Page 1

GF Piping Systems

Electrically Actuated 3-way Ball Valves

Type 167-170

General

• Size: ⅜”–2”

• Material: PVC, CPVC, PROGEF® Standard PP, ABS,

SYGEF®Standard PVDF

• Seat: PTFE

• Seals: EPDM, FPM

• End Connection: Solvent cement socket, threaded, fl anged,

fusion spigot, fusion socket

• Actuator Housing: Glass-fi lled PP

• Voltage: 100-230VAC, 24VDC

• Manual Override: Integrated

• Position Indicator: Optical, integrated

Key Valve Certifi cations

• FDA CFR 21 177.1520: PP and PVDF

• FDA CFR 21 177.2600: EPDM and FPM

• FDA CFR 21 177.1550: PTFE

• USP 25 Class VI (physiological non-toxic): PP and PVDF

Sample Specifi cation

The Type 167-170 3-way Ball Valve shall be used in either open/

close or modulating applications. The actuator shall be a Type

EA25. The ball valve shall be true union and utilize a fl oating ball

design. The ball shall be fully molded and full port with two way

blocking capability. The stem shall be blowout proof, utilizing a

double o-ring seal and a predetermined break point opposite the

media side of the stem seals. The seat carrier shall be adjustable

and reverse threaded. The valve nut threads shall be of buttress

type. Ball seats shall have an elastomeric backing o-ring and all

elastomeric seals shall be of like material. ANSI fl anged versions

shall meet ANSI B16.5 150lb standards. All valves shall be tested

in accordance to ISO9393 and designed to ISO16136 standards. All

valves shall be manufactured under ISO9001 for Quality and

ISO14001 for Environmental Management. Following manual

assembly, every valve shall be tested and certifi ed bubble tight

exceeding Class VI standards. Following actuated assembly, every

valve shall be tested to confi rm functionality.

Page 2

Material Specifi cation

PVC valves shall meet ASTM D1784 cell classifi cation 12454

standards. CPVC valves shall meet ASTM D1784 cell classifi cation 23447-B standards. PP valves shall meet ASTM D584714 cell classifi cation PP0510B66851 standards. ABS valves

shall meet ASTM D3965 cell classifi cation 42222 standards.

PVDF valves shall be type 1, grade 2 according to ASTM D3222

standards. Valves of all materials shall be RoHS compliant.

Key Actuator Certifi cations

• Machinery Directive 2006/42/EC, Annex II B

• EMV Directive CE 2004/108/CE

• EMV VDE 0843 Section 20

• Low Voltage Directive CE 2006/95/CE

• Vibration Testing EN 60068-2-6

• Interface ISO 5211

• Actuators for Inustrial Valves EN 15714-2

Components

Electric Actuator

Optional Features

• Positioner: Current, voltage

• Network: Profi bus DP

• Fail Safe Return: Battery back up, externally powered

board

• Smart Module: Cycle monitoring, cycle counter, cycle extension, motor current monitoring

• Manual Loading Station: Local control box

• Protection Class: IP67 with conduit connection

• Seals: Alternative materials available upon request

• Seat: PVDF

• End Connection: Alternatives available upon request

• Cleaned: Silicone free/oil free

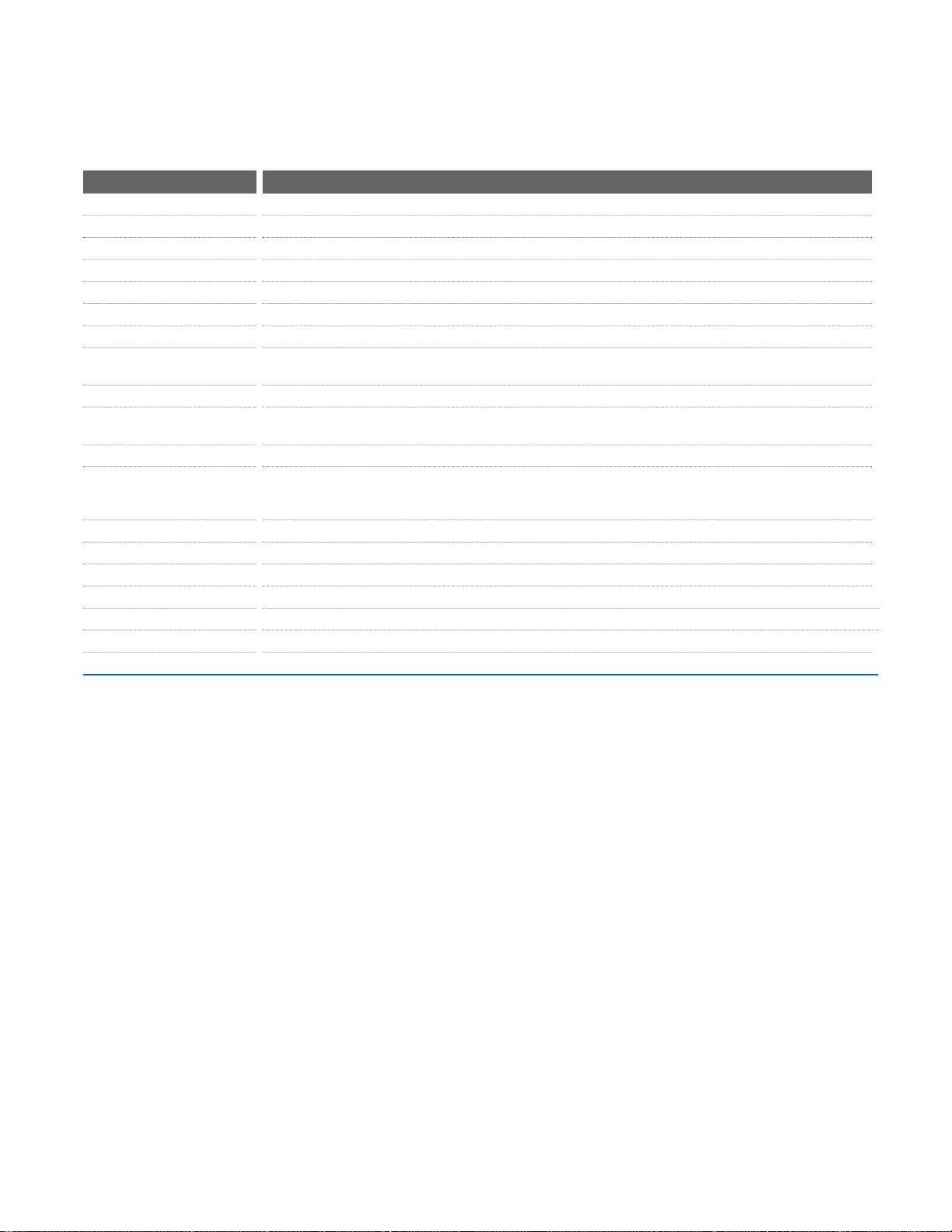

Material Availability

Material Horizontal Vertical

PVC All Sizes All Sizes

CPVC All Sizes -

PP All Sizes -

ABS All Sizes All Sizes

PVDF All Sizes -

Intermediate Kit

Type 543 Ball Valve

2

Page 3

Actuator Technical Data

EA 25

Valve Size ⅜"-2"

Cycle Time 5s/90°

Rated Cycles at 70°F 250,000

Actuating Angle Standard set at 90°, max. 355°

Housing Material Glass-fi lled PP

Position Feedback 230V, 6 Amp

Emergency Manual Override Integrated

Rated Voltage 100- 230V, 50/60 Hz

Rated Voltage Tolerance +/- 15%

Rated Output 35VA @ 100-230VAC

Duty Cycle 100%

Protection Class IP 65 per EN 60529 (3)

Overload Protection Resetting, current-time dependant (1)

Overvoltage Category Category II according to DIN EN 61010-1

Power Connection Connector plug 3 P+ E per DIN EN 175301-03

Pollution Grade Grade 2 according to DIN EN 61010-1

Maximum Elevation 6561 feet

Ambient Temperature 14° to 122°F (2)

Allowable Humidity 90% relative humidity, non condensing

24V, AC/DC, 50/60Hz

40VA @ 24VAC/DC

UL/CSA: For interior use

Nema 4X

(1) Overload protection of the motor is dimension ed so that the motor and the power supply board are protected. As soon as the load is within the torque range, the

actuator will begin operating again.

(2) At temperatures below 14°F and if there is condensation, the heating element should be activated.

(3) Protection class IP67 for use of cable glands and vertical installation.

3

Page 4

Technical Data

Pressure Temperature Curves

The following graphs are based on a 25 year lifetime water or similar media application

PVC CPVC

165

150

135

120

105

90

75

60

Pressure (psi)

45

30

15

0

20 40 60 80 100 120 140 160

Temperature (°F)

165

150

135

120

105

90

75

60

Pressure (psi)

45

30

15

0

20 40 60 80 100 120 140 160 180

Temperature (°F)

165

150

135

120

105

90

75

60

Pressure (psi)

45

30

15

0

20 40 60 80 100 120 140 160 180 200

PVDF

165

150

135

120

105

90

75

60

Pressure (psi)

45

30

15

0

-20 20 60 100 140 180 220 260 300

SDR17 Fusion

SDR11 Fusion

Threaded/Flanged

Temperature (°F)

Temperature (°F)

ABSPP

165

150

135

120

105

90

75

60

Pressure (psi)

45

30

15

0

-60 -40 -20 0 20 40 60 80 100 120 140 160

Temperature (°F)

Pressure-Temperature

Material Temperature Range (ºF) Max Pressure (psi)

PVC 32 to 140 150

CPVC 32 to 176 150

PP 32 to 176 150

ABS -40 to 140 150

PVDF -4 to 284 150

Vacuum Service

The Type 167-170 is rated for full vacuum service. Maximum

di erential pressure of 15psi at 122ºF.

4

Page 5

Porting

Flow Vertical

Options shown turning the valve handle clockwise. Redundant positions not shown.

Vertical L-port Vertical Diverter

0º 0º

180º

90º

270º

90º

Cv Value (gal/min)

Size (inch) d (mm) A-C or B-C

Flow Horizontal L-port

Options shown turning the valve handle clockwise. Redundant positions not shown.

45º

90º

⅜ 16 3.5

½ 20 5.3

¾ 25 10.5

1 32 19.6

1¼ 40 33.6

1½ 50 43.4

2 63 86.1

225º

0º

45º

90º

180º

Cv Value (gal/min)

Size (inch) d (mm) A-B C-B or C-A B-C or A-C

⅜ 16 0.7 3.5 3.5

½ 20 1.1 4.5 4.5

¾ 25 2.1 10.5 10.5

1 32 3.5 19.6 19.6

1¼ 40 6.3 33.6 33.6

1½ 50 7.7 43.4 43.4

2 63 15.4 86.1 86.1

5

Page 6

Porting

Flow Horizontal T-port

Options shown turning the valve handle clockwise. Redundant positions not shown.

90º0º

Dimensions

The following tables are shown in inches unless otherwise specifi ed

PVC Vertical Socket

180º 270º

Cv Value (gal/min)

Size (inch) d (mm) A-B C-B or C-A B-C or A-C

⅜ 16 9.8 2.5 2.8

½ 20 14 3.5 4.9

¾ 25 32.9 9.1 10.5

1 32 55.5 14 17.5

1¼ 40 90.3 26.6 32.9

1½ 50 133.7 32.9 42

2 63 217 62.3 84.7

Inch D H H1 H2 H3 H5 L L1 L2 L5 L6 L7 L8 z

⅜ 1.97 9.09 2.44 2.52 3.66 6.54 4.17 7.17 2.20 3.9 3.27 4.8 1.3 2.64

½ 1.97 9.09 2.44 2.52 3.66 6.54 4.13 7.17 2.20 3.9 3.27 4.8 1.3 2.40

¾ 2.28 9.45 2.83 2.87 3.66 6.54 4.76 7.17 2.60 3.9 3.27 4.8 1.3 2.76

1 2.68 9.45 3.03 2.87 3.66 6.54 5.24 7.17 2.80 3.9 3.27 4.8 1.3 2.99

1¼ 3.31 9.88 3.43 3.31 3.66 6.54 5.98 7.17 3.35 3.9 3.27 4.8 1.3 3.54

1½ 3.82 9.88 3.82 3.31 3.66 6.54 6.50 7.17 3.50 3.9 3.27 4.8 1.3 3.70

2 4.88 10.75 4.41 4.17 3.66 6.54 7.20 7.17 3.98 3.9 3.27 4.8 1.3 4.21

PVC Vertical Threaded NPT

Inch D H H1 H2 H3 H5 L L1 L2 L5 L6 L7 L8 z

⅜ 1.97 9.09 2.44 2.52 3.66 6.54 3.86 7.17 2.20 3.9 3.27 4.8 1.3 2.76

½ 1.97 9.09 2.44 2.52 3.66 6.54 3.86 7.17 2.20 3.9 3.27 4.8 1.3 2.52

¾ 2.28 9.45 2.83 2.87 3.66 6.54 4.41 7.17 2.60 3.9 3.27 4.8 1.3 2.99

1 2.68 9.45 3.03 2.87 3.66 6.54 5.00 7.17 2.80 3.9 3.27 4.8 1.3 3.27

1¼ 3.31 9.88 3.43 3.31 3.66 6.54 5.75 7.17 3.35 3.9 3.27 4.8 1.3 3.90

1½ 3.82 9.88 3.82 3.31 3.66 6.54 6.18 7.17 3.50 3.9 3.27 4.8 1.3 4.37

2 4.88 10.75 4.41 4.17 3.66 6.54 7.20 7.17 3.98 3.9 3.27 4.8 1.3 5.31

6

Page 7

Dimensions

The following tables are shown in inches unless otherwise specifi ed

PVC/CPVC Horizontal Socket

Inch D H H1 H2 H3 H5 H6 L L1 L2 L3 L4 L5 L6 L7 L8M (mm) z z1

⅜ 1.97 9.09 1.10 2.52 3.66 6.54 0.31 4.84 7.17 2.87 1.42 0.98 3.82 3.27 4.80 1.30 6 3.35 1.65

½ 1.97 9.09 1.10 2.52 3.66 6.54 0.31 4.80 7.17 2.87 1.42 0.98 3.82 3.27 4.80 1.30 6 3.03 1.50

¾ 2.28 9.45 1.26 2.87 3.66 6.54 0.31 5.55 7.17 3.39 1.69 0.98 3.82 3.27 4.80 1.30 6 3.62 1.81

1 2.68 9.45 1.42 2.87 3.66 6.54 0.31 6.34 7.17 3.90 1.97 0.98 3.82 3.27 4.80 1.30 6 4.13 2.09

1¼ 3.31 9.88 1.77 3.31 3.66 6.54 0.31 7.36 7.17 4.72 2.36 1.77 3.82 3.27 4.80 1.30 6 4.96 2.48

1½ 3.82 9.88 2.01 3.31 3.66 6.54 0.31 8.39 7.17 5.39 2.72 1.77 3.82 3.27 4.80 1.30 6 5.63 2.83

2 4.88 10.75 2.56 4.17 3.66 6.54 0.31 10.28 7.17 7.05 3.50 1.77 3.82 3.27 4.80 1.30 6 7.28 3.62

PVC/CPVC Horizontal Threaded NPT

Inch D H H1 H2 H3 H5 H6 L L1 L2 L3 L4 L5 L6 L7 L8M (mm) z z1

⅜ 1.97 9.09 1.10 2.52 3.66 6.54 0.31 4.53 7.17 2.87 1.42 0.98 3.82 3.27 4.80 1.30 6 3.35 1.65

½ 1.97 9.09 1.10 2.52 3.66 6.54 0.31 4.49 7.17 2.87 1.42 0.98 3.82 3.27 4.80 1.30 6 3.03 1.50

¾ 2.28 9.45 1.26 2.87 3.66 6.54 0.31 5.16 7.17 3.39 1.69 0.98 3.82 3.27 4.80 1.30 6 3.62 1.81

1 2.68 9.45 1.42 2.87 3.66 6.54 0.31 6.10 7.17 3.90 1.97 0.98 3.82 3.27 4.80 1.30 6 4.13 2.09

1¼ 3.31 9.88 1.77 3.31 3.66 6.54 0.31 7.13 7.17 4.72 2.36 1.77 3.82 3.27 4.80 1.30 6 4.96 2.48

1½ 3.82 9.88 2.01 3.31 3.66 6.54 0.31 8.07 7.17 5.39 2.72 1.77 3.82 3.27 4.80 1.30 6 5.63 2.83

2 4.88 10.75 2.56 4.17 3.66 6.54 0.31 10.28 7.17 7.05 3.50 1.77 3.82 3.27 4.80 1.30 6 7.28 3.62

7

Page 8

Dimensions

The following tables are shown in inches unless otherwise specifi ed

PP/PVDF Horizontal Socket Fusion

d

(mm) D H H1 H2 H3 H5 H6 L L1 L2 L3 L4 L5 L6 L7 L8M (mm) z z1

16 1.97 9.09 1.10 2.52 3.66 6.54 0.31 4.33 7.17 2.83 1.42 0.98 3.82 3.27 4.80 1.30 6 3.35 1.65

20 1.97 9.09 1.10 2.52 3.66 6.54 0.31 4.41 7.17 2.83 1.42 0.98 3.82 3.27 4.80 1.30 6 3.03 1.50

25 2.28 9.45 1.26 2.87 3.66 6.54 0.31 5.08 7.17 3.35 1.69 0.98 3.82 3.27 4.80 1.30 6 3.62 1.81

32 2.68 9.45 1.42 2.87 3.66 6.54 0.31 5.75 7.17 3.86 1.93 0.98 3.82 3.27 4.80 1.30 6 4.13 2.09

40 3.31 9.88 1.77 3.31 3.66 6.54 0.31 6.69 7.17 4.65 2.32 1.77 3.82 3.27 4.80 1.30 6 4.96 2.48

50 3.82 9.88 2.01 3.31 3.66 6.54 0.31 7.60 7.17 5.31 2.68 1.77 3.82 3.27 4.80 1.30 6 5.63 2.83

63 4.88 10.75 2.56 4.17 3.66 6.54 0.31 9.61 7.17 6.93 3.46 1.77 3.82 3.27 4.80 1.30 6 7.28 3.62

PP/PVDF Horizontal Threaded NPT

size D H H1 H2 H3 H5 H6 L L1 L2 L3 L4 L5 L6 L7 L8M (mm) z z1

⅜ 1.97 9.09 1.10 2.52 3.66 6.54 0.31 4.53 7.09 2.87 3.9 0.98 3.82 3.27 4.80 1.30 6 3.35 1.65

½ 1.97 9.09 1.10 2.52 3.66 6.54 0.31 4.49 7.09 2.87 3.9 0.98 3.82 3.27 4.80 1.30 6 3.03 1.50

¾ 2.28 9.45 1.26 2.87 3.66 6.54 0.31 5.16 7.09 3.39 3.9 0.98 3.82 3.27 4.80 1.30 6 3.62 1.81

1 2.68 9.45 1.42 2.87 3.66 6.54 0.31 6.10 7.09 3.90 3.9 0.98 3.82 3.27 4.80 1.30 6 4.13 2.09

1¼ 3.31 9.88 1.77 3.31 3.66 6.54 0.31 7.13 7.09 4.72 3.9 1.77 3.82 3.27 4.80 1.30 6 4.96 2.48

1½ 3.82 9.88 2.01 3.31 3.66 6.54 0.31 8.07 7.09 5.39 3.9 1.77 3.82 3.27 4.80 1.30 6 5.63 2.83

2 4.88 10.75 2.56 4.17 3.66 6.54 0.31 10.28 7.09 7.05 3.9 1.77 3.82 3.27 4.80 1.30 6 7.28 3.62

PP/PVDF Horizontal IR/Butt Fusion Spigot

d

(mm) D H H1 H2 H3 H5 H6 L L1 L2 L3 L4 L5 L6 L7 L8M (mm)

20 1.97 9.09 1.10 2.52 3.70 6.57 0.31 5.75 7.09 2.83 1.42 0.98 3.82 3.27 4.80 1.30 6

25 2.28 9.45 1.26 2.87 3.70 6.57 0.31 6.42 7.09 3.35 1.69 0.98 3.82 3.27 4.80 1.30 6

32 2.68 9.45 1.42 2.87 3.70 6.57 0.31 7.01 7.09 3.86 1.93 0.98 3.82 3.27 4.80 1.30 6

40 3.31 9.88 1.77 3.31 3.70 6.57 0.35 8.03 7.09 4.65 2.32 1.77 3.82 3.27 4.80 1.30 8

50 3.82 9.88 2.01 3.31 3.70 6.57 0.35 9.33 7.09 5.31 2.68 1.77 3.82 3.27 4.80 1.30 8

63 4.88 10.75 2.56 4.17 3.70 6.57 0.35 11.65 7.09 6.93 3.46 1.77 3.82 3.27 4.80 1.30 8

GF Piping Systems

Tel. (714) 731-8800, Toll Free (800) 854-4090, Fax (714) 731-6201

us.ps@georgfi scher.com, www.gfpiping.com

#1334-63 (3/15)

© 2015 Georg Fischer LLC

Printed in USA

Loading...

Loading...