Page 1

Operator’s Manual

GTH-844

GTH-842

GTH-644

with

Maintenance

Information

First Edition

Second Printing

Part No. 114100

Page 2

TABLE OF CONTENTS

SECTION 1 ROUGH TERRAIN FORK LIFT SAFETY SECTION 1-1

Introduction 1-3

Standards And Symbols 1-4

Safety 1-5

Training And Knowledge 1-5

Operator's Responsibilities 1-6

Management's Responsibilities 1-7

Maintenance And Repair 1-8

Operation Safety 1-9

SECTION 2 GENERAL SAFETY 2-1

General Safety Procedures 2-3

Jump Starting 2-8

Proper Load Chart Use 2-9

SECTION 3 CONTROLS AND INSTRUMENTS 3-1

Operator's Compartment 3-3

Joystick Control Functions 3-4

Joystick Control Functions (Button Pushed) 3-5

Service Brakes 3-6

Low Service Brake Pressure Light 3-6

Parking Brake 3-7

Frame Sway Control 3-8

Gauges 3-9

Hydraulic Pump DestrokeButton 3-9

Steering 3-10

Transmission 3-10

Front Axle Differential Lock 3-11

SECTION 4 OPERATION 4-1

Operation And Safety Guidelines 4-3

Before Starting The Engine 4-4

Starting The Engine 4-5

Before Operating The Forklift 4-7

T ransporting A Load 4-11

Placing A Load 4-13

SECTION 5 MAINTENANCE PROCEDURES 5-1

General Safety Practices 5-3

Daily Maintenance 5-5

SECTION 6 MATERIAL SAFETY DA T A 6-1

Material Safety Data Sheets 6-3

California Proposition 65 W arnings 6-4

Page 3

SECTION 1

ROUGH TERRAIN

FORK LIFT SAFETY

1 - 1

Page 4

T ABLE OF CONTENTS

SECTION 1 - ROUGH TERRAIN FORK LIFT SAFETY

Introduction 1-3

Standards And Symbols 1-4

Safety 1-5

Training And Knowledge 1-5

Operator's Responsibilities 1-6

Management's Responsibilities 1-7

Maintenance And Repair 1-8

Operation Safety 1-9

1 - 2

Page 5

ROUGH TERRAIN FORK LIFT SAFETY

INTRODUCTION

Owners, Users, and Operators:

Genie appreciates your choice of our machine for your application. Our number one

priority is user safety , which is best achieved by our joint efforts. W e feel that you make a

major contribution to safety if you, as the equipment users and operators:

1. Comply with OSHA, Federal, State, and Local Regulations.

2. Read, Understand, and Follow the instructions in this and other manuals

supplied with this machine.

3. Use Good Safe W ork Practices in a common sense way .

4. Only have trained/certified operators – directed by informed and

knowledgeable supervision – running the machine.

NOTE: OSHA prohibits the alteration or modification of this machine without written

manufacturer's approval. Use only factory approved parts to service or repair this

machine.

If there is anything in this manual that is not clear or which you believe should be added,

please contact us.

Internet: www .genieind.com

Email: techpub@genieind.com

Thank you!

THIS SYMBOL MEANS YOUR SAFETY IS

INVOLVED! READ, UNDERSTAND AND

FOLLOW ALL DANGER, WARNING AND

CAUTION DECALS ON YOUR ROUGH TERRAIN

FORKLIFT.

1 - 3

Page 6

ROUGH TERRAIN FORK LIFT SAFETY

STANDARDS

SYMBOLS

STANDARDS AND SYMBOLS

Many aspects of rough terrain forklift operation and testing are discussed in standards

published by the American National Standards Institute. These Standards are updated on

a regular basis with addendas. Genie recommends that you purchase and refer to the

following standards.

ANSI B56.6 – Rough T errain Fork Lifts

This Standard can be purchased from:

American National Standards Institute

25 W est 43nd Street, 4th Fl.

New Y ork, New Y ork, 10036

T el. 212.642.4900

Fax. 212.398.0023

The symbols below are used to inform the operator of important information concerning

the operation of this machine.

DANGER – Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury .

W ARNING – Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury .

CAUTION – Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury .

A TTENTION – Indicates a situation which, if not avoided,

may result in property or equipment damage.

1 - 4

Page 7

ROUGH TERRAIN FORK LIFT SAFETY

SAFETY

These are general safety rules, which must be followed. You are also required to read

and understand the Operator's Manual as there are instructions, which are more

detailed specific to this machine.

TRAINING AND KNOWLEDGE

1. Safety must always be the operator's most important concern.

2. This machine must only be operated by trained personnel, who have demonstrated

their ability to do so safely .

3. Comply with the requirements of current Occupational Safety and Health

Administration (OSHA) standards, including 29CFR1910.178; and the American

National Standards Institute (ANSI) B56.6 latest edition.

4. Read and Understand all Decals and W arnings.

5. Read and Understand the Rating Chart.

6. Know that the machine can safety lift each load before attempting to lift.

1 - 5

Page 8

ROUGH TERRAIN FORK LIFT SAFETY

OPERATOR'S RESPONSIBILITIES

1. Read and understand the Operator’s Manual.

2. Know the location and the purpose of the controls, instruments and indicator

lights.

3. Make sure the machine is in proper order and all operational aids and warning

signals are functional before operating.

4. Keep the machine clean, including all instrumentation, windows, lights and other

glazed surfaces.

5. Use protective clothing and safety equipment. Always use approved safety

equipment such as: gloves, safety boots, hard hats, safety glasses and ear

protection where necessary .

6. W ear protective clothing that is snug and belted where required.

7. Store tools and other necessary items in the toolbox.

8. Never lift a load without a Load Rating Chart in the cab.

9. Know the load to be lifted.

10. Be alert, physically fit and free from the influences of alcohol, drugs or

medications that might affect the operator’s eyesight, hearing, or reactions.

11. Keep people, equipment and material out of the work area.

12. Keep a fully charged fire extinguisher and first aid kit in the cab at all times, and

be familiar with how to use these items.

13. Know about movements of other machinery , trucks and personnel at the jobsite.

14. Make sure everyone is in a safe place before moving the boom, forks, load or

outriggers (if so equipped.)

15. Start and stop movements smoothly and swing at speeds that will keep the load

under control.

1 - 6

Page 9

ROUGH TERRAIN FORK LIFT SAFETY

MANAGEMENT'S RESPONSIBILITIES

1. Ensure operators are competent, physically fit, trained and if required licensed.

2. Have a supervisor at the job site to be responsible for job safety .

3. Crew members given specific safety responsibilities and instructed to report any

unsafe conditions to the supervisor.

4. Supply the weight on the load to be lifted to the operator .

5. V erify that all crewmembers are familiar with OSHA, ANSI B56.6 requirements

as well as instructions in the manuals.

1 - 7

Page 10

ROUGH TERRAIN FORK LIFT SAFETY

MAINTENANCE AND REPAIR

1. Practice safe maintenance procedures. Perform all maintenance and repairs in

accordance with instructions provided by the manufacturer in the manuals. Also

heed the warnings on the placards and decals on the machine.

2. Always use supports and braces when working on, under or around the machine

or forks.

3. Shut off the engine and lockout the machine while working on the machine unless

instructions specifically require the engine to be running.

4. Always make sure the machine is stationary prior to performing adjustments or

lubrication.

5. Replace all shields and guards after performing service.

6. Always use a piece of cardboard or paper to search for leaks.

7. When performing work on the hydraulic system:

i . Lower the boom to horizontal.

i i . Support the boom with supports or braces.

iii. Shut down the engine.

iv. Relieve all pressure before disconnecting lines.

v . Ensure all connections are tight before applying pressure.

v i. Repair or replace any damaged line, hose or fitting before

applying pressure.

8. Always have tires serviced and mounted by a qualified person with the proper

tools and guards.

9. Always use an inflation cage during tire inflation.

10. Only perform welding on the machine with approval from the manufacturer.

1 - 8

Page 11

ROUGH TERRAIN FORK LIFT SAFETY

OPERATION SAFETY

1. Always inspect the machine daily . Check for leaks, worn hoses, loose belts,

broken structures, and loose or missing bolts. Repair or replace any worn,

damaged or leaking parts prior to operation of the machine.

2. Only inspect the coolant level when the engine and coolant are cool.

3. Be sure that all guards and screens are secure and in the proper place.

4. Inspect for and clear the work area of any obstructions that could interfere with

proper machine operation. Any obstructions that cannot be cleared should be

clearly marked and avoided during operation.

5. Refueling:

i . Always stop the engine before refueling the machine.

i i . Fill the fuel tank outdoors.

iii. Handle fuel with care, as it is highly flammable. Do not refuel

the machine while smoking or near open flames.

iv. Always clean up spilled fuel.

6. Make sure the machine and access system is clean and free of dirt, oil, grease or

debris.

7. When getting on and off the machine, face the machine, use the steps and

handrails provided, and always maintain a three point contact.

8. Always remain completely inside the cab enclosure while operating the machine.

9. Always wear the seat belt while operating the machine.

10. Always completely lower the boom with the forks resting on the ground before

any work is performed on or around the machine.

11. Do not operate the machine while people are under or near an elevated boom

whether the boom is loaded or unloaded. Falling objects from the forks or

attachment may cause serious injury or death.

1 - 9

Page 12

ROUGH TERRAIN FORK LIFT SAFETY

OPERATION SAFETY

12. Maintain an appropriate clearance from electrical power lines. See the chart

below for minimum safe approach distances.

ecnatsiDhcaorppAefaSmuminiM

egatloVeniLrewoPecnaraelCderiuqeR

Vk05ot0)m00.3(.tf01

Vk002ot05)m06.4(.tf51

Vk053ot002)m01.6(.tf02

Vk005ot053)m26.7(.tf52

Vk057ot005)m76.01(.tf53

Vk0001ot057)m27.31(.tf54

13. Lifting Loads:

i . Using the load chart, confirm that the load is within the rated

capacity of the machine for the required configuration.

i i. Level the machine using the level gauge before lifting loads. Use

the sway control to level the machine only when the boom is at

horizontal or lower . Using the sway control with the boom above

horizontal may cause the machine to overturn.

iii. Verify that the load is secured on the forks before performing a lift.

Rearrange the load if necessary .

i v . Before lowering a maximum load, always retract the boom

completely .

v . Use proper attachments, such as a truss boom, to lift suspended

loads.

14. If the load to be lifted exceeds the capacity of the machine for the given

configuration:

i . Move the machine closer to the load so that the weight of the load

will be within the allowable load chart specifications.

i i. Divide the load into smaller pieces.

iii. Get a larger machine capable of handling the load.

15. Always move a load so that you have maximum machine stability and visibility is

not obstructed. Keep the boom at or below horizontal, with the load close to the

ground.

16. Tilt the forks back towards the machine slightly during travel to ensure stability of

the load.

1 - 10

Page 13

ROUGH TERRAIN FORK LIFT SAFETY

OPERATION SAFETY

17. Inspect the path of travel before beginning movement. A void holes and dropoffs.

18. Traveling on slopes/grades.

i . Ascend and descend slowly and with caution.

i i . When loaded, always travel with the load uphill.

iii. When unloaded,travel with the attachment downhill.

iv. A void turning, travel straight up and down.

19. Always position all wheels in line with the machine before switching the steering

mode.

20. Always position the machine and set the park brake before lifting a load.

21. Do not allow riders on the machine or forks.

22. Do not transport or lift personnel into position with this forklift.

23. When leaving the operator's station:

i . Place the directional controls in neutral.

i i . Apply the parking brake.

iii. Lower the attachment to the ground.

1 - 11

Page 14

ROUGH TERRAIN FORK LIFT SAFETY

NOTES

1 - 12

Page 15

SECTION 2

GENERAL SAFETY

2 - 1

Page 16

T ABLE OF CONTENTS

SECTION 2 - GENERAL SAFETY

General Safety Procedures 2-3

Jump Starting 2-8

Proper Load Chart Use 2-9

2 - 2

Page 17

GENERAL SAFETY

GENERAL SAFETY PROCEDURES

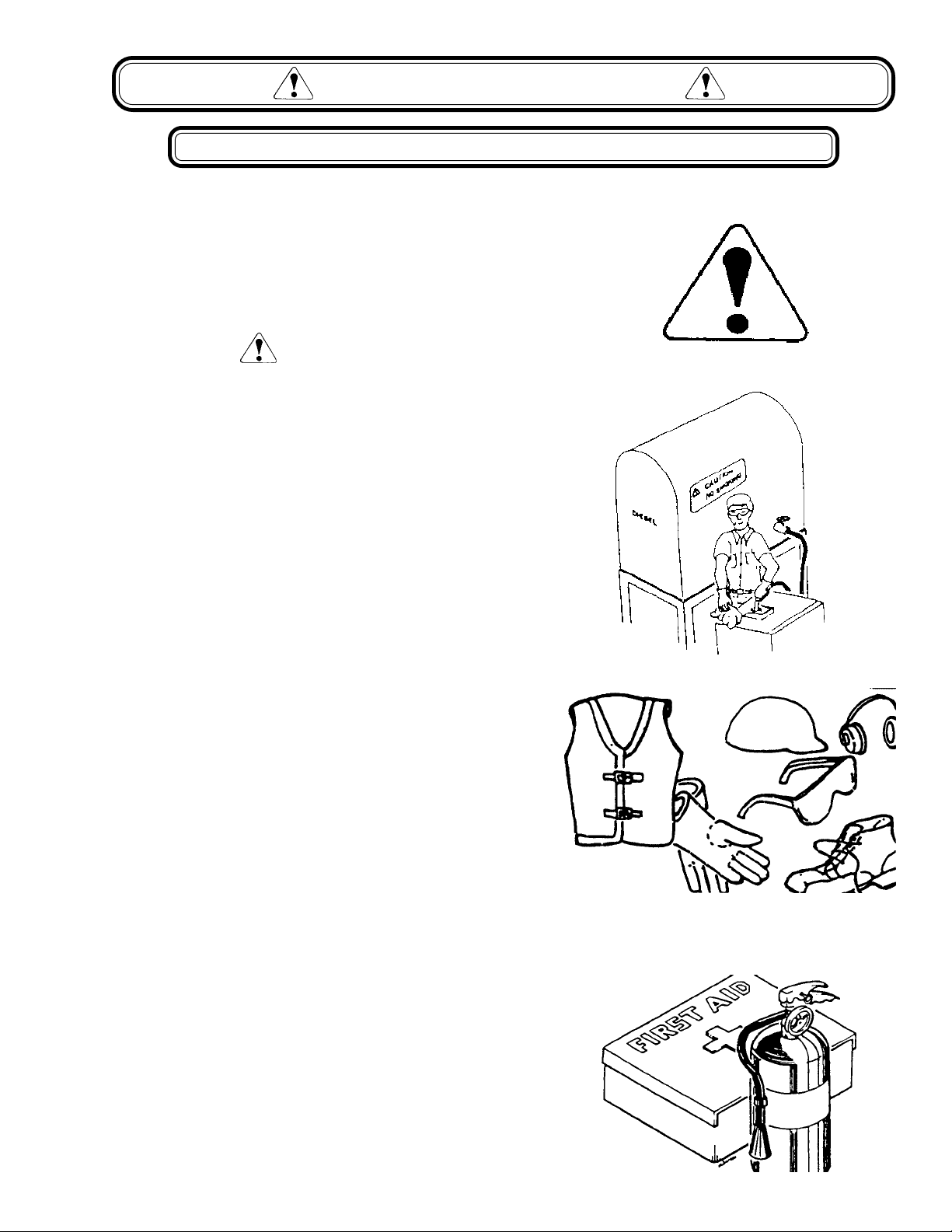

SAFETY ALERT SYMBOL

Stop and take time to read ALL safety alert messages. Follow

all safety messages to avoid injury and/or death.

WARNING

ALWAYS wear eye protection and personal safety equipment.

THE OPERATOR

The operator must be fully trained and qualified to operate this

machine.

Before start-up or machine operation, the operator must learn

the location and purpose of the:

1. Controls

2. Instruments

3 . Indicator lights

4. Safety and instruction labels

ACCIDENT PREVENTION

Use protective clothing and safety equipment. Always use

approved safety equipment such as: gloves, safety boots,

safety hard hats, goggles and ear protection when necessary.

Wear protective clothing that is snug and belted where

required.

FIRE PREVENTION/FIRST AID

Install a first-aid kit and fire extinguisher in the operator's cab.

KEEP THE FIRST-AID KIT and FIRE EXTINGUISHER

properly maintained. Follow the instructions provided with the

first-aid kit and fire extinguisher.

2 - 3

Page 18

GENERAL SAFETY

GENERAL SAFETY PROCEDURES

WELDING PRECAUTIONS

CAUTION

Any unauthorized welding can cause structural failure or

possible personal injury . DO NOT weld on any structural

member. All unauthorized welding will void the warranty .

HAND HOLDS AND STEPS

WARNING

Slips and falls can cause serious injury .

When getting on and off the machine, always maintain a three

point contact with steps and hand rails while facing the machine.

DO NOT use the steering wheel or any other controls as handrails.

NEVER jump on or off the machine.

Be careful of slippery conditions on platforms, steps and

handrails when getting on and off the machine.

ALWAYS shut off the engine before leaving the operator's station.

REFUELING

WARNING

Fires can cause death or severe personal injury.

Handle fuel with care. It is highly flammable. DO NOT refuel the

machine while smoking or when near open flames or sparks.

ALWAYS stop the engine before refueling the machine. Fill the

fuel tank outdoors.

Prevent fires by keeping the machine clean of trash, grease and

debris. AL WA YS clean up spilled fuel.

2 - 4

Page 19

GENERAL SAFETY

GENERAL SAFETY PROCEDURES

HYDRAULIC SAFETY

WARNING

Hot hydraulic oil can cause severe burns. DO NOT work on

the hydraulic system if the oil temperature exceeds

120 degrees F . (49 degrees C).

Before ANYONE works on the hydraulic system:

1 . Lower the boom to the horizontal position.

2 . Support the boom to avoid unintentional lowering.

3. Shutdown the engine.

4 . Remove the key from the ignition.

5 . Clean the area around the oil reservoir cap (A).

FLUIDS UNDER PRESSURE

WARNING

Escaping fluid under pressure can penetrate the skin and can

cause serious personal injury.

Use a piece of cardboard or paper to search for leaks.

DO NOT use hands. Before disconnecting hydraulic lines, be

sure to relieve all line pressure. Before applying pressure to the

system, be sure that all connections are tight. DO NOT apply

pressure to a damaged line, hose or fitting.

If injured by escaping fluid, see a doctor at once. Proper

medical treatment must be administered immediately . A serious

infection or reaction can result without proper medical

treatment.

A

SERVICE TIRES SAFELY

WARNING

An improperly mounted over-pressurized tire can result in tire

explosion causing possible personal injury. An inflation cage

or other safety device must be used during tire inflation.

DO NOT attempt to mount a tire unless you have the proper

equipment and experience to perform the job. If you do not

have the proper qualifications to perform the job have your

dealer or qualified repair service perform the repair.

2 - 5

Page 20

GENERAL SAFETY

GENERAL SAFETY PROCEDURES

CAUTION

USE SEAT BEL T

Always wear the seat belt while operating the machine to

reduce the risk of personal injury.

CAUTION

PRACTICE SAFE MAINTENANCE

Unauthorized modifications to the machine may impair the

safety, machine function and/or af fect machine life.

ALWAYS use a safety support or brace when working on,

under, or around the machine or forks.

DO NOT adjust or lubricate the machine while it is in motion.

SHUT OFF the engine and LOCKOUT the ignition while

working on the machine unless maintenance instructions

require the engine to be running.

REPLACE all the shields and guards after servicing.

NEVER use the machine as a platform for lifting personnel.

CAUTION

BOOM SAFETY

DO NOT enter the DANGER AREA under or around the boom

when the forks are off the ground or while the engine is running.

(See diagram at right for DANGER AREA) .

Serious personal injury could result if the boom should

unexpectedly drop.

Before ANY work is performed in the DANGER AREA

the boom must be COMPLETEL Y lowered and the forks

must be resting on the ground.

2 - 6

DANGER

'$1* (5

Page 21

GENERAL SAFETY

7

7

7

7

GENERAL SAFETY PROCEDURES

AVOID ELECTRICAL POWER LINES

DANGER

REQUIRED CLEARANCE FOR NORMAL VOLTAGE IN

OPERA TION NEAR HIGH VOL T AGE POWER LINES AND

OPERA TION IN TRANSIT WITH NO LOAD AND BOOM

OR MAST LOWERED.

Normal Voltage, kV Minimum Required

(Phase to Phase) Clearance, ft. (m)

Operation Near High V oltage Power Lines

to 50 10 (3.05)

Over 50 to 200 15 (4.60)

Over 200 to 350 20 (6.10)

Over 350 to 500 25 (7.62)

Over 500 to 750 35 (10.67)

Over 750 to 1000 45 (13.72)

Operation in Transit W ith No Load and Boom Lowered

to 0.75 4 (1.22)

Over 0.75 to 50 6 ((1.83)

Over 50 to 345 10 (3.05)

Over 345 to 750 16 (4.87)

Over 750 to 1000 20 (6.10)

WARNING

Always remain completely inside the cab enclosure while

operating the machine.

WARNING

Never operate this machine under the influence of drugs,

alcohol and/or medication which can cause drowsiness.

WARNING

Never transport or lift personnel into position with this

forklift. It is not designed as a personnel lifting device.

23456

23456

23456

23456

2 - 7

Page 22

GENERAL SAFETY

JUMP STARTING

Location: The battery is located under the fuel tank / battery

box cover (A).

JUMP STARTING

Jump starting at the battery or battery replacement is required

when the battery is discharged to the point where the battery

will not crank the starter.

WARNING

Battery posts, terminals, and related accessories contain lead

and lead compounds, chemicals known to the State of California

to cause cancer and reproductive harm.

Batteries also contain other chemicals known to the State of

California to cause cancer.

A

Wash hands after handling.

WARNING

Never jump start the machine directly to the starter or the starter

solenoid. Serious injury or death could result from the machine

moving forward or backward.

WARNING

T o avoid personal injury when jump starting with another

machine, be certain that the machines are not touching. Never

jump start a frozen battery as it will explode. Keep sparks and

flames away from the battery. Lead acid batteries generate

explosive gases when charging. Wear safety glasses when

working near batteries.

The booster battery must be a 12 volt type. The machine used

for jump starting must have a negative ground electrical system.

T o jump start the machine, proceed as follows:

1 . Connect the positive (+) jumper cable to the positive

(+) post of the discharged battery.

2. Connect the other end of the same jumper cable to the

positive (+) post of the booster battery.

3. Connect one end of the second jumper cable to the

negative (-) post of the booster battery.

4 . Make the final cable connection to the engine block or

the furthest ground point away from the battery.

5. Start the engine.

6 . Remove the jumper cables in the reverse order of their

connection (i.e. negative cable ground connection first, etc.)

2 - 8

Page 23

GENERAL SAFETY

PROPER LOAD CHART USE

WARNING

NEVER raise a load and drive to position it. This can cause the

machine to turnover. When placing a load, always move a

loaded machine with the boom angle indicator (B) at 0 degrees

or less. When the machine is as close as possible to where the

load needs to be placed, set the parking brake, raise the load,

then place the load into position.

B

The load chart shows the operating limits of a properly

maintained and operated machine. To use the load chart the

operator must know the weight of the load and how far "out"

and "up" it is to be placed. If the load is heavier than stated on

the load chart, three options can be used:

1. Move the machine closer to the load so that the weight of

the load will fall within the load chart specifications.

2 . Divide the load into smaller pieces so that each piece falls

into load chart specifications.

3. Get a larger machine capable of handling the load within

specifications.

2 - 9

Page 24

GENERAL SAFETY

PROPER LOAD CHART USE

PO Box 97030

18340 NE 76th St

Redmon d WA 9807 3

Manufacturer's rec ommended

capacity is per ANSI B56.6

Stability Tests using standard

homogeneous cu bes 4 x 4 x 4 f t /

1.2 x 1.2 x 1.2 m.

Load capacities at 24 in / 60 cm

load center with standard fork

frame.

Rated lift capacities shown are

with machine on a firm level

surface wi th undamaged, properly

inflated calcium chloride solution

filled tires or optional foam filled

tires. Rear ax l e lock-up en gaged.

Load Limits / Horizontal Boom

Last Fully Visible Letter

Retrac te d 6000 lb s

A Letter Vi si b l e 4000 lbs

B Letter Vi si b l e 3000 lbs

C Letter Visible 2000 lbs

2 - 10

Page 25

GENERAL SAFETY

PROPER LOAD CHART USE

PO Box 97030

18340 NE 76th St

Redmon d WA 980 7 3

Manufactu re r's r ecom men ded

capacity is per ANSI B56.6

Stability Tests using standard

homogeneous cu bes 4 x 4 x 4 f t /

1.2 x 1.2 x 1.2 m.

Load capacities at 24 in / 60 cm

load center with standard fork

frame.

Rated lift capacities shown are

with machine on a firm level

surface with undamaged, properly

inflated calcium chloride solution

filled tires or optional foam filled

tires. Rear axle lock-up engaged.

Load Limits / Ho rizontal Boom

Last Fully Visible Letter

Retrac te d 8000 lb s

A Letter Vi si b l e 6000 lb s

B Letter Vi si b l e 4000 lb s

C Letter Visible 3000 lbs

D Letter Visible 2000 lbs

114071 A

2 - 11

Page 26

GENERAL SAFETY

NOTES

2 - 12

Page 27

SECTION 3

CONTROLS AND INSTRUMENTS

3 - 1

Page 28

T ABLE OF CONTENTS

SECTION 3 - CONTROLS AND INSTRUMENTS

Operator's Compartment 3-3

Joystick Control Functions 3-4

Joystick Control Functions (Button Pushed) 3-5

Service Brakes 3-6

Low Service Brake Pressure Light 3-6

Parking Brake 3-7

Frame Sway Control 3-8

Gauges 3-9

Hydraulic Pump Destroke Button 3-9

Steering 3-10

Transmission 3-10

Front Axle Differential Lock 3-11

3 - 2

Page 29

CONTROLS AND INSTRUMENTS

OPERATOR'S COMPARTMENT

1 . Accelerator Pedal 8 . Hourmeter 15 . Parking Brake Switch 22. Heater Switch

2 . Joystick 4-way Controller 9. Gauges 16 . Pump Off Button 23 . Plug / Turn Signal Wires

3 . Transmission Control Lever 10 . Machine Level Gauge 17 . Front Wiper Switch 24 . Interior Rear V iew Mirror

4 . Steering Selector 11. Plug / 12 Volt Access. 18 . Ignition Switch 25. Frt.Axle Differential Lock

5 . Service Brake Pedal 1 2. Seat 19. Auxiliary Hydraulics 26 . Low Brake Press. Light

6 . Rear Wiper Switch 13 . Frame Level Switch 20 . Steering Wheel 2 7 . Work Lights Switch

7 . Load Chart 14 . Seat Belt 21. Headlight Switch

3 - 3

Page 30

A - Boom Down

B - Boom Up

CONTROLS AND INSTRUMENTS

JOYSTICK CONTROL FUNCTIONS

%

B

A

$

C - Boom Out

D - Boom In

E - Boom Down and Out

F - Boom Up and In

C

&

D

'

G - Boom Up and Out

H - Boom Down and In

3 - 4

Page 31

A - Tilt Down

B - Tilt Back

CONTROLS AND INSTRUMENTS

JOYSTICK CONTROL FUNCTIONS (BUTTON PUSHED)

B

%

$

A

3 - 5

Page 32

CONTROLS AND INSTRUMENTS

SERVICE BRAKES

The brake pedal is the operator's control for the service brakes.

Pushing the service brake pedal (A) activates the service

brakes for all four wheels.

The brakes should be applied during normal operation to stop

machine movement.

A

LOW SERVICE BRAKE PRESSURE LIGHT

WARNING

Insufficient hydraulic pressure to the service brakes may result

in increased stopping distances causing possible injury or

death and/or damage to the machine or property.

The illumination of the "LOW BRAKE PRESSURE" light (B)

when the machine is running indicates this potentially hazardous condition. Should this condition ever exist, discontinue

use of the machine immediately . Contact a qualified service

technician to resolve this problem.

B

PUMP

LOW BRAKE

PARKING

OFF

PRESSURE

BRAKE

REAR

FRONT

HEADLIGHTS

WORKLIGHTS

WIPER

WIPER

3 - 6

Page 33

CONTROLS AND INSTRUMENTS

PARKING BRAKE

WARNING

Failure to set the parking brake before leaving the machine may

result in unintended machine movement and possible injury or

death and/or damage to the machine or property.

The parking brake should be engaged anytime the operator

gets off the machine. To engage the parking brake, toggle the

parking brake switch (C) forward. The red light in the upper

part of the parking brake switch should illuminate.

C

PUMP

LOW BRAKE

PARKING

OFF

PRESSURE

BRAKE

REAR

FRONT

HEADLIGHTS

WORKLIGHTS

WIPER

WIPER

3 - 7

Page 34

CONTROLS AND INSTRUMENTS

FRAME SWAY CONTROL

WARNING

Always ensure that the machine level indicator (B) is at zero (0)

degrees before raising the boom. Raising the boom with an

unlevel machine may cause the machine to overturn, resulting

in injury or death.

WARNING

Use the frame sway control to level the machine only when the

boom angle indicator is at 0 degrees or less. Using the frame

sway control when the angle indicator is more than 0 degrees

may cause the machine to overturn, resulting in injury or death.

The frame sway control (A) is located on the forward side of

the right arm rest. The frame sway control is used in conjunction

with the machine level indicator (B) located in the center of the

cross support that the interior rear view mirror is mounted on.

The sway control switch is either toggled to the left or right

depending on the particular requirement.

A

B

3 - 8

Page 35

CONTROLS AND INSTRUMENTS

The following gauges are used to monitor the

machine:

1 - Fuel Level

2 - W ater T emperature, Engine

3 - Oil Pressure, Engine

4 - Oil T emperature, Powershift T ransmission

5 - Oil Pressure, Powershift Transmission

6 - Voltmeter

GAUGES

34

2

1

5

6

FRONT

PARKING

LOW BRAKE

PUMP

BRAKE

PRESSURE

OFF

REAR

HEADLIGHTSWORKLIGHTS

WIPER

WIPER

HYDRAULIC PUMP DESTROKE BUTTON

DANGER

Depressing the pump destroke button while operating the machine

will cause an immediate loss of hydraulic power, possibly

creating a very dangerous situation. Hydraulic functions that

will be affected are: FORK TILT, LIFT, BOOM EXTEND

and RETRACT , PARKING BRAKE and SW A Y. None of these

functions will operate as long as the button is depressed. The

service brakes will continue to function if the accumulator backup

has a sufficient gas charge.

The pump destroke button (C) is the black push button

switch located on the dash panel.

For example, when starting the machine for the first time on a 30

degree F. day, depress the pump destroke button while starting

the engine. Continue to depress the button for 15 to 20 seconds

after the engine starts. Once the engine is running smoothly,

release the button and the hydraulic pump will engage.

Depressing the pump destroke button will not be required for

all other starts of the day, unless the engine has been allowed

to cool completely .

C

WORKLIGHTS

HEADLIGHTS

FRONT

WIPER

WIPER

PARKING

PUMP

LOW BRAKE

BRAKE

OFF

PRESSURE

REAR

3 - 9

Page 36

CONTROLS AND INSTRUMENTS

STEERING

In addition to the steering wheel, the machine has another

steering control, the steering selector switch.

The steering selector switch (A) is a three-position switch.

The three positions are: 4-wheel, 2-wheel , and oblique.

Switch positions are selected and function as follows:

4-WHEEL Handle rotated forward

2-WHEEL Handle directly centered

OBLIQUE (CRAB) Handle rotated rearward

CAUTION

Before changing steering selections, make sure all four wheels

are in line. Failure to align the wheels to the proper settings

before changing steering positions may cause haphazard steering.

This may result in injury to personnel and/or damage to the

machine or property.

TRANSMISSION

A

The transmission control (B) has one lever that controls both

directional and speed requirements. It is located on the left side

of the steering column.

T o shift into Forward gear gently pull the lever toward you and

move the lever upward.

T o shift into Neutral move the lever to the center position.

T o shift into Reverse gear gently pull the lever toward you and

move the lever downward.

T o shift into a lower speed rotate the lever clockwise.

T o shift into a higher speed rotate the lever counter-clockwise.

When shifting the transmission from forward to reverse while

the machine is in motion the transmission control (B) must be

in 1st or 2nd gear only.

Forward / 1st Low speed/High torque

Forward / 2nd Medium speed/Medium torque

Forward / 3rd High speed/Low torque

B

REAR

PARKING

PUMP

LOW BRAKE

BRAKE

OFF

PRESSURE

FRONT

HEADLIGHTS

WORKLIGHTS

WIPER

WIPER

3 - 10

Page 37

CONTROLS AND INSTRUMENTS

FRONT AXLE DIFFERENTIAL LOCK

The front axle differential lock switch (C) is located near the

operator's left foot. It is a standard feature on all GTH-842 &

GTH-844 models. The purpose for this device is to lock the

front axle differential to gain added traction under certain

conditions.

The front axle differential lock switch must be depressed and

held in order to activate the axle differential lock. Releasing the

switch disengages the axle differential lock.

Use this differential lock when you are unable to drive through

certain types of terrain such as sand, mud, snow, etc.

WARNING

Always bring the front tires to a complete stop before engaging

the front axle differential lock.

Failure to stop the front tires before engaging the front axle

differential lock may result in damage to the front axle.

Never steer the front tires while using the front axle

differential lock.

Steering while the front axle differential lock is engaged may

result in damage to the front axle.

C

3 - 11

Page 38

CONTROLS AND INSTRUMENTS

NOTES

3 - 12

Page 39

SECTION 4

OPERATION

4 - 1

Page 40

T ABLE OF CONTENTS

SECTION 4 - OPERATION

Operation And Safety Guidelines 4-3

Before Starting The Engine 4-4

Starting The Engine 4-5

Before Operating The Forklift 4-7

Transporting A Load 4-11

Placing A Load 4-13

4 - 2

Page 41

OPERATION

OPERATION AND SAFETY GUIDELINES

WARNING

Your safety and the safety of those around you depends upon you using care and judgement in the operation of this equipment.

Know the positions and functions of all controls before attempting to operate this machine. All equipment has limitations.

Understand the speed, braking, steering, stability, and load chart characteristics of this machine before operating. Read the

Operator's Manual and ask questions of your supervisor until you know the machine's limitations. It is very important to read,

fully understand, and follow these operation and safety guidelines.

1. DO NOT operate this machine while people are under or near an elevated boom whether the boom is loaded or unloaded.

Falling objects from the forks or attachment may cause serious injury or death.

2. ALWAYS remain completely within the cab enclosure while operating this machine. Falling debris can cause serious

personal injury or death.

3. NEVER extend a load beyond the load chart band. Machine turn over, component damage, injury or death could occur.

4. ABSOLUTEL Y NO RIDERS SHOULD BE ALLOWED ON THIS MACHINE OR A TT ACHMENTS.

5. NEVER lower a maximum load before retracting it. Machine turn over, component damage, injury or death could occur .

6. INSPECT and clear the working area of any obstructions (rocks, fence, wire, etc.) that could cause machine damage. If

obstructions cannot be cleared, mark the obstructions with a stake or other marker that will be clearly visible to the operator.

7. DO NOT check the engine coolant level if the engine has recently been run. Injury could occur from escaping hot

pressurized coolant.

8. ALWAYS wear the seat belt when operating this machine.

9. ALWAYS inspect the machine daily . Check for leaks, worn hoses, loose belts, or anything out of the ordinary. Repair

and/or replace any worn, damaged or leaking parts immediately. Failure to do so can cause injury or death.

10. CHECK to be sure that all guards and screens are secure and in their proper place.

11. CHECK to be sure that all safety devices such as parking brake, service brake, level gauge, neutral start safety switch,

back-up alarm, and horn are functioning properly. Always make sure mirror is adjusted properly.

12. DO NOT travel on terrain or in dangerous areas that could cause the machine to tip over.

13. DO NOT attempt to start the engine by towing or pushing. Damage to the powershift transmission could result.

14. CARRY A LOAD so that you have maximum machine stability and visibility is not obstructed.

15. AL WAYS level the machine as indicated on the machine level indicator before raising boom. Raising the boom with an

unlevel machine may cause the machine to overturn causing injury or death.

16. USE the frame sway control to level the machine only when the boom position is horizontal or lower . Using the frame

sway control when the boom is higher than a horizontal position may cause the machine to overturn causing injury or death.

17. DO NOT depress the pump destroke button while operating the machine. This button should be used only during cold start

ups. Depressing the button while operating the machine will cause an immediate loss of hydraulic power that will

affect fork tilt, lift, boom extend and retract, sway and all other hydraulic functions. Brakes will continue to function if

the accumulator backup has a sufficient gas charge.

4 - 3

Page 42

OPERATION

BEFORE STARTING THE ENGINE

WARNING

Before starting the engine, be sure that all daily maintenance

items have been performed. See Maintenance section.

Walk around the machine and check for any parts that are

missing, worn, damaged, or leaking. Repair and/or replace

damaged parts.

4 - 4

Page 43

OPERATION

STARTING THE ENGINE

DANGER

Any problems discovered in the steps prior to "BEFORE

ST AR TING THE ENGINE" should be corrected before the

machine is started.

DANGER

NEVER attempt to start the machine without being seated in

the operator's compartment, the parking brake switch (B)

toggled forward in the on position and the transmission

control (C) in the neutral position. Attempting to start the

machine from outside the operator's compartment may result in

property damage, serious injury or death.

DANGER

If the machine should start with the transmission control lever

(C) in gear, stop operation at once or property damage, serious

injury or death may occur. Have a qualified service technician

repair the machine.

Insert the ignition key in the ignition switch (D). Rotate the key

clockwise until the engine starts. Release the key when the

engine starts.

C

REAR

PARKING

PUMP

LOW BRAKE

BRAKE

OFF

PRESSURE

FRONT

HEADLIGHTS

WORKLIGHTS

WIPER

WIPER

DB

4 - 5

Page 44

OPERATION

STARTING THE ENGINE

CAUTION

If the engine fails to start within 30 seconds release the key ,

wait at least 2 minutes to allow the starter motor to cool before

trying again. If the engine fails to start after four attempts,

trouble shoot and correct the problem. DO NOT turn the key if

the engine is running. This may cause damage to the starter

motor.

CAUTION

Attempting to start the engine by towing or pushing the

machine will result in damage to the powershift transmission

and will not start the engine! It also is an unsafe practice that

could cause personal injury.

○○○○○○○○○○

4 - 6

Page 45

OPERATION

BEFORE OPERATING THE FORKLIFT

CAUTION

If any gauge reading does not fall within the set tolerances the

machine must be repaired before operation.

Check the dash mounted gauges for logical readings.

(1) Fuel Level 1/2 to Full

(2) Engine Water Temperature 180 F to 200 F

(3) Engine Oil Pressure 40 to 80 PSI

(4) T ransmission Oil Temperature 180 F to 200 F

(5) T ransmission Oil Pressure 240 to 280 PSI

(6) Voltmeter 12 to 14 V olts

Operate the joystick controller momentarily in all directions.

4

3

2

1

5

6

PARKING

LOW BRAKE

PUMP

BRAKE

PRESSURE

OFF

STANDARD JOYSTICK FUNCTIONS

A - Boom Down

B - Boom Up

C - Boom Out

D - Boom In

E - Boom Down and Out

F - Boom Up and In

G - Boom Up and Out

H - Boom Down and In

FRONT

REAR

HEADLIGHTSWORKLIGHTS

WIPER

WIPER

4 - 7

BUTTON DEPRESSED FUNCTIONS

A - Tilt Forward

B - Tilt Back

Page 46

OPERATION

BEFORE OPERATING THE FORKLIFT

Operate the frame sway control (A) momentarily right and left.

Check the steering operation by turning the steering wheel (B)

approximately 1/4 turn in each direction. If the front and rear

tires are not aligned properly, straighten the rear wheels with

the steering selector valve (C) in the "4 wheel" position. Move

the steering selector valve to the "2 wheel" position. Bring the

front tires into alignment with the rear tires. Place the steering

selector valve back into the "4 wheel" position.

A

C

B

4 - 8

Page 47

OPERATION

BEFORE OPERATING THE FORKLIFT

DANGER

Any problems with the service brakes or the parking brake

found while conducting the daily inspection should be

corrected immediately. Failure to do so could result in injury or

death.

Activate the transmission using the transmission control

lever (D). As soon as the machine starts to move, apply the

service brake pedal. The machine should stop immediately .

D

REAR

PARKING

PUMP

LOW BRAKE

BRAKE

OFF

PRESSURE

FRONT

HEADLIGHTS

WORKLIGHTS

WIPER

WIPER

Apply the parking brake by toggling the parking brake switch

(E) forward. The red light in the upper part of the parking brake

switch should illuminate. The machine should not be able to be

driven with the parking brake in the forward / on position.

Release the parking brake by toggling the parking brake switch

rearward.

4 - 9

PUMP

LOW BRAKE

PARKING

OFF

PRESSURE

BRAKE

REAR

FRONT

HEADLIGHTS

WORKLIGHTS

WIPER

WIPER

E

Page 48

OPERATION

BEFORE OPERATING THE FORKLIFT

DANGER

Never operate the machine with a faulty backup alarm. Doing

so may result in serious injury or death.

Place the transmission control lever (A) in reverse. The backup

alarm should sound. If it does not sound, have the backup

alarm repaired immediately.

A

Check and adjust both the interior rear view mirror (B) and the

exterior right hand mirror (C) if required.

B

REAR

PARKING

PUMP

LOW BRAKE

BRAKE

OFF

PRESSURE

FRONT

HEADLIGHTS

WORKLIGHTS

WIPER

WIPER

C

4 - 10

Page 49

OPERATION

TRANSPORTING A LOAD

WARNING

Transporting a load with the boom extended and the boom

angle indicator arrow (D) reading more than 0 degrees could

cause a roll over hazard.

WARNING

At no time should any load be suspended from the forks by

use of chains, ropes, straps etc. If a load must be suspended

the use of a truss (jib) boom is mandatory. Proper rigging

procedures should always be followed.

The forks should always be tilted back slightly during

transportation to ensure stability of the load.

The load should be kept as low to the ground as possible

while traveling. Always move a loaded machine with the boom

angle indicator (D) at 0 degrees or less.

D

4 - 11

Page 50

OPERATION

TRANSPORTING A LOAD

WARNING

Slower speeds should be used whenever transporting a load.

Always bring the machine to a complete stop before reversing

the transmission control lever (A). Failure to do so can result in

damage to the load, the machine and/or bystanders.

Always keep the boom retracted to ensure greater stability .

A

PUMP

LOW BRAKE

PARKING

OFF

PRESSURE

BRAKE

REAR

FRONT

HEADLIGHTS

WORKLIGHTS

WIPER

WIPER

Always place the load in the center and completely against the

back of the fork frame. By doing so greater stability will result.

IMPORTANT: Never attempt to use the forks and/or attachments for prying wedged or frozen loads free. Damage to the

load, pallet and/or machine could result.

4 - 12

Page 51

OPERATION

PLACING A LOAD

WARNING

Do not sway the machine with the boom angle indicator arrow

(B) at more than 0 degrees. By doing so you could cause a roll

over hazard which may result in injury or death.

DANGER

Always apply the parking brake by toggling the parking brake

switch (C) forward before lifting and/or placing a load. Failure

to do so could allow the machine to roll over which may result

in injury or death.

CAUTION

Always bring the machine to a complete stop before applying

the parking brake (C). Failure to do so will damage the parking

brake disc packs, which may void the axle warranty.

B

REAR

PARKING

PUMP

LOW BRAKE

BRAKE

OFF

PRESSURE

FRONT

HEADLIGHTS

WORKLIGHTS

WIPER

WIPER

Before placing a load, the frame should be leveled. This can be

done by the use of the switch labeled sway control (D) located

on the forward side of the right arm rest. The frame sway

control is used in conjunction with the machine level indicator

(E) located in the center of the cross support that the interior

rear view mirror is mounted on. The sway control switch is

either toggled left or right depending on the particular requirement. Adjust the sway control (D) until the indicator ball on the

level gauge (E) is on the 0 degree mark.

WARNING

Always ensure that the machine level indicator (E) is at zero (0)

degrees before raising the boom. Raising the boom with an

unlevel machine may cause the machine to overturn, resulting

in injury or death.

WARNING

Use the frame sway control to level the machine only when the

boom angle indicator (B) is at 0 degrees or less. Using the

frame sway control when the angle indicator is more than 0

degrees may cause the machine to overturn, resulting in injury

or death.

C

D

E

4 - 13

Page 52

OPERATION

PLACING A LOAD

DANGER

Traveling with a reading of more than 0 degress on the boom

angle indicator arrow (A) may cause a rollover hazard.

A

Gradually move the 4-way controller towards the letter (B) to

lift the load vertically. Hold the controller back until the

required height has been achieved.

Gradually move the 4-way controller towards the letter (E) to

bring the load DOWN and OUT into final position. Lower the

load until the weight is completely off the forks.

Gradually move the 4-way controller towards the letter (F) to

bring the boom UP and IN. This will bring the forks out of the

load. Once the forks are clear of the load the boom can be

lowered.

4 - 14

Page 53

OPERATION

PLACING A LOAD

GTH-644, GTH-842, GTH-844

When placing a load with the Model GTH-644,

GTH-842, or the GTH-844 the rear axle stabilizing

cylinders need to be taken into consideration. When

the boom reaches an angle of

frame leveling and transmission functions are disabled

and the rear axle stabilizing cylinders become locked.

This

functions. To unlock the rear axle stabilizing cylinders

and enable the transmission functions, lower the

boom to a position less than 60 degrees.

DOES NOT affect any boom or fork

60 DEGREES, all

60 degrees

!"#

4 - 15

Page 54

OPERATION

NOTES

4 - 16

Page 55

SECTION 5

MAINTENANCE PROCEDURES

5 - 1

Page 56

T ABLE OF CONTENTS

SECTION 5 - MAINTENANCE PROCEDURES

General Safety Practices 5-3

Daily Maintenance 5-5

5 - 2

Page 57

MAINTENANCE PROCEDURES

GENERAL SAFETY PRACTICES

BEFORE SERVICING

Read the entire Maintenance Procedure Section.

Familiarize yourself with all the safety precautions listed in

Sections 1 & 2.

Pay close attention to all the safety alert symbols.

Be sure you understand the procedures detailed in this

section.

Wear personal protective equipment.

Remove rings and jewelry.

Move the machine to a safe level work place.

Lower the boom and support all raised equipment.

Shut down the machine.

Remove the key from the ignition.

Be careful not to spill fuels and lubricants.

Do not fill or refuel the fuel tank while the engine is running or

hot. Doing so could cause a fire and/or an explosion.

Do not smoke while refueling or working with fuel to avoid a

fire and/or explosion.

IMPORTANT! Always clean up spilled fuel and/or lubricants

to avoid polluting the earth.

5 - 3

Page 58

MAINTENANCE PROCEDURES

GENERAL SAFETY PRACTICES

HYDRAULIC SAFETY

WARNING

Hot hydraulic oil can cause severe burns. DO NOT work on

the hydraulic system if the oil system temperature exceeds

120 degrees F . (49 degrees C.)

Before ANYONE works on the hydraulic system:

1 . Lower the boom to the horizontal position.

2 . Support the boom to avoid unintentional lowering.

3. Shutdown the engine.

4 . Remove the key from the ignition.

5 . Clean the area around the oil reservoir cap (A).

A

FLUID UNDER PRESSURE

WARNING

Escaping fluid under pressure can penetrate the skin and can

cause serious personal injury.

Use a piece of cardboard or paper to search for leaks.

DO NOT use hands! Before disconnecting hydraulic lines, be

sure to relieve all line pressure. Before applying pressure to the

system, be sure that all connections are tight. DO NOT apply

pressure to a damaged line, hose or fitting.

If injured by escaping fluid, see a doctor at once. Proper

medical treatment must be administered immediately. A

serious infection or reaction can result without proper

medical treatment.

WELDING PRECAUTIONS

WARNING

DO NOT weld on any structural member. Any unauthorized

welding can cause structural failure or possible personal

injury. All unauthorized welding or repair procedures will

void the machine warranty.

Before performing any authorized welding, be sure to disconnect the positive lead from the battery. Properly attach the

ground cable of the welder to the frame member that is being

welded. Failure to do so can cause electrical system damage.

5 - 4

Page 59

MAINTENANCE PROCEDURES

DAILY MAINTENANCE

SCHEDULED MAINTENANCE

Maintenace performed quarterly, annually and every

two years must be completed by a person trained and

qualified to perform maintenance on this machine

according to the procedures found in the service manual

for this machine.

Machines that have been out of service for more than

three months must receive the quarterly inspection

before they are put back into service.

PERFORM ENGINE MAINTENANCE

Refer to engine operator's manual.

Check engine oil.

Check coolant level.

Check engine fan.

Open water separator.

PERFORM TRANSMISSION MAINTENANCE

Refer to the transmission operator's manual.

Check transmission oil level.

5 - 5

Page 60

MAINTENANCE PROCEDURES

DAILY MAINTENANCE

CHECK HYDRAULIC OIL LEVEL

Location: Sight glass (B). Behind the rear panel.

T o Check: Move the machine to level ground.

Level the frame.

Completely retract the boom.

Position the forks level.

Lower the boom to the ground.

Oil should be visible 1/2 way in sight glass (B).

CHECK TIRE FOR PROPER INFLATION

Location: Wheel ends.

T o Check: With the valve stem (C) positioned to the top of

the tire, check the tire pressure with the tire cold

and a properly functioning air pressure gauge.

B

Setting: 50 PSI.

DANGER

All tires require a calcium chloride ballast or an optional foam

fill to be operated safely. The loss of ballast can affect the

machine's stability and cause a rollover hazard, resulting in

damage, injury or death.

C

5 - 6

Page 61

SECTION 6

MATERIAL SAFETY DATA

6 - 1

Page 62

T ABLE OF CONTENTS

SECTION 6 - MATERIAL SAFETY DATA

Material Safety Data Sheets 6-3

California Proposition 65 W arnings 6-4

6 - 2

Page 63

MATERIAL SAFETY DATA

MATERIAL SAFETY DATA SHEETS (MSDS)

The Federal Occupational, Safety and Health Administration (OSHA) Standard 29 ctr 1910.1200, and in some

cases state and local Right-T o-Know laws, may require specific MSDS be available to employees prior to

operating this equipment. This may include information on substances contained in the equipment such as

antifreeze, brake fluid, battery acid and hydraulic fluid.

Genie will provide, at no cost, Material Safety Data Sheets which are applicable to their product line. Simply

request them from your local Genie dealer or contact us at:

Genie Industries

PO Box 97030

Redmond, W A 98073-9730

T o ensure a prompt response, please be sure to include your return address and zip code, along with the

machine model and serial number.

6 - 3

Page 64

MATERIAL SAFETY DATA

CALIFORNIA PROPOSITION 65 WARNINGS

The following warnings are required on all off road equipment operating in the State of California. If you are

operating a Genie in the State of California and do not see the approved warning labels,

please contact us for a replacement at no charge. Our address is:

Genie Industries

PO Box 97030

Redmond, W A 98073-9730

CALIFORNIA

Proposition 65 W arning

Diesel engine exhaust and some of its

constituents are known to the State

of California to cause cancer, birth

defects, and other reproductive harm.

CALIFORNIA

Proposition 65 W arning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm.

Batteries also contain other chemicals known to

the State of California to cause cancer .

W ash hands after handling.

6 - 4

Loading...

Loading...