RP 120 "Reach Plus"

Featuring "Electro-Proportional" Control System

Part No. 89-126302 • Initial Issue dated April, 1994 •

TABLE OF CONTENTS

| Introduction | iii |

|---|---|

| Machine Specifications | iv |

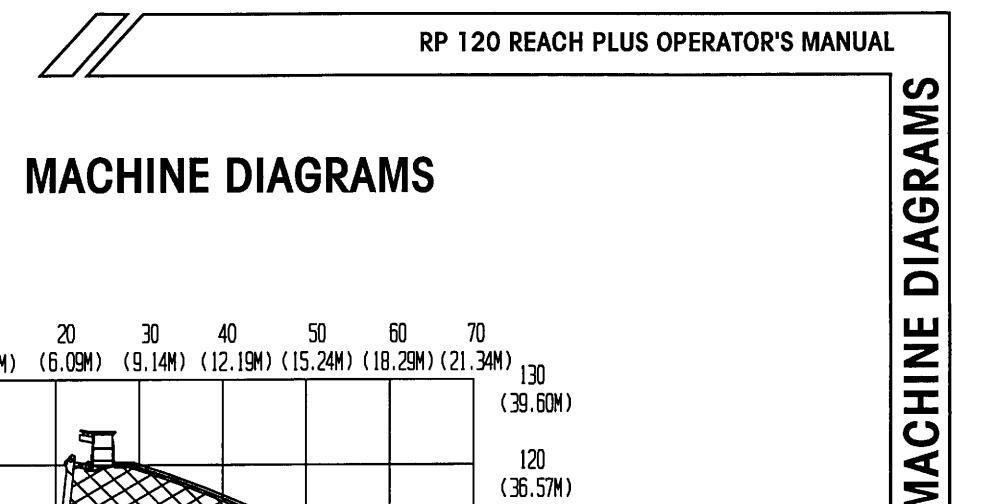

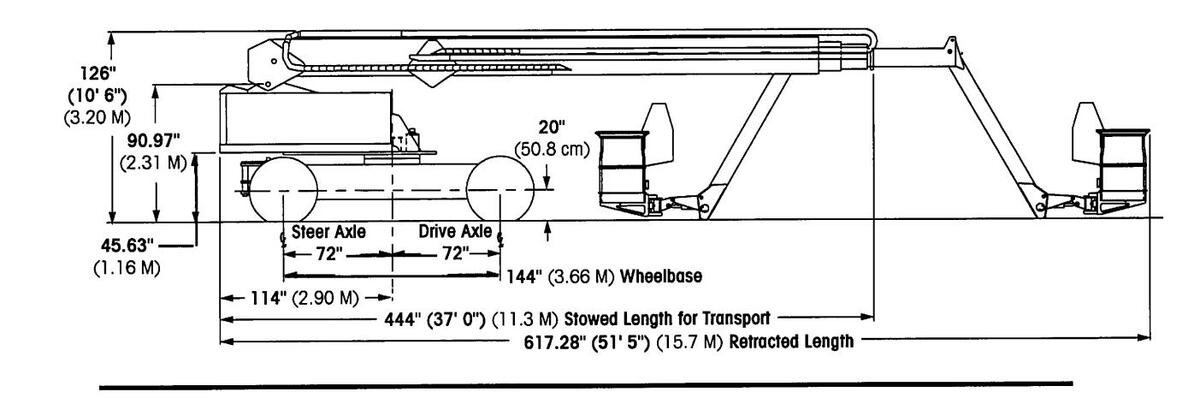

| Machine Diagrams | v |

| Range Diagram | v |

| General Arrangement Diagram | vi |

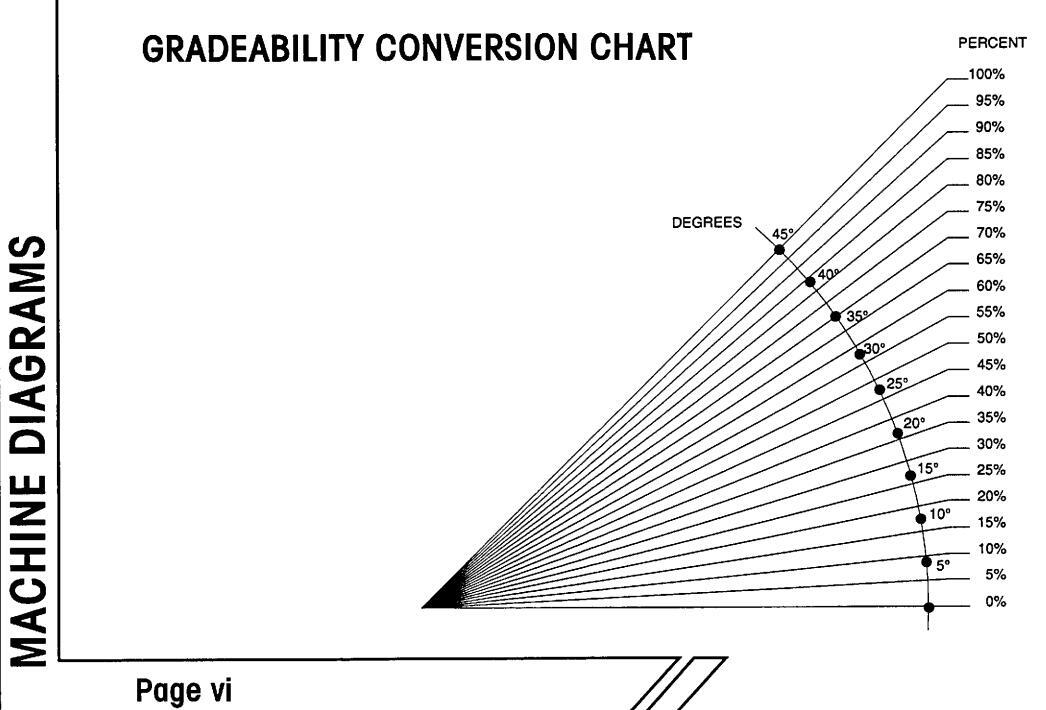

| Gradeability Conversion Chart | vi |

SAFETY

| Safety Symbols | |

|---|---|

| Safety Rules and Precautions | 1-4 |

| Safety-Related Decals | |

| Safety and Control Decal Locations | |

| Safety and Control Decal Identification | 1-13 |

OPERATION

|

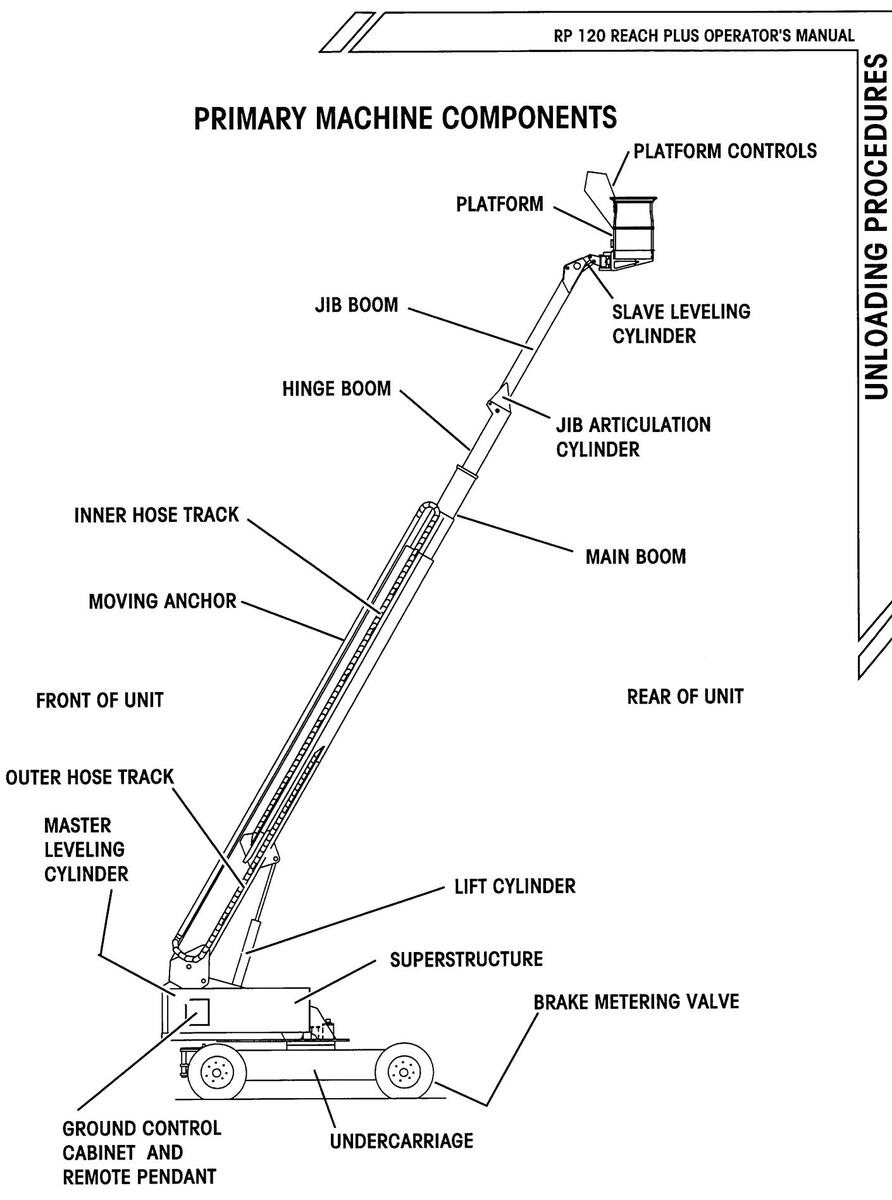

Unloading Procedures

Primary Machine Components |

. 2-3

. 2-7 |

|---|---|

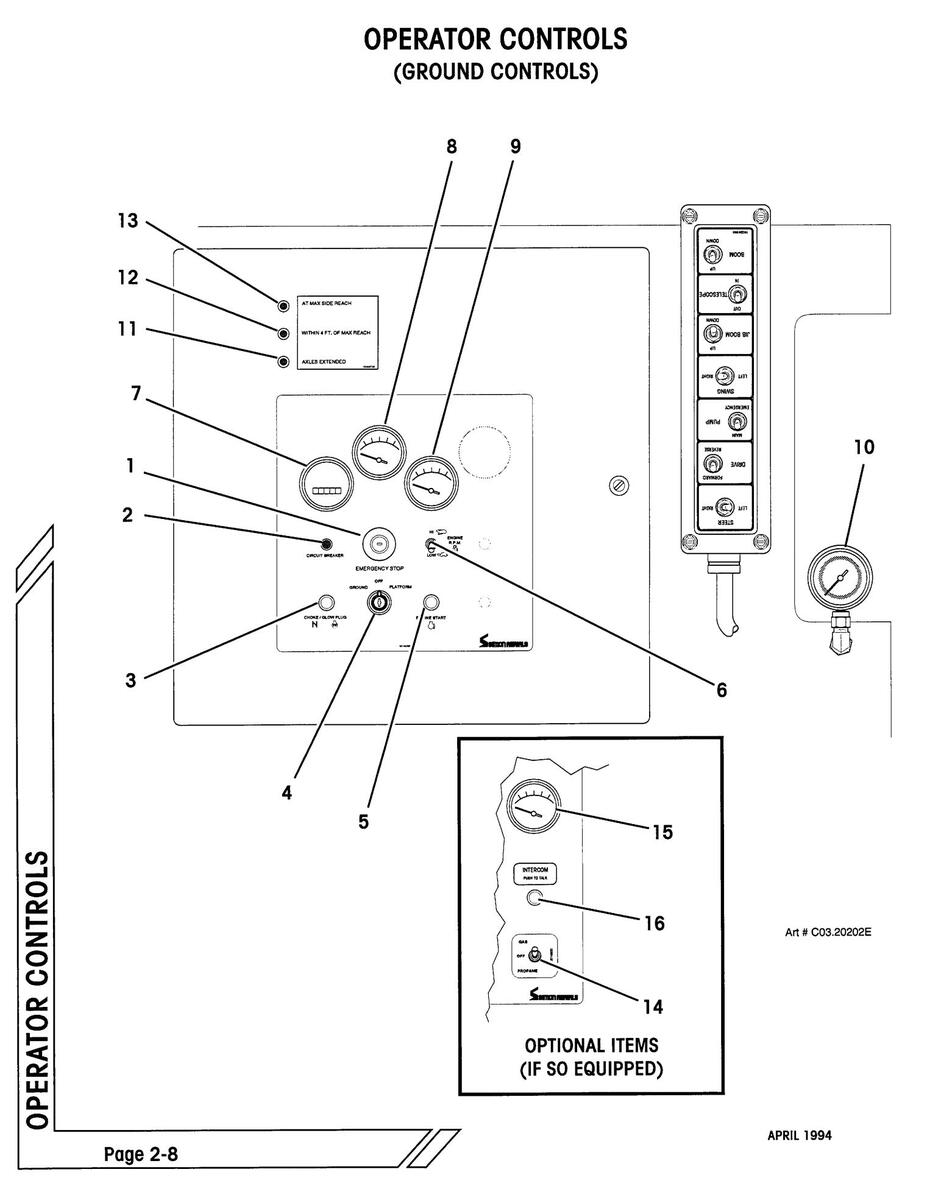

| Ground Controls | . 2-8 |

| 2-12 | |

| Piallorin Conirois | 2-10 |

| Graphic Display | 2-24 |

| Sidii-up Piocedules | າ າຣ |

| Snill Checks | 2-20 |

| Muchine Siun-up | 2-27 |

| Axie Exicitia Procedule | 2-20 |

| Biouria Operation and Checks | 2-01 |

| Operation | 2-40 |

| Cold Weather Operation | 2-19 |

| Driving and Steering | 2-43 |

| Braking | 2-50 |

| Boom Superstructure and Diatform | 2-50 |

| 2-57 | |

| Dual Fuel Engine Operation | 2.52 |

| Diesel Engine Operation | 2-53 |

| Shut-down Procedures | 2-54 |

| Transporting The Unit | 201 |

| Towing Procedures | 2-55 |

| Truck or Trailer Transport | |

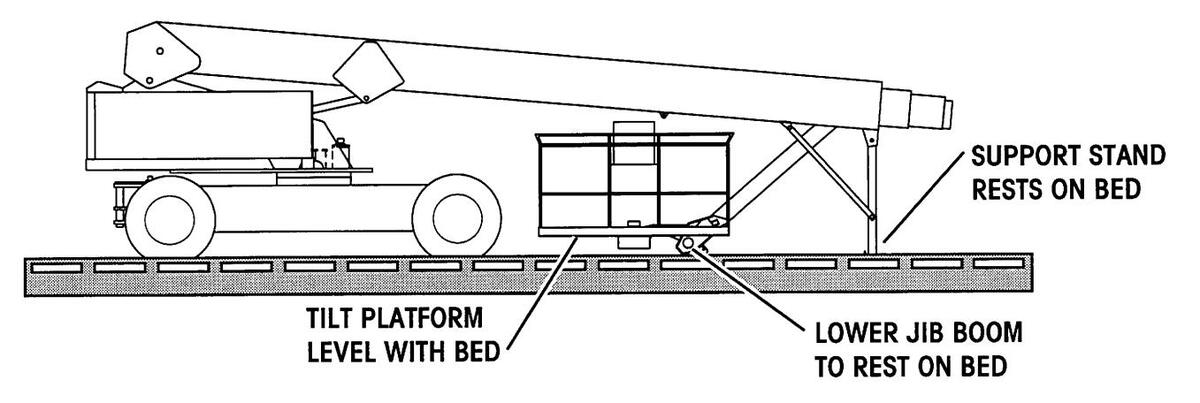

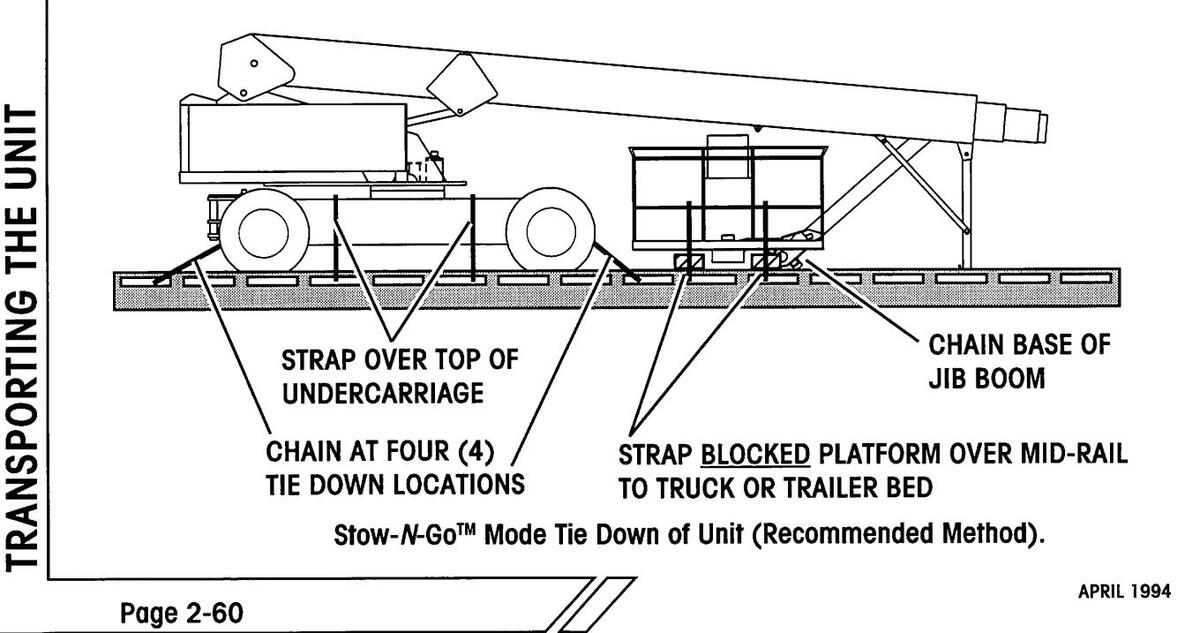

| Boom in STOW- N -GO ™ Mode | 2-56 |

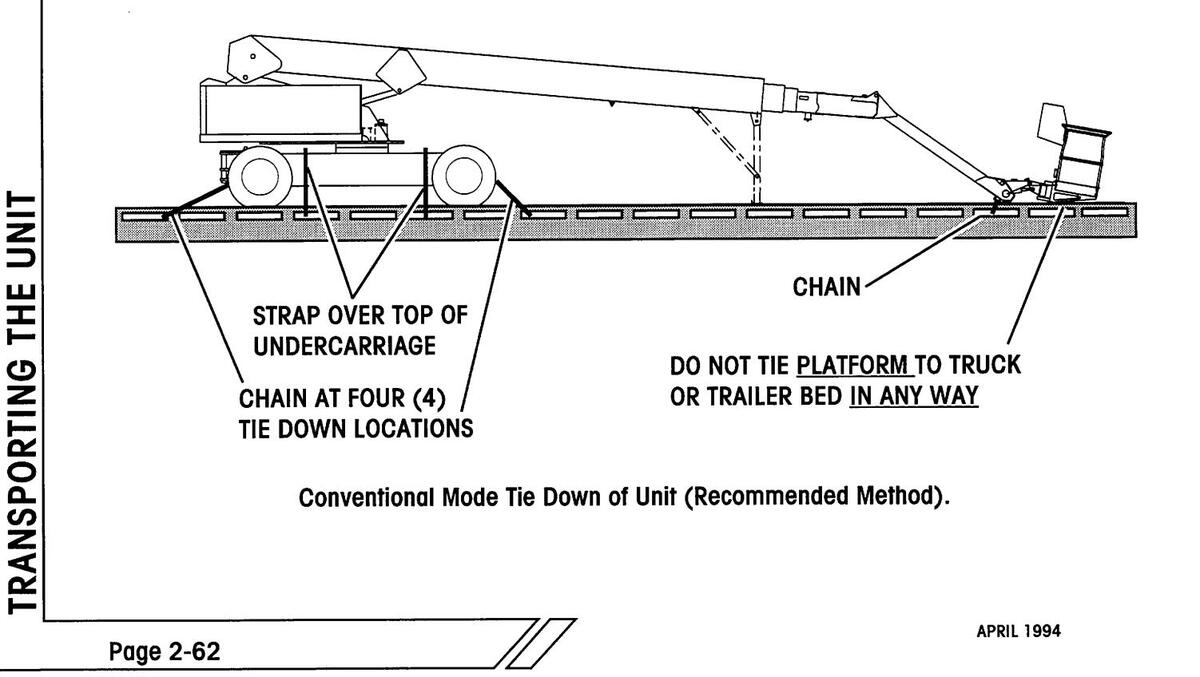

| Boom in Conventional Mode | 2-61 |

| Emergency System and Procedures | |

| Emergency Electrical Pump | 2-63 |

| Unpowered Emergency Movement | 2-64 |

| Emergency Lowering | 2-65 |

TABLE OF CONTENTS

TABLE OF CONTENTS (CONTINUED)

MAINTENANCE

|

General Maintenance Tips

Shift Operational Checklist Weekly Operational Checklist Monthly Operational Checklist |

3-3

3-4 3-7 3-9 .3-11 |

|---|---|

| Troubleshooting | |

| What to check if unit will not start: | 3-13 |

| What to check if functions will not operate: | 3-13 |

| Lubrication Chart | 3-14 |

APPENDIX

| oplicable Standards and Regulations | A-3 |

|---|---|

| NSI/SIA A92.5 - 1992 (Partial) | A-5 |

| 5. Responsibilities of Dealers | A-5 |

| 6. Responsibilities of Owners | A-7 |

| 7. Responsibilities of Users | A-10 |

| 8. Responsibilities of Operators | A-16 |

| 9. Responsibilities of Lessors | A-20 |

| 10. Responsibilities of Lessees | A-21 |

INDEX

Simon Aerials "High Five" Limited Warranty Transfer of Ownership Notice (Business Reply Cards) Catalog Comment Card (Business Reply Cards)

TABLE OF CONTENTS

NTRODUCTION

INTRODUCTION

This Operator's Manual has been designed to provide you with the instructions needed to properly and safely operate your Simon RP 120 Reach Plus Self-Propelled Aerial Work Platform featuring Electro-proportional controls.

THIS OPERATOR'S MANUAL MUST BE READ AND UNDERSTOOD PRIOR TO OPERATING YOUR SIMON SELF-PROPELLED AERIAL WORK PLATFORM.

OPERATORS MUST BE AWARE OF AND COMPLY WITH ALL MANUFAC-TURER'S INSTRUCTIONS AND APPLICABLE OSHA/ANSI SAFETY GUIDE-LINES.

FAILURE TO COMPLY WITH MANUFACTURER'S INSTRUCTIONS AND OSHA/ANSI SAFETY GUIDELINES WILL RESULT IN SERIOUS INJURY OR DEATH.

Your Simon RP 120 has been designed and built to provide many years of safe, dependable service. To obtain the full benefit of your RP, always follow the proper operating and maintenance procedures as outlined in this manual. Only trained, authorized personnel should be allowed to operate or service this machine. Service personnel should read and study this manual in order to gain a thorough understanding of the functions of the unit prior to making any repairs.

MODIFICATIONS OF THIS MACHINE FROM THE ORIGINAL DESIGN AND SPECIFICATION WITHOUT WRITTEN PERMISSION FROM SIMON AERIALS INC. ARE STRICTLY FORBIDDEN. A MODIFICATION MAY COMPROMISE THE SAFETY OF THE MACHINE, SUBJECTING USERS TO SERIOUS INJURY OR DEATH. ANY SUCH MODIFICATION WILL VOID ANY REMAINING WARRANTY.

Simon reserves the right to change, improve, modify or expand features of its equipment at any time. Specifications, models or equipment are subject to change without notice, and without incurring any obligations to change, improve, modify or expand features of previously delivered equipment.

All Simon manuals are periodically updated to reflect changes that occur in the equipment. Please contact the factory with any questions you may have regarding your machine, or the availability of more recent manuals.

MACHINE SPECIFICATIONS

| Working Height Platform Height Horizontal Reach Boom Angle O°) |

|

|---|---|

| Platform Capacity (Unrestricted) | 500 Lbs. / 225 Kg |

| Standard |

30 In. x 60 In. x 42 In.

/

.76 M x 1.52 M x 1.07 M |

| Optional | 36 In. x 96 In. x 42 In./ |

| Stowed Length (STOW- N -GO ™ Position) | 36 Ft 0 In. / 10.97 M |

| Stowed Height |

. 9 Ft 0 In./ 3.04 M

. 8 Ft 0 In./ 2.44 M |

| Machine Width: with axles extended |

11 Ft 8 In./ 3.56 M

12 Ft 0 In./ 3.66 M |

| . 11 in./ 27.9 cm | |

| Maximum Travel Speed: | 47,700 LDS./ 21,030 Kg |

| Boom Stowed (Note 1) |

2.8 MPH

/ 4.5 KPH

0.5 MPH / 0.8 KPH |

| Outside Turning Radius | 24 Ft 0 In. / 7.32 M |

|

. 180°

360° continuous, either direction |

|

| Tire Size | 15 x 22.5 (16 Ply) |

| Tire Pressure (not applicable to foam filled fires) | |

| Fuel Capacity: | |

| 30 Lbs. / 14 Kg | |

| Swing Bearing Bolt Torque |

280 Ff Lbs. / 380 Nm/ 38.7 Kg-m

220 Ff Lbs. / 298 Nm / 30.4 Kg-m 170 Ff Lbs. / 231 Nm / 23.5 Kg-m Two 12 Volt DC Batteries |

|

Engine Availability:

Standard Ford CSG-649, 110 HP (82 Kw), Liquid C Optional Ford CSG-649, 110 HP (82 Kw), Liquid C Deutz F4L912, 71 HP (53 Kw), Air Coole Perkins 4.236, 81 HP (60 Kw), Liquid co |

Cooled, Gasoline

Cooled, Dual Fuel d, Diesel Doled, Diesel |

Note 1: Weight and performance shown represent typical units, and should be used as a general guideline only. Many variables between machines can lead to significant differences in these factors. Accurate figures, when necessary for a particular application, can best be determined by testing of the specific unit.

MACHINE SPECIFICATIONS

Page iv

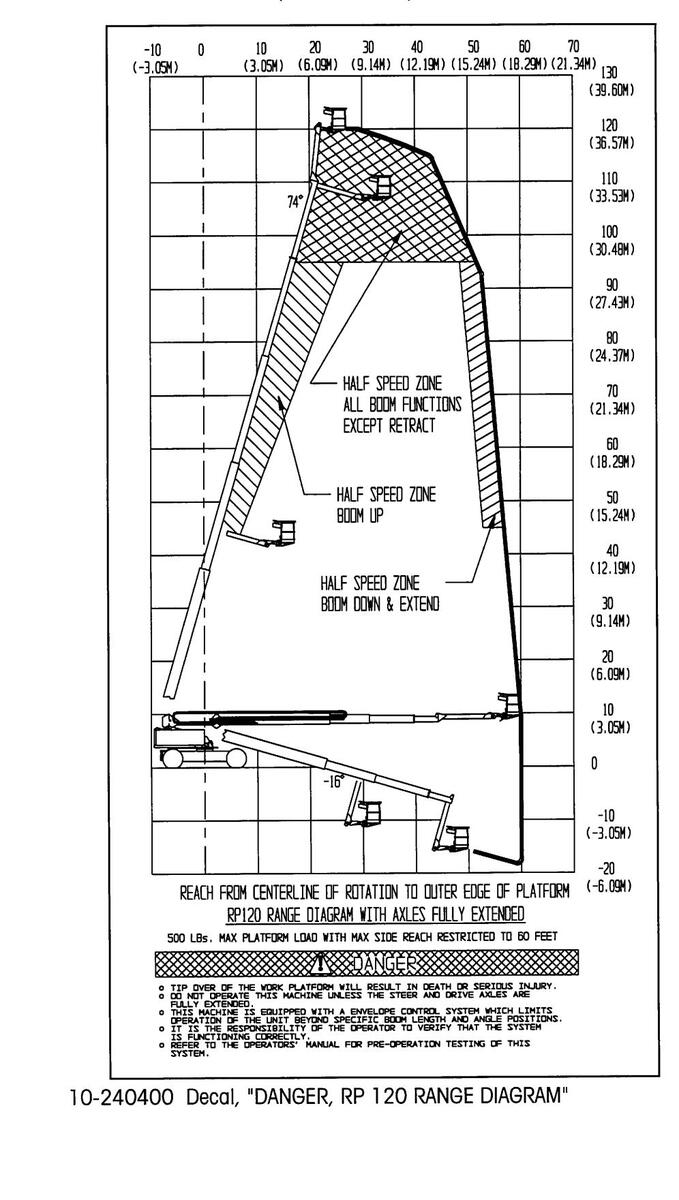

MACHINE DIAGRAMS

RANGE DIAGRAM

APRIL 1994

RP 120 REACH PLUS OPERATOR'S MANUAL

SECTION 1: SAFETY

Page 1- 1

Table of Contents, Section 1

SAFETY

| Cafaty Symbols | 13 |

|---|---|

| Safety Rules and Precautions | 1-4 |

| Safetý-Related Decals | |

| Safety and Control Decal Locations | 1-12 |

| Safety and Control Decal Identification | 1-13 |

SAFETY SYMBOLS

SAFETY SYMBOLS

This manual contains important information on the safe use of your SIMON Self-Propelled Aerial Work Platform. Your failure to read, understand and follow all safety rules, warnings and instructions will unnecessarily expose you and others to dangerous situations. For your safety and the safety of those around you, you must operate your aerial work platform as instructed in this manual.

You, the operator, are the single most important factor for safety when using any piece of equipment. Learn to operate your work platform in a safe manner.

To help you recognize important safety information, we have identified warnings and instructions that directly impact on safety with following signals:

A DANGER

"DANGER" INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN DEATH OR SERIOUS INJURY. THIS SIGNAL WORD IS LIMITED TO THE MOST EXTREME SITUATIONS.

"WARNING" INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY.

A CAUTION

"Caution" indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It is also used to alert against unsafe practices, and for property-damage-only situations.

One final note: The best method to protect yourself and others from injury or death is to use common sense. If you are unsure of any operation, don't start until you are satisfied that it is safe to proceed.

SAFETY RULES AND PRECAUTIONS

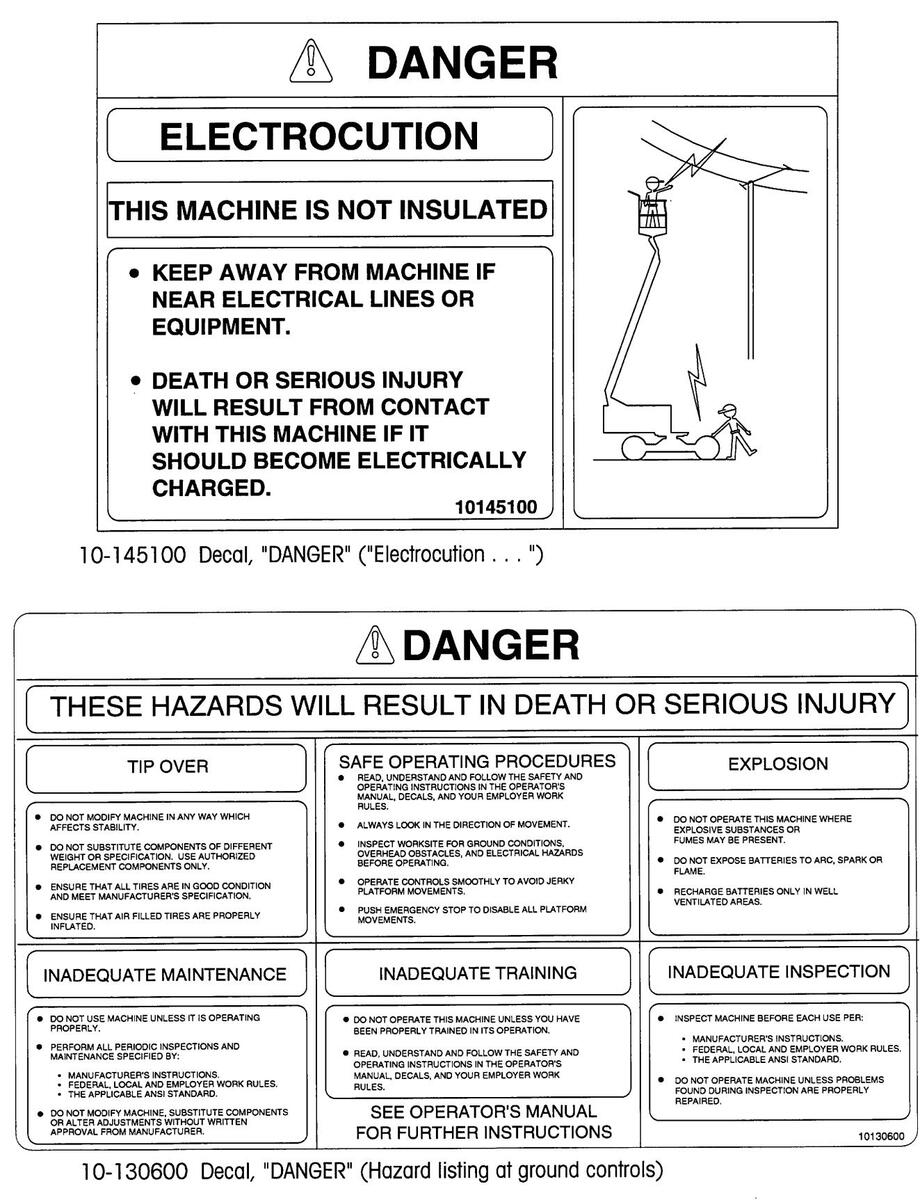

• ELECTROCUTION HAZARD!! THIS MACHINE IS NOT INSULATED!! Maintain safe clearance from electrical lines and apparatus. You must allow for machine sway (side to side movement) when elevated, and electrical line movement. This machine does not provide protection from contact with or proximity to an electrically charged conductor.

You must AVOID CONTACT between any part of the machine, or its load, and any electrical line or apparatus carrying up to 300 volts.

You must maintain a CLEARANCE OF AT LEAST 10 FEET (3.05 M) between any part of the machine, or its load, and any electrical line or apparatus carrying over 300 volts up to 50,000 volts. One foot (30.5 cm) additional clearance is required for every additional 30,000 volts.

DEATH OR SERIOUS INJURY will result from contact with, or inadequate clearance from, any electrically charged conductor.

- Read and understand all safety and control information found on the machine and in this manual before operating the unit.

- Only trained, competent personnel should operate the aerial work platform.

- Be aware of all Government and Local rules which may apply to this machine and its safe operation.

- Approved safety belts must be worn at all times when operating the unit from the platform. In addition, approved headgear and other protective equipment must be worn as required. (In the U.S.A., OSHA approved equipment is required. For other countries, the appropriate equivalent government body should be consulted.)

- NEVER fasten safety belt to an adjacent structure while on the work platform.

- Make sure that entry gate to platform is secured before operating unit from the platform.

- DO NOT block the foot pedal or any function control in the operating position.

- DO NOT exceed the platform capacity of the unit in any configuration. Review the section titled "MACHINE SPECIFICATIONS", earlier in this manual, regarding this model's capacities and dimensions.

SAFETY RULES

SAFETY RULES

SAFETY RULES AND PRECAUTIONS (CONTINUED)

- SECURE all tools and other loose items to prevent injury to persons working on or below the work platform.

- DO NOT weld on the machine unless electrical system and controller are disconnected.

- DO NOT use scaffolding, ladders or similar items to extend your reach while on the work platform.

- DO NOT attempt to climb down the boom assembly, if the unit fails while the operator's platform is raised or extended.

- Since the machine may be operated from its ground controls, precautions should be taken to prevent unauthorized personnel from operating the work platform with the ground controls while the platform is in use.

- The "UNPOWERED EMERGENCY MOVEMENT" procedure (described later in this manual) requires releasing the torque hubs, which results in there being no means to stop the unit's travel. Simon recommends using this procedure only in cases of emergency, and only for a short distance. Be on guard against unit runaway on sloping surfaces. Movement speed shall not exceed 1 M.P.H. (1.6 K.P.H.).

- DO NOT attempt to open any hydraulic line or component without first relieving all system pressures and shutting off fluid flow from the tank.

- DO NOT allow anyone to tamper with, service or operate the machine from the ground control station while personnel are on the platform, except in an emergency.

- DO NOT alter, modify or disable any safety devices or interlocks.

- DO NOT refuel the unit near sparks or open flames. Gasoline and propane vapors, and Diesel fuel fumes are highly explosive.

- DO NOT use the aerial work platform outdoors in electrical storms or in high wind situations.

- DO NOT raise the aerial work platform unless the unit is on a firm, level surface.

- ENSURE THAT the STOW- N -GO™ lock pins are in place and anchored.

SAFETY RULES AND PRECAUTIONS (CONTINUED)

- Use caution to prevent ropes, cords, hoses, etc. from becoming entangled in the unit's boom sections when being raised, lowered or repositioned.

- Ensure that the area surrounding the mobile platform is clear of personnel and equipment before: driving the unit; or raising, lowering or extending the boom; or swinging the superstructure; or, rotating or tilting the platform.

- Maintain a safe distance from overhead and ground obstacles, debris, drop-offs, holes, depressions, electrical wires and other hazards to travel.

- Limit travel speed according to conditions of the ground surface, congestion, slope, location of personnel or any other factors that could cause hazard of collision or injury to personnel.

- DO NOT sit, stand or climb on platform rails.

- DO NOT operate this machine while under the influence of any drugs or alcohol.

- DO NOT operate this machine if you are bothered by heights, seizures, or dizzy spells.

- DO NOT indulge in stunt driving or horseplay while operating this machine.

- Complete the "Operational Checklists" found in this manual (see Table of Contents) at designated intervals.

- Ensure that the machine is in "LOW" drive speed while unloading from a truck or trailer.

- Always attach the unit to a winch when loading or unloading from a truck or trailer. Simon does not recommend unassisted loading or unloading of any aerial work platform.

- With the superstructure swung away from the stowed position, use caution when selecting travel or steering direction. Travel and steer direction will be opposite switch or lever movement. Refer to the large "FORWARD" arrows on the undercarriage of the unit or the location of the superstructure lockpin hole for travel orientation.

SAFETY RULES

SAFETY RULES

SAFETY RULES AND PRECAUTIONS (CONTINUED)

- Check fuel system for leaks or damaged fuel lines before operating unit. If any damage is found, contact your supervisor immediately. Machine shall be removed from service until diagnosis and any necessary repairs have been completed.

- Actuation of the red "EMERGENCY STOP" button will apply brakes immediately, causing unexpected platform movement as the machine comes to a sudden stop. Brace yourself.

- Whenever disengaging the drive torque hubs or before disconnection from towing vehicle, ensure that the unit cannot roll.

- Immediately report any erratic noises, vibrations or malfunctions of the unit to supervisor. Machine shall be removed from service until diagnosis and any necessary repairs have been completed.

- Operating this equipment without all safety and control decals in place can be hazardous.

A CAUTION

- For transporting the machine, the platform must not be tied to the trailer bed in any way.

- Be sure to turn all hydraulic valves back "ON" before starting the machine, or extensive pump damage will occur.

- DO NOT exceed the maximum platform horizontal pull of 100 pounds (45.4 Kg).

- DO NOT use the boom or platform as a crane to lift oversized or hanging loads.

- DO NOT raise, extend, retract, tilt, rotate, or lower the platform into stationary objects, as this will cause damage to mechanical and hydraulic components.

- DO NOT use the platform or boom functions to push or tow the unit or another vehicle.

- Avoid sudden braking or steering, go slowly and leave more maneuvering room during cold weather operation until the machine is warm.

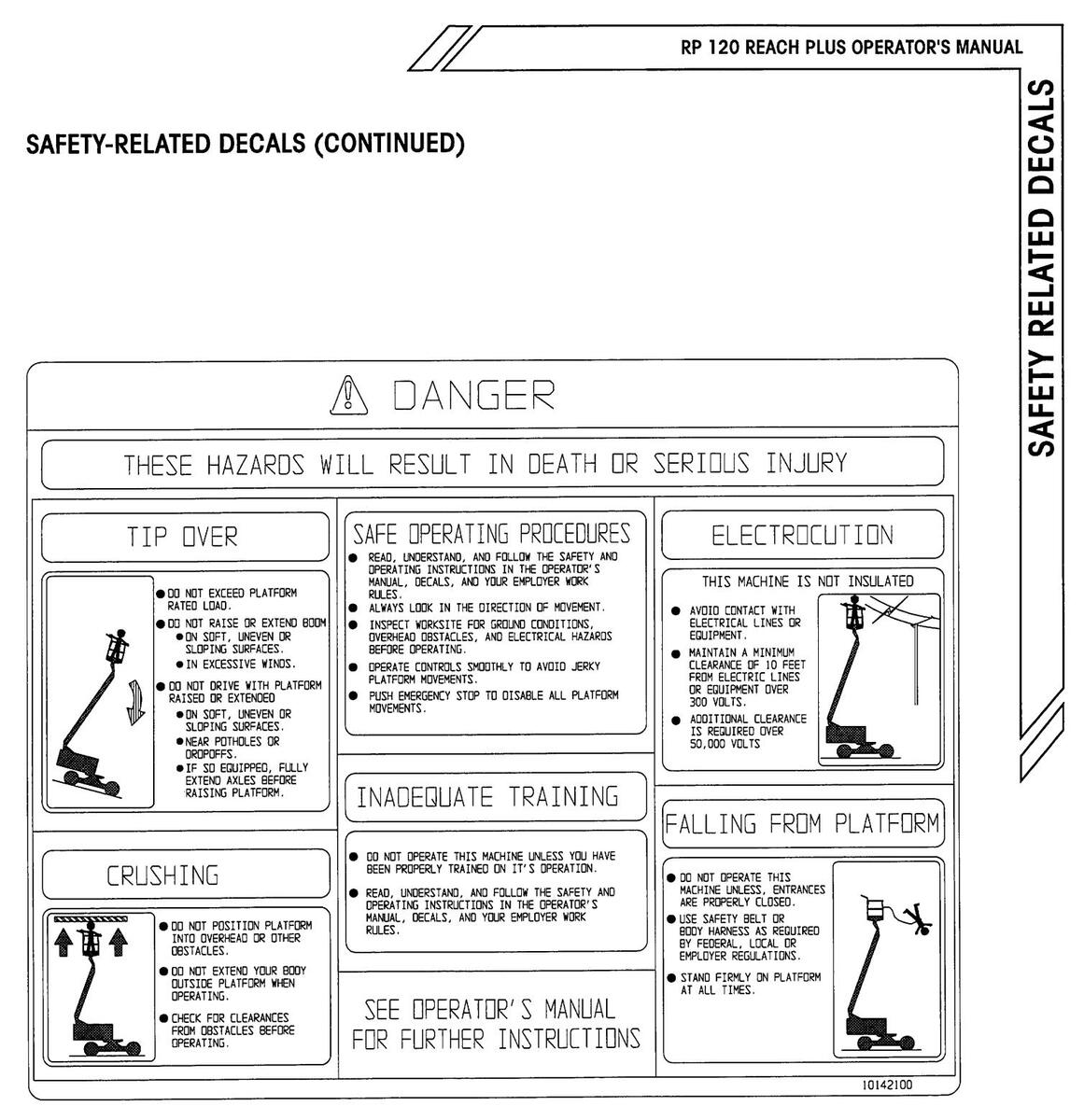

SAFETY-RELATED DECALS

SAFETY RELATED DECALS

10-142100 Decal, "DANGER" (Hazard listing at platform controls)

SAFETY RELATED DECALS

Page 1-10

SAFETY RELATED DECALS

SAFETY-RELATED DECALS (CONTINUED)

WARNING! TO ASSURE FULL AXLE EXTENSION.

TO ASSURE FULL AXLE EXTENSION, ALL FOUR 2" WHITE STRIPES MUST BE FULLY EXPOSED !

10-013100 Decal, "WARNING" ("To Assure Full Axle Extension...")

AT MAX SIDE REACH

WITHIN 4 FT. OF MAX REACH

AXLES EXTENDED

10-240700 Decal, Ground Indicator Lamps

PLATFORM CAPACITY 500 LBs. (225 kg)

10-145300 Decal, Platform Capacity [18-1/4" (464 mm) wide]

PLATFORM CAPACITY 500 LBs. (225 kg)

10-148300 Decal, Platform Capacity [4-1/2" (114 mm) wide]

SAFETY AND CONTROL DECAL LOCATIONS

OPERATING THIS EQUIPMENT WITHOUT ALL SAFETY AND CONTROL DECALS IN PLACE CAN BE HAZARDOUS.

SAFETY AND CONTROL DECAL DESCRIPTIONS

|

ltem

No. |

Part Number | Description | Qty. |

|---|---|---|---|

| 1 | 10-144300 | Placard, Ground Electrical Controls | 1 |

| 2 | 10-240700 | Decal. Ground Indicator Lamps | 1 |

| 3 | 10-224900 | Placard, Remote Control Pendant | 1 |

| 4 | 10-130600 | Decal "DANGER" (Hazard listing at Ground Controls) | 1 |

| 5 | 10-012600 | Decal, "OPEN HYDRAULIC TANK VALVES " | 1 |

| 6 | 10-007200 | Decal, "DISENGAGE LOCK PIN " | 2 |

| 7 | 10-148300 | Decal, "PLATFORM CAPACITY 500 LBS (225 Kg)", | |

| [4-1/2" (114 mm) wide] | 4 | ||

| 8 | 10-145100 | Decal, "DANGER" ("Électrocution ") | 2 |

| 9 | 10-117900 | Placard, "GASOLINE ONLY" | |

| (for versions with gasoline engine) | 1 | ||

| 10-151100 | Placard, "DIESEL FUEL ONLY" | ||

| (for versions with optional Diesel engine) | 1 | ||

| 10 | 10-151300 | Placard, "HYDRAULIC FLUID ONLY " | 1 |

| 11 | 10-012900 | Decal, "FORWARD" with Arrow | 2 |

| 12 | 10-169100 | Placard, Platform Controls | 1 |

| 13 | 10-224500 | Decal, "DISPLAY CONTRAST " | 1 |

| 14 | 10-224600 a | Decal, Boom Function Speed Control | 1 |

| 15 | 10-224600 b | Decal, " ALL AXLES ARE EXTENDED" | 1 |

| 16 | 10-147400 | Decal, Platform Level and Rotate Controls | 1 |

| 17 | 10-142100 | Decal "DANGER" (Hazard listing at Platform Controls) | 1 |

| 18 | 10-013100 | Decal, "WARNING" | |

| ("To Assure Full Axle Extension ") | 2 | ||

| 19 | 2132070 | Decal, Axle Extend Instructions | 1 |

| 20 | 2132080 | Decal, "STEER OR AXLE " | 1 |

| 21 | 10-240400 | Decal, "DANGER, RP 120 RANGE DIAGRAM" | 2 |

| 22 | Call Service | Plate, Serial | 1 |

| 23 | 10-139800 | Decal, "OPERATOR'S MANUAL" | 1 |

| 24 | 10-145300 | Decal, "PLATFORM CAPACITY 500 LBS (225 Kg)", | _ |

| [18-1/4" (464 mm) wide] | 1 |

PLACARD LOCATIONS

RP 120 REACH PLUS OPERATOR'S MANUAL

OPERATION

SECTION 2: OPERATION

Table of Contents, Section 2

OPERATION

| Unloading Procedures |

2-3

2-7 |

|---|---|

| Ground Controls | 2-8 |

| Remote Control Pendant | 2-12 |

| Platform Controls | 2-16 |

| Graphic Display | 2-24 |

| Start-up Procedures | |

| Shift Checks | 2-26 |

| Machine Start-up | 2-27 |

| Axle Extend Procedure | 2-28 |

| Ground Operation and Checks | 2-31 |

| Platform Operation and Checks | 2-40 |

| Operation | |

| Cold Weather Operation | 2-49 |

| Driving and Steering | 2-00 |

| Braking | 2-00 |

| Boom, Superstructure and Platform | 2-01 |

| Gasoline Engine Operation | 2-02 |

| Dual Fuel Engine Operation | 2-52 |

| Shut down Procedures | 2-50 |

| Transporting The Unit | - 07 |

| 2-55 | |

| Truck or Trailer Transport | - 00 |

| Boom in STOW- N -GO™ Mode | 2-56 |

| Boom in Conventional Mode | 2-61 |

| Emergency System and Procedures | |

| Emergency Electrical Pump | 2-63 |

| Unpowered Emergency Movement | 2-64 |

| Emergency Lowering | 2-65 |

OPERATION

JNLOADING PROCEDURES

UNLOADING PROCEDURES

TO AVOID SERIOUS PERSONAL INJURY OR DEATH, ENSURE THAT THE MACHINE IS IN "LOW" DRIVE SPEED WHILE UNLOADING FROM A TRUCK OR TRAILER.

- 1. Inspect the outside of the unit for damage (including the underside). Inspect all hoses, boom sections and cables for chafing or shipping damage. Confirm that all wheel lug nuts and swing bearing bolts are tight (refer to specifications).

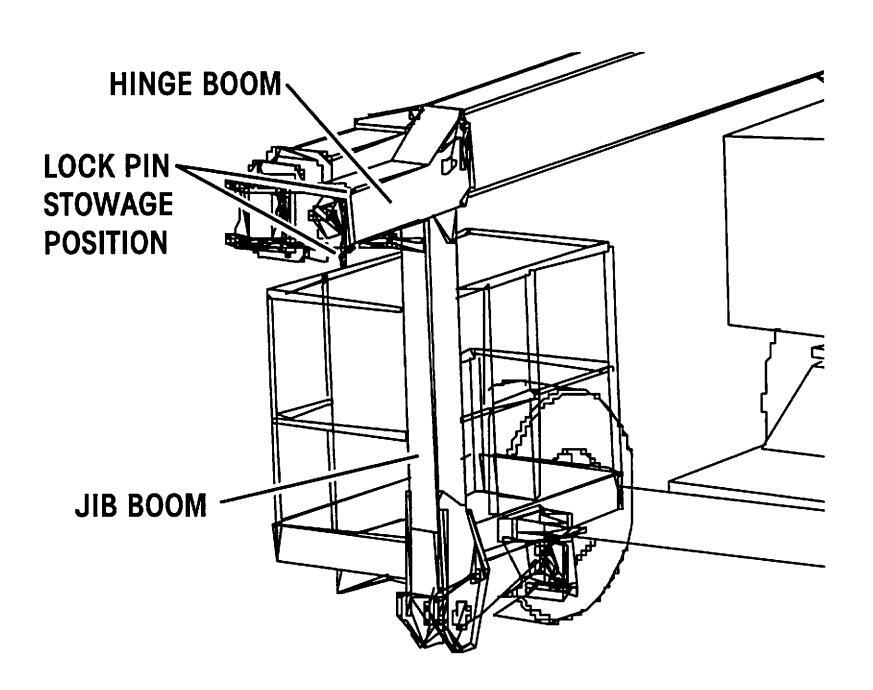

- 2. Remove the pin that locks the superstructure to the undercarriage near the swing bearing. Stow the lock pin in the location provided nearby.

- 3. Unlock and open both side compartments. Inspect all fuel, electrical and hydraulic connections for damage and security.

- 4. Connect battery cables to batteries if required. Check electrolyte level.

- 5. Open the fuel tank valve and check fuel level.

- 6. Check engine oil level, and add as required per engine manufacturer's recommendations.

- 7. Check fluid level at the sight gauge on the hydraulic tank, and add fluid as required (see Lubrication Chart). Check that shutoff valves on the hydraulic tank are open.

- 8. Close side compartment covers.

- 9. Attach the unit to a winch for the unloading procedure.

ALWAYS USE A WINCH TO ASSIST LOADING OR UNLOADING THE UNIT FROM A TRUCK OR TRAILER. CONNECT WINCH CABLE TO THE TIE DOWN LUGS ON THE UNDERCARRIAGE. UNASSISTED LOADING OR UNLOAD-ING OF ANY MOBILE PLATFORM IS NOT RECOMMENDED.

READ AND UNDERSTAND ALL SAFETY, CONTROL AND OPERATING INFORMATION FOUND ON THE MACHINE AND IN THIS MANUAL BEFORE OPERATING THE UNIT.

APRIL 1994

UNLOADING PROCEDURES

UNLOADING PROCEDURES (CONTINUED)

10. Start engine, using the ground controls.

NOTE: Refer to Start-up Procedures and Operator Controls Descriptions in this section.

After a brief warm-up period, select the "HI" engine speed. On the remote control pendant, press and hold the "PUMP" toggle switch to the "MAIN" position, but do not operate any drive or boom function. This is called "deadheading", and will lead to maximum system pressure registering on the gauge at the ground control valve assembly. Refer to the "Machine Specifications" section of this manual for the "Maximum Hydraulic Pressure" for this unit.

Select the "LOW" engine speed and allow the engine to slow to idle speed.

- 11. Remove tie downs from the platform and base of the jib boom.

- 12. Remove the two straps that wrap over the top of the undercarriage. Remove four tie down chains. Remove wheel chocks, if used.

UNLOADING PROCEDURES (CONTINUED)

- 13. Using the remote control pendant, raise the boom so that the platform will clear any obstacles as the machine is driven down the loading ramp.

- 14. Stand in front of the left front wheel (away from the direction of travel) and, using the "DRIVE" toggle in "REVERSE", carefully drive the unit off the truck or trailer with the assistance of a winch. The brakes are automatically released for driving, and will automatically apply when the unit stops.

- 15. Remove the grip end of the pull chain from its stored position on the left side of the main boom, and let it hang free. The boom stowage lock pin has a 5 Ft (1.5 M) long pull chain attached for ease of use. Remove boom lock pins from stowed position, and let hang.

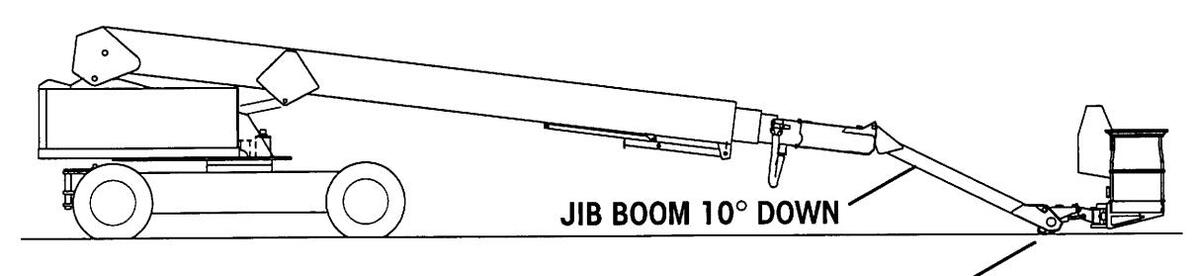

- 16. Raise main boom to horizontal and lower jib boom until it is 60° below the main boom.

Swing Jib Around to Operational Mode.

- 17. Pull the boom stowage lock pin chain to unlock the jib boom. Swing jib and platform around so that the hinge boom aligns with the main boom (see "Operational Mode" illustration, next page).

- 18. Lower the main boom so the boom support stand is slightly off the ground. Pull the pin holding the boom support stand strut to the boom support column, and swing boom support column up. Pin the strut to the underside of base boom.

Raise Boom Support Stand.

UNLOADING PROCEDURES (CONTINUED)

19. Align hinge and main boom holes by moving the jib boom, and insert boom lock pins to secure hinge boom to main boom.

If hinge and main boom holes do not line up, slightly lower main boom onto ground to apply pressure on jib boom.

20. Secure hinge boom to main boom with both boom lock pins and hairpin clips.

21. Turn engine off.

UNLOADING PROCEDURES

Left Hand Side.

OPERATOR CONTROLS

OPERATOR CONTROLS DESCRIPTION (GROUND CONTROL)

| ltem | Control | Location | Description |

|---|---|---|---|

| 1. |

Emergency Stop

Button |

On Ground

Electrical Panel |

Used to stop all functions in an emergency. Push for emergency stop. Pull or rotate clockwise to reset, depending on style used. |

| 2. | Circuit Breaker |

On Ground

Electrical Panel |

Pops out when the 12 Volt electrical circuit is over-

loaded. Push in to reset. |

| 3. |

Choke/

Glow Plug Button |

On Ground

Electrical Panel |

Choke button for gas or dual fuel engines. Press and hold while starting a cold engine. |

| Glow plug button for some Diesels. Press and hold (if so equipped) to preheat combustion chamber before starting a cold engine. | |||

| 4. |

Main Power Key

Switch |

On Ground

Electrical Panel |

Three position main power "On/ Off" switch. Straight up position is "OFF". |

|

Turn key left (counterclockwise) one position to turn

power "ON" for ground control operation. Turn key right (clockwise) one position to turn power "ON" for plat- form control operation. |

|||

| With key switch "OFF", the key may be removed to prevent unauthorized operation. | |||

| 5. |

Engine Start

Button |

On Ground

Electrical Panel |

Press push button to engage engine starter. Release

button immediately upon engine start. If the engine does not start within 10 seconds, the main power key switch must be turned off and then on again to start. |

| NOTE: Main power key switch must be in "GROUND" position. | |||

| 6. |

Engine RPM

(Throttle) Switch |

On Ground

Electrical Panel |

Flip toggle down for "LO" (idle) engine speed. Flip toggle up for "HI" engine speed. |

| IMPORTANT: Engine should not be in "LO" speed while operating any hydraulic functions. | |||

| 7. | Hour Meter |

On Ground

Electrical Panel |

Indicates total elapsed time that the engine has been operated in hours and tenths. |

OPERATOR CONTROLS

OPERATOR CONTROLS DESCRIPTION (GROUND CONTROLS, CONTINUED)

| ltem | Control | Location | Description |

|---|---|---|---|

| 8. | Volt Meter |

On Ground

Electrical Panel |

Indicates electrical system voltage. |

| 9. |

Engine Oil Pres-

sure Gauge |

On Ground

Electrical Panel |

Indicates engine oil pressure. |

| 10. |

Hydraulic Fluid

Pressure Gauge |

Beneath Ground

Valves |

Indicates hydraulic fluid pressure. |

| 11. |

L.E.D. Indicator

(Green) |

On Ground

Electrical Panel |

When lit, indicates that front and rear axles are fully extended, and full range of boom operation is possible. |

| 12. |

L.E.D. Indicator

(Yellow) |

On Ground

Electrical Panel |

When lit, indicates that boom is within 4 Feet (1.22 M) of maximum outreach. Envelope Control System (ECS) will not allow boom functions (Main boom extend or lower, jib boom raise) to extend beyond the perimeter of the performance envelope. |

| 13. |

L.E.D. Indicator

(Red) |

On Ground

Electrical Panel |

When lit, indicates that boom has reached the perim-

eter of the performance envelope. |

| 14. |

Gas/ Off/ Propane

Switch (Optional) |

On Ground

Electrical Panel |

Flip toggle up to use gasoline, down to use propane. In "OFF" position, the engine is not supplied with fuel. |

| 15. |

Engine Coolant

Temperature Gauge (Optional) |

On Ground

Electrical Panel |

Indicates Engine coolant temperature. |

| 16. |

Intercom "Push-

To-Talk" Button (Optional) |

On Ground

Electrical Panel |

Press and hold to talk to operator in platform. Micro-

phone is located in speaker above electrical panel. |

| 17. |

Axle Extend Knob

(Not shown) |

On side of

undercarriage, behind left rear wheel |

Pull knob out to select Axle Extend function. Refer to Axle Extend Procedure in this section. |

| 18. |

Steer Wander

Control Valve (Not shown) |

Near Ground

Electrical Panel |

Available with optional tow package only. Pull valve knob out to allow the steering to be free wheeling Push valve knob in to engage steering. |

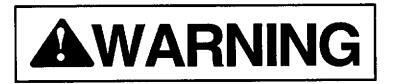

OPERATOR CONTROLS (REMOTE CONTROL PENDANT)

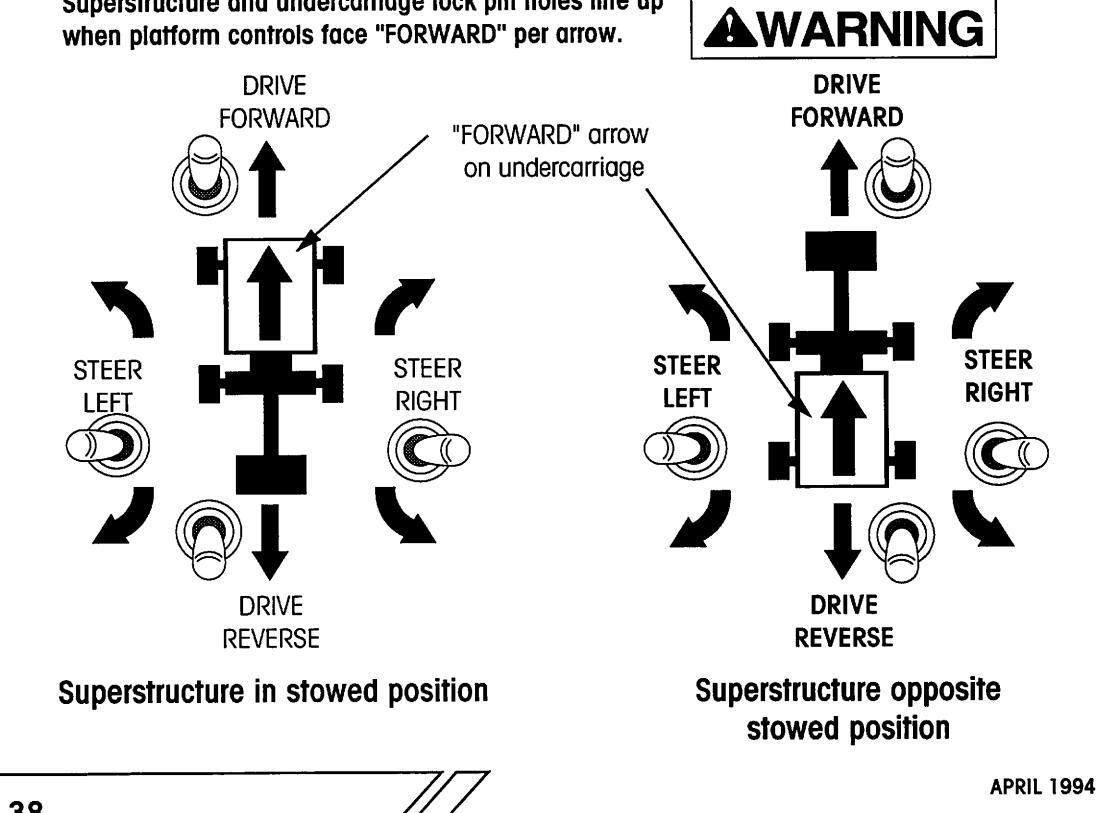

Control operation direction shown here in relation to "FORWARD" arrow on undercarriage. Superstructure and undercarriage lock pin holes line up when platform controls face "FORWARD" per arrow.

OPERATOR CONTROLS

DPERATOR CONTROLS

| ltem | Control | Location | Description |

|---|---|---|---|

| 1. |

Steer Toggle

Switch |

On Remote

Control Pendant |

Push to left and hold to turn steer wheels to left, right to turn to right. To straighten wheels, push and hold switch in opposite direction. |

WITH THE PLATFORM OVER THE STEERING WHEELS, USE CAUTION WHEN SELECTING THE STEERING DIRECTION. STEER DIRECTION WILL BE OPPOSITE SWITCH MOVEMENT. SEE DIAGRAM, FACING PAGE.

During axle extend procedure, the steer switch is used to extend and retract the axles.

2. Drive (Propel) On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant On Remote Control Pendant

WHEN THE PLATFORM IS SWUNG OVER THE STEER-ING WHEELS, USE CAUTION WHEN SELECTING THE TRAVEL DIRECTION. TRAVEL DIRECTION WILL BE OPPOSITE SWITCH MOVEMENT. SEE DIAGRAM, FACING PAGE.

3. Pump Selector On Remote Push up and hold to activate main hydraulic pump, Toggle Switch Control Pendant enabling operation of any of the hydraulic functions (drive, steer, or boom movement) from the ground.

On Remote Push down and hold to activate battery powered emergency hydraulic pump, allowing operation of hydraulic functions (drive, steer or boom movement) from the ground should the engine powered hydraulic pump be disabled.

OPERATOR CONTROLS

OPERATOR CONTROLS (REMOTE CONTROL PENDANT)

Control operation direction shown here in relation to "FORWARD" arrow on undercarriage. Superstructure and undercarriage lock pin holes line up when platform controls face "FORWARD" per arrow.

OPERATOR CONTROLS

| tem | Control | Description | |

|---|---|---|---|

| 4. |

Swing Toggle

Switch |

On Remote

Control Pendant |

Push and hold left to swing the superstructure left (clockwise) and to the right to swing the superstructure right (counterclockwise). |

| 5. |

Jib Boom Toggle

Switch |

On Remote

Control Pendant |

Push up and hold to raise (hoist) jib boom, and down to lower jib boom. |

| 6. |

Boom Telescope

Toggle Switch |

On Remote

Control Pendant |

Push up and hold to extend main boom, and down to retract main boom. |

| 7. |

Main Boom

Toggle Switch |

On Remote

Control Pendant |

Push up and hold to raise (hoist) main boom, and down to lower main boom. |

| 8. |

Pendant Hanger

Knobs |

Back of Remote

Control Pendant |

Used to hang Remote Control Pendant on the panel to the right of the Ground Control Box when not in use. |

Page 2-16

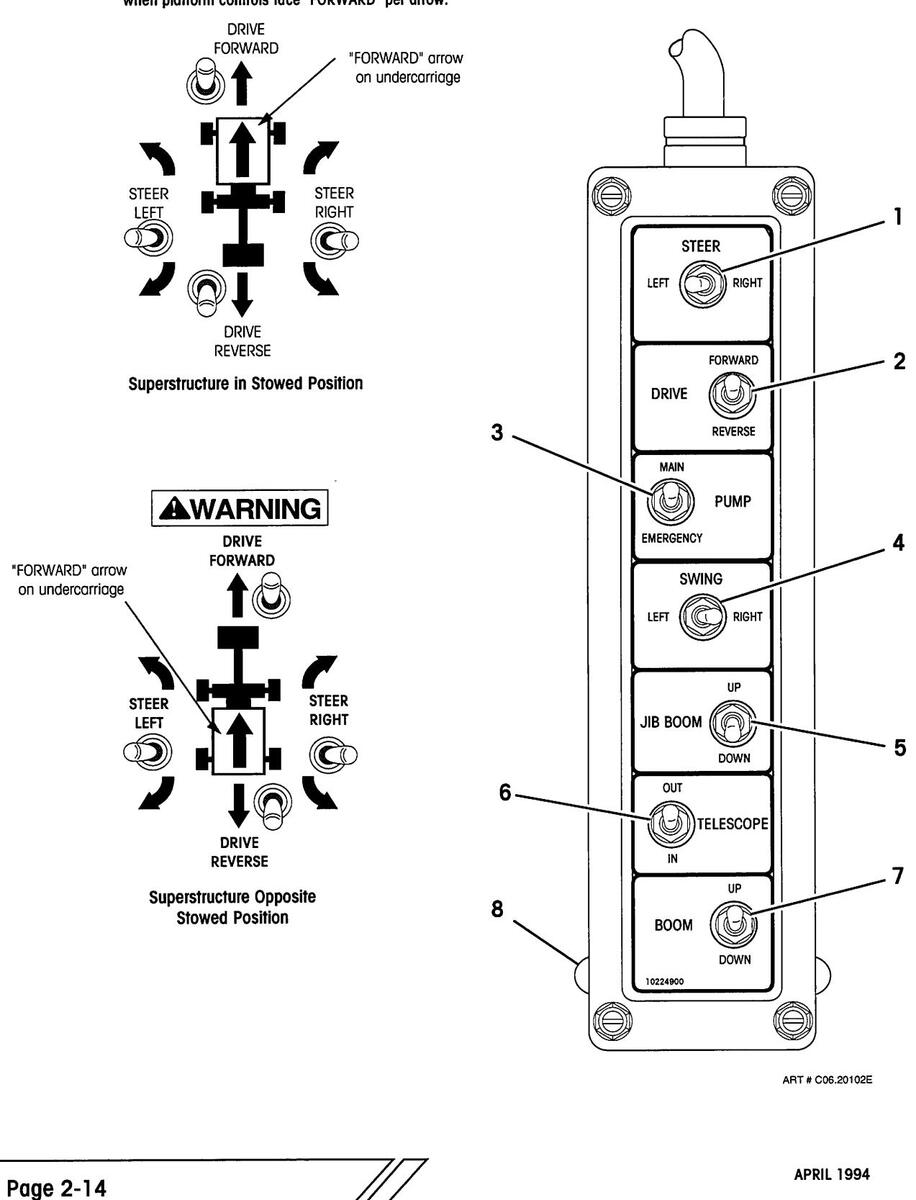

OPERATOR CONTROLS

(PLATFORM CONTROLS)

| item | Control | Location | Description |

|---|---|---|---|

| 1. |

Emergency Stop

Button |

On Platform

Console |

Used to stop all functions in an emergency. Push for emergency stop. Pull or rotate clockwise to reset, depending on style used. |

| 2. |

Off/ On/ Start

Switch |

On Platform

Console |

Three position toggle switch. Up is "OFF". Move to center position to turn ignition "ON", down to engage starter. If the engine does not start within 10 seconds, switch must be turned off and then on again to start. |

| IMPORTANT: Engine will not start with foot pedal depressed. | |||

|

On Platform

Console |

For gasoline engines, press toggle to down position and hold when starting a cold engine. | |

| For some Diesel engines (equipped with glow plugs), press and hold to preheat combustion chamber before starting a cold engine. | |||

| Flip toggle to center position for low (idle) engine speed, up for high (operating) engine speed | |||

| IMPORTANT: Machine should not be in low (idle) speed while operating any hydraulic functions. | |||

| 4. |

Auxiliary Pump

Push Button |

On Platform

Console |

Press and hold to activate battery powered emergency hydraulic pump, allowing operation of drive, steer, boom or platform movement should the engine powered hydraulic pump be disabled. |

| 5. |

Engine Warning

Indicator |

On Platform

Console |

Red light that illuminates to indicate low engine oil pressure or high engine coolant temperature. Engine will shut down automatically if condition does not correct itself in approximately 10 seconds. |

Page 2-18

OPERATOR CONTROLS

OPERATOR CONTROLS DESCRIPTION (PLATFORM CONTROLS, CONTINUED)

| ltem | Control | Location | Description |

|---|---|---|---|

| 6. |

Boom Telescope

Lever |

On Platform

Console |

Lever controls the boom telescope function. Pull back to extend boom. Push forward to retract boom. Boom speed will be proportional to handle movement. |

| 7. |

Main Boom Lift

and Swing Control Lever |

On Platform

Console |

Push lever forward to raise main boom. Pull lever back to lower main boom. Boom speed will be proportional to handle movement. |

|

Push lever to right to swing superstructure to right

(counterclockwise). Push lever to left to swing left (clockwise). Superstructure can rotate 360° continu- ously in either direction. Swing speed will be propor- tional to handle movement. |

|||

| 8. |

Platform Rotate

Lever |

On Platform

Console |

Operate lever in direction of desired platform rotation.

Pull lever counterclockwise to rotate the platform coun- terclockwise. Push lever clockwise to rotate platform clockwise. |

| 9. |

Platform Leveling

Lever |

On Platform

Console |

Push lever forward to tilt platform forward. Pull lever back to tilt platform back. |

| 10. |

"Reach Plus"

Jib Boom Lever |

On Platform

Console |

Push lever forward to raise jib boom. Pull lever back to lower jib boom. Boom speed will be proportional to handle movement. |

| 11. |

Drive Control

Lever |

On Platform

Console |

Controls forward and reverse machine travel at a speed proportional to handle movement. |

WHEN PLATFORM IS SWUNG OVER THE STEERING WHEELS, USE CAUTION WHEN SELECTING THE TRAVEL DIRECTION.

TRAVEL DIRECTION WILL BE OPPOSITE DRIVE CONTROL LEVER MOVEMENT.

SEE DIAGRAM, FACING PAGE.

Page 2-20

FROLS

| ltem | Control | Location | Description | 00 | |||

|---|---|---|---|---|---|---|---|

| 12. | Steer Switch |

On end of Drive

Control Lever |

Move switch left and hold to turn steer wheels to left, and right to turn steer wheels to right. To straighten wheels, push and hold in opposite direction. | RATOR | |||

| OPE | |||||||

|

WHEN PLATFORM IS SWUNG OVER THE

STEERING WHEELS, USE CAUTION WHEN SELECTING THE STEERING DIRECTION. |

|||||||

|

STEERING DIRECTION WILL BE OPPOSITE

STEER SWITCH MOVEMENT. |

|||||||

| SEE DIAGRAM, FACING PAGE. | |||||||

| During axle extend procedure, the steer switch is used to extend and retract the axles. | |||||||

| 13. |

Drive Speed

Switch |

On Platform

Console |

Press switch up for "HIGH" machine travel speed, down

for "LOW" speed. "High" or "Iow" speed travel are available only while main boom is below horizontal and extended less than 9 feet (2.7 Meters). With main boom raised or extended, machine travels only at slowest "creep" speed. |

||||

14. Horn Button On Platform Press button to sound warning horn. Console

OPERATOR CONTROLS

| ltem | Control | Location | Description |

|---|---|---|---|

| 15. |

Display Screen

Contrast Knob |

On Platform

Console |

Allows adjustment of the brightness and contrast of the image on the display screen. |

| 16. |

Boom Speed

Selector (Opt.) |

On Platform

Console |

Allows selection of "HIGH" or "LOW" boom raise, lower, extend or retract speed. |

| 17. |

Axle Extend

L.E.D. (Green) |

On Platform

Console |

When lit, indicates that front and rear axles are fully extended, and full range of boom operation is possible. |

| 18. | Foot Pedal Switch |

On Platform

Floor |

Must be depressed to activate main hydraulic pump,

allowing operation of any hydraulic function (drive, steer, boom or platform movement) from the platform. Depress pedal before selecting function. |

| 19. |

"Talk" Volume

Control Switch |

On Intercom

(Optional) |

Allows adjustment of the volume for "SEND" intercom function. |

| 20. |

"Listen" Volume

Control Switch |

On Intercom

(Optional) |

Allows adjustment of the volume for "RECEIVE" inter-

com function. |

| 21. |

"Power" L.E.D.

Indicator |

Below Display

Screen |

When lit, indicates that computerized Envelope Control System (ECS) is on. |

| 22. |

"OK" L.E.D.

Indicator |

Below Display

Screen |

When lit, indicates that Envelope Control System (ECS) has performed self tests and is functioning properly. |

| 23. |

"Fail" L.E.D.

Indicator |

Below Display

Screen |

When lit, indicates a failure in the Envelope Control System (ECS). |

| 24. |

"Warning" L.E.D.

Indicator |

Below Display

Screen |

When lit, indicates that boom is within 4 Ft (1.22 M) of maximum outreach. |

| 25. |

"Stop" L.E.D.

Indicator |

Below Display

Screen |

When lit, indicates that boom has reached maximum extension. Further outreach is blocked. |

| 26. |

L.E.D. Indicator

(Green) |

On Platform

Console |

When lit, indicates that Envelope Control System (ECS) backup computer is functioning properly. |

| 27. |

Light Switches

(Optional) |

On Lights

(Not Shown) |

Flip switch to turn head lights on and off. Lights are

powered by gel cell battery located on the right side of platform console. Lights blink when battery is close to discharge (approximately 45 minutes). |

OPERATOR CONTROLS

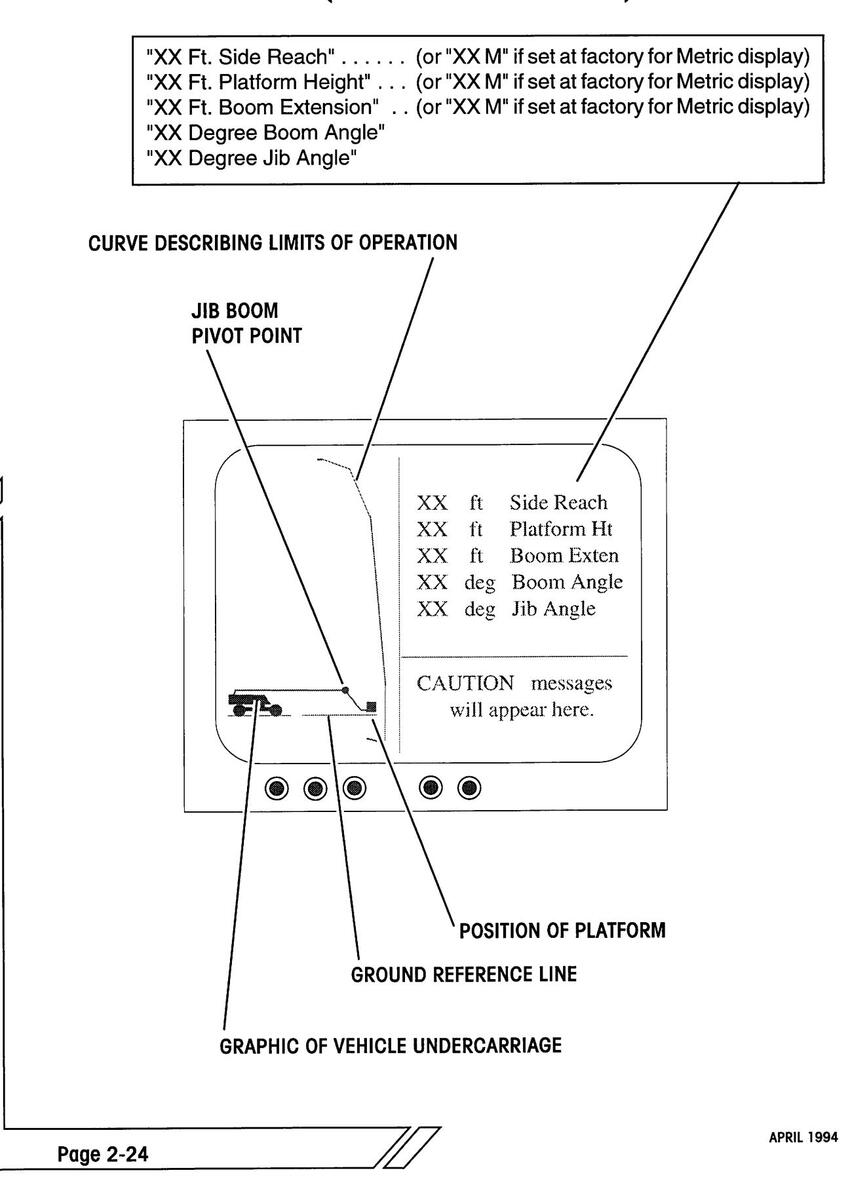

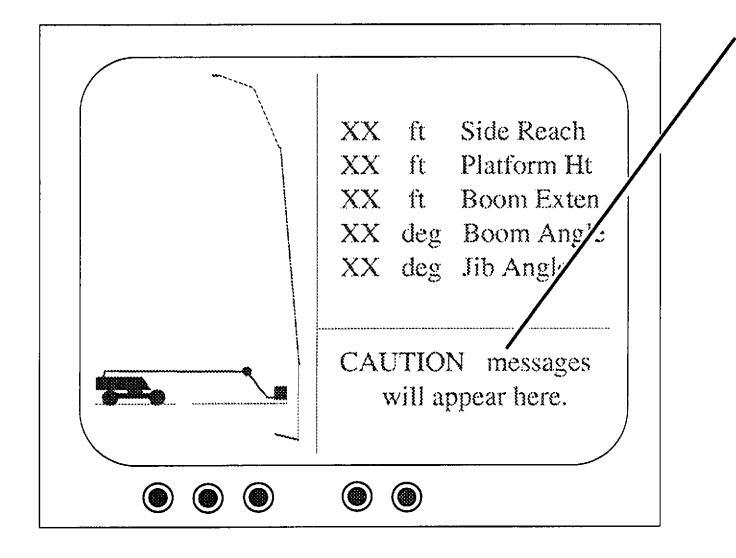

GRAPHIC DISPLAY DESCRIPTION (ENVELOPE CONTROL SYSTEM)

DPERATOR CONTROLS

GRAPHIC DISPLAY DESCRIPTION (ENVELOPE CONTROL SYSTEM)

"Jib Function Only" indicates that the main boom tip has reached the boom side reach limit. The platform can still be extended out further, but only by using the jib boom control.

"Low Speed Boom Down" indicates that, for safety reasons, the ECS (Envelope Control System) has reduced the boom lowering speed.

"Caution: Approaching side reach limit" indicates that the platform is within 4 Ft (1.22 M) of maximum outreach.

"Caution: Maximum side reach" indicates that platform has reached maximum extension. Further outreach is blocked.

"Caution: Chassis Tilted" indicates that chassis (undercarriage) of machine has exceeded the 5 degree maximum angle for safe operation. MACHINE CAN TIP OVER!

- Immediately stop all functions.

- Evaluate the situation, then

- Calmly and carefully remedy the problem causing the excessive chassis angle.

Driving in the opposite direction to straighten the chassis angle or retracting the main boom will normally eliminate the danger. HOWEVER, reversing the function that prompted the warning MAY NOT be the safest action. PROCEED WITH EXTREME CAUTION.

NOTE: For safety reasons, the boom "EXTEND" and boom "DOWN" functions are disabled as long as the "Chassis Tilted" caution is displayed.

SHIFT CHECKS

Before the Simon RP 120 Work Platform is put into use each shift, the following checks should be completed to make sure that the machine is safe and in good condition.

Refer to check lists at back of this manual for periodic maintenance requirements and additional procedures for severe duty applications:

- _____ Visually inspect all machine components, i.e. missing parts, torn or loose hoses, hydraulic fluid leaks, torn or disconnected wires, flat or damaged tires, etc. Both compartment doors can be opened to inspect components inside.

- Check engine oil and fuel levels.

- Check engine coolant level (on liquid cooled units).

- ____ Check battery electrolyte level and connections.

- Check hydraulic fluid level with booms fully retracted and lowered.

- ____ Check that all shutoff valves on the hydraulic tank are open. When open, valve handles will be parallel with the length of the valve.

The shutoff values on the hydraulic tank must be left open at all times, except during repairs or transport. If one or more of these values are closed when the unit is running, extensive pump damage will occur.

- ____ Check wheel lug nuts for tightness. Check tire pressure (see Specification page).

-

____ Check hoses and cables for worn areas.

- ____ Check hose carrier to make sure that it is not bent or sagging.

- _____ Inspect safety belt connections and check for worn areas on the belts.

- ____ Check platform rails and safety gate latch for damage.

- ____ Check pivot pins for security.

- ____ Check that all warning and instructional labels are legible and secure.

Page 2-26

START-UP PROCEDURES

APRIL 1994

MACHINE START-UP

ALL OPERATORS MUST THOROUGHLY READ AND UNDERSTAND THE "SAFETY RULES AND PRECAUTIONS" SECTION OF THIS MANUAL PRIOR TO OPERATING THE MACHINE.

A COMPLETE VISUAL INSPECTION OF THE MACHINE MUST BE PER-FORMED PRIOR TO OPERATIONAL CHECKS.

- Disengage lock pin before swinging the superstructure.

- Ensure that emergency stop buttons on ground control panel and platform control console are disenaaged. Pull out or twist to reset, depending on style.

- Ensure that engine RPM toggle switch is set to "LOW".

- Turn the main power key switch to the "GROUND" position to energize the electrical system.

- Push down on each of the three fastened corners of the tilt alarm located behind the electrical box. The alarm should sound as each corner is pressed beyond 5 degrees.

- While starting a cold engine, for gasoline or dual fuel engines, press choke button, or

for some optional Diesel engines, press glow plug button, and hold it there for 30 to 45 seconds prior to engaging starter motor.

- Press and hold engine start button to start engine. After a brief warm-up period, select the "HI" engine speed setting with the engine R.P.M. toggle switch.

- On the remote control pendant, press and hold the "PUMP" toggle to the "MAIN" position, but do not operate any drive or boom function. This is called "deadheading", and will lead to maximum compensator setting of the pump system pressure registering on the gauge at the ground control valve bank assembly. Refer to the "Machine Specifications" section of this manual for the "Maximum Hydraulic Pressure" for this unit.

- Check that the hydraulic pressure is as stated in the "Machine Specifications" of this manual.

AXLE EXTEND PROCEDURE

The RP 120 Aerial Work Platform is equipped with extendable front and rear axles.

Interlocks at each axle will prevent the boom from extending beyond a short distance or raising above horizontal unless the axles have been extended.

THE RP 120 MODEL IS EQUIPPED WITH INTERLOCKS WHICH LIMIT OPERATION OF THE UNIT WITH RETRACTED AXLES BEYOND SPECIFIC BOOM LENGTH AND ANGLE RANGES.

IT IS THE RESPONSIBILITY OF THE OPERATOR TO VERIFY THAT ALL OF THESE INTERLOCKS ARE FUNCTIONING CORRECTLY.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN DEATH OR SERIOUS INJURY.

To test for proper interlock operation:

• Press and hold the "PUMP" toggle on the remote pendant to the "MAIN" position.

IMPORTANT: The "PUMP" toggle must be pressed to operate any of the machine functions.

- Press and hold the main "BOOM" toggle switch on the remote control pendant to the "UP" position to raise the main boom. Boom should stop when it reaches the horizontal position. If it does not, the interlocks are not functioning properly, and must be repaired.

- Release the "BOOM" toggle.

- Press and hold the "TELESCOPE" toggle switch on the remote control pendant to the "OUT" position to extend the boom. Boom should stop after extending a short distance. If it does not, the interlocks are not functioning properly, and must be repaired.

- Retract the boom fully. Release the "TELESCOPE" toggle.

Note: do not lower the boom at this point.

To extend the axles, make sure unit is on a firm, level surface:

AXLE EXTEND PROCEDURE (CONTINUED)

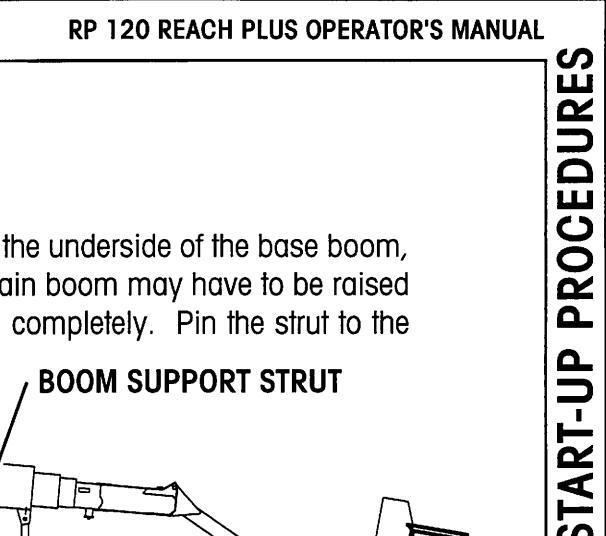

Pull the pin holding the boom support stand strut to the underside of the base boom, and swing the boom support column down. The main boom may have to be raised slightly to allow the support column to swing down completely. Pin the strut to the column.

Raise Boom Support Stand.

SUPERSTRUCTURE WILL BE ROTATED 180 DEGREES. BE SURE BOOM TRAVEL AREA IS CLEAR OF OBSTRUCTIONS.

IMPORTANT: Axle extend procedure using ground controls is described below. Boom should not be in "STOW-N-GO" mode. Extend procedure using platform controls is not recommended.

- Locate the steer/ axle extend selector valve handle, located on the side of the undercarriage behind the left steer wheel. Select "AXLE EXTEND" by pulling handle out.

- Switch the engine "R.P.M." switch on the ground electrical panel to "HIGH". Press and hold the "PUMP" toggle on the remote pendant to the "MAIN" position.

IMPORTANT: The "PUMP" toggle must be pressed to operate any of the machine functions.

- Operate the swing function by pressing the "SWING" toggle right to swing right, or left to swing left. Swing the boom 180 degrees over to the steer axle end of the unit. Release the "SWING" toggle.

- Lower the boom by pressing the "BOOM" toggle to the "DOWN" position. Lower the boom enough to raise the steer tires off of the ground. Release the boom toggle.

- Release the "PUMP" toggle. Remove the hitch pins from the left and right steering tie rods.

AXLE EXTEND PROCEDURE (CONTINUED)

• Press and hold the "PUMP" toggle. Press the "STEER" toggle to the "LEFT" position and hold to extend the steer axles.

IMPORTANT: Make sure that both left and right steer axles extend completely. Axles are fully extended when 2" (50 mm) wide white stripe is fully exposed.

- When steer axles are fully extended, release the steer toggle. Release the "PUMP" toggle.

- Replace the hitch pins into the left and right steering tie rods. Tires may have to be moved slightly to allow pins to drop into holes in tie rods.

- Press and hold the "PUMP" toggle to the "MAIN" position. Press the "BOOM" toggle "UP" to raise the boom, returning the steer tires to the ground and raising the support stand enough to clear any obstacles in the rotate path. Release the "BOOM" toggle.

- Operate the swing function by pressing the "SWING" toggle "RIGHT" to swing right, or "LEFT" to swing left. Swing the boom 180 degrees over to the drive axle end of the unit. Release the "SWING" toggle.

- Lower the boom by pressing the "BOOM" toggle to the "DOWN" position. Lower the boom enough to raise the drive tires off of the ground. Release the "BOOM" toggle.

- Push the "STEER" toggle to the "LEFT" position and hold to extend the drive axles.

IMPORTANT: Make sure that both left and right drive axles extend completely. Axles are fully extended when 2" (50 mm) wide white stripe is fully exposed.

- When drive axles are fully extended, release the "STEER" toggle.

- Press the "BOOM" toggle "UP" to raise the boom, returning the drive tires to the ground and releasing pressure on the support stand. Release the "BOOM" toggle. Release the "PUMP" toggle.

- Pull the pin holding the boom support stand strut to the boom support column, and swing the boom support column up. Pin the strut to the underside of the base boom.

- Check that interlocks at all four wheels are activated properly. If all switches are not activated, boom will not raise or extend beyond a minimal amount.

- Return the extend/ steer valve knob to the steer position.

GROUND OPERATION AND CHECKS (CONTINUED)

If boom is in STOW- N -GO™ storage mode (continued):

- e. Align hinge and main boom holes and insert boom lock pins to secure hinge boom to main boom. If hinge and main boom holes do not line up, slightly lower main boom onto ground surface to apply pressure on jib boom.

- e. Secure hinge boom to main boom with both boom lock pins and hairpin clips (attached).

With boom in operational mode:

BE SURE BOOM TRAVEL AREA IS CLEAR OF OBSTRUCTIONS.

DO NOT OPERATE THE MACHINE IF THE FOLLOWING CHECKS REVEAL A DEFECT.

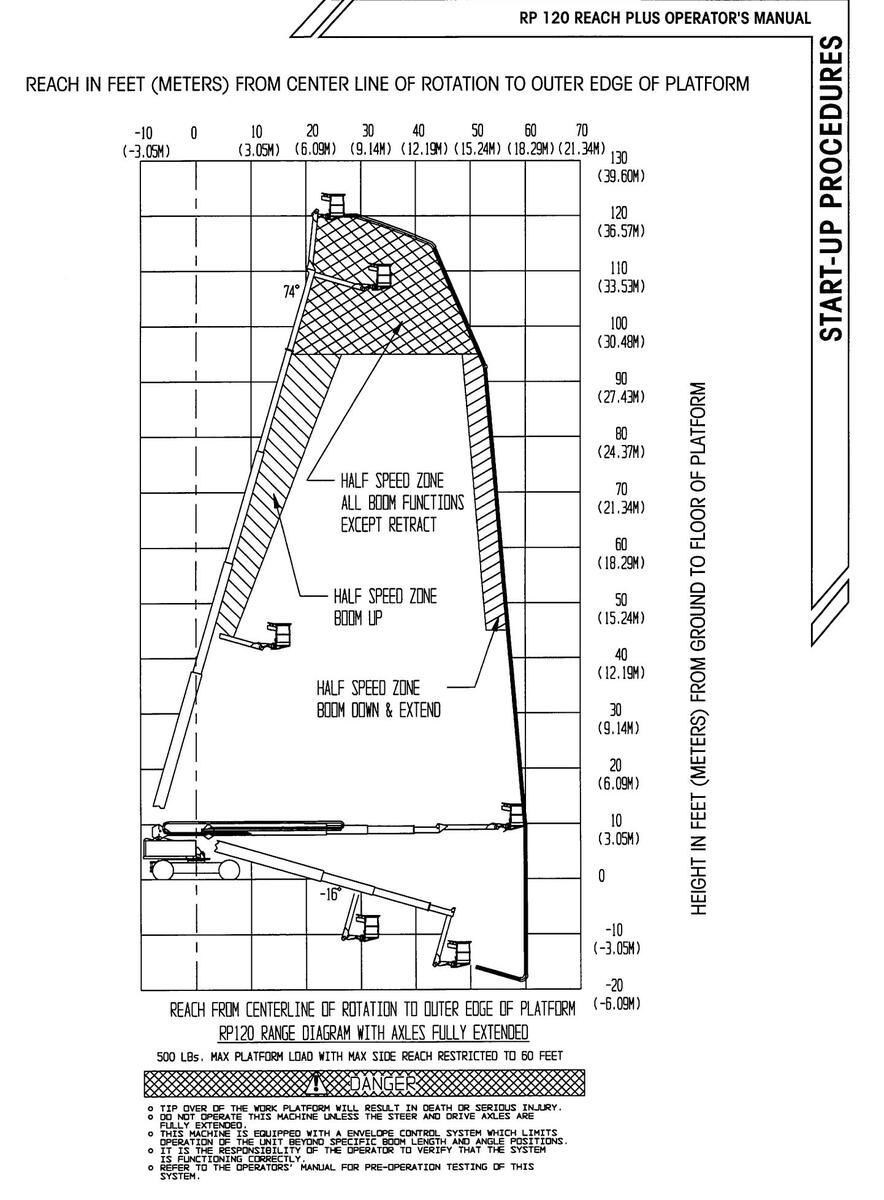

Simon Model RP 120 Aerial Lift Platforms are equipped with various safeguards that prevent the boom from attaining a long horizontal reach. The effect of an overloaded platform or an overextended horizontal reach will cause the unit to tip. Maximum horizontal outreach is 60 feet (18.3 M).

RP 120 MODELS ARE EQUIPPED WITH INTERLOCKS WHICH LIMIT OPERATION OF THE UNIT BEYOND SPECIFIC BOOM LENGTH AND ANGLE RANGES.

IT IS THE RESPONSIBILITY OF THE OPERATOR TO VERIFY THAT ALL OF THESE INTERLOCKS ARE FUNCTIONING CORRECTLY.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN DEATH OR SERIOUS INJURY.

• See diagram on next page for specific boom range. This diagram duplicates those found near the ground and platform controls on the RP 120.

Diagrams mounted near the ground and platform controls of each unit indicate the correct boom angle and length cutoff points for that machine, and shall supersede the information found in this manual.

GROUND OPERATION AND CHECKS (CONTINUED)

REPORT TO YOUR SUPERVISOR IF ANY OF THESE DEFECTS ARE FOUND:

- UNUSUAL NOISES, VIBRATION, UNEVEN OR JERKY OPERATION.

- WORN, LOOSE, DAMAGED, OR MISSING PIVOT PINS.

- HYDRAULIC LEAKS.

- UNLEVEL PLATFORM.

- Perform shift checks (see earlier in this section).

- Perform machine start-up procedures (see earlier in this section).

- Extend axles and open boom into STOW- N -GO™ Operational mode, as required (see earlier in this section).

This is a summary of the ground function operations that must be checked daily prior to operation of the unit. Detailed procedures will be found on the following pages.

- Raise main boom to horizontal.

- Raise jib boom until it stops.

- Lower jib boom to 90° below main boom.

- Extend main boom until it stops.

- Raise main boom to a 30° angle.

- Extend main boom until it stops.

- Attempt lowering of main boom.

- Raise main boom until it stops.

- Extend main boom until it stops.

- Visually inspect main boom.

- Lower main boom until it stops.

- Return the booms to stowed position.

- Swing superstructure left and right.

- Drive the unit back and forth (only reduced speed is available from ground).

- Steer the unit left and right.

- Press emergency stop button while unit is moving.

- Perform the "Platform Operation and Checks" later in this section.

GROUND OPERATION AND CHECKS (CONTINUED)

• Press and hold the "PUMP" togale on the remote pendant to the "MAIN" position.

IMPORTANT: If the "PUMP" toggle is released, all machine movement will stop.

- Press and hold the main "BOOM" toggle switch on the remote control pendant to the "UP" position to raise the main boom to the horizontal position or slightly above. Release the "BOOM" togale.

-

Press and hold the "Reach Plus" "JIB BOOM" toggle switch on the remote control pendant to the "UP" position to raise the jib boom to the end of its movement. Release the toggle.

- ____ Listen for any unusual noises.

- ____ Check for any vibration while the boom travels up.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- Check pivot pin security. Make sure that all retaining bolts and rings are in place on the pin locking point, and have not sheared off.

- Press and hold the "Reach Plus" "JIB BOOM" toggle switch on the remote control pendant to the "DOWN" position to lower the jib boom to the end of its movement (90° below the main boom position). Release the toggle.

-

Press and hold the boom "TELESCOPE" toggle switch on the remote control pendant to the "OUT" position. Extend the boom to the end of its movement. Note that when the boom reaches approximately 56 Ft (17.1 M), the yellow L.E.D. on the ground control panel lights up.

- _____ Listen for any unusual noises.

- Check for any vibration while the boom extends.

- ____ Check for uneven or jerky operation.

- Check for hydraulic leaks.

- When the boom reaches 60 feet or 18.3 meters horizontal distance, the red L.E.D. on the ground control panel lights up. A black line on the side of the tip boom will be exposed. If the black line is more than 6" (152 mm) out from the outer mid boom, the system needs recalibration. Report the situation to your supervisor. Machine shall be removed from service until recalibration has been completed.

- Release the "TELESCOPE" toggle.

GROUND OPERATION AND CHECKS (CONTINUED)

-

Press and hold the main "BOOM" toggle switch on the remote control pendant to the "UP" position to raise the main boom to a 30° anale. Release the "BOOM" togale.

- Listen for any unusual noises.

- Check for any vibration while the boom travels up.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

-

Press and hold the boom "TELESCOPE" toggle switch on the remote control pendant to the "OUT" position. Extend the boom to the end of its movement (approximately 55 feet or 16.8 meters horizontal distance). Note that first the yellow, then the red L.E.D. on the ground control panel lights up.

- Listen for any unusual noises.

- Check for any vibration while the boom travels out.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

The boom will extend out only until the specified distance, then will not extend any further.

- Release the boom "TELESCOPE" toggle switch.

- Press and hold the main "BOOM" toggle switch on the remote control pendant to the "DOWN" position. Boom should not lower. If the boom does lower, the system needs recalibration.

- Release the "BOOM" toggle switch.

-

Press and hold the main "BOOM" toggle switch on the remote control pendant to the "UP" position to raise the main boom to the end of its movement. Release the "BOOM" toggle.

- ____ Listen for any unusual noises.

- ____ Check for any vibration while the boom travels up.

- Check for uneven or jerky operation.

- ____ Check for hydraulic leaks.

START-UP PROCEDURES

GROUND OPERATION AND CHECKS (CONTINUED)

-

Press and hold the boom "TELESCOPE" toggle switch on the remote control pendant to the "OUT" position. Extend the boom to the end of its movement.

- Listen for any unusual noises.

- Check for any vibration while the boom travels out.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- Check pivot pin security. Make sure that all securing bolts are in place on the pin locking point, and have not sheared off.

- Inspect all sides of the boom sections visually for damage along their entire length.

-

Press and hold the main "BOOM" toggle switch on the remote control pendant to the "DOWN" position to lower the main boom to the end of its movement. Note that first the vellow, then the red L.E.D. on the ground control panel lights up.

- Listen for any unusual noises.

- ____ Check for any vibration while the boom travels down.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

The boom will lower only a short distance, then will not lower any further.

- Release the "BOOM" toggle.

-

Return the boom to its stowed position. Push and hold the "TELESCOPE" and main "BOOM" toggle switches on the remote control pendant to the "IN" and "DOWN" positions.

- _____ Listen for any unusual noises.

- Check for any vibration while the boom travels in and down.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- Visually confirm that the platform has remained level during boom travel.

- Release the toggle switches.

GROUND OPERATION AND CHECKS (CONTINUED)

-

Press and hold the "SWING" toggle switch on the remote control pendant left to swing left (clockwise) and right to swing right (counterclockwise). Swing the superstructure a short distance in each direction, then return to the stowed position.

- Listen for any unusual noises.

- Check for any vibration while the superstructure swings.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- Report and repair any problem.

- Release the "SWING" toggle switch.

TAKE EXTREME CARE WHEN SELECTING ANY OF THE TRAVEL FUNCTIONS FROM THE GROUND.

WITH THE PLATFORM SWUNG OVER THE STEERING WHEELS, TRAVEL AND STEERING DIRECTION WILL BE OPPOSITE TO DIRECTIONS INDI-CATED ON PLACARD.

Control operation direction shown here in relation to "FORWARD" arrow on undercarriage. Superstructure and undercarriage lock pin holes line up

START-UP PROCEDURES

Page 2-38

GROUND OPERATION AND CHECKS (CONTINUED)

-

Press the "DRIVE" toggle "FORWARD". The machine will move forward at creep speed. Movement alarm sounds whenever the vehicle is in motion.

- Listen for any unusual noises.

- ____ Check for any vibration while the unit travels.

- Check for uneven or jerky operation.

- ____ Check for hydraulic leaks.

- Report and repair any problem.

- Push the "STEER" switch left and right, and check for proper steering control. Note position of the platform to the steering wheels.

- Return the wheels to the straight ahead position by pressing the "STEER" switch in the opposite direction. When wheels are straight, release the "STEER" switch.

- Press the emergency stop button. All functions (including the engine) should stop immediately. Pull the button out or twist to reset, depending on style installed. Restart engine.

- Press and hold the "PUMP" toggle on the remote pendant to the "MAIN" position. Press the "DRIVE" toggle to "REVERSE". The machine will move backward at creep speed.

- Release the "DRIVE" toggle. The unit will come to a complete stop.

- Return the machine to the stowed position. Press the appropriate toggle switches in turn, while still pressing the deadman button.

- When machine has returned to the stowed position, release the toggles. Release the "PUMP" toggle.

NOTE: All machine operations should stop upon release of the "PUMP" toggle.

- Flip the engine throttle to "LOW" to allow the engine to slow to idle speed.

- Shut the engine off.

PLATFORM OPERATION AND CHECKS

- Complete the Ground Operational Checks before performing the Platform Checks.

- Select "PLATFORM CONTROLS" with the ground/ platform key switch.

WITH BOOM OUT OF "OPERATIONAL MODE" POSITION, DO NOT PLACE ANY LOAD IN THE PLATFORM.

NOTE: To operate from platform, jib boom must not be in STOW- N -GO™ storage mode (see illustration). If boom is in STOW- N -GO™ storage mode, refer to instructions in "Ground Operation and Checks" section, earlier in this manual.

- Open platform control console cover.

- Ensure that the emergency button is released. Pull or twist emergency stop button to reset, depending on style used.

- Move off/ on/ start toggle to center position to turn ignition "ON", down to engage starter, then release it to the "ON" position.

- Flip the engine throttle switch to "OPERATING SPEED".

PLATFORM OPERATION AND CHECKS (CONTINUED)

REPORT TO YOUR SUPERVISOR IF ANY OF THESE DEFECTS ARE FOUND:

- UNUSUAL NOISES, VIBRATION, UNEVEN OR JERKY OPERATION.

- WORN, LOOSE, DAMAGED, OR MISSING PIVOT PINS.

- HYDRAULIC LEAKS.

- UNLEVEL PLATFORM.

- Perform shift checks (see earlier in this section).

- Perform machine start-up procedures (see earlier in this section).

- Extend axles and open boom into STOW- N -GO™ Operational mode, as required (see earlier in this section).

- Perform the "Ground Operation and Checks" earlier in this section.

This is a summary of the platform function operations that must be checked daily prior to operation of the unit. Detailed procedures will be found on the following pages.

- Check to ensure the horn works.

- Raise main boom to horizontal.

- Raise jib boom until it stops.

- Lower jib boom until it stops.

- Extend main boom until it stops.

- Raise main boom to a 30° angle.

- Extend main boom until it stops.

- Attempt lowering of main boom.

- Return the booms to stowed position.

- Swing superstructure left and right.

- Rotate platform left and right.

- Tilt platform forward and back.

- Drive the unit back and forth in "LOW" speed mode.

- Steer the unit left and right.

- Press emergency stop button while unit is moving.

- Raise main boom above horizontal and repeat drive tests (should drive only at "creep" speed, which is much slower than "low" speed in previous test).

- Lower main boom below horizontal and repeat drive tests in "HIGH" speed mode.

PLATFORM OPERATION AND CHECKS (CONTINUED)

BE SURE BOOM TRAVEL AREA IS CLEAR OF OBSTRUCTIONS.

DO NOT OPERATE THE MACHINE IF THESE CHECKS REVEAL ANY DEFECT OR ABNORMALITY.

• Display screen should be functioning (turns on automatically when machine is "on").

NOTE: In cold weather, it may take several minutes for the computer screen display to warm up enough to be seen clearly.

• "Power" and "OK" L.E.D. indicator should be on. If "FAIL" indicator is lit, system servicing is required.

DO NOT OPERATE MACHINE FURTHER UNTIL PROBLEM HAS BEEN CORRECTED.

- Note that green "backup system" L.E.D. indicator should be on.

- Note that green "axles extended" L.E.D. indicator should be on.

- Press the horn button briefly to check that the horn works.

- Press the foot pedal mounted on the floor of the platform.

IMPORTANT: The foot pedal must be activated to operate any of the machine functions.

• Slowly move the middle lever forward to the "BOOM UP" position. The main boom will start to rise. Note that visual display on screen shows main boom rising. Function speed is proportional to the distance the lever is moved. Raise the boom to the horizontal position or slightly above. Slowly return the control lever to the center position.

START-UP PROCEDURES

PLATFORM OPERATION AND CHECKS (CONTINUED)

• Slowly move the Reach Plus lever forward to the "JIB BOOM UP" position. The jib boom will start to rise. Note that visual display on screen shows jib boom rising. Function speed is proportional to the distance the lever is moved.

Raise the jib boom slightly, then lower to the fully down position (approximately 90° below the main boom).

Slowly return the control lever to the center position.

• Slowly move the left lever back to the "EXTEND" position. Extend boom out to the end of its movement. Note that visual display on screen shows boom extending. Extend speed is proportional to the distance the lever is moved.

Note that when the boom reaches approximately 56 Ft (17.1 M) extension (indicated on upper right of display screen),

- the yellow "Warning" L.E.D. under the screen lights up,

- the message "Caution: Approaching side reach limit" appears at the lower right of the screen, and

- shortly afterward, boom extend speed drops by one-half.

- ____ Listen for any unusual noises.

- Check for any vibration while the boom telescopes out.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- _____ Report and repair any problem.

- When the boom reaches approximately 60 feet or 18.3 meters horizontal distance (indicated on display screen),

- the red "Stop" L.E.D. under the screen lights up,

- the message "Caution: Maximum side reach" appears at the lower right of the screen, and

- boom extend motion comes to a stop.

PLATFORM OPERATION AND CHECKS (CONTINUED)

A black line on the side of the tip boom will be exposed. If the black line is more than 6" (152 mm) out from the outer mid boom, the system needs recalibration. Report the situation to your supervisor. Machine shall be removed from service until recalibration has been completed.

- Slowly return the control lever to the center position.

-

Slowly move middle lever forward to "BOOM UP" position. The main boom will start to rise. Function speed is proportional to distance lever is moved. Raise the boom up to a 30° anale (indicated on upper right of display screen).

- Listen for any unusual noises.

- Check for any vibration while the main boom travels up.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- Report and repair any problem.

- Slowly return the control lever to the center position.

-

Slowly move the left lever back to the "EXTEND" position. Extend the boom to the end of its movement (upper right of display screen will indicate less than 60 feet or 18.2 meters side reach). Note that "Caution" messages appear on the screen, and that first the yellow "Warning" then the red "Stop" L.E.D.s under the screen light up.

- ____ Listen for any unusual noises.

- ____ Check for any vibration while the boom travels out.

- Check for uneven or jerky operation.

- ____ Check for hydraulic leaks.

- The boom will extend out only until the specified distance, then will not extend any further.

- Slowly return the control lever to the center position.

START-UP PROCEDURES

PLATFORM OPERATION AND CHECKS (CONTINUED)

- Slowly move middle lever back to the "BOOM DOWN" position. The main boom should not lower more than a minimal amount.

- Slowly return the control lever to the center position.

-

Return the booms to the travel position by slowly operating the levers in the "RETRACT" and "BOOM DOWN" directions in turn.

- Listen for any unusual noises.

- Check for any vibration while the booms lower and retract.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- Report and repair any problem.

- Slowly return the control levers to their center positions.

-

Slowly move the middle lever right to swing right (counterclockwise) and left to swing left (clockwise). Swing speed is proportional to distance lever is moved.

- Listen for any unusual noises.

- Check for any vibration while the unit rotates.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- _____ Report and repair any problem.

- Slowly return the control lever to the center position.

PLATFORM OPERATION AND CHECKS (CONTINUED)

-

Operate the platform rotate function by slowly moving the platform rotate control lever located on the left hand side of the control console. Move the lever in both directions.

- Listen for any unusual noises.

- Check for any vibration while the platform rotates.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- Report and repair any problem.

- Return the platform to the center position. Return the control lever to the center position.

-

Operate the platform level function by slowly operating the platform level control lever, on the left side of the control console. Move the lever in both directions.

- Listen for any unusual noises.

- Check for any vibration while the platform tilts forward or back.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- Report and repair any problem.

- Return the platform to a level position. Return the control lever to the center position.

Control operation direction shown here in relation to "FORWARD" arrow on undercarriage. Superstructure and undercarriage lock pin holes line up

PLATFORM OPERATION AND CHECKS (CONTINUED)

• Switch the drive speed toggle switch to "LOW".

IMPORTANT: Jib should be raised for sufficient ground clearance.

WITH THE PLATFORM SWUNG OVER THE STEERING WHEELS, USE CAUTION WHEN SELECTING THE TRAVEL DIRECTION. TRAVEL AND STEERING DIRECTION WILL BE OPPOSITE CONTROL OPERATION.

• Slowly move the drive control lever forward. The machine should smoothly accelerate in the direction of control lever movement.

Movement alarm sounds whenever the vehicle is in motion.

- Listen for any unusual noises.

- Check for any vibration while the unit travels.

- Check for uneven or jerky operation.

- Check for hydraulic leaks.

- Report and repair any problem.

- Operate the steer switch and check for proper steering control. Note position of the platform to the steering wheels.

- Return the wheels to the straight ahead position.

- Slowly move the drive control lever backward. The machine will smoothly accelerate in the direction of the control lever movement.

Movement alarm sounds whenever the vehicle is in motion.

• Press emergency stop button. All functions (including engine) should stop immediately.

BRACE YOURSELF FOR UNEXPECTED PLATFORM MOVEMENT AS THE MACHINE COMES TO A SUDDEN STOP.

ACTUATION OF THE RED "EMERGENCY STOP BUTTON" WILL APPLY BRAKES IMMEDIATELY!

PLATFORM OPERATION AND CHECKS (CONTINUED)

- Reset emergency stop button and restart engine.

- Raise the main boom to above horizontal, and repeat the drive tests. Machine should travel a maximum of 0.5 M.P.H. (0.8 K.P.H.). This condition is referred to as "creep speed", and is the maximum rate of travel with the main boom raised or extended.

NOTE: At "creep speed", a tire makes one complete revolution in approximately twenty (20) seconds. If one revolution takes less than fifteen (15) or more than twenty-five (25) seconds, the machine must be adjusted to bring the "creep speed" back to 0.5 M.P.H (0.8 K.P.H.).

- Return the machine to the straight ahead position, with main boom below horizontal and fully retracted. Position jib boom for adequate ground clearance for travel.

- Switch the drive speed toggle to "HIGH", and repeat the drive tests.

- Move all levers and switches back to their neutral positions. Release the foot pedal.

NOTE: All machine motion should stop upon release of the foot pedal.

• Flip off/ on/ start switch to the "OFF" position to shut off the engine.

Page 2-48

DPERATION

OPERATION

DUE TO THE DESIGN OF THE SIMON RP 120 IT IS POSSIBLE TO DRIVE THROUGH LOCATIONS IN WHICH IT WOULD BE UNSAFE TO RAISE THE PLATFORM.

THE OPERATOR MUST BE AWARE OF THE ENVIRONMENT. DO NOT RAISE THE PLATFORM IF THE MACHINE IS NOT ON A FIRM LEVEL SURFACE!

DO NOT RELY ONLY ON THE TILT ALARM TO WARN YOU OF AN UNSAFE CONDITION.

SAFE OPERATION BEGINS WITH A SAFE OPERATOR.

Perform Start-Up Procedures. Remember to place the ground/ platform control switch in the "PLATFORM CONTROLS" position before going to the platform for operation.

Enter platform, close and secure safety gate, and attach safety belt.

COLD WEATHER OPERATION

- In below zero weather, the hydraulic fluid should be allowed to warm before full operation of the unit.

- Check for water contamination of the fluid.

- Check for and remove ice on the platform, swing gear teeth and steering linkage prior to operation.

- Check that all valve levers operate smoothly, and return freely to the neutral position.

A CAUTION

Avoid sudden braking or steering, go slow and leave more maneuvering room during cold weather operation.

NOTE: In cold weather, it may take several minutes for the computer screen display to warm up enough to be seen clearly.

DRIVING AND STEERING

ENSURE THAT THE ROUTE OF TRAVEL IS CLEAR OF PERSONNEL AND DEBRIS.

Press the foot switch. Slowly push the drive control lever "FORWARD" to provide forward travel, or pull the lever back for reverse travel.

NOTE: The speed of the unit is proportional to the distance the lever is moved.

To steer, press the steer switch on the end of the drive control lever to the left or right as required.

Although the unit can be driven with the platform positioned at either end of the unit, the operator may find driving easier when the platform is over the non-steering axle.

The stowed position can be identified by the large "Forward" arrows on the undercarriage, or by the line up of the lock pin holes. When driving with the platform over the opposite axle, remember that all directions given to the steer and drive controls will be reversed.

When descending a ramp (incline), it is necessary to control the speed of the unit. To slow the unit, move the drive control lever slowly toward the center "neutral" position.

BRAKING

For parking, the brakes are automatically applied when the drive control lever is in the center "neutral" position.

RELEASE OF THE DRIVE CONTROL LEVER OR ACTUATION OF THE RED "EMERGENCY STOP" BUTTON WILL APPLY BRAKES IMMEDIATELY!

BRACE YOURSELF FOR UNEXPECTED PLATFORM MOVEMENT AS THE MACHINE COMES TO A SUDDEN STOP.

OPERATION

OPERATION

BOOM, SUPERSTRUCTURE AND PLATFORM

ALL SIMON MODELS WITH EXTENDIBLE AXLES ARE EQUIPPED WITH INTERLOCKS WHICH LIMIT OPERATION OF THE UNIT BEYOND SPECIFIC BOOM LENGTH AND ANGLE RANGES.

IT IS THE RESPONSIBILITY OF THE OPERATOR TO VERIFY THAT ALL OF THESE INTERLOCKS ARE FUNCTIONING CORRECTLY.

REFER TO "AXLE EXTEND PROCEDURE" AND "GROUND OPERATION AND CHECKS" SECTIONS OF THIS MANUAL FOR INSTRUCTIONS REGARDING PRE-OPERATION TESTING OF THESE INTERLOCKS.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN DEATH OR SERIOUS INJURY.

Press the foot pedal, then select the required function. Available functions are:

- Main boom UP or DOWN

- Main boom EXTEND or RETRACT

- Jib boom UP or DOWN

- Superstructure swing LEFT or RIGHT

- Platform level FORWARD or BACKWARD

- Platform rotate LEFT or RIGHT

Each function can be selected by moving the appropriate lever in the proper direction.

- When closer than 2 Ft (.6 M) to side reach limit, or when platform height is greater than 45 Ft (13.7 M), boom extend function slows to half speed.

- When platform height is greater than 95 Ft (28.9 M), all boom functions (except retract) operate at half speed.

NOTE: Function speeds are proportional to the distance levers are moved.

Multiple control operation is possible by selecting more than one function at a time.

GASOLINE ENGINE OPERATION

• Press the "START" button and press the "CHOKE" button (at ground station) or operate the start and choke toggles (at platform). As soon as the engine starts, release both switches.

DUAL FUEL ENGINE OPERATION

GASOLINE OPERATION

• Operate the machine as normal.

GASOLINE TO PROPANE SWITCHING

This switching can only be done using the ground controls. The machine should only be switched to propane while the engine is running.