2.64 3.15 0.37 0.35 0.0616

1)

For dimensions 3/8" & 1/2", the two mounting blocks need to be ordered separately and have to be assembled.

167 482 238 0.59 0.98 0.67 1 .65 1 .83 0.30

3

L

1

H

L

L

2

3

LDH1Weight

1

¬ ‡

Page 11

Operation

I

I

Ball Valves

Part Numbers for Type 343, Horizontal Model, L-port Ball

PVC

Inch with solvent cement socket, ASTM with taper female thread, NPT

size EPDM seals FPM* seals EPDM seals FPM* seals

3/8 161 343 081 161 343 091 161 343 101 161 343 111

1/2 161 343 082 161 343 092 161 343 102 161 343 112

3/4 161 343 083 161 343 093 161 343 103 161 343 113

III

1 161 343 084 161 343 094 161 343 104 161 343 114

1-1/4 161 343 085 161 343 095 161 343 105 161 343 115

1-1/2 161 343 086 161 343 096 161 343 106 161 343 116

II

II

2 161 343 087 161 343 097 161 343 107 161 343 117

CPVC

Inch with solvent cement socket, ASTM with taper female thread, NPT

size EPDM seals FPM* seals EPDM seals FPM* seals

3/8 163 343 081 163 343 091 163 343 101 163 343 111

1/2 163 343 082 163 343 092 163 343 102 163 343 112

III

3/4 163 343 083 163 343 093 163 343 103 163 343 113

1 163 343 084 163 343 094 163 343 104 163 343 114

1-1/4 163 343 085 163 343 095 163 343 105 163 343 115

1-1/2 163 343 086 163 343 096 163 343 106 163 343 116

2 163 343 087 163 343 097 163 343 107 163 343 117

Polypropylene

d DN metric fusion socket metric IR/butt fusion Inch

mm Dmm EPDM Seals FPM* Seals EPDM Seals FPM* Seals size

16 10 167 343 001 167 343 011 N/A N/A 3/8

20 15 167 343 002 167 343 012 167 343 062 167 343 072 1/2

25 20 167 343 003 167 343 013 167 343 063 167 343 073 3/4

32 25 167 343 004 167 343 014 167 343 064 167 343 074 1

40 32 167 343 005 167 343 015 167 343 065 167 343 075 1

III

I

50 40 167 343 006 167 343 016 167 343 066 167 343 076 1

63 50 167 343 007 167 343 017 167 343 067 167 343 077 2

-1/4

-1/2

10

Polypropylene

II

I

II

Inch with taper female thread, NPT

size EPDM seals FPM* seals

3/8 167 343 161 167 343 171

1/2 167 343 162 167 343 172

3/4 167 343 163 167 343 173

1 167 343 164 167 343 174

1-1/4 167 343 165 167 343 175

1-1/2 167 343 166 167 343 176

2 167 343 167 167 343 177

PVDF

d DN metric fusion socket metric IR/butt fusion threaded NPT Inch

mm mm FPM* seals FPM* seals FPM* seals size

16 10 175 343 011 N/A 175 343 071 3/8

III

20 15 175 343 012 175 343 052 175 343 072 1/2

25 20 175 343 013 175 343 053 175 343 073 3/4

32 25 175 343 014 175 343 054 175 343 074 1

40 32 175 343 015 175 343 055 175 343 075 1-1/4

50 40 175 343 016 175 343 056 175 343 076 1-1/2

63 50 176 343 017 175 343 057 175 343 077 2

www.us.piping.georgefischer.com

* FPM seals are made of Viton® or equal materials.

®

Viton

is a registered trademark of DuPont Dow Elastomers.

10.55

Page 12

Operation

I

I

Part Numbers for Type 343, Horizontal Model, T-port Ball

PVC

Inch with solvent cement socket, ASTM with taper female thread, NPT

size EPDM seals FPM* seals EPDM seals FPM* seals

3/8 161 343 281 161 343 291 161 343 301 161 343 311

1/2 161 343 282 161 343 292 161 343 302 161 343 312

3/4 161 343 283 161 343 293 161 343 303 161 343 313

1 161 343 284 161 343 294 161 343 304 161 343 314

III

1-1/4 161 343 285 161 343 295 161 343 305 161 343 315

1-1/2 161 343 286 161 343 296 161 343 306 161 343 316

2 161 343 287 161 343 297 161 343 307 161 343 317

II

CPVC

Inch with solvent cement socket, ASTM with taper female thread, NPT

size EPDM seals FPM* seals EPDM seals FPM* seals

3/8 163 343 281 163 343 291 163 343 301 163 343 311

1/2 163 343 282 163 343 292 163 343 302 163 343 312

3/4 163 343 283 163 343 293 163 343 303 163 343 313

III

1 163 343 284 163 343 294 163 343 304 163 343 314

1-1/4 163 343 285 163 343 295 163 343 305 163 343 315

1-1/2 163 343 286 163 343 296 163 343 306 163 343 316

II

2 163 343 287 163 343 297 163 343 307 163 343 317

Polypropylene

d DN metric fusion socket metric IR/butt fusion Inch

mm mm EPDM seals FPM* seals EPDM seals FPM* seals size

16 10 167 343 201 167 343 211 N/A N/A 3/8

20 15 167 343 202 167 343 212 167 343 262 175 343 272 1/2

25 20 167 343 203 167 343 213 167 343 263 175 343 273 3/4

32 25 167 343 204 167 343 214 167 343 264 175 343 274 1

40 32 167 343 205 167 343 215 167 343 265 175 343 275 1

III

I

50 40 167 343 206 167 343 216 167 343 266 175 343 276 1

63 50 167 343 207 167 343 217 167 343 267 175 343 277 2

-1/4

-1/2

Polypropylene

II

Inch with taper female thread, NPT

size EPDM seals FPM* seals

3/8 167 343 361 167 343 371

1/2 167 343 362 167 343 372

3/4 167 343 363 167 343 373

1 167 343 364 167 343 374

1-1/4 167 343 365 167 343 375

1-1/2 167 343 366 167 343 376

2 167 343 367 167 343 377

PVDF

d DN metric fusion socket metric IR/butt fusion threaded NPT Inch

mm mm FPM* seals FPM* seals FPM* seals size

16 10 175 343 111 N/A 175 343 171 3/8

20 15 175 343 112 175 343 152 175 343 172 1/2

III

I

II

25 20 175 343 113 175 343 153 175 343 173 3/4

32 25 175 343 114 175 343 154 175 343 174 1

40 32 175 343 115 175 343 155 175 343 175 1-1/4

50 40 175 343 116 175 343 156 175 343 176 1-1/2

63 50 176 343 117 175 343 157 175 343 177 2

10.56

* FPM seals are made of Viton® or equal materials.

®

is a registered trademark of DuPont Dow Elastomers.

Viton

¬ ‡

Page 13

Product Specification

Ball Valves

*FPM seals are made of

®

or equal materials.

Viton

®

Viton

is a registered trademark of DuPont Dow Elastomers.

Type 343 True Union 3-Way

Ball Valve - PVC

PVC true union 3-way ball valves 3/8"

through 2" shall be available in horizontal configuration and have either solvent

cement socket or threaded pipe connections. Horizontal configurations shall be

supplied with a union connection on the

outlet branch, it having its own individual

ball seat (seal) enabling the option to be

supplied with a "T" ported ball for flowthrough operation. Incorporated into its

design safety features is a blow-out

proof stem and the ability to hold

pressure when the downstream union nut

is removed. Seats shall be PTFE with

backing rings creating self-adjusting

seals and constant operating torque.

Backing rings and seals shall be EPDM

or FPM*. The handle shall include in its

design a key for removal of the seat

carrier in addition to having sufficient

elevation to permit hand clearance. Seat

carrier shall have left-hand threads to

prevent possible unscrewing when

threaded end connectors are removed

from pipe. Material shall meet or exceed

the requirements of 12454-B according

to the classifications and requirements of

ASTM D-1784. Socket end connection

dimensions shall conform to ASTM D-

2467. Threaded pipe connections shall

be in accordance with ASTM D-2464

which references ANSI B1.20.1 (was

B2.1) for tapered pipe threads. Optional

flanged version shall be in accordance

with ANSI B16.5, class 150 flanges. The

valve, type 343, shall carry a pressure

rating of 150 psi at 68°F as supplied by

George Fischer, Inc., Tustin, CA 92780.

Type 343 True Union 3-Way

Ball Valve - CPVC

CPVC true union ball valves 1/2"

through 2" shall be available in horizontal configuration and have either solvent

cement socket or threaded pipe connections. Horizontal configurations shall be

supplied with a union connection on the

outlet branch, it having its own individual

ball seat (seal) enabling the option to be

supplied with a "T" ported ball for flowthrough operation. Incorporated into its

design safety features is a blow-out

proof stem and the ability to hold

pressure when the downstream union nut

is removed. Seats shall be PTFE with

backing rings creating self-adjusting

seals and constant operating torque.

Backing rings and seals shall be EPDM

or FPM*. The handle shall include in its

design a key for removal of the seat

carrier in addition to having sufficient

elevation to permit hand clearance. Seat

carrier shall have left-hand threads to

prevent possible unscrewing when

threaded end connectors are removed

from pipe. Material shall meet or exceed

the requirements of 23447-B according

to the classifications and requirements of

ASTM D-1784. Socket end connection

dimensions shall conform to ASTM F439

(formerly D-2467). Threaded end connections shall conform to the dimensions

as listed in ASTM F437 (formerly D-2464)

which references ANSI B1.20.1 (was

B2.1) for tapered pipe threads. The

valve, type 343, shall carry a pressure

rating of 150 psi at 68°F as supplied by

George Fischer, Inc., Tustin, CA 92780.

10

www.us.piping.georgefischer.com

10.57

Page 14

Product Specification

*FPM seals are made of

Viton® or equal materials.

®

is a registered

Viton

trademark of DuPont Dow

Elastomers.

10.58

Type 343 True Union 3-way

Ball Valve - PVDF

PVDF true union 3-way ball valves 1/2"

through 2" (20 mm - 63 mm) shall be

available in horizontal configuration and

have either metric fusion socket or

threaded type pipe connections. Horizontal configurations shall be supplied

with a union connection on the outlet

branch, it having its own individual ball

seat (seal) enabling the option to be

supplied with a "T" ported ball for flowthrough operation. Incorporated into its

design safety features is a blow-outproof stem and the ability to hold

pressure when the downstream union nut

is removed. Seats shall be PTFE with

backing rings creating self-adjusting,

constant operating torque sealing

characteristics. Backing rings and seals

shall be FPM*. The handle shall include

in its design a key for removal of the seat

carrier in addition to providing sufficient

height to permit hand clearance. Seat

carrier shall have left-hand threads to

prevent possible unscrewing when

threaded end connector is installed on

the pipe. Material shall meet or exceed

the requirements of ASTM D 3222 as

pertains to a natural, unpigmented,

virgin, noncompounded polyvinylidene

fluoride compound having a minimum

tensile strength of 7800 psi/538 bar at

73°F/20°C when tested in accordance

with ASTM D 638 and shall have a

flexural strength of 10,700 psi/738 bar

at 73°F/20°C when tested according to

ASTM D 790. End connections shall be

as outlined in ASTM D 2657 for fusion

socket joining, and shall be compatible

with metric pipe and fittings as manufactured by George Fischer, Inc. Threaded

end connections shall be in accordance

with ASTM D 2464 which references

ANSI B 1.20 (was B 2.1) for tapered pipe

threads. The valve, Type 343, shall carry

a pressure rating of 150 psi/10 bar at

68°F/20°C as supplied by George

Fischer, Inc., Tustin, CA 92780.

Type 343 True Union 3-way

Ball Valve – Polypropylene

Polypropylene true union 3-way ball

valves 1/2" through 2" (20 mm – 63 mm)

shall be available in horizontal configuration and have either metric fusion socket

or threaded type pipe connections.

Horizontal configurations shall be supplied with a union connection on the

outlet branch, it having its own individual

ball seat (seal) enabling the option to be

supplied with a "T" ported ball for flowthrough operation. Incorporated into its

design safety features is a blow-out-proof

stem and the ability to hold pressure

when the downstream union nut is

removed. Seats shall be PTFE (Teflon

®

)

with backing rings creating self-adjusting,

constant operating torque sealing characteristics. Backing rings and seals shall be

EPDM or FPM*. The handle shall include

in its design a key for removal of the seat

carrier in addition to providing sufficient

height to permit hand clearance. Seat

carrier shall have left-hand threads to

prevent possible unscrewing when

threaded end connector is installed on the

pipe. Material shall meet or exceed the

requirements of ASTM D 4101 as pertains

to a type I homopolymer compound

having a minimum tensile strength of 4350

psi/300 bar at 73°F/20°C when tested in

accordance with ASTM D 638 and shall

have a melt point which initiates at 316°F/

158°C. The melt flow index (at 374°F/

190°C/50 N) shall be 0.4 –0.8 grams per

10 minutes in accordance with ASTM D

1238. End connections shall be as outlined in ASTM D 2657 for fusion socket

joining, and shall be compatible with

metric pipe and fittings as manufactured

by George Fischer, Inc. Threaded end

connections shall be in accordance with

ASTM D 2464 which references ANSI B

1.20 (was B 2.1) for tapered pipe threads.

Optional flanged version shall be in

accordance with ANSI B 16.5 class 150

flanges. The valve, Type 346, shall carry a

pressure rating of 150 psi/10 bar at 68°F/

20°C as supplied by George Fischer, Inc.,

Tustin, CA 92780.

¬ ‡

Page 15

Ball Valves

Component Parts for Type 343 PVC True Union Ball Valve

No. Part/Material Qty 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

OD d 16 mm d 20 mm d 25 mm d 32 mm d 40 mm d 50 mm d 63 mm

ID DN 10 mm DN 15 mm DN 20 mm DN 25 mm DN 32 mm DN 40 mm DN 50 mm

Seal sets: 161 484 941 161 484 941 161 484 942 161 484 943 161 484 944 161 484 945 161 484 946

8 Backing seals EPDM 3

9 Body seal EPDM 3

10 Face seal EPDM 3

11 Stem seals EPDM 2

Seal sets: 161 486 951 161 486 951 161 486 952 161 486 953 161 486 954 161 486 955 161 486 956

8 Backing seals FPM 3

9 Body seal FPM 3

10 Face seal FPM 3

11 Stem seals FPM 2

Ball sets, L-port: 161 486 015 161 486 015 161 486 016 161 486 017 161 486 018 161 486 019 161 486 020

5.1 L-port ball PVC 1

7 Ball seals PTFE 3

6.1 Stem PVC 1

11 Stem seals EPDM 3

12.1 Handle PVC 1

Ball sets, L-port: 161 486 027 161 486 027 161 486 028 161 486 029 161 486 030 161 486 031 161 486 032

5.1 L-port ball PVC 1

7 Ball seals PTFE 3

6.1 Stem PVC 1

11 Stem seals FPM 3

12.1 Handle PVC 1

Ball sets, T-port: 161 486 039 161 486 039 161 486 040 161 486 041 161 486 042 161 486 043 161 486 044

5.2 T-port ball PVC 1

7 Ball seals PTFE 3

6.2 Stem PVC 1

11 Stem seals EPDM 2

12.2 Handle PVC 1

10

Ball sets, T-port: 161 486 051 161 486 051 161 486 052 161 486 053 161 486 054 161 486 055 161 486 056

5.2 T-port ball PVC 1

7 Ball seals PTFE 3

6.2 Stem PVC 1

11 Stem seals FPM 2

12.2 Handle PVC 1

www.us.piping.georgefischer.com

10.59

Page 16

Component Parts for Type 343 PVC True Union Ball Valve (continued)

No. Part/Material Qty 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

OD d 16 mm d 20 mm d 25 mm d 32 mm d 40 mm d 50 mm d 63 mm

ID DN 10 mm DN 15 mm DN 20 mm DN 25 mm DN 32 mm DN 40 mm DN 50 mm

Central parts, L-port: 161 490 439 161 490 439 161 490 440 161 490 441 161 490 442 161 490 443 161 490 444

1 Body PVC 1

5.1 L-port ball PVC 1

7 Ball seals PTFE 3

8 Backing seals EPDM 3

9 Body seal EPDM 3

2 Union bush PVC 3

6.1 Stem PVC 1

11 Stem seals EPDM 2

12.1 Handle PVC 1

Central parts, L-port: 161 490 450 161 490 450 161 490 451 161 490 452 161 490 453 161 490 454 161 490 455

1 Body PVC 1

5.1 L-port ball PVC 1

7 Ball seals PTFE 3

8 Backing seals FPM 3

9 Body seal FPM 3

2 Union bush PVC 3

6.1 Stem PVC 1

11 Stem seals FPM 2

12.1 Handle PVC 1

Central parts, T-port: 161 490 461 161 490 461 161 490 462 161 490 463 161 490 464 161 490 465 161 490 466

1 Body PVC 1

5.2 T-port ball PVC 1

7 Ball seals PTFE 3

8 Backing seals EPDM 3

9 Body seals EPDM 3

2 Union bush PVC 3

6.2 Stem PVC 1

11 Stem seals EPDM 2

12.2 Handle PVC 1

Central parts, T-port: 161 490 472 161 490 472 161 490 473 161 490 474 161 490 475 161 490 476 161 490 477

1 Body PVC 1

5.2 T-port ball PVC 1

7 Ball seals PTFE 3

8 Backing seals FPM 3

9 Body seal FPM 3

2 Union bush PVC 3

6.2 Stem PVC 1

11 Stem seals FPM 2

12.2 Handle PVC 1

3 Valve ends with 1 161 482 377 161 482 378 161 482 379 161 482 380 161 482 381 161 482 382 161 482 383

socket, PVC ASTM

3 Valve ends, PVC NPT 1 161 482 389 161 482 390 161 482 391 161 482 392 161 482 393 161 482 394 161 482 395

3 Valve ends with 1 161 482 345 161 482 346 161 482 347 161 482 348 161 482 349 161 482 350 161 482 351

spigot, PVC ISO/DIN

4 Union nuts, PVC 1 161 340 617 161 340 617 161 340 618 161 340 619 161 340 620 161 340 621 161 480 522

10.60

¬ ‡

Page 17

Ball Valves

Component Parts for Type 343 PP True Union Ball Valve

No. Part/Material Qty 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

OD d 16 mm d 20 mm d 25 mm d 32 mm d 40 mm d 50 mm d 63 mm

ID DN 10 mm DN 15 mm DN 20 mm DN 25 mm DN 32 mm DN 40 mm DN 50 mm

Seal sets: 161 484 941 161 484 941 161 484 942 161 484 943 161 484 944 161 484 945 161 484 946

8 Backing seals EPDM 3

9 Body seal EPDM 3

10 Face seal EPDM 3

11 Stem seals EPDM 2

Seal sets: 161 484 951 161 484 951 161 484 952 161 484 953 161 484 954 161 484 955 161 484 956

8 Backing seals FPM 3

9 Body seal FPM 3

10 Face seal FPM 3

11 Stem seals FPM 2

Ball sets, L-port: 167 482 190 167 482 190 167 482 191 167 482 192 167 482 193 167 482 194 167 482 195

5.1 L-port ball PP 1

7 Ball seals PTFE 3

6.1 Stem PP 1

11 Stem seals EPDM 2

12.1 Handle ASA 1

Ball sets, L-port: 167 482 202 167 482 202 167 482 203 167 482 204 167 482 205 167 482 206 167 482 207

5.1 L-port ball PP 1

7 Ball seals PTFE 3

6.1 Stem PP 1

11 Stem seals FPM 2

12.1 Handle ASA 1

Ball sets, T-port: 167 482 214 167 482 214 167 482 215 167 482 216 167 482 217 167 482 218 167 482 219

5.2 T-port ball PP 1

7 Ball seals PTFE 3

6.2 Stem PP 1

11 Stem seals EPDM 2

12.2 Handle ASA 1

10

Ball sets, T-port: 167 482 226 167 482 226 167 482 227 167 482 228 167 482 229 167 482 230 167 482 231

5.2 T-port ball PP 1

7 Ball seals PTFE 3

6 Stem PP 1

11 Stem seals FPM 2

12.2 Handle ASA 1

www.us.piping.georgefischer.com

10.61

Page 18

Component Parts for Type 343 PP True Union Ball Valve (continued)

No. Part/Material Qty 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

OD d 16 mm d 20 mm d 25 mm d 32 mm d 40 mm d 50 mm d 63 mm

ID DN 10 mm DN 15 mm DN 20 mm DN 25 mm DN 32 mm DN 40 mm DN 50 mm

Central parts, L-port: 167 482 137 167 482 137 167 482 138 167 482 139 167 482 140 167 482 141 167 482 142

1 Body PP 1

5.1 L-port ball PP 1

7 Ball seals PTFE 3

8 Backing seals EPDM 3

9 Body seal EPDM 3

2 Union bush PP 3

6 Stem PP 1

11 Stem seals EPDM 2

12.1 Handle ASA 1

Central parts, L-port: 167 482 148 167 482 148 167 482 149 167 482 150 167 482 151 167 482 152 167 482 153

1 Body PP 1

5.1 L-port ball PP 1

7 Ball seals PTFE 3

8 Backing seals FPM 3

9 Body seal FPM 3

2 Union bush PP 3

6 Stem PP 1

11 Stem seals FPM 2

12.1 Handle ASA 1

Central parts, T-port: 167 482 159 167 482 159 167 482 160 167 482 161 167 482 162 167 482 163 167 482 164

1 Body PP 1

5.2 T-port ball PP 1

7 Ball seals PTFE 3

8 Backing seals EPDM 3

9 Body seals EPDM 3

2 Union bush PP 3

6 Stem PP 1

11 Stem seals EPDM 2

12.2 Handle ASA 1

Central parts, T-port: 167 482 170 167 482 170 167 482 171 167 482 172 167 482 173 167 482 174 167 482 175

1 Body PP 1

5.2 T-port ball PP 1

7 Ball seals PTFE 3

8 Backing seals FPM 3

9 Body seal FPM 3

2 Union bush PP 3

6 Stem PP 1

11 Stem seals FPM 2

12.2 Handle ASA 1

3 Valve ends with 1 167 480 159 167 480 160 167 480 161 167 480 162 167 480 163 167 480 164 167 480 165

socket, PP

3 Valve ends with 1 167 480 527 167 480 528 167 480 529 167 480 530 167 480 531 167 480 532 167 480 533

spigots, PP

3 Valve ends with 1 167 480 166 167 480 167 167 480 168 167 480 169 167 480 170 167 480 171 167 480 172

parallel female

thread Rp, PP

3 Valve ends with 1 167 480 452 167 480 453 167 480 454 167 480 455 167 480 456 167 480 457 167 480 458

tapered female

thread NPT, PP

3 Butt fusion spigots, 1 — 167 480 546 167 480 547 167 480 548 167 480 549 167 480 550 167 480 551

PP SDR11

4 Union nuts, PP 1 167 480 786 167 480 786 167 480 787 167 480 788 167 480 789 167 480 790 167 480 791

12 Handles, ASA 1 160 480 115 160 480 115 160 480 116 160 480 117 160 480 118 160 480 119 160 480 120

10.62

¬ ‡

Loading...

Loading...