Page 1

GF Piping Systems

Electrically Actuated Ball Valve

Type 104

General

• Size: ½”–2”

• Material: PVC, CPVC, ABS

• Seat: PTFE

• Seals: EPDM or FPM

• End Connection: Solvent cement socket, threaded

• Actuator Housing: Glass-fi lled PP

• Voltage: 110 VAC, 220 VAC, 24 VDC

• Duty cycle: 75%

• Limit Switches: Two SPST 5A

Optional Features

• Voltage: 12VAC, 12VDC, or 24VAC

• End Connection: Flanged

Key Certifi cations

• NSF 61: PVC and CPVC

Specifi cation

The Type 104 Ball Valve shall be true union and utilize a fl oating ball

design. The actuator shall be single voltage with a manual override.

Two position switches for feedback shall be standard. The ball shall

be fully molded and full port with two way blocking capability. The

stem shall be blowout proof, utilizing a double o-ring seal and a predetermined break point opposite the media side of the stem seals.

The seat carrier shall be adjustable and reverse threaded. The handle shall double as a seat carrier adjustment or removal tool. The

valve nut threads shall be of buttress type. Ball seats shall have an

elastomeric backing o-ring and all elastomeric seals shall be of like

material. ANSI fl anged versions shall meet ANSI B16.5 150lb standards. All valves shall be tested in accordance to ISO9393 and designed to ISO16136 standards. All valves shall be manufactured under ISO9001 for Quality and ISO14001 for Environmental Management.

Following assembly, every valve shall be tested and certifi ed bubble

tight exceeding Class VI standards.

Page 2

Technical Data

EA 04

Nominal torque Mdn 14.8 ft-lb

Peak torque 18.4 ft-lb

Control time 7 seconds/90º ±10% without load

Actuating angle 90°–270°

L/W/H (Actuator only) 7.0"/4.1"/5.2"

Housing materials Polyamide

Position indicator Optical, integrated

Emergency manual override Integrated, standard

Rated voltage +5% 110 VAC, 50/60 Hz

Consumption at peak torque +/- 5% 110 VAC: 0.15 A - 33 W

Duty cycle 75% at 77°F/15 min

Protection class IP 65

Power connector plug 3 P+ E per DIN EN 175301-03

Limit switch connector plug DIN 3337 (mini DIN)

Weight 3.8 Pounds

Limit switches 2 SPDT Micro, 5A 250V

Ambient temperature -4° – 158°F

Important Note: Some residual voltage may be present on the closed terminal when the valve is in the open state and on the open terminal when in the closed

state. For position indication the auxiliary limit switches should be used. The power terminals should not be used for position indication.

220 VAC, 50/60 Hz

24 VDC, 50/60 Hz

220 VAC: 0.15 A - 33 W

24 VDC: 0.55 A - 13.2 W

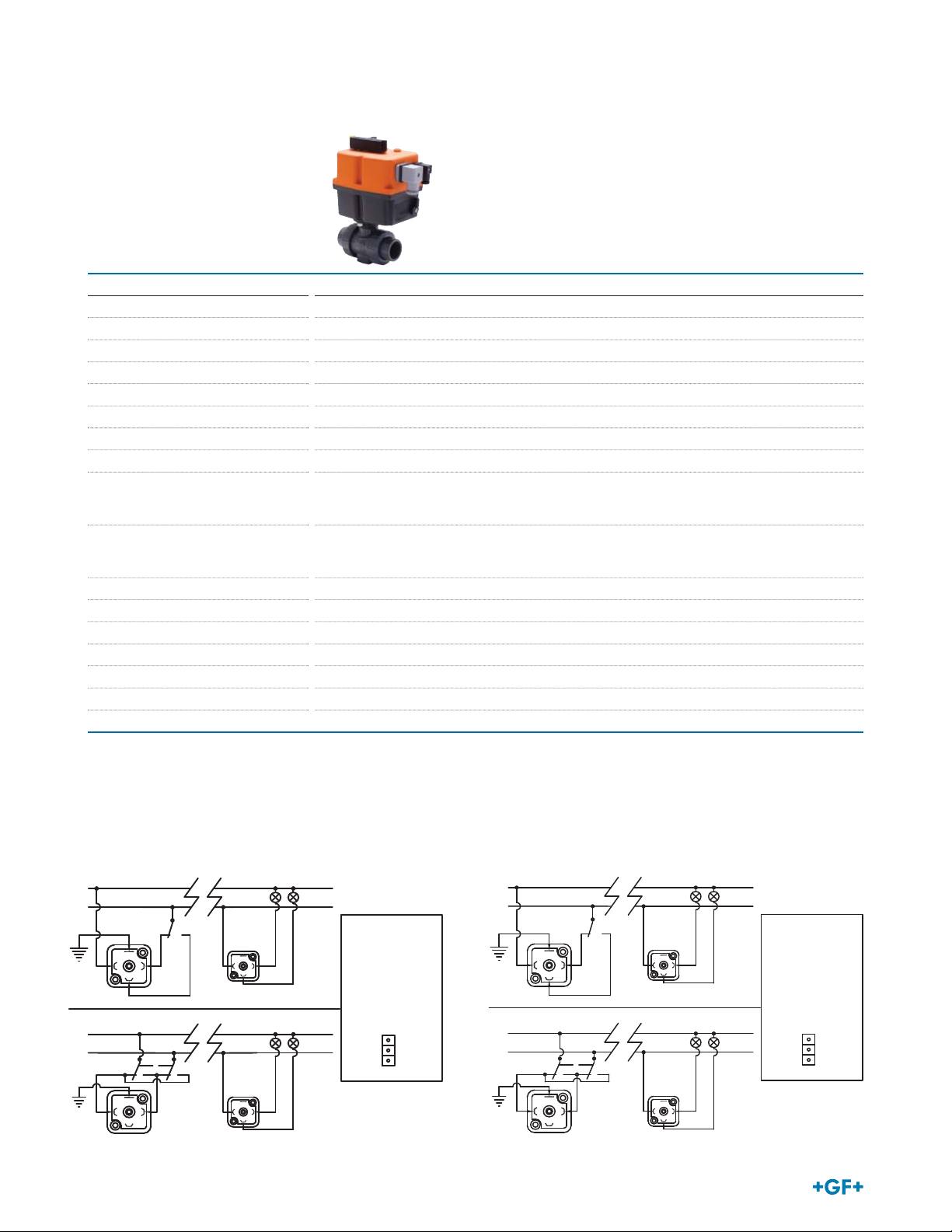

Wiring Diagrams

SCHEMATIC DIAGRAM / ELECTRIC WIRING

N

VAC

L

OPEN

CLOSE

21

3

SCHEMATIC DIAGRAM / ELECTRIC WIRING

-

VDC

+

OPEN

1

2

CLOSE

2

SCHEMATIC DIAGRAM / ELECTRIC WIRING

N

CLOSE

1

3

CLOSE

1

3

OPEN

ACTUATOR

INTERNAL

OPEN

CONFIGURATION

SELECT

JUMPER

AC or DC

IN PCB

AC

DC

R20

2

2

VAC

L

OPEN

CLOSE

1

-

VDC

+

OPEN

1

2

3

SCHEMATIC DIAGRAM / ELECTRIC WIRING

CLOSE

2

CLOSE

1

3

CLOSE

1

3

OPEN

ACTUATOR

INTERNAL

OPEN

CONFIGURATION

SELECT

JUMPER

AC or DC

IN PCB

AC

DC

R20

2

2

Page 3

0

Pressure Temperature Curves

The following graphs are based on a 25 year lifetime water or similar media application

PVC

240

225

210

195

180

165

150

135

120

105

90

Pressure (psi)

75

60

45

30

15

0

20 40 60 80 100 120 140 160

Threaded/Flanged

Socket

Temperature (°F)

ABS

165

150

135

120

105

90

75

60

Pressure (psi)

45

30

15

0

-60 -40 -20 0 20 40 60 80 100 120 140 160

Temperature (°F)

CPVC

240

225

210

195

180

165

150

135

120

105

90

Pressure (psi)

75

60

45

30

15

0

20 40 60 80 100 120 140 160 180

Threaded/Flanged

Temperature (°F)

Socket

Flow

The following information is based on water applications at 68º F

Pressure Loss

10

1

0.1

.01

1 10 100 1000 10000

3/8"

1/2"

3/4"

1"

Flowrate (GPM)

1-1/4"

1-1/2"

2"

2-1/2"

3"

4"

Cv Value

Size (inch) d (mm) Cv (gal/min)

½ 20 12.9

¾ 25 24.5

1 32 49.0

1¼ 40 70.0

1½ 50 112.0

2 63 217.1

3

Page 4

Dimensions

Socket/threaded

Flanged

All materials

All materials

Inch D H H1 H2 H3 L1 L2 L3 L4 M

½ 1.97 6.61 1.06 0.47 5.7 1.9 5.2 2.2 0.98 M6

¾ 2.28 6.8 1.18 0.47 5.7 1.9 5.2 2.2 0.98 M6

1 2.68 6.82 1.42 0.47 5.7 1.9 5.2 2.2 0.98 M6

1¼ 3.31 6.98 1.73 0.59 5.7 1.9 5.2 2.2 1.77 M8

1½ 3.82 7 2.01 0.59 5.7 1.9 5.2 2.2 1.77 M8

2 4.88 7.25 2.52 0.59 5.7 1.9 5.2 2.2 1.77 M8

PVC/CPVC

Socket Threaded Flanged

Inch

½ 4.13 2.4 3.86 2.56 5.87 3.5 2.38 0.5 0.57

¾ 4.76 2.76 4.37 2.92 6.5 3.88 2.75 0.5 0.58

1 5.24 2.99 5 3.23 7.24 4.25 3.13 0.5 0.66

1¼ 6.06 3.54 5.79 3.85 8.11 4.63 3.5 0.5 0.69

1½ 6.46 3.7 6.18 4.33 8.7 5 3.88 0.5 0.76

2 7.2 4.21 7.2 5.31 9.88 6 4.75 0.63 0.82

LzLzLD1D4D5R

ABS

d (mm)

20 3.74 2.52

25 4.33 2.83

32 4.84 3.11

40 5.57 3.7

50 6.18 3.74

63 7.2 4.21

Socket

Lz

GF Piping Systems

Tel. (714) 731-8800, Toll Free (800) 854-4090, Fax (714) 731-6201

us.ps@georgfi scher.com, www.gfpiping.com

#1334-60 (3/15)

© 2015 Georg Fischer LLC

Printed in USA

Loading...

Loading...