REFERENCE ONLY

[I

236507

[I

•

,

,

•

~

~

REFERENCE ONLY

Table of Contents

Foreward ..........................................

Safety Precautions

Identification Of The Axle ...........

Cleaning and Inspection

Lubrication Specifications

Torque Limits and Specifications

Exploded View

Parts List

Axle Assembly Instructions ......

Differential Tooth Contact Charts ..........................

Maintenance Intervals and Procedures

Symbols

Model 25S34 Disassemby .............

Removal of Wheel Ends

Removal of Drive Flange

Removal of Axle Assembly .......................................... ......................................................

Disassembly of Drive Flange and Steer Knuckle

...

..

.................

..

....

..............

..

....................................................................

.....................................................................................................

..

..............................

........

...

.....................

...

..................................................................................................

...

..

............................................................

..............

.... .....

.......... ..

...................

..

.. ..

............

.....

..............................................................

...

............. : ................

.............................................

..................................

..

................................................................................

..

......

...................................................................................

.........

...................

...

....................................

........................................

............... ..

..

................................

.....................

..

....

.. ..

...

..................

..........................................................

.............

................................................. 13

...

....................

....

........................................

................................. 1

...

........................................ 2

...

.......

....

.......

...

........................................ 4

.................... ............. 7

.......

..................... ..

..................................

.......

...

...............

...

...........

.....................

...

.................. 3

...

...... 6

. 11-12

...

...... 18

............... 19

...

...

.. .........

.. ............ 23

...

...

..

..

10

16

20

20

21

23

....

Removal and Disassembly of Front and Rear Trunnions ....................

..

Removal and Disassembly of Steer Cylinder

Removal of Seals and Bushings from Ax

le

Removal of Ax

Disassembly of Carrier ....

Disassembly of Inner

Reassembly of Model 25S34 .

Reassembly of Trunnions .........

Reassembly of Carrier Housing ........

Pinion Shim Selection ...............................................

Pinion Shim Selection Cha

Reassembly of Axle Housings .................

Reassembly of Wheel Ends

Reassembly of Steer Cylinder .........

Installation of Front and Rear Trunnions ......................................

Bleeding The Brake System ......................................................................................................... 55 •

Housings ..................................................

........

....................................................

Yoke

and Shaft Assembly ............................

...

..............................................

..

.............

..

..........

rt .........................................................

.. ..

.........................................

....

......................................

...............................

le

Housings ..........................

.. ..

....................

...........

.....................................

.....................

.........

.......................................

....

.....................................

.... ..

........................................................ 38 4

.. .. ..

...

.......

...

......................................... 34

.......................................... 36

.. ....

.......................................... 39

...

...............

....

..........

...

..................................... 26

....

...............................

.............................

.........

............................... 44

...

.. ....

.........................

.... ........

............

...

........................ 36

....................

....

....................... 52 C

.......

..

25

27

...........

...

..

29

....

.......

31

..........

.............. 54 C

..

37

.......... 48 C

~

~

«:>1999

DANA CORPORATION

~

~

~

REFERENCE ONLY

..

MAINTENANCE MANUAL MOOEL

25534

AXLE

Foreward

This manual has been prepared to provide the customer and the maintenance personnel with

information and instructions on the maintenance and repair of the Spicer Off Highway Products.

Extreme care has been exercised in the design and selection of materials and manufacturing of

these units. The slight outlay

proper lubrication and inspection at stated intervals, and such adjustments as may be indicated

will be reimbursed many times

In

order to become familiar with the various parts of the product , it's principle of operation,

troubleshooting, and adjustments, it is urged that the mechanic study the instructions

manual carefully and use it as a reference when performing maintenance and repair operations.

Whenever repair

Products approved parts

or non-approved parts may endanger proper operation and performance of the equipment.

Spicer Off Highway products does not warrant repair or replacement parts, nor failures resulting

from the use of parts which are not supllied or approved by Spicer Off Highway Products.

Important: Always furnish the distributor with the serial and model number when ordering parts.

or

replacement of component parts is required, only Spicer Off Highway

as

in

personal attention and cost required to provide regular and

in

low cost operation and trouble free service.

listed

in

the applicable parts manual should

be

used. Use of "will fit"

in

this

1

REFERENCE ONLY

MAINTENANCE MANUAL MOOEL 25534

Safety Precautions

To

reduce the chance of personal injury and/or property damage, the following instructions

must be carefully observed .

Proper service and repair are important to the safety of the service technician and the safe,

reliable operation of the machine. If replacement parts are required the part must be replaced

with one

lesser quality.

of

the same part number or with an equivalent part. Do not use a replacement part of

The service procedures recommended

service and repair. Some of these procedures require the use of tools specifically designed for

the purpose.

Accordingly, anyone who intends to use a replacement part, service procedure or tool which is

not recommended must first determine that neither his safety nor the safe operation of the

machine will be jeopardized by the replacement part, service procedure or tool selected.

It

is important to note that this manual contains various 'Cautions' and 'Notices ' that must be

carefully observed in order to reduce the risk

possibility that improper service or repair may damage the unit or render it unsafe. It is also

important to understand that these 'Cautions' and 'Notices' are not exhaustive, because it is

of

impossible to warn

follow these instructions.

all the possible hazardous consequences that might result from failure to

in

this manual are effective methods of performing

of

personal injury during service or repair, and the

2

REFERENCE ONLY

MAINTENANCE MANUAL MODEL

25534

AXLE

Identification

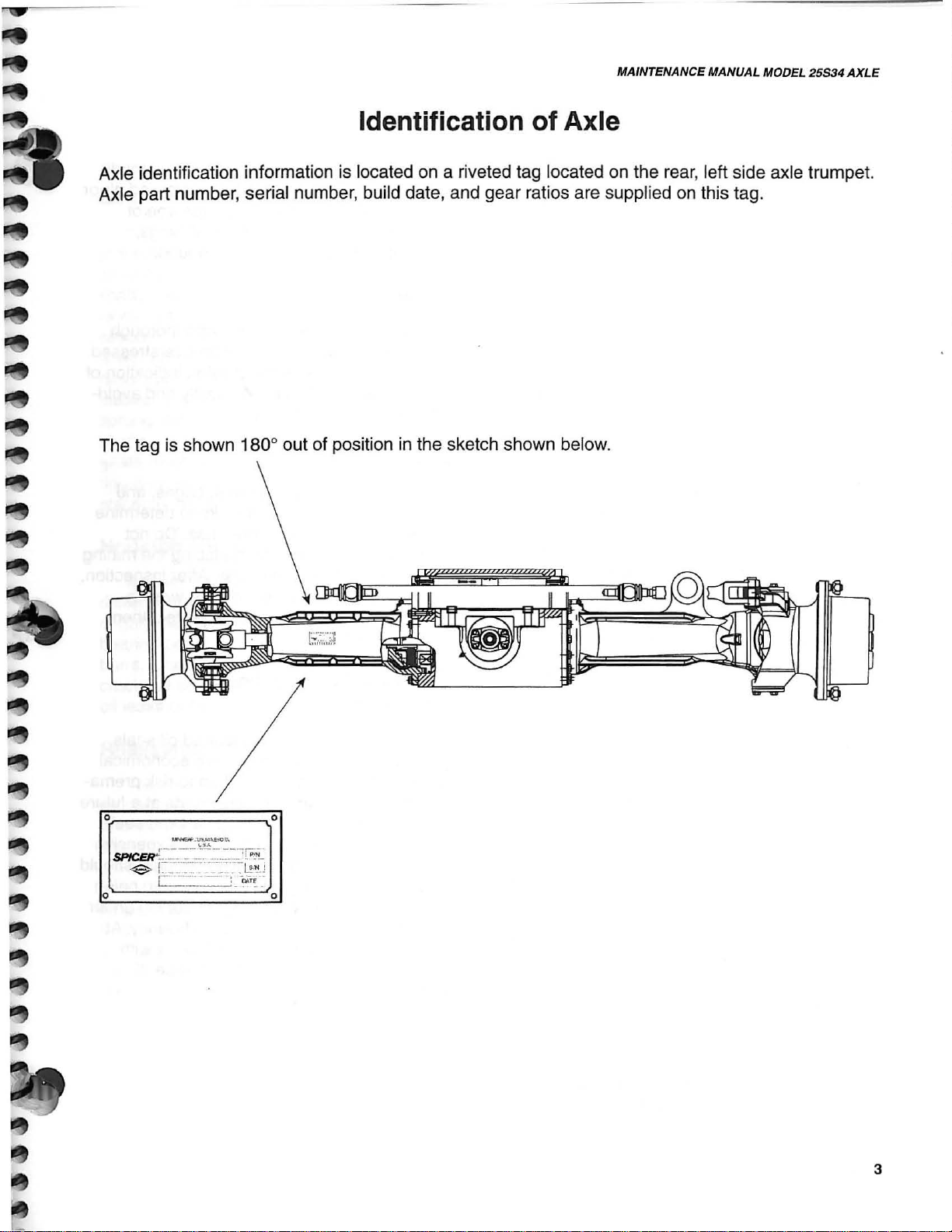

Axle identification information is located

Axle part number, serial number, build date, and gear ratios are supplied on this tag.

The tag is shown 180

0

out of position

on

a riveted tag located on the rear, left side axle trumpet.

in

the sketch shown below.

of

Axle

o

o

o

3

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

Cleaning and Inspection

Cleaning

Clean all parts thoroughly using solvent

type cleaning fluid.

parts be immersed in cleaning fluid and agitated slowy until parts are thoroughly cleaned

of all old lubricants and foreign materials.

It

is recommended that

Caution

Care should be exercised to avoid skin

rashes, fire hazards and inhalation of vapors

when using solvent type cleaners.

Bearings

Remove bearings from cleaning fluid and

strike larger side of cone flat against a bock of

wood to dislodge solidified particles of lubri-

in

cant. Immerse again

out particles . Repeat above operation until

bearings are thoroughly clean. When drying

bearings, use moisture-free compressed air,

being careful to direct air stream across bearings as to avoid spinning. Bearings may be

rotated slowly by hand to facilitate the drying

process.

cleaning fluid to flush

Thoroughly dry all parts cleaned immedi-

ately by using moisture-free compressed air or

soft lintless absorbent wiping rags free of

abrasive materials such as metal filings,

contaminated oil or laping compound.

Inspection

The importance of careful and thorough

inspection of all parts cannot be overstressed.

Replacement of all parts showing indication of

wear or stress will eliminate costly and avoid-

able failures at a later date.

Bearings

Carefully inspect all rollers, cages, and

cups for wear, chipping or nicks to determine

fitness of bearings for further use.

replace a bearing without replacing the mating

cup or cone at the same time. After inspection,

dip bearings in clean light oil and wrap in

clean lintless cloth or paper to protect them

until installed.

Do

not

Oil Seals, Gaskets and

Retaining Rings

Housing

Clean interior and exterior of housings,

bearing caps, etc., thoroughly. Cast parts may

be cleaned

alkali solutions, providing these parts do not

have ground or polished surfaces. Parts

should remain in solution long enough to be

throughly cleaned and heated. This will aid the

evaporation of the cleaning solution and rinse

water. Parts cleaned

throughly rinsed with clean water to remove all

traces of alkali. Cast parts may also be

cleaned with steam cleaner.

in

hot solution tanks with mild

in

solution tanks must be

Replacement of spring loaded oil seals,

gaskets, and snap rings is more economical

when unit is disassembled than to risk premature overhaul to replace these parts at a future

time. Loss of lubricant through a worn seal

in

may result

parts of the assembly. Sealing member should

be

handled carefully, particularly when being

installed. Cutting, scratching, or curling under

lip of seal seriously impairs its efficiency. At

reassembly, lubricate lips of oil seals with

Multipurpose Lithium grease. "Grade 2"

(MS107C).

failure of other more expensive

Caution

Care should be exercised to avoid skin

rashes and inhalation of vapors when using

alkali cleaners.

4

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

Cleaning and Inspection (Cont.)

AXLE

Gears and Shafts

If magna-flux process is available, use

process to check parts. Examine teeth and

ground

shafts carefully for wear, pitting, chipping,

nicks, cracks,

cracked

is worn through, replace with

nicks

Inspect shafts to

sprung, bent,

shafts are true. Differential pinions and side

gears

ring

placed as a set if either is damaged.

and

polished surfaces

or

scoring. If gear teeth are

or

show

spots

may

be removed with suitable hone.

make

or

splines twisted,

must

be replaced as sets. Differential

gear

and spiral pinion must also be re-

where case hardening

certain they are not

of

new

all gears and

gear. Small

and

that

Housing and Covers

Inspect housing, covers, planet spider, and

differential case to

oughly cleaned and

bearing bores, etc., are free from nicks or

burrs.

cracks

oil leaks

Check

or

condition which cause subsequent

or

failures.

be

certain they are thor-

that

mating surfaces,

all parts carefully

for

evidence

of

Torque values specified in text

B.B,

manual are for class

presently used in production. On all axles

being overhauled, bolts should

described above and torque value chart consulted

for

correct torque.

10.9 hardware where

of

this

be

identified as

At Reassembly

Apply Thread Locking

Compound Where Noted

Guidelines

A.

On

end) apply compound on female threaded

component part.

B.

On nuts, apply compound to the

thread

C. Apply compound to coat the full length

circumference

D.

Remove excess compound from mating

parts after fastener installation.

for

application where to apply:

bolts, capscrews, and studs (anchor

male

of

the mating fastener.

and

of

thread engagement.

Reassembly

The

reassembly instructions describe the

procedure to be followed when reassembling

and installing components of axle. Instructions

covering reassembly

cal unless otherwise noted.

Important: Class

fastening hardware have been used in the

production of the axle assemblies covered

the manual. A table of proper torque values

the fastener classes above are provided within

this manual. The class of hardware

determined by the markings contained on the

head

of

each capscrew. Class 12.9 torque

values needs to be used on all sockethead

caps crew used with this assembly.

of

Axle

of

opposite side is identi-

B.B

and 10.9 and 12.9

may

in

for

be

5

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

Lubrication Specifications

Recommended Lubricants

for

Spicer 25 S 34 Axle

Initial and Service Fill

Select high quality gear lubricant type GL5 that conforms to MIL-L-21

Select the highest

the oil application chart shown below.

oil

viscosity compatible with the prevailing ambient temperature

Capacities

Recommended

75W90

Each wheel end

Axle Center Section

Total

Axle

MI-l-21

050

Viscosity

Capacity

Grade

Based

13.5 qts.

16.5 qts.

on

Prevailinq

1.5 qts.

Ambient

05

specifications.

Temperature

as

shown

on

Celsius

Fahrenheit

Actuator

80W90

-40 -30 -15

-40

-22

5

Prevailing Ambient Temperatures

0

32

10

50

20

68

30

86

Internal Liquid Cooled Brake Fluids

oils

recommended

1. Motor oil

2.

Transmission lubricants meeting the following specs:

a)

Caterpillar TO-4

b)

John Deere J20

c)

Military MIL-PRF-2104G

d)

Allison C-4

3. Hydraulic

4. Synthetic gear oils

oil

for

use

in

API SE/CD

C,

the

D

liquid

40 49

104 120

cooled brake

circuit

6

REFERENCE ONLY

'W

Torque Limits and Specifications

Housing:

Housing ArmfTrumpet Bolts

Carrier Cover

Brake Port Fittings

Bleeder Screws

Differential Torques:

Adjusting Ring Clip Bolt

Drive Gear Capscrews

Cap Bolts

Pinion Nut

Wheel End Assembly:

Hub Retainer Capscrews (with Loctite 271)

Planetary Retaining Screws

Wheel End Fill/Drain Plug

MAINTENANCE MANUAL MODEL

110-120 ft-Ibs (156-162 Nm)

115-120 ft-Ibs (156-162 Nm)

7-10 ft-Ibs

7-10 ft-Ibs (9.5-13.5 Nm)

15-17 ft-Ibs

90-100 ft-Ibs (122-135 Nm)

75-90 ft-Ibs

220-280 ft-Ibs (298-380 Nm)

115-120 ft-Ibs (156-162 Nm)

110-120 ft-

40 -45 ft-

(9

.5-13.5 Nm)

(9

.5-13 .5 Nm)

(101

-122 Nm)

Ibs

(149-162 Nm)

Ibs

(54-61 Nm)

25534

AXLE

Knuckles and Steer Cylinder:

King Pin Retainer Bolts

U-Joint Flange Screws

Steer Cylinder Mounting Bolts

Tie Rod Socket Assembly (with Loctite 271)

ne

Rod Lock Nut

80-90 ft-Ibs (108-122 Nm)

55-60 ft-Ibs (74-81 Nm)

80-90 ft-Ibs (108-122 Nm)

192-207 ft-Ibs (260-280 Nm)

221

ft-Ibs (299 Nm)

7

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

Torque For Bolts, Capscrews, Studs and Nuts as Supplied

~

~

~

Grade 5 Identification,

Dashes 120

0

Apart

~

Grade

Fastener

Size

1/4-

20

1/4-28

5/16-18

5/16-24

3/8-16

3/

8-24

80-90 Lbs.

180-200 Lbs. In.

25-28 Lbs.

3 Radial

on

Head

5

Lubricated

In

.

Ft.

of

and

Grade 8

Bolt

Plated

[9-10 N.m] 110-120 Lbs. In.

[21-23 N.m] 215-240 Lbs. In.

[34-38 N.

Dashes 600 Apart

m)

35-40 Lbs. Ft.

Identification,

on

Head

®

Grade 8

Lubricated

and

6 Radial

of

Bolt

Plated

[13-14 N.m)

[24-27 N.

[48-54 N.

m)

m)

7/16-14

7/16

-

20

1/

2-13

1/2-20

9/16-12

9/16-18

5/

8-11

5/8-18

3/

4-10

3/4-16

7/8-9

7/8-14

1-8

1-12

1-1

/8-7

1-1

/8-12

1-1/4-7

1-1

/4-12

40-45 Lbs.

65-70 Lbs.

90-100 Lbs. Ft. [125-135 N.

125-140 Lbs.

220-245 Lbs.

330-360 Lbs.

475-525 Lbs.

650-720 Lbs.

900-1000 Lbs.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

[54-61 N.m)

[88-95 N.m]

[170-190 N.m] 175-190 Lbs . Ft.

[300-330 N.m]

[450-490 N.

[645-710 N.m] 725-800 Lbs.

[880-975 N.m] 1050-1175 Lbs. Ft.

[1220-1360 N.m) 1475-1625 Lbs. Ft.

m)

m)

Lb

s.

60-65

90-100 Lbs.

125-140 Lbs.

300-330 Lbs. Ft. [410-450 N.

475-525 Lbs.

Ft.

Ft.

Ft.

Ft.

Ft.

[82-88 N.

[125-135 N.

[170-190 N.m]

[240-260 N.m]

[645-710 N.m]

[985-1085 N.m]

[1425-1600 N.m]

[2000-2200 N.m]

m]

m)

m]

,,

:

8

REFERENCE ONLY

...

MAINTENANCE MANUAL MODEL 25534

TorquelTension Charts

Coarse Threated Fasteners Coarse Threated Fasteners

Thread

Class

M5XO

M6X1

M8X1.25

M10X1 .5

M12X1.75

M14X2

M16X2

M20X2.5

M24X3

M30X3.5

M36X4

Size

B.B

.8

Tor~ue

Nm

5-6 43-53

8-10 71-88

20-25 177-221

40-45

70-78 52-59

110-125 81-92

170-190 125-140

340-380 251-280

580-650

1150-1300 848-959

2000-2250

Lb-Ft

Lb-In

30-33

428-479

1479-1660

Thread Size

Class

10.9

M5XO.8 7-8

M6X1 12-14

M8X1.25 30-35

M10X1.5 60-65 40-48

M12X1.75 100-110

M14X2 155-180 114-133

M16X2 240-270

M20X2.5 450-500

M24X3

M30X3.5 1600-1800

M36X4

Nm Lb-In

800-900

2800-3150 2065-2323

Torque

AXLE

62-71

106-124

Lb-Ft

22-26

74-81

177-199

332-369

590-664

1180-1328

SAE

"

0"

Coarse Threated Fasteners

Thread

Class 12.9

Size

Nm Lb-In

M5XO

.8

M6X1

M8X1.25

M10X1.5

M12X1.75

M14X2

M16X2 280-320 207-236

M20X2.5

M24X3 900-1050 664-774

M30X3.5 1850-2100 1364-1549

M36X4

8-10

14-16 124-142

34-40

70-75

115-130

180-210

550-600

3250-3700 2397-2729

Torque

71-88

Lb-Ft

26-30

52-55

85-96

133-155

406-443

.3125-24

.3750-24

.4375-20

.5000-20

.5625-18

.7500-16

.8750-14

1.0625-12

1

1.6250-12

1.8750-12

Ring Thread

Thread

Size

.3

125-12 88-102

Nm

4-7

7-11

9-13

14-18

16-20

27-34

41-47

61-38

102-115

102-115 75-85

Torque

Lb-Ft

3-5

5-8

7-10

10-1

12-15

20-25

30-35

45-50

65-75

75-85

3

NOTE: Socket head capscrews are all Class 12.9

9

REFERENCE ONLY

~

o

23

"

(J-::-::

~

27

"-

31

30

~

ms:

><

0

~a,

o

CD

a,-

CD

I\)

16

a,CJ1

<C/)

~.

~

:;;

n1

~

~

~

>e

~

....

g

143

~

~

'"

'"

REFERENCE ONLY

MAINTENANCE MANUAL MODEL

25534

AXLE

Model

Item

No. Description

1 Carrier Sub·Assy

2 Bearing Cup-Roller

3 Bearing

4 Shim-ADJ

5 Gear

6 Spacer-Collapsible

7 Bearing Cup-Roller

8 Bearing Cone-Roller ....

9 Thrustwasher-Brg

1 0 Seal-Oil ................

11

Deflector-Seal ......

12

End

13

Washer-Pinion Nut .....

14 Nut-Pinion ...........

15 Case (Diff

16

Thrustwasher-Differential Gear

17 Gear-Differential

18

Thrustwasher-Differential Pinion ...................... 2

19

Pinion-Differential .........................

20 Shaft-Differenti

21

Pin-Roll ..........

22 Bearing Cone-Roller

23

Gear & Pinion Assy-Spiral Bevel .......

24 Screw-Drive Gear ...........................

25 Bearing Cup-Roller ....................

26 Cap-Differential Brg (Part of Iteml) .......

27 Bolt-Hex .......

28

Ring-Adjusting

Cl

29

30 Washer-Flat .......

31

Bolt-Hex ........

32

Co

33

Washer-Flat .................

34 Bolt-Hex ...........................................................

35

Plug-Pipe (Internal Drive) ................................. 1

36

Plug-Pipe (Inte

37

Plate-Spring

38

Spring-Compressi

39

Glyd

40

Ring-O Inner ..........................................

41 Piston-Park .............................

42

Ring-O Outer .................................................... 2

43

Glyd

Con

& Pinion Assy-Spiral

Yoke

ip-Adjusting Ring .............

ver-Carrier .................................................... 1

Ring

Ring

..

........................

..

......................................... 1

e-Roller ............

..........

...

....................................

Bevel

..

.......................

...

........................................ 1

........

.....

...........

..

........................................... 1

........

...............

..........................................................

........

.........

.....................................

Std)

.................................................. 1

.............

al

Std & TIL

......

...

................................ ................. 4

......

.................

........................

rnal

Backing ........................................ 2

Inner .

........

Outer ..........

.................................. 2

.......... ................................... 1

..

....................................... 2

............................................ 2

...........

Drive) ................................. 1

on

........................................ 20

............

...........................

....

................ 1

...

.......................

...

...................... 1

............

........

..................... 1

..................

........

.............

............................

.............................. 2

............................

.......

......

....

..

........................ 2

.... ..

...

................... 1

...

............

........... 2

....

................ 2

....

........... 1

..

.............

...

.......

............. 2

......

..............

...................

.....................

....

........... 2

25534

Parts List

Item

Qty.

44

45

...

..... 1

...... 1

..... 1

...

....

...

..

12

....

. 2

..

.....

..

12

12

..

....... 2

1

1

1

1

1

2

2

2

46

47

48

49

50

51

52

53

54

55

56

57 Coupling-Splined ................................................ 2

58

59

60

61

62

63

64

65A Shaft-Axle Right

65B

66 Washer-Flat .......................................................

67 Bolt-Hex ............................................................. 32

68

69

70 Fitling-Hyd Brake .......................................

71

72 Screw-Flange

73 Ring-Snap .........

74

75

76

77 Seal-Oil .......................

78 Seal-Oil .............

79 Bushing-Spindle ..........................

80

81

82 Retainer-Grease

83 Bearing

84

85

Axle

No. Description

Yoke-Center

Cross-U Join!.. .... ............................................... 4

Seal Assy ......

Bearing

Ring-Snap .....................................

Housing-

Tilt

Eye

Bushing-Spindle .......................

Seal-Oil .........

Seal-Oil ..................................

Shaft-Inner

Ring-O ................

Bushing-Flange ..........

Ring-O Outer ..................................................

Glyd

Piston-Service .............

Ring-O Inner ..................................................

Glyd Ri

Plate-

Disc Assy-Friction ....................

Shaft-Axle Left ................................................... 1

Seat-Insert

Screw-Bleeder ..........................

Strap-Bearing ......................................

Spacer ................................................................ 2

Ring-O ..................................................

End Yoke

Knuckle-Steering

Knuckle-Steering

Bearing Cone-Roller ...

Seal-Oil ...........

...

...

...............................

Race

Assy-U Joint ................................

Axle

....

......................

Bushing

Ring

ng

Lining

Cup

...

..

..................................................

Yoke

................................................. 2

Outer ......................

Inner .................................................. 2

Stop ...............................................

..........

...

.........................................

12

..............................

-Roller .........................................

..........

.................................... 2

.......

............

...

.......

.......

..................... 2

....

.....

.........

.....

....

..................

.......................... 2

...

....

...................... 2

..

.........

...

.................................. 2

....

....................................

....

......................

...

......................

...

........................

.......................... 4

Point ..........................

..

...............

..

............................................... 2

LH

RH ...........

...

.....

...

.........................

...

........................

..

......

....

............................ 2

.......................................... 1

....

.......

.........

..........

.........

............................... 4

.......................................... 4

.............. 2

...................

...

..............

....

......

..............

............

....

.................. 4

...

.......

.........

.......

......

...

.......

....

Qly.

16

16

12

NR

..

2

2

...

. 2

..

2

....

. 2

10

....

8

...

1

32

4

..

4

....

. 4

...

....

........ 2

..

...

........ 1

...

. 4

8

2

2

2

11

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

Model 25S34 Axle

Parts List (cont.)

Item

No.

Description

86

Shim-Formed .................................................

...

87 Cap-King Pin

88 Washer-Flat ..............

89 Bolt-Hex .................. ' ...............

90 Fitting-Grease ....

91

Washer-Flat ...........................

92 Bolt-Stop ....................................... .................... 2

93 Seal-Oil . ..................... ....

94

Bearing Cone-Roller Inner ................................ 2

95

Bearing Cup-Roller Inner .................................. 2

96

Bolt-Wheel

97 Hub-Wheel ....................................................... 2 124 Large Retaining Wire ......................................... 2

98 Nut-Wheel

99 Bearing Cup-Roller Outer ..........

100 Bearing Cone-Roller Outer

101

Ring-Snap ............

102 Hub-Planetary ...........

103 Gear-Planetary Ring .........................

104A Shim-Adj .003" .

104B Shim-Adj .002" ................................................

104C Shim-Adj .005"

1040 Shim-Adj .010"

104E Shim-Adj .020" ................................................

104F Shim-Adj .030"

105 Plate-Retaining

106 Bolt-Hex ........

1 07 Washer-Thrust Large ........................................ 2

1 08 Washer-Thrust Small

109 Gear-Input

110 Washer-Drive Flange ........................................ 2 142 Seal-Grease ....................................................... 2

111

Plug-Pipe (Internal Drive) ................................. 2 143 Trunnion Beam-Front ........................... ............. 1

112 Screw-Socket Head .......................................... 4

.......................................

....................................... 12

...

.....

....

....

..............................

...

............. ..... ...........

RH

.............................................

..

..................................................... 20 125 Boot .................................................................... 2

..................

...

........

................................. 2 128 Arm-Steering ...................................................... 2

...

...............

...

............................................

..

..............................................

...

.............................................

...

.............................................

..

............................................... 2 137 Trunnion Beam-Rear .................

...

....................

.. ..

...

....

............................................. 2

...

...

..................................... 2 140 Bushing-Spindle ................................................. 2

......

........................... 2 118 Washer-Thrust ....................................

...

...

................. 2

...

...................

...

............. 2 130 Shim-Adj ...........................................................

......................

QIy. No. Description

NR

......... 4

...

...... 12

........... 4

...

2

....

20 123 Socket Assy .....................................................

.......... 2

..

2

NR

NR

NR

NR

NR

NR

...

12

Item

113

Flange-Drive Planetary .....................................

114 Ring-Snap .......................................................... 6

115

Shaft-Planet Gear ............................................... 6

116

Washer-Drive Flange ......................................... 12

117 Bearing Needle .................

119

Gear-Spur ......... ........ .......................

120 Cylinder Assy-Steering ...............................

121

Washer-Flat ........................................................ 3

122 Bolt-Hex .............................................................. 3

126 Small Retaining Wire .......................................... 2

127 Jamnul.. .

129 Pin-Clevis ..... ...................................................... 2

131

Ring-O ................................................................ 4

132 Bushing-Synthetic .............................................. 2

133 Washer-Flat ....................................................... 2

134 Ring-Snap ...............................................

135 Pin-Dowel ........................................................... 2

136 Fitting-Grease ..................................................

138 Pin-Locating ....................................................... 4

139 Ring-O ................................................................ 2

141

Thrustwasher-Brg .............................................. . 2

..

.......................................................... 2

..

............................

................ 6

...

...................... 1

..

........ 6

..

...

....

Qty.

..

2

..

432

...... 1

...

2

NR

.... 2

...

2

12

REFERENCE ONLY

MAINTENANCE

Axle Assembly Instruction

MANUAL

MODEL

25534

AXLE

1. Surface must be dry and free from sealing compounds, nicks, burrs, and rust.

2. Coat with

E.P.

lithium grease Grade 2

(MS107C).

3. Coat with E.

P.

lithium grease Grade 2

(MS017D) .

4.

Coat with E.P. lithium grease Grade 1

(MS107B).

5. Use with Loctite

6.

Use Permatex #2 sealer.

7.

Apply Loctite 609 on bushing o.

271

thread locker.

d.

8. Tighten pinion nut to 220/280 ft-Ibs

(298-380 Nm) to obtain rolling torque of

20-40 in-Ibs (2.25 - 4.5 Nm). Rotate the

pinion 3 complete revolutions to seat the

bearings, during fourth revolution take

highest reading as measured torque.

9. Adjust nuts to obtain proper differential

case position - .004-.008 backlash.

Torque nuts to 85 ft-Ibs (115 Nm) to

preload bearings, install lock clip.

10. Shim top and bottom equally to obtain

8-15 ft-Ibs (10.8-20 Nm) of effort required

to rotate the knuckle at the king pin. With

the tie rod assemby attached an effort of

15-25 ft-Ibs (20-34 Nm)

11.

Install shims between knuckle and re-

is

required.

tainer to achieve 50-90 in-Ibs

(5.6-10.1 Nm) rotating torque without oil

seal installed.

12. Apply continuous bead of Loctite 515

inside wheel bolt circle. Clamp wheel end

assembly for a least 15 minutes in 4

locations around bolt circle.

13. Torque to

221 ft-

Ibs

(299 Nm).

14. Torque to 192-207 ft-Ibs

(269-280-Nm) .

15. If a thermal assembly aid is being used,

(expanding by heating to 275°F ±25 °F

[135°C

±3

.90°C]) a check must be made

after parts have reached the same tem

perature within 20°F [-6, 7°C] of ambient

to

be

sure the bearing is positioned solidly

against it's respective shoulder. Check by

attempting to

Slip

a .002" feeler gage

between the bearing and the mating part.

1

REPLACE CAPSCREW

AFTER REMO

TIGHTEN TO

90·100 FT.LB

(122·135 Nm).

S.

VA

L.

TIGHTEN TO

15·17 FT. BS.

(2

0·2 9 NM)

2

CRUSH SLEEVE CANNOT

AFTER TARGET ROTATING TORQUE HAS

BEEN REACHED

8

2

6

BE RE·USED

13

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

TIGHTEN

115-120 FT. LBS.

(156-162

TO

Nm)

TIGHTEN TO

35-45 FT. LBS.

61

(47.4-

Nm)

2

TIGHTEN

15-17 FT. LBS.

(9.5-13.5

TO

Nm

)

TIGHTEN TO

110-120

(149-162

FT.

Nm)

TIGHTEN BRAKE FITTINGS

AND BLEEDER SCREWS TO

7-10 FT. LBS.

(9.

5-13

.5 Nm)

~~~~~~~r~~~~~~~~~~iI

LBS--:

Refer to page 15 for reference number identification_

12

TIGHTEN

80-90

(108-122 Nm)

FT.

TO

LBS.

\

":

3

10

10

14

5

TIGHTEN TO

55-60 FT. LBS.

(74

.5-81.2 Nm)

3

REFERENCE ONLY

11

nGHTENTO

lIS-120FT.

(156-162 Nm)

'--

___

LBS.

TIGHTEN TO

35-45

FT

(47.4-61 Nm)

. LBS.

MAINTENANCE MANUAL MODEL 25534

TIGHTEN TO

115-120FT.16S

(156-162

Nm)

AXLE

2

6

4

Refer to page 15 for reference number identification.

14

13

15

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

Spiral Bevel and Hypoid Tooth Bearing Contact Chart

1

ADDENDUM 1

t DEDENDUM

1

PROFILE

~

.............

MOVE

PINION TOWARD

GEAR IN THIS DIRECTION ..............-

MOVE

PINION

GEAR IN THIS

AWAY

DIREcnON

~

FROM

f 1

All contact bearings shown below are on Right Hand spiral

ring gear - the drive is on the convex side of the tooth.

Fig. 1

Typical preferred bearing on both sides of tooth

while under a light load.

Fig. 2

Toe

bearing

To

move bearing toward heel increase backlash

within limits by moving gear away from pinion.

Heel bearing

and could result in early gear failure.

bearing toward toe decrease backlash within limits by

on

both sides of tooth - gear set noisy.

Fig. 3

on

both sides of tooth - gear set noisy

moving gear toward pinion.

* ,

MOVE

, PINION IN THIS DIRECTION

GEAR AWAY

To

FROM

move

MOVE

GEAR

PINION IN THIS DIRECTION

TOWARD

i..

~

Fig. 4

Low bearing on gear and high bearing on pinion.

Correct by pulling pinion away from gear

(increase mounting distance).

Fig. 5

High bearing on gear and low bearing on pinion.

Correct by moving pinion toward gear

(decrease mounting distance).

Backlash

Backlash should be measured with a dial indicator rigidly mounted with the

stem perpendicular to the tooth surface at the extreme heel.

16

REFERENCE ONLY

)

MAINTENANCE

MANUAL

MODEL

25534

Spiral Bevel and Hypoid Tooth Bearing Contact Chart

"",,"'7?I"""""'-

All contact bearings shown. below are

ring gear - the drive is

on

the convex side of the tooth.

on

Left Hand spiral

Fig. 1

Typical preferred bearing on both sides of tooth

while under a light load.

...............

MOVE PINION TOWARD

GEAR

IN

THIS DIRECTION ...............

MOVE

PINION

GEAR IN THIS

AWAY

otAECnON

FROM

MOVE

PINION

~

GEAR

TOWARD

IN

THIS DIRECTION

AXLE

l..

~

Fig. 2

Toe bearing

To

move bearing toward heel increase backlash

on

both sides of tooth - gear set noisy.

within limits by moving gear away from pinion.

Fig. 3

Heel bearing

and could result

on

both sides

in

of

tooth - gear set noisy

early gear failure.

To

move

bearing toward toe decrease backlash within limits by

moving gear toward pinion.

Fig. 4

Low bearing

on

gear and high bearing on pinion.

Correct by pulling pinion away from gear

(increase mounting distance) .

Fig.5

High bearing on gear and low bearing on pinion.

Correct by moving pinion toward gear

(decrease mounting distance).

Backlash

Backlash should

be

measured with a dial indicator rigidly mounted with the

stem perpendicular to the tooth surface at the extreme heel.

17

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

Maintanance Intervals and Procedures

Checking Oil Level

in

Drive

Steer Axles

For off-highway operation, check lubricant

level after each 250 hours of operation. Always maintain lubricant level to bottom of filler

plug hole. Drain oil every 1000 operating

hours or one year, whichever comes first.

To

check oil levels in axles with differential

drive and planetary wheel ends, the axles

should be run first, then allowed to stand for a

minimum of five minutes on a level surface.

This procedure will allow the oil to drain back

to it's normal level. After the five minute inter-

oil

val proceed as follows; remove

rear of axle housing for oil level inspection. If

the oil level is not to the bottom of the filler

hole add lubricant as needed.

filler plug

in

Checking and Filling Planetary

Wheel Ends

Drive Steer Joint Lubrication

Lubricate the axle shaft universal joints

every time the units are disassembled with

E.P.

lithium grease, Grade 2 - (MS107D) or

equivalent. Grease king pins every 50 operating hours with the same type of lubricant..

Draining

Draining is best accomplished immediately

after vehicle has been operated a short time

or completed a short trip. The lubricant is then

warm and will flow freely, allowing full drain-

in

age

desirable

housing cover and allow sufficient time for

lubricant to drain. Planetery wheel ends rotate wheel until filler/drain hole is down.

Remove plug and allow sufficient time for

draining.

minimum time. This is particularly

in

cold weather.

Housing - remove lower plug on axle

Always check lubricant level in the wheel

end with the wheel hub filler/drain plug hole at

3 or 9 o'clock. Remove the filler/drain plug; if

the oil level is below the fill hole add lubricant

as necessary. Reinstall the plug.

Filling Drive Steer Axles

Fill axle housing through filler hole until

lubricant is at bottom of filler hole. Axles with

planetary wheel ends; follow procedure in

"checking and filling planetary wheel ends."

Flushing

After draining, axles should be flushed.

Replace drain plug and fill axles to proper

lever with a light fushing oil or fuel oil. Operate

the axle for a short period of time

at 1000 to 1500 rpm engine speed with the

vehicle on a level surface. Be sure to drain all

flushing oil before refilling with new oil. Inspect

the magnetic drain plug for metal or other

foreign matter indicative of wear or possible

problems .

in

low gear

18

REFERENCE ONLY

Symbols

MAINTENAf:/CE

MANUAL

MODEL 25534

AXLE

Smontaggio

[tJ

Disassembly of assembly groups

~

Montaggia di sottogruppi

Reassemble

GJ

Smontaggio di particollari in90mbranti

~1'~

Ll-"'

Remove obstruction parts

Montaggio di particollari in90mbranti

,l;"-<J.

l:.t.:J

Reinstall - remount parts which

Attenzione, indicazione importante

&

Attention! Important Noti

• Controliare regolare p.e. coppie, misure, pressione etc.

Check - adjust e.g. torque, dimensions, pressures etc.

T = Attrezzature speciali

g

T = Special tool

di

sottogruppi

to

form assembly group

ce

P=

= Page

P

had

obstructed disassembly

Pagina

-;£] Rispettare direzione di montaggio

__

Note direction of installati

Controllare

Visual inspection

:I

Eventualimente riutil izzable (sostituire se necessario)

¢

Possiblv still serviceable, renew

Sostituire can ogni montaggio

~

Renew

esaminare

at

each reassembly

on

contrallo visuale

if

necessary

Togliere - mettere la sicura

Unlock - lock e.g. split pin, locking plate, etc.

K/' Mettere

"

!~

8

0

~

E8

~

~PUlire

la

Lock - adhere (liquid sealant)

Evitare danni ai maleriali, danni ai pezzi

Guard against material

Marchiari prima della smontaggio

Mark before disassembly, observe marks

Carricare rlempire (olio - Iubrificante)

Filling - topping up - refilling e.g. oil, cooling water, etc.

Scarricare olio, lubrificante

Drain off oil, lubricant

Tendere

lighten

Insere pressione nel circuito idraulico

Apply pressure into hydraulic circuit

To

sicura, incollare (mastice liquido)

damage

, damage to parts

(per

- clamp; tightening a clamping device

clean

il

montagglo)

when

reassembled

19

L

REFERENCE ONLY

MAINTENANCE MANUAL MODEL

?5S34

Model 25S34 Disassembly

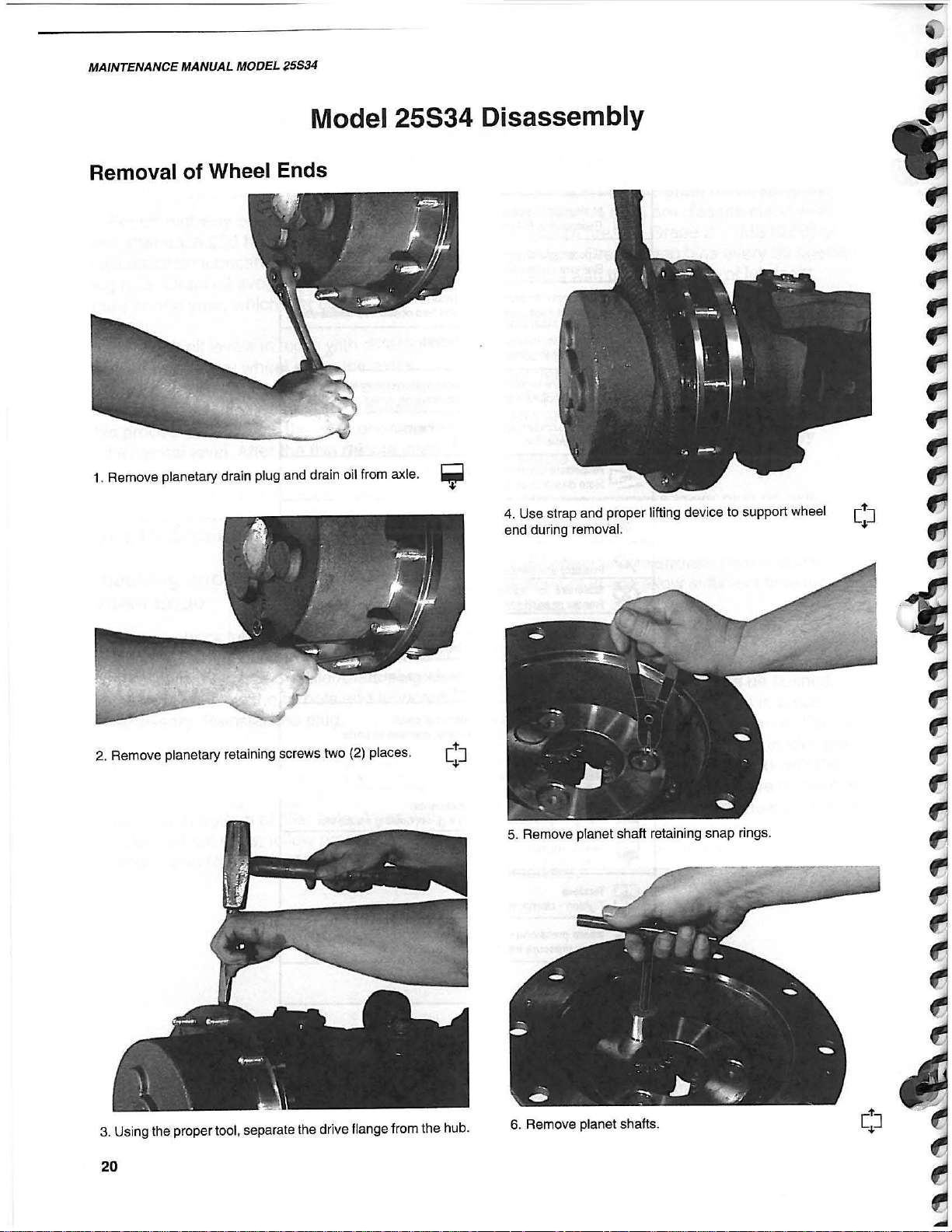

Removal of Wheel Ends

1.

Remove planetary drain plug and drain oil from axle. =

.,.

2. Remove planetary retaining screws two

(2)

places .

4. Use strap and proper lifting device to support wheel

end

during

5.

Remove

removal

planet

.

shaft

retaining

snap

rings.

[t

]

~

3. Using the proper tool. separate the drive flange from the hub.

20

6. Remove planet shafts.

REFERENCE ONLY

7. Remove planet thrust washers.

MAINTENANCE

MANUAL

Removal of Drive Flange

MODEL

25534

AXLE

gear

.

~

B. Remove planet

cloth

to

prevent damage

9. Pla

net

gear,

assemblies. Place planet

to

gear

needle

bearing

and

teeth.

spacer

gears

removed

on

.

shop

!~

11.

12.

Drive

steer

Remove

cylinder

shims

and

clevis

O-rings

pin

from

from

steer

steer

arm.

arm.

Discard

O-rings.

21

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25S34

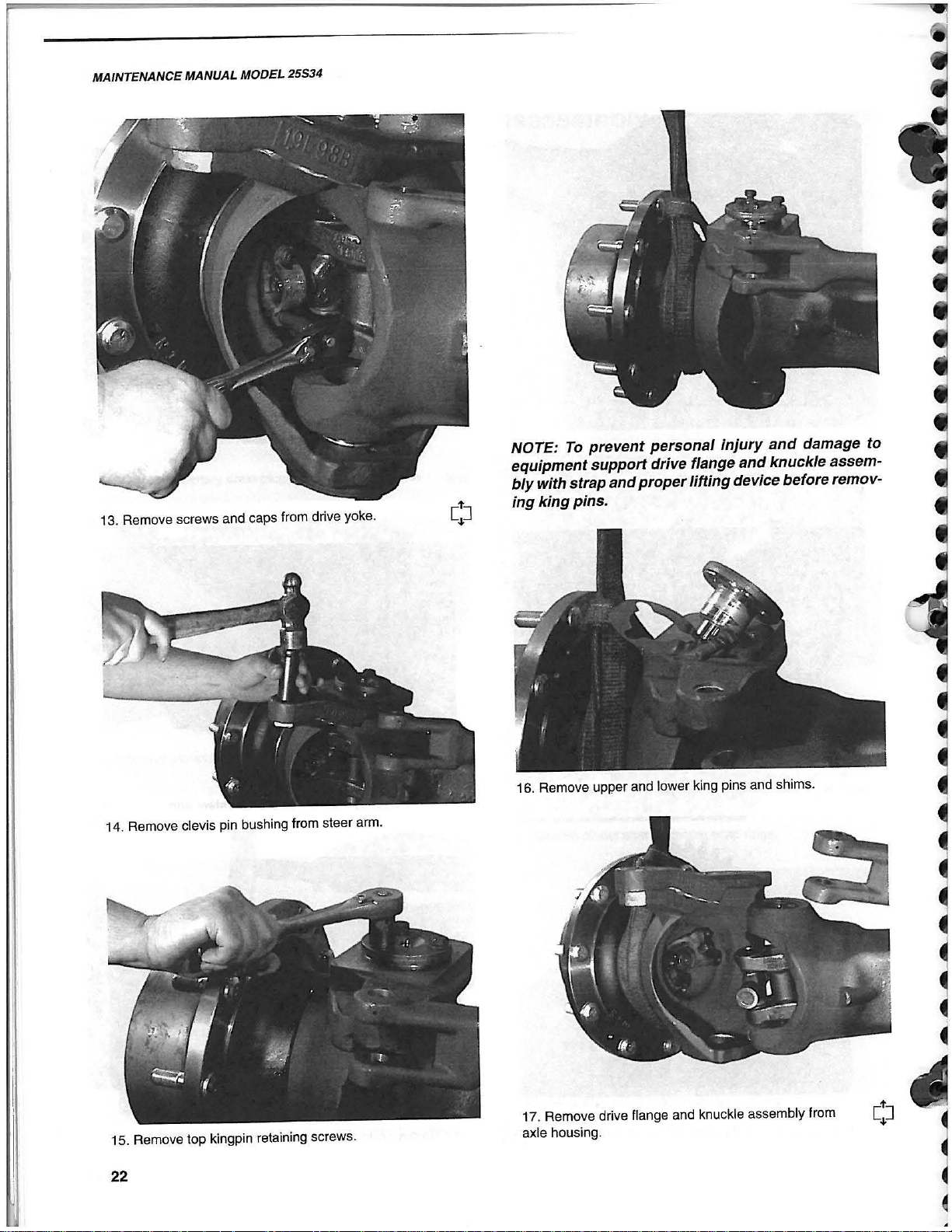

13.

14.

Remove

Remove

screws

clevis

and

pin

caps

from

bushing

from

drive

steer

yoke

arm.

NOTE:

equipment

bly

ing

.

16.

To

prevent

support

with strap

king

pins

Remove

upper

and

.

and lower

personal

drive flange

proper

lifting

king

injury

and

damage

and

knuckle assem-

device before remov-

pins and

shims

.

to

17. Remove drive flange and knuckle assembly from

axle

15.

Remove

top

kingpin

retaining

screws

.

housing

.

22

REFERENCE ONLY

rw

Removal

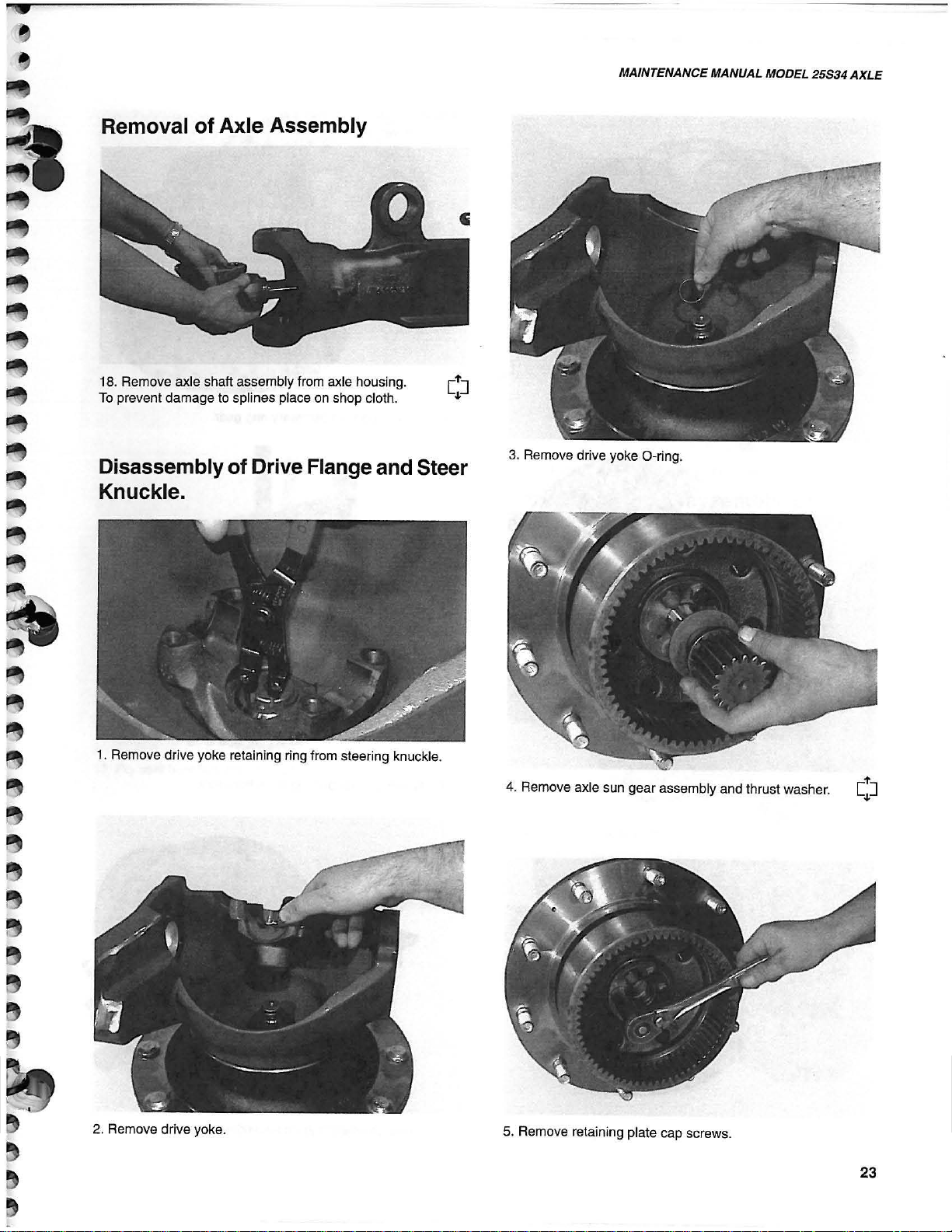

18. Remove axle shaft assembly from axle housing.

To

prevent damage to splines place

Disassembly

of

Axle Assembly

of

Drive Flange and Steer

on

shop cloth.

Knuckle.

MAINTENANCE MANUAL MODEL

3.

Remove drive yoke O-ring .

25534

AXLE

1. Remove drive yoke retaining ring from steering knuckle.

L

It

!r

/

.'

./

..

-:

/

\J

Ii

~).

.~

~

.

-

'"

2-

2.

Remove drive yoke.

4. Remove axle sun gear assembly and thrust washer.

5. Remove retaining plate cap screws.

23

REFERENCE ONLY

r.

MAINTENANCE MANUAL MODEL 25534

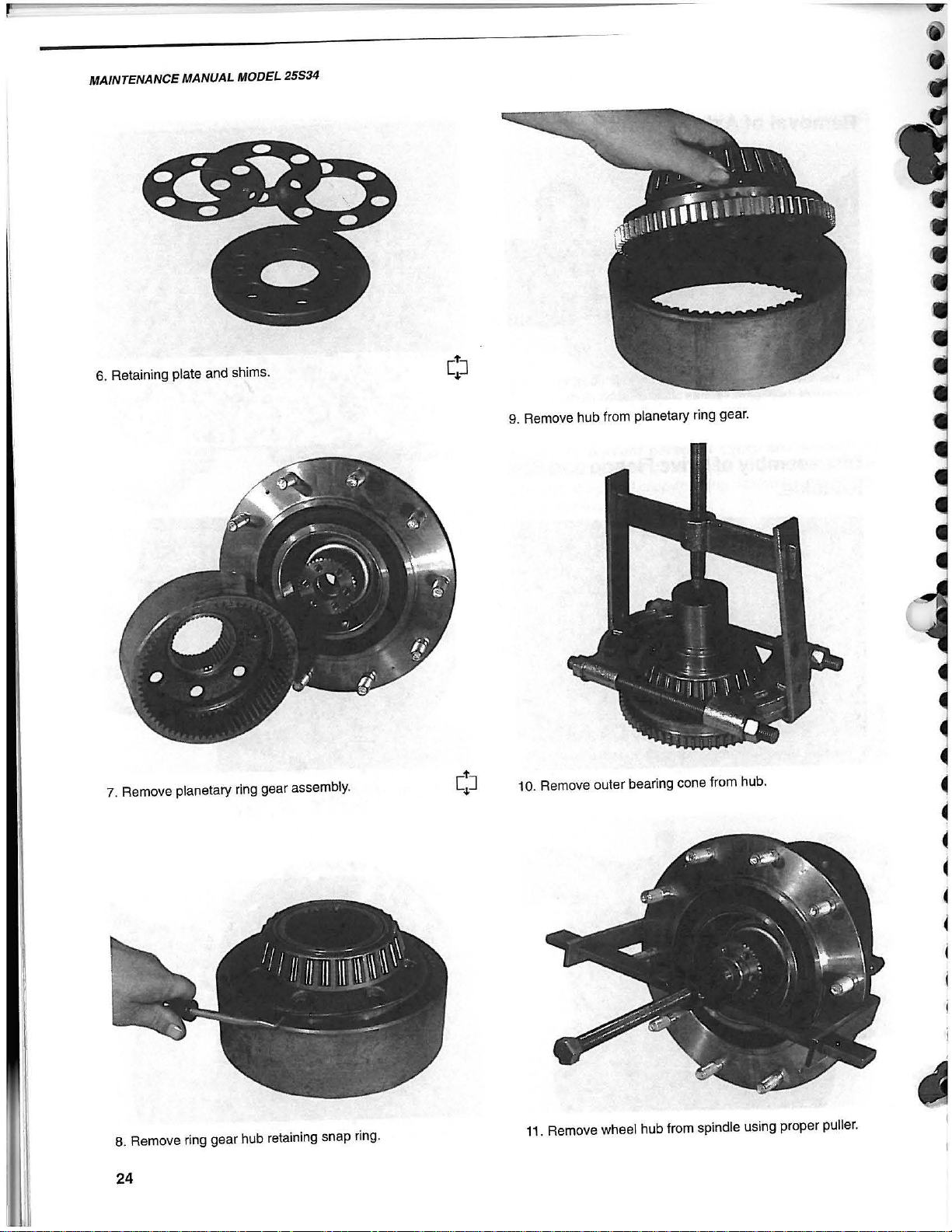

6. Retaining plate and shims.

9. Remove hub from planetary ring gear.

7. Remove planetary ring gear assembly.

8.

Remove

24

ring

gear

hub

retaining

snap

ring

Remove

11.

.

Remove wheel hub from spindle using proper puller.

outer

bearing

cone

from

hub.

10.

REFERENCE ONLY

'.

12. Hub removed from steering knuckle assembly.

15. Remove

MAINTENANCE MANUAL MODEL

inner

and

outer bearing

cups

.

25534

AXLE

Removal and Disassembly of Front

and Rear Trunnions

hub

13. Pry seal from

14.

Remove

inner

and discard.

bearing

cone

1.

Remove

2.

.

Remove

rear

rear

trunnion

trunnion

beam.

beam

thrust

washer

.

25

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

3.

Remove

bushing

if

damaged.

and

rear

O-rings

trunnion

for

grease

seal. Inspect trunnion

damage. Remove

and

discard

Removal and Disassembly

Cylinder

1. Loosen

jam

nut

on

socket

assembly

to remove steering arm.

of

Steer

4.

Remove

5.

Remove

and discard if damaged.

front

trunnion

front trunnion beam thrust

beam.

washer

and

seal. Inspect

2.

Remove steer cylinder retaining screws.

3.

Remove

steer

cylinder

from

carrier

housing

.

26

REFERENCE ONLY

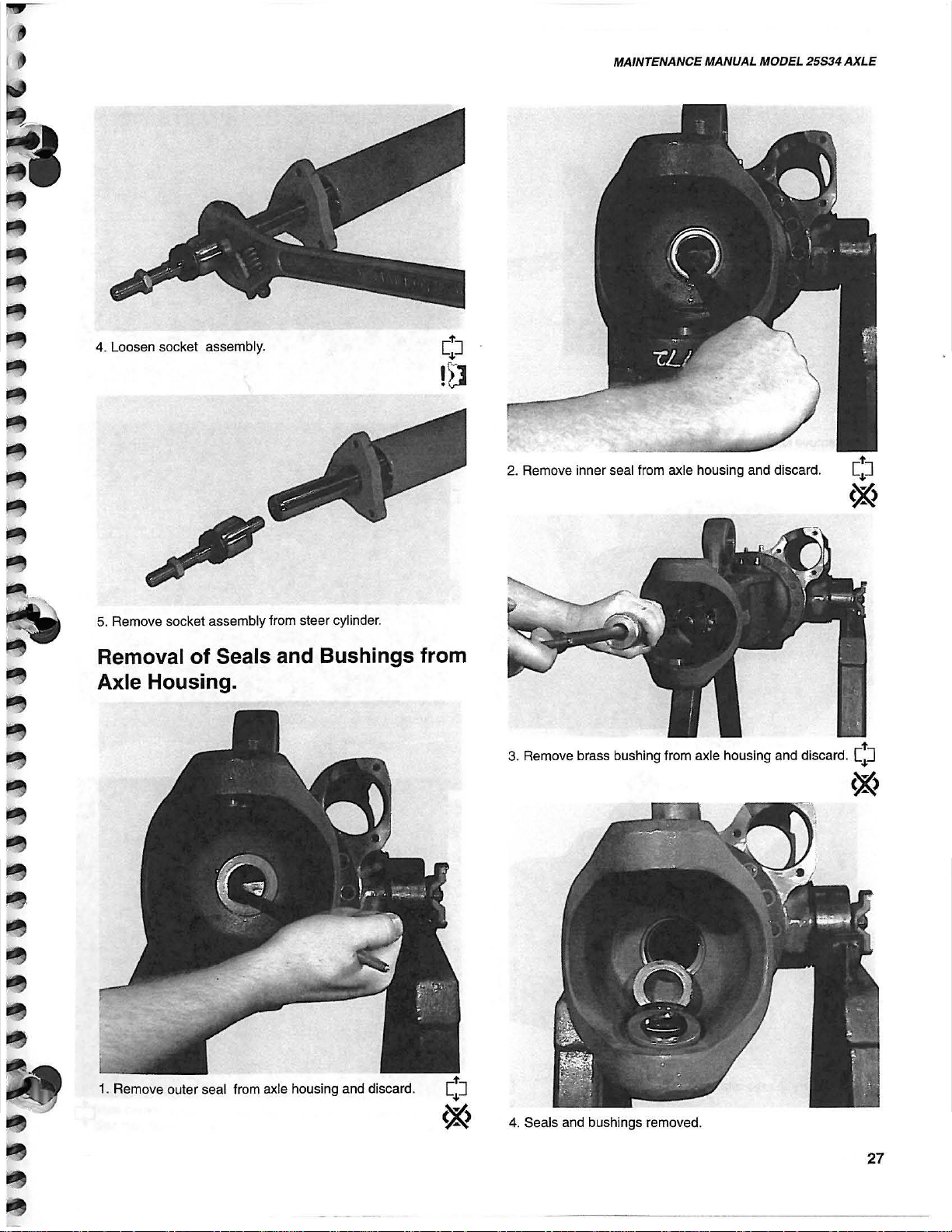

4.

Loosen

socket

assembly.

2.

Remove

MAINTENANCE

inner

seal

from

axle

MANUAL

housing

MODEL 25S34

and

discard.

AXLE

5.

Remove

socket

assembly

from

steer

cylinder.

Removal of Seals and Bushings from

Axle Housing.

3. Remove brass bushing from axle housing and discard.

C:J

~

4. Seals

and

bushings

removed

.

27

REFERENCE ONLY

MAINTENANCE MANUAL MOOEL 25534

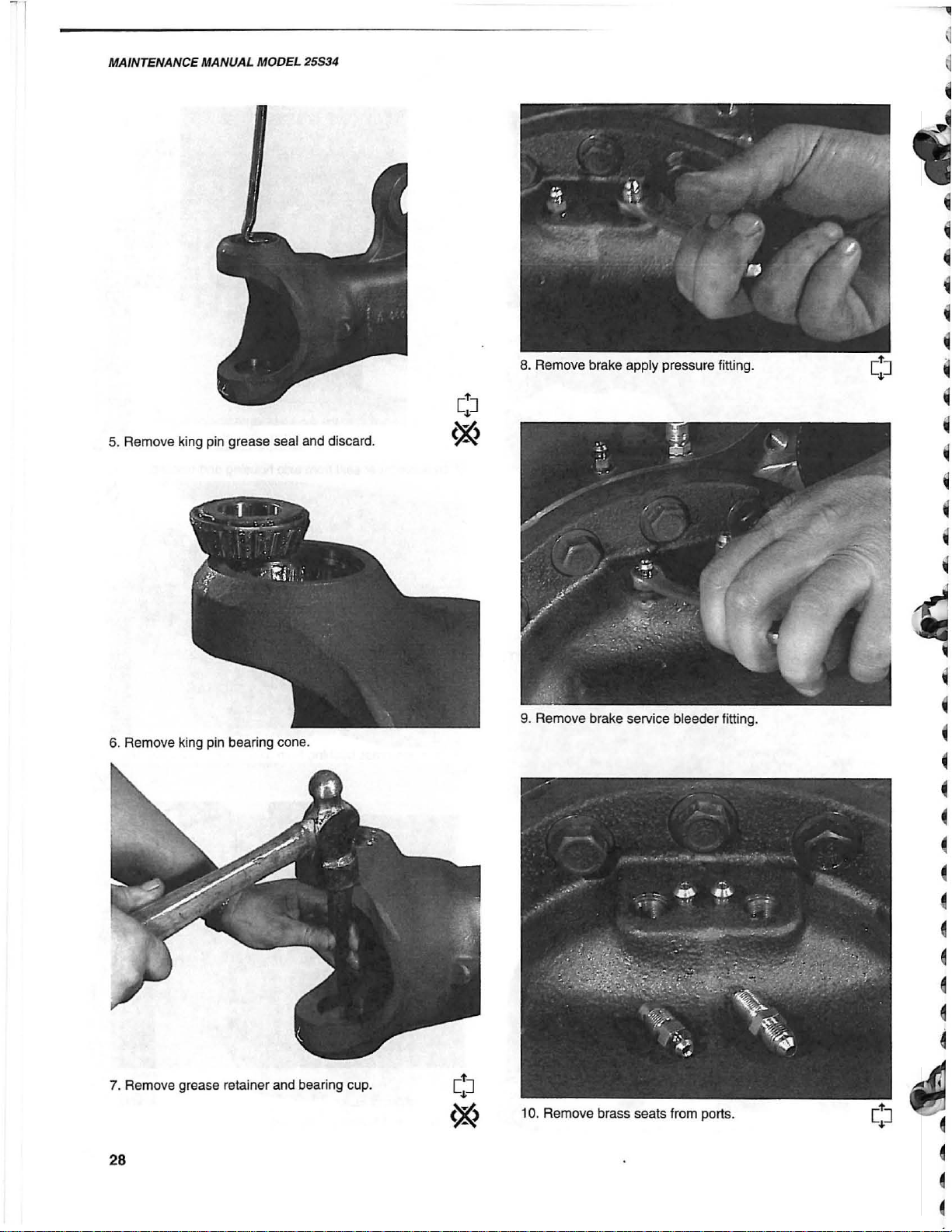

5. Re

move

king pin grease seal and discard.

~

~

~

~

•

•

•

•

•

~

•

~

6.

Remove

king pin bearing cone.

9.

Remo

ve brake service bleeder titting.

•

•

~

7.

Remo

ve grease retainer and beari

28

ng

cup.

REFERENCE ONLY

•

Removal

NOTE: To

housing a lift

used

1.

Remove

to

support

axle

prevent

of

Axle

personal

strap

axle

housing

Housings.

injury

and

proper

housing.

retaining

and

lifting

screws.

damage to axle

device

must

be

3.

Remove

MAINTENANCE MANUAL MODEL 25534

brass

bushing

from

axle

housing

AXLE

.

4. Remove spring backing plate.

2.

Using

lifting

device

slowly

swing

axle

from

carrier

disc may fall

housing

as

brake

out.

Caution: springs may

springs,

housing

piston, shaft

away

and

be

under pressure.

5.

Remove

axle

shaft.

29

REFERENCE ONLY

PAGES 30-33 MISSING

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

I

.:,:

~

18. Remove oil seal, thrust washer and outer bearing

cone.

19. Remove inner and outer bearing cups.

'\ \\

21. Remove pinion mounting

Disassembly

of

Inner

Assembly.

height

shims.

Yoke and Shaft

1. Remove retaining rings.

20. Remove inner bearing cone from pinion gea r.

34

2. Place shaft assembly in fixture. Press bearing cup down until

bearing cup on bottom side can be removed. Make sure there is

clearance for bottom bearing.

REFERENCE ONLY

..

•

..

l

~

I

3.

Tum over the axle shaft assembly. Supporting the

to

drive

center yoke, press on the shaft ear

bearing

bearing cup beyond the surface of the yoke.

cup.

Make

sure

there

is

clearance

up

for

the

MAINTENANCE MANUAL MODEL 25534

AXLE

4.

Separale the axle shaft from the center yoke. Repeat the

previous

steps

separating

the

outer

yoke

from

the

cent

er

yoke.

6. U

se a dr

groove

time

until

iver

and

install

complete.

to

press

retaining

the

bearing

ring. Do this

cup

below

procedure

the

retaining

one

side

ring

at

a

5.

Installation

drive the bearing cups

ings

if

is

necessary

the rever

.

se

of

disasse

mbly

. Use a press and

10 the surface of the yoke. Grease bear-

35

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

Reassembly of Model 25534

Reassembly of Trunnions

1.

When

replacing

installation

2.

If

trunnion

and align hole in bushing with grease fitting hole

Reinstall grease fitting.

tool

bushing

trunnion

as

not

to

damage

is

to

bushing

be

replaced,

use

bushing

proper

.

remove

grease

in

trunnion .

[~J

!n

fitting

3. If locator pins are to be replaced, twist to remove .

Install new pins

4. tnstall new O-ring if required.

by

tapping until seated.

36

REFERENCE ONLY

Reassembly of Carrier Housing

1.

Install

new

inn

er

and

outer

bearing

cups.

[!J

3. Ins

tall

new

MAINTENANCE MANUAL MODEL

inner

beari

ng

cone

on

pinion

shaft

.

25534

AXLE

2. Install mounting distance shim(s) on pinion shaft. If new ring

and

pinion

are

to

be

installed, refer

Instructions/Chart on pages 40/41.

to

Pinion

Shim

Selection

/

(I.un

't\;,.-'

, \ . '

" .

\ ' ' ' \

4.

Press new i

5. Ins

tall

the preload spacer. Install new spacer at each overhaul.

pinion

nner

from

bearing

rear

or

cone

carrier

\

"-

'f

on

pinion

housing

~

gear

shaft.

and ins

tall

37

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

-

.,

Pinion Shim Selection

......

Carrier housing pinion measurement is

written inside the carrier housing.

......

The

nominal pinion measurement is 6.426

inches.

......

On

the

pilot end

numbers are listed.

......

Gearset Ld. numbers - to insure the ring

and pinion are matched. If the numbers on

new

the

use this gearset!

match to insure compatibiity.

......

Etched on the pinion will be a plus (+) sign

and a number, a minus

number

sents the amount in thousandths

added

pinion measurement to properly locate the

pinion shaft .

gearset

or

or

subtracted from the nominal

of

the pinion several

do

not match - DO NOT

The Ld. numbers MUST

(-)

sign and a

a zero (0). This number repre-

of

an inch

Using the Pinion Shim

Selection Chart

1. Locate the gage room measurement

written inside the carrier housing.

2.

Determine the pinion nominal measurement (on chart).

3. Locate the pinion adjustment number on

the pinion pilot - listed

minus

4. Scan across from the gage room measurement

column .

5. The shim thickness listed at this location

should

pinion bearing and the pinion shaft.

6. Follow the pinion reloading instructions

listed under Assembly Instruction

Notes #8 .

number, or

to the appropriate pinion adjustment

be

installed between the inner

a O.

as

a plus number,

......

(+) 2 requires a .002 thicker shim be added

between the inner bearing cone and

pinion shaft than a shaft marked O.

......

H 2 requires a .002 thinner shim be

added between the inner bearing cone and

pinion shaft than a shaft marked O.

......

The required thickness shim will be

selected from the pinion shim selection

chart listed in the specifications section.

the

38

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

Pinion Shim Selection Chart

AXLE

Gage Room

Measurement

& Bearing

6.468

6.469

6.47

6.471

6.472

6.473

6.474

6.475 6.426

6.476 6.426

6.477 6.426

6.478

6.479

Pinion

Nominal

6.426

6.426

6.426 0.046

6.426

6.426

6.426

Pinion Pinion Pinion Pinion Pinion Pinion

Adjustment Adjustment Adjustment Adjustment Adjustment

j-2)

Pinion Shim Pinion Shim Pinion Shim Pinion Shim Pinion Shim Pinion Shim

0.044 0.043 0.042 0.041 0.

0.045 0.044 0.043

(-1) (+0)

(+1}

0.042

(+2) (+3)

04

0.041

0.045 0.044 0.043 0.042

0.047 0.046 0.045 0.044

0.043 0.042

0.048 0.047 0.046 0.045 0.044

0.049

0.048

0.047

0.046 0.045 0.044

Adjustment

0.039

0.04

0.041

0.043

6.426 0.05 0.049 0.048 0.047 0.046 0.045

0.051 0.05 0.049 0.048 0.047 0.046

0.052 0.

051

0.053 0.052 0.

0.05 0.049 0.048

051

0.05 0.049 0.048

0.047

6.426 0.054 0.053 0.052 0.051 0.05 0.049

6.426 0.055 0.054 0.053 0.052 0.

051

0.

05

Pinion Shim Selection Chart

Pinion Pinion

Gage Room

Measurement

6.468

6.469

6.47

6.471

6.472

Nominal Adjustment Adjustment

& Bearing

(+4) (+5)

Pinion Shim Pinion Shim Pinion Shim Pinion Shim Pinion Shim

6.426 0.038 0.037 0.036 0.035 0.034

6.426 0.039 0.038 0.037 0.036 0.035

6.426 0.04 0.039 0.038 0.037 0.036 0.035

6.426 0.

6.426

041

0.042

6.473 6.426 0.043 0.042

Pinion Pinion

Adjustment

(+6)

Adjustment

0.04 0.039 0.038 0.037 0.036

0.041 0.

04

0.041

6.474 6.426 0.044 0.043 0.042 0.041

6.475

6.476 6.426

6.477 6.426

6.478

6.479 6.426

6.426 0.045 0.044 0.043 0.042 0.041

0.046 0.045 0.044 0.043

0.047 0.046 0.045 0.044 0.043

6.426 0.048 0.047 0.046 0.045

0.049 0.048 0.047

Pinion Pinion Pinion

Adjustment

(+7) (+8)

Adjustment

(+9)

Pinion Shim

0.033

0.034

0.039 0.038 0.037

0.

04

0.039

0.038

0.04 0.039

0.

04

0.042 0.041

0.042

0.044 0.043

0.046 0.045 0.044

39

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

..

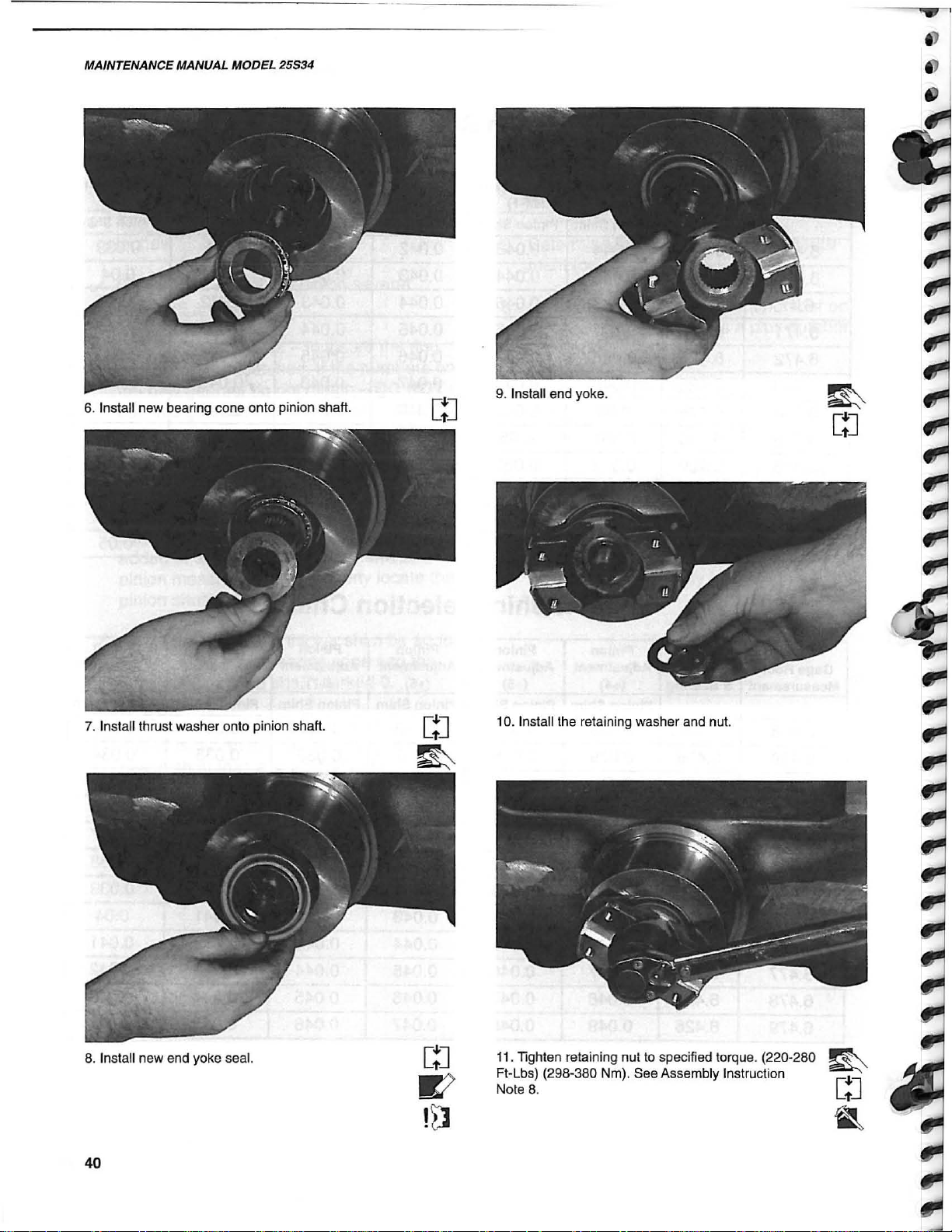

6.

Install

new

bearing

7. Install thrust washer onto pinion

cone

onto pinion

shaft.

sha~.

9. Install end yoke.

[~J

[~J

10. Install the retaining washer and nut.

8.

Install new end yoke seal.

40

. Tighten retaining nut

Ft-Lbs) (298-380 Nm). See Assembly Instruction

Nole 8.

to

specified torque. (220-280

11

REFERENCE ONLY

...

12. Using an inch/pound torque wrench take a reading

determine rolling torque. 20-40 In-Lbs. (2.25-4.5 Nm).

to

MAINTENANCE MANUAL MODEL 25534

15. Side gears and thrust washer installed.

AXLE

13.

Press

new

bearing

14. Install thrust washers,

into

differential

cones

case.

onto

differential

top

and bottom side

case.

gear

16. Install both pinion gears and thrust washer then

rotate

to

align

shaft

bore

with

gears

and

washers.

17. Install pinion gear shaft aligning hole

with roll pin hole in differential case.

in

shaft

41

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

-

...,

18. With holes aligned, drive roll pin into shaft.

19.

Clean

surfaces.

retaining

differential

Position

bolts.

ring

case

gear

and

and

ring

install

gear

mounting

new

21. Assemble bearing cups

cones

.

22.

Install

differential

install retaining caps, torque

(101-122 Nm).

case

on

differential bearing

into

carrier

housing

to

75-90

Ft.

Lbs.

and

[!J

E8

20. Torque bolts to 90-100

42

Ft.

Lbs. (122-135 Nm).

23. Install adjusting rings.

[!J

REFERENCE ONLY

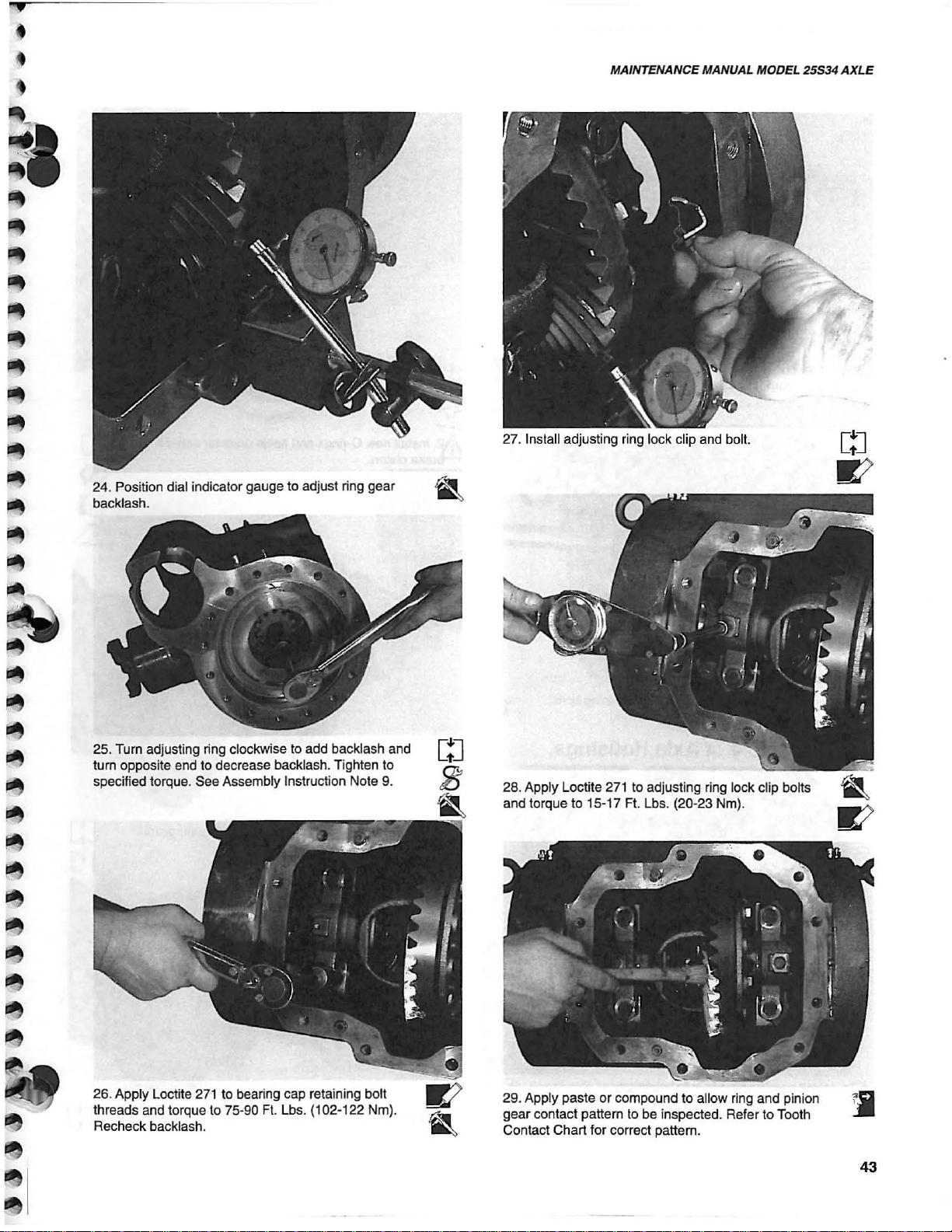

24. Position dial indicator gauge to adjust ring gear

backlash.

MAINTENANCE MANUAL MODEL 25534

27. Install adjusting ring lock clip and bolt.

AXLE

to

25. Turn adjusting ring clockwise

turn opposite end to decrease backlash . Tighten to

specified torque. See Assembly Instruction Note 9.

26. Apply Locme

threads and torque to 75Recheck backlash.

271

to bearing cap retaining bolt

90

add backlash and

Fl.

Lbs. (102-122 Nm).

28. Apply Loctite

and torque to 15-17 Ft.

29. Apply paste or compound to allow ring and pinion

gear

contact

Contact Chart for correct pattern.

271

pattern

to

adjusting ring lock clip bolts

Lb

s. (20-23 Nm).

to

be

inspected.

Refer

to

Toot

h

43

REFERENCE ONLY

MAINTENANCE MANUAL MODEL 25534

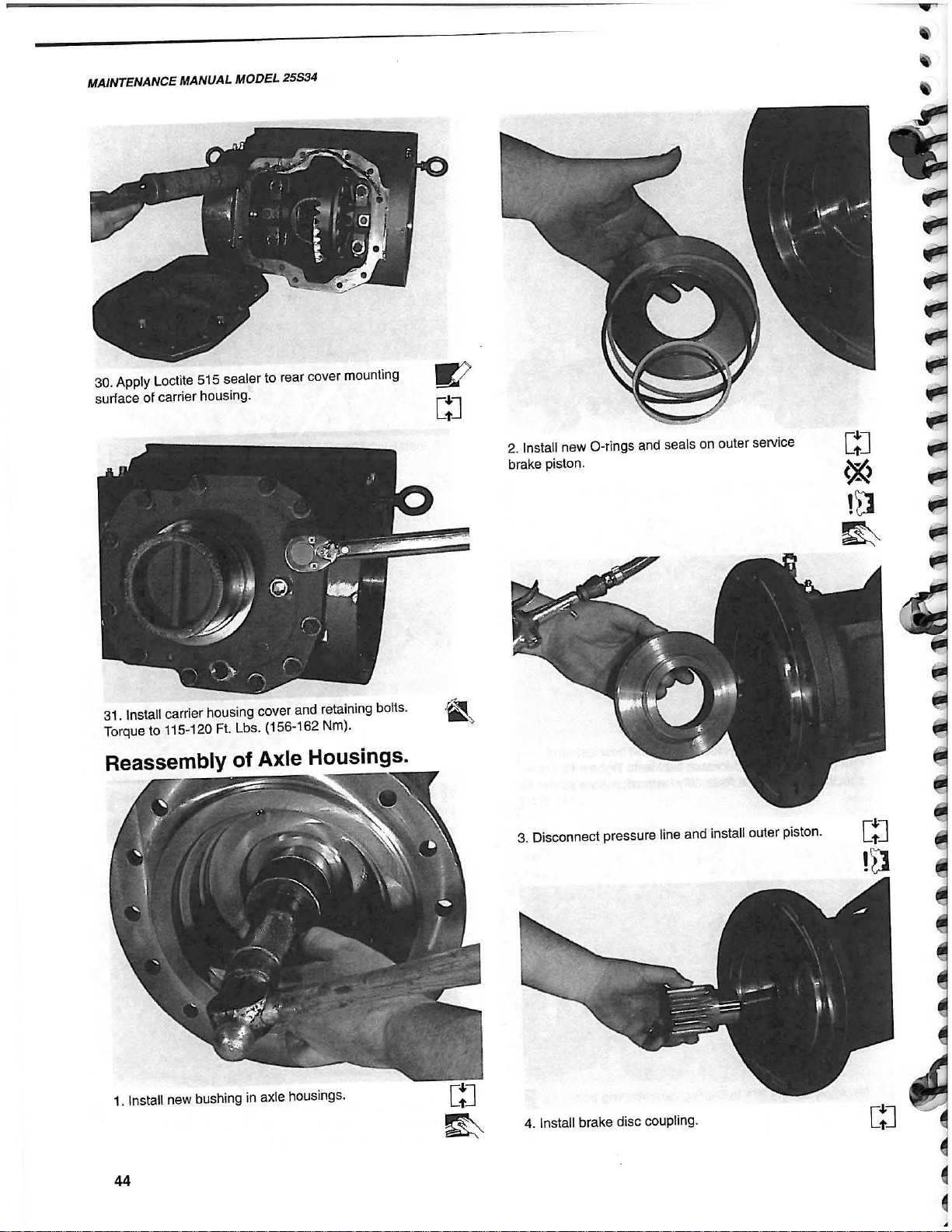

30. Apply Loctite 515 sealer to rear cover mounting

surrace

of

carrier

housing.

2.

Install

brake

new

piston.

O-rings

and

seals

on

outer

service

31.

Install

carrier

housing

Torque to 115-120 Ft. Lbs. (156-162 Nm).

Reassembly

1. Install new bushing in axle housings.

cover

and

retaining

of

Axle Housings.

bolts

.

3. Di

sconnect

pressure

line

and

install

outer

piston.

[~J

!~

4. Install brake disc coupling.

44

REFERENCE ONLY

•

,..

---

"

,j )

~

~

jI!It

~

~

.

5. Install brake disc

disc and alternating with (4) four friction disc.

in

axle housing starting with a steel

MAINTENANCE MANUAL MODEL

8. Install parking brake springs.

25534

AXLE

6.

Install

new

Q-rings

brake

piston.

7. Install inner parking brake piston.

and

seals

on

inner

parking

9. Install new O-ring to axle housing.

10. Install axle shaft into axle housing. Be sure to

install

on

correct

side

.

GJ

.&

45

REFERENCE ONLY

I 1

MAINTENANCE MANUAL MODEL

11.

Install parking brake spring backing plate

carrier

housing

.

25834

in

13. Install new axle housing bolts and torque to

110-120

Ft.

Lbs. (199-162 Nm).

12. Using a lifting device balance the axle housing

and

install

into

carrier

housing

46

.

REFERENCE ONLY

MAINTENANCE MANUAL MOOEL

25534

AXLE

16. Torque fittings

to

84-120 In. Lbs. (9.5-13.5 Nm).

19. Apply grease to bearing cone and cup prior to installation.

20. Using proper tool, install grease seal being careful

not

to

damage seal.

!t3

new

bushing and seal into end of

.

47

18. Using proper tool, drive bearing cup down until

seated properly.

21. Install

axle

housing

REFERENCE ONLY

MAINTENANCE MANUAL

Reassembly of Wheel Ends .

MODEL

25S34

"

1.

Install new inner and outer bearing cups and

cones

in hub

.

.....

m""!1

! I

I

. I

. 1

'.

II

Ilnnrlli

4.

Press

new

outer

bearing

bearing may ease installation. (Do not exceed 275 .

degrees). See Assembly Instruction Note 15 (pg. 15).

-

-\

! 1

onto

ring

~

\

\

~\

gear

hub

. Heating

[!J

,.

!n

2.

Install

new

hub

seal

using

proper

3. Assemble wheel end onto knuckle.

48

driver

.

5. Position ring gear hub into ring gear.

6. Install hub retaining ring into gear assembly.

[!J

[!J

REFERENCE ONLY

,

•

•

l

!if

'"

pit

'"

!If

~

!it

~

~

~

6. Position planetary ring gear, knuckle and hub.

MAINTENANCE MANUAL MODEL 25534

9. Install retaining plate cap screws with Loctite

and tighten.

AXLE

271

7. Assemble ring gear

8. Install

Assembly Instruction Note

shims

on

and bearing preload retainer plate. See

splines of knuckle.

11

.

10. Check rolling torque on wheel after torquing bolts •

to 115/120 Ft. Lbs. (156-162 Nm).

11.

Press a new

if

required.

thrust

washer

on

sun

gear

shaft

49

l

REFERENCE ONLY

MAINTENANCE MANUAL

MODEL

25534

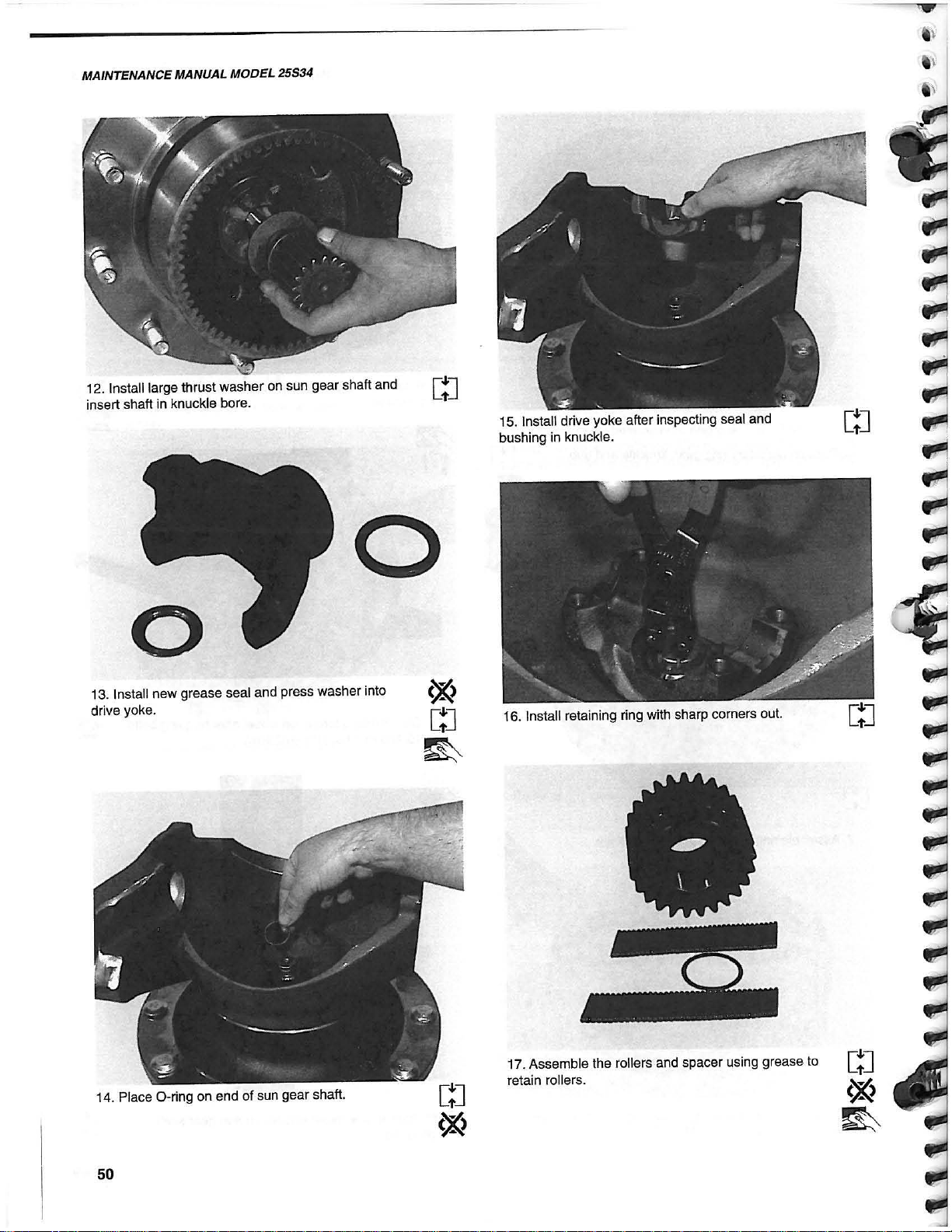

12. Install large thrust washer on sun gear shaft and

insert shaft in knuckle bore.

o

o

13.

Install

new

grease

seal

and

press

washer

drive yoke.

into

Ct"'J

15. Install drive yoke after inspecting seal and

bushing in knuckle.

[!J

to

14. Place O-ring on end of sun gear shaft.

50

17. Assemble the rollers and spacer using grease

retain

rollers

.

REFERENCE ONLY

•

MAINTENANCE MANUAL MODEL

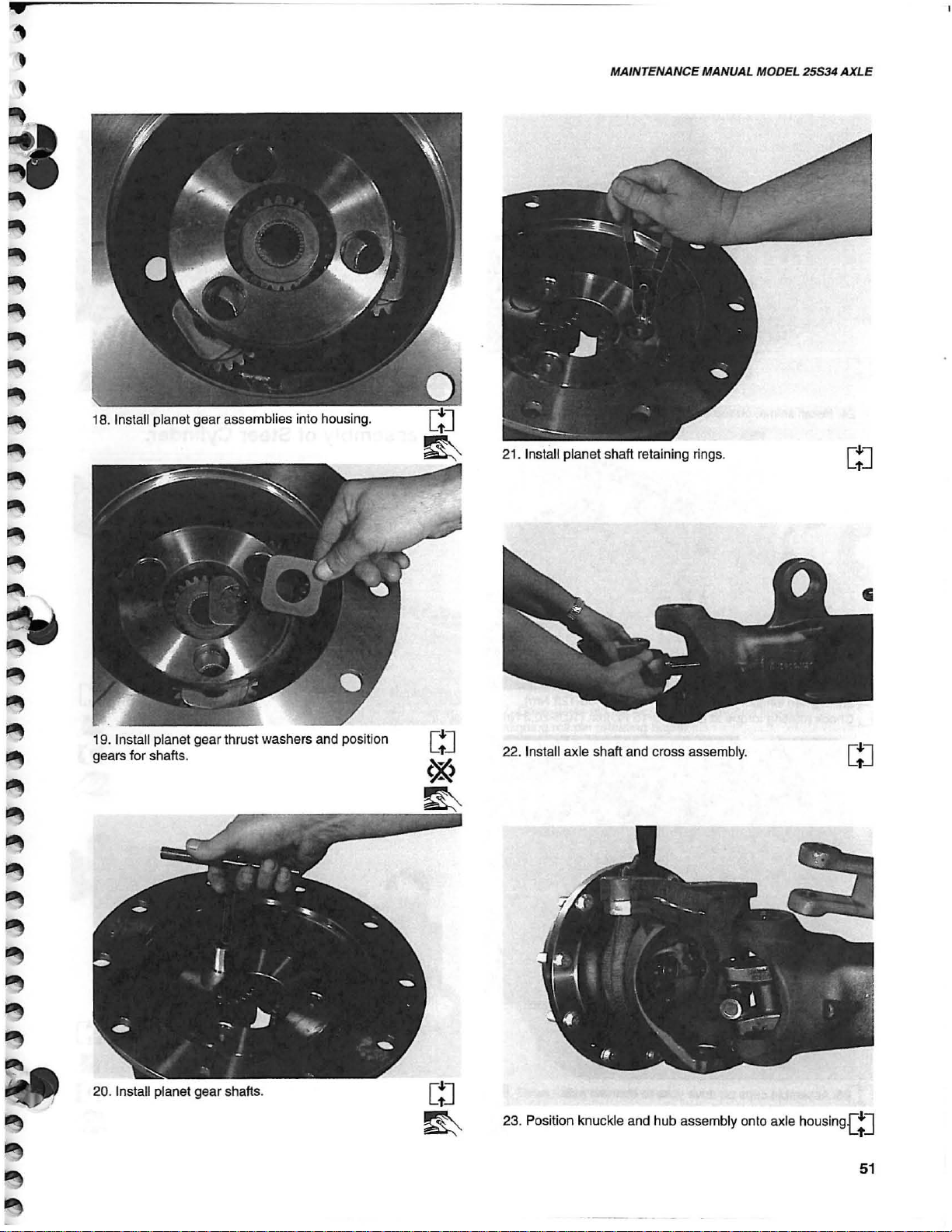

21

. Inslall planet shaft retaining rings.

25534

AXLE

19. Install planet gear thrust washers and position

gears for shafts.

20. Install planet gear shafts.

22. Install axle shaft and cross assembly.

23. Position knuckle and hub assembly onto axle housi

ng[!J

51

REFERENCE ONLY

MAINTENANCE MANUAL MODEL

25534

27.

lighten

55-60

yoke cap bolts

Ft.

Ibs. (74.5-81.3 Nm).

to

specified torque.

24. Install shims,

lighten

25.

Check rotating torque at kingpin 8-15 Ft.-Ibs. (10.8-20.3 Nm).

on

top and bottom kingpins.

kingpin bolts to 80-90 Ft.-Ibs. (108-122 Nm).

Reassembly of Steer Cylinder.

1 . Assemble socket assembly

271

Apply Loctite

(260-280 Nm).

and torque to 192-207

to

steer cylinder.

Ft.

Lbs.

2. Install steer cylinder into axle housing cradle.

26. Assemble caps

shatt assembly.

on

drive yoke

to

connect axle

[!J

•

52

REFERENCE ONLY

M

,

~

,.

~

~

~

~

r-

r.-

..

3. Install steer cylinder retaining bolts and tighten to

specified torque.

80-90 Ft.-Lbs. (108-122 Nm).

6.

Position

MAINTENANCE MANUAL MODEL 25534

steer

arm,

shims

and

O-ring

on

knuckle

AXLE

.

GJ

4. Install steering arm and torque to 121

(299 Nm).

Ft.

Lbs.

7.

Dri

ve

clevis

pin

through

aligning roll pin retaining holes.

8. Drive

roll

pin into

bore

clevis pin.

of

arm

and

knuckle,

GJ

GJ

,.

53

REFERENCE ONLY

-------

_

.-

---

MAINTENANCE MANUAL MODEL 25534

9. Apply loctite 515 on face

flange assembly. See Assembly Instruction Note 12.

of

hub and install drive

2.

Install

rear

trunnion

assembly

onto

carrier

housing.

. ;

[!J

10. Install planetary retaining bolt two (2) places. Torque

to

40-45 Ft.-Lbs. (54-61 Nm). See Assembly Instruction t

Note 12.

Installation

of

Front and Rear

Trunnions.

1.

Install

V-ring

seal

and

thrust

mount.

Grooves

are

to

face

washer

out.

on

rear

trunion

C"'J

.,

3. Install front trunnion V-ring and thrust washer.

Grooves to face out.

4.

Install

front

trunnion

housing.

mount

assembly

on

carrier

GJ

54

REFERENCE ONLY

PW

!WI

:&

,.

•

•

.,

.,

.,

;.e

;.e

;.e

•

~

~

,.,

Bleeding the Brake System

1.

Fill the master cylinder reservoir with

approved fluid before starting the bleeding

operation. Keep the reservoir at least half

full of fluid at all times during the bleeding

operation. (Note:

drained at any time during the bleeding

operation, air will enter the system and

rebleeding will be necessary).

2.

Start the brake bleeding operation at the

brake head with the

master cylinder.

3.

While applying pressure from the pressure

bleeder tank (or when mechanically bleeding, depress the brake pedal) open the

bleeder screw and observe the flow of

fluid. The pressure will move the fluid

through the system and out the open

bleeder screw carrying with it any air

(evidenced by bubbles

that was trapped in the line and cylinder.

if

the master cylinder

longest

line to the

in

the flow of fluid)

is

MAINTENANCE MANUAL MODEL 25S34

4. Close the bleeder screw when the flow of

fluid appears free

solid. Reopen screw momentarily, then

tighten.

NOTE: Fluid drained during the bleeding

operation shall not be re-used

because of possible contamination

during the bleeding operation. The

fluid level

should be replenished after each