Page 1

™

GCL-MJ&MH

Medium Duty Operator

JACKSHAFT/HOIST

111852.501539

08-12

TensiBelt

PROPER APPLICATION

Door Type Operator Type HP/Max Door Weight

Sec

tional Jackshaft/Hoist

(Vertical Lift and

Lift Clearance Type

Rolling Steel

(Sidemount,

Chain Couple)

NOT FOR R E SIDENTIAL U S E

™

(Available in 1/2HP only)

Sectional = 620 lbs.

Rolling Steel = 580 lbs.

This Installation Manual provides the information required to install, troubleshoot and

maintain a GCL-MJ&MH

™

Commercial / Industrial Door Operator.

Page 2

Table of Contents

Section 1 How to use this manual .......................................1.1

Section 2 Safety Information & Instructions.....................2.1

Section 3 Critical Installation Information........................3.1-3.2

Section 4 Installation.................................................................4.1-4.7

Rolling Steel-Front of Hood.................................4.1-4.2

Wall Mount ...............................................................4.3

Sectional Side Mount Chain Couple ................4.4-4.6

Clutch and Brake Adjustment ............................4.6

Hand Chain Installation ........................................4.7

Section 5 Wiring..........................................................................5.1-5.7

Line Voltage Wiring................................................5.1

Low Voltage Control Wiring................................5.2

External Wire Diagram ..........................................5.3

Control ..............................................................5.4

Wall

terlock Switches ..................................................5.5

In

Radio Control & Photocell Wiring .................... 5.6

Sensing Edge Wiring .............................................5.7

Important Safety Instructions............................5.8

Section 6 Operator Setup Procedures ................................6.1-6.8

Control Panel............................................................6.1

Setting Constant Contact ....................................6.2

Setting Limit Travel ................................................6.3

Setting Limit Overrun ...........................................6.4

Monitored Reversing Devices.............................6.5

Max Run Timer.........................................................6.6

Setting the Mid-Stop .............................................6.7

Changing Open & Close Modes ........................6.8

Section 7 Special Operator Features ..........................................7.1-7.2

Operator Cycle Count & Firmware Version...........7.1

Operator Type..................................................................7 2

Section 8 Troubleshooting.............................................................8.1-8.4

Display Operation ..........................................................8.1

Error Codes.......................................................................8.1-8.2

Run Codes.........................................................................8.2-8.3

LED Indicators .................................................................8.4

STB Indicators..................................................................8.5

Section 9 Service & Maintenance ................................................9.1

Section 10 Appendix A.............................................................. 10.1-10.9

Basic Operator Parts...........................................10.1-10.2

Basic Shaft Assembly Parts..............................10.3-10.4

Basic Electric Box Parts......................................... 10.5

Appendix B, Screw Terminal Assignme

Appendix C, LCD Display Readouts...................10.7-10.9

Run Codes.................................................................10.7

Section 11 Warranty.........................................................................11.1

nts.........10.6

9.01-8.01................................................................sedoC rorrE

GCL-MJ&MH

Medium Duty Operator

TOC

www.geniecompany.com 08-12

Page 3

Section 1: How to use this manual

The 11 sections of this Installation Manual provide the information required to install,

troubleshoot and maintain an GCL-MJ&MH™ commercial/industrial door operator.

Section 2

Provides important defining information related to safety terminology used throughout this manual, as

well as safety related instructions which must be followed at all times while doing any

steps/tasks/instructions detailed in this manual.

Section 3

Details pre-installation concerns/issues/decisions that are recommended to be considered and/or

esolved prior to beginning any commercial door operator installation.

r

WARNING

Failure to correctly perform all steps in sections 4-6 can result in serious injury or death.

Sections 4-6

Provide step by step installation and set-up instructions for the GCL-MJ&MH™ commercial door operator. Each

section is written such that it must be followed in a step by step order

installation.

Sections 7-8

Detail important features and troubleshooting information for typical installation and normal operations

t may occur.

tha

Sections 9-11

ovide related information on service and maintenance items, operator drawings for use in

Pr

troubleshooting and service activities, along with important warranty and returned goods policy

information.

FOR ASSISTANCE CALL 1-800-843-4084

to complete a successful

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

1.1

Page 4

Section 2: Safety Information & Instructions

Commercial/Industrial Sectional and Rolling Steel Doors are large, heavy objects that move with the help of springs under high tension

and electric motors. Since moving objects, springs under tension, and electric motors can cause injuries, your safety and the safety

of others depend on you reading the information in this manual. If you have any questions or do not understand the information

presented, call your nearest service representative. For the number of your local Genie® Dealer, call 800-OK-GENIE, and for Genie®

Factory Technical Advice, call 800-843-4084.

In this Manual, the words Danger, Warning, and Caution are used to stress important safety information. The word:

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in injury or property damage.

The word NOTE is used to indicate important steps to be followed or important considerations.

POTENTIAL HAZARD EFFECT PREVENTION

WARNING

Could result in

Serious Injury

MOVING DOOR

ELECTRICAL SHOCK

HIGH SPRING TENSION

or Death

WARNING

Could result in

Serious Injury

or Death

WARNING

Could result in

Serious Injury

or Death

WARNING

Do Not operate unless the doorway is in sight and free of

obstructions. Keep people clear of opening while door is moving.

Do Not allow children to play with the door operator.

Do Not change operator control to momentary contact unless an

external reversing means is installed.

Do Not operate a door that jams or one that has a broken spring

Turn off electrical power before removing operator cover.

When replacing the cover, make sure wires are not pinched or near

moving parts.

Operator must be electrically grounded.

Do Not try to remove, repair or adjust springs or anything to which

door spring parts are fastened, such as, wood block, steel bracket,

cable or any other structure or like item.

Repairs and adjustments must be made by a trained service

representative using proper tools and instructions.

IMPORTANT

READ PRIOR TO ANY DOOR OPERATION

1. Read manual and warnings carefully.

2. Keep the door in good working condition.

Periodically lubricate all moving parts of

door.

3. If door has a sensing edge, check

operations monthly. Make any necessary

repairs to keep it functional.

4. AT LEAST twice a year, manually operate

door.

The Door should open and close freely. If it

does not, the door must be taken out of

service and a trained service representative

must correct the condition causi

the malfunction.

5. The Operator Motor is protected against

overheating by an internal thermal protector.

If the operator ceases to function because

motor protector has tripped, a trained service

technician may need to correct the condition

which caused the overheating. When motor

has cooled, thermal protector will

automatically reset and normal operation can

be resumed.

6. In case of power failure, the door can be

operated manually by pu

cable to disconnect the operator drive system

7. Keep instructions in a prominent location

near the pushbutton.

ng

lling the release

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

2.1

Page 5

Section 3: Critical Installation Information

Job Site Issues to Consider/Concerns

The following list of items should be considered prior to selecting an operator for a given job site.

1-Available power supply.

2-Type of door.

3-Potential operator mounting obstructions. Items to consider include, but are not limited to: side room, room above door shaft,

surface integrity, power supply location, and convenient chain hoist and release cable positioning.

4-Size of door for appropriate

6-Door activation needs/requirements. Examples include 3 button control stations, 1 button control stations, radio controls, pull

key switches, etc. See “Entrapment Protection” section below.

7-Interlock switches are required under certain conditions for

ENTRAPMENT PROTECTION

The installation of a fail safe external reversing device (such as a monitored reversing edge or photocell system, etc.) is required on all momentary contact electronically

operated commercial doors. If such a reversing device is not installed, the operator will revert to a constant contact control switch for operation (Closing only).

The Reversing Devices currently UL Approved with are:

1)

MillerEdge ME, MT and CPT series monitored edge sensors used in combination with Timer-Close Module P/N OPABTCX.S, or OPAKMEIGX.S INTERFACE MODULE.

2) Residential Safe-T-Beam® Monitored Photocells from The Genie® Company, model OSTB-BX (P/N 38176R).

3) Series II Commercial Safe-T-Beam®, Monitored Photocells P/N OPAKPE.S.

4) Series II Commercial Safe-T-Beam®, NEMA4 Monitored Photocells P/N OPAKPEN4GX.S.

operator torque and door travel speed selection.

gde gnisrever era selpmaxE .tnempiuqe yrosseccA-8

doors .cte ,sthgil gninraw ,syaler lortnoc yrailixua,),tcatnoc yratnemom sa etarepo ot tes

rof deriuqer( smaeb llecotohp ro/dna se

and corrosiveness of the location.

ssenitsud ,ssenpmad dna noitacol rotarepo edulcni redisnoc ot smetI .tnemnorivne gnitnuom rotarepO-5

.5.5 egap eeS .skcol rood dna srood ssap htiw srood

room below door shaft, available mounting

cords, loop detectors, photoelectric controls,

WARNING:

CAUTION:

Check working condition of door before installing the operator. Door must be free from sticking and binding. If equipped, deactivate

any door locking device(s). Door repairs and adjustments, including cables and spring assemblies MUST be made by a trained service

representative using proper tools and instructions.

GCL-MJ&MH

DO NOT apply line voltage until instructed to do so.

Medium Duty Operator

www.geniecompany.com 08-12

3.1

Page 6

Section 3: Critical Installation Information

ENTRAPMENT PROTECTION

The GCL-MJ&MH™ can be used with the following UL Approved entrapment devices in compliance with UL325 requirements active starting August 29, 2010.

UNTIL ONE OF THESE MONITORED EXTERNAL ENTRAPMENT DEVICES IS INSTALLED, THE OPERATOR WILL NOT ALLOW MOMENTARY CONTACT OPERATION IN THE CLOSE DIRECTION.

LISTED DEVICES ALLOWABLE DOOR WIDTH

MillerEdge ME, MT and CPT series monitored edge sensors used in combination with

Timer-Close Module or OPAKMEIGX.S Interface Module.

Residential Safe-T-Beam® Monitored Photocells model OSTB-BX P/N 38176R.

Commercial Photoeye Kit P/N OPAKPE.S

NEMA4 Monitored Photocells P/N OPAKPEN4GX.S.

ANY WIDTH

30 FEET

30 FEET

35 FEET

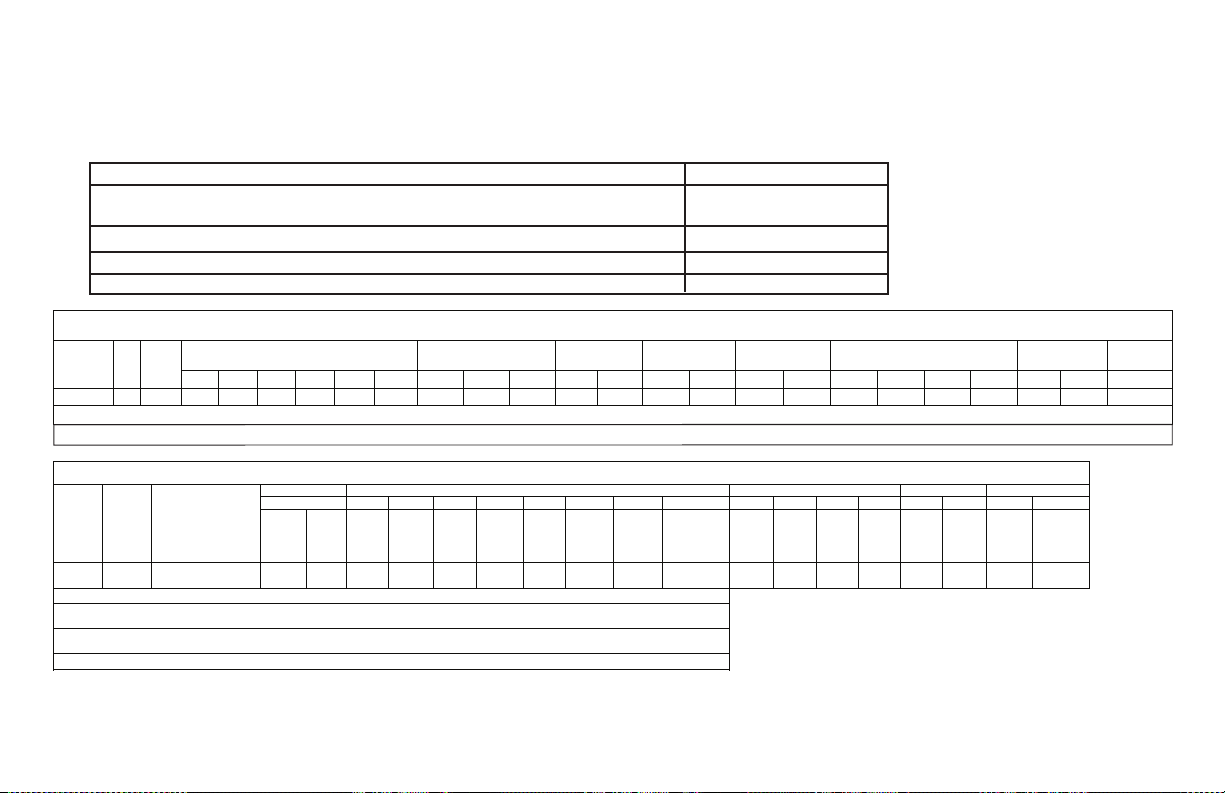

Rolling Steel Door Chart (sq. ft.)

Mode l H P

GCL-MJ&MH 1/2 YES

Note: Total door weight and not square footage is the critical factor in selecting the proper operator. These Sq.Ft. measurements are based on square doors, e.g. 16' x 16'.

Unbalanced Fire Shutters have a maximum square footage of 52 for 22GA. steel and 42 for 20GA. steel.

UL

Lis ted

16GA. 18GA. 20GA. 22GA. 24GA. 26GA. 18GA. 20GA. 22GA.

197 246 246 338 394 394 148 148 197

STEEL, NON-INSULATED STEEL, INSULATED

ALUM. STL/SST

126 126

ALUM. STL/SST 20GA. 22GA.

300 200 N/A

FIRESTAR 2” SLATGRILLESCOUNTER DOOR

Sectional Door Chart (sq. ft.)

Door S er ies ->

UL L is tedHPMod el

GCL-MJ

1/2

GCL-MH

S=Jackshaft,SideMount

T=Trolley

Note: Total door weight, and not the square footage, is the critical factor in selecting the proper operator.

Square footage measurements are based on "square doors." (Example=16' x 16')

NOTE: Doors that require special windloading and wide doors, normally require increased strutting (reinforcement). Strutting doors can significantly increase door

weight beyond weight shown. Consult Customer Service for the impact of wind load andstrutting on square foot limits.

NOTE: "PU-FIP" stands for "polyurethane, foamed-in-place." If no notation is present, insulation is "polystyrene, layed-iin-place."

Ye s TS 620 170 120 230 160 270 200 300 256 256 256 240 160 256 256 210 144

Mounting

Type

C=Jackshaft,CenterMount

216 216 ins. 220 220 ins. 2415 2415 ins. 2411 2411 ins. 125 150 200 200-20 5150 5200 451 452

Max.

16GA.

Door

Flush

Weight

Steel

(Lbs)

CommercialSteelInsulated&Non-Insulated Thermospan Thermomark

16GA.

Flush

Steel

Insulated

20GA.

Ribbed

Steel

20GA.

Ribbed

Steel

Insulated

24GA.

Ribbed

Steel

24GA.

Ribbed

Steel

Insulated

Nominal

24GA.

Ribbed

Steel

Nominal

24GA.

Ribbed Steel

Insulated

PU/FIP

Insulated

FIRESTAR 3” SLAT

16GA. 18GA. 20GA. 22GA.

N/A N/A

N/A N/A N/A

PU/FIP

PU/FIP

Insulated

Insulated

PU/FIP

PU/FIP

Insulated

1.38"

Insulated

2"

2"

20GA.

Exterior

Raised

Panel

1.38"

PU/FIP

Insulated 1/4" or 1/2"

Raised

Panel

2"

FIRESTAR 3” SLAT

INSULATED

20GA. 22GA.

N/A N/A 256

Aluminum

1/8" Glass

1.38"

Glass

1.38"

SHEET DOOR

26GA

.

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

3.2

Page 7

Section 3: Critical Installation Information

IMPORTANT

INSTALLATION INSTRUCTIONS

WARNING -

To reduce the risk of severe injury or death:

1) READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2) Install only on a properly operating and balanced door. A door that is operating

improperly could cause severe injury. Have qualified service personnel make

repairs to cables, spring assemblies and other hardware before installing the operator.

3) Remove all pull ropes and remove, or make inoperative, all locks (unless mechanically

and/or electronically interlocked to the power unit) that are connec

before installing the operator.

4) Install the door operator at least 8 feet above the floor if the operator has exposed

moving parts.

5) Do not connect the door operator to the power source until instructed to do so.

6) Locate the control station: (a) within sight of the door, (b) a minimum of 5 feet above

the floor so that small children cannot reach it, and (c) away from all moving parts

of the door.

7) Install the Entrapment Warning Placard next to the control station and in a

prominent location.

8) For products having a manual release, instruct the end user on the operation of the

manual release.

ted to the door

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

3.3

Page 8

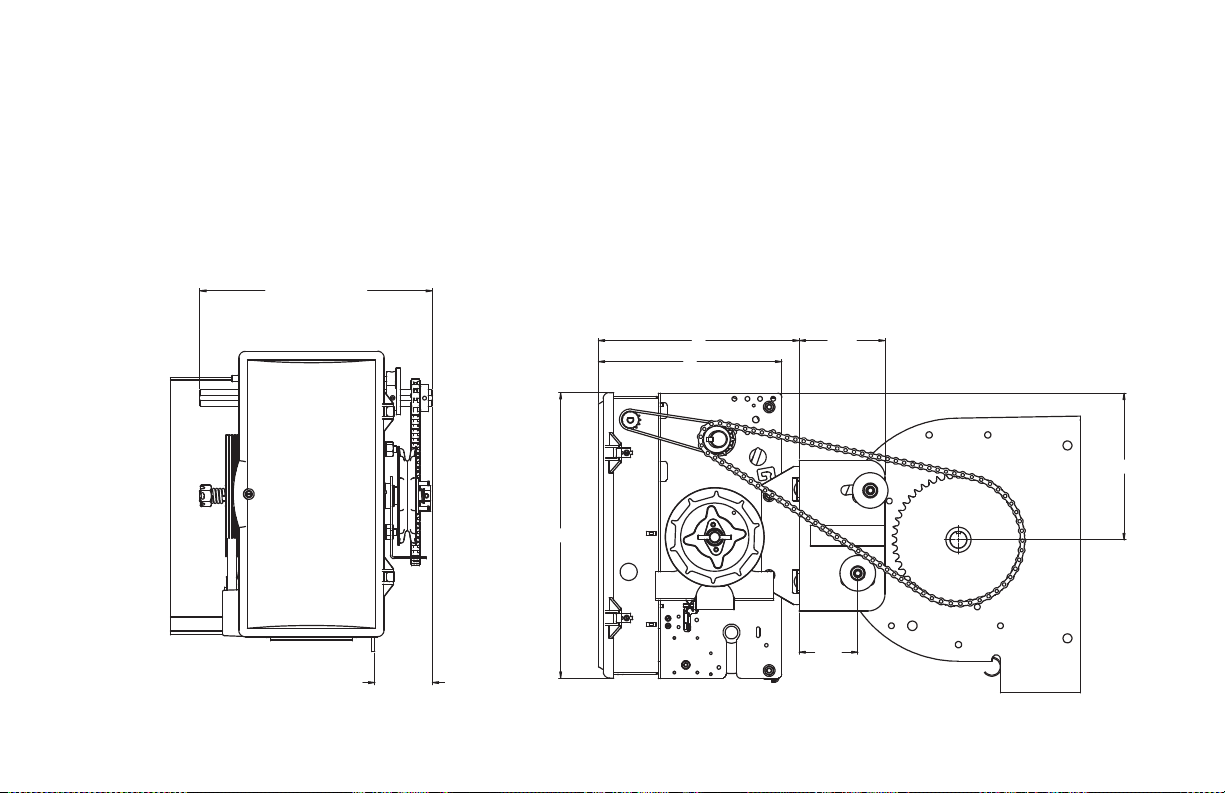

Section 4: Installation

Rolling Steel/Grill Doors

Front of Hood

The Rolling Steel Door Operator can be assembled for right-hand or left-

mounting .dooH fo tnorF

hand

Each model can also be wall mounted (next pages).

1) Mounting hardware and instruction will be supplied based

on door specifications.

(Typical mounting arrangements shown in figures 1 and 2.)

:

13-7/8"

(OUTPUT SHAFT LENGTH)

(WIDTH OF OPERATOR)

Figure 1

GCL-MJ&MH

Medium Duty Operator

3-7/16"

(OPERATOR

SIDE ROOM REQ'D.))

12"

11"

5-1/8"

Figure 2

17"

3-1/2"

www.geniecompany.com 08-12

8-3/4"

4.1

Page 9

Front of Hood (continued)

5) Attach operator assembly to end plate as shown using hardware provided. Fig 3.

NOTE: At this time, hand tighten only, the mounting bracket nuts

where it attaches to the head plate. This allows for adjustment

in order to tension the drive chain.

Attach Operator to Door: Front of Hood.

1) Attach 12 tooth sprocket to operator output shaft.

2) Align keyways and insert key into sprocket and output

shaft

keyway.Do not tighten set screw at this time.

3) Attach door sprocket to door shaft. Do not tighten

at this time.

4) Assemble chain using chain master link.

5) Place assembled chain over door shaft sprocket and

around the

6) Adjust operator position

12 tooth sprocket.

to remove slack from

the chain.

7) Tighten operator mounting bracket nuts.

8) Tighten sprocket set screws.

Figure 3

GCL-MJ&MH

Medium Duty Operator

SOCKET BUTTON HEAD CAP SCREW IS

FACTORY WELDED TO THE HEAD PLATE

112146.0001

(GMX Mounting Bracket)

111983.0001

(GMX Mounting Bracket)

www.geniecompany.com 08-12

24121C

(Hex nut w/lkwshr, 5/16-18)

086420.0506

(Bolt, 5/16-18 x 3/4)

086420.0510

(Bolt, 5/16-18 x 1-1/4)

24121C

(Hex nut w/lkwshr, 5/16-18)

080352.0714

(Hex nut, 7/16-14)

FLAT WASHER

4.2

Page 10

Wall Mount

™

The GCL-MJ&MH

by using an

Attach wall mount brackets to operator using the 4 mounting

1)

bolts and nuts supplied(Hand-tighten until later).

Position the

2)

Attach 12 tooth sprocket to operator output shaft.

3)

Align keyways and insert key into sprocket and

output

4)

Attach door sprocket to door shaft. Do not tighten yet.

5)

Assemble chain using chain master link.

6)

Place assembled chain over door shaft sprocket and

operator sprocket.

7)

Raise

Ensure

8)

Tighten operator mounting bracket nuts.

9)

Align chain and secure operator to wall.

10)

Tighten operator chain sprocket set screws.

11)

Slide operator in the wall bracket mounting

holes if necessary for fine adjust of chain tension.

JACKSHAFT VERSION

Rolling Steel unit can be wall mounted

optional “Wall Mount Kit.” (P/N 111011.0001.S).

operator in the brackets as shown.

shaft keyway. Do not tighten set screw yet.

or lower operator to remove

slack from the chain.

operator output shaft is parallel with door shaft.

The release

cable must

be attached

before

mounting

the unit.

RELEASE CORD

where necessary

Fig.4.

15"

(TYPICAL SIDE ROOM)

13-7/8"

(OUTPUT SHAFT LENGTH)

(WIDTH OF OPERATOR)

VERTICALLY ALIGN

SPROCKETS/CHAIN

LOCK DOWN HOLES

MUST BE USED TO

ENSURE MAINTAINING

OPERATOR POSITION

LOCK DOWN HOLES

MUST BE USED TO

ENSURE MAINTAINING

OPERATOR POSITION

Figure 4.

12-1/4" TO 11"

5" TO 3-3/4"

19-5/8"

(HEIGHT OF OPERATOR

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

4.3

Page 11

Sectional Doors—Chain Couple

The Wall Mount Operator can be assembled for right hand

mounting above or below the door shaft. Fig.5A.

NOTE:The operator output shaft extends 3-7/8" on each side of the

operator frame.

1) Attach 12 tooth sprocket to operator output shaft.

2) Align keyways and insert key into sprocket and output shaft

keyway. Do not tighten set screw at this time.

at this time.

4) Assemble chain using chain connecting link.

5) Place assembled chain over door shaft sprocket and operator sprocket.

6) Raise or lower operator to remove slack from the chain.

7) Be certain operator output shaft is parallel with door shaft.

8) Align chain and secu

9) Tighten operator sprocket set screws.

INSTALLATION TIP:

While sprocket set screws are loose,

help align chain. A properly tensioned drive chain should deflect no

more than 1/2" when thumb pressure is applied mid-way between the 2

sprockets.While there is no hard and fast rule governing chain tension, it

must be tight enough to prevent clicking, popping and jumping the

teeth of the sprocket. The 1/2" guideline will insure sufficient tension.

NOTE: If using slotted mounting holes to mount unit

least 2 lockdown holes in opposite corners to firmly mount unit to wall.

re

operator to wall or mounting pad.

if possible, manually operate door to

nethgit ton oD.tfahs rood ot tekcorps rood hcattA)3

Fig.5

, you must use at

B.

Fig. 5B

Figure 5A

Figure 5B

GCL-MJ&MH

Medium Duty Operator

.

www.geniecompany.com 08-12

4.4

Page 12

Chain Couple

For Hollow Counterbalance Door Shaft:

1) Use non-threaded hole in door shaft sprocket as a guide and

drill a 3/8" diameter hole through one side of the door shaft.

Fig. 6A.

Insert clevis pin through sprocket and shaft to hold sprocket

2)

in position.

3) Drill through opposite side of shaft to obtain proper hole

alignment. Fig. 6B.

Insert clevis pin through both holes and secure with cotter pin.

4)

Fig. 6C.

For Solid Counterbalance Door Shaft:

1) Insert k

ey into door shaft keyway.

2) Slide sprocket into place and secure with set screws.

To Complete the Installation:

If needed, realign operator spr

ocket with door sprocket. If you have

excessive door shaft movement, an optional chain tension plate is

available.Fig. 7A

& 7B, pg 4.6.

I

Figure 6A

L

Figure 6B

Figure 6C

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

4.5

Page 13

Chain Couple

Spreader Bracket

Bracket is available as an optional kit, P/N 111005.0001.S

Installation of optional chain spreader bracket: Fig 7A & 7B.

1) Place sprocket, upper plate and bearing assembly on door shaft

as shown.

2) Place lower plate, bearing assembly and sprocket on operator

shaft as shown.

3) Install door and operator sprockets and chain assembly as

described on page 4.4.

4) Install bolts and nuts through plates.

5) Tighten and align chain and plate and secure operator to wall.

6) Tighten spreader bracket bolts.

PL

SPROCKET

GOES ON FIRST

GCL-MJ&MH

DOOR

SHAFT

Figure 7A

Medium Duty Operator

OPERATOR

SHAFT

SPROCKET

GOES ON LAST

Figure 7B

www.geniecompany.com 08-12

4.6

Page 14

Clutch Adjustment Fig. 8

.detsujda eb nac taht hctulc elyts noitcirf a evah srotarepo ehT

NOTE:The clutch is intended to provide protection for the door, the

operator and associated equipment. It is not intended for entrapment

protection.

To Adjust the Clutch

1) Decrease the tension on the clutch until the operator will not lift

2) Gradually increase tension until the operator will perform a

3) Insert a cotter pin through the adjustment castle nut and bend a

NOTE: Periodically check the system for proper clutch action. If clutch

ts to slip after working properly for some time , check manual

star

operation of door BEFORE adjusting clutch. The door may not be

operating freely or the counterbalance spring may need adjusting.

Repairs and adjustments must be performed by a trained service

representative using proper tools and instructions.

or.

the do

Turning the adjustment castle nut counter-clockwise will

decrease tension and clockwise will increase tension.

complete open and close cycle without clutch slippage.

leg of the cotter pin to hold it in place.

Brake Adjustment Fig. 9

1) Loosen the Adjustment Bracket Lock Nut/Bolt.

2) Slide the Adjustment Bracket as needed to reach the desired

spring tension.

When properly adjusted, the pivot arm should

move with very little effort.

3) Re-tighten the Adjustment Bracket Lock Nut/Bolt.

Figure 8

Figure 9

BRAKE ADJUSTMENT

LOCK NUT AND BOLT

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

4.7

Page 15

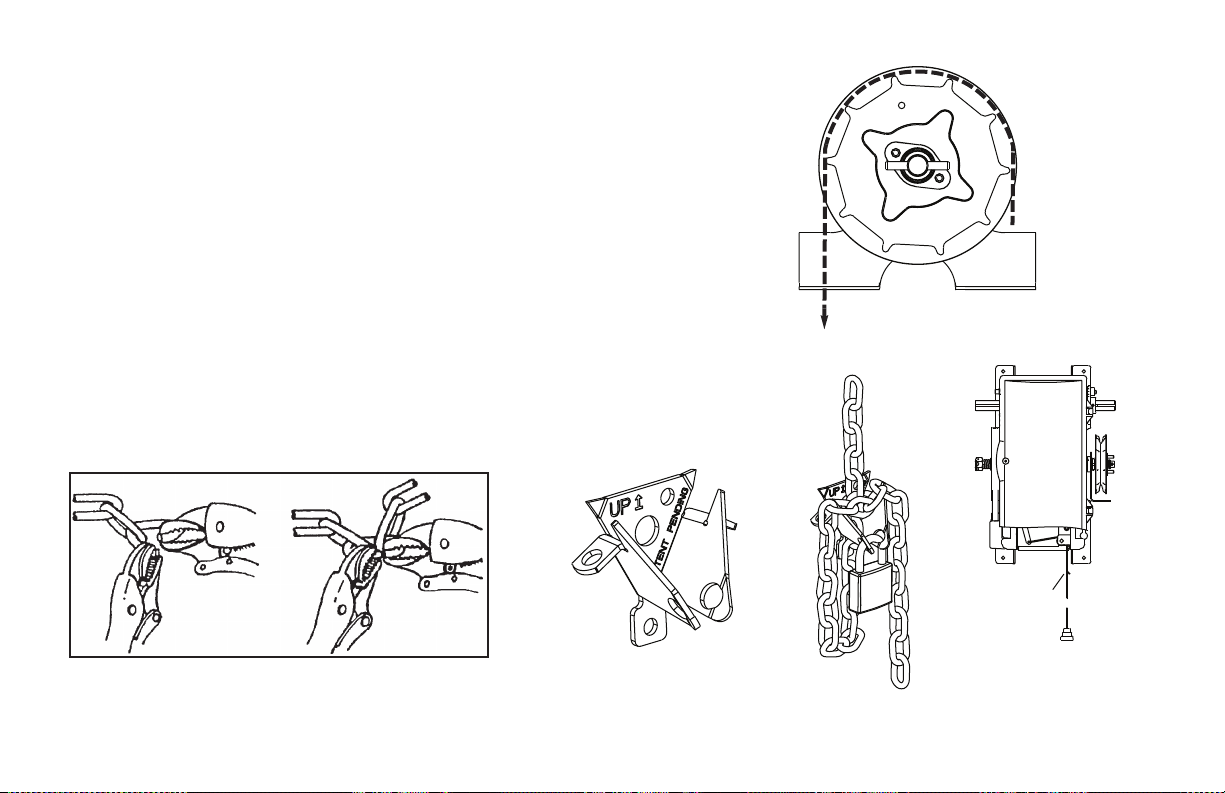

Hand Chain & Keeper

1) Route the hand chain through the chain guide, around the

pocket wheel and back through the chain guide. Fig.10.

2) Connect the hand chain ends together as shown in Fig 11

by twisting open the last link on one end of the chain, and

slipping the last link on the opposite end onto the open link.

3) Twist open link closed again.

4) Mount chain keeper to wall in line with chain approximately

4 feet from floor.

5) Loop chain around keeper as shown. Fig. 12.Optional Padlock

not provided

6) Install release cable. Fig. 13.

NOTE:T

hand chain before connecting the link ends together.

o insure smooth operation, make sure there are no twist in the

.

.

Figure 10

RELEASE CORD

Figure 11

GCL-MJ&MH

Medium Duty Operator

Figure 12

www.geniecompany.com 08-12

Figure 13

4.8

Page 16

Section 5: Wiring

Line Voltage Wiring

Fig.1

WARNING

• DO NOT apply power to operator until instructed to do so.

• The Genie® Company recommends that line voltage

wiring be performed by a qualified electrician.

• Be sure that electrical power has been disconnected from

the input power wires being connected to the operator

prior to handling these wires. An appropriate lock-out /

tag-out procedure is recommended.

• Line voltage wiring must meet all local building codes.

• Make sure operator voltage, phase and frequency

nameplate ratings are identical to the job site line

voltage ratings.

• Input power wiring must be properly sized for the

operators amperage rating lo

educe the risk of electric shock, make sure the chassis

• To r

of this unit is properly grounded.

1) Remove LINE VOLTAGE INPUT PLUG and install proper

fittings and 1/2"conduit.

2) Route proper LINE VOLTAGE wires into operator.

3) Locate LINE INPUT terminals on circuit board. Using

correct connectors, attach wires to LINE INPUTS, and GROUND

terminal. Fig. 2.

Keep low voltage and line voltage wires separate.

•

• Route all line voltage wires as shown.

• Plug all unused conduit holes.

cated on the nameplate.

Figure 1

ROUTE LINE VOLTAGE

WIRING IN SHADED

AREA AS SHOWN

LINE INPUT

TERMINALS

LINE

GROUND

HIGH VOLTAGE

INPUT PLUGS

Figure 2

LINE IN

POWER CONNECTIONS

L1/ 1

LINE

120V

(HOT)

240V

LINE 1

N/ L2

NEUTRAL

LINE 2

GND

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

5.1

Page 17

Low Voltage Control Wiring (general) Fig. 3

1) Connect all LOW VOLTAGE control circuit wires to this side

of unit using 1/2" conduit or flexible convoluted tubing.

Keep low voltage and line voltage wires separate.

Route all low voltage control wiring as shown. This includes

all control circuit wires such as wall controls, timers and single

button input devices as well as radio control and safety circuit

wiring. See Figs 2 through 13 in this section.

Plug all unused conduit holes.

NOTE: For a detailed description of control wire terminals see

Appendix B.

RADIO

CONTROL

TERMINALS

LOW VOLTAGE

CONTROL WIRE

TERMINALS

LOW

VOLTAGE

INPUT

PLUGS

% G%

G C P

GH%OH%OCGPCGP%UNUN

ROUTE LOW VOLTAGE

WIRING IN SHADED

AREA AS SHOWN

Figure 3

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

5.2

Page 18

LINE IN

POWER CONNECTIONS

L1/ L1

N/ L2

LINE

(HOT)

LINE 1

NEUTRAL

LINE 2

120V

240V

GND

OPEN

CLOSE

STOP

3-BUTTON

STATION

GCL-MJ&MH

OPEN CLOSE

MULTIPLE 3-BUTTON

STATION INSTALLATIONS

REQUIRE THE STOP

BUTTON TO BE WIRED

IN SERIES. See Fig. 5, pg 5.4

Medium Duty Operator

External Wire Diagram

See Appendix B for detailed description of terminals.

CONTROL SIGNAL TERMINAL STRIP

STOP GND 1-BTN

REMOVE JUMPER

IF STOP BUTTON

IS USED

SERIES II SAFE-T-BEAM

(CONNECT STB WIRES TO EITHER TERMINAL)

CLASS 2 SUPPLY 0-40 VDC

N-O

ODC

STB

N-O

SAFETY

OPAKMEIGX.S

INTERFACE

MODULE

SAFETY

®

(STB)

1-BTN

STATION

N/O

KEY

SWITCH

STATION

N/O

CARD

READER

N/O

O/C

PULL

SWITCH

N/O

ODC

STB

www.geniecompany.com 08-12

EXT

EXT

INTLK

INTLK

REMOVE JUMPER

WHEN INSTALLING

EXTERNAL INTERLOCK

SENSING EDGE SWITCH

(DO NOT CONNECT 2-WIRE

MONITORED SENSING EDGE

SWITCH TO THESE INPUTS)

MONITORED SENSING EDGE

PWR

20-40 VDC @ 315mA

MAX CURRENT

EXTERNAL RADIO TERMINAL STRIP

CLASS 2 SUPPLY 0-40 VDC

PWR

NOM

+ 24VDC

RAD GND

RELAY

GND

RADIO

+

-

THRU-BEAM

PHOTOCELLS

+

-

5.3

Page 19

Wall Control

1) For one 3 - button installation, make connections as

shown in Fig. 4.

2) For a multiple 3 - button installations, make connections as

shown in Fig. 5.

For single button accessory controls, make connections as

3)

shown in Fig. 6.

NOTE: If an External STOP button is NOT being installed, a jumper

wire must b

shown in Fig. 6.

as

NOTE: Long Distance Relay K

distanc

Wall Control(s) must be located so that the door is within

sight of the user and far enough from the door, or positioned,

such that the user is prevented from coming in contact with

the door while operating the controls.

Attach the Warning placard adjacent to the Wall

Control. Fig. 4A

Attach the Caution label adjacent to the Wall Con Fig. 4B.

e installed between the "STOP" AND "GND" terminals

it wiring is not required for long

e control runs and should not be used

WARNING:

.

trol.

Figure 5

WARNING:

If momentary contact control is to be used, a monitored

Figure 6

external reversing device such as a photocell system or sensing edge

switch must be used. See pages 5.6-5.7 for installation of entrapment

protection devices.

Figure 4

GCL-MJ&MH

Medium Duty Operator

11 735

Figure 4B

Thi s do or is ope rated by a lim ited -dut y ope rato r.

Figure 4A

Entrapment

Warning

Placard

www.geniecompany.com 08-12

CAUTION

To p reven t th e mo tor p rotec tor from trip ping,

do not excee d 15 cyc les o f op enin g

and clo sing per hour.

NOT FOR RESIDENTIAL USE

5.4

Page 20

Interlock Switches

1) Optional external interlock switches are required with some

Sectional or Rolling Steel Doors to prevent the door from

operating under certain conditions including the following:

If the door is equipped with a functioning door lock, an

interlock switch must be installed to prevent electric

operation when the lock is engaged.

If the door is equipped with a pedestrian pass-through door,

an interlock switch must be installed at the pass-through

door in order to prevent electrical operation when the

pass-through door is open.

Pass door interlock:

Should be open when

door is open.

Closed when door is

closed.

OPEN CLOSE

SWITCH

(N.O.)

CONTROL SIGNAL TERMINAL STRIP

STOP GND 1 BTN

ODC

ODC

STB

STB

SAFETY

N O

N O

EXT

INTLK

INTLK

EXT

SAFETY

NOTE: If External Interlock is used, THE JUMPER WIRE BETWEEN THE

EXT INTLK TERMINALS MUST BE REMOVED.

Switches must

Side lock interlock:

Should be open when door is locked.

Closed when door is unlocked.

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

be set in

the field.

Figure 7

ANGLE

SWITCH

(N.C.)

TRACK

STANDARD

SLIDELOCK

5.5

Page 21

Radio Control Installation

1) For a 3-wire radio control installation, make connections as shown in Fig.8.

NOTE: PWR terminal supplies 20 – 40VDC. Radios used must be compatible with this voltage range.

NOTE: If no voltage is present at PWR terminal, check fuse on circuit board.

Series II Safe-T-Beam® Monitored Photocells

1) Monitored SERIES II (STB) photocells can be installed as shown in Fig. 9. Wiring to

these photocells can be connected to either terminal (they are not polarity sensitive).

(Troubleshooting in Section 8)

NOTE: Monitored Sensing device must be installed or unit will be Constant Contact Close.

WARNING

CLOSE button will override external reversing devices, including photocells.

:

Actuating operator using constant contact on the

Figure 8

PWR

20-40 VDC @ 300mA

MAX CURRENT

EXTERNAL RADIO TERMINAL STRIP

CLASS 2 SUPPLY 20-40 VDC

RAD GND

PWR

RELAY

NOM

+24VDC

GND

RADIO

LOCATED

OUTSIDE

ELECTRIC

BOX

Figure 9

CONNECT WIRES TO EITHER TERMINAL.

(NOT POLARITY SENSITIVE

SERIES II (STB)

RESDENTIAL SAFE-T-BEAM

DOOR

)

CONTROL SIGNAL

TERMINAL STRIP

ODC

STB

ODC

STB

2) To Mount Photocells: (Kit includes detailed Instructions).

Determine location for mounting. They do not need to be directly adjacent to the door but must

be somewhere along the wall where there will be an unobstructed line between them.

Screws provided for mounting on soft material (wood, drywall, etc.) They must extend out away

from the wall sufficiently that no door hardware breaks the plane of the photo-beam.

WARNING

:

Photocell systems provide entrapment protection

when mounted near the doorway in such a way that the lower portion of an

individual’s leg will break the photocell beam during normal walking conditions.

Commercial Non-Monitored Photocells

1) Nominal 24 Volt DC Commercial photocells with normally open contacts can be connected

as shown in Fig. 11.

NOTE: Blue wire supplies 20 – 40VDC. Photocells used must be

NOTE: If no voltage is present at Blue wire, check fuse on circuit board.

GCL-MJ&MH

Medium Duty Operator

compatible with this voltage range.

www.geniecompany.com 08-12

Fig 10.

Figure 11

Figure 10

CONTROL SIGNAL

TERMINAL STRIP

N-O

N-O

SAFETY SAFETY

RECE VER

+

-

THRU-BEAM

PHOTOCELLS

Top of lens

to floor.

EXT RADIO CONNECTOR

Blue

REL

NOM

24VDC

RADIO

+

TRANSM TTER

-

Orange

Yellow

GND

PWR

20 40 VDC @ 250mA

MAX CURRENT

5.6

Page 22

Sensing Edge Switch Installation

Figure 12 shows an example of a typical sensing edge installation. Left hand side is shown but

right hand is a mirror image of this.

1A) If wiring from sensing edge switch to operator is coiled cord or 2 wire jacketed cord:

• Install junction box 12” above the center of the door opening on same side as

sensing switch.

• Secure one end of cord to junction box using a cable clamp.

1B) If connection is to be made through a take up reel cord:

• Install on same side as sensing edge switch and above door opening and

slightly to the side.

• Install junction box adjacent to take up reel and route the stationary cord from

the reel to the box and secure with a cable clamp.

NOTE: Do not use a take-up-reel on a monitored edge. They have slip connections in them

that momentarily break contact which causes false reversals.

2) Secure other end of cord (straight, coiled or reel) to sensing edge switch

enclosure using a cable clamp.

3) Connect wires of cord to sensing edge switch using wire nuts or other suitable

wire connectors.

4) Run a straight 2 wire cord from the junction box (Step 1)

to the operator

electrical box.

• Secure using cable clamp on each end.

5) Join wires in cord from operator to wires in cord from switch using wire nuts or

other suitable wire connectors.

6A) Monitored sensing or reversing edge connects to optional Timer-Close Module

terminals shown in Fig. 13A.

6B) Monitored slanimret BTS CDO draob tiusric niam ot stcennoc egde gnisnes

using the optional OPAKMEIGX.S as shown in Fig. 13B.

7) Operate the door to make certain cord is free to travel and does not become

snared during door opening or closing.

• Check sensing edge switch for proper operation.

WARNING:

Actuating the operator using constant contact on the CLOSE

button will override external reversing devices, including sensing edges or

reversing edges.

Figure 12

COIL TO

CONTROL BOX

Figure 13A

NOTE Monitored 2-wire

sensing or reversing

edge can only be used

in combination with a

Timer-Close Module.

Figure 13B

NOTE: Monitored sensing

edge connects to main

circuit board ODC STB

terminals using optional

OPAKMEIGX.S

INTERFACE MODULE.

SENSING

JUNCTION BOX

TIMER-CLOSE MODULE TERMINAL STRIP

MON

EDGE

MAIN CIRCUIT BOARD

ODC

STB

GND

ODC

STB

EDGE

SENSING EDGE SWITCH

NTERFACE MODULE

SENSING EDGE SWITCH

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

5.7

Page 23

IMPORTANT

SAFETY INSTRUCTIONS

WARNING

-

To reduce the risk of severe injury or death:

) READ AND FOLLOW ALL INSTRUCTIONS.

1

2

) Never let children operate or play with door controls. Keep the remote control (where

provided) away from children.

3

) Personnel should keep away from a door in motion and keep the moving door in sight until it

is completely closed or opened. NO ONE SHOULD CROSS THE PATH OF A MOVING DOOR.

4

) Test the door’s safety features at least once a month. After adjusting either the force or the

limit of travel, retest the door operator’s safety features.

5

) For products having a manual release, if possible, use the manual release only when the door

is closed. Use caution when operating the release while the door is open. Weak or broken

springs may cause the door to fall rapidly, causing severe injury or death.

6

) KEEP DOOR PROPERLY OPERATING AND BALANCED. See Door Manufacturer’s Owner’s Manual.

An improperly operating or improperly balanced door could cause severe injury or death. Have

only trained door

) SAVE THESE INSTRUCTIONS.

7

systems technicians make repairs to cables, spring assemblies and hardware.

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

5.8

Page 24

Section 6: Operator Setup Procedure

Control Panel

These operators include a full function control panel including a liquid crystal

display (LCD), calibration keys and Open, Close and Stop keys for on board

operator control.See Fig.1. The open, close and stop keys function as a 3-button

wall control. The Display will show current operator conditions and calibration

information. Due to limited character space,some displays

See Appendix C (pgs.10.7-10.9) for full display descriptions.

Operator includes a non-volatile memory. The unit will remember all

calibration settings plus error code and run code logs, if power is removed

from unit.

NOTE: During Setup, refer to Caution Label for limited use (pictured on

page 5.4).

will be abbreviated.

LCD DISPLAY

Operation Keys,

operates unit

like a 3-button

wall station.

OPEN

CLOSE

STOP

:

DANGER

Do Not make contact with components inside the control panel

except for the Keypad Keys. Fig. 1.

Control Operating Modes

Operator control boards operate in two modes: Run Mode and Calibration

Mode. The control board should normally operate in the Run Mode. The

is calibrated in Calibration Mode.

With the operator standing idle

PRESS CAL/RUN TO TOGGLE BETWEEN OPERATING MODES.

(*** = current operating mode).

NOTE: The CAL/RUN key will not toggle between operator modes while

the operator is running.

GCL-MJ&MH

After power is supplied to the operator,

***”

>

Medium Duty Operator

CAL

Calibration &

Run Mode

Toggle Key.

operator

www.geniecompany.com 08-12

Display

Backlighting

Toggle Key.

RUN

SCROLL

SCROLL

Scroll Keys, used in

Calibration Mode.

Figure 1

SET

CLEAR

Set/Clear Key,

used to reset

and adjust

calibration

settings.

6.1

Page 25

Setting Constant Contact

These operators are shipped from the factory with both open and close

operating modes set to constant contact – stop (C – STP) If your unit is set

to Momentary Contact (MOM) Open and/or CLOSE, reset the

operating modes by taking the following steps:

1) Press CAL/RUN to enter calibration mode. Fig. 2.

Press SET/CLEAR until display reads “OPEN MODE >C-STP.” Fig. 3.

2)

3) Press SCROLL (DN) until display reads “CLOSE MODE.” Fig. 4.

4) Press SET/CLEAR until display reads “CLOSE MODE >C-STP.”

Fig. 5.

WARNING:

is not used, then the operator will run Constant Contact Close.

Verify close mode is set to “C-STP”and NOT “C-REV”or “MOM”

before continuing.

ress CAL/RUN to return to run mode.

5) P

If a monitored external reversing device

IDLE DOWN LIMIT

Door closed operator

standing by

Figure 2

OPEN MODE C-STP

Figure 3

CLOSE MODE MOM

Figure 4

CLOSE MODE C-STP

Figure 5

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

6.2

Page 26

Setting Limit Travel

1) Engage door to Operator.

NOTE: Verify open and close operating modes are set to constant

contact – Stop (C-STP). See page 6.2 for details.

2) Press CAL/RUN until operator is in run mode.

3) Press and hold OPEN Key on Control Panel. Run door to

desired open position, release OPEN Key.

4) Push LIMIT LOCKING BAR away from Limit Sensors and

turn Open Limit Travel Nut until travel nut arrow and open limit

sensor arrow are aligned and the display reads “IDLE>UP LIMIT.”

elease the LIMIT LOCKING BAR and make sure bar seats

5) R

completely into both Travel Nuts.Fig.6.

Press and hold CLOSE key on Control Panel. Run door to

6)

within 2" above floor, release Close button.

UP LIMIT TRAVEL NUT

L MIT SENSOR ALIGNMENT ARROWS

Figure 6

LIMIT LOCKING BAR

NOTE: If the

operator stops while t

reads “GDO shut

down>MRT / Hit key to reset,” see page 6.6 "Resetting

rying to set limits and the display

Max Run Timers".

7) Push LIMIT LOCKING BAR away from Limit Sensors and

turn Close Limit Travel Nut until travel nut arrow and close limit

sensor arrow are aligned and the display reads “IDLE >DOWN

LIMIT.” Fig. 7.

Run door fully Open and Closed with Open & Close Keys on

8)

control panel and make final adjustments as necessary to make

sure that door opens fully and closes no more than 2" above

the floor.

GCL-MJ&MH

Medium Duty Operator

IDLE DOWN LIMIT

Figure 7

www.geniecompany.com 08-12

6.3

Page 27

Setting Limit Overrun

WARNING:

external reversing devices, including photocells and sensing edges or

reversing edges. Therefore,any externally connected devices will be

disabled during that portion of the door travel controlled by the Limit

Overrun function.

The Down Limit Overrun function should be used to close the door no

more than the final 2".

A)

The Limit Overrun setting is a matter of trial and error. The goal is to adjust

the Limit Overrun until an appropriate seal is obtained between the bottom

edge of the door and the floor.

B)

The Limit Overrun setting can be varied between 0 and 9. 0 - disables the

Limit Overrun so that the door stops at the down limit switch setting.

9 - causes the greatest amount of door travel beyond the limit switch setting.

Door should close gently with

on rolling steel slats.

1) Press CAL-RUN to enter calibration mode

2) Press scroll ( ) until the display reads “LIMIT OVERRUN >(0-9).” Fig. 8.

3) Press SET/CLEAR until the display reads the desired value.

4) Press the OPEN key to open the door a few feet,then release

5) Press the CLOSE key to close the door and hold until the operator stops.

6) Check the door seal and repeat steps 3-5 until the appropriate

seal

is obtained between the door and the floor.

CAUTION:

9, Reset the Limit Overrun back to 0 and reset the Down Limit position as

described on pg. 6.3. Then adjust the Limit Overrun as instructed above.

7) Press CAL-RUN to return to run mode.

The Limit Overrun function will override

light tension on door cables,or minimal stacking

If proper seal cannot be obtained at a setting of

LIMIT OVERRUN 0

Figure 8

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

6.4

Page 28

Monitored Reversing Devices

ODC Safe-T-Beams® (OPTIONAL)

1) If operator is in RUN mode, press CAL/RUN to enter calibration mode.

2) Press SCROLL (up or down) until display reads “ODC STB>ON” or

SCROLL

CAL

RUN

NOTE: Installation of Series II Monitored Photocells DOES NOT make the operator

unit legal for residential use.

“ODC STB>OFF” Figure 9.

3) Press SET/CLEAR key to toggle between ON and OFF.

4) Press SCROLL (up or down)

5) Press CAL/RUN to return to run mode.

WARNING:

SCROLL

SET

CLEAR

CAL

RUN

to shift to a new function and lock setting.

Photocell systems provide entrapment

protection when mounted near the doorway in such a way

that the lower portion of an individuals leg will break the

photocell beam during normal walking through the doorway.

If an alternative mounting location is chosen, it must be

approved by the facility owner.

Current UL Approved Monitored Reversing Devices (See page 5.7)

1) MillerEdge ME and MT series monitored edge sensors used in

combination with Timer-Close Module P/N OPABTCX.S or OPAKMEIX.S INTERFACE MODULE.

2) MillerEdge ME and MT series monitored edge sensors (Direct connect through STB inputs).

(Direct connect through STB inputs).

3) Residential Safe-T-Beam® Monitored Photocells from The Genie® Company,

model OSTB-BX (P/N 38176R).

4) Monitored Photocells (P/N OPAKPEN4GX.S.).

ODC STB ON

CAL

RUN

SCROLL

SCROLL

Figure 9

SET

CLEAR

OPEN

CLOSE

STOP

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

6.5

Page 29

Max Run Timer

This operator will automatically set its maximum run timers (MRT)

when the unit is run two full cycles from limit to limit, without stopping,

in the run mode. The Max Run Timer is a feature that prevents the unit

from running continuously in the event of a slipping clutch, etc.

NOTE:The MRT’s are set to the time required to run from one limit to

the other

operator stops and may reverse. The operator will not respond to

any command until it is reset by pressing one of the calibration keys

or by cycling power to the unit.

, plus 5 seconds (nominal). When the MRT is exceeded, the

Resetting the Max Run Timers

The Maximum Run timers can be reset using this procedure:

1) Press CAL/RUN to enter calibration mode.

2) Press Scroll ( ) until display

Press SET/CLEAR until display reads “MAX RUN TMR >CLEAR.”

3)

FIG. 10.

Press CAL/RUN to return to run mode.

4)

Cycle door fully open and fully closed (two full cycles) without stopping.

5)

reads “MAX RUN TMR >SET.”

MAX RUN TMR CLR

Figure 10

NOTE:The Max R

travel limits are adjusted.

CAUTION:

The Mid-Stop feature must be turned off

to properly set the maximum run timers.

GCL-MJ&MH

un Timers must be reset each and every time the

Medium Duty Operator

www.geniecompany.com 08-12

6.6

Page 30

Setting the Mid-Stop

This operator includes a programmable Mid-Stop. This feature allows

the operator to stop at a user selectable point when opening. It is used

when operating very tall doors that seldom open to their full height.

The Mid-Stop does not affect the operator when closing.

1) To operate door to full open position from mid-stop, press open

button again.

NOTE: Setting of the MID-STOP should only be performed AFTER Travel

Limit and M

To set the Mid-Stop:

1)

2) Press the CLOSE key to close the door to the down limit.

3) Press SCROLL ( ) until the display reads “MID-STOP >CLEAR.

NOTE: If the display reads MID-STOP >SET at this point, first clear the

MID-ST

4) Press the OPEN key to open the door and release the key

5) Press the SET/CLEAR until the display reads “MID-STOP >SET.”

6) Press C

To clear the Mid-Sto

1) Press CAL/RUN to enter calibration mode.

2) Press SCROLL ( ) until the display reads MID-STOP >SET.

3) Press SET/CLEAR until the display r

4) Press CAL/RUN to return to run mode.

ax Run Timer settings have been made.

Press CAL/RUN to enter calibration mode.

”

Fig. 11.

OP as described below then repeat steps 1-3 and continue.

when the door is at the desired Mid-Stop height.

AL/RUN to return to run mode.

p:

eads MID-STOP >CLR

MID-STOP CLR

Figure 11

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

6.7

Page 31

Changing Open and Close Modes

NOTE: Once the travel limit and safety modes have been set, the OPEN and

CLOSE modes may be set for Momentary Contact if desired.

WARNING

If momentary contact control is to be used, a monitored

external reversing device such as a photocell system or sensing

edge switch must be used.

NOTE:The radio control input will not operate when the open or close

mode is set in the Constant Contact mode. Operating modes affect all

control inputs and keys.

To set the OPEN mode: Fig. 12

1) Press CAL/RUN to enter the calibration mode.

2) Press SCROLL ( ) or ( ) until display reads “OPEN MODE >.”

This displays current setting.

3) Press SET/CLEAR until the display reads the desired operating mode:

C-STP = Constant contact is required to open door.Door will

stop if button or key is released before operat

MOM = Momentary contact will cause door to open to limit.

4) Press CAL/RUN to return to run mode.

To set the CLOSE mode: Fig. 13.

1) Press CAL/RUN to enter the calibration mode.

2) Press SCROLL ( ) or ( ) until display reads “CLOSE MODE >“.

This displays current setting.

3)

Press SET/CLEAR until the display reads the desired operating mode:

C-STP = Constant contact is required to close door. Door will

stop if button or key is released before operator reaches its limit.

C-REV = Constant contact is required to close the door. Door

will reverse automatically if close button or key is released

before door reaches down limit.

MOM = Momentary contact will cause door to close to limit.

4) Press CAL/RUN to return to run mode.

GCL-MJ&MH

.

Medium Duty Operator

or reaches its limit.

www.geniecompany.com 08-12

OPEN MODE MOM

Figure 12

CLOSE MODE MOM

Figure 13

6.8

Page 32

Section 7: Special Operator Features

Operator Cycle Count

These operators include a built-in cycle counter that store the count with

or without power to the operator.

To view the Cycle Count:

Press CAL/RUN to enter calibration mode.

1)

2) Press SCROLL ( ) or ( ) until display reads “CYCLES >.”

his will display current cycle count.

T

3) Press CAL/RUN to return to run mode.

Fig. 1

Circuit Board Firmware Version Fig. 2

These operators can display the version number of the firmware used in

the on-board micro-controller.

To view this version number:

1) Press CAL/RUN to enter calibration mo

2) Press SCROLL ( ) or ( ) until the display reads “GDO V# >.”

This will display the current firmware version number.

3) Press CAL/RUN to return to run mode.

de.

CYCLES 1

Figure 1

GDO V# 4.00.1

GCL-MJ&MH

Medium Duty Operator

Figure 2

www.geniecompany.com 08-12

7.1

Page 33

Operator Type Fig.3

These operators are available for use in jackshaft or trolley configurations.

The same control board is used for either configuration, however the control board must be set for the appropriate GDO configuration. A board set

for trolley mode will not work in a jackshaft operator and vice-versa.

NOTE:The GDO type is factory set. The installer should not have to set

eature. However,if the GDO type is inadvertently changed, or if a

this f

board needs to be replaced in the field, follow these instructions to set

GDO type.

1) Press CAL/RUN to enter calibration mode.

2) Press SCROLL ( ) or ( ) until display reads “GDO TYPE >.”

This will display the current GDO t

3) Press SET/CLEAR until display indicates

( J-SHAFT or TROLLEY)

4) Press CAL/RUN to return to run mode.

ype.

correct GDO type

GDO TYPE J-SHAFT

Figure 3

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

7.2

Page 34

Section 8: Troubleshooting

Display Operation in Run Mode

The operators display their status on the LCD display. Each time the

operator runs, stops,reverses or refuses to run, the display will indicate why

the action did, or did not, take place.

Once an error code has been generated, the operator will continue

to display the error code while the operator is not running. This error code

can be cleared by pressing the STOP button or STOP key on the keypad.The

error code will automatically clear when the operator stops at the down

limit. Error codes will continue to be stored in the operator’s Error

Code Memory after they have been cleared from the display in the

Run Mode.

Error Codes

To aid in troubleshooting problems, the operators include an error code

memory that stores the last 10 error events. These codes are stored with or

without power.The last error code detected is also displayed on the LCD until

the stop button or key is pressed or the operator stops at the down limit.

The error code memory stores the last 10 error codes in sequence. Once 10

codes are stored, the oldest code is erased to make room for the newest

code.These codes are displayed in calibration mode. The display will flash

the number of the error code and the 2-digit error code followed by a

description of the error code. Fig. 1 & 2.

ERROR CODE 1 41

Figure 1

REV ONE BUTTON

Figure 2

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

8.1

Page 35

Error Codes (cont’)

To view the error code memory: (Fig. 1 & 2)

1) Press CAL/RUN to enter calibration mode.

2) Press SCROLL ( ) or ( ) until display reads

“ERROR CODE 1 .”

The display will begin flashing the error code number and

2-digit error code followed by its description.

Reminder: Error code number 1 is the latest code generated.

3) Press SET/CLEAR. The display will now read “ERROR CODE 2 >.”

This is the error code which was generated before error code 1.)

(

4) Repeat step 3 until all 10 error codes have been displayed or

move on to step 5 when ready.

5) Press CAL/RUN to return to run mode.

NOTE: For all error codes see Appendix C, Pages 10.8 - 10.9.

>

Run Codes

These operators also include a run code memory that stores the last 10 run

events.These codes are stored with or without power. Each time the

operator runs or stops, it generates a code that it stores in this memory

(Why the operator ran or stopped). Used together with the er

memory, it becomes a powerful troubleshooting aid.

The run code memory stores the last 10 error codes in sequence. Once 10

codes are stored, the oldest code is erased to make room for the newest

code.These codes are displayed in calibration mode.The display will flash

the number of the run code and the 2-digit run code followed by a

description of the run code. Fig

. 3 & 4.

ror code

RUN CODE 1 3C

Figure 3

HALT DOWN LIMIT

Figure 4

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

8.2

Page 36

Run Codes (cont’)

To view the run code memory: (Fig. 3 & 4)

1) Press CAL/RUN to enter calibration mode.

2) Press SCROLL ( ) or ( ) until display reads “RUN CODE 1 >.”

The display will begin flashing the run code number and code

followed by its description.

Remember: run code number 1 is the latest code generated.

3) Press SET/CLEAR. The display will now read “RUN CODE 2 >.”

This is the run code which was generated before run code 1.)

(

4) Repeat step 3 until all 10 run codes have been displayed or

move on to step 5 when ready.

5) Press CAL/RUN to return to run mode.

NOTE: For all run c

TROUBLESHOOTING EXAMPLE USING RUN AND ERROR CODE

MEMORIES.

Fig. 5.

1. In Calibration Mode, display and write down each Run Code

and Error Code stored in memory.

2. List as shown below.

efer to Appendix C to interpret the codes.

3. R

In this example, the operator was opened using

the keypad and stopped at the up limit. The OPEN wall button

was then activated, causing the “6D” code to be generated since

the operator could not open when it is already at the up limit.

The CLOSE wall button was then activated, causing the operator

to close. While closing, the Normally-Open (N-O) Safety Input

was activated, causing the operator to stop and then reverse,

stopping at the up limit.

odes see Appendix C, Page 10.7.

the OPEN key on

ERROR

CODES

NUMBER

1

2

3

4

5

6

7

8

9

10

CODE

45

6D

00

00

00

00

00

00

00

00

00

Figure 5

REVERSED DUE TO ACTIVE

N-O SAFETY INPUT

WOULD NOT OPEN —

ALREADY AT UP LIMIT

OPERATOR STORES “00” CODES IN UNUSED RUN AND ERROR

CODE MEMORY LOCATIONS FROM THE FACTORY.

AS ERROR OR RUN CODES ARE

RECORDED, THE “00” CODES ARE REPLACED WITH VALID CODES

STOPPED AT UP LIMIT

STOPPED DUE TO ACTIVE

N-O SAFETY INPUT

CLOSED FROM

CLOSE WALL BUTTON

STOPPED AT UP LIMIT

OPENED FROM

OPEN KEY ACTIVATION

RUN

CODES

CODE

3D

35

20

3D

14

00

00

00

00

00

NUMBER

1

2

3

4

5

6

7

8

9

10

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

8.3

Page 37

LED Indicators Fig. 6

These operators include a self-diagnostic circuit board using

troubleshooting LED indicators to signal the technician of

a problem.

TROUBLESHOOTING

LED S

STB

ENAB

+ 24

VAC

EXT

INTLK

HOIST

INTLK

DETAIL

Figure 6

SB

EAB

+ 24

VC

ET

IT K

HO T

IT K

HOIST

INTERLOCK

EXTERNAL

INTERLOCK

+ 24 VOLTSDCSTB

ON ON ON

OFF

ON ON

OFF OFF

OFF OFF OFF

TROUBLESHOOTING LED’s

ENABLE

OFF

ON

INDICATION

STB DISABLED

STB ENABLED

ON

NORMAL OPERATING CONDITION

HOIST INTERLOCK SWITCH OPEN:

1) HOIST RELEASE NEEDS RESET.

2) HOIST INTERLOCK CONNECTOR NOT PLUGGED IN.

3) HOIST INTERLOCK DEFECTIVE.

EXTERNAL INTERLOCK OPEN

POWER SUPPLY PROBLEM:

1) CHECK AC POWER SUPPLY.

2) CHECK MAIN POWER FUSE.

3) CHECK SECONDARY FUSE (2A).

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

8.4

Page 38

Monitored Photocell Self-diagnostic Troubleshooting Chart

SOURCE (RED LED

ON

OFF

OFF

2 BLINKS, PAUSE

(REPEAT)

2 BLINKS, PAUSE

(REPEAT)

3 BLINKS, PAUSE

(REPEAT)

4 BLINKS, PAUSE

(REPEAT)

)

SENSOR (GREEN LED

ON

OFF

ON

ON

OFF

ON

ON

WARNING:

)

INDICATED CONDITION

NORMAL OPERATION

1. POWER HEAD NOT POWERED

2. WIRING FROM POWER HEAD BAD

1. WIRING TO SOURCE MISSING OR BAD

2. POWER HAS BEEN INTERRUPTED

1. BEAM NOT ALIGNED

2. BEAM OBSTRUCTED

3. SENSOR DEFECTIVE

1. WIRE TO SENSOR MISSING OR BAD

2. SENSOR DEFECTIVE

1. SENSOR RECEIVING INTERFERENCE

REQUIRED ACTION

NONE REQUIRED

1. CHECK BREAKERS, FUSES, PLUGS

2. CHECK WIRING FOR OBVIOUS SHORTS

1. CHECK WIRING

2. REMOVE POWER AND REAPPLY

1.CHECK ALIGNMENT

2. CHECK FOR OBSTRUCTION

3. CALL CUSTOMER SERVICE

1. CHECK WIRING

2. CALL CUSTOMER SERVICE

1.

ATTEMPT TO DETERMINE SOURCE OF

INTERFERENCE

2. CALL CUSTOMER SERVICE

1. SOURCE NOT SENDING PULSES

2. SOURCE DEFECTIVE

Actuating the operator by using constant contact

on the CLOSE button will override external reversing devices,

including photocells.

1. CALL CUSTOMER SERVICE

2. CALL CUSTOMER SERVICE

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

8.5

Page 39

Section 9: Service and Maintenance

Maintenance Schedule

The following table provides a schedule of recommended Service and

Maintenance items to be completed by a trained service representative.

CAUTION:

Failure to perform the recommended Service & Maintenance

may result in premature failure of the operator.

SERVICE ITEM SERVICE INTERVAL (FREQUENCY)

EVERY 6 MO. EVERY 12 MO. EVERY 36 MO.

OR OR OR

5,000 CYCLES 10,000 CYCLES 30,000 CYCLES

MANUAL

OPERATION OF

DOOR

DRIVE CHAIN

TENSION

PHOTOCELL/

*

SENSING EDGE

OPERATION

CLUTCH

ADJUSTMENT

BRAKE

ADJUSTMENT

CHECK FOR LOSE

OR MISSING

HARDWARE

CHECK LIMIT

POSITION

GEAR TRAIN

WEAR

*

ALL EXTERNAL REVERSING DEVICES SHOULD BE CHECKED MONTHLY.

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 08-12

9.1

Page 40

Basic Hoist Operator Parts

23

138

22

135

137

21

167

Section 10: Appendix A

161 160

164

159

168

37

165

127

133

129

PARTS LIST

ITEM NO.

110380.0001

1

110380.0002

110847.0001

21

110847.0002

110450.0001

22

110449.0001

23

108190.0001

37

110443.0001

39

125

110503.0001

127

110807.0001

111007.0001

128

8115B17

129

110809.0001

130

131

110807.0001

132

107978.0001

110502.0001

133

110522.0001

134

135

110521.0001

136

110808.0001

110549.0001

137

110824.0001

138

111051.0001

159

160

111051.0002

161

110803.0001

110804.0001

164

110805.0001.S

165

110425.0001

167

110425.0002

168

DESCRIPTIONPART NUMBER

ELECTRIC MOTOR, 1/2HP, 120V

ELECTRIC MOTOR, 1/2HP, 240V

BRAKE SOLENOID, 115V

BRAKE SOLENOID, 230V

BRAKE BAND

BRAKE RELEASE LEVER

INTERLOCK SWITCH

BRAKE PULLEY

BRAKE RELEASE LINK

BRAKE PIVOT BRACKET

BRAKE RELEASE—CLEVIS PIN

BRAKE RELEASE—SPEED NUT

BRAKE RELEASE ROD RIVET

BRAKE RELEASE ARM BRACKET

RELEASE PULLEY

HANDWHEEL RELEASE ARM

BRAKE POST—FLOATING

BRAKE POST—FIXED

BRAKE ADJUSTMENT PLATE

BRAKE SOLENOID COVER

BRAKE RELEASE SPRING

OPERATOR CHASSIS LEFT

OPERATOR CHASSIS RIGHT

OPERATOR CHASSIS SUPPORT BRACE

SUPPORT BRACKET

WIRE GUARD BRACKET

LEFT MOUNTING BRACKET

RIGHT MOUNTING BRACKET

GCL-MJ&MH

134

39

Medium Duty Operator

136

161

1

132

130

www.geniecompany.com 08-12

125131

128

10.1

Page 41

Basic Jackshaft Operator Parts

23

135

137

21

138

22

167

Section 10: Appendix A

161 160

164

159

SEE SEPARATE ILLUSTRATED

PARTS BREAKDOWN FOR

OUTPUT SHAFT ASSY

SEE SEPARATE

ILLUSTRATED

PARTS BREAKDOWN

FOR INTERMEDIATE SHAFT ASSY

168

37

133

PARTS LIST

ITEM NO.

110380.0001

1

110380.0002

110847.0001

21

110847.0002

110450.0001

22

110449.0001

23

108190.0001

37

110443.0001

39

128

110815.0001

110867.0001

130

131

111143.0001

132

107978.0001

18586A04.S

133

110522.0001

134

135

110521.0001

136

110808.0001

110549.0001

137

110824.0001

138

111051.0001

159

160

111051.0002

161

110803.0001

111804.0001

164

110803.0001

166

110425.0001

167

110425.0002

168

176

110805.0001

DESCRIPTIONPART NUMBER

ELECTRIC MOTOR, 1/2HP, 120V

ELECTRIC MOTOR, 1/2HP, 240V

BRAKE SOLENOID, 115V

BRAKE SOLENOID, 230V

BRAKE BAND

BRAKE RELEASE LEVER

INTERLOCK SWITCH

BRAKE PULLEY

BRACKET PIVOT

RELEASE SPRING

RELEASE BRACKET

RELEASE PULLEY

COLD HEADED PIN

BRAKE POST—FLOATING

BRAKE POST—FIXED

BRAKE ADJUSTMENT PLATE

BRAKE SOLENOID COVER

BRAKE RELEASE SPRING

OPERATOR CHASSIS LEFT

OPERATOR CHASSIS RIGHT

OPERATOR CHASSIS SUPPORT BRACE

MOTOR MOUNT

SUPPORT BRACE

LEFT MOUNTING BRACKET

RUGHT MOUNTING BRACKET

WIRE GUARD

GCL-MJ&MH

39

Medium Duty Operator

134

136

176

131161

1

132

130

www.geniecompany.com 08-12

128

10.2

Page 42

Basic Shaft Assembly Parts

4240

CLUTCH KIT

94 29 29104

99

153

116

115

INTERMEDIATE SHAFT ASSEMBLY

(HOIST)

3841 44 45 4746 48

150

106 153

119

Appendix A (cont’)

PARTS LIST

ITEM NO.

7

110478.0003

29

110813.0001

32

106064.0001

34

110872.0001

38

111125.0001

40

080401.0624

41

075197.0000

42

110472.0001

44

086649.0029

45

108015.0001

46

075193.0000

47

111037.0001

110881.0001

48

91

107967.0001

110876.0001

92

080415.0025

94

96

110313.0010

110463.0001

99

102

080340.0074

104

110543.0001

105

110545.0001

106

110391.0001

115

110313.0008

116

110818.0001

119

110313.0010

110465.0001.S

150

110482.0001

151

110819.0002

152

110819.0001

153

DESCRIPTIONPART NO.

OUTPUT SHAFT

INTERMEDIATE SHAFT BEARINGS

OUTPUT SHAFT BUSHINGS

HANDWHEEL

CLUTCH PULLEY

COTTER PIN

CLUTCH SPRING

SLOTTED CLUTCH NUT

CLUTCH THRUST WASHER

MOVABLE CLUTCH PLATE

CLUTCH LINING

CLUTCH DISC

DOWEL PIN

CHAIN GUARD

BUSHING, .627 ID

E-RING

SPRING PIN, .250 X .188

INTERMEDIATE SHAFT

SQUARE KEY STOCK, 3/16

SPRKT, 25T-40T, #35CH, 3/8P

HANDWHEEL SPRING

SPACER WASHER

WAVE WASHER

SPRING PIN

SPRCKT, 23T, #25CH, 1/4P, W/KEY

SPRKT, 40T, #35CH, 3/8P

PLAIN WASHER

PLAIN WASHER

102

32 1517 106 32 152

104

106

102

106

150

OUTPUT SHAFT ASSEMBLY

(DIRECT)

91

9

106

2

34

106

96

105

G PIN, .188 DIA. x 1 38NIRPS

HANDWHEEL KIT

GCL-MJ&MH

Medium Duty Operator

www.geniecompany.com 0 8-12

10.3

Page 43

Basic Shaft

Assembly Parts

INTERMEDIATE

SHAFT ASSEMBLY (JACKSHAFT)

2

1

OUTPUT SHAFT ASSEMBLY

(INDIRECT)

3 4 5 6 7 8

9

19

20 21 22 23

Appendix A (cont’)

9

10 11 12

13

14

15 16

22 20

17

18

13

PARTS LIST

ITEM NO.

1

110472.0001

080401.0624

2

075197.0000

3

4

111324.0001.S

5

110881.0001.S

6

075193.0000

7

111037.0001

8

110819.0001

086649.0029

9

10

110392.0001

11

110387.0001

12

110817.0001

110813.0001

13

108015.0001

15

8

14

15

16

17

18

19

20

21

22

23

24

25

080415.0021

110818.0001

110389.0001

110816.0001

110460.0003

110819.0002

110478.0003

106064.0001

110482.0003

080415.0025

110818.0002

DESCRIPTIONPART NO.

SLOTTED NUT, 5/8-11

COTTER PIN

CLUTCH SPRING

CLUTCH PULLEY ASSY

DOWEL PIN

CLUTCH LINING

CLUTCH DISC

PLAIN WASHER

PLAIN WASHER

INTERMEDIATE SHAFT

SLIDER

SPRKT & ENGAGEMENT PLATE

BEARING

MOVABLE CLUTCH DISC

E-RING

WAVE WASHER

RELEASE SPRING

ROUND END KEY, .188 X 1.500

SPRKT, 23T, #25CH, 1/4P, W/KEYWAY

PLAIN WASHER

OUTPUT SHAFT, W/KEYWAY

BUSHING

SPRKT, 40T, #35CH, 3/8P, W/KEYWAY

E-RING

WAVE WASHER

GCL-MJ&MH

24

Medium Duty Operator

25 24

www.geniecompany.com 08-12

10.4

Page 44

Basic Electric Box Parts

35

139

Appendix A (cont’)

232221

2026 26 25 24 23 21 272524

140

139

12

GCL-MJ&MH

13

19

Medium Duty Operator

WIRING LAYOUT - HOIST

JACKSHAFT

DIFFERENCE

OR

2

17

www.geniecompany.com 08-12

PARTS LIST

ITEM NO.

2

110405.0001

110405.0002

112365.0001.S

12

110846.0001

13

110846.0002

17

110957.0001

19

110830.0001

110830.0002

20

111048.0001

21

109876.0003

22

110818.0003

077538.0000

23

24

110823.0001

25

110550.0001

26

110459.0001

601332.0001

27

111851.0001

35

15

080415.0021

110423.0001

139

140

110870.0001

DESCRIPTIONPART NO.

ELEC BOX ASSY, 115V

ELEC BOX ASSY, 230V

KIT, PCB

TRANSFORMER, 120V

TRANSFORMER, 240V

FUSE KIT

CAPACITOR, 115V

CAPACITOR, 230V

LIMIT SHAFT

E-RING

WAVE WASHER

BUSHING, 3/8/ID

PUSH-ON RETAINING RING

LIMIT TRIGGER

TRAVEL NUT

SPRKT, 14T, 1/4P, 3/8 BORE

COVER ASSY, ELEC BX

E-RING

E-BOX HINGE

E-BOX LATCH

10.5

Page 45

Screw Terminal Assignments

11-POSITION

INPUT

TERMINAL BLOCK

INSIDE ELECTRIC BOX

2-POSITION TERMINAL

BLOCK

(INSIDE ELECTRIC BOX)

OPEN

CLOSE

STOP

GND

1-BTN

ODC STB

ODC STB

N-O REVERSE

N-O REVERSE

EXT INTLK

EXT INTLK

L1 / L1

N / L2

Causes door to open if not at Up Limit.

Causes door to close if not at Down Limit.

Causes a moving door to stop.

Common ground connection for Open, Close, Stop &

Causes door to open if not at Up Limit or Mid-Stop Limit.

Causes door to close if at Up Limit or Mid-Stop Limit.

Causes door to stop if opening.

Reverses a closing door if photocell beam is blocked.

NOTE: STB's must be enabled in Calibration Mode.

Reverses a closing door if photocell beam is blocked.

NOTE: STB's must be enabled in Calibration Mode.

Causes a closing door to reverse.

Causes a closing door to reverse.

Causes a moving door to stop.

Prevents the operator from running when contact is open.

Operates even if microcontroller is non-functional.