Genie AWP Super Series, IWP Super Series Service Manual

Service Manual

Serial Number Range

AWP Super Series

from 3896-101

99999

21194

87799

87800

IWP Super Series

from 4096-101

4413

4205

11999

from IWPG-12000

Part No. 38139

Rev B11

September 2016

to 3801-

from AWP02-

to AWP16Gfrom AWPG-

to 4001from IWP02to IWP16G-

Service Manual September 2016

Introduction

Introducti on Introducti on

Important Inform ation

Important

Read, understand and obey the safety rules and

operating instructions in the appropriate Operator's

Manual on your machine before attempting any

maintenance procedure.

This manual provides detailed scheduled

maintenance information for the machine owner

and user. It also provides troubleshooting and

repair procedures for qualified service

professionals.

Basic mechanical, hydraulic and electrical skills are

required to perform most procedures. However,

several procedures require specialized skills, tools,

lifting equipment and a suitable workshop. In these

instances, we strongly recommend that

maintenance and repair be performed at an

authorized Genie dealer service center.

Technical Publications

Genie has endeavored to deliver the highest

degree of accuracy possible. However, continuous

improvement of our products is a Genie policy.

Therefore, product specifications are subject to

change without notice.

Readers are encouraged to notify Genie of errors

and send in suggestions for improvement. All

communications will be carefully considered for

future printings of this and all other manuals.

Contact Us:

Internet: www.genielift.com

E-mail: awp.techpub@terex.com

Find a Manual for this Model

Compliance

Machine Classification

Group A/Type 1 as defined by ISO 16368

Machine Design Life

Unrestricted with proper operation, inspection and

scheduled maintenance.

Go to http://www.genielift.com

Use the links to locate Service Manuals,

Maintenance Manuals, Service and Repair

Manuals, Parts Manuals and Operator's Manuals.

Copyright © 1996 by Terex Corporation

38139 Rev B, December 2001

First Edition, Second Printing

'Genie', 'AWP' and 'IWP' are registered trademarks of Terex

South Dakota. in the U.S.A. and many other countries. “Super

Series” is a trademark of Terex South Dakota.

ii AWP Super Series • IWP Super Series Part No. 38139

September 2016 Service Manual

Introduction

Revision History

Revision History

Revision Date Section Procedure / Page / Description

B8 5/2015 Maintenance Removed C-6

B9 8/2016 Repair 5-4

B10 9/2016 Introduction Serial Number Legend

B11 9/2016 Schematics Page 166

Reference Examples:

Section – Maintenance, B-3

Section – Repair Procedure, 4-2

Section – Fault Codes, All charts

Section – Schematics, Legends and schematics

Electronic Version

Click on any content or procedure in the Table of Contents to view

the update.

Part No. 38139 AWP Super Series • IWP Super Series iii

Service Manual September 2016

Introduction

Revision History (continued)

Revision Date Section Procedure / Page / Description

Reference Examples:

Section – Maintenance, B-3

Section – Repair Procedure, 4-2

Section – Fault Codes, All charts

Section – Schematics, Legends and schematics

Electronic Version

Click on any content or procedure in the Table of Contents to view

the update.

iv AWP Super Series • IWP Super Series Part No. 38139

September 2016 Service Manual

To August 31,

From September 1, 2016

Introduction

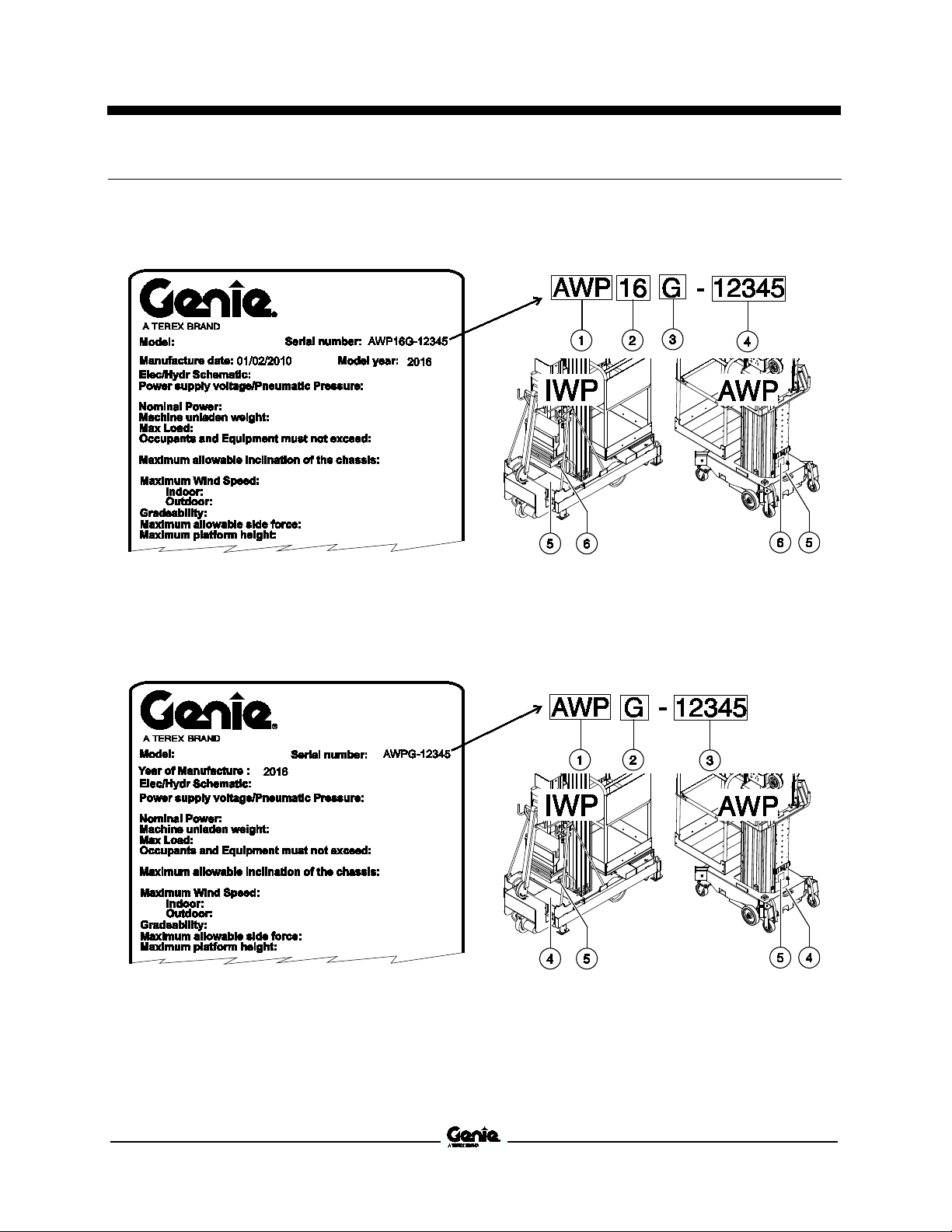

Serial Number Legend

2016

1 Model

2 Model year

3 Facility code

1 Sequence number

2 Serial number (stamped on chassis)

3 Serial label

1 Model

2 Facility code

3 Sequence number

1 Serial number (stamped on chassis)

2 Serial label

Part No. 38139 AWP Super Series • IWP Super Series v

Service Manual September 2016

Safety Rules

Section 1 Safety Rules

General Saf ety R ules

Danger

Failure to obey the instructions and safety rules in

this manual and the appropriate Operator's Manual

on your machine will result in death or serious

injury.

Many of the hazards identified in the operator's

manual are also safety hazards when maintenance

and repair procedures are performed.

Do Not Perform Maintenance

Unless:

You are trained and qualified to perform

maintenance on this machine.

You read, understand and obey:

• manufacturer's instructions and safety rules

• employer's safety rules and worksite

regulations

• applicable governmental regulations

You have the appropriate tools, lifting

equipment and a suitable workshop.

vi AWP Super Series • IWP Super Series Part No. 38139

September 2016 Service Manual

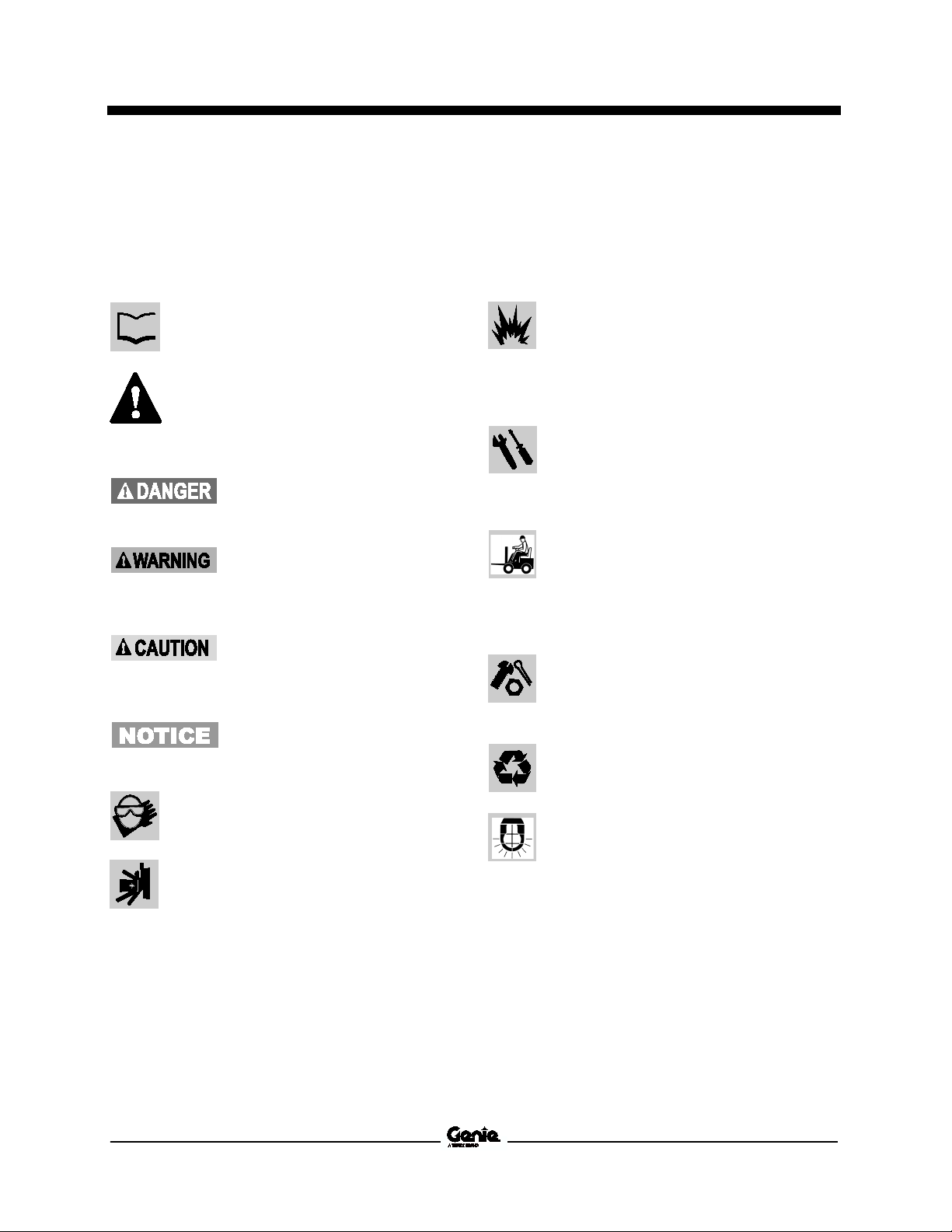

Read each procedure thoroughly. This

manual and the decals on the machine,

use signal words to identify the following:

Safety alert symbol

t

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates a imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which

may result in property damage.

Be sure to wear protective eye wear and

other protective clothing if the situation

warrants it.

Be aware of potential crushing hazards

such as moving parts, free swinging or

unsecured components when

placing loads. Always wear approved

steel

Be sure to keep sparks, flames and

lighted tobacco away from flammable and

combustible materials like battery gases

and engine fuels. Always have an

approved fire extinguisher within easy

reach.

Be sure that all tools and working areas

are prop

use. Keep work surfaces clean and free of

debris that could get into machine

components and cause damage.

Be sure any forklift, overhead crane or

other lifting or supporting device is fully

capable of supporting and stabili

weight to be lifted. Use only chains or

straps that are in good condition and of

ample capacity.

Be sure that fasteners intended for one

time use (i.e., cotter pins and self

nuts) are not reused. These components

may fail if they are us

Be sure to properly dispose of old oil or

other fluids. Use an approved container.

Please be environmentally safe.

Be sure that your workshop or work area

is properly ventilated and well lit.

Safety Rules

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

—used to aler

a potentially hazardous

, if not avoided,

Workplace Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

erly maintained and ready for

ed a second time.

zing the

-locking

-toed shoes.

Part No. 38139 AWP Super Series • IWP Super Series vii

lifting or

September 2016

Table of Contents

Introduction Introduction .......................................................................................................... ii

Important Information .............................................................................................. ii

Find a Manual for this Model ................................................................................... ii

Revision History ..................................................................................................... iii

Serial Number Legend ........................................................................................... v

Section 1 Safety Rules ......................................................................................................... vi

General Safety Rules ............................................................................................. vi

Section 2 Specifications ..................................................................................................... 17

AWP-15S, 20S and 25S Specifications ............................................................... 17

AWP30S, 36S and 40S Specifications ................................................................ 18

AWP Narrow Base Specifications ........................................................................ 19

AWP Rough Terrain Base Specifications ............................................................ 20

IWP Specifications ............................................................................................... 21

AWP/IWP Performance and Hydraulic Specifications ......................................... 22

Hydraulic Hose and Fitting Torque Specifications ............................................... 23

Torque Procedure ................................................................................................ 24

SAE and Metric Fasteners Torque Charts ........................................................... 26

viii AWP Super Series • IWP Super Series Part No. 38139

September 2016

Table of Contents

Section 3 Scheduled Maintenance Procedures ............................................................... 27

Introduction ........................................................................................................... 27

Pre-Delivery Preparation Report .......................................................................... 31

Maintenance Inspection Report............................................................................ 33

Checklist A Procedures ..................................................................................... 35

A-1 Inspect the Manuals and Decals.................................................................... 35

A-2 Perform Pre-operation Inspection .................................................................. 36

A-3 Perform Function Tests ................................................................................. 36

A-4 Inspect for Damage and Loose or Missing Parts........................................... 37

A-5 Check for Hydraulic Leaks ............................................................................. 38

A-6 Check the Hydraulic Oil Level ........................................................................ 38

A-7 Test the Base Operation - IWPS Models ....................................................... 39

A-8 Test the Auxiliary Platform Lowering Operation ............................................ 39

A-9 Test the Manual Platform Lowering Operation .............................................. 40

A-10 Inspect the Columns for Damage ................................................................ 40

A-11 Check the Sequencing Cables .................................................................... 41

A-12 Check the Interlock System for Proper Operation ....................................... 41

A-13 Test the Power and Function Controls ........................................................ 43

A-14 Inspect the Lifting Chains and Idler Wheels ................................................ 43

A-15 Inspect the Breather Cap ............................................................................. 44

A-16 Check the Tire Pressure -

AWPS Models with Rough Terrain Base Option .......................................... 45

A-17 Check the Air Supply Lubricator Oil Level - Air Models ............................... 45

A-18 Check the Air Supply Lubricator Drip Rate - Air Models ............................. 46

A-19 Check the Air Filter/Regulator Canister - Air Models ................................... 46

Part No. 38139 AWP Super Series • IWP Super Series ix

September 2016

Table of Contents

Checklist B Procedures ..................................................................................... 47

B-1 Inspect the Battery ........................................................................................ 47

B-2 Inspect the Electrical Wiring .......................................................................... 47

B-3 Inspect All Welds ........................................................................................... 48

B-4 Test the Tilt-back Operation (if equipped) ..................................................... 48

B-5 Check the Lifting Chain Adjustment .............................................................. 50

B-6 Clean and Lubricate the Columns ................................................................. 51

B-7 Test the Lifting Capacity ................................................................................ 51

B-8 Adjust the Sequencing Cables ...................................................................... 52

B-9 Inspect for Proper Outrigger Length - AWPS Models ................................... 53

B-10 Inspect and Lubricate the Outrigger Leveling Jack Footpads -

AWPS Models ............................................................................................. 55

B-11 Test the Level Sensing Operation - IWPS Models ...................................... 55

B-12 Check the Chain Adjustment, IWP-20S Models with Outreach Option....... 56

Checklist C Procedures ..................................................................................... 57

C-1 Inspect and Lubricate the Casters and Wheels ............................................ 57

C-2 Inspect the Mast Assembly for Wear ............................................................ 57

C-3 Inspect and Lubricate the Lifting Chains ....................................................... 59

C-4 Replace the Hydraulic Oil .............................................................................. 59

C-5 Replace the Auxiliary Platform Lowering Batteries ....................................... 61

x AWP Super Series • IWP Super Series Part No. 38139

September 2016

Table of Contents

Section 4 Repair Procedures ............................................................................................. 63

Introduction ........................................................................................................... 63

Base Assembly ................................................................................................... 65

1-1 Interlocks ........................................................................................................ 65

1-2 Base Components IWPS Models ................................................................... 66

1-3 Foot Pump Manifold Components - IWPS Models (to SN IWP09-8269) ....... 70

1-4 Foot Pump Manifold Components -

IWPS Models (from SN IWP09-8270) .......................................................... 71

1-5 Power Wheel Assist Manifold Components -

IWPS Models (to SN 4097-990) ................................................................... 72

1-6 Power Wheel Assist Manifold Components -

IWPS Models (from SN 4097-997 to 4099-2532) ......................................... 73

1-7 Power Wheel Assist Manifold Components -

IWPS Models (from SN 4099-2533) ............................................................. 74

Ground Controls ................................................................................................. 75

2-1 How to Test the Transformer - AC Models .................................................... 75

2-2 How to Test the AC Contactor - AC Models .................................................. 76

Hydraulic Power Unit ......................................................................................... 77

3-1 Hydraulic Power Unit - AC Models

(to SN AWP03-27389 and IWP03-5150) ...................................................... 77

3-2 Hydraulic Power Unit - AC Models

(from SN AWP03-27390 to AWP08-60145) ................................................. 78

3-3 Hydraulic Power Unit - DC Models

(to SN AWP03-27401 and IWP03-5122) ...................................................... 80

3-4 Hydraulic Power Unit Components - Air Powered Models

(to SN AWP04-27778) .................................................................................. 82

3-5 Hydraulic Power Unit ...................................................................................... 85

3-6 Hydraulic Pump .............................................................................................. 87

3-7 Valve Adjustment ........................................................................................... 87

3-8 How to Test the Motor Start Solenoid - DC Models ....................................... 88

Part No. 38139 AWP Super Series • IWP Super Series xi

September 2016

Table of Contents

Power Pack ......................................................................................................... 89

4-1 Power Pack .................................................................................................... 89

Mast Components .............................................................................................. 90

Mast Components ................................................................................................ 90

5-1 Lift Cylinder .................................................................................................... 91

5-2 Mast Assembly .............................................................................................. 92

5-3 Glide Pads ..................................................................................................... 97

5-4 Lifting Chains ................................................................................................. 98

Tilt-back Frame, AWP-36S and 40S Models .................................................. 101

6-1 Tilt-back Frame ............................................................................................ 101

Platform ............................................................................................................. 103

7-1 Platforms ...................................................................................................... 103

7-2 Platform Control Box .................................................................................... 104

7-3 Platform Outreach Chain ............................................................................. 105

xii AWP Super Series • IWP Super Series Part No. 38139

September 2016

Table of Contents

Section 5 Schematics ........................................................................................................ 107

Introduction ......................................................................................................... 107

Electrical Component and Wire Color Legends ................................................. 108

Electrical Symbol Legend ................................................................................... 110

Hydraulic Symbols Legend ................................................................................. 111

Electrical Schematics - AWP Models ............................................................. 113

Electrical Schematic - AWP Super Series DC Models

(from SN 3896-101 to 3896-300)................................................................ 114

Electrical Schematic - AWP Super Series DC Models

(from SN 3896-301 to 3896-430)................................................................ 115

Electrical Schematic - AWP Super Series DC Models

( from SN 3896-431 to AWP07-54898) ...................................................... 118

Electrical Schematic - AWP Super Series DC Models with Standard Base

(from SN AWP07-54899) ............................................................................ 119

Electrical Schematic - AWP Super Series DC Models with Narrow Base

(from SN AWP07-54899) ............................................................................ 122

Electrical Schematic - AWP Super Series DC CE Models

(from SN 3896-432 to AWP07-54898) ....................................................... 123

Electrical Schematic - AWP Super Series DC CE Models with Standard Base

(from SN AWP07-54899) ............................................................................ 126

Electrical Schematic - AWP Super Series DC CE Models with Narrow Base

(from SN AWP07-54899) ............................................................................ 127

Electrical Schematic - AWP Super Series DC TUV Models

(from SN 3896-431) .................................................................................... 130

Part No. 38139 AWP Super Series • IWP Super Series xiii

September 2016

Table of Contents

Electrical Schematic - AWP Super Series AC Models

(from SN 3896-103 to 3896-303) ............................................................... 131

Electrical Schematic - AWP Super Series AC Models

(from SN 3896-304 to 3896-450) ............................................................... 134

Electrical Schematic - AWP Super Series AC Models

(from SN 3896-451 to AWP07-54898) ....................................................... 135

Electrical Schematic - AWP Super Series AC Models with Standard Base

(from SN AWP07-54899 to AWP07-57594) ............................................... 138

Electrical Schematic - AWP Super Series AC Models with Narrow Base

(from SN AWP07-54899 to AWP-57594) ................................................... 139

Electrical Schematic - AWP Super Series AC Models with Standard Base

(from SN AWP07-57595) ........................................................................... 142

Electrical Schematic - AWP Super Series AC Models with Narrow Base

(from SN AWP07-57595) ........................................................................... 143

Electrical Schematic - AWP Super Series AC CE Models

(from SN 3896-451 to AWP07-54898) ....................................................... 146

Electrical Schematic - AWP Super Series AC CE Models with Standard Base

(from SN AWP07-54899 to AWP07-57594) ............................................... 147

Electrical Schematic - AWP Super Series AC CE Models with Narrow Base

(from SN AWP07-54899 to AWP07-57594) ............................................... 150

Electrical Schematic - AWP Super Series AC CE Models with Standard Base

(from SN AWP-57595) ............................................................................... 151

Electrical Schematic - AWP Super Series AC CE Models with Narrow Base

(from SN AWP07-57595) ........................................................................... 154

Electrical Schematic - AWP Super Series AC TUV Models

(from SN 3896-461) ................................................................................... 155

xiv AWP Super Series • IWP Super Series Part No. 38139

September 2016

Table of Contents

Electrical Schematics - IWP Models ............................................................... 157

Electrical Schematic - IWP Super Series DC Models

(from SN 4096-101 to 4096-287)................................................................ 158

Electrical Schematic - IWP Super Series DC Models

(from SN 4096-288 to 4096-341)................................................................ 159

Electrical Schematic - IWP Super Series DC Models

(from SN 4096-342 to IWP07-7065) ........................................................... 162

Electrical Schematic - IWP Super Series DC Models

(from SN IWP07-7066) to IWP15-9621 ...................................................... 163

Electrical Schematic - IWP Super Series DC Models

(from SN 4096-342 to IWP07-7065) ........................................................... 166

Electrical Schematic - IWP Super Series DC Models with Power Assist ........... 167

Electrical Schematic - IWP Super Series DC Models with Power Assist

(Directional Valve Coils Powering Function Manifold)................................ 170

Electrical Schematic - IWP Super Series DC TUV Models ................................ 171

Electrical Schematic - IWP Super Series DC TUV Models with Outreach......... 174

Electrical Schematic - IWP Super Series DC TUV

Models with Power Assist ........................................................................... 175

Electrical Schematic - IWP Super Series DC TUV

Models with Power Assist and Outreach .................................................... 178

Electrical Schematic - IWP Super Series DC TUV Models with Power Assist

(Directional Valve Coils Powering Function Manifold)................................ 179

Part No. 38139 AWP Super Series • IWP Super Series xv

September 2016

Table of Contents

Electrical Schematic - IWP Super Series AC Models

(from SN 4096-105 to 4096-285) ............................................................... 182

Electrical Schematic - IWP Super Series AC Models

(from SN 4096-286 to 4096-355) ............................................................... 183

Electrical Schematic - IWP Super Series AC Models

(from SN 4096-356 to IWP07-7065) .......................................................... 186

Electrical Schematic - IWP Super Series AC Models

(from SN IWP07-7066 to IWP07-57594) ................................................... 187

Electrical Schematic - IWP Super Series AC Models

(from SN IWP07-57595) ............................................................................. 190

Electrical Schematic - IWP Super Series AC TUV Models

(With Base Mounted Junction Box) ............................................................ 191

Electrical Schematic - IWP Super Series AC TUV Models

(Without Base Mounted Junction Box) ....................................................... 194

Electrical Schematic - IWP Super Series AC TUV Models with Outreach ........ 195

Hydraulic Schematics - All Models ................................................................ 197

Hydraulic Schematic - AWP Super Series Models ............................................ 198

Hydraulic/Pneumatic Schematic - AWP Super Series Models .......................... 199

Hydraulic Schematic - IWP Super Series Models without Power Assist ........... 202

Hydraulic Schematic - IWP Super Series Models with Power Assist ................ 203

Hydraulic Schematic - IWP Super Series

Models with Power Assist and Brake ......................................................... 205

xvi AWP Super Series • IWP Super Series Part No. 38139

September 2016 Service Manual

Model

15S

20S

25S

Standard Base

Height, working maximum

21 ft 4 in

6.5 m

26 ft 1 in

8.0 m

30 ft 9 in

9.4 m

Height, platform maximum

4 in

4.7 m

20 ft 1 in

6.1 m

24 ft 9 in

7.6 m

Lift capacity

all models except Canada

350 lbs

159 kg

350 lbs

159 kg

350 lbs

159 kg

Lift capacity

models sold in Canada only

300 lbs

136 kg

300 lbs

136 kg

300 lbs

136 kg

Machine weight

(DC / AC and Air

718 / 628 lbs

326 / 285 kg

764 / 674 lbs

347 / 306 kg

817 / 727 lbs

371 / 330 kg

Height, stowed

78 in

198 cm

78 in

198 cm

78 in

198 cm

Width

29 in

73.6 cm

29 in

73.6 cm

29 in

73.6 cm

Length

46 in

117 cm

46 in

117 cm

46 in

117 cm

Outrigger

(l x w) Domestic

60 ¾ x 52 ¾ in

154 x 134 cm

60 ¾ x 52 ¾ in

154 x 134 cm

60 ¾ x 52 ¾ in

154 x 134 cm

Outrigger footprint

(l x w) CSA

60 ¾ x 52 ¾ in

154 x 134 cm

69 ¼ x 61 ¼ in

175.6 x 155.3 cm

83 ½ x 75 ½ in

212 x 191 cm

Outrigger footprint

(l

60 ¾ x 52 ¾ in

154 x 134 cm

60 ¾ x 52 ¾ in

154 x 134 cm

69 ¼ x 61 ¼ in

175.6 x 155.3 cm

Outrigger footprint*

(l x w) CE Outdoor

69 ¼ x 61 ¼ in

175.6 x 155.3 cm

83 ¼ x 75 ¼ in

211.5 x 191.2 cm

89 x 81 in

225.9 x 205.6 cm

Corner access/wall

Domestic

15 ¾ / 8 in

39.7 / 20.3 cm

14 ½ / 5 ½ in

36.9 / 7.4 cm

14 / 3 in

35.1 / 7.4 cm

Corner access/wall access*

CSA

15 ¾ / 8 in

39.7 / 20.3 cm

20 ¼ / 9 ¾ in

51.2 / 24.5 cm

28 ¾ / 14 ¼ in

73 / 36.2 cm

Corner access/wall access*

CE Indoor

8 in

39.7 / 20.3 cm

14 ¼ / 5 ½ in

36.9 / 7.4 cm

19 ¼ / 7 ¼ in

48.6 / 18.2 cm

Corner access/wall access*

CE Outdoor

21 ½ / 12 ¼ in

54.6 / 30.8 cm

30 / 16 ¾ in

76 / 42.4 cm

32 ½ / 17 in

82.5 / 43.4 cm

Platform Dimensions

Standard platform

(L x W x H) gated or sliding mid

27 x 26 x 44 ¾ in

69 x 66 x 114 cm

Gated narrow platform

(L x W x H)

26 x 20 x 44 ¾ in

66 x 51 x 114 cm

Gated ultra

(L x W x H)

22 x 18 x 44 ¾ in

56 x 46 x 114 cm

Standard fiber platform

(L x W x H)

29 x 26 ½ x 43 ½ in

74 x 67 x 110 cm

Specifications

Section 2 Specificati ons

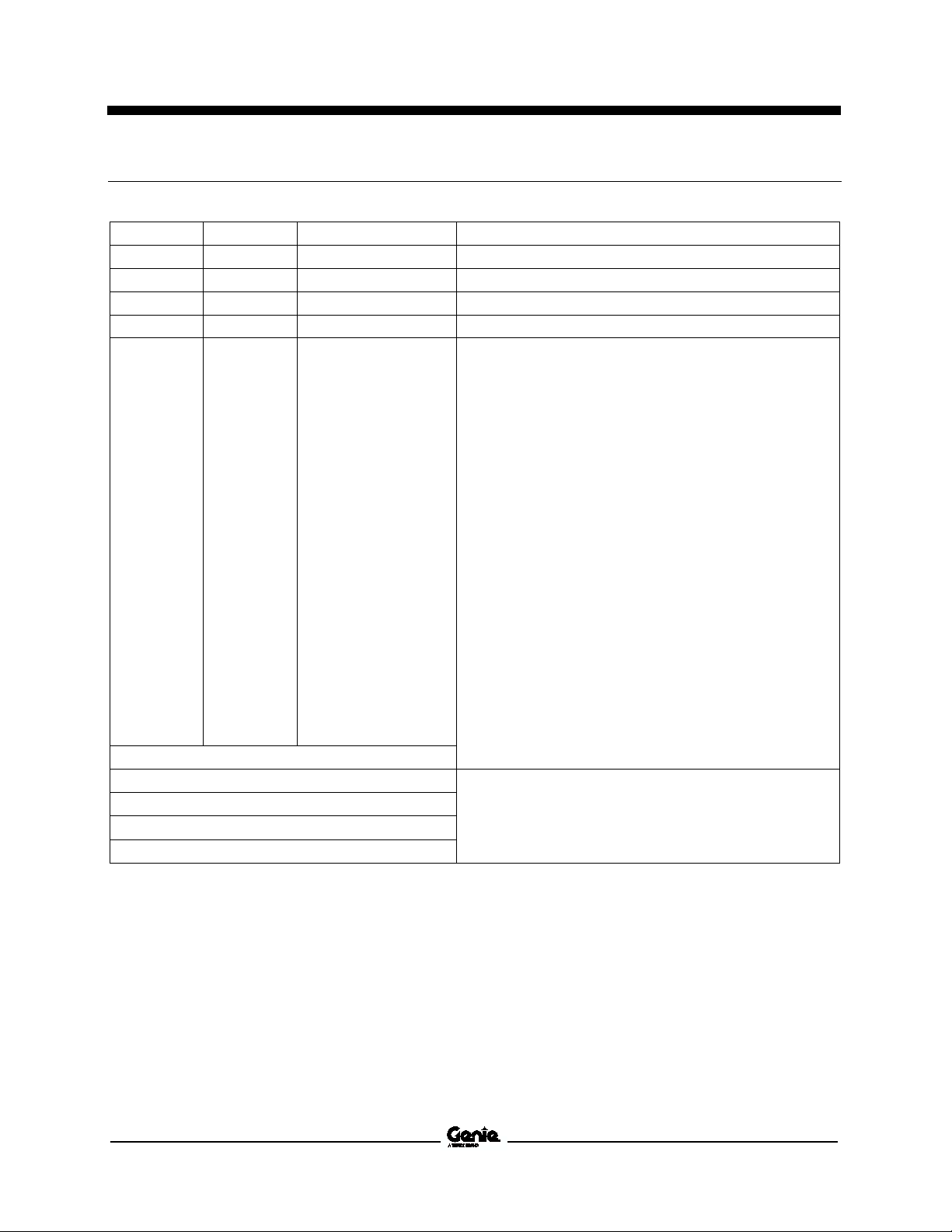

AWP-15S, 20S and 25S Specifications

AWP-

15 ft

models)

AWP-

AWP-

footprint

x w) CE Indoor

access*

15 ¾ /

*Corner of platform top rail to corner of wall with ability to rotate the leveling jack.

- all models

-narrow platform

-rail

Part No. 38139 AWP Super Series • IWP Super Series 17

Service Manual September 2016

Model

30S

36S

40S

Standard Base

Height, working maximum

35 ft 6 in

10.8 m

42 ft 5 in

12.9 m

46 ft 3 in

14.1 m

Height, platform maximum

29 ft 6 in

9.0 m

36 ft 6 in

6.1 m

40 ft 3 in

12.3 m

Lift capacity

all models except Canada

350 lbs

159 kg

350 lbs

159 kg

300 lbs

136 kg

Lift capacity

models sold in Canada only

300 lbs

136 kg

300 lbs

136 kg

300 lbs

136 kg

Machine weight

(DC / AC and Air models)

831 / 741 lbs

377 / 336 kg

1107 / 1017 lbs

502 / 461 kg

1130 / 1040 lbs

513 / 472 kg

Height, stowed

78 in

198 cm

109 ½ in

278 cm

109 ½ in

278 cm

Width

29 in

73.6 cm

29 in

cm

29 in

73.6 cm

Length

46 in

117 cm

55 in

140 cm

55 in

140 cm

Outrigger footprint

(l x w) Domestic

69 ¼ x 61 ¼ in

175.6 x 155.3 cm

83 ¼ x 75 ¼ in

211.5 x 191.2 cm

89 x 81 in

225.9 x 205.6 cm

Outrigger footprint

(l x w) CSA

97 ½ x 89 ½ in

cm

117 ¼ x 109 ¼ in

297.8 x 278 cm

117 ¼ x 109 ¼ in

297.8 x 278 cm

Outrigger footprint

(l x w) CE Indoor

75 ½ x 67 ½ in

192 x 171.4 cm

83 ¼ x 75 ¼ in

211.5 x 191.2 cm

89 x 81 in

225.9 x 205.6 cm

Outrigger footprint*

(l x w) CE Outdoor

117 ¼ x 109 ½ in

7.8 x 278 cm

117 ¼ x 109 ¼ in

297.8 x 278 cm

117 ¼ x 109 ¼ in

297.8 x 278 cm

Corner access/wall access*

Domestic

18 ½ / 4 ¾ in

46.6 / 11.9 cm

28 ½ / 14 ½ in

72.7 / 36.2 cm

31 ¼ / 14 ½ in

79.4 / 37.1 cm

Corner access/wall access*

CSA

37 / 18 ¾ in

47.8 cm

52 / 31 ¼ in

132.5 / 79.3 cm

50 ¾ / 28 ¾ in

128.8 / 73 cm

Corner access/wall access*

CE Indoor

22 ¼ / 8 in

56.6 / 20.3 cm

28 ½ / 14 ½ in

72.7 / 36.2 cm

31 ¼ / 14 ½ in

79.4 / 37.1 cm

Corner access/wall access*

CE Outdoor

50 ¾ / 28 ¾ in

cm

52 / 31 ¼ in

132.5 / 79.3 cm

50 ¾ / 28 ¾ in

128.8 / 73 cm

Platform Dimensions

Narrow fiber platform

(L x W x H)

26 x 22 x 43 ½ in

66 x 56 x 110 cm

Extra large platform

(L x W x H)

Front and side entry platform

(L x W x H)

30 x 28 x 44 ¾ in

76 x 71 x 114 cm

Specifications

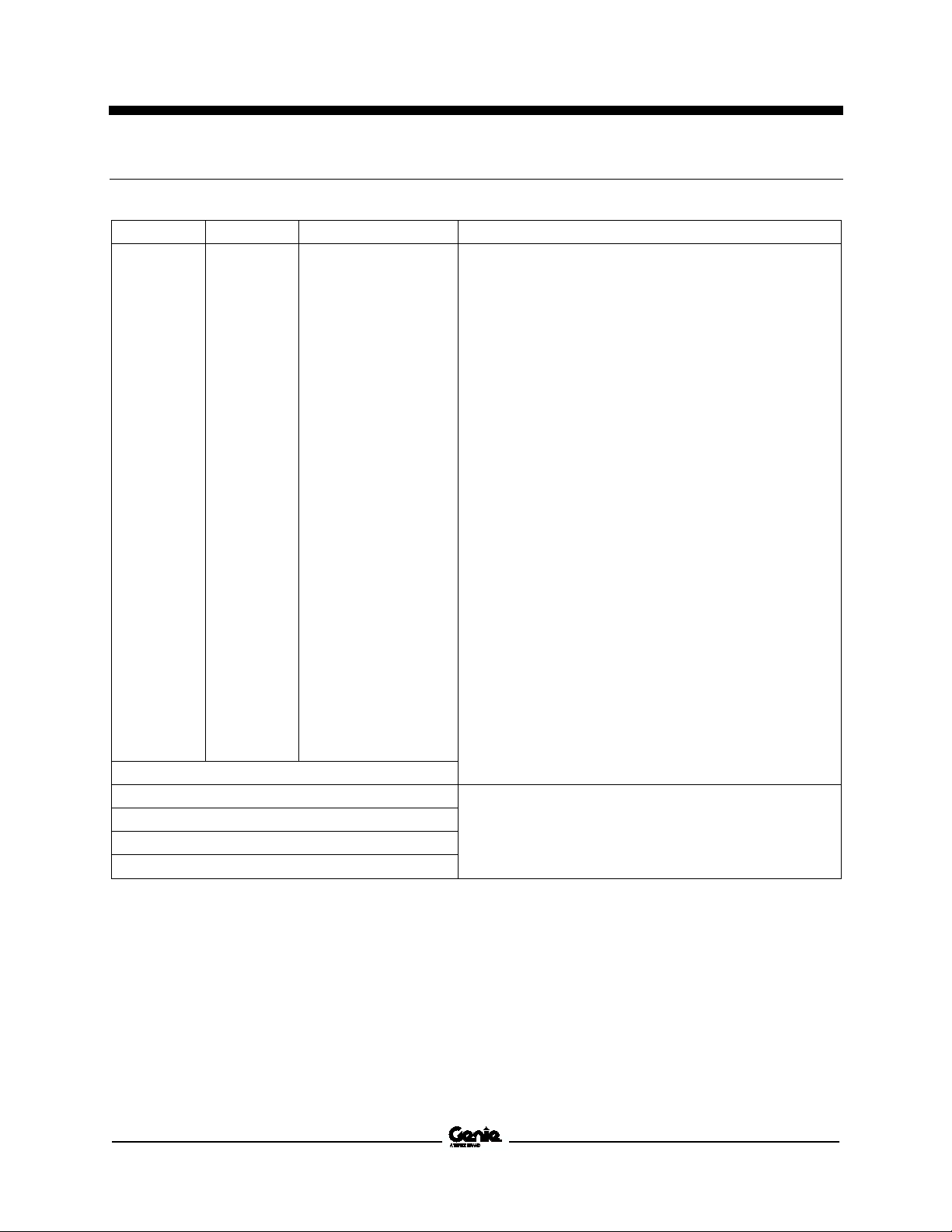

AWP30S, 36S and 40S Spec ific ati ons

AWP-

AWP-

73.6

AWP-

247.5 x 227.2

29

94.1 /

128.8 / 73

*Corner of platform top rail to corner of wall with ability to rotate the leveling jack.

- all models

30 x 28 x 44 ¾ in

76 x 71 x 114 cm

18 AWP Super Series • IWP Super Series Part No. 38139

September 2016 Service Manual

Model

15S

20S

25S

30S

Narrow Base

Machine weight

(DC / AC and Air models)

711 / 621 lbs

322 / 282 kg

745 / 655 lbs

338 / 297 kg

780 / 690 lbs

353 / 313 kg

814 / 724 lbs

369 / 328 kg

Height, stowed 78 in

198 cm

78 in

198 cm

78 in

198 cm

78 in

198 cm

Width

22 in

55.8 cm

22 in

55.8 cm

22 in

55.8 cm

22 in

55.8 cm

Length

49 ½ in

125.7 cm

49 ½ in

125.7 cm

49 ½ in

125.7 cm

49 ½ in

125.7 cm

Outrigger footprint

(l x w) Domestic

64 x 48 ¼ in

162.5 x 122.5 cm

64 x 48 ¼ in

162.5 x 122.5 cm

64 x 48 ¼ in

162.5 x 122.5 cm

71 ½ x 58 in

181.6 x 147.3 cm

Outrigger

(l x w) CSA

71 ½ x 58 in

181.6 x 147.3 cm

74 ½ x 65 ½ in

189.2 x 166.3 cm

83 ¼ x 74 in

211.4 x 187.9 cm

95 ¼ x 89 ¾ in

241.9 x 227.9 cm

Outrigger footprint

(l x w) CE Indoor

64 x 48 ¼ in

162.5 x 122.5 cm

71 ¼ x 58 in

181.6 x 147.3 cm

in

181.6 x 147.3 cm

74 ½ x 65 ½ in

189.2 x 166.3 cm

Outrigger footprint*

(l x w) CE Outdoor

83 ¼ x 74 in

211.4 x 187.9 cm

83 ¼ x 74 in

211.4 x 187.9 cm

95 ¼ x 89 ¾ in

241.9 x 227.9 cm

112 x 112 in

284.4 x 284.4 cm

Corner access/wall access*

Domestic

40.6 / 27.9 cm

14 ¼ / 8 ½ in

36.2 / 7.4 cm

13 / 6 in

33 / 15.2 cm

18 ½ / 7 ¼ in

47 / 18.4 cm

Corner access/wall access*

CSA

22 ½ / 14 ¾ in

57.1 / 37.5 cm

24 ½ / 14 in

62.2 / 35.5 cm

28 ¾ / 15 in

73 / 38.1 cm

37 ½ / 18 ½ in

95.2 / 47 cm

Corner acce

CE Indoor

16 / 11 in

40.6 / 27.9 cm

21 / 12 ¼ in

53.3 / 31.1 cm

19 ½ / 9 ¾ in

49.5 / 24.7 cm

22 / 9 in

55.8 / 22.8 cm

Corner access/wall access*

CE Outdoor

31 ½ / 20 ¼ in

80 / 50.8 cm

30 / 17 ½ in

76.2 / 44.4 cm

38 ¾ / 21 in

98.4 / 53.3 cm

51 / 26 ½ in

129.5 / 67.3 cm

Platform Dimensions

Gated ultra

(L x W x H)

22 x 18 x 44 ¾ in

56 x 46 x 114 cm

Narrow fiber platform

(L x W x H)

26 x 22 x 43 ½ in

66 x 56 x 110 cm

Gated narrow platform

(L x W x H)

26 x 20 x 44 ¾ in

66 x 51 x 14 cm

Specifications

AWP Narrow Base Sp ecific atio ns

AWP-

footprint

16 / 11 in

ss/wall access*

*Corner of platform top rail to corner of wall with ability to rotate the leveling jack.

AWP-

AWP-

71 ¼ x 58

AWP-

Part No. 38139 AWP Super Series • IWP Super Series 19

-narrow platform

Service Manual September 2016

Model

15S

20S

25S

30S

Rough Terrain Base

Machine weight

(DC / AC and Air models)

625 lbs

324.5 / 283.7 kg

750 / 660 lbs

339.7 / 298.9 kg

784 / 694 lbs

355.3 / 314.6 kg

819 / 729 lbs

371 / 330.2 kg

Height, stowed 79 in

201 cm

79 in

201 cm

79 in

201 cm

79 in

201 cm

Width

29 ½ in

75 cm

29 ½ in

75 cm

29 ½ in

75 cm

29 ½ in

75 cm

Length

58 in

147 cm

58 in

147 cm

58 in

147 cm

58 in

147 cm

Outrigger footprint

(l x w) Domestic

64 x 48 ¼ in

162.5 x 122.5 cm

64 x 48 ¼ in

162.5 x 122.5 cm

64 x 48 ¼ in

162.5 x 122.5 cm

71 ½ x 58 in

181.6 x 147.3 cm

Outrigger footprint

(l x w) CSA

71 ½ x 58 in

181.6 x 147.3 cm

74 ½ x 65 ½ in

189.2 x 166.3 cm

83 ¼ x 74 in

211.4 x 187.9 cm

95 ¼ x 89 ¾ in

241.9 x 227.9 cm

Outrigger footprint

(l x w) CE Indoor

64 x 48 ¼ in

162.5 x 122.5 cm

71 ¼ x 58 in

181.6 x 147.3 cm

71 ¼ x 58 in

181.6 x 147.3 cm

74 ½ x 65 ½ in

189.2 x 166.3 cm

Outrigger footprint*

(l x w) CE Outdoor

83 ¼ x 74 in

211.4 x 187.9 cm

83 ¼ x 74 in

211.4 x 187.9 cm

95 ¼ x 89 ¾ in

241.9 x 227.9 cm

112 x 112 in

284.4 x 284.4 cm

Corner access/wall access*

Domestic

16 / 11 in

40.6 / 27.9 cm

14 ¼ / 8 ½ in

36.2 / 7.4 cm

13 / 6 in

33 / 15.2 cm

18 ½ / 7 ¼ in

47 / 18.4 cm

Corner access/wall access*

CSA

22 ½ / 14 ¾ in

57.1 / 37.5 cm

24 ½ / 14 in

62.2 / 35.5 cm

28 ¾ / 15 in

73 / 38.1 cm

37 ½ / 18 ½ in

95.2 / 47 cm

Corner access/wall access*

CE Indoor

in

40.6 / 27.9 cm

21 / 12 ¼ in

53.3 / 31.1 cm

19 ½ / 9 ¾ in

49.5 / 24.7 cm

22 / 9 in

55.8 / 22.8 cm

Corner access/wall access*

CE Outdoor

31 ½ / 20 ¼ in

80 / 50.8 cm

30 / 17 ½ in

76.2 / 44.4 cm

38 ¾ / 21 in

98.4 / 53.3 cm

51 / 26 ½ in

129.5 / 67.3 cm

Platform Dimensions

Standard platform

(L x W x H) gated or sliding mid

27 x 26 x 44 ¾ in

69 x 66 x 114 cm

Narrow fiber platform

(L x W x H)

in

Gated ultra

(L x W x H)

22 x 18 x 44 ¾ in

56 x 46 x 114 cm

Front and side entry platform

(L x W x H)

Gated narrow platform

(L x W x H)

26 x 20 x 44 ¾ in

66 x 51 x 14 cm

Extra large

(L x W x H)

Standard fiber platform

(L x W x H)

29 x 26 ½ x 43 ½ in

74 x 67 x 110 cm

Specifications

AWP Rough T errai n B ase Speci fic ation s

AWP-

715 /

16 / 11

*Corner of platform top rail to corner of wall with ability to rotate the leveling jack.

AWP-

AWP-

AWP-

20 AWP Super Series • IWP Super Series Part No. 38139

-narrow platform

-rail

platform

26 x 22 x 43 ½

66 x 56 x 110 cm

30 x 28 x 44 ¾ in

76 x 71 x 114 cm

30 x 28 x 44 ¾ in

76 x 71 x 114 cm

September 2016 Service Manual

Model

20S

25S

30S

Height, working maximum

26 ft 5 in

8.1 m

30 ft 5 in

9.3 m

35 ft 6 in

10.8 m

Height, platform maximum

20 ft 5 in

6.2 m

24 ft 5 in

7.4 m

29 ft 6 in

9.0 m

Lift capacity

350 lbs

159 kg

350 lbs

159 kg

350 lbs

159 kg

Lift capacity

with outreach option

300 lbs

136 kg

--

--

--

--

Machine weight

(DC / AC models)

1245 / 1345 lbs

565 / 610 kg

1290 / 1390 lbs

585 / 630 kg

1290 / 1390 lbs

585 / 630 kg

Height, stowed

base fully lowered/base raised

76 in / 78 in

198 cm / 203 cm

76 in / 78 in

198 cm / 203 cm

76 in / 78 in

198 cm / 203 cm

Width

32 in

81 cm

32 in

81 cm

--

--

Length

60 in

152 cm

60 in

152 cm

--

--

Width

--

--

--

--

40 in

102 cm

Length

--

--

--

--

60 in

152.4 cm

Platform length

27 in

69 cm

27 in

69 cm

27 in

69 cm

Platform width

26 in

66 cm

26 in

66 cm

26 in

cm

Platform height 44 ¾ in

114 cm

44 ¾ in

114 cm

44 ¾ in

114 cm

Corner access

6 in

15 cm

6 in

15 cm

6 in

15 cm

Specifications

IWP Specific ati ons

IWP-

- Standard Base

- Standard base

- Wide Base

IWP-

IWP-

- Wide Base

66

Part No. 38139 AWP Super Series • IWP Super Series 21

Service Manual September 2016

Platform function speed, maximum

AWP

and 30S

AC

DC

Platform up

40 seconds

30 seconds

Platform down

28 seconds

28 seconds

AWP-36S

AC

DC

Platform up

40 seconds

52 seconds

Platform down

42 seconds

42 seconds

AWP-40S

AC

DC

Platform up

65 seconds

48 seconds

Platform down

38 seconds

38 seconds

IWP - All models

AC

DC

Platform up

40 seconds

30 seconds

Platform down

28 seconds

28 seconds

Power Source AWP Models

DC models

12V

AC model

110V or 220V

Air model

100 psi / 6.9 bar

Power Source IWP Models

DC models

12V

AC model

110V or 220V

Ambient Operating Temperature

-

-

Hydraulic System

Hydraulic fluid

Chevron Rando HD equivalant

Hydraulic tank capacity

all models

3 quarts

2.8 liters

Hydraulic System Pressure

All models

1600 psi

110 bar

Hydraulic system capacity (includes tank)

IWP

3.7 quarts

3.5 liters

IWP

3.7 quarts

3.5 liters

IWP

3.7 quarts

3.5 liters

AWP

3.7 quarts

3.5 liters

AWP

3.7 quarts

3.5 liters

AWP

3.7 quarts

3.5 liters

AWP

3.7 quarts

3.5 liters

AWP

4.0 quarts

3.8 liters

AWP

3.9 quarts

3.7 liters

Specifications

AWP/IWP Per form anc e a nd Hydr auli c S peci fica tio ns

-15S, 20S, 25S

-

-20S

-25S

-30S

-15S

-20S

-25S

-30S

-36S

-40S

20°F to 135°F

29°C to 57°C

22 AWP Super Series • IWP Super Series Part No. 38139

September 2016 Service Manual

Specifications

Hydraulic H ose a nd Fi tti ng T orque Sp ecifi cati ons

Hydraulic Hose and Fitting

Torque Specifications

Your machine is equipped with Parker Seal-Lok™

ORFS or 37° JIC fittings and hose ends. Genie

specifications require that fittings and hose ends be

torqued to specification when they are removed

and installed or when new hoses or fittings are

installed.

Seal-Lok™ Fittings

(hose end - ORFS)

SAE Dash Size Torque

-4 10 ft-lbs / 13.6 Nm

-6 30 ft-lbs / 40.7 Nm

-8 40 ft-lbs / 54.2 Nm

-10 60 ft-lbs / 81.3 Nm

-12 85 ft-lbs / 115 Nm

-16 110 ft-lbs / 150 Nm

-20 140 ft-lbs / 190 Nm

-24 180 ft-lbs / 245 Nm

SAE O-ring Boss Port

(tube fitting - installed into Aluminum)

(all types)

SAE Dash Size Torque

-4 14 ft-lbs / 19 Nm

-6 23 ft-lbs / 31.2 Nm

-8 36 ft-lbs / 54.2 Nm

-10 62 ft-lbs / 84 Nm

-12 84 ft-lbs / 114 Nm

-16 125 ft-lbs / 169.5 Nm

-20 151 ft-lbs / 204.7 Nm

-24 184 ft-lbs / 249.5 Nm

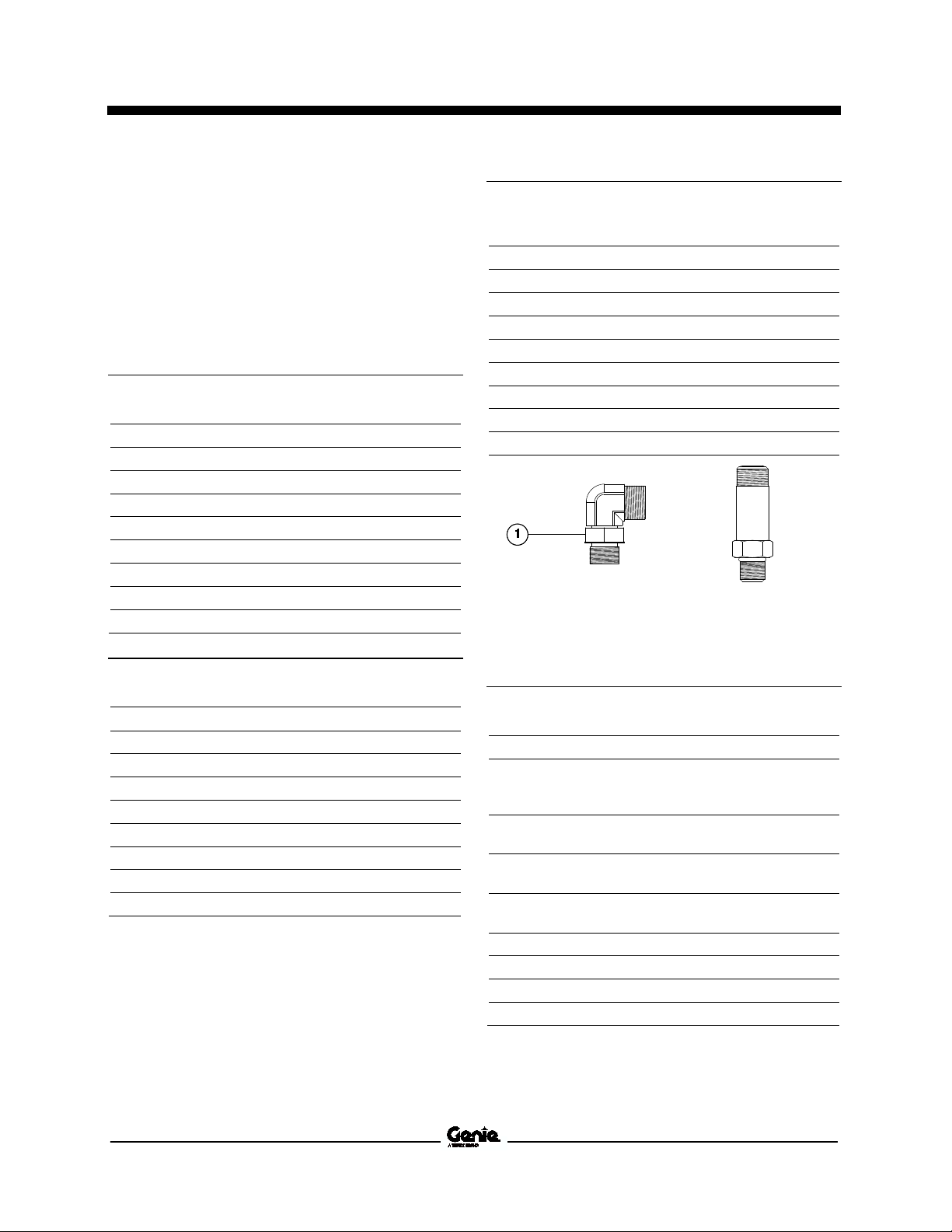

Adjustable Fitting Non-adjustable fitting

1 jam nut

JIC 37° Fittings

(swivel nut or hose connection)

SAE Dash Size Thread Size Flats

-4 7/16-20 2

-6 9/16-18 1 ¼

-8 3/4-16 1

-10 7/8-14 1

-12 1 1/16-12 1

-16 1 5/16-12 1

-20 1 5/8-12 1

-24 1 7/8-12 1

SAE O-ring Boss Port

(tube fitting - installed into Steel)

SAE Dash Size Torque

-4 ORFS / 37° (Adj)

ORFS (Non-adj)

37° (Non-adj)

-6 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-8 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-10 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-12 (All types) 135 ft-lbs / 183 Nm

-16 (All types) 200 ft-lbs / 271.2 Nm

-20 (All types) 250 ft-lbs / 339 Nm

-24 (All types) 305 ft-lbs / 413.5 Nm

15 ft-lbs / 20.3 Nm

26 ft-lbs / 35.3 Nm

22 ft-lbs / 30 Nm

35 ft-lbs / 47.5 Nm

29 ft-lbs / 39.3 Nm

60 ft-lbs / 81.3 Nm

52 ft-lbs / 70.5 Nm

100 ft-lbs / 135.6 Nm

85 ft-lbs / 115.3 Nm

Part No. 38139 AWP Super Series • IWP Super Series 23

Service Manual September 2016

Specifications

Torque Proce dur e

Torque Procedure

Seal-Lok™ fittings

1 Replace the O-ring. The O-ring must be

replaced anytime the seal has been broken.

The O-ring cannot be re-used if the fitting or

hose end has been tightened beyond finger

tight.

Note: The O-ring in Parker Seal Lok™ fittings and

hose end are custom-size O-rings. They are not

standard size O-rings. They are available in the

O-ring field service kit (Genie part number 49612).

2 Lubricate the O-ring before installation.

3 Be sure the O-ring face seal is seated and

retained properly.

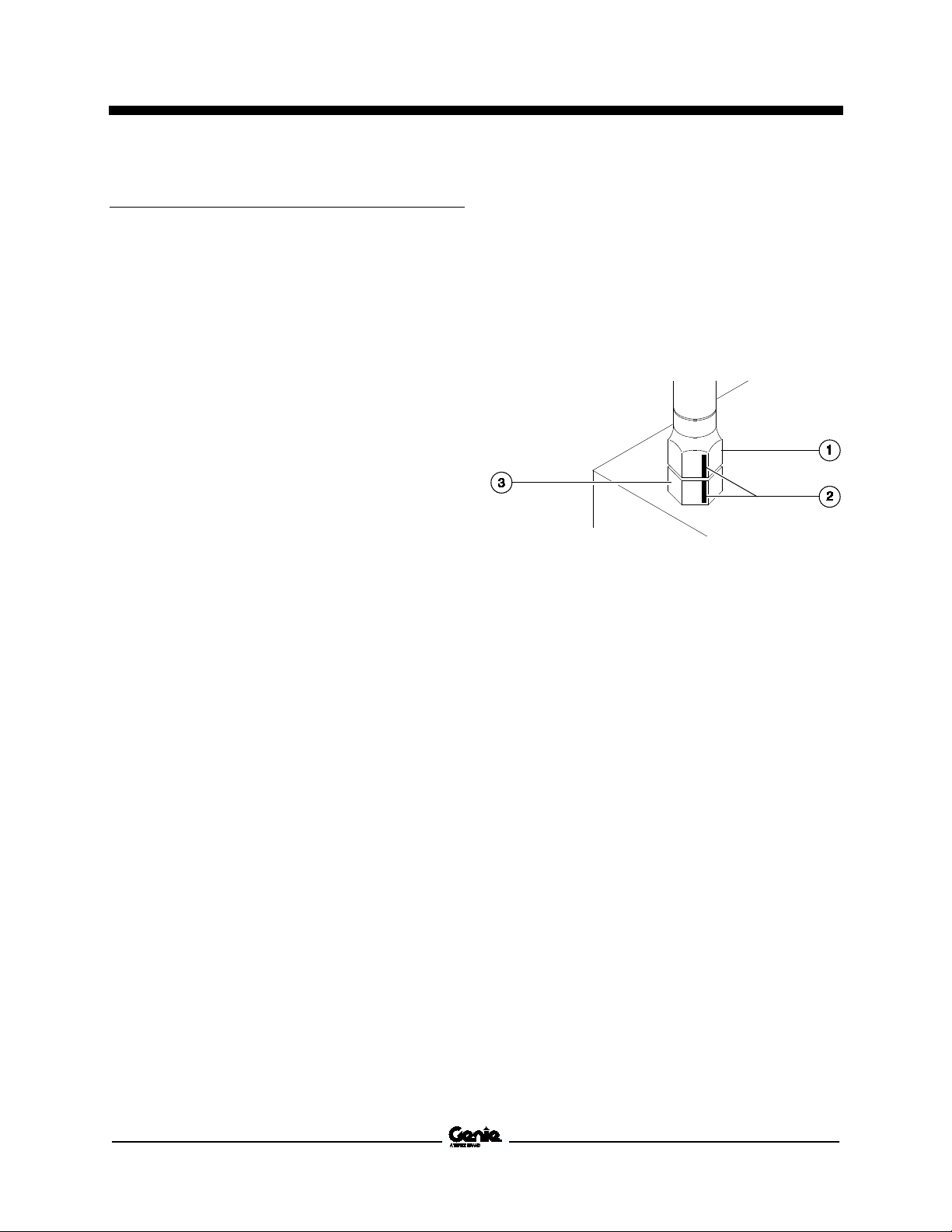

JIC 37° fittings

1 Align the tube flare (hex nut) against the nose

of the fitting body (body hex fitting) and tighten

the hex nut to the body hex fitting to hand tight,

approximately 30 in-lbs / 3.4 Nm.

2 Using a permanent ink marker, make a

reference mark on one the flats of the hex nut

and continue the mark onto the body of the

hex fitting. Refer to Illustration 1.

4 Position the tube and nut squarely on the face

seal end of the fitting, and tighten the nut

finger tight.

5 Tighten the nut or fitting to the appropriate

torque. Refer to the appropriate torque chart in

this section.

6 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

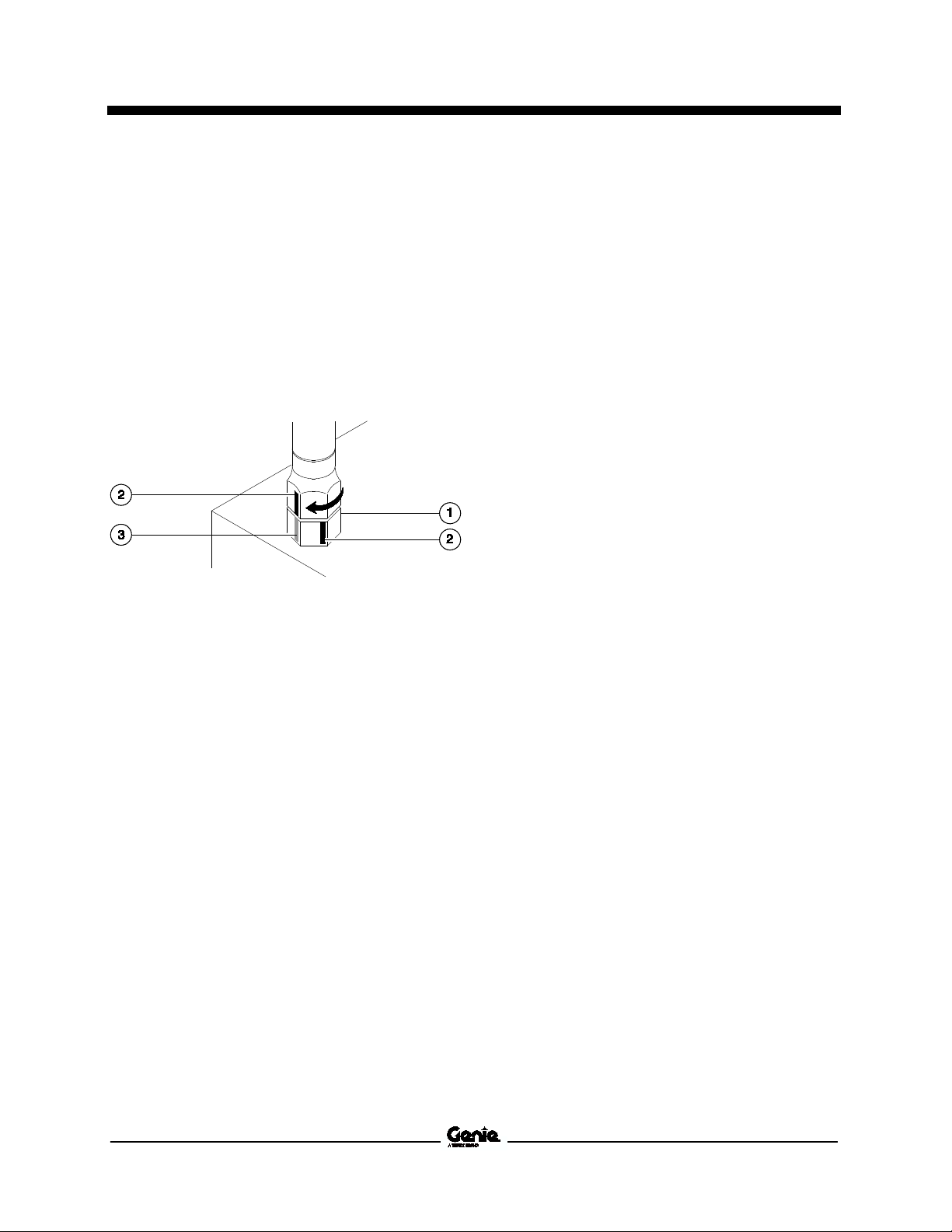

Illustration 1

1 hex nut

2 reference mark

3 body hex fitting

24 AWP Super Series • IWP Super Series Part No. 38139

September 2016 Service Manual

Specifications

3 Working clockwise on the body hex fitting,

make a second mark with a permanent ink

marker to indicate the proper tightening

position. Refer to Illustration 2.

Note: Use the JIC 37° Fitting table in this section to

determine the correct number of flats, for the

proper tightening position.

Note: The marks indicate the correct tightening

positions have been determined. Use the second

mark on the body hex fitting to properly tighten the

joint after it has been loosened.

Illustration 2

1 body hex fitting

2 reference mark

3 second mark

4 Tighten the hex nut until the mark on the hex

nut is aligned with the second mark on the

body hex fitting.

5 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

Part No. 38139 AWP Super Series • IWP Super Series 25

Service Manual September 2016

Specifications

SAE and Metr ic F aste ners Tor que C har ts

26 AWP Super Series • IWP Super Series Part No. 38139

September 2016 Service Manual

Failure to perform each

procedure as presented and

scheduled may cause death,

serious injury or substantial

damage.

Scheduled Maintenance Procedures

Section 3 Scheduled M aint ena nce Pr oce dur es

Introducti on

Observe and Obey:

Maintenance inspections shall be completed

by a person trained and qualified on the

maintenance of this machine.

Scheduled maintenance inspections shall be

completed daily, quarterly, and annually as

specified on the Maintenance inspection

Report. The frequency and extent of periodic

examinations and tests may also depend on

national regulations.

Machine Configuration:

Unless otherwise specified, perform each

procedure with the machine in the following

configuration:

• Machine parked on a firm, level surface

• Key switch in the off position with the key

removed

• The red Emergency Stop button in the off

position at both the ground and platform

controls

• Wheels chocked

• All external AC power supply disconnected

from the machine

• Platform in the stowed position

Immediately tag and remove from service a

damaged or malfunctioning machine.

Repair any machine damage or malfunction

before operating the machine.

Use only Genie approved replacement parts.

Machines that have been out of service for a

period longer than 3 months must complete the

quarterly inspection.

Part No. 38139 AWP Super Series • IWP Super Series 27

Service Manual September 2016

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Indicates a imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Indicates that tools will be required to

perform this procedure.

Indicates that new parts will be required to

perform this procedure.

Indicates that dealer service will be

required to perform this procedure.

Indicates that a cold motor or pump will be

required to perform this procedure.

Scheduled Maintenance Procedures

About This Section

This section contains detailed procedures for each

scheduled maintenance inspection.

Each procedure includes a description, safety

warnings and step-by-step instructions.

Maintenance Symbols Legend

Note: The following symbols have been used in this

manual to help communicate the intent of the

instructions. When one or more of the symbols

appear at the beginning of a maintenance

procedure, it conveys the meaning below.

Symbols Legend

or moderate

Indicates that a specific result is expected

after performing a series of steps.

Indicates that an incorrect result has occurred

after performing a series of steps.

28 AWP Super Series • IWP Super Series Part No. 38139

September 2016 Service Manual

Inspection Checklist

Daily or every 8 hours A

Quarterly or every 250 hours

A + B

Annually or every 1000 hours

A + B + C

Scheduled Maintenance Procedures

Pre-delivery Preparation Report

The pre-delivery preparation report contains

checklists for each type of scheduled inspection.

Make copies for each inspection. Store completed

forms as required.

Maintenance Schedule

The Scheduled Maintenance Procedures section

and the Maintenance Inspection Report have been

divided into subsections. Use the following chart to

determine which group(s) of procedures are

required to perform a scheduled inspection.

Maintenance Inspection Report

The maintenance inspection report contains

checklists for each type of scheduled inspection.

Make copies of the Maintenance Inspection Report

to use for each inspection. Maintain completed

forms for a minimum of 4 years or in compliance

with your employer, jobsite and governmental

regulations and requirements.

Part No. 38139 AWP Super Series • IWP Super Series 29

Service Manual September 2016

This page intentionally left blank.

30 AWP Super Series • IWP Super Series Part No. 38139

Loading...

Loading...