Page 1

Elektrischer Stellantrieb

Typ EA 21/31/42

Bedienungsanleitung

Electrical Actuator Unit

Type EA 21/31/42

Instruction Manual

Page 2

English

Index of content

1. Introduction ..................................................................36

General Information ...................................................................... 36

2. EC Manufacturer’s Declaration ..................................36

3. Intended use .................................................................37

4. Safety Information .......................................................37

4.1 Due care required by the operator ......................................... 37

4.2 Special hazards ........................................................................ 37

4.3 Transport and Storage ............................................................ 38

5. Actuator Design ............................................................38

5.1 Wiring Diagram for Standard Version .................................... 39

5.2 Error message ......................................................................... 39

5.3 DIP switch in case of error ...................................................... 40

6. Setting Up the Actuator ............................................... 40

6.1 Emergency Manual Override ...................................................41

6.2 Dimensional drawings of the

Electrical Actuator Type E A 21/31 ............................................. 42

6.3 Technical Specications ..........................................................43

7. Mounting and Connecting Supplementary Kits ...........44

7.1 Heating Element ....................................................................... 44

7.2 Fail-safe return ........................................................................ 45

7.3 Additional Limit Switches ........................................................ 47

7.3.1 Additional 4 Limit Switches ........................................... 48

7.4 Middle Positioning .................................................................... 49

7.5 Monitoring print ........................................................................ 52

7.6 Position Signalization .............................................................. 58

7.7 Positioner .................................................................................. 60

8. TROUBLESHOOTING ....................................................66

Ordering Information ....................................................... 67

Notizen/Notice/Note ............................................................................ 68

37

Page 3

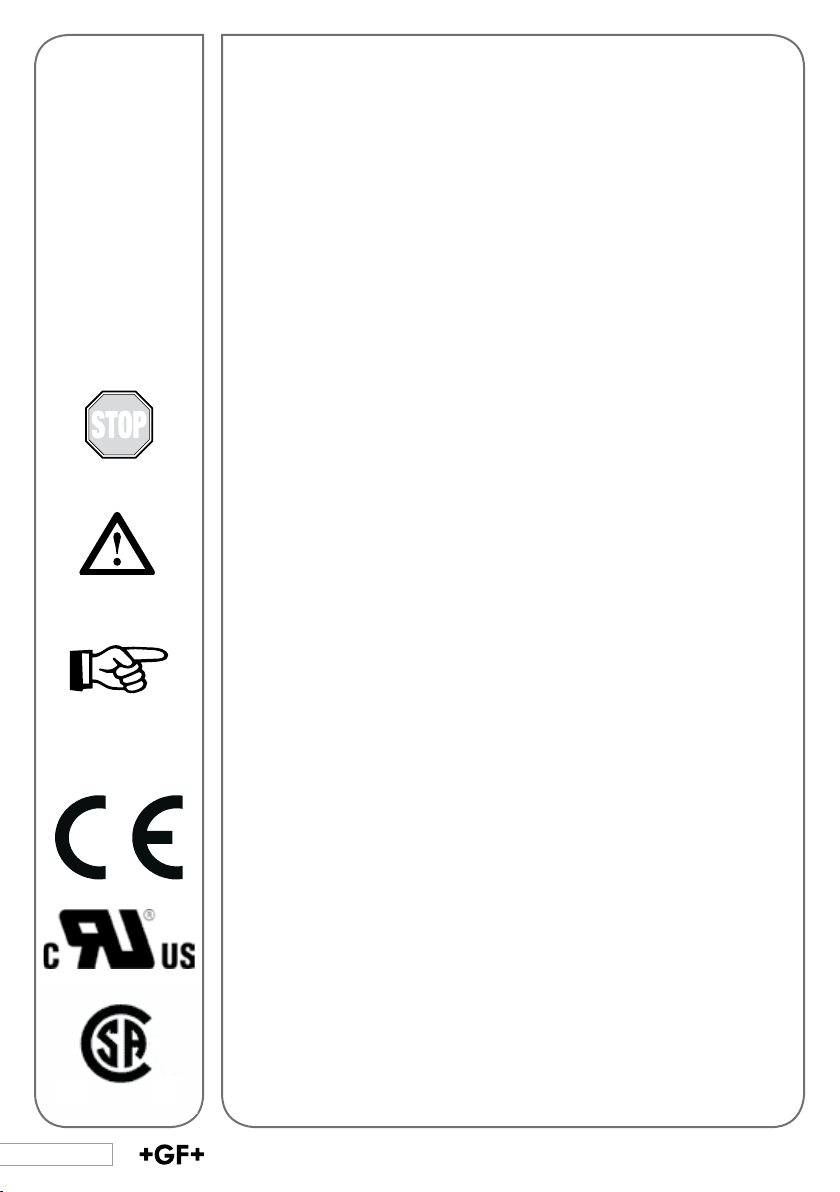

Warning

Beantragt/pending

symbols

Danger

Hazard

1. Introduction

This instruction manual contains all the pertinent information on the design, installation and operation of the electrical actuator type EA 21/31/42.

General Information

Hazard notices

Hazard notices are used in this manual to warn you of possible injuries or

damages to proper ty. Please read and follow these hazard notices at all

times!

Meaning

Imminent acute danger!

Failure to comply could result in death or extremely serious injury.

Possible acute danger!

Failure to comply could result in serious injury.

Dangerous situation!

Failure to comply could lead to injur y or damage to proper ty.

Caution

38

2. EC Manufacturer’s Declaration

The manufacturer, Georg Fischer Piping Systems Ltd., CH 8201 Schaffhausen, declares that the electrical actuator EA 21 / 31 / 42 is not a ready-to-

use machine in the sense of the EC Machine Directive and therefore cannot

meet all the requirements of this directive.

Operation of these actuators is prohibited until conformity of the entire

system into which the valve and the actuator have been installed is established according to the EC Directives listed below.

Applied EC Directives:

06/95 EC EC Low Voltage Directive

89/336 EEC EC Directive on Electromagnetic

Compatibility

Page 4

Modications to the actuator which have an effect on the technical data

given in this instruction manual and its intended use, i.e. signicantly alter

the actuator, render this manufacturer’s declaration null and void.

3. Intended use

When mounted on a valve and connected to a system control and provided

that the actuator data corresponds to the electrical control and the valve,

the purpose of this actuator is:

• to actuate valves with up to 180° pivoting (ball valves and buttery

valves),

• to indicate the previously calibrated end positions of the valve via electrical signal to the system control (accessory), and

• in case of a power supply interruption the actuator valve remains in its

current position (without accessory). Please use emergency manual

override or install fail-safe return.

The actuator is not intended for uses other than those listed above. If the

instructions contained in this manual are not observed, the manufacturer is

excluded from all liability for the above mentioned products.

4. Safety Information

4.1 Due care required by the operator

The actuator described herein was designed and manufactured with consideration to the respective harmonized European standards. It corresponds

to the latest technology and the technical specications contained under

section 6.3.

Safety on the job can, however, only be realized if the operator warrants that

• the actuator is only used as indicated under section 3,

• he is familiar with this instruction manual and the manual of the corresponding valve and adheres to the instructions contained therein and

• he has taken the necessary measures against electrostatic inuence.

4.2 Special hazards

Under normal conditions, the actuator may only be operated with the

cover closed.

If work is performed on the actuator with the cover removed, the supply

and control voltage must rst be disconnected. Adjustments, which need

to be done in the energized state, should be carried out with special insulated tools.

39

Page 5

In addition, the operating instructions of the manual valve

must be observed. They are an integral component of this

manual.

4.3 Transport and Storage

The actuators must be handled, transported

and stored with care. Please note the following

points:

• The actuators should be transported and/or stored in

their original unopened packaging.

• The actuators must be protected from harmful physical

inuences such as dust, heat (humidity).

• It is important that the connections are neither damaged by mechanical nor by thermal inuences.

• Prior to installation, the actuators should be inspected

for transport damages. Damaged actuators must not be

installed.

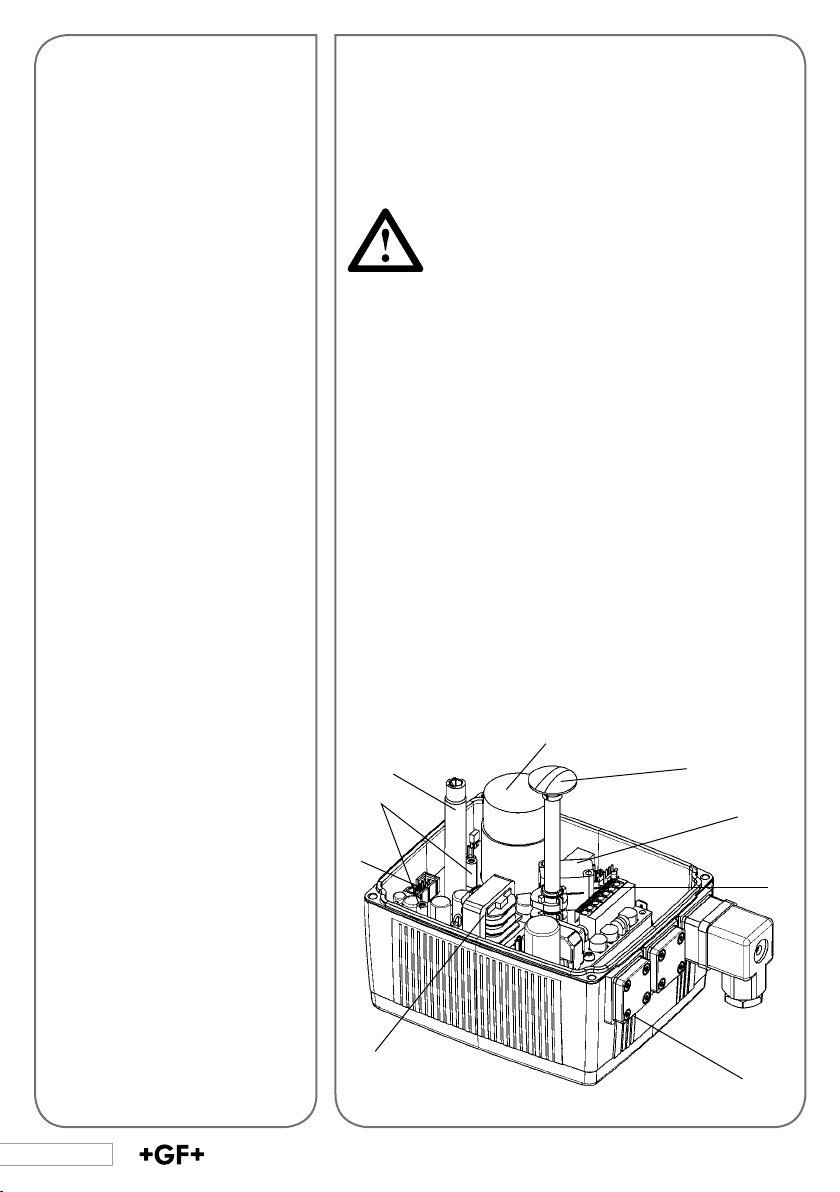

5. Actuator Design

The standard version of the EA 21/31/42 electrical actuator

consists of the following elements: gear unit, direct current

motor, electrical board and components for end position

limiting.

1. Limit switches S1 and S2

2. Direct current motor

3. Optical position indicator

4. Plug X1 for accessories

5. Terminal strip for external

connections max. 1.5 mm

6. Wide range power supply,

without protection against

accidental contact

7. Shaft for emergency manual

override

8. Connections for DIN plug or

cable gland

9. Assembly bolts for accessories

40

For special applications, the actuator can be equipped additionally with various supplementary kits (see section 7).

2

7

9

2

4

6

3

1

5

8

Page 6

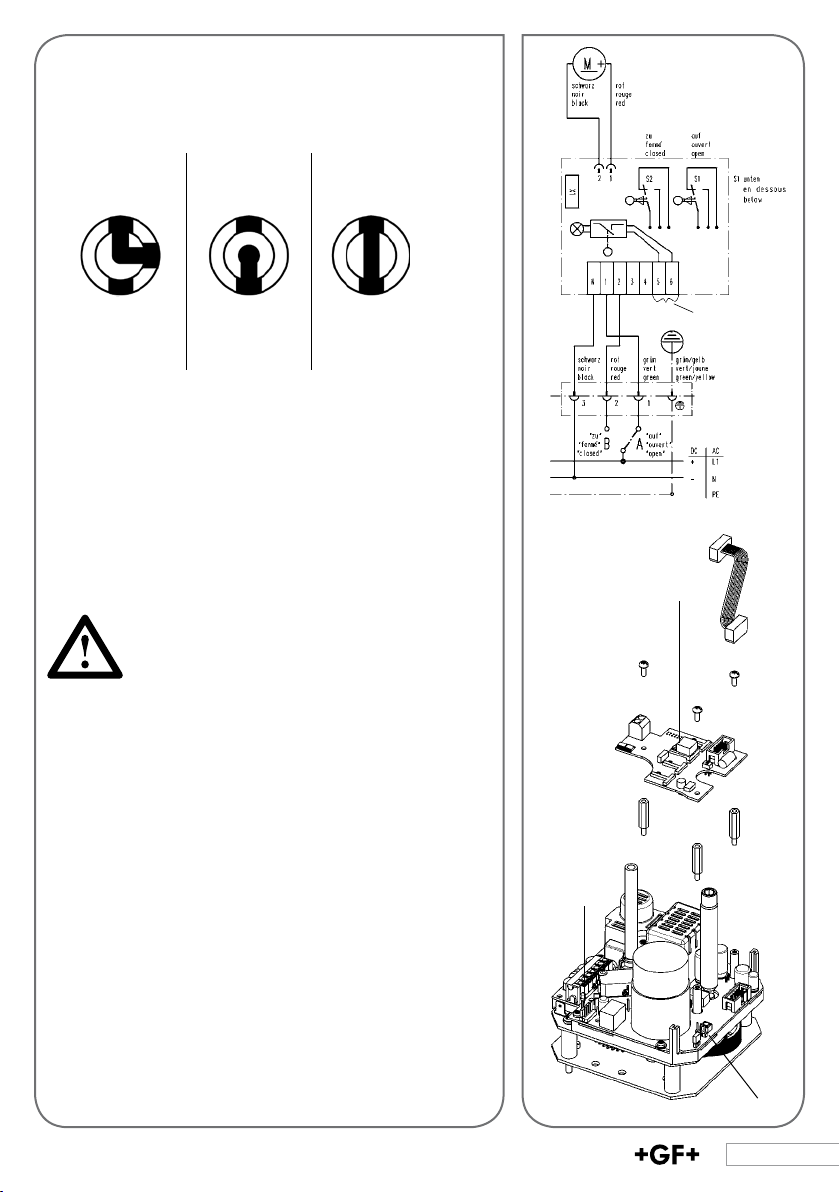

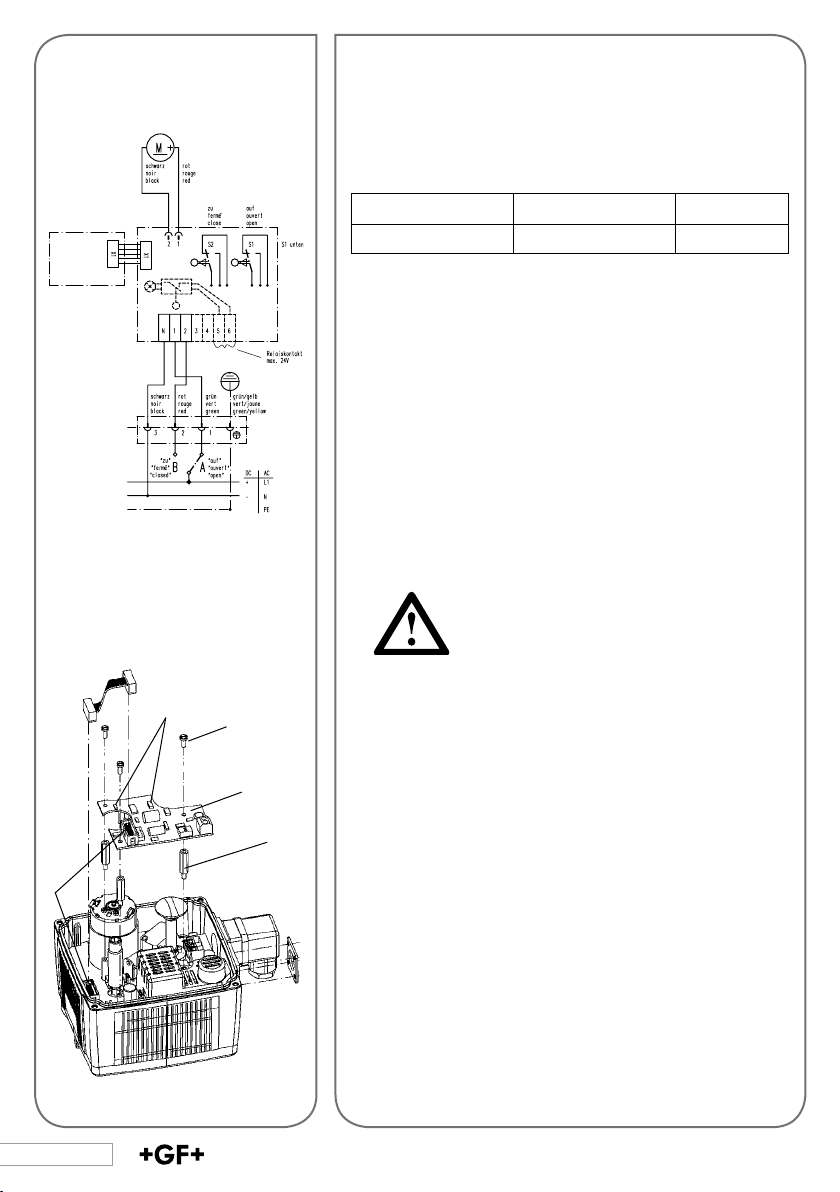

5.1 Wiring Diagram for Standard Version

Position indicator

3-way

horizontal

A

B

B−C

A−C

vertical

A

C

B

A−C

B−C

2-way

A

C

A−B

C

B

C

closed

open

Installation note

If the actuator is directly connected to the power supply, it

is necessary to install a disconnector between the actuator

and the power supply (do not disconnect the earth cable).

Cross-section of the external cables max. 1,5 mm2.

To avoid water owing into the actuator, make sure the cable

entry point is not upturned.

The EA 21/31/42 has a temperature control (ready-tooperate monitoring).

Due to the loading of the power supply capacitor

when rst time switching on the actuator current

peaks can occur for a few micro seconds. Therefore we recommend to connect the actuator in

accordance with accompanying wiring diagram.

5.2 Error message

If an error occurs, the red LED (8) on the base board will

light up.

If the monitoring print is installed, the LED (7) on the BCD

switch (10) which selected value has been exceeded will also

light up red.

Releai scontact

max. 2 4V

10

With all occurring error messages the ready-to-operate

signal will be off (terminals 5,6 no passage).

Eliminating the error message

Check the error cause, if necessar y carry out the appropriate maintenance.

To eliminate the message, activate the reset switch (9) on

the base board while the supply voltage is still connected

or briey disconnect the actuator from the mains voltage.

(Not effective with cycle counter)

8

9

41

Page 7

The two LEDs will go out and the actuator is ready to operate again.

1 2

1 2

1 2

1

In case of malfunc-

ON

tion the actuator

OFF

remains on the

current position

(delivery state)

In case of malfunc-

ON

tion the actuator

OFF

turns to the OPEN

position

In case of

ON

malfunction the

OFF

actuator turns

to the CLOSED

position

S2: «Cl osed», top

S1: «Open», bottom

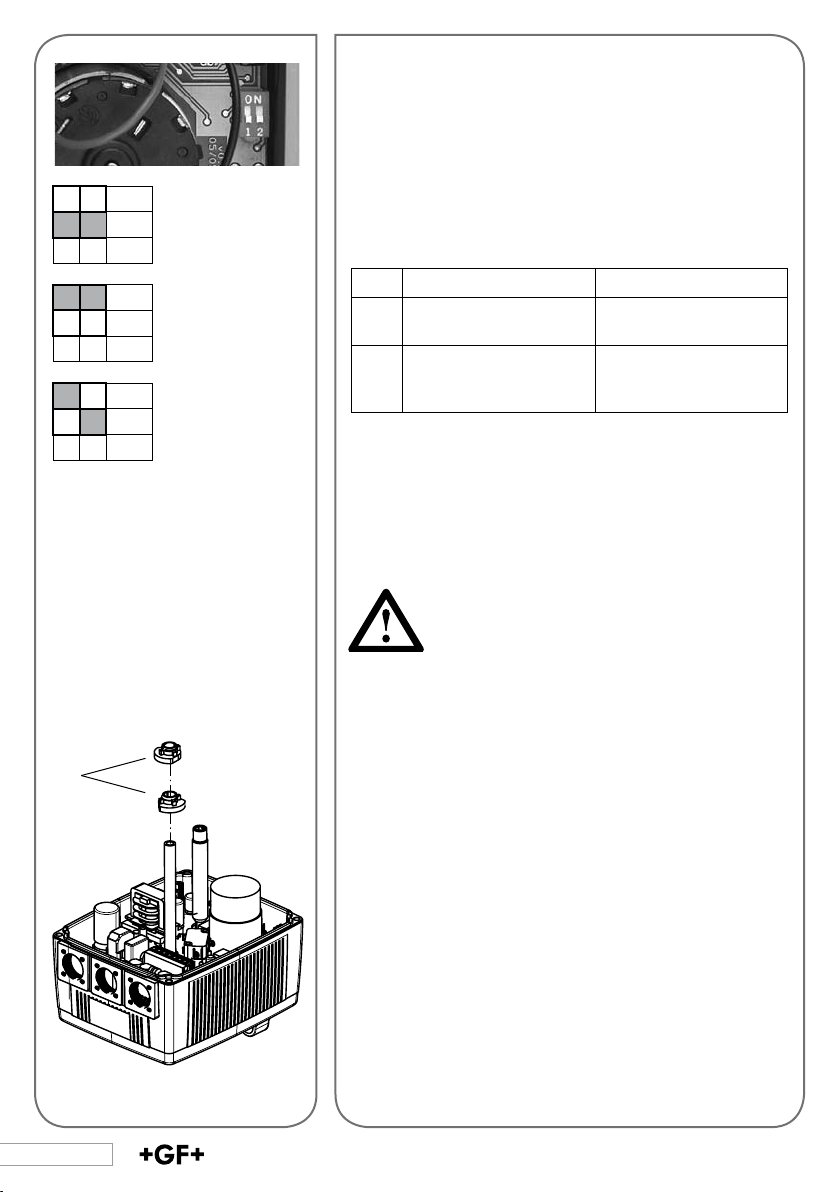

5.3 DIP switch in case of error

In case of an error the actuator can be set to the CLOSED or

the OPEN position with the help of the DIP switch. The DIP

switches need to be set as follows:

DIP 1 DIP 2

Position of DIP 2 effec-

ON

tive

Actuator remains in the

OFF

current position (DIP 2

Actuator turns to the

OPEN position

Actuator turns to the

CLOSED position

not effective)

(refer to explanation on the left)

6. Setting Up the Actuator

Attention

Check the following before connecting the actuator to the

mains:

• Does the main voltage correspond to the specications given on the type plate

• Has the actuator been connected correctly

(see Section 5.1)

• Fuse ≥ 6 A

Adjustments

If a complete valve is supplied by Georg Fischer, no further

adjustments are required. After installation by the customer

or after repair, the end positions should be checked and

adjusted if necessary.

42

Limit switch allocation

Switch S1 (bottom) opens at “open” position

Switch S2 (top) opens at “closed” position

Procedure

• Set both switching cams (1) to S1 and S2 so that the

rotating angle is less than 90°.

• Let the actuator turn until a limit switch is activated.

• By adjusting the respective switching cam, the end

position can be set since the actuator follows the cam.

Page 8

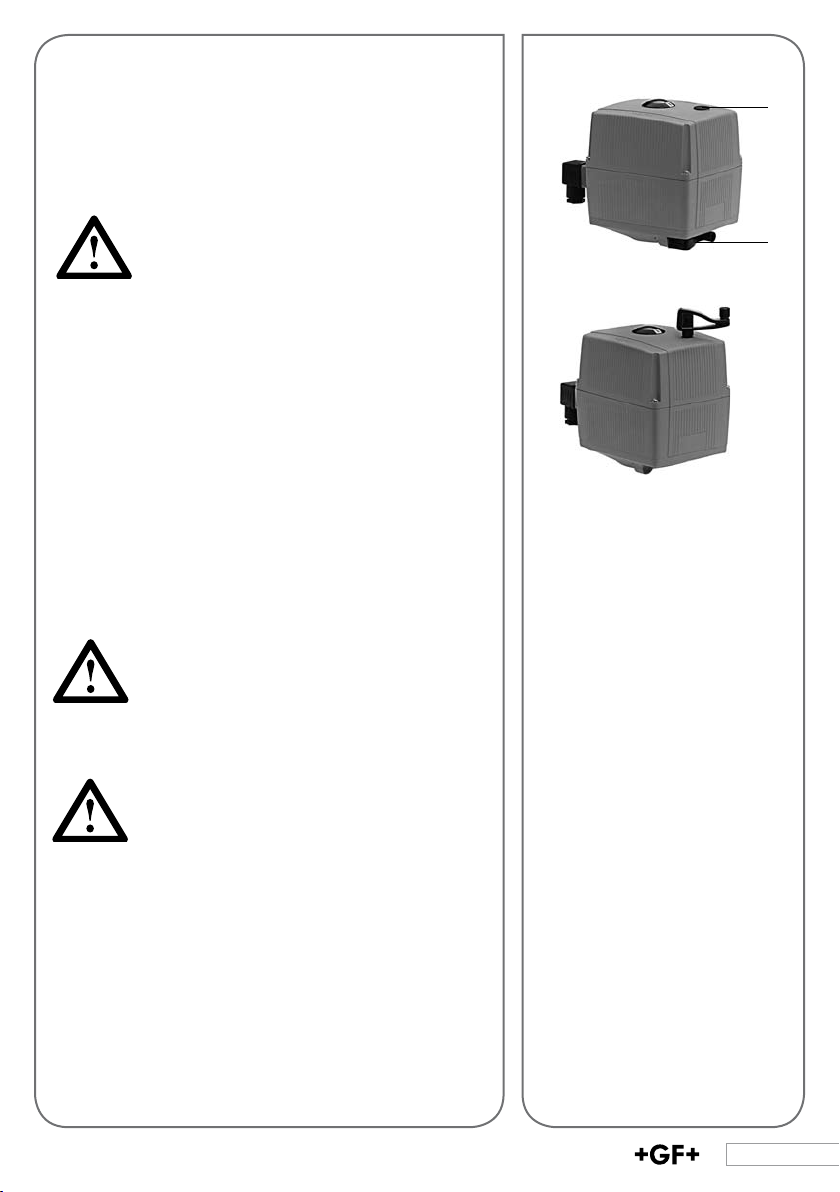

6.1 Emergency Manual Override

Assembly

1. Pull the crank (1) out of the bracket

2. Remove cover screw (2) with the provided crank (1)

3. Insert the crank in the hexagon shaft in the opening

2

After usage, please screw back on the

screw corer (2) to avoid liquids, humidity or

dust entering the actuator!

Function

Push the crank down to the stop. This activates a micro

switch that disconnects the actuator from the current. When

letting go the crank, the actuator is energized again.

With 9 revolutions, the actuator EA21 turns by 90°

With 27 revolutions the actuator EA31 turns by 90°

With 41 revolutions the actuator EA42 turns by 90°

Direction of rotation

Clockwise = CW = close

Counterclockwise = CCW = open

Note the “open” and “closed” position on

the optical indicator

Disconnect the connector plug.

If that is not possible, after usage pull the

crank rapidly out of the opening. (Actuator

might start turning)

1

43

Page 9

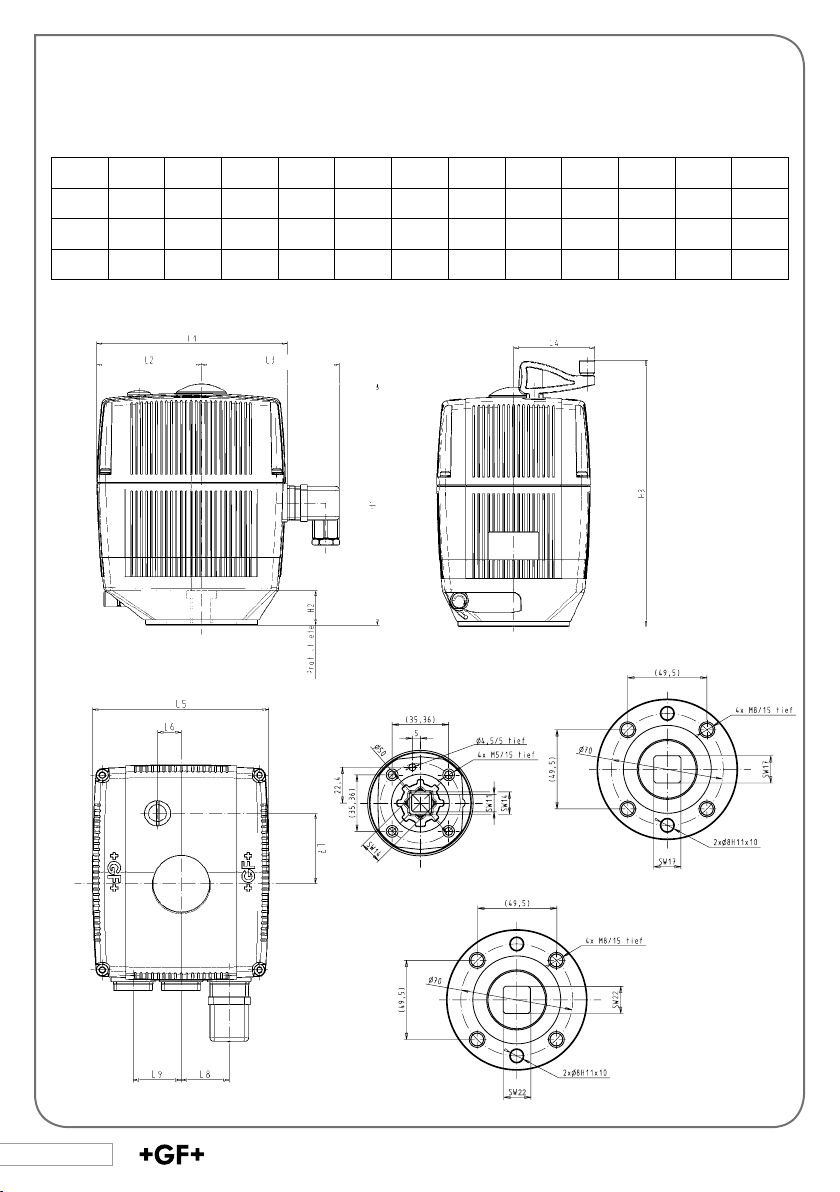

6.2 Dimensional drawings of the Electrical Actuator Type EA 21/31/42

22

L1 L2 L3 L4 L5 L6 L7 L8 L9 H1 H2 H3

150 82.5 108 64.3 122 16 49 33 33 167 20 188.5

EA21

150 82.5 108 64.3 122 16 49 33 33 190 25 211.5

EA31

150 82.5 108 64.3 122 16 49 33 33 208 25 229.5

EA42

EA21/F05 EA31/F07

EA42/F07

44

Page 10

6.3 Technical Specications

EA21 EA31 EA42

Rated voltage 100 – 230V, 50/60 Hz

Rated voltage tolerance

Rated output @ 24V AC/DC

@ 100 – 230V AC

Electric impedance 230V, 100kΩ

24V = /24V, 50/60 Hz

+/- 10%

22 VA

40 VA

32 VA

40 VA

24V, 4.7kΩ

40 VA

60 VA

Altitude over NN (UL /CSA)

Protection class

< 2000m

IP 65 per EN 60529 *(3) UL/CSA: indoors use

Duty cycle 100% (6) 50% 35%

Overload protection current/time-dependent (resetting) *(1)

temperature dependent

Electrical connections Connector plug 3 P+E per DIN EN 175301-803

Cable gland M20 x 1,5 according to ISO 724

Nominal torque Mdn

10 Nm 60 Nm 100 Nm

Actuating angle max. 180°, set to 90°

Control time 5 s / 90° at Mdn 15 s / 90° at Mdn 25 s / 90° at Mdn

Peak torque 20Nm 120 Nm 250 Nm

Ambient temperature -10° to + 50°C (2) -10° to + 50°C (2)

Allowable humidity max. 90% relative humidity, non condensing

Pollution grade (4) 2

Over voltage category (4) II

Housing material PP breglass reinforced, ame retardant,external stainless

steel screws, non-losable

Position indication optical, integrated

Emergency manual override integrated

Flange pattern (5) F05 F07 F07

(1) Overl oad protec tion of the motor i s dimensioned so th at the motor and t he power supp ly board

are pro tected. As s oon as the loa d is in the torque

rang e, the actuato r runs again .

(2) For te mperatur es below -10°C as w ell as

conde nsation, th e heating elem ent no. 198 190

086 sh ould be built i n.

(3) Pro tection ra ting IP 67 for use of c able glands

and ver tical ins tallation

(4) Per E N 61010-1

(5) Per IS O 5211

(6) Reduc ed Duty cy cle for UL cer tication

45

Page 11

Wiring diagram

Heating element kit

7. Mounting and Connecting

Supplementary Kits

7.1 Heating Element

Description Technical data Code

Heating element 24 V= 199 190 086

The heating element is mounted on the base board and is

connected electrically via a at cable (X1). The temperature

is measured with a temperature sensor, which is mounted

on this element, and between approx. 0 - 5°C the heating

element is switched on.

Mounting the heating element (board)

1. Disconnect the actuator from the supply voltage.

2. Remove actuator cover.

3. Take the board out of its packaging and check for damages.

Do not touch the board itself. Electrostatic

discharge can damage the components.

4

46

LED on =

heating operation

2

4. Screw the three distance bolts (1) into the assembly

bolts. Screw hand-tight.

5. Fasten the board (3) on the distance bolts with the sup-

3

1

plied screws (2).

6. Plug the at cable into the X1 (4) connector.

7. Put the cover back onto the actuator.

8. Reconnect to supply voltage.

The heating element may not heat at temperatures over

+ 5 °C, but in case it is switched on it might heat up to

10-15 °C.

Page 12

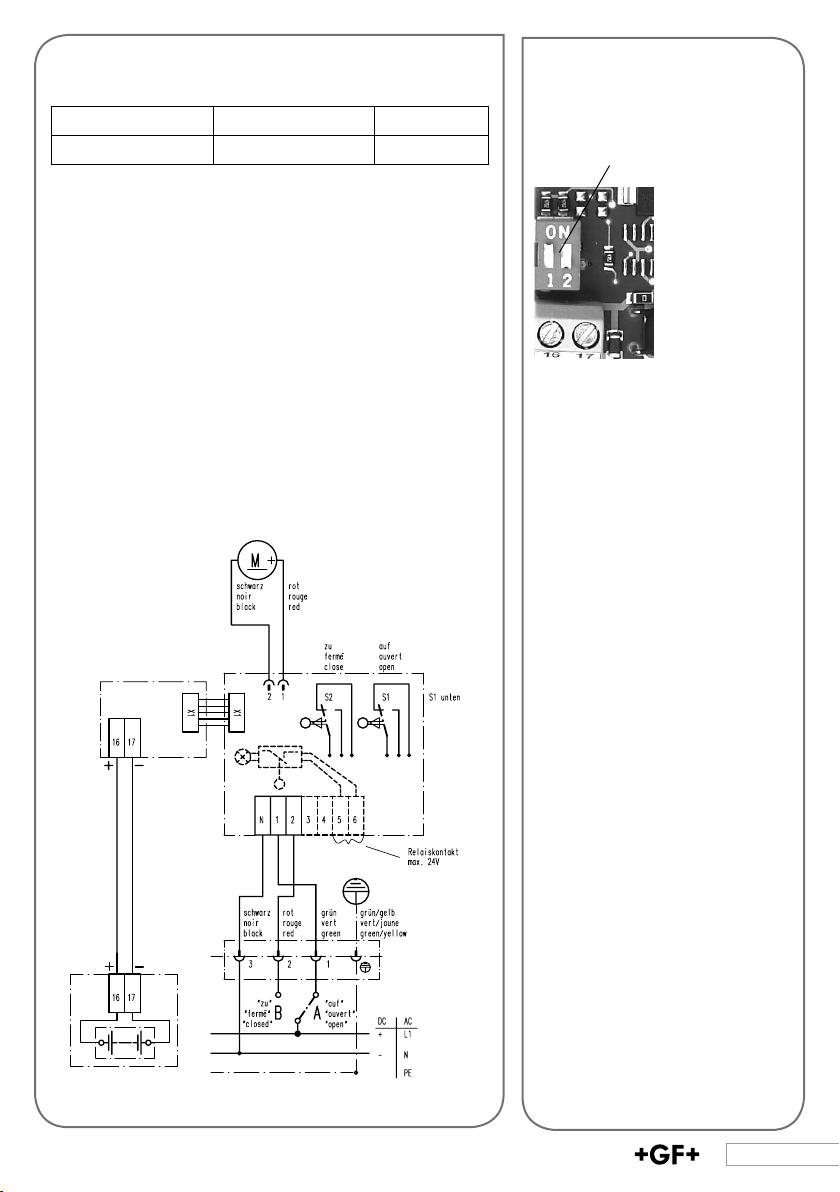

7.2 Fail-safe return

Description Technical data Code

Fail-safe return 24 V= 199 190 085

The fail-safe return unit is mounted on the base board and

is connected electrically via a at cable.

The fail-safe return unit is connected to the batter y via

a two-core wire. If the supply voltage is interrupted, the

electronics will switch to the storage battery automatically

after 5 sec. With the DIP switches (5), the functions “move

to the CLOSED position” or “move to the OPEN position” can

be selected.

Both switches ON: Actuator moves to OPEN

Both switches OFF: Actuator moves to CLOSED

The storage battery is charged continuously. Full charging

takes approximately 15 hours. Expected lifetime approx. 7

years.

DIP sw itch

Wiring diagram

Possible cycles per day:

EA 21 : 10

EA 31 : 04

EA 42 : 02

47

Page 13

Mounting the fail-safe return (board)

1. Disconnect the actuator from the supply voltage.

2. Take the board out of its packaging and check for damages.

Do not touch the board itself. Electrostatic discharge can

damage the components.

3. Screw the three distance bolts (1) into the assembly bolts. Screw hand-

tight.

4. Fasten the board (3) on the distance bolts with the supplied screws (2)

and washers.

5. Plug the at cable into the X1 connector.

6. Reconnect to supply voltage.

LED on

= normal operation / blinks with battery oper ation

2

3

LED on = b atter y operation

4

6

5

1

48

Battery

Rechargeable battery

Connect the battery via the second plug or cable gland to the terminals 16

and 17 (4). (we recommend 2x1.5mm2)

Attention must be given to the polarity. Charge the battery

for at least 15 hours.

In case the fail-safe return and the monitoring print are

installed both together, make sure that the adjustments will

not interfere one another.

Page 14

7.3 Additional Limit Switches

Wiring diagram

Description Technical

data

Kit with 2 additional*

limit switches Ag-Ni

Kit with 2 additional*

limit switches Au

Kit with 2 additional

limit switches NPN

Kit with 2 additional

limit switches PNP

Mounting set for 4 limit

switches

* The switches are wired as openers according to the diagram. It is possible for the customer to convert to closer by

rewiring.

(Terminal 8 > 7 and terminal 10 > 9).

250 V ~, 6 A 199 190 092

30 V =, 100 mA 199 190 093

10-30 V=,

100 mA

10-30 V=,

100 mA

Code

199 190 096

199 190 095

199 190 097

Mounting the limit switches

1. Disconnect the actuator from the supply voltage.

2. Remove the screws from the limit switches S1 and S2.

3. Mount the limit switch kit (1) on S1 and S2 as shown.

B)

B)

4. Tighten with the new, longer screws.

5. Mount the additional switching cams (2) as well as the

spacer rings (3).

1

2

3

49

Page 15

Setting the limit switch position

1. Reconnect the actuator to the supply voltage.

The switch position may only be set with an

extra-low voltage under 50 V.

2. Move the actuator to the two end positions and set the

respective switching points.

The switching cams can be adjusted with a screwdriver

size 2.

3. Disconnect the actuator from the supply voltage.

4. Connect limit switches.

5. Close the actuator with the housing cover and connect to

the supply voltage.

7.3.1 Additional 4 Limit Switches

Analog to the mounting instructions for the 2 additional limit

switches the EA 21/31/42 can be expanded to include 4 limit

switches.

The mounting sequence for the individual parts is equal to

the 2 additional limit switches.

50

For stability purposes additionally the

mounting set for 4 limit switches must also

be used. The fully assembled unit can be

seen in the picture below.

Page 16

7.4 Middle Positioning

Description Technical data Code

Middle positioning 199 190 094

The kit is mounted on the limit switches S1, S2 and serves to

move the actuator to a third position ( e.g. 3-way ball valve

into the middle position).

Wiring diagram

51

Page 17

Mounting the middle positioning kit

1. Disconnect the actuator from the supply voltage.

2. Remove the screws of the limit switches S1 and S2

3. Connect the plug of the kit to the four-pole slot (1).

Make sure that the multipoint socket connector of the plug

ts into the socket board of the four-pole plug.

4. Attach the two switches S3 and S4 of the kit to S1 and S2. When doing

this, switch S3 (assigned to PIN1, 2) must be down and switch S4 (PIN 3,

4) on top. (see wiring diagram).

5. Fasten the two switches S3 and S4 with the longer screws supplied.

S4

S3

(1)

52

Overview on activation

Actuator moves

in position

OPEN 1 S1 CCW*

CLOSED 2 S2 CW**

MIDDLE 3 S3 CCW

* CCW – Counter Clock Wise – G egen Uhr zeigersinn

** CW – Clock Wis e – Im Uhrzeigersin

> Move actuator to position “OPEN” (CCW): Put terminal 1 under current

> Switch S1 is activated.

> Move actuator to position “CLOSED” (CW): Put terminal 2 under current

> Switch S2 is activated.

> Move actuator to middle position (CCW / CW): Put terminal 3 under

current > Switch S3/S4 is activated.

Terminal

under current

Activated

switch

Direction of rotation of the actuator

S4 CW

Page 18

Setting the end positions

Setting the opening angle from 90° to 180°

• Turn switching cam 2 of switch S2 counter clockwise (top view) by 90°.

• Reconnect the actuator to the supply voltage

• Move the actuator into position “CLOSED” (terminal 2 under current)

• Turn cam 2 until reaching the desired position. (see position of the ball)

• Replace the standard position indicator by the new 3-way position indi

cator

Standard position indicator 3-way position indicator

-

Setting the middle position

• Move the actuator to the OPEN position (terminal 1 under current)

• Place the additional switching cam on the shaft. For this, rst remove

the position indicator again and put it back on again in the same position

after wards

• Place cam 3 upon cam 2 (cam 4 still stays on top of the switches)

• Put cam 3 into the same position as cam 2 and turn it clockwise by 90°

• Move actuator to the “middle” position (terminal 3 under current)

• Readjust cam 3 until reaching the desired middle position (see position

of the valve)

• Now Place cam 4 upon cam 3 in the same position as cam 3. Adjust cam

4 after wards. Its corner ank should activate switch S4 (S3 and S4 are

activated, the two nocks of the cams indicate to the opposite direction).

• Close the actuator with the housing cover. The middle position is now

set.

OPEN MIDDLE CLOSED

53

Page 19

BCD switch DIP switch

1 5 2 3 4

7.5 Monitoring print

Description Technical data Code

Monitoring print 199 190 099

The monitoring print is mounted on the base board and is

connected electrically with a at cable. The monitoring print

enables ve functions:

1. Cycle time extension

2. Cycle time monitoring

3. Monitoring a selected maximum number of cycles

4. Monitoring a selected maximum of motor current

5. Position feedback signal 4-20mA (see page 26)

These monitor settings are made via the BCD switches 1 to

4. They are described in the following pages. The switches

must be plugged in order for the function to be active. The

functions work independently of one another. BCD switches

(1 to 4) can be connected individually.

1. Cycle time extention (Vario)

2. Cycle time monitoring

3. Cycle counter

4. Current monitoring

5. Position feedback

Wiring diagram

54

Page 20

Mounting the monitoring print

1. Disconnect the actuator from the supply voltage.

2. Take the board out of the packaging and check for dama-

ges.

Do not touch the board itself. Electrostatic

discharge can damage the components.

3. Screw the three distance bolts (1) into the assembly bolts.

Hand-tighten.

4. Fasten the board (3) to the distance bolts (1) with the

screws (2).

5. Insert the BCD switch (4) for the desired function. Secure

it with the help of the nipple supplied.

6. Select the desired switch setting with a screwdriver.

Monitoring print kit

4

3

2

1

7

2

4

3

1

7. Plug the at cable into the X1 (7) connector.

8. Reconnect to supply voltage.

The board has been connected correctly, when:

1. The LED (9) above the BCD switches blinks green.

2. The LED (6) lights up green.

9 6

8 5

4

3

2

1

1. Cycle time extention (Vario)

2. Cycle time monitoring

3. Cycle counter

4. Current monitoring

5. Position feedback

55

Page 21

Error message

10

If an error occurs, the red LED (8) on the base board lights

up.

In case the monitoring print is installed, the LED (10) on the

BCD switch which selected value has been exceeded will

also light up red.

With all occurring error messages the ready-to-operate

signal will be off.

Eliminating the error message

Check the error cause, if necessar y carry out the appropriate maintenance.

To eliminate the message, activate the reset switch (9) on

8

the base board while the supply voltage is still connected

or briey disconnect the actuator from the mains voltage.

The two LEDs will go out and the actuator is ready to operate again.

The ready-to-operate module can react the

fail-safe mode as well. Resetting the error

message does not reset the cycle counter!

1 2

1 2

1 2

56

In case of malfunc-

ON

tion the actuator

OFF

remains in its

position (delivery

state)

In case of malfunc-

ON

tion the actuator

OFF

moves to the OPEN

position

In case of malfunc-

ON

tion the actuator

OFF

moves to the

CLOSED position

9

DIP switch in case of error

With the help of the DIP switch, the actuator can be moved

to the CLOSED or OPEN position in case of an error. For this,

the DIP switches need to be adjusted as follows:

DIP 1 DIP 2

ON Position of DIP 2

effective

OFF Actuator remains in its

position

Actuator moves to the

OPEN position

Actuator moves to the

CLOSED position

(DIP 2 not effective)

(please refer to example on the left)

Page 22

Cycle time extension (Vario)

Description Technical data Code

Cycle time extension 199 190 080

The cycle time extension increases the cycle time of the

electric actuator. To do this, the actuator rides clocked to

the end positions (OPEN or CLOSED).

The corresponding values are contained in the following

table. These values apply for 90° angle. Cycle time without

BCD: 5s for 90° (EA21); 15s for 90° (EA31); 25s for 90° (EA42)

Switch setting Cycle time monitoring [s]

EA21 EA31 EA42

0 Deli very posi tion 8 20 30

1 12 25 35

2 15 30 40

3 19 35 45

4 25 40 50

5 30 50 55

6 35 60 65

7 35 60 75

The switch positions 8 – 9 have the function of position 7.

The extension of the cycle time is also active in case of failure or reset operation.

57

Page 23

Cycle time monitoring

Description Technical data Code

Cycle time

monitoring

Cycle time monitoring monitors the duration of a pre-set

cycle time of the electric actuator. If the cycle exceeds the

pre-set time, a failure is reported (see error message, page

20). For the corresponding value please refer to the table

below (values are valid for 90° actuation).

Switch setting Cycle time monitoring [s]

EA21 EA31 EA42

0 7 10 15

1 10 D elivery

posit ion

2 15 20 25

3 20 25 Del ivery

4 25 30 35

5 30 35 40 Del ivery

6 35 40 50

7 40 45 60

5 6 8 9

8 45 55 70

9 50 70 85

199 190 082

15 20

30

posit ion

posit ion

1 2

1 2

58

Both switches on ON

ON

- Error message

OFF

without stopping the

actuator

Both switches on OFF

ON

- Error message with

OFF

stopping the actuator

(delivery position)

Cycle counter

Description Technical data Code

Cycle counter 199 190 083

This function allows setting a desired number of cycles. As

soon as the number of cycles exceeds the set value, an error

is reported (see error message, page 20). With the help of

the DIP switch (8) on the monitoring print it can be preset, if

the actuator should keep moving in this case, or if it should

move to its security position and remain there. (refer to

section error message).

Page 24

Switch setting Number of cycles

0 1

1 10.000

2 20.000

3 30.000 (3)

4 40.000 (2)

5 50.000 (1)

6 60.000

7 70.000

8 80.000

9 90.000

Current monitoring

Description Technical data Code

Current

monitoring

This function monitors the motor current. If the motor

current is greater than the pre-set value, a malfunction is

repor ted.

Switch setting Max. motor current/mA

0 200

1 400

2 600 (1)

3 800

4 1.000 (2)

5 1.200

6 1.400 (3)

7 1.600

8 1.800

9 2.000

199 190 081

(1) Delivery position EA21

(2) Delivery position EA31

(3) Delivery position EA42

Reset „Number of Cycles“

Turn the BCD-Switch in the Position O (Position corresponding

to 1 Cycle). Drive the actuator

into CLOSE Position and back to

OPEN Position. The LED lights

up. Press the reset button on the

basic print and the cycle counter

will be cleared. Now the BCD

Switch can be set to the desired

number of cycles again. (refer

to table)

When setting the BCD switches, make sure

that the set function do not block one another.

Example BCD1 cycle timeposition position 3 = 19s

EA21: BCD2 cycle time monitoring position 0 = 7s

59

Page 25

7.6 Position Signalization

Description Technical data Code

Position

signalization

The position signalization enables determining the exact

mechanical position of a valve. Output signal is a current of

4 – 20 mA. (4mA-CLOSED, 20mA-OPEN).

The position signalization can be combined with the positioner or the monitoring print.

The position signalization board is mounted on the limit

switches S1, S2 and is connected electrically to the positioner or the monitoring print via a system cable.

Mounting the position signalization

1. Disconnect the actuator from the supply voltage.

1

2

3

2. Remove the screws of the limit switches S1 and S2.

3. Remove the position indicator (1).

4. Place the position signalization board in the position

shown on S1 and S2 and fasten with the longer screws.

5. Insert the toric magnet (3) so that the notches are on the

top.

Again place the position indicator (1) on the axis in one of

the end positions.

199 190 084

60

6. Connect the position signalization board to the controller or monitoring print via the system cable (2).

Reconnect to the power supply.

The board has been connected correctly when the LED

(4) lights up green.

If the position signalization is used

together with additional limit switches,

the position signalization as to be in

stalled above the limit switches.

Page 26

Setting the position signalization

For the position sensor (4) to recognize the OPEN and

CLOSED positions, a single learning run with 360° must be

done. After the learning run, the OPEN and CLOSED positions are set.

Further learning runs can be done between the end positions (depending on the switching cams S1 and S2).

The way how the jumper is placed on the position signalization determines if the learning run happens with 360° or if it

happens between the end positions.

Jumper connects both PINs: learning run 360°

Jumper doesn’t connect the PINs: learning run bet

ween the end positions

When position signalization is mounted ex

factory, a learning run with 360° has been

already done. In this case the jumper is

placed on only one PIN. When the position

signalization is mounted by the customer a

360° learning run has to be done. Therefore

the two PINs need to be connected by the

jumper.

Subsequent modications on the switching

cams requires a new learning run.

7

4

5

6

Learning run 360° (Position signalization

kit subsequently installed)

It is necessary to separate the actuator from

the valve, to avoid damage to the valve. Before doing the learning run set the jumper so

it connects the two PINs. Complete learning

run. Then reset the jumper to its original

position and remount the actuator.

Doing a learning run

Press the button (5) on the board for ca. 2s. (The LED (6) will

go out briey. As soon as the LED lights up again, release

the button). The actuator will do a learning run with several

longer pauses.

61

Page 27

During this run, the LED (6) will blink. While the LED (6) is blinking, the

actuator is in the learning mode. The learning run is only nished when the

LED lights continuously.

7

If the position signalization is combined with the monitoring print, the

output signal 4 – 20 mA can be processed on the terminals 18, 19 (7) on the

board of the monitoring print. (4 mA > CLOSED / 20 mA > OPEN).

If the position signalization is connected to the positioner, the latter will

process the signal.

7.7 Positioner

Description Technical data Code

Positioner type PE 25 199 190 100

The positioner type PE 25 controls a user-dened valve position proportional to a given set value. This can be 0-10V or 4-20mA.

Power supply needs to be galvanically isolated.

62

The return of the valve position (actual value) is realized with the position

signalization.

The control parameters are pre-set ex factor y and do not need to be changed.

Page 28

Signal conguration

The four DIP switches on the controller print serve for the

conguration of the signals.

DIP switch:

ON

OFF

S1 S2 S 3 S4

Switch combination

Signal type S1 S2

0-10 V OFF OFF

4-20 mA ON ON

S3: ON: input inverted

OFF: input not inverted

S4: ON: use S3L Master

OFF: use S3L Slave

Example:

Set signal value 4 – 20 mA, not inverted, use S3L Slave

ON

OFF

S1 S2 S 3 S4

DIP switch

LED‘s

63

Page 29

Description Technical data Code

Positioner type PE 25 galvanic isolated 199 190 101

The positioner type PE 25 controls a user-dened valve position proportional to a given set value. This can be 0-10V or 4-20mA.

The return of the valve position (actual value) is realized with the position

signalization. The control parameters are pre-set ex factory and do not

need to be changed.

64

The return of the valve position (actual value) is realized with the position

signalization.

The control parameters are pre-set ex factor y and do not need to be changed.

Page 30

Signal conguration

The four DIP switches on each of the three switch blocks

on the controller print serve for the conguration of the

signals.

DIP Schalter Block 1 - 3:

ON

OFF

S1 S2 S 3 S4

Switch combination

DIP switch

Block 1

S1 S2 S 3 S4

DIP switch

Block 2

Signal type S1 S2

0-10 V OFF OFF

4-20 mA ON ON

S3: ON: input inverted

OFF: input not inverted

S4: ON: use S3L Master

OFF: use S3L Slave

DIP switch

Block 3

S1 S2 S 3 S4

Example:

Set signal value 4 – 20 mA,

not inverted, use S3L Slave

DIP Switch Block 1

All switches must

ON

be set to OFF

OFF

S1 must be

ON

set to ON

OFF

S2-S4 must be

set to OFF

S1 S2 S 3 S4

DIP Switch Block 2DIP Switch Block 3

ON

OFF

LED‘s

65

Page 31

Mounting the positioner

1. Disconnect the actuator from the supply

voltage.

2. Take the controller board out of the packaging and

check for damages.

Do not touch the board itself. Electrostatic

discharge can damage the components.

3. Place the board vertically on the back side of the base

board on plug X1. (see page 47)

Make sure that the board is inserted exac

tly in the guides at the side.

Setting the position signalization see Section 9.6

Connecting the positioner

For the positioner to receive the set value signal, connect

the terminals of the set value inputs 20 to 23 for the corresponding values. (see table below) Cable cross-sectional

area max. 1.5mm

2.

EA 21 mit montiertem Stellungsregler und Positionserfassung.

66

Mind the conguration of the set value (see signal conguration):

Terminal assignment Positioner 199 190 100:

20 SET value input current

21 SET value input voltage

22 -

23 SET value input ground

30 Position signalization signal

31 Position signalization ground

Page 32

Terminal assignment Positioner 199 190 101:

27 SET value input current / voltage

28 Output 12 V DC

29 SET value input ground

30 Position signalization signal

31 Position signalization ground

Mind the conguration of the set value

The 4 – 20 mA current signal at the terminals 30, 31 can be

evaluated, if necessar y.

(4 mA: CLOSED; 20 mA: OPEN)

When the set value and the position indicator have been

connected, reconnect the actuator to the supply voltage (see

wiring diagram).

The positioner has been connected correctly, when the

green LEDs 1,2, and 4 light up green.

If the LED 3 lights red, the controller is not working (see

LED combination).

Check the connections if necessar y and make sure the

poling of the set input is correct.

LED combination

Colour

LED

green green red green

1 2 3 4

After the positioner is correctly connected, do a learning

run.

67

Page 33

4

7

Setting the position signalization

For the position sensor (4) to recognize the OPEN and

CLOSED positions, a single learning run with 360° must

5

6

be done. After the learning run, the OPEN and CLOSED

positions are set.

Further learning runs can be done between the end posi-

tions (depending on the switching cams S1 and S2).

The way how the jumper is placed on the position signaliza-

tion determines if the learning run happens with 360° or if it

happens between the end positions.

Jumper (7) connects both PINs: learning run 360°

Jumper doesn’t connect the PINs: learning run between

the end positions

When position signalization is mounted ex

factory, a learning run with 360° has been

already done. In this case the jumper is

placed on only one PIN. When the position

signalization is mounted by the customer a

360° learning run has to be done. Therefore

the two PINs need to be connected by the

jumper.

Subsequent modications on the switching

cams requires a new learning run.

68

Learning run 360° (Position signalization

kit subsequently installed)

It is necessary to separate the actuator from

the valve, to avoid damage to the valve.

Before doing the learning run set the jumper so it connects

the two PINs. Complete learning run. Then reset the jumper

to its original position and remount the actuator.

Doing a learning run

Press the button (5) on the board for ca. 2s. (The LED (6) will

go out briey. As soon as the LED lights up again, release

the button). The actuator will do a learning run.

During this run, the LED (6) will blink. While the LED (6) is

blinking, the actuator is in the learning mode. The learning

run is only nished correctly when the LED lights continuously.

Page 34

69

Page 35

8. TROUBLESHOOTING

Problem Possible causes Remedy

Motor does not run no mains voltage available error at customer side

(terminals 1,2,3)

internal wiring error check wiring of actuator

switching cams S1 and S2 see point 6

set incorrectly

motor blocked

Motor only runs in limit switch defective replace limit switch

one direction

Overload protection reacts

(self-resetting)

Valve does not close or

open correctly not adjustedt

torque of valve too high clean and lubricate valve

duty cycle too high increase cycle time

switching cams S1 and/or S2 see point 6

use emergency manual override,

check the valve

reduce ambient temperature

For ser vice please contact the specialist at your Georg Fischer sales company.

In case an end position is not reached, the actuator shuts off automatically after

2 minutes and reports error message.

70

Page 36

Ordering Information

Description Code

Actuator EA21 100–230 V~ 198 150 182

Actuator EA21 24 V=/~ 198 150 183

Actuator EA31 100–230 V~ 198 150 184

Actuator EA31 24 V=/~ 198 150 185

Actuator EA42 100–230 V~ 198 150 186

Actuator EA42 24 V=/~ 198 150 187

Limit switch kit Ag-Ni 199 190 092

Limit switch kit Au 199 190 093

Limit switch kit Middle Position 199 190 094

Limit switch kit PNP 199 190 095

Limit switch kit NPN 199 190 096

Mounting set for 4 limit switches 199 190 097

Fail-safe return incl. battery kit 199 190 085

Heating element 199 190 086

Heating element + fail-safe return incl. battery kit 199 190 087

Monitoring print 199 190 099

Cycle time extension 199 190 080

Cycle time monitoring 199 190 082

Cycle counter 199 190 083

Motor current monitoring

Position signalization 199 190 084

Positioner PE 25 199 190 100

Positioner PE 25 galvanic isolated 199 190 101

Testing adaptor kit for RS 232 inter face 198 151 426

Battery kit (spare) 198 151 317

Crank 198 151 307

Cover screw kit

Kit of plugs 198 000 502

Adaptor Set for F05 SW14/11 198 000 587

Adaptor SW14 for F05 198 204 057

Reduction SW11 for F05 198 803 145

199 190 081

198 000 503

71

Page 37

Notizen/Notice/Note

72

Page 38

Notizen/Notice/Note

73

Page 39

700.278.045

GMST 5886/1/4a (5.07)

© Georg Fischer Piping Systems Ltd

CH-8201 Schaffhausen/Switzerland, 2006

Printed in Switzerland

Loading...

Loading...