Genie PLUS 3060L, 2060L Owner’s Manual

©pe_'at et} and

e

3559935907

2060

3060

AC POWERED SCREW DRIVE OPENERS

COHTEHTS

Warranty Information ...................2

Your Documentation Package ..........3

Safety Information ..................... 4

Safety Features ......................... 4

Important Installation Instuctions ....... 4

Pre-lnstallation Checklist .............. 5-8

Adjustments ......................... 9-10

Programming the Remote Control ..... 11

Installing lightbulb and lens ............ 12

Scheduled Maintenance ............... 13

Troubleshooting Guide ............. 14-15

Wiring Diagram ........................ 16

Parts Lists and Exploded Views ...... 17-18

Accessories ............................ 19

(k)MRLETE WITH II,_I"ELLICO[}E

!E!OTE COST ;;'_r_ AH© ,<I_;D_ ........,J RuL s ,sES II

For up to 7'-6" tall Doors. (Extension Kit available for 8' Doors)

Included Wall Control MUST be installed prior to Operation of

this Garage Door Operator.

Safe-T-Beam ®Safety Reverse System Must be Installed and

the Force Controls MUST be Properly Set to dose door.

This Equipment meets or exceeds all Federal, State and UL325

Safety Requirements.

Please call us: 1-800-3S-GENIE (354-3643)

www.geniecompany.com

Please have Model information

ready when calling.

What s ceve_'ed?

Anydefectinmaterialandproductworkmanshipfrompersonal,normalhouseholduse

inaccordancewiththeOwner'sManual.

Fo_'hew o_9?

MODEL2060L...20 years on motor, 3 years all other parts.

MODEL3060L... Lifetime* on motor,3 years all other parts.

MODEL3060C ... Lifetime _ on motor, 3 years all other parts.

*Lifetime = For as long asyou own your home.

Who gets rise, v_:_a_s'a_ty

This warranty is limited to the consumer who originally purchased the product.

Thiswarrantyappliesonlyto unitsinstalledandoperatedwithin the countrywhere

theywerepurchased.

L, ¢_ tat _sns

IMPLIEDWARRANTIES,INCLUDINGTHOSEOF FITNESSFORA PARTICULARPURPOSEAND

MERCHANTABILITY(AN UNWRITTENWARRANTYTHATTHE PRODUCTISFITFORORDI-

NARYUSE),ARELIMITEDTO ONEYEARFROMTHEDATEOF PURCHASE.GENIEWILL NOT

PAYFOR:LOSSOF TIME;INCONVENIENCE;LOSSOF USEOFYOURGENIEPRODUCTOR

PROPERTYDAMAGECAUSEDBYYOURGENIEPRODUCTORITSFAILURETOWORK;ANY

SPECIAL,INCIDENTALOR CONSEQUENTIALDAMAGES;ORANY DAMAGESRESULTING

FROMMISUSEOR MODIFICATIONOFYOUR GENIEPRODUCT.

Some states and provinces do not allow limitations on how long an implied warranty

lastsor the exclusion of incidental or consequential damages, sothe above limitations or

exclusions may not apply to you.

This warranty isthe only one we will give on your Genie product, and it sets forth all our

responsibilities regarding your Genie product.There are no other express warranties.

State and province rights:This warranty givesyou specific legal rights, andyou may also

haveother rights which vary from state to state and province to province.

How to get wa_'_'a_ty se_'v<e,

To obtain warranty service for your Genie product, you must provide proof of the date

and place of purchase of the product.

Call the GenieConsumer Connection toll free at 1.800.354.3643to speak in person to a

trained Genie representative for assistance in diagnosing the problem and arranging

to supply you with the required parts for do-it-yourself repairs.Trained service repre-

sentatives are available Monday-Friday, 8:00 a.m.- 11:00 p.m.,Eastern Time, and on

Saturday, 10:00 a.m.to 8:00 p.m.,Eastern Time (subject to holidays) You may also get

the information you need at www.geniecompany.com.

You also may obtain warranty service from Genie authorized dealers by calling the

Genie Customer Service at 1.800.354.3643or by visiting www.geniecompany.com

before scheduling warranty service.If warranty service is provided by an authorized

dealer, Genie will provide all required parts under warranty at no charge to you, but

the dealers are independent business people and may render a bench or service call

charge for their services.Genie will not reimburse you or otherwise be responsible for

those charges.

Wesuggest that you retain your original packing material inthe event we choose to

repair or replaqce your Genie Product and request that you ship it to us. Besure to

include your name,address,telephone number, proof of date and place of purchase

and a description of the operating problem.After repairing or replacing, your Genie

product, we will ship it to your home at no cost to you for parts and labor, but you will

have to pay a minimum of %.00 for shipping and handling charges.

Your choice of either one of the above-described service options isyour exclusive

remedy under this warranty.

What th wa_'_'a_ty does _ot cove_'

This warranty does not cover batteries (which are considered replaceable parts), installa-

tion, commercial use,defects resulting from accidents, damage while intransit to our

service location or damage resulting from alterations, misuse or abuse, lack of proper

maintenance, unauthorized repair or modification of the product, affixing of any attach-

ment not provided with the product, programming of the Remote Control Devices,

Safe-T-Beam®adjustment/cleaning, staples through wiring, pinched or broken wires,

Carriage disengaged, ForceControl adjustments, door out of balance, broken springs

or cables,power outages, use of extension cords, missing or damaged parts on dis-

counted, clearanced, final sale or taped cartons, phantom operations (labor isnot cov-

ered if Opener is functioning properly while technician is in garage),fire, flood, or acts of

God,or other failure to follow the Owner's Manual.

Pleasenote the following information,so it isavailable if you

needto call us.

Date Purchased / /

SerialNumber

Operator Model

Remote Control Model

Dealer Name

DealerAddress

City

State

Zip

NOTE

Please keep original or photocopy of your sales

rece!ptwith this manual for future reference should

service ever be required.

FORANSWERS:CALL1.800.354.3643

Model Number and

Serial Number are

located on front

panel inside

the lens.

Visit Our Website at: www.geniecompany.com

SAVETHESEINSTRUCTIONS

The documentation provided with your opener has been carefully designed and organized to make the assembly, operation,and continued

maintenance of your product as easy and safe as possible.This material consists of two main items.

While it is recommended that all documents be retained for future reference, this manual should contain most of the information that you

will need over the lifetime of your product.The manual is designed in a "flip-flop"configuration with the english version in one half of the

book and the spanish / french version in the other half.The basic contents of this manual are:

i,.ii ", i ,, ..

i}F SIII

¢ a , )A;, A

Warranty Information

Pre Installation Checklist to be reviewed prior to any

assembly or installation

Necessary Adjustments

Programming Remote Devices _e

Maintenance and Troubleshooting

Parts Explosions

Accessory Order Form

Door Opener Association Safety and Maintenance Brochure (DASMA)

Entrapment Warning Label -To be Adhered in close proximity

to wall control

siisl_i _c. ce

%<. SiOl_

<h / c _;,.. i.

iDI=I_iII_

[ ill]q .xl_i(' .i,;'Ksi()l]

Assembly a_'_d/_}stallatio_'_ Peste_

This poster is intended to give a convenient lay flat media to be used at the site of assembly and installation. Color coding is used to

highlight steps and other information as clearly as possible.This poster is Tri-Lingual with english instructions highlighted with a blue

background.The basic contents of this Poster are:

(_e _e

Quick Reference Poster ....................._

Pictorial and step by step opener assembly mstruclons -.- _:_ ......

nsta at on nstruct ons . ,_ .........::........._., _, .Pictorial and step by step opener ........_;'--,

") .... . _.i._., _///'

(> f' /_:o{' / _ ..........................................

IT IS CRITICAL THAT ALL SAFETY WARNINGS MARKED CLEARLY IN BOTH

THE MANUAL AND POSTER ARE READ, UNDERSTOOD AND FOLLOWED.

The Genie Company is constantly striving to improve our products and the documentation that comes with them. If you have any

suggestions or ideas for improving this product and it's documentation, please forward them to:

The Genie Company

22790 Lake Park Blvd.

Alliance, Ohio 44601-3498

2060-3060 eng.qxd 11/9/05 11:02 AM Page 4

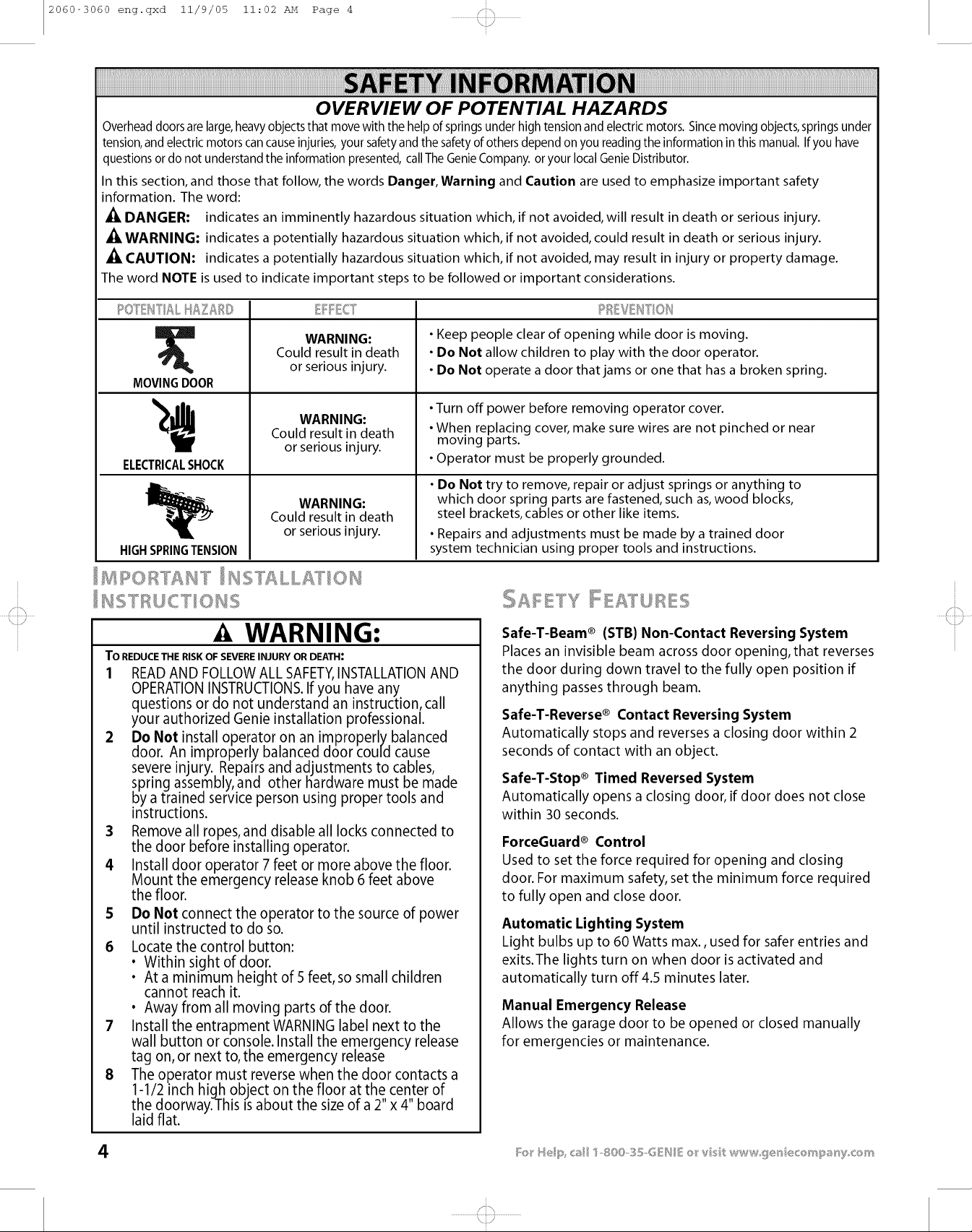

OVERVIEW OF POTENTIAL HAZARDS

Overheaddoors arelarge,heavy objects that movewith the help of springsunder high tension and electric motors. Sincemoving objects,springs under

tension, and electric motors can causeinjuries, your safety and the safetyof others depend on you reading the information in this manual. If you have

questions or do not understand the information presented, callThe GenieCompany. or your local Genie Distributor.

In this section, and those that follow, the words Danger, Warning and Caution are used to emphasize important safety

information. The word:

.i_ DANGER: indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

-_ CAUTION: indicates a potentially hazardous situation which, if not avoided, may result in injury or property damage.

The word NOTE is used to indicate important steps to be followed or important considerations.

Could result in death • Do Not allow children to play with the door operator.

WARNING: • Keep people clear of opening while door is moving.

MOVINGDOOR

or serious injury. • Do Not operate a door that jams or one that has a broken spring.

i

'\ b/

........_i]i17.......

WARNING:

Could result in death

or serious injury.

ELECTRICALSHOCK

WARNING:

Could result in death

or serious injury.

HIGHSPRINGTENSION

• Turn off power before removing operator cover.

• When replacing cover, make sure wires are not pinched or near

moving parts.

• Operator must be properly grounded.

• Do Not try to remove, repair or adjust springs or anything to

which door spring parts are fastened, such as,wood blocks,

steel brackets, cables or other like items.

• Repairs and adjustments must be made by a trained door

system technician using proper tools and instructions.

WARNING:

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH:

1 READAND FOLLOW ALL SAFETY,INSTALLATIONAND

OPERATIONINSTRUCTIONS.If you have any

questions or do not understand an instruction, call

your authorized Genie installation professional.

2 Do Not install operator on an improperly balanced

door. An improperly balanced door could cause

severe injury. Repaffs and adjustments to cables,

spring assembly, and other hardware must be made

by a trained service person using proper tools and

instructions.

3 Remove all ropes, and disable all locks connected to

the door before installing operator.

4 Install door operator 7 feet or more above the floor.

Mount the emergency release knob 6 feet above

the floor.

5 Do Not connect the operator to the source of power

until instructed to do so.

6 Locate the control button:

Within sight of door.

At a minimum height of 5 feet, so small children

cannot reach it.

• Away from all moving parts of the door.

7 Install the entrapment WARNING label next to the

wall button or console. Install the emergency release

tag on, or next to, the emergency release

8 The operator must reverse when the door contacts a

1-1/2 inch high object on the floor at the center of

the doorway.This isabout the size ofa 2"x 4" board

laid flat.

........\X7.......

Safe-T-Beam ® (STB) Non-Contact Reversing System

Places an invisible beam across door opening, that reverses

the door during down travel to the fully open position if

anything passesthrough beam.

Safe-T-Reverse ® Contact Reversing System

Automatically stops and reverses a closing door within 2

seconds of contact with an object.

Safe-T-Stop ® Timed Reversed System

Automatically opens aclosing door, if door does not close

within 30 seconds.

ForceGuard ® Control

Used to set the force required for opening and closing

door. For maximum safety, set the minimum force required

to fully open and close door.

Automatic Lighting System

Light bulbs up to 60 Watts max., used for safer entries and

exits.The lights turn on when door isactivated and

automatically turn off 4.5 minutes later.

Manual Emergency Release

Allows the garage door to be opened or closed manually

for emergencies or maintenance.

4

i

........................._:i ........................

I <_I"Js_<, %%%1,<÷Is_, 01]11-I<_ iiy 1(oI]l

2060-3060 eng.qxd 11/9/05 11:02 AM Page 5

This Opener includes parts and supplies needed to install in most garages and

connect to most garage doors. There are many variations of garages and garage

doors. A few additional parts and supplies may be needed to install Opener into

your garage and connect to your garage door. While checking items listed

below, note any additional items you will need.

• 12'+ Tape Measure ° Pencil ° Ladder ° Level

i

'\ b/

WARNING:

If your door sticks, binds, or is out of

balance, have it adjusted by a Genie Factory

Authorized Dealer. Door springs, cables,

pulleys, brackets and associated hardware

are under extreme tension and can cause

serious injury or death.

........<17.......

Check condition of vertical stile in center of door (Figure 2), and its connection

to door's top and bottom beams.

A If door frame is nailed together and not a solid connection, door frame

must be braced or reinforced before installing Opener.

B If door is"lightweight"(made with frame and skin - not solid), door

(including door frame) must be braced or reinforced before

installing Opener.

C A door opener reinforcement bracket may also be needed to connect

garage door to Opener's Door Bracket. This Opener is designed for

installation on a properly braced sectional door or solidly braced

one-piece door.

D Contact your Genie Factory Authorized Dealer or dealer of your garage

door for any necessary bracing and a door opener reinforcement

bracket (if needed) before proceeding.

E If you have a wooden door, measure door's thickness. (1/4" x 2") Lag

Screws are included for installing Door Bracket onto door. If your door

is less than 2"thick, brace door or use shorter Door Bracket Lag

Screws (1/4" x 1-1/4"- not included)

I;_L 6HP_ZH ] O I_iRAs]"lOF_l

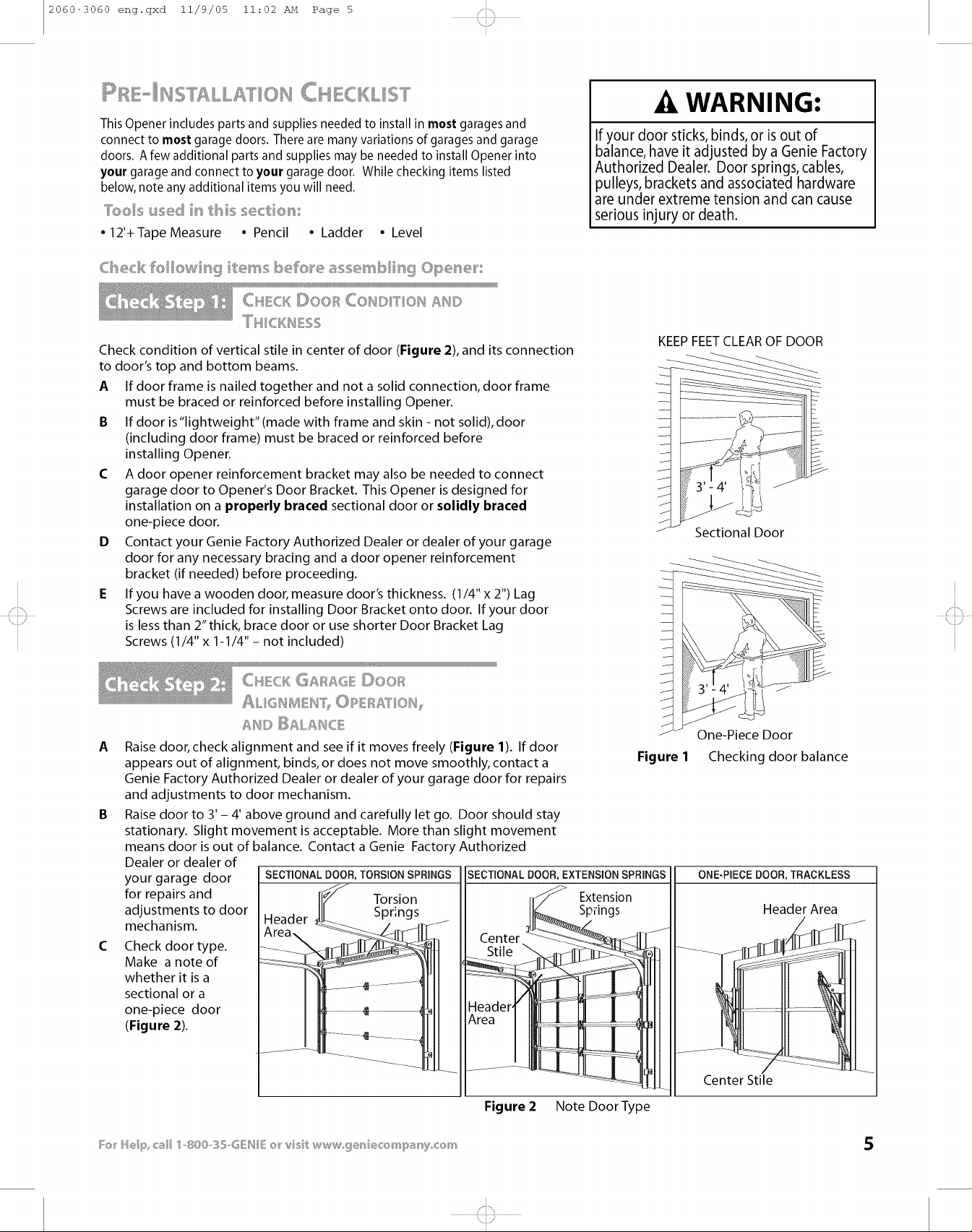

A Raisedoor, check alignment and see if it moves freely (Figure l). Ifdoor

appears out of alignment, binds, or does not move smoothly, contact a

Genie Factory Authorized Dealer or dealer of your garage door for repairs

and adjustments to door mechanism.

B Raise door to 3' - 4' above ground and carefully let go. Door should stay

stationary. Slight movement is acceptable. More than slight movement

means door is out of balance. Contact a Genie Factory Authorized

Dealer or dealer of

your garage door

for repairs and

adjustments to door

mechanism.

C

Check door type.

Make a note of

whether it is a

sectional or a

one-piece door

(Figure 2).

SECTIONALDOOR,TORSIONSPRINGS SECTIONALDOOR,EXTENSIONSPRINGS

Torsion Extension

Header Springs Springs

Center

Stile

KEEPFEETCLEAR OF DOOR

One-Piece Door

Figure 1

Checking door balance

ONE-PIECEDOOR,TRACKLESS

Header Area

........<17.......

Figure 2 Note Door Type

i

.........................L_IN ........................

i

Center Stile

5

2060-3060 eng.qxd 11/9/05 11:02 AM Page 6

........\ii7 .......

Measure garage door height (7'-6", 8'-0", or taller) with

tape measure.

A If door height is 7'-6" or less, continue with Check Step 4.

B If door height is8'-0", you need a Rail Extension

Kit. (Figure 3) (See Accessories Order Form, page 19).

C If door height is taller than 8'-O",you will require a different rail.

Contact an Genie Customer Service Representative at 1-800-

35-GENIE.

CH_iG DOO_ M_it%[;@H:{/_:E_

NOTE

The header isa heavily reinforced section of the wall just

above the top of the garage door opening.

ABFind vertical center line of door and header:

• Close door.

• Measure door width at top.

• Mark a point at center of door and on header directly

above door. Draw a center line to connect points.

Find Header Bracket mounting height (Figure 4):

(Do not attach Header Bracket).

• Raise door, watching top edge of door and stop door

when its edge reaches its highest point.

• Measure distance ("H") from top edge of door to floor.

- For sectional doors, add 2-1/2" to"H" Mark a point

on center line. Bottom of Header Bracket will be

installed here.

- For one-piece doors, add 6" to "H" Mark this point on

center line. Bottom of Header Bracket will be

installed here.

Rail Extension for

8' door

Figure 3 Rail Extension Kit

SECTIONAL DOOR

HEADER

H

........\ii7 .......

ONE-PIECE DOOR

NOTE

For both types of doors:

- Ifthe ceiling in your garage is so low that there is

not at least a 3" space above the Header Bracket

mountingpoint, contact a Genie Factory

AuthorizedDealer.

If a door spring is in the way, place the Header

Bracket above the spring. Do Not move the door spring.

WARNING:

Door springs are under extremely high tension and should be

handled ONLYby atrained professional.

C

Check wall for a stud or a solid header at your mark:

(If checking a finished wall, a stud finder may be helpful).

• If location is above Header, a 2"x 6" board must be

screwed to studs beside your mark with at least two Lag

Screws and Flat Washers (not provided).

• Transfer your mark to new mounting board.

6

H ÷ 6"

HEADER

Figure 4 Find Highest Point of Travel

.........................L_IN........................

2060-3060 eng.qxd 11/9/05 11:02 AM Page 7

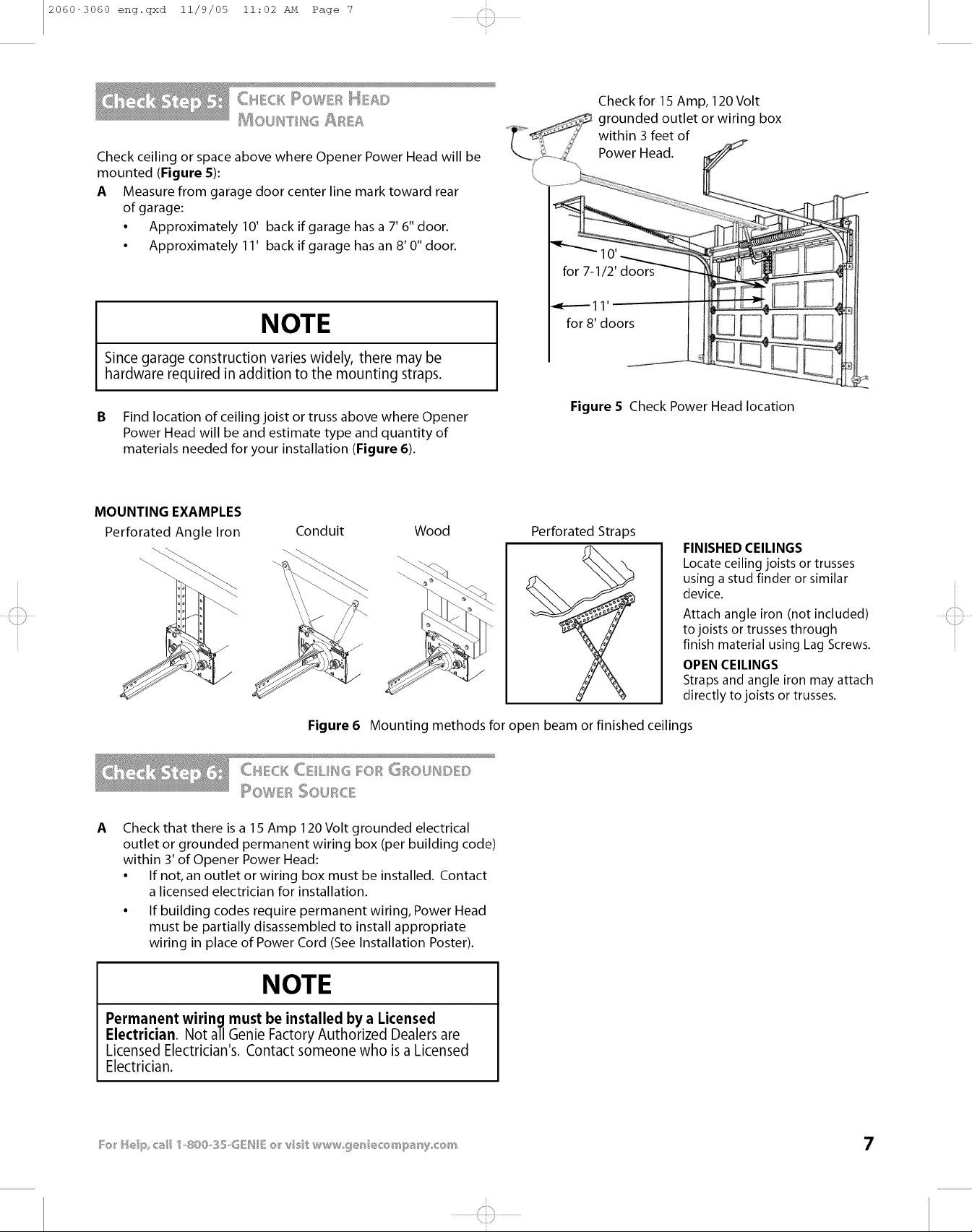

Check ceiling or space above where Opener Power Head will be

mounted (Figure S):

A Measure from garage door center line mark toward rear

of garage:

° Approximately 10' back if garage has a 7' 6" door.

° Approximately 11' back if garage has an 8' 0" door.

NOTE

Since garage construction varies widely, there may be

hardware required in addition to the mounting straps.

i

Check for 15 Amp, 120 Volt

......_ grounded outlet or wiring box

'\- S: . &£ Power Head. J

il V//

within 3 feet of

for 7-1/2'

.... :--T&:.........

.......;"" k]ii':

........\X7.......

B Find location of ceiling joist or truss above where Opener

Power Head will be and estimate type and quantity of

materials needed for your installation (Figure 6).

MOUNTING EXAMPLES

Perforated Angle Iron

A

Check that there is a 15 Amp 120 Volt grounded electrical

outlet or grounded permanent wiring box (per building code)

within 3' of Opener Power Head:

• If not, an outlet or wiring box must be installed. Contact

a licensed electrician for installation.

• If building codes require permanent wiring, Power Head

must be partially disassembled to install appropriate

wiring in place of Power Cord (See Installation Poster).

Conduit Wood

Figure 6 Mounting methods for open beam or finished ceilings

Figure S Check Power Head location

Perforated Straps

FINISHED CEILINGS

Locate ceiling joists or trusses

using a stud finder or similar

device.

Attach angle iron (not included

to joists or trusses through

finish material using Lag Screws.

OPEN CEILINGS

Straps and angle iron may attach

directly to joists or trusses.

........\X7.......

NOTE

Permanent wiring must be installed by a Licensed

Electrician. Not all Genie Factory Authorized Dealers are

Licensed Electrician's. Contact someone who is a Licensed

Electrician.

.........................':i ........................

7

i

2060-3060 eng.qxd 11/9/05 11:02 AM Page 8

(_HECH SAH> -BBJWv _'

MOL/;K_"BY5 [_;_,, ,RE L,OC£]"/OH

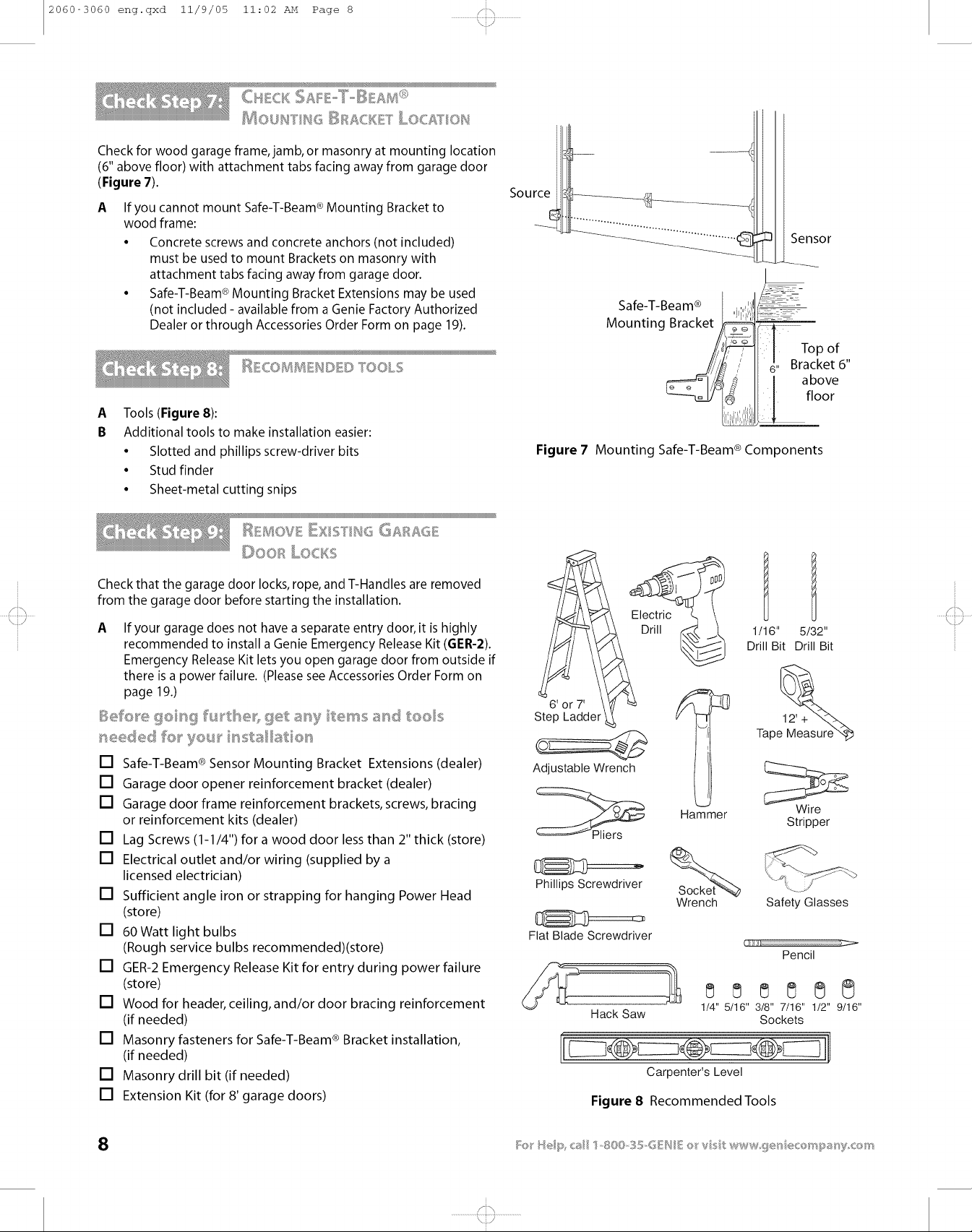

Check for wood garage frame, jamb, or masonry at mounting location

(6" above floor) with attachment tabs facing away from garage door

(Figure 7).

A

Ifyou cannot mount Safe-T-Beam® Mounting Bracket to

wood frame:

• Concrete screws and concrete anchors (not included)

must be used to mount Brackets on masonry with

attachment tabs facing away from garage door.

• Safe-T-Beam ®Mounting Bracket Extensions may be used

(not included - available from a Genie Factory Authorized

Dealer or through Accessories Order Form on page 19).

A

Tools (Figure 8):

B

Additional tools to make installation easier:

• Slotted and phillips screw-driver bits

° Stud finder

° Sheet-metal cutting snips

i

Source

Safe-T-Beam ®

Mounting Bracket

i _ilJi ' : ).z_-_

J 'hi

i ," II 6" Bracket6

6 Ill floor

_,q_!,J,L

Figure 7 Mounting Safe-T-Beam ® Components

Sensor

:2-_--1__-

i]l t = --;=±

To0o

II J above

........_]i17.......

Doo_<{Locls

Check that the garage door locks, rope, and T-Handles are removed

from the garage door before starting the installation.

Ifyour garage does not have a separate entry door, it is highly

recommended to install a Genie Emergency Release Kit (GER-2).

Emergency Release Kit lets you open garage door from outside if

there is a power failure. (Please see Accessories Order Form on

page 19.)

Befo_e 9ob_{F u_tBe_)get _y terns _'_d tools

_'_eeded fo_ you_

[] Safe-T-Beam ®Sensor Mounting Bracket Extensions (dealer)

[] Garage door opener reinforcement bracket (dealer)

[] Garage door frame reinforcement brackets, screws, bracing

or reinforcement kits (dealer)

[] Lag Screws (1-1/4") for a wood door less than 2" thick (store)

[] Electrical outlet and/or wiring (supplied by a

licensed electrician)

[] Sufficient angle iron or strapping for hanging Power Head

(store)

[] 60 Watt light bulbs

(Rough service bulbs recommended)(store)

[] GER-2 Emergency Release Kit for entry during power failure

(store)

[] Wood for header, ceiling, and/or door bracing reinforcement

(if needed)

[] Masonry fasteners for Safe-T-Beam ® Bracket installation,

(if needed)

[] Masonry drill bit (if needed)

[] Extension Kit (for 8' garage doors)

6' or 7'

Step Ladder

Adjustable Wrench

Phillips Screwdriver

Flat Blade Screwdriver

Hack Saw Sockets

Figure 8 Recommended Tools

Drill

Hammer Wire

Wrench

888888

1/4" 5/16" 8/8" 7/16" 1/2" 9/16"

Carpenter's Level

1/16" 5/32"

Drill Bit Drill Bit

Stripper

Safety Glasses

( I_/ I)1

Pencil

........q17.......

£]

8

i

.........................L_IN........................

2060-3060 eng.qxd 11/9/05 11:02 AM Page 9

i

_£1q _E A q%.,EAHD _E}LtUSTMEKI%

tCOICI 0", , ..... _"_=*

IIougB Setti_'_g of Lissit Swit_:cBes

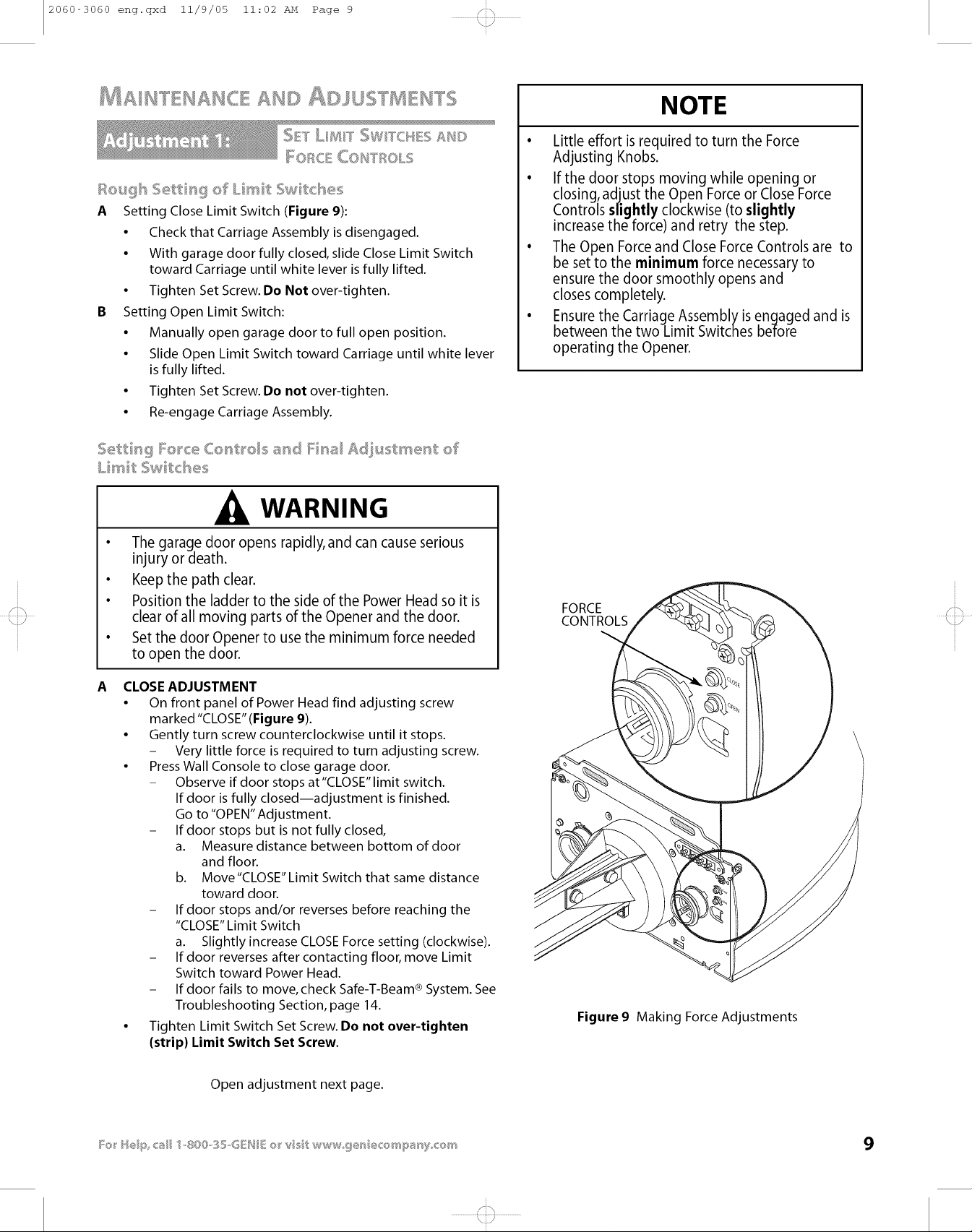

A Setting Close Limit Switch (Figure 9):

• Check that Carriage Assembly is disengaged.

• With garage door fully closed, slide Close Limit Switch

toward Carriage until white lever is fully lifted.

• Tighten Set Screw. Do Not over-tighten.

B Setting Open Limit Switch:

• Manually open garage door to full open position.

° Slide Open Limit Switch toward Carriage until white lever

is fully lifted.

• Tighten Set Screw. Do not over-tighten.

• Re-engage Carriage Assembly.

kis_it :s,4J c_e,s

WARNING

NOTE

o

Little effort is required to turn the Force

Adjusting Knobs.

• If the door stops moving while opening or

closing, adjust the Open Force or Close Force

Controls slightly clockwise (to slightly

increase the force) and retry the step.

• The Open Forceand Close Force Controls are to

be setto the minimum force necessary to

ensure the door smoothly opens and

closes completely.

• Ensure the Carriage Assembly isengaged and is

between the two Limit Switches before

operating the Opener.

/i%

........_i]17.......

• The garage door opens rapidly, and can cause serious

injury or death.

• Keepthe path clear.

• Position the ladder to the side of the Power Head so it is

clear of all moving parts of the Opener and the door.

• Set the door Opener to use the minimum force needed

to open the door.

A CLOSE ADJUSTMENT

• On front panel of Power Head find adjusting screw

marked "CLOSE" (Figure 9).

• Gently turn screw counterclockwise until it stops.

- Very little force is required to turn adjusting screw.

• Press Wall Console to close garage door.

- Observe if door stops at"CLOSE" limit switch.

If door is fully closed--adjustment is finished.

Go to "OPEN" Adjustment.

- If door stops but is not fully closed,

a. Measure distance between bottom of door

and floor.

b. Move "CLOSE" Limit Switch that same distance

toward door.

- If door stops and/or reverses before reaching the

"CLOSE" Limit Switch

a. Slightly increase CLOSE Force setting (clockwise).

- If door reverses after contacting floor, move Limit

Switch toward Power Head.

- If door fails to move, check Safe-T-Beam ®System. See

Troubleshooting Section, page 14.

• Tighten Limit Switch Set Screw. Do not over-tighten

(strip) Limit Switch Set Screw.

FORCE

CONTROLS

Figure 9 Making Force Adjustments

,/i'%

........\117.......

Open adjustment next page.

9

i

.........................L_IN ........................

........ki17.......

2060-3060 eng.qxd 11/9/05 11:02 AM Page 10

WARNING

• A moving grage door can cause serious injury or death.

• Keepthe path clear.

• Position the ladder to the side of the Power Head so it is

clear of all moving parts of the Opener and the door.

• Set the door Opener to use the minimum force needed

to open the door.

B OPEN ADJUSTMENT

• On front panel of Power Head find adjusting screw

marked "OPEN" (Figure 9).

• Gently turn screw counterclockwise until it stops.

- Very little force is required to turn adjusting screw.

• Press Wall Console to close garage door.

- Observe if door stops at"OPEN" limit switch.

If door is fully open--adjustment is finished.

- If door stops but is not fuly open,

a. Measure distance between bottom of door

top of door opening.

b. Move "OPEN" Limit Switch that same distance

toward Power Head.

- If door stops before reaching the"OPEN" Limit Switch

a. Slightly increase OPEN Force setting (clockwise).

- If door fails to move, see Troubleshooting Section,

pages 15.

C Run Door Opener

• Cycle opener a few times to double check settings.

Repeat adjustment steps as necessary.

i

'\ b/

........ki17.......

SITTIH6 <CI _U'_+{°"__= Jl.= &_=

I,_IVIB,sI I<iIIHCTlOH

NOTE

Limit Switch and Force Adjustments must be completed

before checking the contact reverse function (Figure 10 ).

A Open garage door using Wall Console.

B Lay a 2" x 4" board flat in center of doorway.

C Close door using Wall Console.

D Check that door stops and reverses within 2 seconds after it

contacts board:

• If door does not reverse, decrease Close Force until

door reverses.

• If door still does not reverse, move Limit Switch

toward door.

E Check Safe-T-Beam ® System operation:

• If beam is blocked, door will not close.

NOTE

Thedoor mustcontact the 2" x 4" board beforethe Carriageactivates

the CloseLimit Switch. If not,readjustthe CloseLimit Switch.

2" x 4" board

laid flat

Figure 10 Checking Contact Reverse

10

i

.........................L<IN........................

2060-3060 eng.qxd 11/9/05 11:02 AM Page 11

'\ 1./

........_:]:7.......

}"E

NOTE

EachRemote Control must be programmed

separately.

• The Remote Controls will not cause the door

Opener to close the garage door if the Safe-T-

Beam®System is malfunctioning.

• When programming the Remote Controls, they

must be at least 24" from the Antenna Wire.

• Ifthe red Learn Indicator Light blinks

approximately 4 times per second,

programming has stopped. If programming

has stopped, repeat the above steps.

• EachButton on a 2 or 3 Button Remote Control

isfor a different Opener. You cannot use more

than one Button per Remote, per Opener.

• A maximum of seven Remote Controls or

Wireless Keypads can be stored into the

Receiver at one time. Ifa Remote Control

becomes lost, or if you want to delete a Remote

Control or Wireless Keypad, see"To EraseAll

Receiver Memory."

A To program one Button of a Remote Control (Figure 12):

• Locate Learn Button and Learn Indicator Light near

Terminal Strip on Power Head (Figure 13).

• Press and release Learn Button. Red Learn Indicator

Light will blink 2 times per second.

• Press Remote Control Button once within 30

seconds. Red Learn Indicator Light will stay lit.

• Press Remote Control Button again. Red Learn

Indicator Light will go out, indicating that

memory is stored.

B Program each additional Remote using step A above

(up to seven).

7b

E%ase All _es_etes f_os_ Pewe_ Mead _{e_"_'_e_y

A

Press and hold Learn Button on Power Head for 10

seconds or until Learn Indicator Light goes out.

Memory is erased:

• Program Transmitter/Receiver again as needed.

To _eplace _Res_ete Co_d_'ol Ba e_y'

A FOR NON-FLASHLIGHTMODELS

• Pop off the back of the transmitter.

- Use coin, pen, screwdriver or any similar device.

- Replace old Battery with new coin type battery.

• Replace back of remote.

B FOR FLASHLIGHT MODELS

• Slide open battery cover.

- Replace old Battery with new AAA battery.

• Replace battery cover.

WARNING

A moving garage door may causeserious injury or death.

• Keeppeople clear of opening while door is moving.

• Do not allow children to play with the Remote Controls.

If the Safety Reversedoes not work properly:

• Close the door and disconnect the Opener using the

Emergency ReleaseCord.

• Do not usethe door Opener,Remote Controls, or

Wireless Keypad.

• Referto the door and door Opener Owner's Manuals

before attempting any repairs.

[Ies_ote Co_ _01 Opera io_

A Press Button on Remote Control. Garage door will move.

B Press Button again. Garage door will stop:

• The door automatically stops at the end of the open or

close cycle.

C Press Button again. Garage door will reverse.

315 Mhz _-f_-_'-_ _ 315 Mhz

__ Switch _ Switch

Frequency _I Frequency

1 Button Compact Remote 3 Button Compact Remote

w/Docking Station w/Docking Station

Figure 12 Genie Remote Controls

Receiver Learn

Code Button

Receiver

Figure 13 Learn Code Button and Indicator Light

D Some Remote Controls are equipped with a flashlight.The

logo is the button which operates the light. There is a

backlight under the button.When it does not light, it

indicates the battery needs replaced.

Flashlight Button Switch

J

\\ /'

1 Button Remote 3 Button Remote 3 Button Large

w/Flashlight w/Flashlight Remote

Figure 14 Genie Remote Controls

390 Mhz

,2 S_ i

Frequency

w/Flashlight

........\::7 .......

11

,f] "_

.........................L_:N ........................

2060-3060 eng.qxd 11/9/05 11:02 AM Page 12

Your garage door opener (GDO) features a unique

dual frequency remote control system for reliable

service in today's crowded airwaves. Overcrowded

airwaves may intermittently interfere with GDO's

remote control system. The dual frequency feature

greatly reduces the possibility of unwanted

interference.

The receiver in the GDO's powerhead can receive

signals at 315 AND 390 MHz.The remote isfactory

set at 315 MHz. See Figure 12 on page 11 for

frequency selector switch.

Switch your remote control frequency when:

• Remote does not have adequate range.

• Remote works inconsistently with fresh battery

installed - LEDfeedback lights up when pressing

button.

• Programming your car's HomeLink ® system.

Toprogram a HomeLink ®device:

(This GDO is HomeLink ®compatible.)

• Use a small flat screwdriver to switch the

frequency selector to 390 MHz.

• Follow the HomeLink ® instructions in your car

owner's manual.

• Reset the remote control frequency to 315 MHz for

everyday use.

'\ b/

/

Transmitters comply with all United Statesand Canadian legal requirements

as of the date of manufacture. No warranty is made that they comply with all

legal requirements of any other jurisdiction. If transmitters are to be used in

another country, the importer must determine compliance with any local

laws and regulations which may differ from United Statesand Canadian

requirements prior to use,

Lostransmisores cumplen contodas las reglamentaciones Jegalesde los

Estados Unidos ydel Canadfi, en la fecha de fabficaci6n. Ninguna garantia

se da que cumplan con todas asreglamentaciones legales de ninguna otra

jurisdicci6n+ Si los transmisores se van a utilizar en otto pais, el importador

debe determinar si cumplen con las reglamentaciones y leyes locales que

puedan serdiferentes a las reglamentaciones de los Estados Unidos y del

Canad4, antes de usar los mismos+

Les_metteurs sont conformes _ la r_glementation am@icaine et canadienne

compter de bur date de fabrication. Aucune garantie n'est stipuJ_e

indiquant qu'ils sont conformes _ routes les prescriptions juridiques d'autres

autorit_s. Siles@metteurssont utilis@sdans d'autres pays,il incombe

I'importateur d'en d_terminer leur conformit_ aux lois et r@gleslocales

pouvant diff@rerde celles des t_tats-Uniset du Canada avant toute

utilisation desdits @metteurs+

Sendeger_te entsprechen allen gesetzlichen Bestimmungen inden USA und

Kanada zum Zeitpunkt der Herstellung.Wir Obernehmen keine

Gew_ihrleistung for die Einhaltung aller gesetzlichen Bestimmungen in

anderen L_indern. Sollen Sendeger_ite in anderen L_ndern eingesetzt werden,

so muss der Importeur vor dem Gebrauch sicherstellen, dass die Sendegerate

auch solchen Iokalen Bestimmungen entsprechen, welche von den

Bestimmungen der USAund Kanadas abweichen+

........_i]17.......

tH _LLL/6HT_ULB akan+LEHS

Installtwo 60Watt lightbulbs(notincluded)into LightSockets

(Figure13):

• Roughservice,130Voltbulbsarerecommended.

Holdthe lens,with the bottom hingespointingup,againstthepower

headmetalfront cover(Figure14).

• Insert(2)#8-32x3/8"PhillipsHexHeadScrewsthrough the Bottom

hingesandinto holesprovidedin metalfrontcoverof PowerHead

(Figure14).Tightenscrews.

• FlipLensup andfastenwith (2)#8-32x 3/8"PhillipsPanHeadScrews

whereindicated.

........_i]17.......

12

Figure 13 Install Lightbulbs Figure 14 Attach Lens

........................._<i........................

Loading...

Loading...