Page 1

Instruction Manual

Electrical Actuator Unit

Type EA ¢1

¥ ‡

Page 2

The technical data is not

binding and not an expressly

warranted characteristic of the

goods. It is subject to change.

Please consult our General

Conditions of Supply.

58

¥ ‡

Page 3

Table of Contents

Page

1. Introduction/General Information 60

2. Manufacturer‘s Declaration 60

3. Intended Use 61

4. Safety Tips 62

4.1 Due Care Required of the Operator

4.2 Special Hazards

4.3 Transport and Storage

5. Actuator Design 64

5.1 Wiring Diagram for Standard Version

6. Valve Design 66

6.1 Mounting on the Ball Valve ¢07

6.2 Overview of Ball Valve System

Type ¢07

7. Setting Up the Actuator/Valve 70

7.1 Emergency Manual Override

8. Technical Specifications for EA ¢1 72

9. Mounting and Connecting 73

the Supplementary Kits

9.1 Heating Element

9.2 Fail-safe Return

9.3 Additional Limit Switches

10. Fastening Plate 82

11. Troubleshooting 83

12. Subcomponents/Spare Parts 84

¥ ‡

59

Page 4

¢. Introduction

This instruction manual contains all the pertinent

information on the design, installation and operation of the electrical actuator type EA 11 .

General Information

Hazard notices

Hazard notices are used in this manual to warn you

of possible injuries or damages to property. Please

read and abide by these warnings at all times!

Warning symbols

Danger

Warning

Caution

Meaning

Imminent acute danger!

Failure to comply could result in death

or extremely serious injury.

Possible acute danger!

Failure to comply could result in

serious injury.

Dangerous situation!

Failure to comply could lead to injury

or damage to property.

2. EC Manufacturer‘s Declaration

The manufacturer, Georg Fischer Piping Systems

Ltd, CH-8201 Schaffhausen, declares that the

electrical actuator EA 11 is not a ready-to-use

machine in the sense of the EC Machine Directive

and cannot therefore meet all the requirements of

this directive.

60

¥ ‡

Page 5

Operation of these actuators is prohibited until

conformity of the entire system into which the

valve and the actuator have been installed is

established according to the EC Directives listed

below.

Applicable EC Directives:

72/23 EEC EC Low Voltage Directive

89/336 EEC EC Directive on Electromagnetic

Compatibility

Modifications to the actuator which have an

effect on the technical data given in this instruction manual and its intended use, i.e. significantly alter the actuator, render this

manufacturer‘s declaration null and void.

3. Intended Use

Warning

When mounted on a valve and connected to a

system control, the purpose of this actuator is to

ł actuate valves with 90° pivoting (ball valves and

butterfly valves),

ł indicate the previously calibrated end positions

of the valve via electrical signal to the system

control (accessory), and

ł provided that the actuator data corresponds to

the electrical control and the valve and

ł in case of interruption in the supply voltage,

warrant that the actuator/valve remains in the

current position. Please use emergency manual

override or install fail-safe return.

The actuator is not intended for uses other than

those listed here. If the instructions contained in this

manual are not observed, the manufacturer is

excluded from all liability for the above mentioned

products.

¥ ‡

Warning

61

Page 6

Warning

4. Safety Tips

4.1 Due care required of the operator

The actuator described herein was designed and

manufactured with consideration to the respective

harmonized European standards. It corresponds to

the latest technology and the technical specifications contained under Section 8.

Safety on the job can, however, only be realized if

the operator warrants that

ł the actuator is only used as indicated under

Section 3,

ł he is familiar with this instruction manual and the

manual of the corresponding valve and adheres

to the instructions contained therein and

ł he has taken the necessary measures against

electrostatic influence.

4.2 Special hazards

62

Warning

Under normal conditions, the actuator may only

be operated with the cover closed.

If work is performed on the actuator with the

cover removed, the supply and control voltage

must first be disconnected. Adjustments, which

need to be done in the energized state, should

be carried out with special insulated tools.

In addition, the operating instructions of the

manual valve must be observed. They are an

integral component of this manual.

¥ ‡

Page 7

4.3 Transport and storage

The actuators must be handled, transported and

stored with care. Please note the following points:

ł The actuators should be transported and/or

stored in their original unopened packaging.

ł The actuators must be protected from harmful

physical influences such as dust, heat (humidity).

ł It is important that the connections are neither

damaged by mechanical nor thermal influences.

ł Prior to installation, the actuators should be in-

spected for transport damages. Damaged actu-

ators must not be installed.

Warning

¥ ‡

63

Page 8

5. Actuator Design

The standard version of the EA 11 electrical

actuator consists of the following elements:

gear unit, direct current motor, electrical board,

and components for end position limiting.

For special applications, the actuator can be

equipped additionally with various supplementary

kits (see Section 9).

/

)

V

$

&

1 Limit switches S1 and S2

2 Direct current motor

3 Optical position indicator

4 Plug for accessories

5 Terminal strip for external connections

max. ¢.5 mm

2

6 Electrical supply unit, without protection

against accidental contact

7 Shaft for emergency manual override

8 Connections for DIN plug or

cable gland

9 Assembly bolt for accessories

§

!

%

(

64

¥ ‡

Page 9

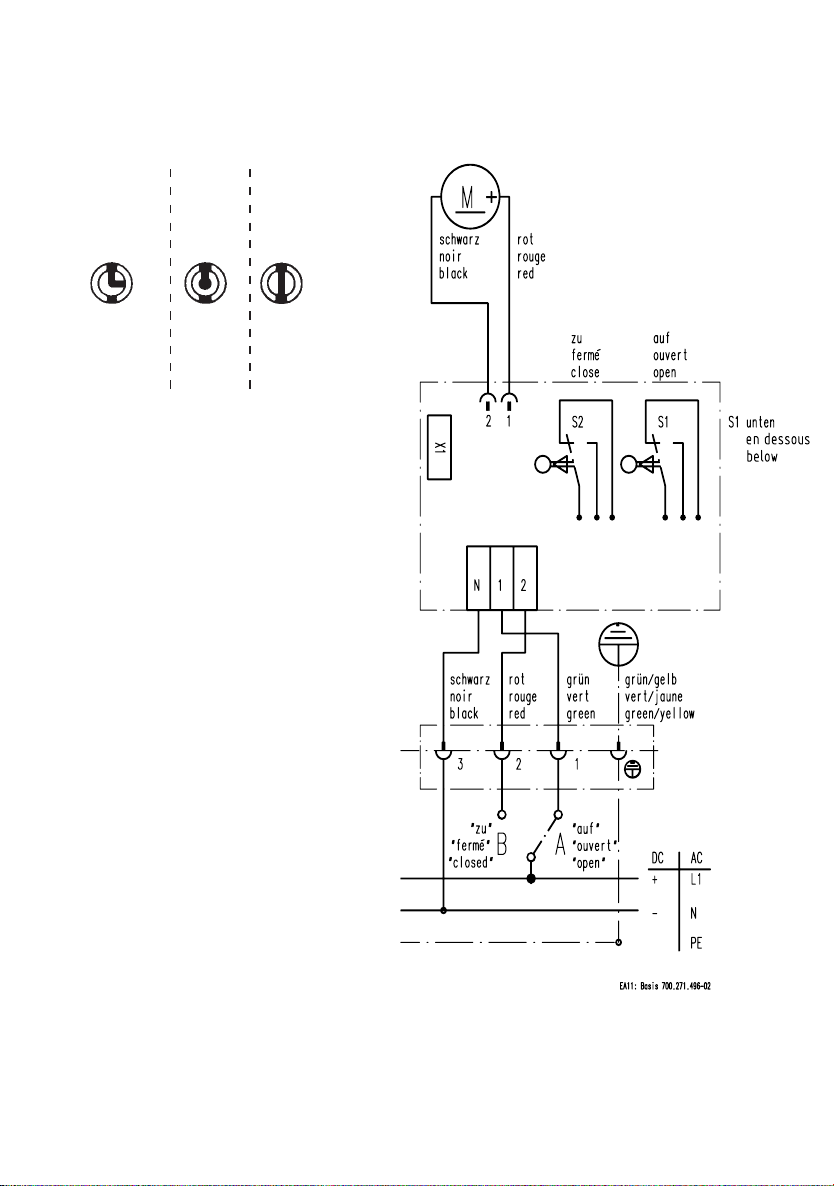

5.1 Wiring Diagram for Standard Version

Position indicator

2/2-way3/2-way

horizontal

A

B

B–C

A–C

vertical

A

C

B

B–C

A–C

A

C

B

C

A–B

C

closed

open

Installation note

If the actuator is connected

direct to the power-supply,

it is necessary to install a

switch-disconnector between

the actuator and the powersupply (do not disconnect the

earthcable).

To avoid water flowing into

the actuator it is necessary

that the cable insertion ist not

upturned.

¥ ‡

65

Page 10

6. Valve Design

The EA ¢1 electrical actuator can be mounted on

ball valves type 546, DN10–50, by using the correct coupling piece and selecting a suitable adapter plate with clamps.

The actuators are supplied ex works in the «open»

position. See Section 6.¢ for the individual assembly

components required for the ball valve type ¢07.

Both end positions in the actuator have been preset

in the factory. It is necessary to readjust these after

installation at the customer (see Section 7).

How to assemble (see Fig. 6.1)

3a

close

open

Screw the adapter plate with the fixed clamps

2

tightly onto the actuator (note the cam positions).

3

Mount the multifunctional module on the ball valve.

1 Housing

2 Housing cover

3 Indexing disk* with switching cams 3a

4

5

4 Screws

5 Connector plug 3P + E per DIN EN

175301-803* (formerly DIN 43650)

1

* only for MF module version with pre-assembled

microswitches

Remove housing cover (2).

The MF module can be mounted on the ball

valve type 546 in the opened or closed

position.

66

¥ ‡

Page 11

Spigot is asymmetrical.

The spigot position must be idential with one of the

two illustrations.

A Stem position for closed ball valve

B Stem position for open ball valve

Place the MF module on the ball valve

Make sure the contours match!

Note the square (a) and round (b) contours as well

as the position of the asymmetrical recesses (c) of

the stem.

Tighten the 4 pre-assembled screws (Torx).

The MF module is now firmly connected with the

ball valve.

Insert the coupling and the coupling piece* in the

multifunctional module.

Fasten the actuator with the adapter plate to the

multifunctional housing using the provided clamps.

*coupling piece only for DN10–25

Actuator and valve must have the same position, «open» or «closed».

¥ ‡

67

Page 12

Actuator

Type EA ¢1

Coupling piece

Adapter plate

PT-Schr KA 4x¢6

Clamp

Allen screws

Coupling

6.1 Ball Valve Type ¢07

Screws

Multifunctional module

(without microswitches)

Ball valve type 546

68

¥ ‡

Page 13

6.2 Overview of Ball Valve System

Type ¢07

1 Actuator type EA ¢1

2 Coupling piece DN10–25

3 Adapter plate DN10–50

4 Multifunctional module DN10–50

5 Ball valve type 546 DN10–50

1

2

3

4

DN 10/155DN 20

Note: Screw saving

The actuator fixing screws are assured with «Locitite 243» or equivalent.

Note: Mounting of coupling and coupling piece

First plug the coupling piece into the actuator. Then fix the adapter plate

with four screws on the actuator. Next push the coupling into the coupling piece.

The coupling with the mounted coupling piece does not fit through the

hole of the adapter plate!

2

3

4

DN 25

5

5

3

4

DN 32

5

DN 40

5

3

4

DN50

5

¥ ‡

69

Page 14

7. Setting Up the Actuator

Attention

Check the following before connecting the actuator

to the mains:

ł Does the mains voltage correspond to the speci-

fications given on the typeplate

ł Has the actuator been connected correctly

(see Section 5.1)

Adjustments

If a complete valve is supplied by Georg Fischer,

no further adjustments are required.

After installation by the customer or after repair

work, the end positions should be checked and if

necessary adjusted.

Limit switch allocation

Switch S1 (bottom) opens at «open» position

Switch S2 (top) opens at «closed» position

Procedure

Set both switching cams (1) to S1* and S2* so that

the rotating angle is less than 90°.

Let the actuator turn until a limit switch is activated.

By adjusting the respective switching cam, the end

position can be set since the actuator follows the

cam.

70

* S1: «open», bottom

S2: «closed», top

!

¥ ‡

Page 15

7.1 Emergency Manual Override

Assembly and function

Assembly

Pull the crank (1) out of the retainer

Remove cover screw (2) with the crank (1)

Insert the crank in the hexagon shaft* under the

opening

V

* see illustration, page 60, no. 7

Function

Push the crank down to the stop.

With nine revolutions, the ball is rotated by 90° .

Direction of rotation:

Clockwise = CW = close

Counterclockwise = CCW = open

Note the «open» and «closed» position

on the optical indicator.

Disconnect the connector plug.

If that is not possible, pull the crank

rapidly out of the opening.

!

¥ ‡

71

Page 16

8. Technical Specifications

Actuator EA ¢1

Rated voltage 100–230 V, 50/60 Hz

24 V =/24 V, 50/60 Hz

Rated voltage tolerance w 10%

Rated output 22 VA at 24 V AC/DC

40 VA at 100–230 V AC

Electric impedance 230V, 100k

24V, 4k7

Altitude l 2000m

Protection class IP 65 per EN 60529

3)

UL/CSA: Indoor use

Duty cycle 40% at 25 °C / ¢5 min

Overload protection current/time dependent

(resetting)

1)

Electrical connections Connector plug 3 P+E per

DIN EN 175301-803

(formerly DIN 43650)

additional cable entry point

for PG ¢1

Control time 5 s / 90° at Mdn

Actuating angle max. 270°, set to 90°

Nominal torque 10 Nm

Peak torque 20 Nm

Ambient temperature –10° to +45 °C

Allowable humidity max. 80% up to 31 °C

Pollutiongrade

Overvoltage-category

5)

5)

2

II

2)

4)

Housing materials PP fiberglass reinforced,

flame retardant,

external stainless steel screws

Position indicator optical, integrated

Emergency manual override integrated

72

1)

Overload protection of the motor is dimensioned so that the motor

and the power supply board are protected. As soon as the load is

in the torque range, the actuator runs again.

2)

For temperatures below –10 °C as well as condensation, the

heating element no. 198 ¢90 086 should be built in (see Section 9.1).

3)

Protection rating IP67 for use of cable glands and vertical

installation.

4)

Linear decreasing to 50% relative humidity with 40 °C

5)

Per EN 6¢0¢0-¢

¥ ‡

Page 17

9. Mounting and Connecting

Supplementary Kits

9.1 Heating element

Description Technical data Code

Heating element 24 V= 199 190 086

Wiring diagram

The heating element is mounted on the base board

and is connected electrically via a flat cable (X1).

The temperature is measured with a temperature

sensor, which is mounted on this element, and

between approx. 0–5 °C the heating element is

switched on or off, respectively.

¥ ‡

73

Page 18

LED shines

= heating operation

Heating element kit

LED shines

= normal operation

74

¥ ‡

Page 19

Mounting the heating element (board)

Disconnect the actuator from the supply voltage.

Take the board out of its packaging and

check for damages.

Do not touch the board itself. Electrostatic

discharge can damage the components.

Screw the three distance bolts (1) into the

assembly bolts.

Screw hand-tight.

Fasten the board (3) to the distance bolts

with the screws (2).

Plug the flat cable into the X1 connector.

Reconnect to supply voltage.

The heating element may not heat at temperatures over +5 °C.

!

!

§

V

¥ ‡

75

Page 20

9.2 Fail-safe Return

Description Technical data Code

Fail-safe return 24 V= 199 190 085

Wiring diagram

OPEN

CLOSE

76

The fail-safe return unit is mounted on the base

board and is connected electrically via a flat cable.

If the supply voltage is interrupted, the electronics

will switch to the storage battery automatically

after 5 sec. With a touch control, the function «Go

to the CLOSED or OPEN position» can be selected.

Position ¢/2: CLOSED, position ON: OPEN

(always both, see at left). The storage battery is

charged continuously.

Full recharging takes approximately ¢5 hours.

¥ ‡

Page 21

Fail-safe return kit

LED shines

= normal operation

LED shines

= accu operation

¥ ‡

77

Page 22

!

$

!

§

Mounting the fail-safe return (board)

Disconnect the actuator from the supply voltage.

Take the board out of its packaging and

check for damages.

Do not touch the board itself. Electrostatic

discharge can damage the components.

V

Screw the three distance bolts (1) into the

assembly bolts.

Screw hand-tight.

Fasten the board (3) to the distance bolts

with the screws (2).

Plug the flat cable into the X1 connector.

Reconnect to supply voltage.

LxWxH ¢86x80x55

78

Rechargeable battery

Connect the battery via the second plug or cable

gland to the terminals ¢6 and ¢7 (4).

Attention must be given to the polarity.

Charge the battery for at least ¢2 hours.

¥ ‡

Page 23

9.3 Additional 2 Limit Switches

Description Technical data Code

Kit with 2 additional 250 V p, 6 A 199 190 092

limit switches Ag, Ni

If the limit switch kit is mounted in the factory, the

switches are wired as opener according to the

diagram. It is possible for the customer to convert to

closer by rewiring.

(8 . 7 and ¢0 . 9).

¥ ‡

79

Page 24

Limit switches kit

80

¥ ‡

Page 25

Mounting the limit switches

Disconnect the device from the supply

voltage.

Remove the screws from the limit switch S2 and S1.

Mount the limit switch kit (1) on S1 and S2 as

shown.

Tighten with the new, longer screws.

Mount the additional switching cams (2) as well as

the spacer rings.

Setting the limit switch position

Reconnect to the supply voltage.

The switching cams can be adjusted with a screwdriver size 2.

An instrument (e.g. ohm meter) must be used

for setting the switching position.

!

V

Move the actuator to the two end positions and set

the respective switching points.

Connect limit switches (disconnect the device from

the supply voltage).

Close the actuator with the housing cover and

connect to the supply voltage.

¥ ‡

81

Page 26

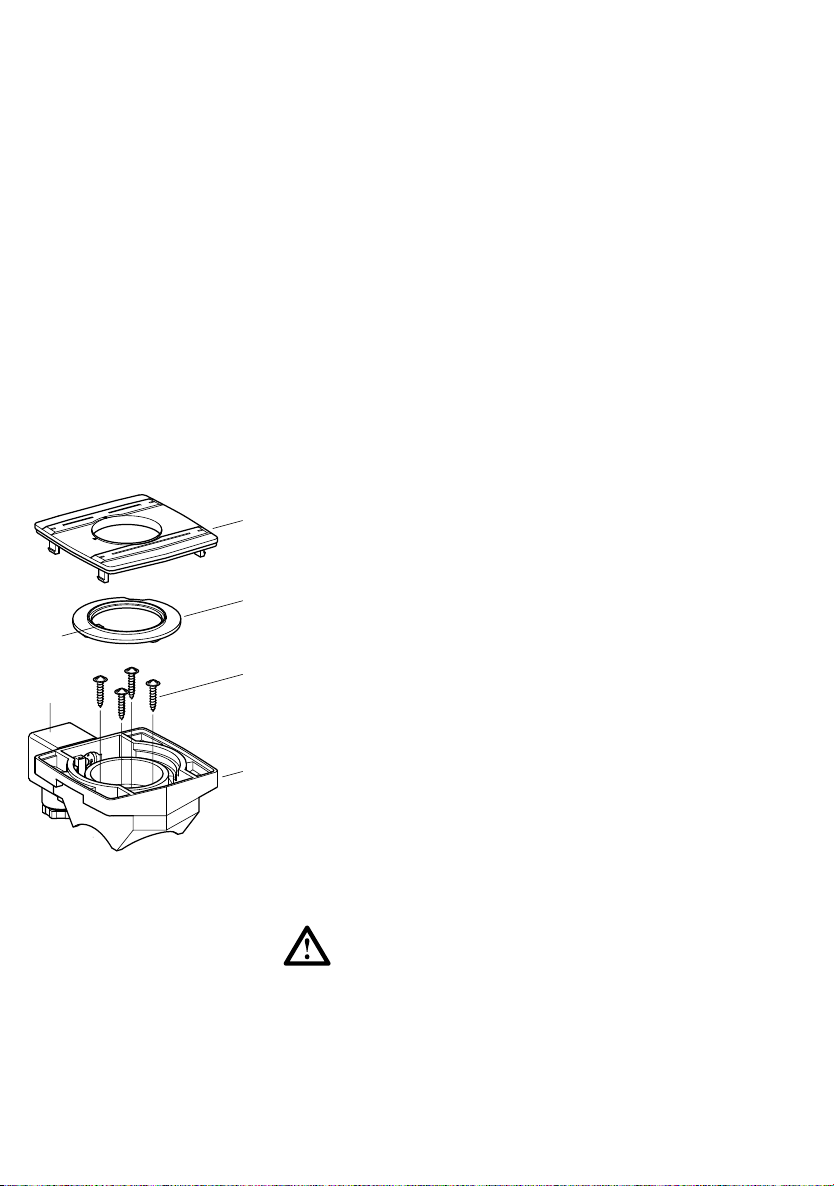

¢0. Fastening Plate

With the fastening plate for the ball valve type 546,

forces are absorbed which could occur during

valve operation (e.g. initial breakaway torque). In

implementing the fastening plate, working forces

are not transmitted to the piping system.

In piping systems which are subject to temperature

fluctuations, longitudinal or bending forces occur if

thermal expansion is hindered. So as not to impair

valve functioning, these forces must be absorbed

by the appropriate fixed points

the valve.

The fastening plate is available in two sizes for the

dimension range DN 10 to DN 50. Two screws to

fasten on the ball valve are included in the scope

of delivery.

Measurement d ¢6–32 d 40–63

L 106 149

B 48 54

H 20 20

L1 92 134

L2 62 104

L3 31 52

L4 41 62

L5 25 45

H1 14 14

H2 24 24

D 6.5 8.5

Fastening

screws M6x14 M8x18

in front of or behind

DN ¢5–25 DN 32–50

82

¥ ‡

Page 27

¢¢. Troubleshooting

Problem Possible causes Remedy

Motor does not run No mains voltage Error at customer

Motor only runs in Change-over relay Replace base

one direction does not work board

Overload protection Friction torque of Clean and lubricate

reacts (self re- valve too high valve

setting)

Valve does not close Switching cams S1 See Point 7

or open correctly and/or S2 not

(Kl 1, 2, 3) side

Internal wiring Check wiring of

error actuator

Switching cams S1 See Point 4

and S2 incorrectly set

Motor blocked Use emergency

manual override,

check valve,

replace motor

Motor defective Replace motor

Duty cycle too Increase cycle time

high

Reduce ambient

temperature

adjusted

For service please contact the specialist at your

Georg Fischer sales company.

¥ ‡

83

Page 28

¢2. Subassemblies/Spare Parts

Description Code

Actuator EA¢1 100–230 V~ 198 150 180

Actuator EA¢1 24 V=/~ 198 150 181

Base circuit board 100–230 V~ 198 140 000

Base circuit board 24 V=/~ 198 140 001

Limit switch kit Ag, Ni 199 190 092

Fail-safe return with battery 199 190 085

Heating element 199 190 086

Heating element + fail-safe return with battery 199 190 087

Battery kit 198 151 317

Plug complete 198 000 502

Crank 198 151 307

Cover Screw kit 198 000 503

Multifunctional module without limit switches

(empty)

Dimensions Code

DN 10/15 167 482 680

DN 20/25 167 482 681

DN 32/40 167 482 682

DN 50 167 482 683

84

Adapter plate incl. coupling

Dimensions Code

DN 10/15 198 150 556

DN 20/25 198 150 557

DN 32/40 198 150 558

DN 50 198 150 559

Ball valve type 546 see separate datasheet

¥ ‡

Page 29

Notes

¥ ‡

85

Page 30

86

¥ ‡

Page 31

¥ ‡

87

Page 32

¥ ‡

Piping Systems

A Georg Fischer Rohrleitungssysteme GmbH, Sandgasse 16, 3130 Herzogenburg

Tel. +43(0)2782/856 43-0, Fax +43(0)2782/856 64, office@georgfischer.at, www.georgfischer.at

AUS George Fischer Pty Ltd, 186–190 Kingsgrove Road, Kingsgrove NSW 2008, Tel. +61(0)2/95 54 39 77, Fax +61(0)2/95 02 25 61

sales@georgefischer.com.au, www.georgefischer.com.au

B/L Georg Fischer NV/SA, Digue du Canal 109-¢¢¢ — Vaartdijk 109-¢¢¢, 1070 Bruxelles/Brüssel

Tél. +32(0)2/556 40 20, Fax +32(0)2/524 34 26, info.be@be.piping.georgfischer.com, www.georgfischer.be

BR George Fischer Ltda, Av. das Nações Unidas 21689, 04795-100 São Paulo, Brasil,

Tel. +55(0)11/5687 1311, Fax +55(0)11/5687 6009

CH Georg Fischer Rohrleitungssysteme (Schweiz) AG, Amsler-Laffon-Strasse ¢, Postfach, 8201 Schaffhausen

Tel. +41(0)52 631 30 26, Fax +41(0)52 631 28 97, info@rohrleitungssysteme.georgfischer.ch, www.piping.georgfischer.ch

CHINA Georg Fischer Piping Systems Ltd Shanghai, No. 2Ý8 Kang Qiao Dong Rd., Shanghai 201319

Tel. +86(0)2¢/58 13 33 33, Fax +86(0)2¢/58 13 33 66, info@cn.piping.georgfischer.com, www.cn.piping.georgfischer.com

D Georg Fischer GmbH, Daimlerstraße 6, 73095 Albershausen, Tel. +49(0)7161/302-0, Fax +49(0)7161/3 0 2 111

info@georgfischer.de, www.rls.georgfischer.de

Georg Fischer DEKA GmbH, Kreuzstrasse 22, 35232 Dautphetal-Mornshausen

Tel. +49(0)6468/915-0, Fax +49(0)6468/915 221/222, info@dekapipe.de, www.dekapipe.de

DK/IS Georg Fischer A/S, Rugvænget 30, 2630 Taastrup, Tel. +45 70 22 19 75, Fax +45 70 22 19 76

info@dk.piping.georgfischer.com, www.georgfischer.dk

E Georg Fischer S.A., Alcalá, 85, 2

info@georgfischer.es, www.georgfischer.es

F George Fischer S.A.S., 105–1¢3, rue Charles Michels, 93208 Saint-Denis Cedex 1

Tél. +33(0)1/49 22 ¢3 4¢, Fax +33(0)¢/49 22 ¢3 00, info@georgefischer.fr, www.georgefischer.fr

GB George Fischer Sales Limited, Paradise Way, Coventry, CV2 2ST, Tel. +44(0)2476/535 535, Fax +44(0)2476/530 450

info@georgefischer.co.uk, www.georgefischer.co.uk

GR Georg Fischer S.p.A., Athens Branch, 101, 3rd September Str., 10434 Athen

Tel. +30(0)1/882 0491, Fax +30(0)1/881 0291, info@piping-georgfischer.gr

I Georg Fischer S.p.A., Via Sondrio 1, 20063 Cernusco S/N (MI), Tel. +3902/921 861, Fax +3902/921 407 85-6

office@piping.georgfischer.it, www.georgfischer.it

ID George Fischer Representative Office, c/o Wisma Aria, 3rd Floor, Jl. H.O.S. Cokroaminoto 81, Jakarta 10310, Indonesia

Tel. +62(0)21/391 48 62, Fax +62(0)21/391 48 63

IND George Fischer Piping Systems Ltd, India Branch Office, Solitaire Corporate Park, 532, Building No. 5, 3rd Floor, Chakala

Ghatkopar Link Road, Andheri (E), 400 093 Mumbai, Tel. +91(0)22/820 2362, Fax +91(0)22/820 2462,

branchoffice@georgefischer.net

J Georg Fischer Ltd, 13–8, Nanbanaka 1-chome, Naniwa-ku, 556-0011 Osaka

Tel. +81(0)6/6635 2691, Fax +81(0)6/6635 2696, info@georgfischer.jp, www.georgfischer.jp

N Georg Fischer AS, Rudsletta 97, ¢35¢ Rud, Tel. +47(0)67 18 29 00, Fax +47(0)67 13 92 92

info@no.piping.georgfischer.com, www.georgfischer.no

NL Georg Fischer N.V., Postbus 35-8160, 8161 PA Epe, Tel. +31(0)578/678222, Fax +31(0)578/621768

info.vgnl@nl.piping.georgfischer.com, www.georgfischer.nl

PL Georg Fischer Sp. z o.o., ul. Radiowa 1A, 01-485 Warszawa, Tel. +48(0)22/638 91 39, Fax +48(0)22/638 00 94

www.georgfischer.pl

RO Georg Fischer Rohrleitungssysteme AG, Rep. Office Romania, 11 Barbu Delavrancea, 70000 Bucharest - Sector 1

Tel. +40(0)1/222 91 36, Fax +40(0)1/222 91 77, office@georgfischer.ro

S/FIN Georg Fischer AB, Box113, 12523 Älvsjö-Stockholm, Tel. +46(0)8/506 77 500, Fax +46(0)8/749 23 70

info@georgfischer.se, www.georgfischer.se

SGP George Fischer Pte Ltd, ¢5 Kaki Bukit Road 2, KB Warehouse Complex, 4¢7 845 Singapore

Tel. +65(0)67 47 06 ¢¢, Fax +65(0)67 47 05 77, info@georgefischer.com.sg, www.georgefischer.com.sg

USA George Fischer Inc., 2882 Dow Avenue, Tustin, CA 92780-7258 Tel. +1(714) 731 88 00, Toll Free 800/854 40 90

Fax +1(714) 7 3¢ 62 01, info@us.piping.georgefischer.com, www.us.piping.georgefischer.com

Export Georg Fischer Rohrleitungssysteme AG, Ebnatstrasse ¢¢¢, Postfach, CH-820¢ Schaffhausen, Tel. +41(0)52 63¢ ¢¢ ¢¢

Fax +41(0)52 63¢ 28 93/631 28 58, export@piping.georgfischer.com, www.piping.georgfischer.com

198.151.118

Fi 5746/¢,2,4 (7.05) © Georg Fischer Rohrleitungssysteme AG, CH-820Ý Schaffhausen/Schweiz, 2004 Printed in Switzerland

a

, 28009 Madrid, Tel. +34(0)9¢/781 98 90, Fax +34(0)9¢/426 08 23,

Loading...

Loading...