Page 1

Operator's Manual

Serial Number Range

GR™-12

from GRP-60000

from GRR-10001

ANSI/CSA

North America

South America

Asia

GR™-15

GR™-20

with

Maintenance

Information

Original Instructions

Sixth Edition

First Printing

Part No. 1297723GT

Page 2

Operator's Manual Sixth Edition • First Printing

GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Front Matter

Contents

Introduction ............................................................1

Symbol and Hazard Pictorials Definitions ..............5

General Safety .......................................................7

Personal Safety ................................................... 13

Work Area Safety ................................................ 14

Legend ................................................................ 21

Controls ............................................................... 22

Inspections .......................................................... 25

Operating Instructions ......................................... 39

Transport and Lifting Instructions ....................... 48

Maintenance ....................................................... 53

Specifications ...................................................... 55

Copyright © 2000 Terex Corporation

Sixth Edition: First Printing, June 2020

Genie is a registered trademark of Terex South Dakota, Inc. in

the U.S.A. and many other countries.

“GR” is a trademark of Terex South Dakota, Inc.

These machines comply with

ANSI/SIA A92.20

CAN/CSA B354.6

Page 3

Sixth Edition • First Printing Operator's Manual

Introduction

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 1

Introduction

About this manual

Genie appreciates your choice of our machine for

your application. Our number one priority is user

safety, which is best achieved by our joint efforts.

This book is an operation and daily maintenance

manual for the user or operator of a Genie

machine.

This manual should be considered a permanent

part of your machine and should remain with the

machine at all times. If you have any questions,

contact Genie.

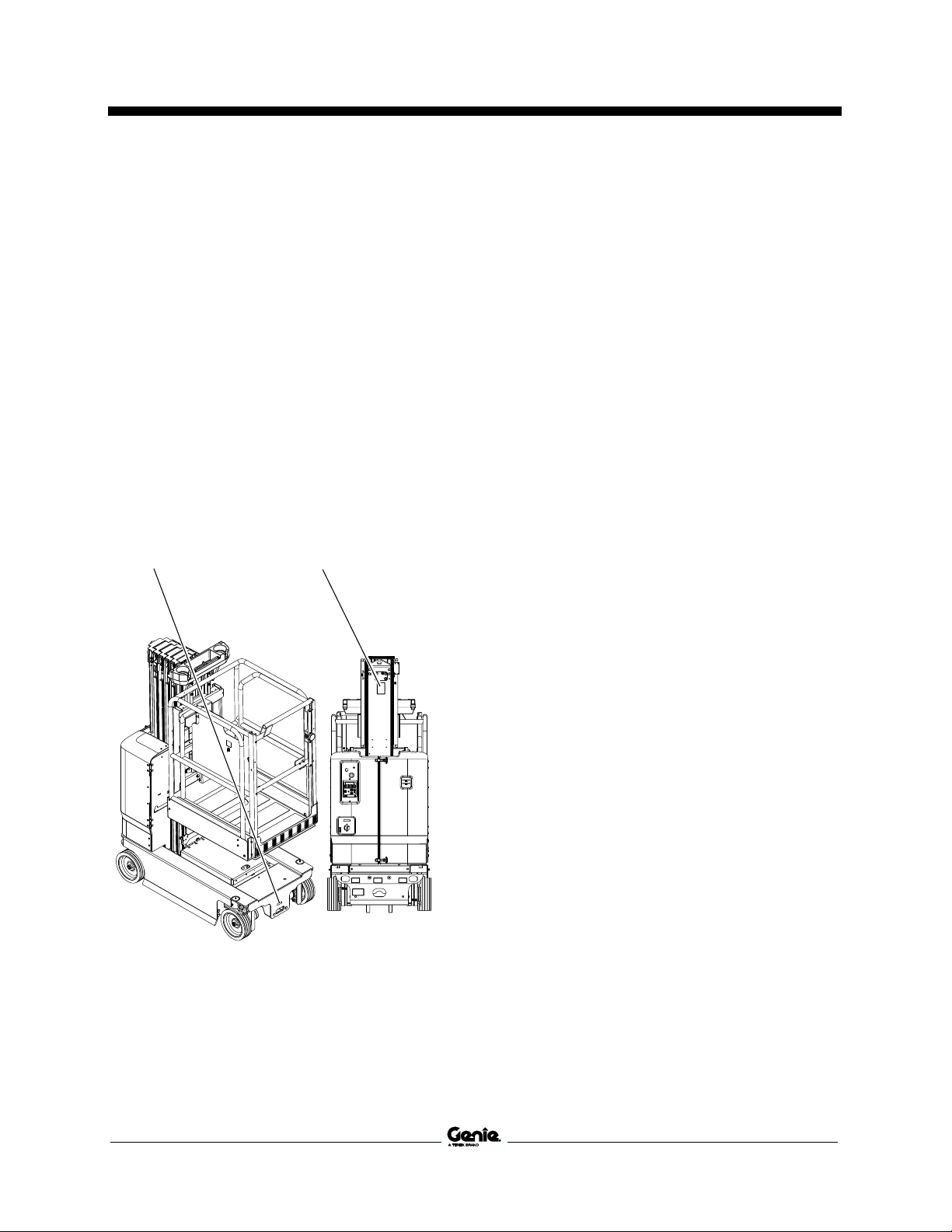

Product Identification

The machine serial number is located on the serial

label.

Serial number stamped

on chassis

Serial label located on

chassis

Intended Use and Familiarization

Guide

The intended use of this machine is to lift

personnel, including tools, and materials to an

aerial work site. Before operating the machine, it’s

the operator’s responsibility to read and

understand this familiarization guide.

Each person must be trained to operate a

Mobile Elevating Work Platform (MEWP).

Familiarization with the MEWP must be given

to each person who is authorized, competent

and trained.

Only trained and authorized personnel should

be permitted to operate the machine.

The operator is responsible to read,

understand, and obey the manufacturer’s

instructions and safety rules provided in the

Operator’s Manual.

The Operator’s Manual is located in the

manual storage container, at the platform.

For specific product applications, see

Contacting The Manufacturer.

Page 4

Operator's Manual Sixth Edition • First Printing

Introduction

2 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

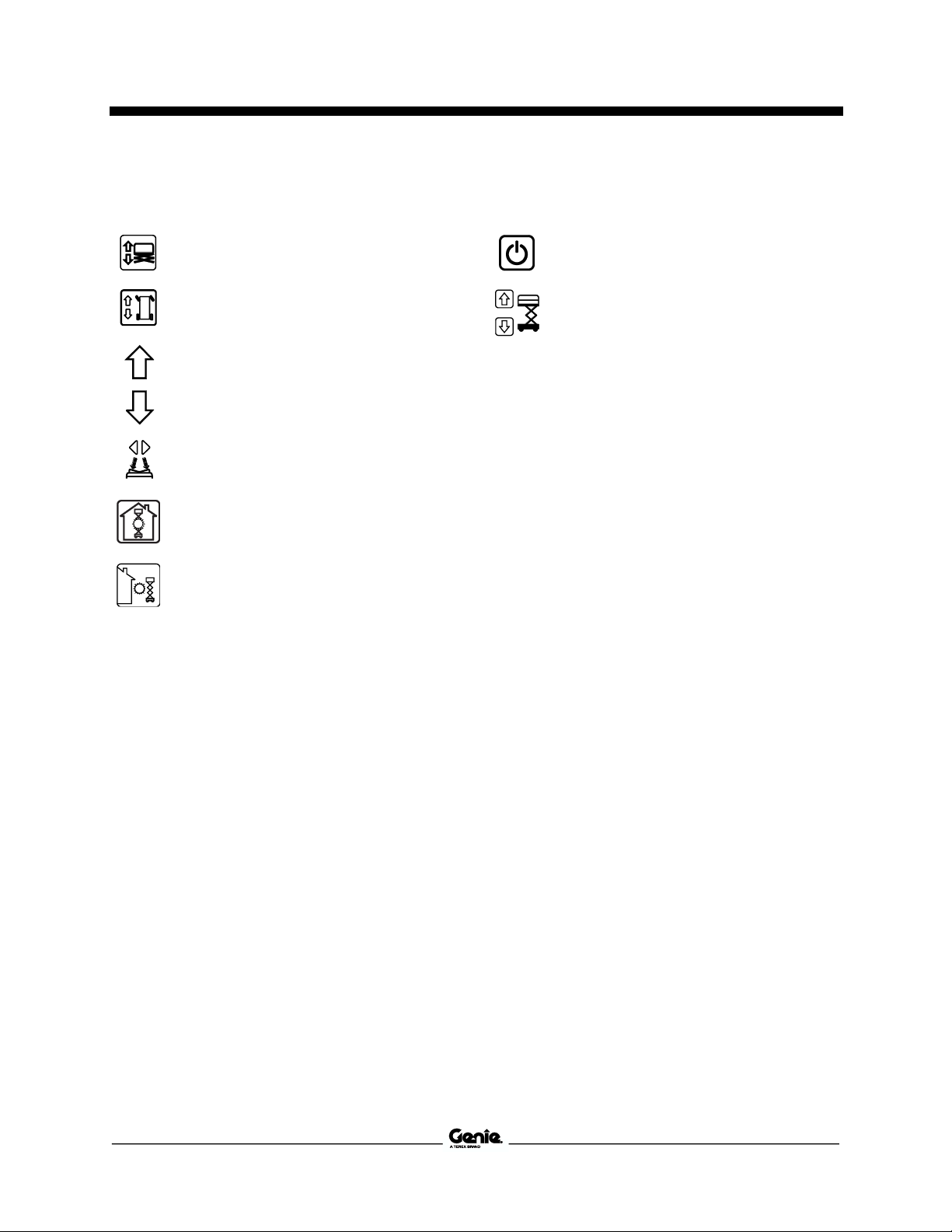

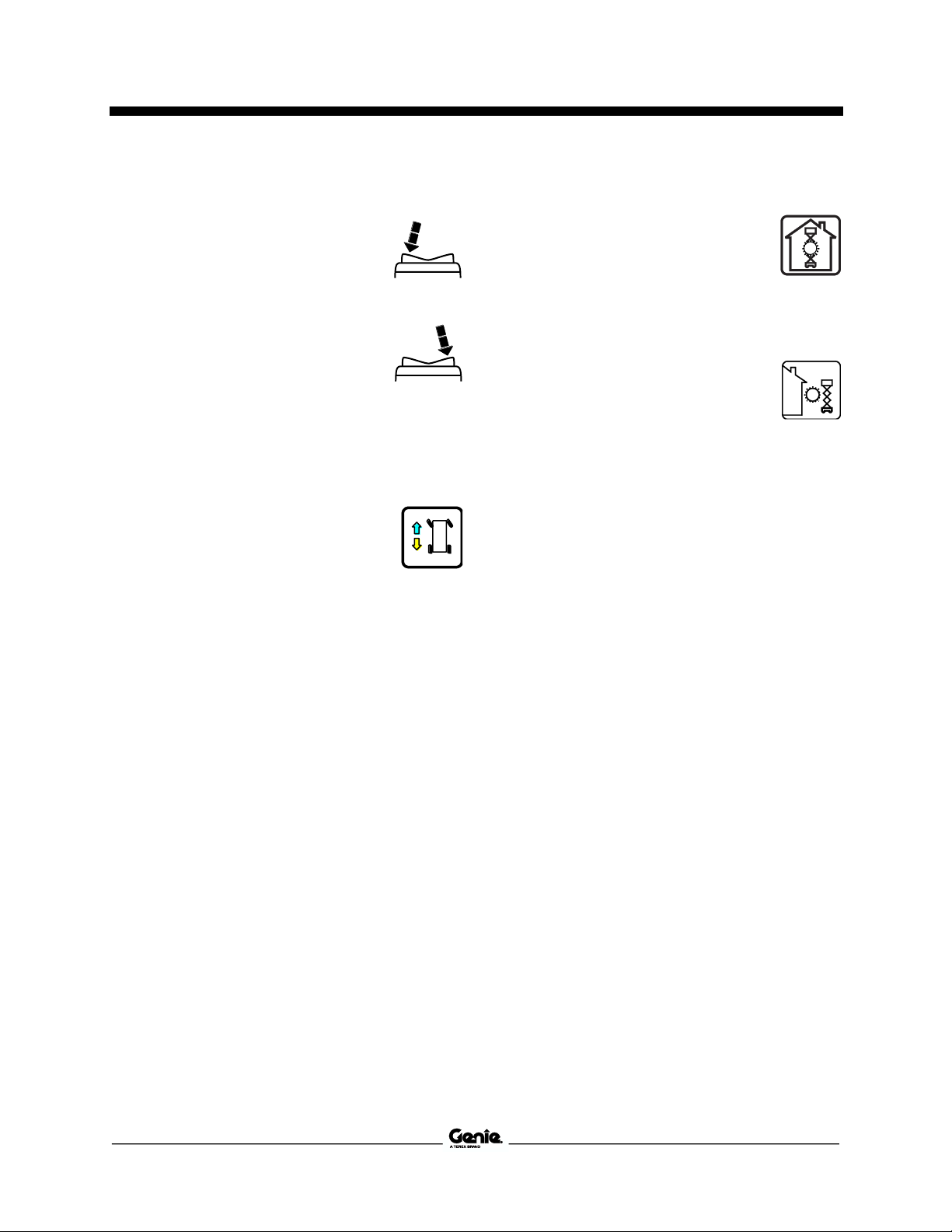

Platform controls symbology and related

machine movement:

Lift function enable button

Drive function enable button

Platform up/down (when lift function

selected)

Drive forward/reverse (when drive function

selected)

Steer right/left (when drive function

selected)

Area of operation, indoor use button

Area of operation, outdoor use button

Ground controls symbology and related

machine movement:

Lift function enable button

Platform up/down button

Sequential functions and movement:

Drive and steer.

Interlocked functions:

Elevated drive speed.

Elevated drive in an off-level condition.

All platform and ground controls.

Limitations of use:

The intended use of this machine is to lift

personnel, including tools, and materials to an

aerial work site.

Do not elevate the platform unless the machine

is on firm level ground.

Page 5

Sixth Edition • First Printing Operator's Manual

Introduction

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 3

Bulletin Distribution and Compliance

Safety of product users is of paramount

importance to Genie. Various bulletins are used by

Genie to communicate important safety and

product information to dealers and machine

owners.

The information contained in the bulletins is tied to

specific machines using the machine model and

serial number.

Distribution of bulletins is based on the most

current owner on record along with their

associated dealer, so it is important to register

your machine and keep your contact information

up to date.

To ensure safety of personnel and the reliable

continued operation of your machine, be sure to

comply with the action indicated in a respective

bulletin.

To view any open bulletins for your machine, visit

us on the web at www.genielift.com.

Contacting the Manufacturer

At times it may be necessary to contact Genie.

When you do, be ready to supply the model

number and serial number of your machine, along

with your name and contact information. At

minimum, Genie should be contacted for:

Accident reporting

Questions regarding product applications and

safety

Standards and regulatory compliance information

Current owner updates, such as changes in

machine ownership or changes in your contact

information. See Transfer of Ownership, below.

Transfer of Machine Ownership

Taking a few minutes to update owner information

will ensure that you receive important safety,

maintenance and operating information that

applies to your machine.

Please register your machine by visiting us on the

web at www.genielift.com or by calling us toll free

at 1-800-536-1800.

Page 6

Operator's Manual Sixth Edition • First Printing

Introduction

4 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Danger

Failure to obey the instructions and

safety rules in this manual will result

in death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

Know and understand the safety rules

before going on to the next section.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

You read, understand and obey the

manufacturer’s instructions and safety rules—

safety and operator’s manuals and machine

decals.

You read, understand and obey employer’s

safety rules and worksite regulations.

You read, understand and obey all applicable

governmental regulations.

You are properly trained to safely operate the

machine.

Safety Sign Maintenance

Replace any missing or damaged safety signs.

Keep operator safety in mind at all times. Use mild

soap and water to clean safety signs. Do not use

solvent-based cleaners because they may

damage the safety sign material.

Hazard Classification

Decals on this machine use symbols, color coding,

and signal words to identify the following:

Safety alert symbol—used to alert

you to potential personal injury

hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates a hazardous situation

which, if not avoided, will result in

death or serious injury.

Indicates a hazardous situation

which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation

which, if not avoided, could result

in minor or moderate injury.

Indicates a property damage

message.

Page 7

Sixth Edition • First Printing Operator's Manual

Symbol and Hazard Pictorials Definitions

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 5

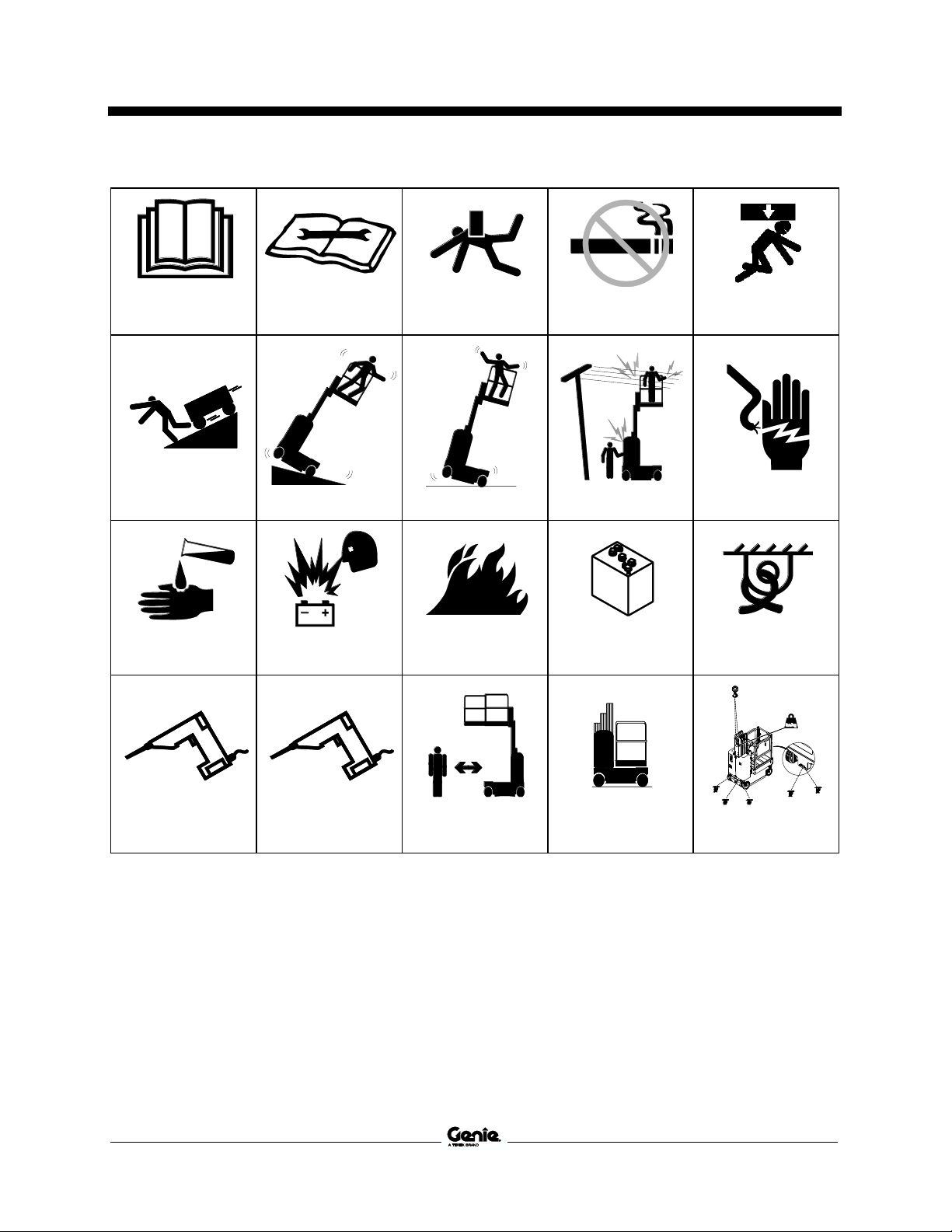

Symbol and Hazard Pictorials Definitions

Read the operator’s

manual

Read the service

manual

Crush hazard

No smoking

Collision hazard

Collision hazard

Tip-over hazard

Tip-over hazard

Electrocution hazard

Electrocution hazard

Burn hazard

Explosion hazard

Fire hazard

Batteries used as

counterweights

Tiedown

Voltage rating for

power to platform

Pressure rating for air

line to platform

Keep away from

moving parts

Move machine to

level ground

Lifting & tie down

instructions

Page 8

Operator's Manual Sixth Edition • First Printing

Symbol and Hazard Pictorials Definitions

6 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

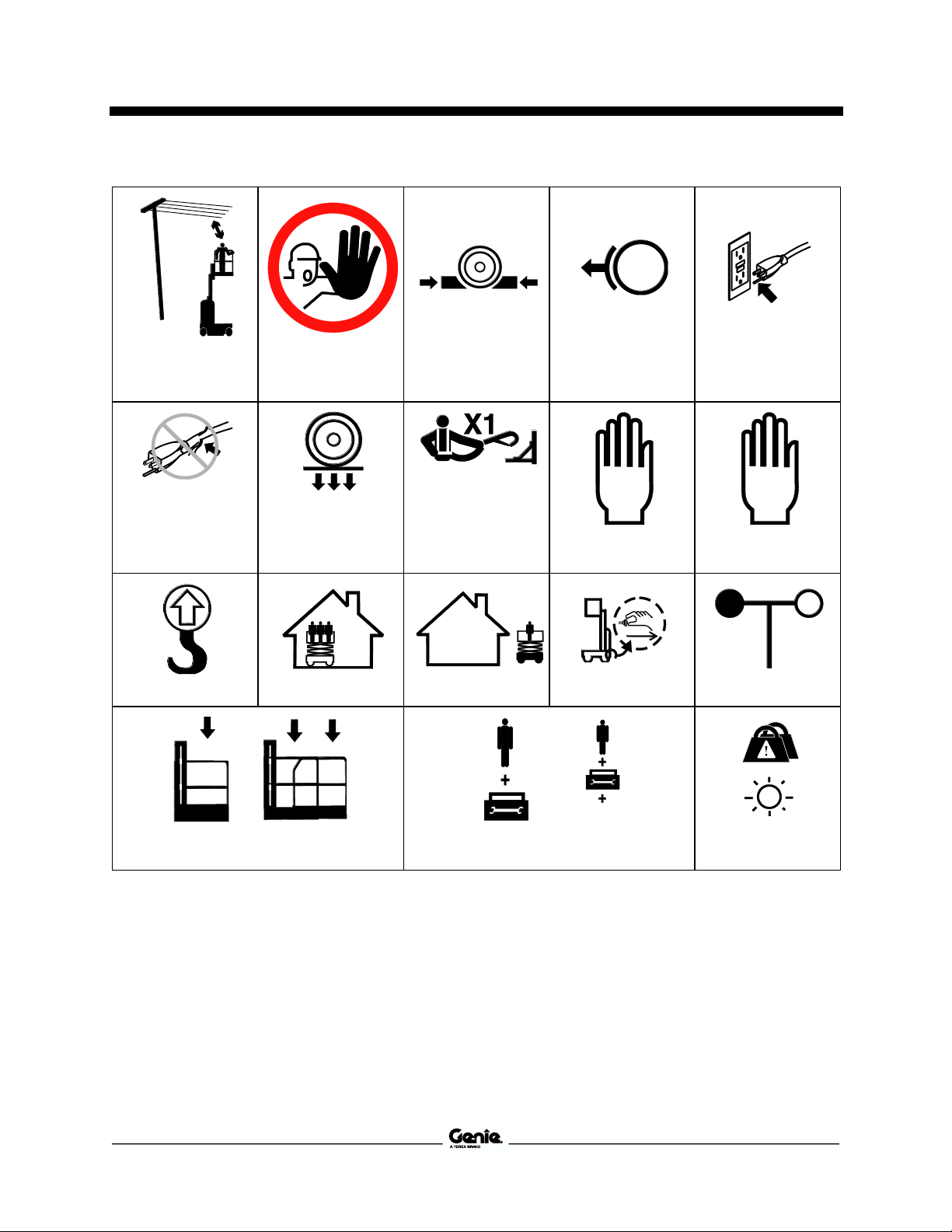

Maintain required

clearance

Access by trained

and authorized

personnel only

Chock the wheels

Release brakes

Grounded AC

3-wire only

Replace damaged

wires and cords

Wheel load

Lanyard anchorage

points

Side force

Manual force

Lifting point

Indoor

Outdoor

Auxiliary lowering

Wind speed

Maximum capacity

Maximum capacity including occupant, tools,

materials and options

Platform overloaded

Page 9

Sixth Edition • First Printing Operator's Manual

General Safety

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 7

General Safety

Page 10

Operator's Manual Sixth Edition • First Printing

General Safety

8 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Page 11

Sixth Edition • First Printing Operator's Manual

General Safety

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 9

Page 12

Operator's Manual Sixth Edition • First Printing

General Safety

10 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Page 13

Sixth Edition • First Printing Operator's Manual

General Safety

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 11

Page 14

Operator's Manual Sixth Edition • First Printing

General Safety

12 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Page 15

Sixth Edition • First Printing Operator's Manual

Personal Safety

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 13

Personal Safety

Personal Fall Protection

Personal fall protection equipment (PFPE) is not

required when operating this machine. If PFPE is

required by job site or employer rules, the

following shall apply:

All PFPE must comply with applicable

governmental regulations and must be inspected

and used in accordance with the manufacturer’s

instructions.

Page 16

Operator's Manual Sixth Edition • First Printing

Work Area Safety

14 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Work Area Safety

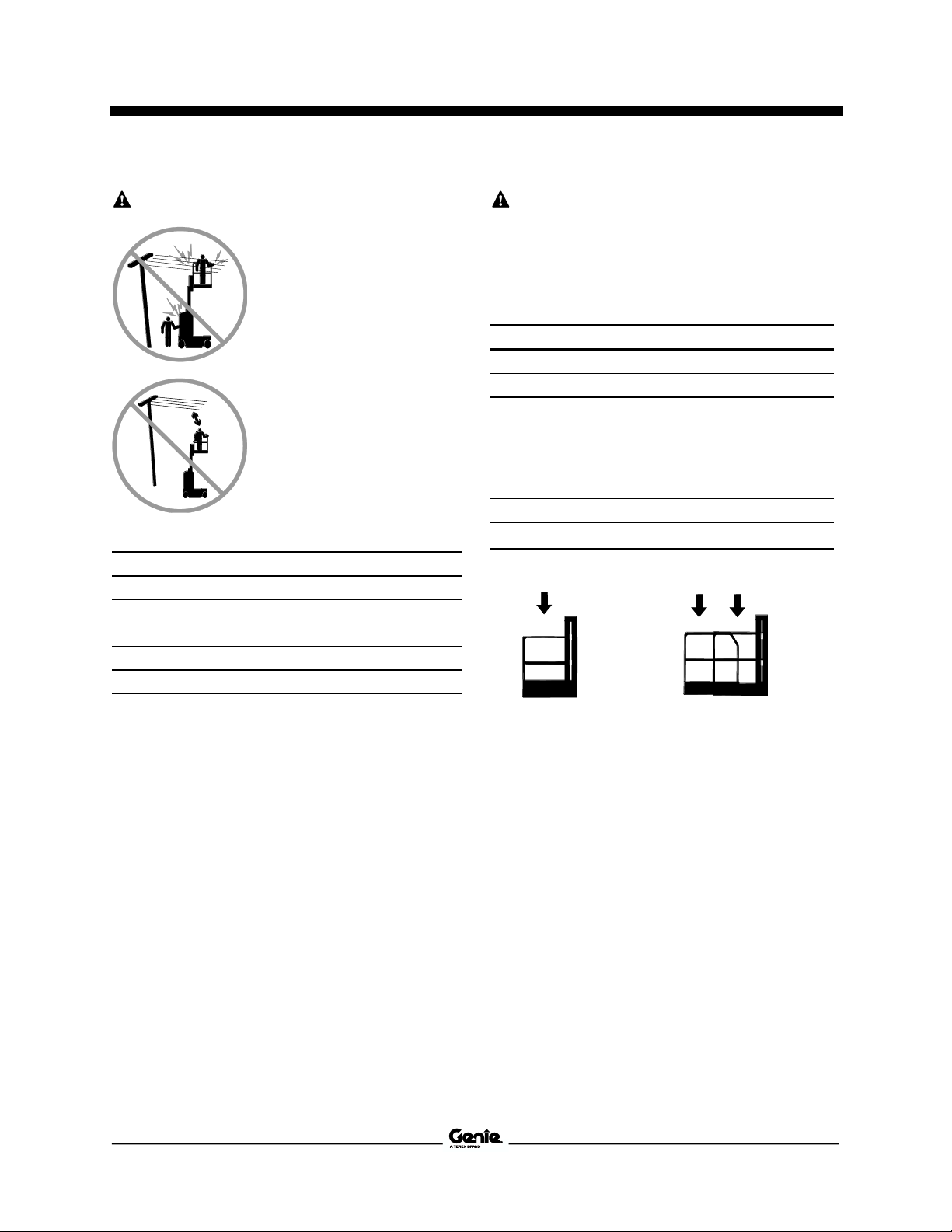

Electrocution Hazards

This machine is not

electrically insulated and

will not provide protection

from contact with or

proximity to electrical

current.

Obey all local and

governmental regulations

regarding required

clearance from electrical

power lines. At a minimum,

the required clearance

contained in the chart

below must be followed.

Line Voltage

Required Clearance

0 to 50KV

10 ft

3.05 m

50 to 200KV

15 ft

4.60 m

200 to 350KV

20 ft

6.10 m

350 to 500KV

25 ft

7.62 m

500 to 750KV

35 ft

10.67 m

750 to 1000KV

45 ft

13.72 m

Allow for platform movement, electrical line sway

or sag, and beware of strong or gusty winds.

Keep away from the machine if it contacts

energized power lines. Personnel on the ground or

in the platform must not touch or operate the

machine until energized power lines are shut off.

Do not operate the machine during lightning or

storms.

Do not use the machine as a ground for welding.

Tip-over Hazards

Occupants, equipment and materials shall not

exceed the maximum platform capacity or the

maximum platform capacity of the platform

extension. Weight in trays is part of the total

platform load.

Maximum capacity - GR-12 and GR-15

Standard platform

Platform without extension

500 lbs

227 kg

Platform retracted

500 lbs

227 kg

Platform extended – Platform

only

250 lbs

113 kg

Platform extended –

Extension only

250 lbs

113 kg

Work tray station (option)

50 lbs

22 kg

Maximum occupants

1

500 lbs / 227 kg

Extension only

250 lbs/113 kg

Platform only

250 lbs/113 kg

Page 17

Sixth Edition • First Printing Operator's Manual

Work Area Safety

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 15

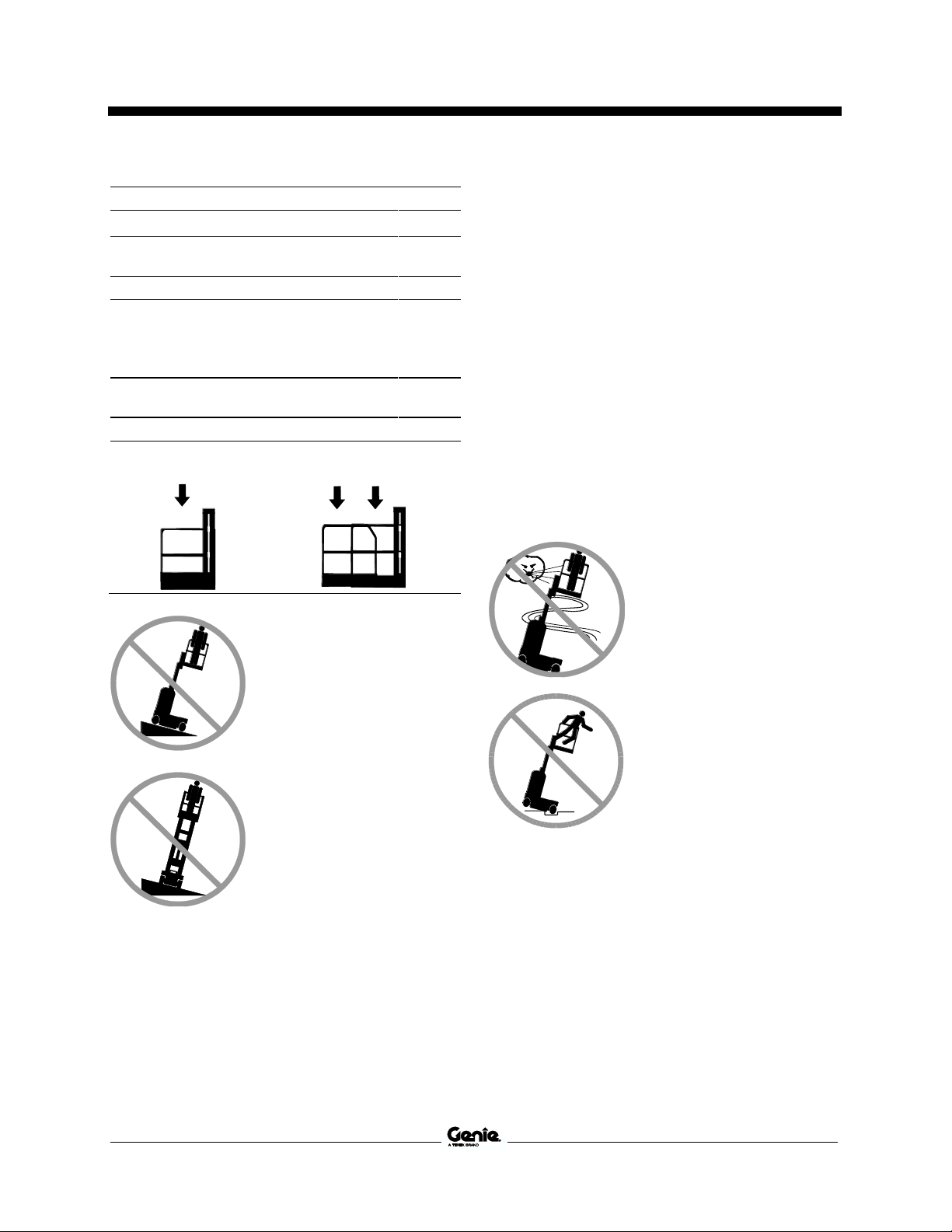

Maximum capacity - GR-20

Standard platform

Platform without

extension

350 lbs

159kg

Platform retracted

350 lbs

159 kg

Platform extended –

Platform only

100 lbs

45 kg

Platform extended –

Extension only

250 lbs

113 kg

Work tray station

(option)

50 lbs

22 kg

Maximum occupants

1

350 lbs/159 kg

Extension only

250 lbs/113 kg

Platform only

100 lbs/45 kg

Do not raise the platform

unless the machine is on a

firm, level surface.

Do not depend on the tilt

alarm as a level indicator.

The tilt alarm sounds at the

platform controls and the

ground controls when the

machine is on a severe

slope.

If the tilt alarm sounds:

Lower the platform. Move the machine to a firm,

level surface. If the tilt alarm sounds when the

platform is raised, use extreme caution to lower

the platform.

Do not drive over 0.5 mph / 0.8 km/h with the

platform raised.

Do not raise the platform when wind speeds may

exceed 28 mph / 12.5 m/s. If wind speeds exceed

28 mph / 12.5 m/s when the platform is raised,

lower the platform and do not continue to operate

the machine.

Follow ratings for allowable side force and number

of occupants shown below.

Outdoor use: Do not operate the machine

outdoors with the indoor use button selected.

Do not operate the machine

in strong or gusty winds. Do

not increase the surface area

of the platform or the load.

Increasing the area exposed

to the wind will decrease

machine stability.

Use extreme care and slow

speeds while driving the

machine in the stowed

position across uneven

terrain, debris, unstable or

slippery surfaces and near

holes and drop-offs.

Page 18

Operator's Manual Sixth Edition • First Printing

Work Area Safety

16 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Do not drive the machine on or near uneven

terrain, unstable surfaces or other hazardous

conditions with the platform raised.

Do not use the machine as a crane.

Do not push the machine or other objects with the

platform.

Do not contact adjacent structures with the

platform.

Do not tie the platform to adjacent structures.

Do not place loads outside the platform perimeter.

The work station tray is considered part of the

platform.

Do not use the platform controls to free a platform

that is caught, snagged, or otherwise prevented

from normal motion by an adjacent structure. All

personnel must be removed from the platform

before attempting to free the platform using the

ground controls.

Do not push off or pull

toward any object outside

of the platform.

Maximum allowable

side force

Maximum occupants

45 lbs / 200 N

1

Do not alter or disable the limit switches.

Do not alter or disable machine components that

in any way affect safety and stability.

Do not replace items critical to machine stability

with items of different weight or specification.

Do not use batteries that weigh less than the

original equipment. Batteries are used as

counterweight and are critical to machine stability.

Each battery must weigh a minimum of

62 lbs/28 kg.

Do not modify or alter a mobile elevating work

platform without prior written permission from the

manufacturer. Mounting attachments for holding

tools or other materials onto the platform,

toeboards, or guard rail system can increase the

weight in the platform and the surface area of the

platform or the load.

Do not place or attach fixed

or overhanging loads to

any part of this machine.

Do not place ladders or

scaffolds in the platform or

against any part of this

machine.

Do not transport tools and

materials unless they are

evenly distributed and can

be safely handled by

person(s) in the platform.

Page 19

Sixth Edition • First Printing Operator's Manual

Work Area Safety

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 17

Do not use the machine on

a moving or mobile surface

or vehicle.

Be sure all tires are in good

condition, castle nuts are

properly tightened and

cotter pins are properly

installed.

Crushing Hazard

Keep hands and limbs out of mast.

Do not work under the platform or mast without the

battery cover raised.

Use common sense and planning when operating

the machine with the controller from the ground.

Maintain safe distances between the operator, the

machine and fixed objects.

Operation on Slopes Hazards

Do not drive the machine on a slope that exceeds

the slope and side slope rating of the machine.

Slope rating applies to machines in the stowed

position.

Maximum slope rating, stowed

position

30% (16.7°)

Maximum side slope rating, stowed

position

30% (16.7°)

Note: Slope rating is subject to ground conditions

with one person in the platform and adequate

traction. Additional platform weight may reduce

slope rating. See Driving on a Slope in the

Operating Instructions section.

Fall Hazards

The guard rail system provides fall protection. If

occupant(s) of the platform are required to wear

personal fall protection equipment (PFPE) due to

job site or employer rules, PFPE and its use shall

be in accordance with the PFPE manufacturer’s

instructions and applicable governmental

requirements. Use approved lanyard attachment

point provided.

Keep the platform floor clear of debris.

Close the entry gate before operating.

Do not sit, stand, or climb

on the platform guard

rails. Maintain a firm

footing on the platform

floor at all times.

Do not climb down from

the platform when raised.

Do not enter or exit the

platform unless the

machine is in the stowed

position.

Page 20

Operator's Manual Sixth Edition • First Printing

Work Area Safety

18 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Collision Hazards

Be aware of limited sight

distance and blind spots

when driving or operating.

Be aware of extended platform position when

moving the machine.

The machine must be on a level surface and

wheels chocked or secured before releasing the

brakes.

Operators must comply with employer, job site,

and governmental rules regarding use of personal

protective equipment.

Check the work area for

overhead obstructions or

other possible hazards.

Be aware of crushing

hazards when grasping

the platform guard rail.

Do not lower the platform

unless the area below is

clear of personnel and

obstructions.

Limit travel speed

according to the condition

of the ground surface,

congestion, slope,

location of personnel, and

any other factors which

may cause collision.

Observe and use color-coded direction arrows on

the platform controls and the platform decal plate

for drive and steer functions.

Do not operate a machine in the path of any crane

or moving overhead machinery unless the controls

of the crane have been locked out and/or

precautions have been taken to prevent any

potential collision.

No stunt driving or horseplay while operating a

machine.

Page 21

Sixth Edition • First Printing Operator's Manual

Work Area Safety

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 19

Bodily Injury Hazard

Do not operate the machine with a hydraulic oil or

air leak. An air leak or hydraulic leak can penetrate

and/or burn skin.

Improper contact with components under any

cover will cause serious injury. Only trained

maintenance personnel should access

compartments. Access by the operator is only

advised when performing a pre-operation

inspection. All compartments must remain closed

and secured during operation.

Explosion and Fire Hazards

Do not operate the machine or charge the battery

in hazardous locations or locations where

potentially flammable or explosive gases or

particles may be present.

Damaged Machine Hazards

Do not use a damaged or malfunctioning machine.

Conduct a thorough pre-operation inspection of

the machine and test all functions before each

work shift. Immediately tag and remove from

service a damaged or malfunctioning machine.

Be sure all maintenance has been performed as

specified in this manual and the appropriate Genie

service manual.

Be sure all decals are in place and legible.

Be sure the operator's, safety, and responsibilities

manuals are complete, legible, and in the storage

container located on the machine.

Component Damage Hazards

Do not use any battery charger greater than 24V

to charge the batteries.

Do not use the machine as a ground for welding.

Page 22

Operator's Manual Sixth Edition • First Printing

Work Area Safety

20 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Battery Safety

Burn Hazards

Batteries contain acid.

Always wear protective

clothing and eye wear when

working with batteries.

Avoid spilling or contacting

battery acid. Neutralize

battery acid spills with baking

soda and water.

Do not expose the batteries or the charger to

water or rain during charging.

Explosion Hazards

Keep sparks, flames, and

lighted tobacco away from

batteries. Batteries emit

explosive gas.

The battery tray may remain

open during the entire

charging cycle.

Do not contact the battery

terminals or the cable

clamps with tools that may

cause sparks.

Component Damage Hazard

Do not use any battery charger greater than 24V

to charge the batteries.

Electrocution/Burn Hazards

Connect the battery charger to a

grounded, AC 3-wire electrical

outlet only.

Inspect daily for damaged cords,

cables and wires. Replace

damaged items before operating.

Avoid electrical shock from contact with battery

terminals. Remove all rings, watches and other

jewelry.

Tip-over Hazard

Do not use batteries that weigh less than the

original equipment. Batteries are used as

counterweight and are critical to machine stability.

Each battery must weigh a minimum of

62 lbs/28 kg.

Lifting Hazard

Use the appropriate number of people and proper

lifting techniques when lifting batteries.

Lockout After Each Use

1 Select a safe parking location—firm level

surface, clear of obstruction and traffic.

2 Lower the platform.

3 Turn the key switch to the off position and

remove the key to secure from unauthorized

use.

4 Charge the batteries.

Page 23

Sixth Edition • First Printing Operator's Manual

Legend

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 21

Legend

1 Pothole guard

2 Non-steer tire

3 Auxiliary lowering valve

4 Transport tie-down

5 Forklift pockets

6 Battery charger display

7 Covers

8 Hydraulic oil level indicator

9 Ground controls

10 Mast

11 Brake release pump knob

(under covers)

12 Platform controls

13 Manual storage container

14 Lanyard anchorage point

15 Tool Tray

16 GFCI outlet

17 Battery compartment cover

18 Battery cover latch

19 Steer tire

20 Platform extension release

pedal

21 Platform extension entry gate

Page 24

Operator's Manual Sixth Edition • First Printing

Controls

22 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Controls

The ground control station is to be used as a means to raise the platform for function tests and for storage

purposes. The ground control station can be used in the event of an emergency to rescue an

incapacitated person in the platform.

Ground Control Panel

1 7A breaker for electrical circuits

2 Red Emergency Stop button

Push in the red Emergency Stop button to the off

position to stop all functions. Pull out the red

Emergency Stop button to the on position to

operate the machine.

3 Menu down button

4 Menu enter button

5 Platform up button

6 Platform down button

7 Lift function enable button

Press and hold this button to activate the lift

function.

8 Menu escape button

9 Menu up button

10 LCD diagnostic readout

11 Key switch for platform/off/ground selection

Turn the key switch to the platform position and

the platform controls will operate. Turn the key

switch to the off position and the machine will be

off. Turn the key switch to the ground position

and the ground controls will operate.

12 Tech Pro Link Connector

Page 25

Sixth Edition • First Printing Operator's Manual

Controls

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 23

Platform Control Panel

1 Red Emergency Stop button

Push in the red Emergency Stop button to the

off position to stop all functions. Pull out the

red Emergency Stop button to the on position

to operate the machine.

2 Lift function button

Push this button to activate the lift

function.

3 Horn button

Press the horn button and the horn

will sound. Release the horn

button and the horn will not sound.

4 Drive speed select button

Press this button to activate the

slow drive function. The indicator

light will be on when slow drive is

selected.

5 Proportional control handle and function

enable switch for drive, steer, and lift functions

Lift function: Press and hold the function

enable switch to enable the lift function on the

platform control handle. Move the control

handle in the direction indicated by the blue

arrow and the platform will raise. Move the

control handle in the direction indicated by the

yellow arrow and the platform will lower. The

descent alarm should sound while the platform

is lowering.

Drive function: Press and hold the function

enable switch to enable the drive function on

the platform control handle. Move the control

handle in the direction indicated by the blue

arrow on the control panel and the machine

will move in the direction that the blue arrow

points. Move the control handle in the direction

indicated by the yellow arrow on the control

panel and the machine will move in the

direction that the yellow arrow points.

Page 26

Operator's Manual Sixth Edition • First Printing

Controls

24 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

6 Thumb rocker switch for steer function

Press the left side of the thumb

rocker and the machine will turn in

the direction the blue triangle

points on the platform control

panel.

Press the right side of the thumb

rocker and the machine will turn in

the direction the yellow triangle

points on the platform control

panel.

7 LED diagnostic readout, battery charge

indicator and lift/drive mode indicator

8 Drive function button

Push this button to activate the

drive function.

9 Indoor use button

Press this button for indoor use

Note: Selecting indoor use permits

elevating to maximum indoor

platform height. Refer to

specification pages.

10 Outdoor use button

Press this button for outdoor use

Note: Selecting outdoor use

permits elevating to maximum

outdoor platform height. Refer to

specification pages.

Page 27

Sixth Edition • First Printing Operator's Manual

Inspections

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 25

Inspections

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

Know and understand the pre-operation

inspection before going on to the next

section.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Pre-operation Inspection

Fundamentals

It is the responsibility of the operator to perform a

pre-operation inspection and routine maintenance.

The pre-operation inspection is a visual inspection

performed by the operator prior to each work shift.

The inspection is designed to discover if anything

is apparently wrong with a machine before the

operator performs the function tests.

The pre-operation inspection also serves to

determine if routine maintenance procedures are

required. Only routine maintenance items specified

in this manual may be performed by the operator.

Refer to the list on the next page and check each

of the items.

If damage or any unauthorized variation from

factory delivered condition is discovered, the

machine must be tagged and removed from

service.

Repairs to the machine may only be made by a

qualified service technician, according to the

manufacturer’s specifications. After repairs are

completed, the operator must perform a preoperation inspection again before going on to the

function tests.

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer’s specifications and

the requirements listed in the responsibilities

manual.

Page 28

Operator's Manual Sixth Edition • First Printing

Inspections

26 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Pre-operation Inspection

Be sure that the operator’s, safety, and

responsibilities manuals are complete, legible

and in the storage container located in the

platform.

Be sure that all decals are legible and in place.

See Inspections section.

Check for hydraulic oil leaks and proper oil

level. Add oil if needed. See Maintenance

section.

Check for battery fluid leaks and proper fluid

level. Add distilled water if needed. See

Maintenance section.

Check the following components or areas for

damage, improperly installed, or missing parts and

unauthorized modifications:

Electrical components, wiring, and

electrical cables

Hydraulic power unit, reservoir, hoses,

fittings, cylinders and manifolds

Battery pack and connections

Drive motors

Tires and wheels

Ground strap

Limit switches, alarms and horn

Beacons (if equipped)

Nuts, bolts and other fasteners

Platform entry mid-rail or gate

Sequencing cables and pulleys

Wear pads

Pothole guards

Lanyard anchorage points

Platform extension (if equipped)

Work trays (if equipped)

Brake release components

Battery cover

Mast columns and counterweight

Platform control joystick

Platform overload components

Check entire machine for:

Cracks in welds or structural components

Dents or damage to machine

Excessive rust, corrosion or oxidation

Verify that all structural and other critical

components are present and all associated

fasteners and pins are in place and properly

tightened.

Note: If the platform must be raised to inspect the

machine, make sure that the battery cover is in

place to prevent the mast sections and platform

from coming down. See Operating Instructions

section.

Page 29

Sixth Edition • First Printing Operator's Manual

Inspections

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 27

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to

use.

Know and understand the function tests

before going on to the next section.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Function Test Fundamentals

The function tests are designed to discover any

malfunctions before the machine is put into

service. The operator must follow the step-by-step

instructions to test all machine functions.

A malfunctioning machine must never be used. If

malfunctions are discovered, the machine must be

tagged and removed from service. Repairs to the

machine may only be made by a qualified service

technician, according to the manufacturer’s

specifications.

After repairs are completed, the operator must

perform a pre-operation inspection and function

tests again before putting the machine into

service.

Page 30

Operator's Manual Sixth Edition • First Printing

Inspections

28 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

At the Ground Controls

1 Select a test area that is firm, level and free of

hazards.

2 Be sure the batteries are connected.

3 Pull out the platform and ground red

Emergency Stop button to the on position.

4 Turn the key switch to ground control.

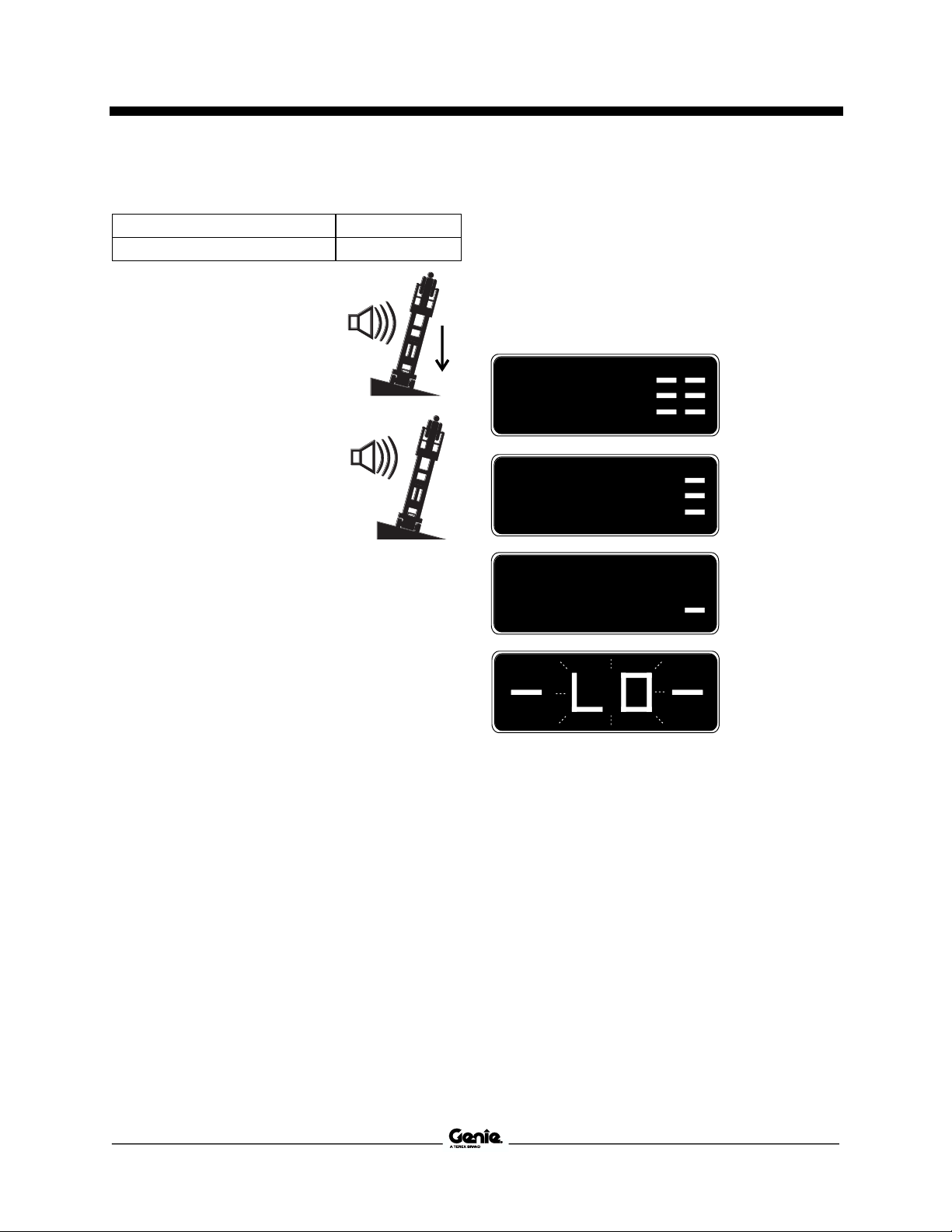

5 Observe the diagnostic LED readout on the

platform controls.

Result: The LED should look like the picture

below.

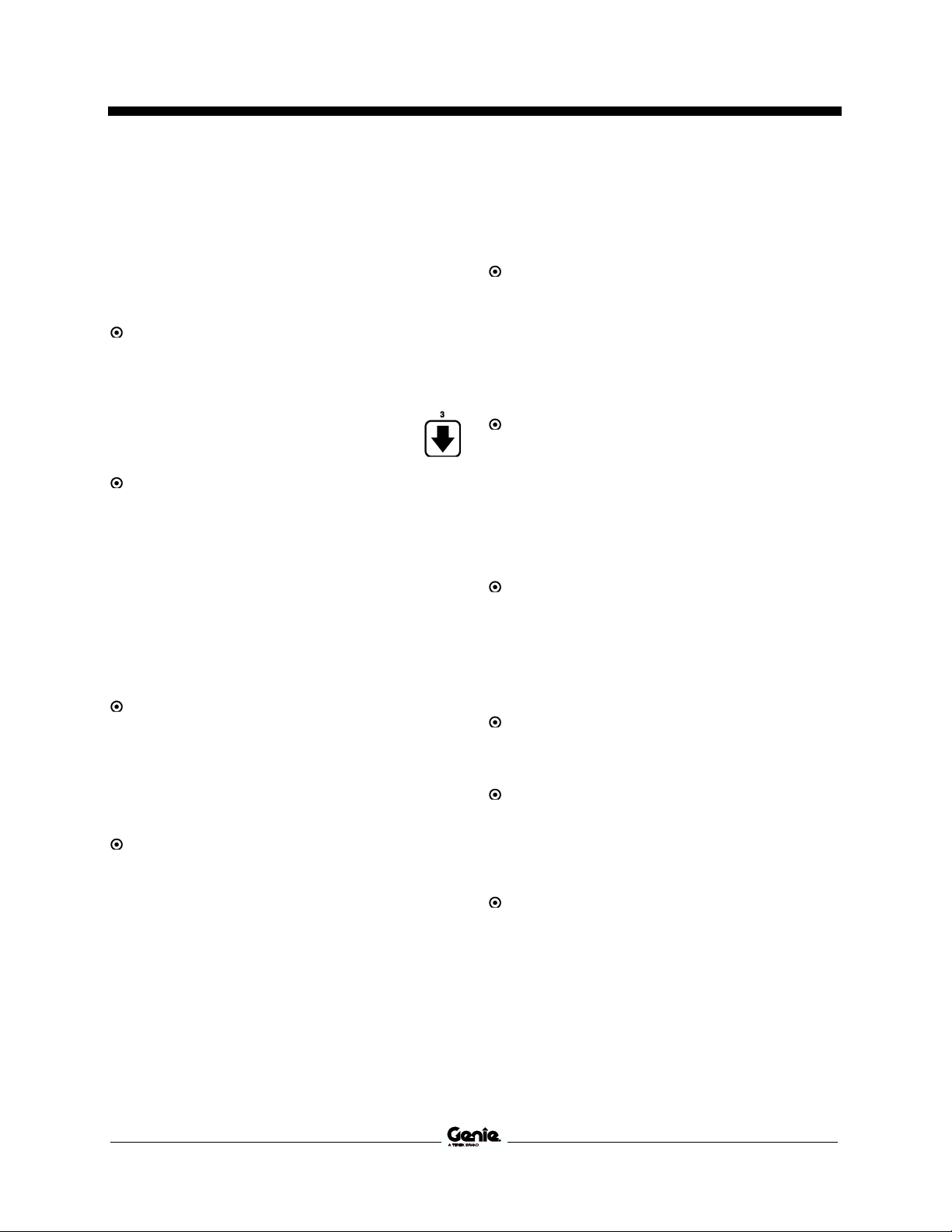

6 Observe the diagnostic LCD readout on the

ground controls.

Result: The LCD should look like the picture

below.

Test Emergency Stop

7 Push in the ground red Emergency Stop

button to the off position.

Result: No functions should operate.

8 Pull out the red Emergency Stop button to the

on position.

Test the Up/Down Functions

The audible warnings on this machine and the

standard horn all come from the same central

alarm. The horn is a constant tone. The descent

alarm sounds at 60 beeps per minute. The alarm

sounds at 180 beeps per minute when the pothole

guards have not deployed and when the machine

is not level. An optional automotive-style horn is

also available.

9 Do not press the lift function enable button.

10 Press the platform up or platform down button.

Result: The lift function should not operate.

11 Do not press the platform up or platform down

buttons.

12 Press the lift function enable button.

Result: The lift function should not operate.

13 Press and hold the lift function enable button,

and press the platform up button.

Result: The lift function should not operate.

14 Press the Enter button to cycle between indoor

and outdoor area of operation.

15 Select the outdoor area of operation.

16 Press and hold the lift function enable button,

and press the platform up button.

Result: The platform should raise.

17 Press and hold the lift function enable button,

and press the platform down button.

Result: The platform should lower.The descent

alarm should sound while the platform is

lowering.

Page 31

Sixth Edition • First Printing Operator's Manual

Inspections

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 29

Test Auxiliary Lowering

18 Activate the up function by pressing the lift

enable button and platform up button, and

raise the platform approximately 2 ft. / 60 cm.

19 Pull the auxiliary lowering knob located at the

base of the machine below the mast.

Result: The platform should lower. The

descent alarm will not sound.

Test the Tilt Sensor Operation

20 Press the ground control down button

(button 3)

Result: The ground control LCD screen will

display the status of the tilt sensor. The X and

Y values (pitch and roll) will be displayed.

21 Turn the key switch to platform control.

At the Platform Controls

Test Emergency Stop

22 Push in the platform red Emergency Stop

button to the off position.

Result: No functions should operate.

Test the Horn

23 Pull out the red Emergency Stop button to the

on position.

24 Press the horn button.

Result: The platform alarm, chassis alarm, and

automotive horn (if equipped) should sound.

Test the Function Enable Switch and the

Up/Down Functions

25 Press the outdoor use button.

Result: The outdoor use button should

illuminate.

26 Do not hold the function enable switch on the

control handle.

27 Slowly move the control handle in the direction

indicated by the blue arrow, then in the

direction indicated by the yellow arrow.

Result: No functions should operate.

28 Press the lift function button.

29 Wait seven seconds for the lift function to time

out.

30 Slowly move the control handle in the direction

indicated by the blue arrow, then in the

direction indicated by the yellow arrow.

Result: The lift function should not operate.

31 Press the lift function button.

32 Press and hold the function enable switch on

the control handle. Slowly move the control

handle in the direction indicated by the blue

arrow.

Result: The platform should raise. The pothole

guards should deploy.

33 Release the control handle.

Result: The platform should stop raising.

34 Press and hold the function enable switch on

the control handle. Slowly move the control

handle in the direction indicated by the yellow

arrow.

Result: The platform should lower. The

descent alarm should sound while the platform

is lowering.

Page 32

Operator's Manual Sixth Edition • First Printing

Inspections

30 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Test the Outdoor Use Button

35 Do not press and hold the function enable

switch on control handle.

36 Press the outdoor use button.

Result: The LED under the outdoor button will

illuminate.

37 Press the lift function enable button.

38 Press and hold the function enable switch on

the control handle. Slowly move the control

handle in the direction indicated by the blue

arrow.

GR-12: Result: The platform should raise to

9 ft 1 in/2.76 m and stop. The alarm should

sound. The platform controls LED readout

should display OHL.

GR-15: Result: The platform should raise to

11 ft 1 in/3.37 m and stop. The alarm should

sound. The platform controls LED readout

should display OHL.

GR-20: Result: The platform should raise to

15 ft 6 in/4.72 m and stop. The alarm should

sound. The platform controls LED readout

should display OHL.

Test the Drive Function Button

39 Press the drive function button.

40 Wait seven seconds for the drive function to

time out. Slowly move the control handle in the

direction indicated by the blue arrow, then in

the direction indicated by the yellow arrow.

Result: No functions should operate.

Test the Steering

Note: When performing the steer and drive

function tests, stand in the platform facing the

steer end of the machine.

41 Press the drive function button.

42 Press and hold the function enable switch on

the control handle.

43 Press the thumb rocker switch on top of the

control handle in the direction indicated by the

blue triangle on the control panel.

Result: The steer wheels should turn in the

direction indicated by the blue triangle.

44 Press the thumb rocker switch on top of the

control handle in the direction indicated by the

yellow triangle, on the control panel.

Result: The steer wheels should turn in the

direction indicated by the yellow triangle.

Page 33

Sixth Edition • First Printing Operator's Manual

Inspections

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 31

Test Drive and Braking

45 Press the drive function button.

46 Press and hold the function enable switch on

the control handle.

47 Slowly move the control handle in the direction

indicated by the blue arrow on the control

panel until the machine begins to move, then

return the control handle to the center position.

Result: The machine should move in the

direction that the blue arrow points on the

control panel, then come to an abrupt stop

when the control handle is returned to the

center position.

48 Slowly move the control handle in the direction

indicated by the yellow arrow on the control

panel until the machine begins to move, then

return the control handle to the center position.

Result: The machine should move in the

direction that the yellow arrow points on the

control panel, then come to an abrupt stop

when the control handle is returned to the

center position.

Note: The brakes must be able to hold the

machine on any slope it is able to climb.

Test Drive Tilt Cutout

Note: Perform this test from the ground with the

platform controller. Do not stand in the platform.

49 Fully lower the platform.

50 Drive the machine onto a slope where the

chassis angle is greater than 1.5° side to side.

51 Raise the platform to approximately

7 ft/2.13 m.

Result: The platform should stop and the tilt

alarm will sound at 180 beeps per minute. The

platform controls LED readout should display

LL and the ground controls LCD should

display LL: Machine Tilted.

52 Press the drive function button.

53 Press and hold the function enable switch on

the control handle.

54 Move the control handle in the direction

indicated by the blue arrow, then move the

control handle in the direction indicated by the

yellow arrow.

Result: The drive function should not work in

either direction.

55 Fully lower the platform.

56 Drive the machine.

Result: The machine should drive.

57 Return to level ground and raise the platform

in excess of approximately 7 ft/2.13 m.

Page 34

Operator's Manual Sixth Edition • First Printing

Inspections

32 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

58 Drive the machine onto a slope where the

pitch angle is greater than 1.5° side to side.

Result: The machine should stop once the

machine reaches 1.5° of chassis tilt and the tilt

alarm will sound at 180 beeps per minute. The

platform controls LED readout should display

LL and the ground controls LCD should

display LL: Machine Tilted

59 Return to level ground and fully lower the

platform.

60 Drive the machine onto a slope where the

chassis angle is greater than 3° front to back.

61 Raise the platform to approximately

7 ft/2.13 m.

Result: The platform should stop and the tilt

alarm will sound at 180 beeps per minute. The

platform controls LED readout should display

LL and the ground controls LCD should

display LL: Machine Tilted.

62 Press the drive function button.

63 Press and hold the function enable switch on

the control handle.

64 Move the control handle in the direction

indicated by the blue arrow, then move the

control handle in the direction indicated by the

yellow arrow.

Result: The drive function should not work in

either direction.

65 Fully lower the platform.

66 Drive the machine.

Result: The machine should drive.

67 Return to level ground and raise the platform

in excess of approximately 7 ft/2.13 m.

68 Drive the machine onto a slope where the

pitch angle is greater than 3° front to back.

Result: The machine should stop once the

machine reaches 3° of chassis tilt and the tilt

alarm will sound at 180 beeps per minute. The

platform controls LED readout should display

LL and the ground controls LCD should

display LL: Machine Tilted

69 Fully lower the platform and return to level

ground.

Test Elevated Drive Speed

70 Raise the platform approximately 4 ft / 1.2 m

from the ground.

71 Press the drive function button.

72 Press and hold the function enable switch on

the control handle.Slowly move the control

handle to full drive position.

Result: The maximum achievable drive speed

with the platform raised should not exceed

0.72 ft / 22 cm per second.

If the drive speed with the platform raised exceeds

0.72 ft / 22 cm per second, immediately tag and

remove the machine from service.

Page 35

Sixth Edition • First Printing Operator's Manual

Inspections

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 33

Test the Pothole Guards

Note: The pothole guards should automatically

deploy when the platform is raised. The pothole

guards activate limit switches that allow the

machine to continue to function. If the pothole

guards do not deploy, an alarm sounds and the

machine will not drive or steer.

73 Raise the platform.

Result: When the platform is raised

approximately 4 ft / 1.2 m from the ground, the

pothole guards should deploy.

74 Press on the pothole guards on one side, and

then the other.

Result: The pothole guards should not move.

75 Lower the platform.

Result: The pothole guards should return to

the stowed position.

76 Place a 2x4 or similar piece of wood under a

pothole guard.

77 Raise the platform.

Result: Before the platform is raised

approximately 7 ft / 2.1 m from the ground, an

alarm should sound. The platform controls

LED readout should display PHS and the

ground controls LCD should display PHS:

Pothole Guard Stuck.

78 Press the drive function button.

79 Press and hold the function enable switch on

the control handle.

80 Slowly move the control handle in the direction

indicated by the blue arrow, then in the

direction indicated by the yellow arrow.

Result: The machine should not move forward

or backward.

81 Press the drive function button.

82 Press and hold the function enable switch on

the control handle.

83 Press the thumb rocker switch on top of the

control handle in the direction indicated by the

blue and yellow triangles on the control panel.

Result: The steer wheels should not turn left or

right.

84 Fully lower the platform.

85 Remove the 2x4 or similar piece of wood.

Page 36

Operator's Manual Sixth Edition • First Printing

Inspections

34 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

Know and understand the workplace

inspection before going on to the next

section.

5 Only use the machine as it was intended.

Workplace Inspection

Fundamentals

The workplace inspection helps the operator

determine if the workplace is suitable for safe

machine operation. It should be performed by the

operator prior to moving the machine to the

workplace.

It is the operator’s responsibility to read and

remember the workplace hazards, then watch for

and avoid them while moving, setting up, and

operating the machine.

Workplace Inspection Checklist

Be aware of and avoid the following hazardous

situations:

drop-offs or holes

bumps, floor obstructions, or debris

sloped surfaces

unstable or slippery surfaces

overhead obstructions and high voltage

conductors

hazardous locations

inadequate surface support to withstand all

load forces imposed by the machine

wind and weather conditions

the presence of unauthorized personnel

other possible unsafe conditions

Page 37

Sixth Edition • First Printing Operator's Manual

Inspections

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 35

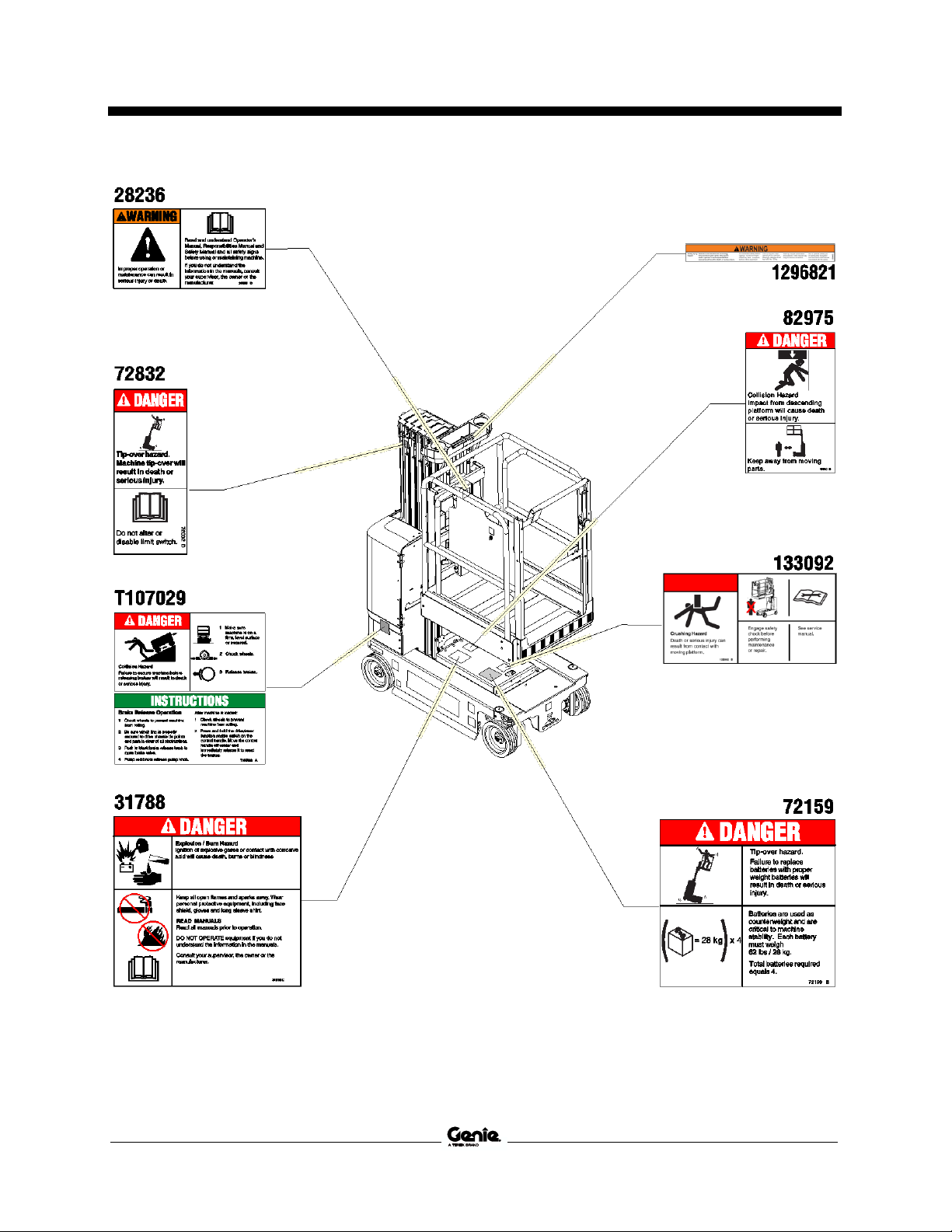

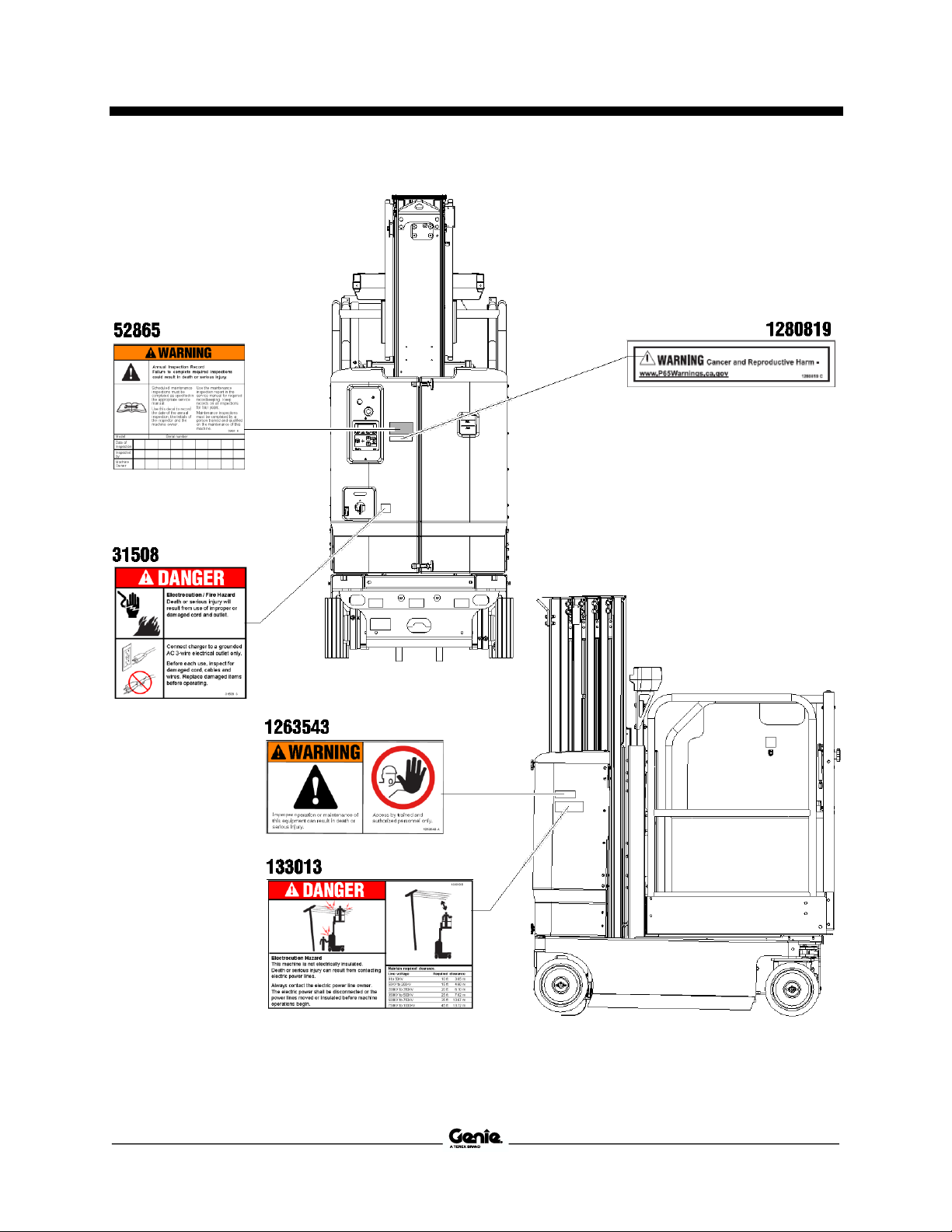

Inspection for Decals with Words

Determine whether the decals on your machine

have words or symbols. Use the appropriate

inspection to verify that all decals are legible and

in place.

Part No. Decal Description

Qty

28174 Label – Power to Platform, 230V*

2

28235 Label – Power to Platform, 115V*

2

28236 Warning – Improper Operation

1

28373 Label – Forklift Pocket

2

31508 Danger – Electrocution Hazard

1

31788 Danger – Explosion/Burn Hazard

1

38122 Label – Manual Storage

1

38149 Label – Patents

1

43658 Label – Power to Charger, 230V*

1

44736 Danger – Tip-over Hazard, Tilt Alarm

1

44980 Label – Power to Charger, 115V*

1

52475 Label – Transport Tie-down

3

52865 Warning – Annual Inspection Record

1

72086 Label – Lifting Point

1

72159 Danger – Tip-over Hazard, Batteries

1

72188 Label – Directional Arrows

2

72832 Danger – Do Not Alter Limit Switch

1

72970 Instructions – Battery Charger

Operation

1

82366 Label – Chevron Rando*

1

82836 Label – Auxiliary Lowering

1

82975 Warning – Collision Hazard

1

97815 Label – Lower Mid-rail*

1

114325 Instructions – Battery Connection

Diagram

1

133013 Danger – Electrocution Hazard

1

133092 Danger – Crushing Hazard, Use Safety

Chock

1

133586 Instructions – Operation, Ground

Control

1

137605 Label – Emergency Stop, Platform

Control

1

137656 Label – Drive/Steer Direction,

Platform Control

1

220283 Warning – Unauthorized Use Hazard*

1

1263543 Warning – Compartment Access

1

Part No. Decal Description

Qty

1270489 Label – Wheel Load, GR, GRC

4

1272242 Label – Machine Registration/Owner

Transfer

1

1280819 Label – Warning, Prop 65

1

1281175 Label – Lanyard Anchorage Point, Fall

Restrained

1

1283228 Label – GCON, GR, Tech Pro

1

1283810 Label – Platform Control Panel

1

1283878 Label – Tech Pro Link

1

1293165 Danger – Tip-over, Crush Hazard

1

1293324 Label – ICES-2/CAN-2 Compliance

1

1294398 Label – ANSI/CSA Compliant

1

1294635 Label – Platform Overload LED

Indicator Light

1

1296034 Label – Smartlink Dual Zone

2

1296295 Label – Fault Codes

1

1296619 Label – Maximum Capacity, 350 lbs,

Side Force 45 lbs*

1

1296621 Label – Maximum Capacity, 500 lbs,

Side Force 45 lbs*

1

1296821 Decal – Warning, Tool Box

1

1297735 Label – Transport Diagram

2

T107029 Danger/Instructions – Brake Release

Safety and Operation

1

T107894 Label – Tire Specifications

4

* These decals are model, option or

configuration specific.

Page 38

Operator's Manual Sixth Edition • First Printing

Inspections

36 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Page 39

Sixth Edition • First Printing Operator's Manual

Inspections

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 37

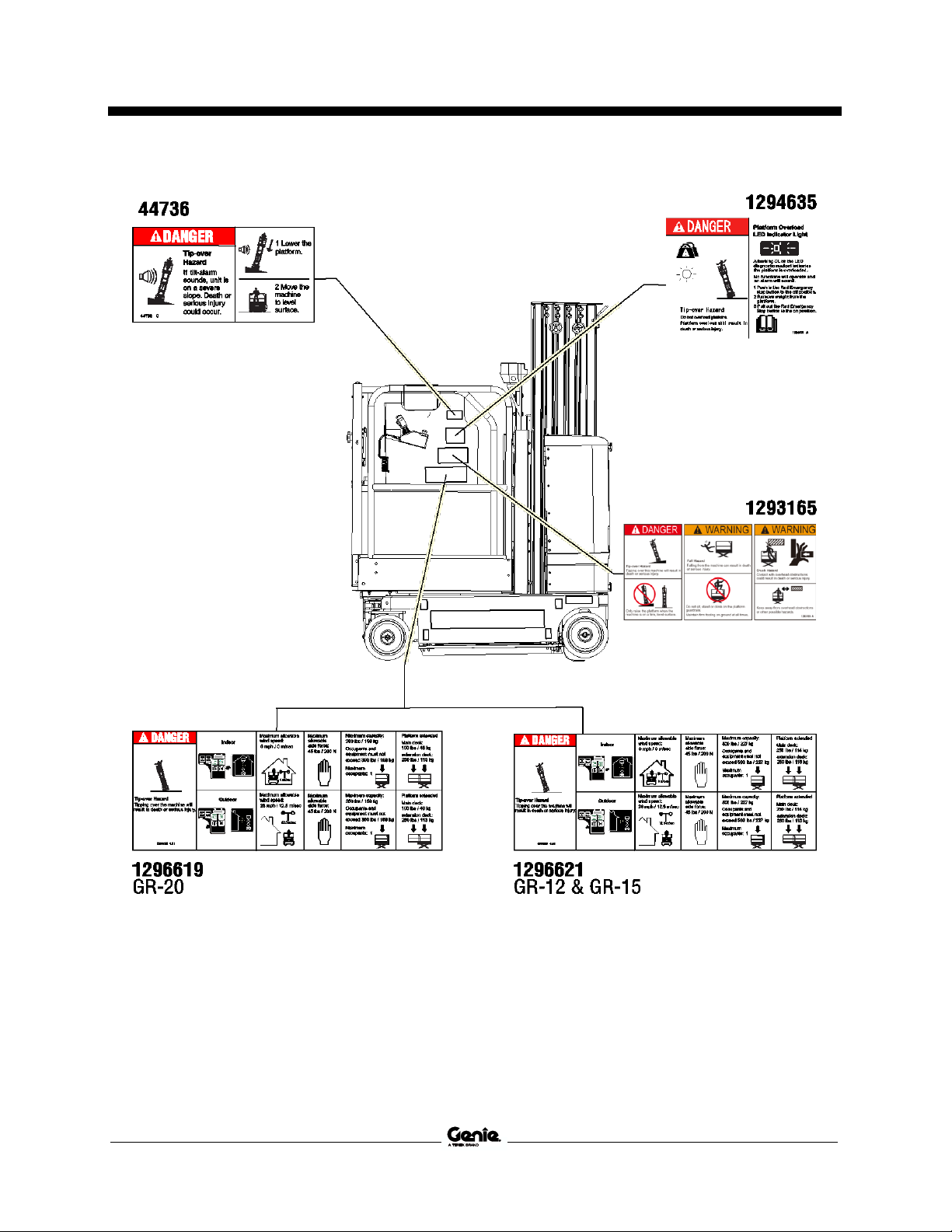

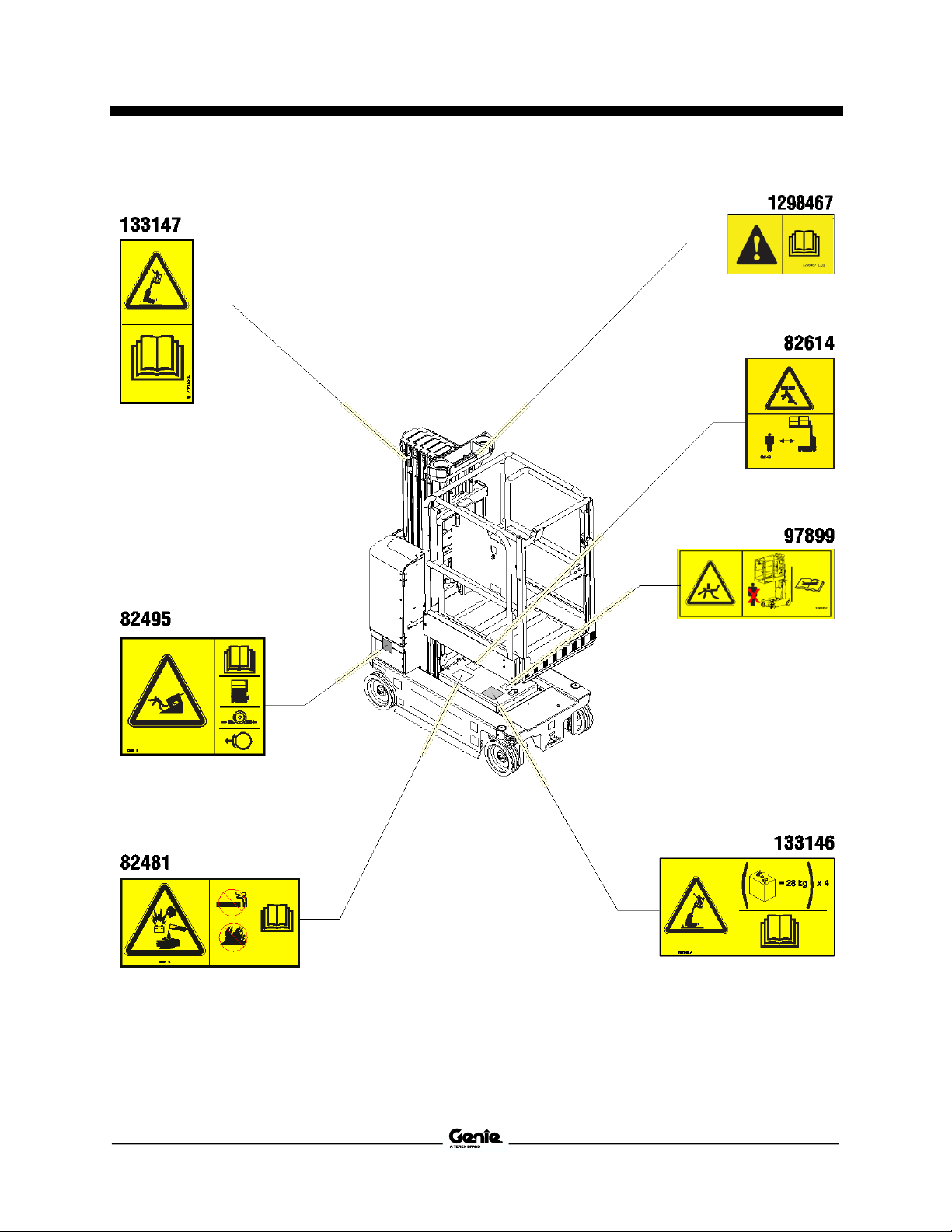

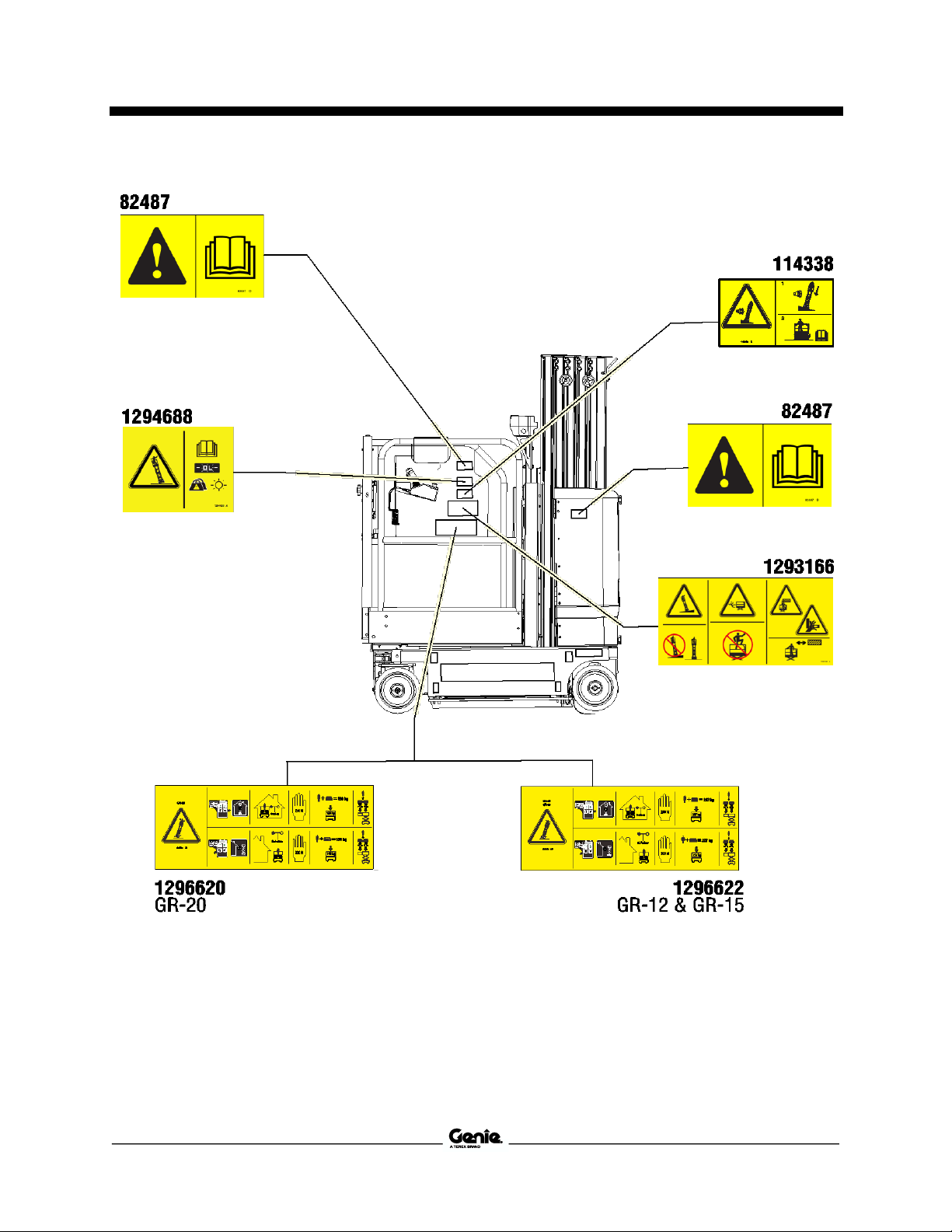

Inspection for Decals with

Symbols

Determine whether the decals on your machine

have words or symbols. Use the appropriate

inspection to verify that all decals are legible and

in place.

Part No. Decal Description

Qty

28174 Label – Power to Platform, 230V*

2

28235 Label – Power to Platform, 115V*

2

43658 Label – Power to Charger, 230V*

1

44980 Label – Power to Charger, 115V*

1

52475 Label – Transport Tie-down

3

72086 Label – Lifting Point

1

72188 Label – Directional Arrows

2

82481 Label – Battery/Charger Safety

1

82487 Label – Read the Manual

2

82495 Label – Brake Release Safety and

Operating Instructions

1

82614 Warning – Collision Hazard

1

82666 Label – Forklift Pocket

2

82836 Label – Auxiliary Lowering

1

97815 Label – Lower Mid-rail*

1

97899 Label – Use Safety Chock

1

114334 Label – Electrocution Hazard, Plug

1

114338 Label – Tip-over Hazard, Tilt Alarm

1

133015 Danger – Electrocution hazard

1

133146 Danger – Tip-over Hazard, Batteries

1

133147 Label – Tip-over Hazard, Limit Switch

1

137605 Label – Emergency Stop, Platform

Control

1

137656 Label – Drive/Steer Direction,

Platform Control

1

1263542 Label – Compartment Access

1

1270489 Label – Wheel Load, GR, GRC

4

1272242 Label – Machine Registration/Owner

Transfer

1

1281175 Label – Lanyard Anchorage Point, Fall

Restrained

1

1283228 Label – GCON, GR, Tech Pro

1

1283810 Label – Platform Control Panel

1

1283878 Label – Tech Pro Link

1

Part No. Decal Description

Qty

1293166 Danger, Warning – Tip-over, Crush

Hazard

1

1294398 Label – ANSI/CSA Compliant

1

1294688 Label – Platform Overload LED

Indicator Light

1

1296034 Label – Smartlink Dual Zone

2

1296620 Danger – Max. Capacity, Side Force,

GR*

1

1296622 Danger – Max. Capacity, Side Force,

GR*

1

1297735 Label – Transport Diagram

2

1298467 Label – Read the Manual

1

* These decals are model, option or

configuration specific.

Page 40

Operator's Manual Sixth Edition • First Printing

Inspections

38 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Page 41

Sixth Edition • First Printing Operator's Manual

Operating Instructions

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 39

Operating Instructions

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was

intended.

Fundamentals

The Operating Instructions section provides

instructions for each aspect of machine operation.

It is the operator’s responsibility to follow all the

safety rules and instructions in the operator’s,

safety, and responsibilities manuals.

Using the machine for anything other than lifting

personnel, along with their tools and materials, to

an aerial work site is unsafe and dangerous.

Only trained and authorized personnel should be

permitted to operate a machine. If more than one

operator is expected to use a machine at different

times in the same work shift, they must all be

qualified operators and are all expected to follow

all safety rules and instructions in the operator’s,

safety, and responsibilities manuals. That means

every new operator should perform a preoperation inspection, function tests, and a

workplace inspection before using the machine.

Page 42

Operator's Manual Sixth Edition • First Printing

Operating Instructions

40 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Emergency Stop

Push in the red Emergency Stop button to the off

position at the ground controls or the platform

controls to stop all functions.

Repair any function that operates when either red

Emergency Stop button is pushed in.

Auxiliary Lowering

Pull the auxiliary lowering knob to

lower the platform.

Operation from Ground

1 Be sure the battery pack is connected before

operating the machine.

2 Turn the key switch to ground control.

3 Pull out both ground and platform red

Emergency Stop buttons to the on position.

To Position Platform

1 At the control panel, press Enter button to

cycle between indoor and outdoor area of

operations.

Note: Area of operation can only be changed when

the machine is in the stowed position.

2 Press and hold the lift function enable.

3 Press the platform up or down button.

Operation from Platform

1 Be sure the battery pack is connected before

operating the machine.

2 Turn the key switch to platform control.

3 Pull out both ground and platform red

Emergency Stop buttons to the on position.

To Position Platform

1 Press the Indoor or

Outdoor use button.

Note: Area of operation can

only be changed when the

machine is in the stowed

position.

2 Press the lift function button. On the

LED screen, a circle below the lift

function symbol will turn on.

If the control handle is not moved within seven

seconds of pushing the lift function button, the

circle below the lift function symbol will turn off and

lift function will not operate. Press the lift function

button again.

3 Press and hold the function enable switch on

the control handle.

4 Move the control handle in the direction

indicated by the markings on the control panel.

Page 43

Sixth Edition • First Printing Operator's Manual

Operating Instructions

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 41

To Steer

1 Press the drive function button. On the LED

screen, a circle below the drive function

symbol will turn on.

If the control handle is not moved within seven

seconds of pushing the drive function button, the

circle below the drive function symbol will turn off

and drive function will not operate. Press the drive

function button again.

2 Turn the steer wheels with the

thumb rocker switch located on

the top of the control handle.

To Drive

1 Press the drive function button. On the LED

screen, a circle below the drive function

symbol will turn on.

If the control handle is not moved within seven

seconds of pushing the drive function button, the

circle below the drive function symbol will turn off

and drive function will not operate. Press the drive

function button again.

2 Press and hold the function enable switch on

the control handle.

3 Increase speed: Slowly move the control

handle off center.

Decrease speed: Slowly move the control

handle toward center.

Stop: Return the control handle to center or

release the function enable switch.

Use the color-coded direction arrows on the

platform controls and on the platform to identify the

direction the machine will travel.

Machine travel speed is restricted when the

platform is raised.

Battery condition will affect machine performance.

Machine drive speed and function speed will drop

when the battery level indicator is flashing.

To select drive speed

The drive controls can operate in two different

drive speed modes. When the drive speed button

light is on, slow drive speed mode is active. When

the button light is off, fast drive speed mode is

active.

Press the drive speed button to select

the desired drive speed.

Note: When the platform is elevated,

the drive speed button light is always

on, indicating elevated drive speed.

Page 44

Operator's Manual Sixth Edition • First Printing

Operating Instructions

42 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Driving on a slope

Determine the slope and side slope ratings for the

machine and determine the slope grade.

Maximum slope rating,

stowed position:

30% (17°)

Maximum side slope

rating, stowed position:

30% (17°)

Note: Slope rating is subject to ground conditions

with one person in the platform and adequate

traction. Additional platform weight may reduce

slope rating.

To determine the slope grade:

Measure the slope with a digital inclinometer OR

use the following procedure.

You will need:

carpenter’s level

straight piece of wood, at least 3 feet/1 m long

tape measure

Lay the piece of wood on the slope.

At the downhill end, lay the level on the top edge

of the piece of wood and lift the end until the piece

of wood is level.

While holding the piece of wood level, measure

the vertical distance from the bottom of the piece

of wood to the ground.

Divide the tape measure distance (rise) by the

length of the piece of wood (run) and multiply by

100.

Example:

Piece of wood = 144 inches (3.6 m)

Run = 144 inches (3.6 m)

Rise = 12 inches (0.3 m)

12 in ÷ 144 in = 0.083 x 100 = 8.3% grade

0.3 m ÷ 3.6 m = 0.083 x 100 = 8.3% grade

If the slope exceeds the maximum slope or side

slope rating, then the machine must be winched or

transported up or down the slope. See Transport

and Lifting section.

Page 45

Sixth Edition • First Printing Operator's Manual

Operating Instructions

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 43

Operational indicator codes

If the platform controls LED or ground controls

LCD diagnostic readout displays an operational

indicator code such as LL, the fault condition must

repaired or removed before resuming machine

operation. Push in and pull out the red Emergency

Stop button to reset the system.

LED Readout

LCD Readout

Operational Indicator Codes

Code

Condition

LL

Off-Level

OL

Platform Overloaded

CH

Chassis Mode Operation

PHS

Pothole Guard Stuck

ND

No Drive (option)

OHL

Outdoor Height Limit

For further information, please consult the

appropriate Genie Service Manual. A code and a

description of a code can also be viewed at the

ground controls LCD display.

Platform Overload

If the platform controls LED diagnostic readout

displays a flashing OL and the ground controls

LCD diagnostic readout displays OL: Platform

Overloaded, the platform is overloaded and no

functions will operate. An alarm will sound.

1 Push in the red Emergency Stop button to the

off position.

2 Remove weight from the platform.

3 Pull out the red Emergency Stop button to the

on position.

LED Readout

LCD Readout

When the platform is being raised or lowered, a

self-check function will be performed near

maximum height. The machine may stop and an

alarm may sound. If the machine is not

overloaded, normal operation will resume.

Overload Recovery

If the ground controls LCD diagnostic readout

displays Overload Recovery, the auxiliary lowering

system has been used while the platform was

overloaded. For information on how to reset the

message, please consult the appropriate Genie

Service Manual.

Page 46

Operator's Manual Sixth Edition • First Printing

Operating Instructions

44 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Tilt Sensor Activation Settings

Chassis Angle (side to side)

1.5°

Chassis Angle (front to back)

3°

If the tilt alarm sounds while

raising the platform, lower the

platform and move the machine

to a firm, level surface. If the tilt

alarm sounds when the platform

is raised, use extreme caution to

lower the platform.

When the platform controls LED

readout displays LL, the ground

controls LCD displays LL:

Machine Tilted, and the tilt

alarm sounds at 180 beeps per

minute, the following functions

are affected: drive, steer, and

elevate functions are disabled.

Return the machine to level

ground to restore lift functions.

Operation from Ground with Controller

Maintain safe distances between the operator,

machine and fixed objects.

Be aware of the direction the machine will travel

when using the controller.

Battery Level Indicator

Use the LED diagnostic readout to determine the

battery level.

Note: When a blinking LO code appears on the

platform controls LED display, the machine must

be taken out of service and charged, otherwise all

machine functions will be disabled.

Full Charge

Half Charge

Low Charge

LO Flashing

Page 47

Sixth Edition • First Printing Operator's Manual

Operating Instructions

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 45

To Extend and Retract Platform

(if equipped)

1 Step on the platform extension release pedal.

2 Grasp the platform guard rails carefully and

push to extend the platform.

3 Step on the platform extension release pedal

and pull the guard rails to retract the platform.

Lift Tools Work Tray Instructions

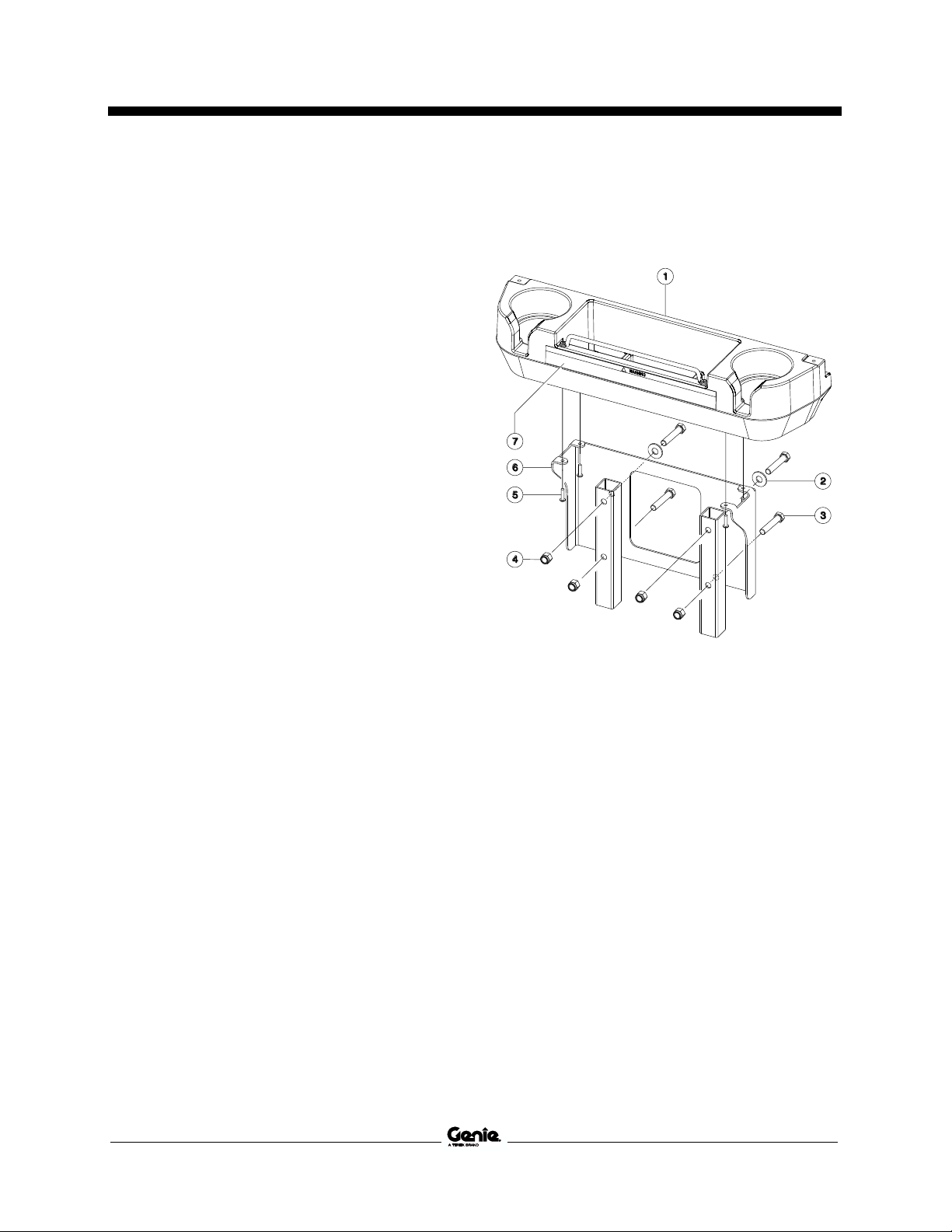

The Lift Tools Work Tray assembly consists of one

tray and a mounting bracket with hardware.

1 lift tool work tray

2 washer, flat, 3/8"

3 bolt, 3/8-16 x 2"

4 nut, nylock, 3/8-16

5 bolt, #10-24 x 0.50"

6 tool tray bracket

7 decal, warning

Page 48

Operator's Manual Sixth Edition • First Printing

Operating Instructions

46 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Observe and Obey: Lift Tools

Work Tray Installation

Lift Tools Work Tray must be installed on the

inside of the platform.

Only one Lift Tools Work Tray can be used per

machine.

Mount Lift Tools Work Tray on the top of the

Platform Support near the mast only.

Be sure the Lift Tools Work Tray is secured to

the Platform Support.

Lift Tools Work Tray lanyard is for tools only.

Do not attach personal safety lanyard.

Lift Tools Work Tray Operation

1 Place the load so that it rests inside the Lift

Tools Work Tray.

The Lift Tools Work Tray assembly weighs

4 lbs / 1.8 kg.

Maximum capacity of Lift Tools Work Tray is

50 lbs / 23 kg.

Tip-over hazard. The weight of Lift Tools Work

Tray assembly and the load in the Lift Tools

Work Tray assembly will reduce the rated

platform capacity of the machine and must be

factored into the total platform load.

After Each Use

1 Select a safe parking location—firm level

surface, clear of obstruction and traffic.

2 Lower the platform.

3 Turn the key switch to the off position and

remove the key to secure from unauthorized

use.

4 Charge the batteries.

Page 49

Sixth Edition • First Printing Operator's Manual

Operating Instructions

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 47

Battery and Charger Instructions

Observe and Obey:

Do not use an external charger or booster

battery.

Charge the battery in a well-ventilated area.

Use proper AC input voltage for charging as

indicated on the charger.

Use only a Genie authorized battery and

charger.

To Charge Battery

1 Be sure the batteries are connected before

charging the batteries.

2 The compartment may remain closed for the

entire charging cycle.

Maintenance-free batteries

1 Connect the battery charger to a grounded AC

circuit.

2 The charger will indicate when the battery is

fully charged.

Standard Batteries

1 Remove the battery vent caps and check the

battery acid level. If necessary, add only

enough distilled water to cover the plates. Do

not overfill prior to the charge cycle.

2 Replace the battery vent caps.

3 Connect the battery charger to a grounded AC

circuit.

4 The charger will indicate when the battery is

fully charged.

5 Check the battery acid level when the charging

cycle is complete. Replenish with distilled

water to the bottom of the fill tube. Do not

overfill.

Page 50

Operator's Manual Sixth Edition • First Printing

Transport and Lifting Instructions

48 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Transport and Lifting Instructions

Observe and Obey:

Genie provides this securement information as

a recommendation. Drivers are solely

responsible for making sure machines are

properly secured and the correct trailer is

selected pursuant to US Department of

Transportation regulations, other localized

regulations, and their company policy.

Genie customers needing to containerize any

lift or Genie product should source a qualified

freight forwarder with expertise in preparing,

loading and securing construction and lifting

equipment for international shipment.

Only qualified mobile elevating work platform

operators should move the machine on or off

the truck.

The transport vehicle must be parked on a

level surface.

The transport vehicle must be secured to

prevent rolling while the machine is being

loaded.

Be sure the vehicle capacity, loading surfaces

and chains or straps are sufficient to withstand

the machine weight. Genie lifts are very heavy

relative to their size. See the serial label for

the machine weight. See the inspections

section for the serial label location.

The machine must be on a level surface or

secured before releasing the brakes.

Do not drive the machine on a slope that

exceeds the uphill, downhill or side slope

rating. See Driving on a Slope in the Operating

Instructions section.

If the slope of the transport vehicle bed

exceeds the uphill or downhill maximum slope

rating, the machine must be loaded and

unloaded using a winch or forklift as described

in the brake release operation. See the

Specifications section for the slope ratings.

Page 51

Sixth Edition • First Printing Operator's Manual

Transport and Lifting Instructions

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 49

Brake Release Operation

1 Chock the wheels to

prevent the machine from

rolling.

2 Be sure the winch line is properly secured to

the drive chassis tie points and the path is

clear of all obstructions.

3 Push in the black brake

release knob to open the

brake valve.

4 Pump the red brake release pump knob.

After the machine is loaded:

1 Chock the wheels to prevent the machine from

rolling.

2 Pull out the red Emergency Stop button at

both the ground and platform controls to the

on position, and turn the key switch to the

platform position.

3 Press the drive function button.

4 Press and hold the function enable switch on

the control handle. Move the control handle off

center and immediately release it to reset the

brakes.

5 Push the red Emergency stop button at both

the ground and platform controls to the off

position.

Towing the GR-12, the GR-15, and the GR-20 is

not recommended. If the machine must be towed,

do not exceed 2 mph / 3.2 km/h.

Page 52

Operator's Manual Sixth Edition • First Printing

Transport and Lifting Instructions

50 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Securing to Truck or Trailer for

Transit

Always use the extension deck lock when the

machine is transported.

Turn the key switch to the off position and remove

the key before transporting.

Inspect the entire machine for loose or unsecured

items.

Use the tie-down points on the chassis for

anchoring down to the transport surface.

Use chains or straps of ample load capacity.

Use a minimum of 2 chains or straps.

Adjust the rigging to prevent damage to the

chains.

Page 53

Sixth Edition • First Printing Operator's Manual

Transport and Lifting Instructions

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 51

Observe and Obey:

Only qualified riggers should rig and lift the

machine.

Only qualified forklift operators should lift the

machine with a forklift.

Be sure the crane capacity, loading surfaces

and straps or lines are sufficient to withstand

the machine weight. See the serial label for

the machine weight.

Lifting the Machine with a Forklift

Be sure the extension deck, controls and

component trays are secure. Remove all loose

items on the machine.

Fully lower the platform. The platform must remain

lowered during all loading and transport

procedures.

Use the forklift pockets located on both sides of

the chassis, below the covers.

Position the forklift forks in position with the forklift

pockets.

Drive forward to the full extent of the forks.

Raise the machine 6 in / 15 cm and then tilt the

forks back slightly to keep the machine secure.

Be sure the machine is level when lowering the

forks.

Lifting the machine from the side

can result in component

damage.

Page 54

Operator's Manual Sixth Edition • First Printing

Transport and Lifting Instructions

52 GR™-12 • GR™-15 • GR™-20 Part No. 1297723GT

Loading the Machine With a

Crane

Fully lower the platform. Be sure the extension

deck, controls and component trays are secure.

Remove all loose items on the machine.

Use the lifting eye mounted on the rear mast

column.

Make sure the mast is fully lowered.

Inspect the entire machine and remove any loose

or unsecured items.

Adjust the rigging to prevent damage to the

machine and to keep the machine level.

Page 55

Sixth Edition • First Printing Operator's Manual

Maintenance

Part No. 1297723GT GR™-12 • GR™-15 • GR™-20 53

Maintenance

Observe and Obey:

Only routine maintenance items specified in

this manual shall be performed by the

operator.

Scheduled maintenance inspections shall be