Page 1

GF Piping Systems

Instruction Manual

Electrical Actuator Unit Type EA 11/ 21/ 31/ 42

Page 2

Electrical actuator type EA 11

Translation of the original instructions

Disclaimer

The technical data are not binding. They neither constitute expressly warranted

characteristics nor guaranteed properties nor a guaranteed durability. They are

subject to modification. Our General Terms of Sale apply.

Observe instruction manual

The instruction manual is part of the product and an important element within the

safety concept.

Read and observe instruction manual.

Always have instruction manual available by the product.

Give instruction manual to all subsequent users of the product.

2

Page 3

Electrical actuators type EA 11/ 21/ 31/ 42 Content

Content

Content ............................................................................................................................ 3

1 Intended

2 Regarding this document......................................................................................... 4

2.1 Safety Instructions and Warnings .....................................................................

2.2 Other related documents .................................................................................. 5

2.3 Product variants and types described .............................................................. 5

3 Safety and responsibility .......................................................................................... 5

4 Transport and storage ............................................................................................. 6

5 Technical data .......................................................................................................... 7

5.1 Dimensions ............................................................

6 Design and function ................................................................................................. 11

6.1 Design EA11 ....................................................................................................... 11

6.2 Design EA21/31/42 ....................................................

6.3 Identification ...................................................................................................... 13

6.4 Position indicator .............................................................................................. 13

6.5 Operating mode on standard operation/ limit switch allocation ..................... 14

6.5.1 Overload protection .................................................................................... 14

6.5.2 Safety position ............................................................................................

7 Installation ................................................................................................................ 15

7.1 Interfaces .........................................................

7.2 Connect

7.3 Assembly actuator with valve ........................................................................... 19

7.4 Adjusting limit switches .................................................................................... 21

8 Operation .................................................................................................................. 22

8.1 Funct

8.2 Usi

8.2.1 Preparation ................................................................................................. 23

8.2.2 Procedure ...........................................................

.3 Ready to operate (only EA21 – 42) .................................................................... 24

8

8.4 Error signal ........................................................................................................ 25

8.4.1 Display fault signal ..................................................................................... 25

8.4.2 Remove fault report ................................................................................... 25

9 Maintenance ............................................................................................................. 26

10 Troubleshooting list .............................................................................................. 27

11 Spare parts list ..................................................................................................... 28

12 Accessories ........................................................................................................... 28

13 CE Declaration of incorporation ........................................................................... 31

14 Disposal ................................................................................................................. 32

use ............................................................................................................. 4

4

............................................ 9

........................................ 12

14

.................................................. 15

ion diagram EA11/ 21 /31/ 42 .............................................................. 18

ional test ................................................................................................... 22

ng manual emergency override .................................................................. 22

........................................ 23

3

Page 4

Intended use Electrical actuators type EA 11/ 21/ 31/ 42

1 Intended use

The electrical actuators EA 11/21/31/42 are intended for mounting on a valve and for

connection to a control system.

The electrical actuators EA 11/21/31/42 are intended to activate valves with pivoting

movements up to 180° (e. g. ball valves and butterfly valves).

The product is not intended for any types of use other than those described here.

Failure to follow the instructions in this manual shall lead to the termination of the

manufacturer's liability for the above mentioned products.

2 Regarding this document

This document contains all necessary information for the installation, operation and

service of the product.

2.1 Safety Instructions and Warnings

This instruction manual contains warning notices that shall prevent you from death,

injuries or material damages. Always read and observe these warning notices!

Warning symbol Meaning

Imminent danger!

CAUTION

WARNING

WARNING

Failure to observe these warnings could result in death or very

serious injuries.

Measurements to avoid the danger.

Possible imminent danger!

Failure to observe these warnings could result in very serious

injuries.

Measurements to avoid the danger.

Dangerous situation!

Failure to observe these warnings could result in small

injuries.

Measurements to avoid the danger.

Dangerous situation!

CAUTION

4

Failure to observe these warnings could result in material

damages.

Measurements to avoid the danger.

Page 5

Electrical actuators type EA 11/ 21/ 31/ 42 Safety and responsibility

Further symbols and labels

Symbol Meaning

Notes: Especially important information.

Call for action: Here, you have to do something.

2.2 Other related documents

Document Document number

Georg Fischer planning fundamentals industry GMST 5989

Assembly instructions accessories complete GFDO 6319

These documents can be obtained from your local representative of GF Piping

Systems or at www.gfps.com

2.3 Product variants and types described

Type EA11 24V AC/ DC and 100 – 230V AC

Type EA21 24V AC/ DC and 100 – 230V AC

Type EA31 24V AC/ DC and 100 – 230V AC

Type EA42 24V AC/ DC and 100 – 230V AC

3 Safety and responsibility

Only use product as intended, see intended use.

Do not use any damaged or faulty product. Throw out any damaged product

immediately.

Product and accessories should only be operated by people who have the

necessary training, knowledge or experience.

Regularly train personnel on all locally accepted regulations on occupational

safety and environmental protection, especially on pressure-retaining pipelines.

Make sure that all personnel know, understand and follow the instruction manual

and the instructions contained therein.

Follow the instruction manual of the manual valve. It is an integral part of this

electrical actuator manual.

Take precautions against electrostatic hazards.

5

Page 6

Transport and storage Electrical actuators type EA 11/ 21/ 31/ 42

WARNING

Only work with cover removed in exceptional cases!

Danger of injury and/or damage to property.

Branch off feed and control voltage connections beforehand.

Only carry out adjustments on live parts with specially insulated tools.

WARNING

Voltage too high!

Danger of injury and/or damage to property.

Only use recommended power soures.

Make sure that 24V devices are only connected to voltages that meet the

requirements of an protective extra low-voltage circuit (SELV).

4 Transport and storage

Transport and/or store product in unopened original packaging.

Protect product from dust, heat and moisture.

Ensure that the product has not been damaged neither by mechanical nor thermal

influences.

Check product before assembly for transport damage.

6

Page 7

Electrical actuators type EA 11/ 21/ 31/ 42 Technical data

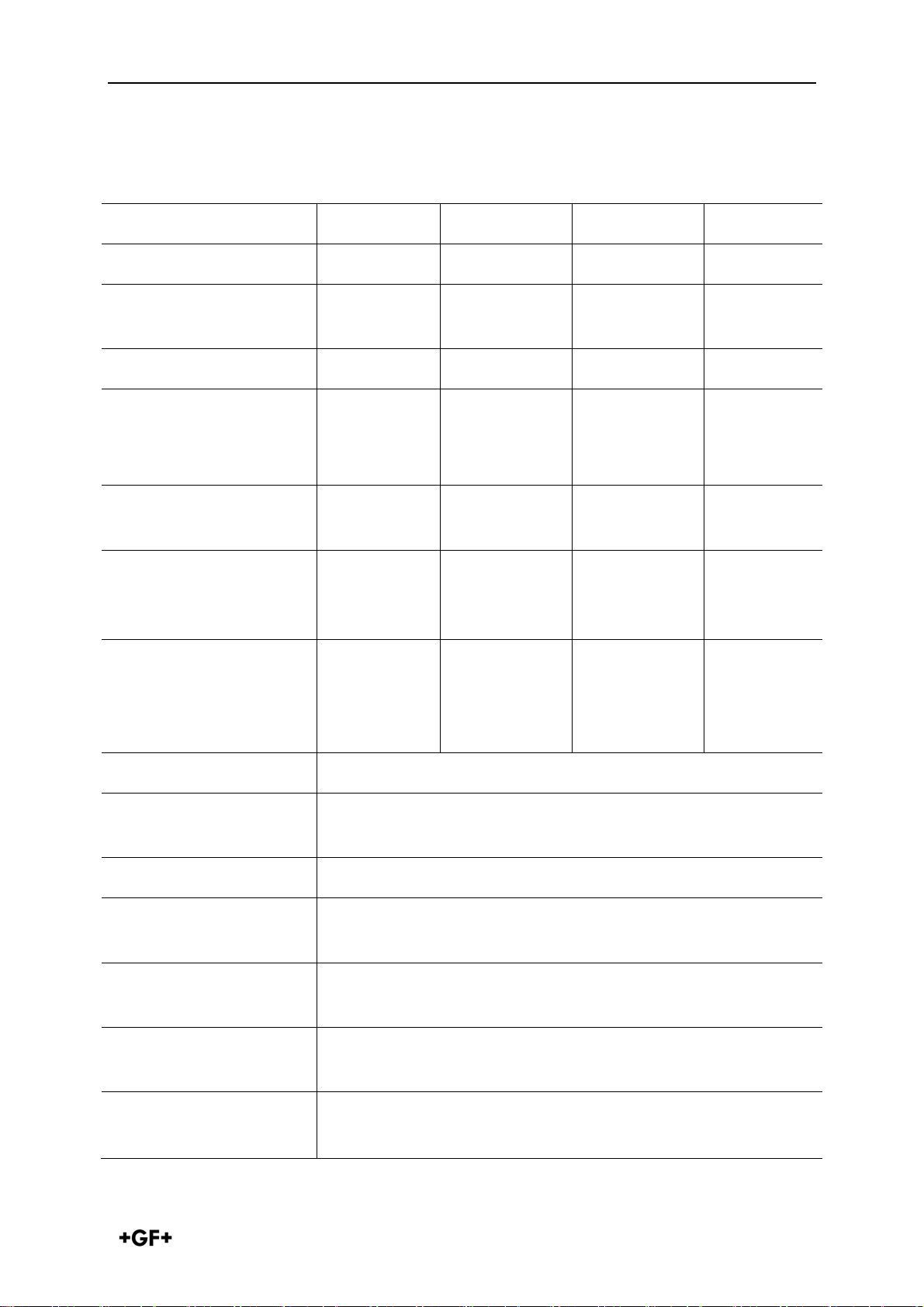

5 Technical data

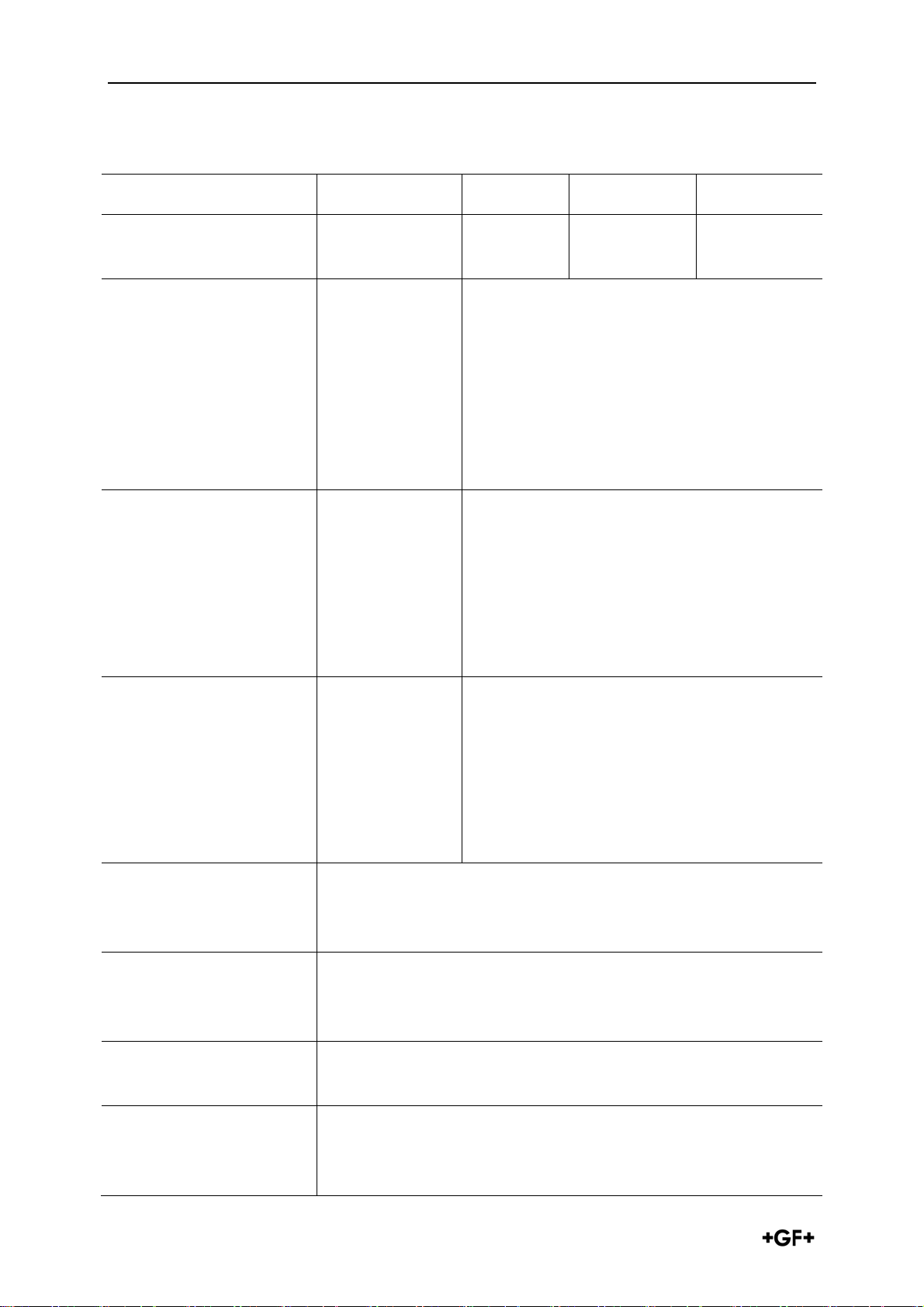

EA11 EA21 EA31 EA42

Nominal torque Mdn

Peak torque

Control time

L/W/H

Flange interface/

shaft

Actuating cycles at

20°C and Mdn

Nominal output

at 24V AC/DC

at 100 – 230 V AC

Duty cycle (ED)

10 Nm 10 Nm 60 Nm 100 Nm

20 Nm 20 Nm 120 Nm 250 Nm

5 s/90° at

Mdn

129/122/138 150/122/167 150/122/190 150/122/208

F05/

Spline with

adapter

150,000 250,000 100,000 75,000

22 VA

40 VA

40% at 25°

C/15 min

5s/90° at Mdn

F05/

Spline WS11/

14

22 VA

40 VA

100%

reduced duty

cycle for UL

certification

15s/90° at

Mdn

F07/

WS17

32 VA

40 VA

50% 35%

25s/90° at

Mdn

F07/

WS22

40 VA

60 VA

Actuating angle

Housing material

Position indicator

Manual emergency

override

Rated voltage

Rated voltage

tolerance

Input impedance

max. 180°, set to 90°

PP glass fibre reinforced , flame-retardant, external rust

proof screws

optical integrated

integrated

100 – 230V, 50/60 Hz

24 = /24V, 50/60 Hz

+/- 10%

230V, 100kΩ

24V, 4.7kΩ

7

Page 8

Technical data Electrical actuators type EA 11/ 21/ 31/ 42

EA11 EA21 EA31 EA42

Weight

Ambient temperature

Electrical connection

Overload protection

1.857 kg 2.193 kg 3.536 kg 4.995 kg

-10° to + 45° C

Connector plug

3 P+E as per

EN 175301-803

(formerly DIN

43650),

additional

cable entry for

PG11

Current/timedependent

(resetting)

-10° to +

50° C

Connector plug 3 P+ E as per DIN EN

175301-803

Cable screw connection M20x1.5 as per

ISO 724

Current/time-dependent (resetting),

temperature-dependent.

The overload protection of the engine is

dimensioned in such a way that engine

and supply board are protected. As soon

as the load is in the torque range, the

actuator continues to run.

-10° to + 50° C -10° to + 50°

C

Permitted humidity

Protection class

Overvoltage category

as per DIN EN

61010-1

Height above sea level

(UL/CSA)

Degree of

contamination as per

DIN EN 61010-1

max. 80% to

31° C, reducing

in a straight

line to 50%

relative

humidity at 40°

C

IP65 as per EN60529, UL/CSA: use in internal rooms

IP67 as per EN60529: use of cable glands and vertical

assembly

II

< 2000m

2

max. 90% relative humidity, noncondensing

8

Page 9

Electrical actuators type EA 11/ 21/ 31/ 42 Technical data

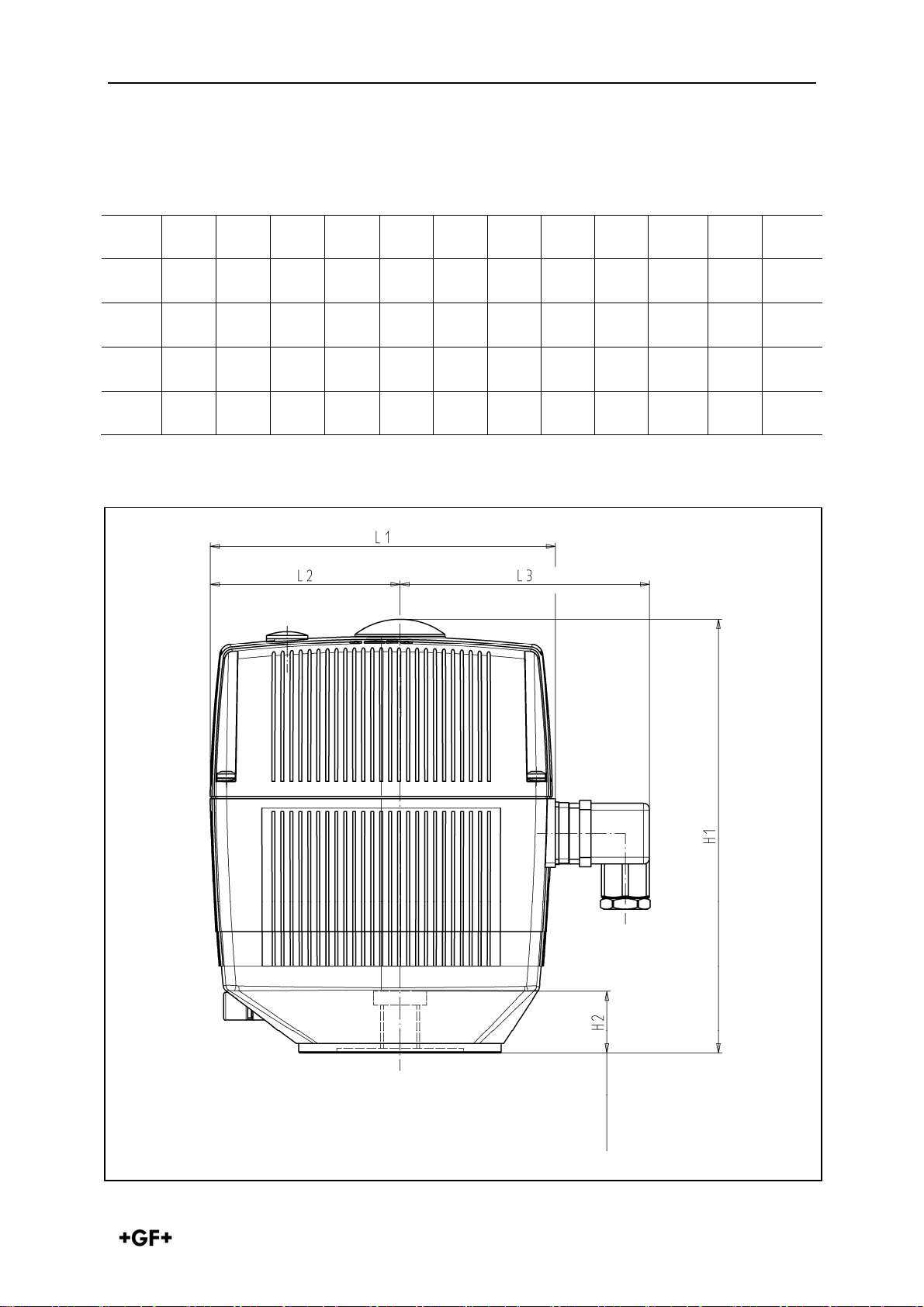

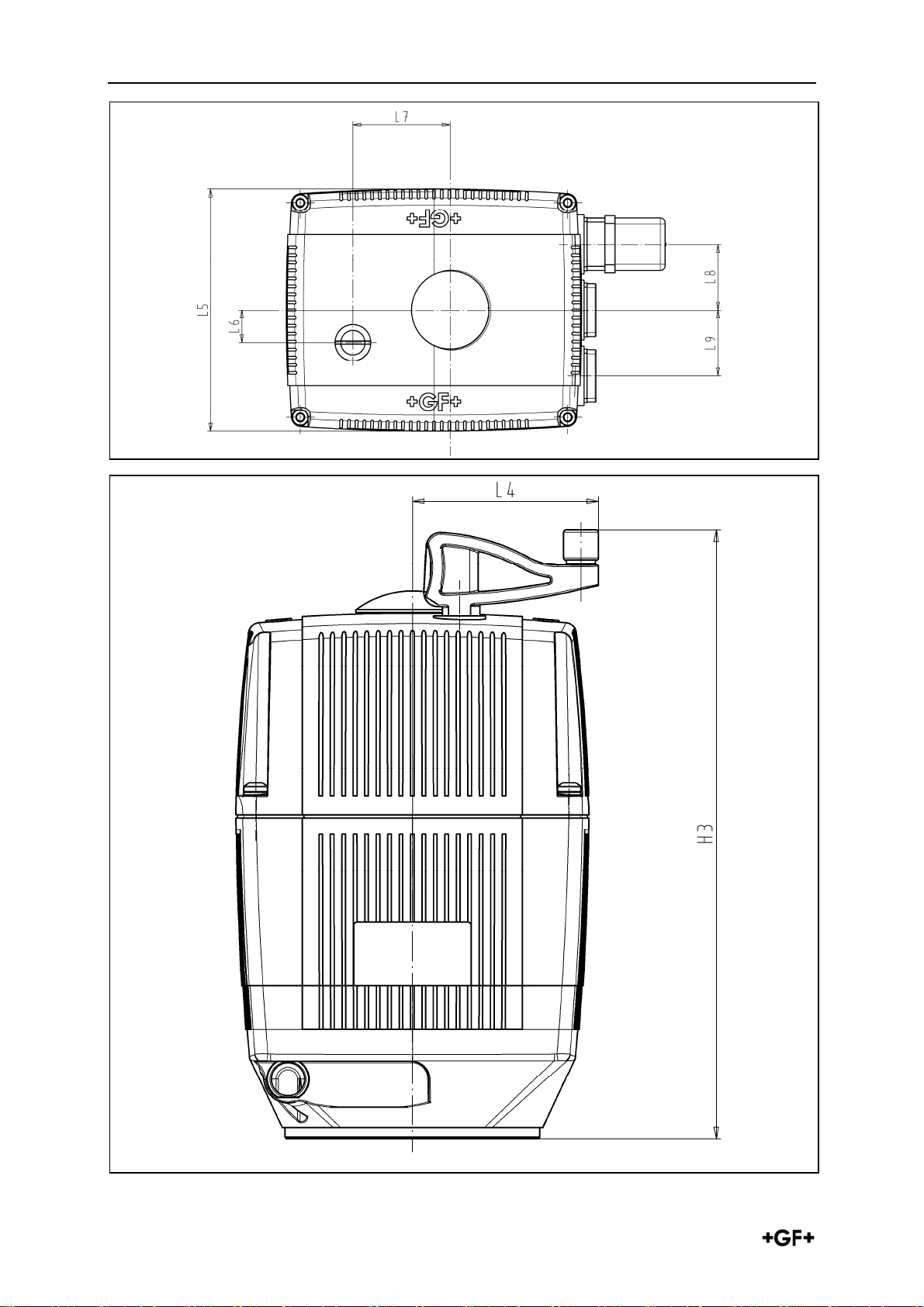

5.1 Dimensions

L1 L2 L3 L4 L5 L6 L7 L8 L9 H1 H2 H3

EA11

EA21

EA31

EA42

130 82.5 88 64.3 122 16 49 33 - 137.5 20 159.5

150 82.5 108 64.3 122 16 49 33 33 167 20 188.5

150 82.5 108 64.3 122 16 49 33 33 190 25 211.5

150 82.5 108 64.3 122 16 49 33 33 208 25 229.5

Profile depth

9

Page 10

Technical data Electrical actuators type EA 11/ 21/ 31/ 42

10

Page 11

Electrical actuators type EA 11/ 21/ 31/ 42 Design and function

6 Design and function

6.1 Design EA11

7

8

9

1

2

3

4

bb. 1

Pos. Name Pos. Name

1

2

3

4

5

For special applications, the actuator may also be fitted with accessories, see section

Accessories.

6

Direct current motor

Position indicator

Limit switches S1 and S2

Connection terminal for external

connections max. 1.5mm2

Connection option for

accessories

6

7

8

9

Wide power supply range,

without fitted contact protection

Plug X1 for accessories

Assembly bolts for accessories

Shaft for manual emergency

override

5

11

Page 12

Design and function Electrical actuators type EA 11/ 21/ 31/ 42

6.2 Design EA21/31/42

9

10

1

2

3

4

5

6

7

8

Pos. Name Pos. Name

1

2

3

4

5

For special applications, the actuator may also be fitted with accessories, see section

Accessories.

Visual position indicator

Shaft for manual emergency

override

Plug X1 for accessories

Direct current motor

Limit switches S1 and S2

6

7

8

9

10

Connection terminal for external

connections max. 1.5mm2

Modular gearbox

Connection option for accessories

Multi-voltage power supply unit,

without fitted contact protection

Assembly bolts for accessories

12

Page 13

Electrical actuators type EA 11/ 21/ 31/ 42 Design and function

6.3 Identification

Type label (e. g. EA31)

1

Order number

2

Housing material

3

Voltage type

4

5

6

7

8

Duty cycle/protection type

Nominal output

Serial number

Approvals & CE-mark

6.4 Position indicator

The position indicator displays the valve position. The valve position can be read on

the fitted cover.

GF actuators are always delivered in the "Open" position.

When the cover is fitted, the following image can be seen:

2-way

3-way horizontal

3-way vertical

Image

"Closed“ position

"Open“ position

C B – C A – C

A-B A – C B – C

13

Page 14

Design and function Electrical actuators type EA 11/ 21/ 31/ 42

6.5 Operating mode on standard operation/ limit switch allocation

The actuator moves from the "Closed" position to the "Open" position by applying live

voltage to the nominally open "S1" terminal. By applying live voltage to the normally

closed "S2" terminal, the actuator will move from the "Open" position to the "Closed"

position. Remember only to apply live voltage to one terminal at a time. The final

positions are defined by the two limit switches S1 and S2.

2

1

Switching cam that is set to limit

1

switch S1, position "Open“

Switching cam that is set to limit

2

switch S2, position "Closed“

6.5.1 Overload protection

The supply unit of the EA21/31/42 has an overload protection that protects the direct

current motor and the supply board from overheating. The overload protection is

activated as soon as the load exceeds the torque range. The actuator continues to run

as soon as the load is within the torque range and the temperature has gone down.

6.5.2 Safety position

In case of power failure, the actuator stays in its current position. If the actuator is

fitted with the accessory "fail-safe return unit“, it can automatically return to a safety

position after a power failure.

14

Page 15

Electrical actuators type EA 11/ 21/ 31/ 42 Installation

7 Installation

WARNING

Too high current peaks the first time the actuator is switched on by

charging the mains capacitor!

Danger of injury and/or malfunction.

Connect and operate actuator as per connection diagram, see Section 7.2

Connection diagram

7.1 Interfaces

EA 11/ F05

deep

deep

15

Page 16

Installation Electrical actuators type EA 11/ 21/ 31/ 42

EA 21/F05

deep

deep

EA 31/F07

deep

16

Page 17

Electrical actuators type EA 11/ 21/ 31/ 42 Installation

EA 42/F07

deep

17

Page 18

Installation Electrical actuators type EA 11/ 21/ 31/ 42

7.2 Connection diagram EA11/ 21 /31/ 42

below

Relay contact

max. 24V

EA 11

EA 21, 31, 42

18

Page 19

Electrical actuators type EA 11/ 21/ 31/ 42 Installation

7.3 Assembly actuator with valve

The electrical actuator can be assembled on the following valves with the appropriate

coupling piece and suitable adapter:

EA11 EA21 EA31 EA42

2-way ball

valve to DN

50

e. g. ball valve

type 546

DN10-DN50

2-way ball

valve to DN

100

e. g. ball valve

type 546

DN65-DN100

3-way ball

valve to DN

50

e. g. ball valve

type 543

- -

-

- -

- -

-

Butterfly

valves

e. g. butterfly

valve type

567/568

- -

19

Page 20

Installation Electrical actuators type EA 11/ 21/ 31/ 42

Valve 2-way ball valve 3-way ball valve Butterfly valve

Type 546 543 567

+

Actuator

EA

= Type

21 DN10 – DN50

11

21

31 DN65 – DN100

107 130 131 132 133 134 135 175 176 177 178 140 141 142 143

Observ

ation

metric

metric

metric

metric

ANSI

BS

JIS

horizontal

horizontal

horizontal

vertical

PVC-U

PVC-C

ABS

PP-H

x x x x x x x x x x x

x x x x x x x x x x

x x x x x x x x x x

x x x x x x x x x x

568

31 to DN150

42 of DN200

Wafer

Lug

Lug ANSI

Lug JIS

PP-N

PVDF

x x x x x x x x x x

In addition to this manual, please also follow the specifications of the valve

manufacturer.

Before assembling actuator on valve, see assembly instructions for the

intermediate parts

Before installation, compare technical data of the actuator with the control and the

valve. Only install actuator if the data matches.

Before installation, check plugs and terminals for possible damage.

Make sure that no damaged parts are used.

Have installation and assembly only carried out by specialist staff.

If actuator for system requires the protection class IP67:

- Use cable gland connections.

- Mount actuator vertically.

If device is directly controlled:

- Fit a circuit-breaker on site.

- Do not connect grounding conductor.

20

Page 21

Electrical actuators type EA 11/ 21/ 31/ 42 Installation

Requirements

- Cross section of the power lines max. 1.5 mm2.

- Fuse size: > 6 A.

Ensure that actuator is only connected to voltages that meet the requirements on

a protective extra low voltage circuit (PELV).

Connect actuator, see Section 7.2 Connection diagram

To prevent water getting into actuator, ensure that cable plug is not pointing

upwards.

If temperatures under -10°C plus water condensation are to be expected:

fit "heating element“ accessory.

7.4 Adjusting limit switches

The two end positions in the actuator have been factory set to 90°. A

readjustment may be required after assembly by the customer.

Disconnect actuator from voltage.

Open cover. To do so, loosen the 4 screws.

Position both switching cams S1 and S2 (Fig. see Section 6.5) in such a way to each

other that the angle of rotation is less than 90°.

Connect actuator to voltage and let it rotate until a limit switch is activated.

Adjust limit switch until the desired end position is set.

Repeat procedure as required until desired end positions are set.

Fit cover and fasten with the 4 screws.

21

Page 22

Operation Electrical actuators type EA 11/ 21/ 31/ 42

8 Operation

WARNING

Too high current peaks the first time the actuator is switched on by

charging the mains capacitor!

Danger of injury and/or malfunction.

Connect and operate actuator as per connection diagram, see Section 7.2

Connection diagram

Before commissioning the system, carry out a functional test of the product.

8.1 Functional test

WARNING

Working with actuator cover removed!

Danger of injury and/or damage to property.

Disconnect connections of the feed and control voltage.

Only carry out adjustments on live parts with specially insulated tools.

Before actuator is connected to mains voltage:

Make sure that main voltage matches details on type label

Make sure that actuator is connected properly

Check fuse: > 6 A

Check that valve position matches position indicator of the actuator.

Make sure that actuator and valve are connected correctly and tightly.

Using the manual emergency override, the actuator can also open or close the

valve without mains voltage, see Section 10.1

8.2 Using manual emergency override

The integrated manual emergency override is used to move the actuator manually to

another position. The integrated manual emergency override allows the actuator to

continue operating temporarily if there is no power.

if the actuator constantly or frequently fails: change actuator.

22

Page 23

Electrical actuators type EA 11/ 21/ 31/ 42 Operation

8.2.1 Preparation

Remove crank handle 1 from the holder.

Remove cover screw 2 with crank handle 1.

Insert crank handle in hexagonal bolt under the opening.

8.2.2 Procedure

WARNING

Actuator unintentionally restarting!

Danger of injury due to opening or closing of the valve through connection

terminals powered on again.

Remove connector plug during manual operation.

Disconnect actuator elsewhere.

Press crank handle as far as it will go.

Micro-switch that disconnects the actuator is activated.

To power the actuator on again: let crank handle go.

To open or to close valve: turn crank handle.

Direction of rotation Function

Clockwise (CW) close

Counter clockwise (CCW) open

Type Number of rotations Angle

EA11 9 90°

EA21 9 90°

EA31 27 90°

EA42 41 90°

23

Page 24

Operation Electrical actuators type EA 11/ 21/ 31/ 42

WARNING

Damage to the actuator by short circuit or corrosion!

Moisture and/or dirt in the actuator.

Make sure that no water has got into the actuator.

Screw cover screw 2 after using the manual emergency override back

into the actuator.

Take crank handle 1 away.

Screw cover screw 2 on again. Beforehand make sure that no water has entered

the actuator.

Put crank handle 1 back into holder.

8.3 Ready to operate (only EA21 – 42)

The EA 21/ 31/ 42 has a temperature monitor (ready for operation monitor).

Make sure that actuator is properly connected, see section 7.2 Connection

diagram.

24

Page 25

Electrical actuators type EA 11/ 21/ 31/ 42 Operation

8.4 Error signal

8.4.1 Display fault signal

In the case of a fault report

- the red LED 8 on the main board lights up. If the monitoring print is installed,

the particular LED lights up red on the BCD switch 10, if its set value is

exceeded.

- the ready to operate signal does not apply (terminal 5,6 no passage).

8.4.2 Remove fault report

Check cause of fault

If necessary, carry out relevant maintenance, see Section 10 fault repair

Repair the fault either while the supply voltage is still connected or while the

actuator is briefly disconnected from the mains voltage. (Not effective in cycle

monitoring).

To repair, activate the reset switch 9 on motherboard.

25

Page 26

Maintenance Electrical actuators type EA 11/ 21/ 31/ 42

9 Maintenance

WARNING

Defective product quality through use of spare parts, not provided by GF

Piping Systems!

Danger of injury.

Only use the listed spare parts, see section Spare parts list.

Set maintenance intervals as per the conditions of use (e. g. actuating cycles,

medium, ambient temperature).

As part of the regular system inspection, carry out the following maintenance

activities.

Maintenance interval Maintenance activity

Check that cover of the manual emergency override is

correctly fitted. If necessary, fit cover.

regular

regular

regular

For questions regarding the maintenance of the product, please contact your

GF Piping Systems representative.

Check that housing cover of the actuator is fitted with

4 screws.

If necessary, complete screws.

Check if grating noises are coming from the actuator.

Replace actuator, see assembly instructions on the

structure valve with actuator

Check that position display matches signal of the

control.

If necessary, adjust limit switch, see Section adjust

limit switches.

26

Page 27

Electrical actuators type EA 11/ 21/ 31/ 42 Troubleshooting list

10 Troubleshooting list

Problem Possible cause Solution

No mains voltage available. Check voltage source.

Actuator does not

react

Actuator only runs in

one direction

Overload protection is

activated

Valve closes or does

not open fully

Internal wiring fault

Switching cams S1 and S2 set

wrong

Motor locked

Limit switch faulty

Valve is dirty

Duty cycle too high

Too high ambient temperature

Switching cam S1 and/or S2

not adjusted

Correct wiring of the

actuator, see Section 7

Adjust limit switch, see

Section 7.2

Use manual emergency

override, see Section 10.1

Use manual emergency

override, see Section 10.1

Clean valve, see manual on

the valve

Extend cycle time with

accessories "Actuating cycle

extension“

If possible, reduce ambient

temperature

Adjust limit switch, see

Section 7.2

Valve stem twisted Replace valve stem

If an end position is not reached, the actuator switches off automatically after

2 minutes and displays a fault report.

7

2

Page 28

Spare parts list Electrical actuators type EA 11/ 21/ 31/ 42

11 Spare parts list

Name Code

Actuator EA11 100–230 V~ 198 150 180

Actuator EA11 24 AC/DC 198 150 181

Actuator EA21 100–230 V~ 198 150 182

Actuator EA21 24 V=/~ 198 150 183

Actuator EA31 100–230 V~ 198 150 184

Actuator EA31 24 V=/~ 198 150 185

Actuator EA42 100–230 V~ 198 150 186

Actuator EA42 24 V=/~ 198 150 187

Manual emergency key 198 151 307

Manual emergency cover (lock screw) 198 000 503

12 Accessories

Name Function Code EA11 EA21-42

In a power cut, the

Fail-safe return unit

Heating element

Battery set 198 151 317 x x

Kit 2 additional* limit

switches AgNi

Kit 2 additional* limit

switches Au

Kit 2 additional limit

switches NPN

fail-safe return unit

can be used to control

a preset safe position.

Prevents formation of

condensate in the

actuator

Position feedback for

the actuator with two

mechanical limit

switches

199 190 085 x x

199 190 086 x x

199 190 092 x x

199 190 093 x

199 190 096 x

28

Page 29

Electrical actuators type EA 11/ 21/ 31/ 42 Accessories

Name Function Code EA11 EA21-42

Kit 2 additional limit

switches PNP

Assembly set 4 limit

switches

Middle position 199 190 094 x

Monitoring print 199 190 079 x

Position detection 199 190 084 x

Positioner type PE25 199 190 100 x

Test adapter kit for

RS232 interface

Connection to an AS-i

AS Interface module

ASEV 2400

network (supply in

combination with limit

switch kit)

199 190 095 x

199 190 097 x

198 151 426 x

199 190 562 x x

Set of plugs

Adapter SW 14 for F05

Adapter SW 11 for F04

Reducing bush WS11

for F05

Heating element and

fail-safe return unit

For the connection of

accessories

Modification for valves

with F05 interface

Modification for valves

with F04 interface

Adjustment for valves

with F05 interface and

width across flat 11

Combined board of

heating element and

fail-safe return unit

198 000 502 x x

198 204 057 x EA21

198 000 587 x EA21

198 803 145

x EA21

199 190 087 x x

9

2

Page 30

CE Declaration of incorporation Electrical actuators type EA 11/ 21/ 31/ 42

13 CE Declaration of incorporation

CE declaration of incorporation for incomplete machines (Machinery directive

2006/42/EC, Annex II B) and CE declaration of conformity as per EMV- and low

voltage directive (2004/108/CE), (2006/95/CE)

Manufacturer:

Georg Fischer Piping Systems Ltd., Ebnatstrasse 111, 8201 Schaffhausen /

Switzerland

Person authorised to compile technical documentation:

Georg Fischer Piping Systems Ltd., R&D Manager,

Ebnatstrasse 111, 8201 Schaffhausen / Switzerland

We hereby confirm that the following incomplete machine

Electrical actuator

Type: EA11, EA21, EA31, EA42

Variants: 24V AC/DC, 100-230V AC

Article numbers: 198 150 180, 198 150 181, 198 150 182, 198 150 183, 198 150 184,

198 150 185, 198 150 186, 198 150 187

fulfils all the basic requirements of the machine directive 2006/42/EC, as far as the

scope of delivery allows.

We further declare that the special technical documentation has been compiled in

accordance with Annex VII, Section B of this directive. We shall forward this, if

requested, to the competent authorities via the aforementioned authorised person.

Commissioning is prohibited until it has been established that the entire machine,

into which the aforementioned incomplete machine is to be incorporated, meets the

provisions of the machine directive 2006/42/EC.

The incomplete machine also meets the requirements of the following European

directives and the national legal provisions implementing them and the relevant

harmonised standards below:

Electromagnetic compatibility – Directive EMV (2004/108/CE)

Low voltage directive (2006/95/CE)

EN 15714-2 (Electrical actuators for industrial valves)

ISO 5211 (actuator interface)

EN 60068-2-6 (vibration tests)

VDE 0843 section 20 (EMV requirements)

Name: Antonio De Agostini

Position: R&D Manager

Georg Fischer Piping Systems

Date: 2013-08-09

30

Page 31

GF Piping Systems

Worldwide at home

Our sales companies and representatives

ensure local customer support in over 100 countries

www.gfps.com

Argentina / Southern South America

Georg Fischer Central Plastics

Sudamérica S.R.L.

Buenos Aires, Argentina

Phone +54 11 4512 02 90

gfcentral.ps.ar@georgfischer.com

www.gfps.com/ar

Australia

George Fischer Pty Ltd

Riverwood NSW 2210 Australia

Phone +61 (0) 2 9502 8000

australia.ps@georgfischer.com

www.gfps.com/au

Austria

Georg Fischer

Rohrleitungssysteme GmbH

3130 Herzogenburg

Phone +43 (0) 2782 856 43-0

austria.ps@georgfischer.com

www.gfps.com/at

Belgium / Luxembourg

Georg Fischer NV/SA

1070 Bruxelles/Brüssel

Phone +32 (0) 2 556 40 20

be.ps@georgfischer.com

www.gfps.com/be

Brazil

Georg Fischer Sist. de Tub. Ltda.

04795-100 São Paulo

Phone +55 (0) 11 5525 1311

br.ps@georgfischer.com

www.gfps.com/br

Canada

Georg Fischer Piping Systems Ltd

Mississauga, ON L5T 2B2

Phone +1 (905) 670 8005

Fax +1 (905) 670 8513

ca.ps@georgfischer.com

www.gfps.com/ca

China

Georg Fischer Piping Systems Ltd

Shanghai 201319

Phone +86 21 3899 3899

china.ps@georgfischer.com

www.gfps.com/cn

Denmark / Iceland

Georg Fischer A/S

2630 Taastrup

Phone +45 (0) 70 22 19 75

info.dk.ps@georgfischer.com

www.gfps.com/dk

Finland

Georg Fischer AB

01510 VANTAA

Phone +358 (0) 9 586 58 25

Fax +358 (0) 9 586 58 29

info.fi.ps@georgfischer.com

www.gfps.com/fi

France

Georg Fischer SAS

95932 Roissy Charles de Gaulle Cedex

Phone +33 (0) 1 41 84 68 84

fr.ps@georgfischer.com

www.gfps.com/fr

Germany

Georg Fischer GmbH

73095 Albershausen

Phone +49 (0) 7161 302-0

info.de.ps@georgfischer.com

www.gfps.com/de

India

Georg Fischer Piping Systems Ltd

400 076 Mumbai

Phone +91 224007 2001

branchoffice@georgfischer.com

www.gfps.com/in

Italy

Georg Fischer S.p.A.

20063 Cernusco S/N (MI)

Phone +39 02 921 861

it.ps@georgfischer.com

www.gfps.com/it

Japan

Georg Fischer Ltd

556-0011 Osaka,

Phone +81 (0) 6 6635 2691

jp.ps@georgfischer.com

www.gfps.com/jp

Korea

Georg Fischer Piping Systems

271-3 Seohyeon-dong Bundang-gu

Seongnam-si, Gyeonggi-do

Seoul 463-824

Phone +82 31 8017 1450

Fax +82 31 8017 1454

kor.ps@georgfischer.com

www.gfps.com/kr

Malaysia

George Fischer (M) Sdn. Bhd.

40460 Shah Alam, Selangor Darul Ehsan

Phone +60 (0) 3 5122 5585

my.ps@georgfischer.com

www.gfps.com/my

Mexico / Northern Latin America

Georg Fischer S.A. de C.V.

Apodaca, Nuevo Leon

CP66636 Mexico

Phone +52 (81) 1340 8586

Fax +52 (81) 1522 8906

mx.ps@georgfischer.com

www.gfps.com/mx

Middle East

Georg Fischer

Piping Systems (Switzerland) Ltd

Dubai, United Arab Emirates

Phone +971 4 289 49 60

gcc.ps@georgfischer.com

www.gfps.com/int

Netherlands

Georg Fischer N.V.

8161 PA Epe

Phone +31 (0) 578 678 222

nl.ps@georgfischer.com

www.gfps.com/nl

New Zealand

Georg Fischer Ltd

13 Jupiter Grove, Upper Hutt 5018

PO Box 40399, Upper Hutt 5140

Phone +64 (0) 4 527 9813

nz.ps@georgfischer.com

www.gfps.com/nz

Norway

Georg Fischer AS

1351 Rud

Phone +47 67 18 29 00

no.ps@georgfischer.com

www.gfps.com/no

Poland

Georg Fischer Sp. z o.o.

05-090 Sekocin Nowy

Phone +48 (0) 22 31 31 0 50

poland.ps@georgfischer.com

www.gfps.com/pl

Romania

Georg Fischer

Piping Systems (Switzerland) Ltd

020257 Bucharest - Sector 2

Phone +40 (0) 21 230 53 80

ro.ps@georgfischer.com

www.gfps.com/int

Russia

Georg Fischer

Piping Systems (Switzerland) Ltd

Moscow 125047

Phone +7 495 258 60 80

ru.ps@georgfischer.com

www.gfps.com/ru

Singapore

George Fischer Pte Ltd

11 Tampines Street 92, #04-01/07

528 872 Singapore

Phone +65 6747 0611

sgp.ps@georgfischer.com

www.gfps.com/sg

Spain / Portugal

Georg Fischer S.A.

28046 Madrid

Phone +34 (0) 91 781 98 90

es.ps@georgfischer.com

www.gfps.com/es

Sweden

Georg Fischer AB

117 43 Stockholm

Phone +46 (0) 8 506 775 00

info.se.ps@georgfischer.com

www.gfps.com/se

Switzerland

Georg Fischer

Rohrleitungssysteme (Schweiz) AG

8201 Schaffhausen

Phone +41 (0) 52 631 30 26

ch.ps@georgfischer.com

www.gfps.com/ch

Taiwan

Georg Fischer Co., Ltd

San Chung Dist., New Taipei City

Phone +886 2 8512 2822

Fax +886 2 8512 2823

www.gfps.com/tw

United Kingdom / Ireland

George Fischer Sales Limited

Coventry, CV2 2ST

Phone +44 (0) 2476 535 535

uk.ps@georgfischer.com

www.gfps.com/uk

USA / Caribbean

Georg Fischer LLC

Tustin, CA 92780-7258

Phone +1 (714) 731 88 00

Toll Free 800 854 40 90

us.ps@georgfischer.com

www.gfpiping.com

Vietnam

George Fischer Pte Ltd

136E Tran Vu, Ba Dinh District, Hanoi

Phone +84 4 3715 3290

Fax +84 4 3715 3285

International

Georg Fischer

Piping Systems (Switzerland) Ltd

8201 Schaffhausen/Switzerland

Phone +41 (0) 52 631 30 03

Fax +41 (0) 52 631 28 93

info.export@georgfischer.com

www.gfps.com/int

The technical data are not binding. They neither constitute expressly

warranted characteristics nor guaranteed properties nor a guaranteed durability.

They are subject to modification. Our General Terms of Sale apply.

700.278.082

GFDO_6323_1_2_4_6 (08.13)

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2013

Printed in Switzerland

Loading...

Loading...