Page 1

Page 2

Operator’s Manual First Edition • Ninth Printing

Important

Read, understand and obey these safety rules and

operating instructions before operating this machine.

Only trained and authorized personnel shall be

permitted to operate this machine. This manual should

be considered a permanent part of your machine and

should remain with the machine at all times. If you

have any questions, call Genie.

Contents

Page

Safety Rules .............................................................. 1

Controls ..................................................................... 8

Legend ....................................................................... 9

Pre-operation Inspection ........................................... 10

Maintenance ............................................................. 12

Function Tests.......................................................... 15

Workplace Inspection................................................ 18

Operating Instructions............................................... 19

Battery Charging Instructions.................................... 21

Transport Instructions ............................................... 22

Tilt-back Operation Instructions ................................ 25

Decals ...................................................................... 29

Specifications ........................................................... 31

Contact us:

Internet: http://www.genielift.com

e-mail: awp.techpub@terex.com

Copyright © 1996 by Genie Industries

First Edition: Ninth Printing, September 2014

"Genie" and "AWP" are registered trademarks

of Genie Industries in the U.S.A. and many other

countries. "Super Series" is a trademark of Genie

Industries.

This machine complies with

ANSI/SIA 92.3-1990.

Printed on recycled paper

Printed in U.S.A.

Genie AWP Super Series Part No. 37168

Page 3

Operator’s ManualFirst Edition • Ninth Printing

Safety Rules

Danger

Failure to obey the instructions and

safety rules in this manual will

cause death or serious injury.

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator's

manual.

1 Avoid hazardous situations.

Know and understand the safety rules before

going on to the next section.

2 Always perform a pre-operation inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

You read, understand and obey:

- manufacturer’s instructions and

safety rules—operator’s manual and

machine decals

- employer’s safety rules and worksite

regulations

- applicable governmental regulations

You are properly trained to safely operate the

machine.

Part No. 37168 Genie AWP Super Series 1

The first time this machine is set up for use, a

breather cap is installed. See Pre-operation

Inspection section.

Page 4

Operator’s Manual First Edition • Ninth Printing

SAFETY RULES

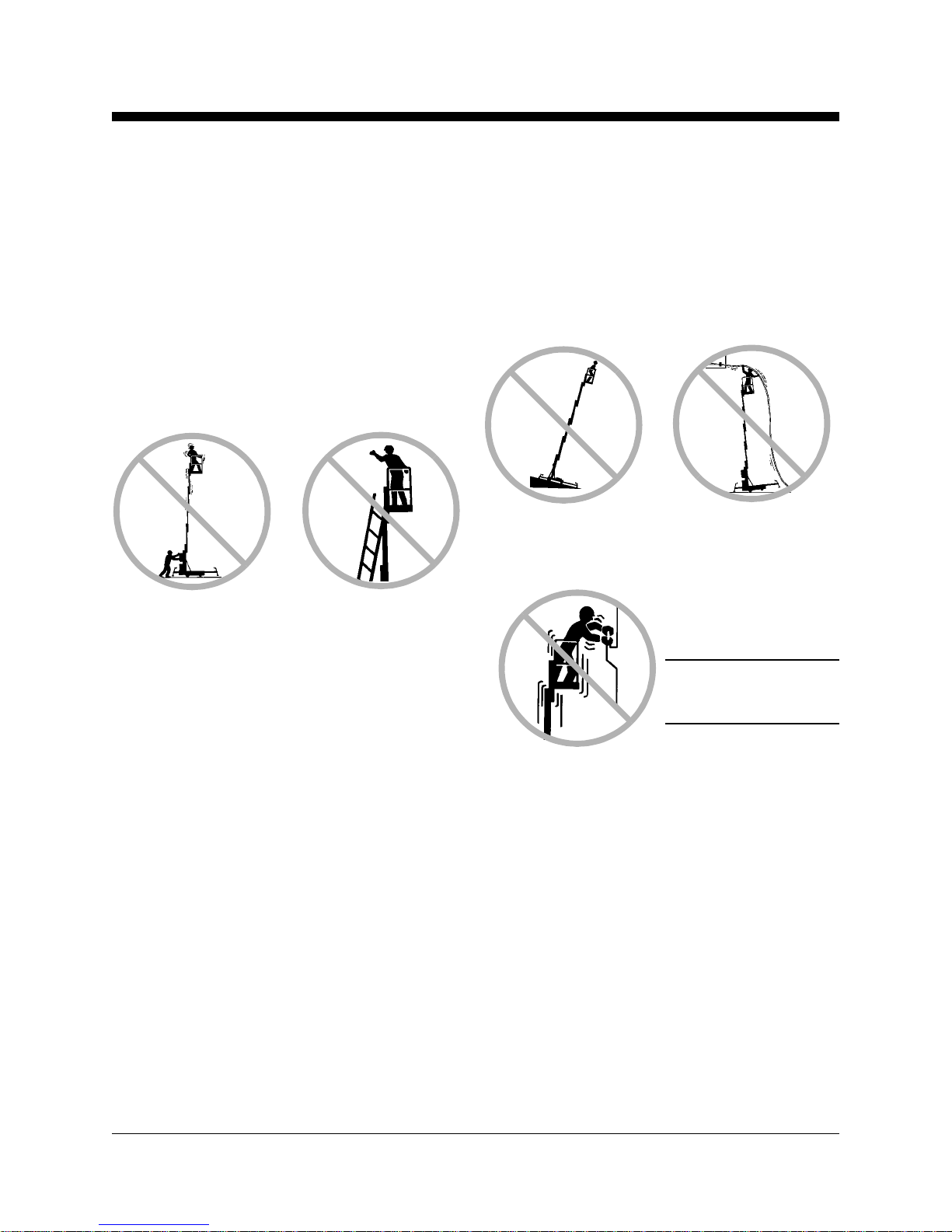

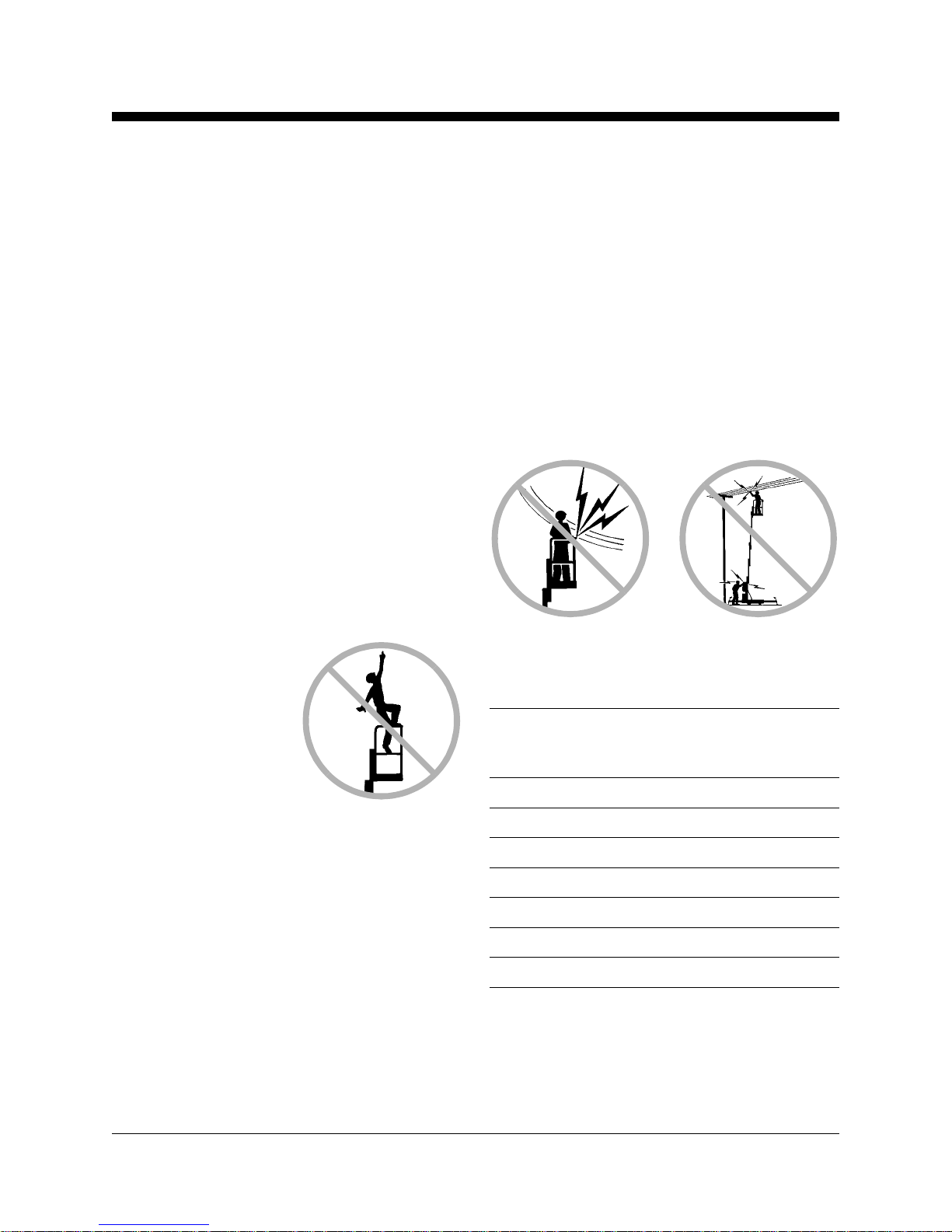

Tip-over Hazards

Do not raise the platform unless the base is level,

all four outriggers are properly installed and the

leveling jacks firmly contact the floor.

Do not adjust or remove the outriggers while the

platform is occupied or raised.

Do not move the machine while the platform is

raised.

Do not place ladders or scaffolds in the platform or

against any part of this machine.

Do not place or attach overhanging loads to any

part of this machine.

Do not raise the platform unless the machine is

level. Do not set the machine up on a surface

where it cannot be leveled using only the leveling

jacks. Do not use chocks, blocks or shims of any

kind to level the machine.

Do not cause a horizontal force or side load to the

machine by raising or lowering a fixed or

overhanging load.

Do not push off or pull

toward any object outside

the platform.

Maximum allowable

manual force

45 lbs 200 N

Do not use the machine on a moving or mobile

surface or vehicle.

2 Genie AWP Super Series Part No. 37168

Page 5

Operator’s ManualFirst Edition • Ninth Printing

SAFETY RULES

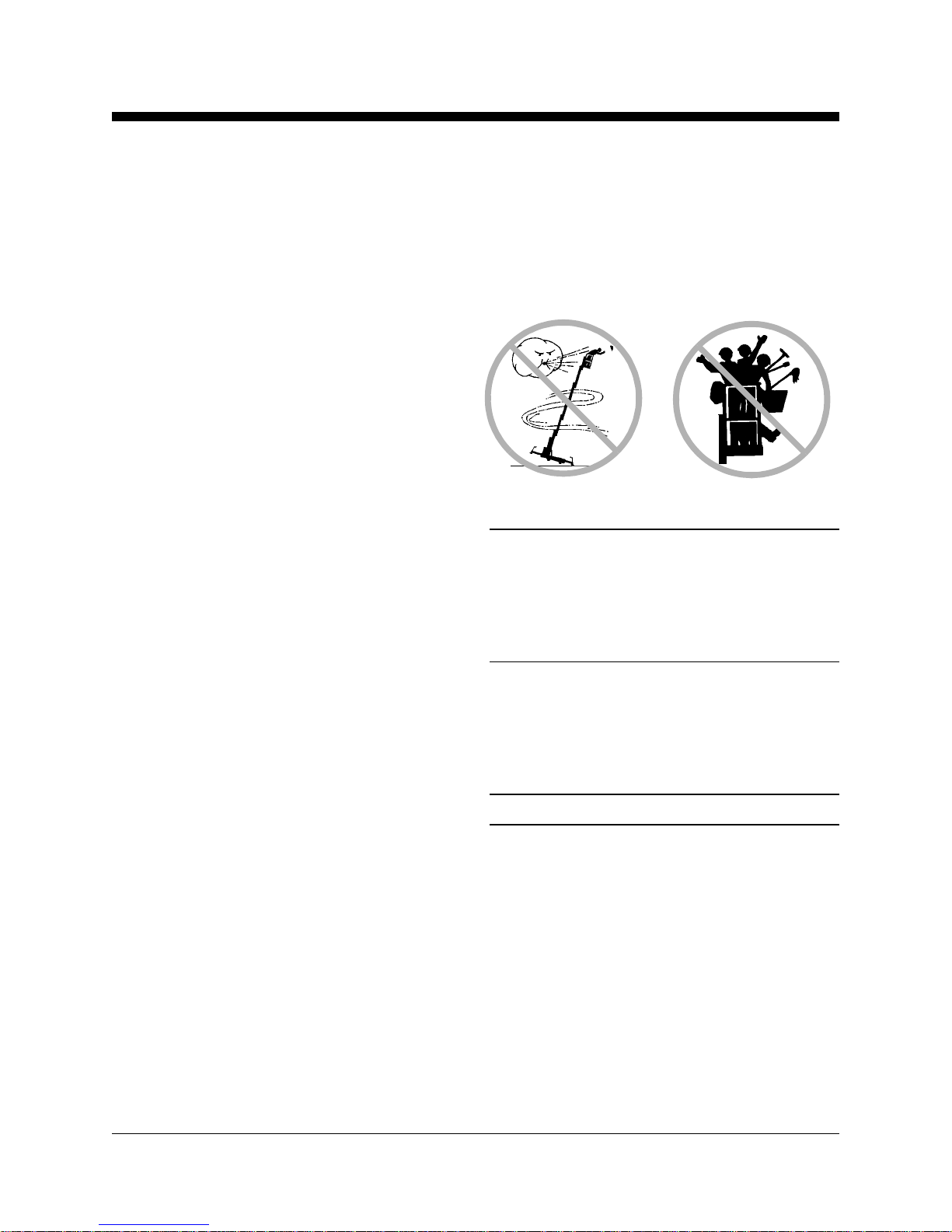

ANSI / CSA models: Do not raise the platform

when wind speeds may exceed 28 mph / 12.5 m/s.

If wind speeds exceed 28 mph / 12.5 m/s when

platform is raised, lower the platform and do not

continue to operate the machine.

CE/AUS standard base models with outdoor

outriggers: Do not raise the platform when wind

speeds may exceed 28 mph / 12.5 m/s. If wind

speeds exceed 28 mph / 12.5 m/s when platform is

raised, lower the platform and do not continue to

operate the machine.

CE/AUS standard base models with indoor

outriggers: Indoor use only. Do not raise the

platform when wind speeds may exceed 0 mph / 0

m/s. If wind speeds exceed 0 mph / 0 m/s when

platform is raised, lower the platform and do not

continue to operate the machine.

CE/AUS Narrow or RT base models: Indoor use

only. Do not raise the platform when wind speeds

may exceed 0 mph / 0 m/s. If wind speeds exceed

0 mph / 0 m/s when platform is raised, lower the

platform and do not continue to operate the

machine.

Do not operate the machine in strong or gusty

winds. Do not increase the surface area of the

platform or the load. Increasing the area exposed to

the wind will decrease machine stability.

Do not exceed the rated platform load capacity.

Maximum capacity (all models except Canada)

AWP-15S 350 lbs 159 kg

AWP-20S 350 lbs 159 kg

AWP-25S 350 lbs 159 kg

AWP-30S 350 lbs 159 kg

AWP-36S 350 lbs 159 kg

AWP-40S 300 lbs 136 kg

Maximum capacity (models sold in Canada only)

AWP-15S 300 lbs 136 kg

AWP-20S 300 lbs 136 kg

AWP-25S 300 lbs 136 kg

AWP-30S 300 lbs 136 kg

AWP-36S 300 lbs 136 kg

AWP-40S 300 lbs 136 kg

Part No. 37168 Genie AWP Super Series 3

Maximum occupancy 1 person

Page 6

Operator’s Manual First Edition • Ninth Printing

SAFETY RULES

Do not operate the machine near drop-offs, holes,

bumps, debris, unstable or slippery surfaces or

other possible hazardous conditions.

Do not alter or disable machine components that in

any way affect safety and stability.

Do not replace items critical to stability with items

of different weight or specification. Use only Genie

authorized replacement parts.

Do not push the Genie AWP from the platform side

of the machine.

When moving the machine with a forklift or other

transport vehicle, the platform should be fully

lowered, the machine should be turned off and no

personnel shall remain in the platform.

Do not use the machine to lift material or

equipment. The machine is intended to lift

personnel and tools to an aerial work site.

Fall Hazards

Do not sit, stand or climb

on the platform guard rails.

Maintain a firm footing on

the platform floor at all

times.

Do not exit the platform

while raised. If a power

failure occurs, have ground

personnel activate the manual lowering valve.

Electrocution Hazards

This machine, even with an optional fiberglass

platform, is not electrically insulated and will not

provide protection from contact with or proximity to

electrical current.

Keep away from the machine if it contacts

energized power lines or becomes electrically

charged. Personnel on the ground or in the platform

must not touch or operate the machine until

energized power lines are shut off.

Maintain safe distances from electrical power lines

and apparatus in accordance with applicable

governmental regulations and the following chart.

Minimum Safe

Voltage Approach Distance

Phase to Phase Feet Meters

0 to 300V Avoid Contact

300V to 50KV 10 3.05

Keep the platform floor clear of debris.

Lower the platform entry mid-rail or gate before

operating.

4 Genie AWP Super Series Part No. 37168

50KV to 200KV 15 4.60

200KV to 350KV 20 6.10

350KV to 500KV 25 7.62

500KV to 750KV 35 10.67

750KV to 1000KV 45 13.72

Page 7

Operator’s ManualFirst Edition • Ninth Printing

SAFETY RULES

Allow for platform movement, electrical line sway

or sag and movement due to strong or gusty winds.

Do not use the machine as a ground for welding.

Do not operate an AC powered machine or a DC

battery charger unless using a 3-wire grounded

extension cord connected to a grounded AC circuit.

Do not alter or disable 3-wire grounded plugs.

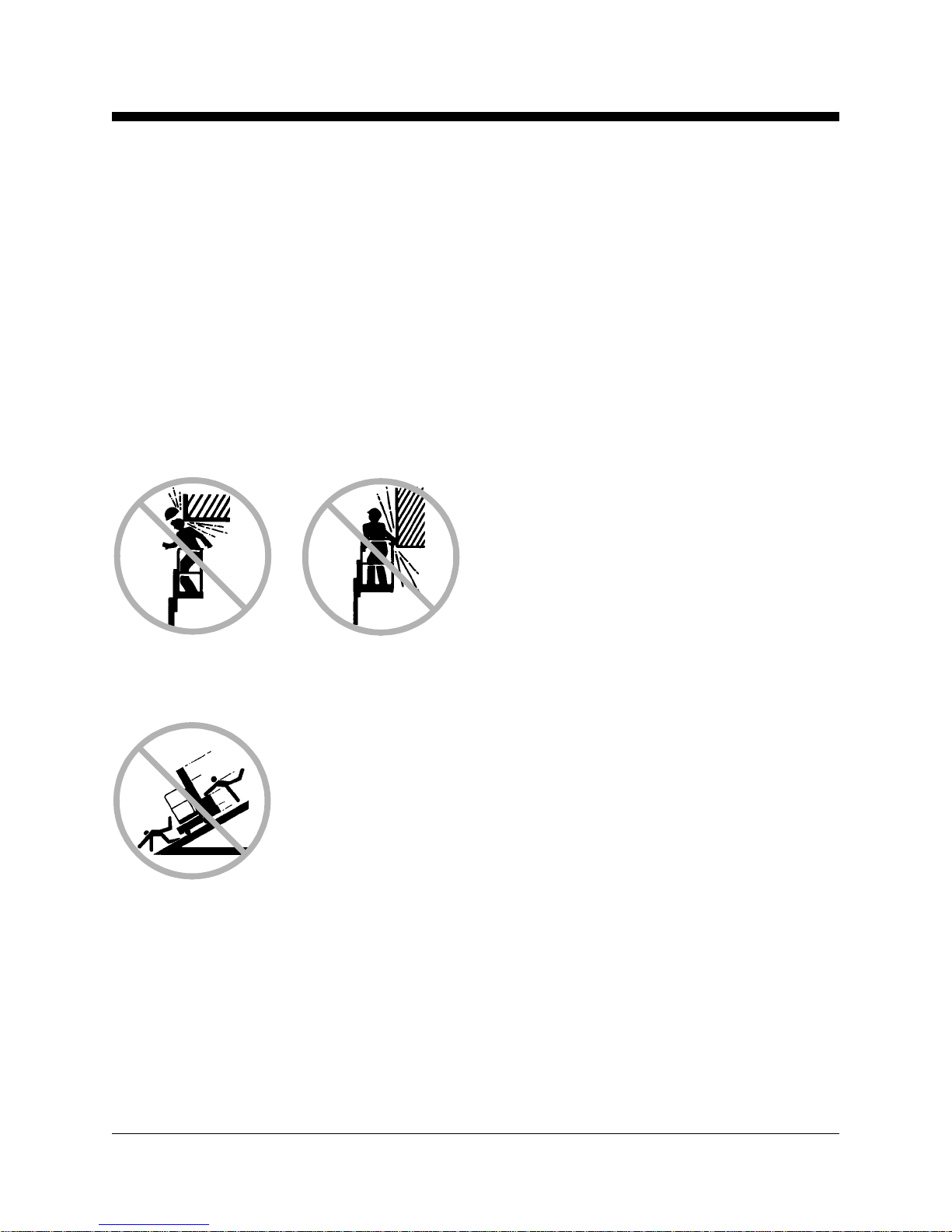

Collision Hazards

Check the work area for overhead obstructions or

other possible hazards.

Be aware of crushing hazard when grasping the

platform guard rail.

Do not lower the platform

unless the area below is

clear of personnel and

obstructions.

Improper Use Hazard

Do not leave the machine unattended unless the

key is removed to secure from unauthorized use.

Bodily Injury Hazard

Do not operate the machine with a hydraulic oil or

air leak. An air leak or hydraulic leak can penetrate

and/or burn skin.

Damaged Machine Hazards

Do not use a damaged or malfunctioning machine.

Be sure all maintenance has been performed

as specified in this manual and the Genie AWP

Super Series service manual.

Be sure all decals are in place and legible.

Be sure the operator’s, safety and responsibilities

manuals are complete, legible and in the storage

container located on the platform.

Conduct a thorough pre-operation inspection of the

machine and test all functions before each

work shift. Immediately tag and remove from

service a damaged or malfunctioning machine.

Do not use the machine as a ground for welding.

Use common sense and

planning to control the

movement of the machine

on or near inclines.

Stay clear of descending

platform.

Part No. 37168 Genie AWP Super Series 5

Page 8

Operator’s Manual First Edition • Ninth Printing

SAFETY RULES

Battery and Charger Safety

- DC Models

Burn Hazards

Batteries contain acid. Always wear protective

clothing and eyewear when working with batteries.

Avoid spilling or contacting

battery acid. Neutralize

battery acid spills with

baking soda and water.

The battery pack must

remain in an upright

position.

Explosion Hazards

Electrocution Hazards

Connect the charger to a

grounded AC circuit only.

Do not expose the battery

or charger to water and/or

rain.

Before each use, inspect

for damage. Replace

damaged components

before operating.

Lifting Hazard

The battery pack weighs 90 lbs / 40.8 kg. Use the

appropriate number of people and proper lifting

techniques when lifting the battery pack.

Batteries emit explosive

gas. Keep sparks, flames

and lighted tobacco away

from the battery.

Charge the battery in a wellventilated area.

Do not disconnect charger DC output wires from the

battery when the charger is on.

6 Genie AWP Super Series Part No. 37168

Page 9

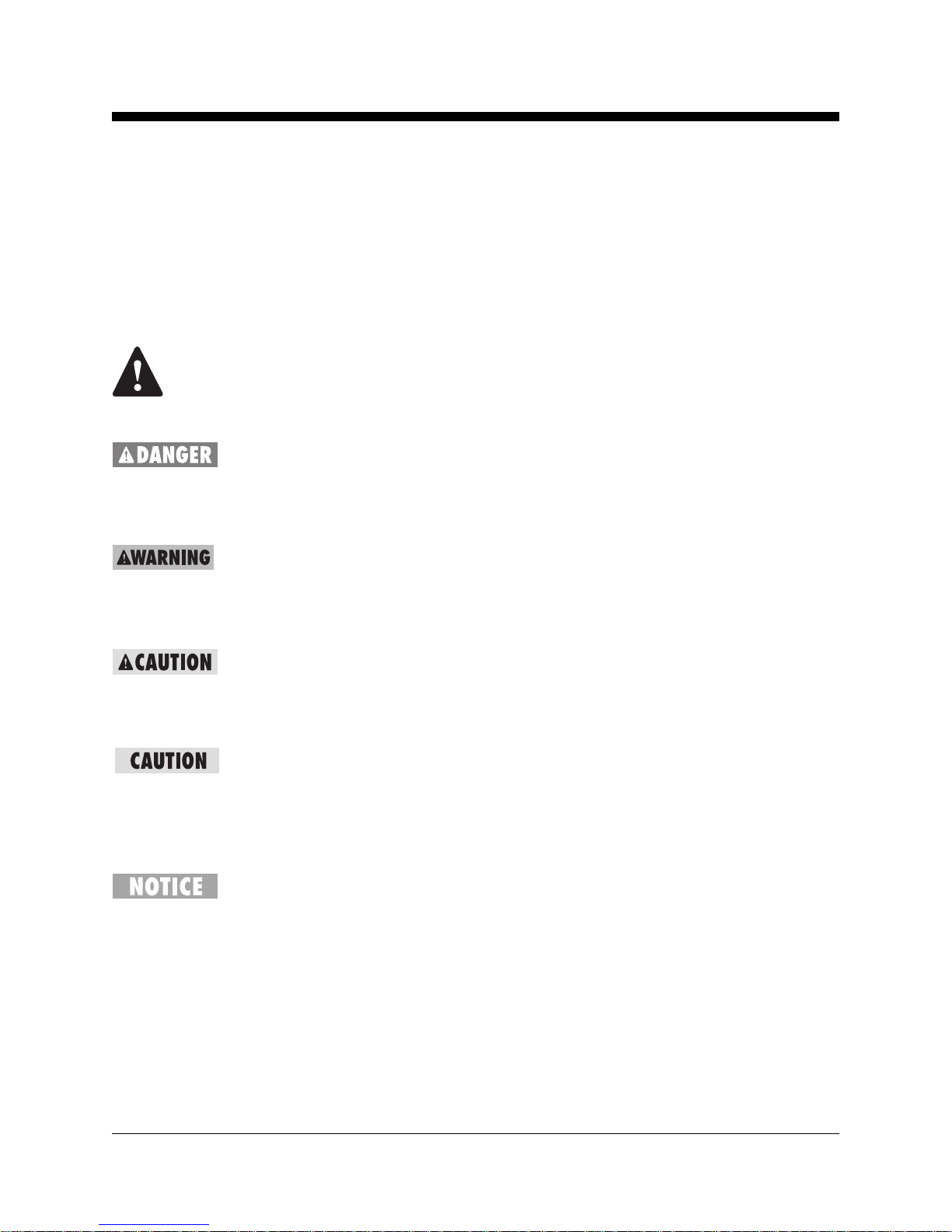

Decal Legend

Genie product decals use symbols, color coding

and signal words to identify the following:

Safety alert symbol—used to alert

personnel to potential personal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Red—used to indicate the

presence of an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury.

Operator’s ManualFirst Edition • Ninth Printing

SAFETY RULES

Orange—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Yellow with safety alert symbol—

used to indicate the presence of a

potentially hazardous situation

which, if not avoided, may cause

minor or moderate injury.

Yellow without safety alert

symbol—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, may result in property

damage.

Green—used to indicate operation

or maintenance information.

Part No. 37168 Genie AWP Super Series 7

Page 10

Operator’s Manual First Edition • Ninth Printing

Controls

Ground Controls AC and DC Models

1 2

7 6 5

3 4

Ground Controls Air Models

38

12

Platform Controls ANSI & CSA

19 10

8 Genie AWP Super Series Part No. 37168

Platform Controls CE

9

1

10

1 Red Emergency Stop button

2 Key switch

3 Outrigger interlock display

lights (four)

4 Low battery indicator light for

auxiliary lowering

5 DC models: Low battery

indicator light

6 Power light

7 Auxiliary platform lowering

button

8 Air pressure gauge

9 Control activate button

10 Up/Down switch

Page 11

Operator’s ManualFirst Edition • Ninth Printing

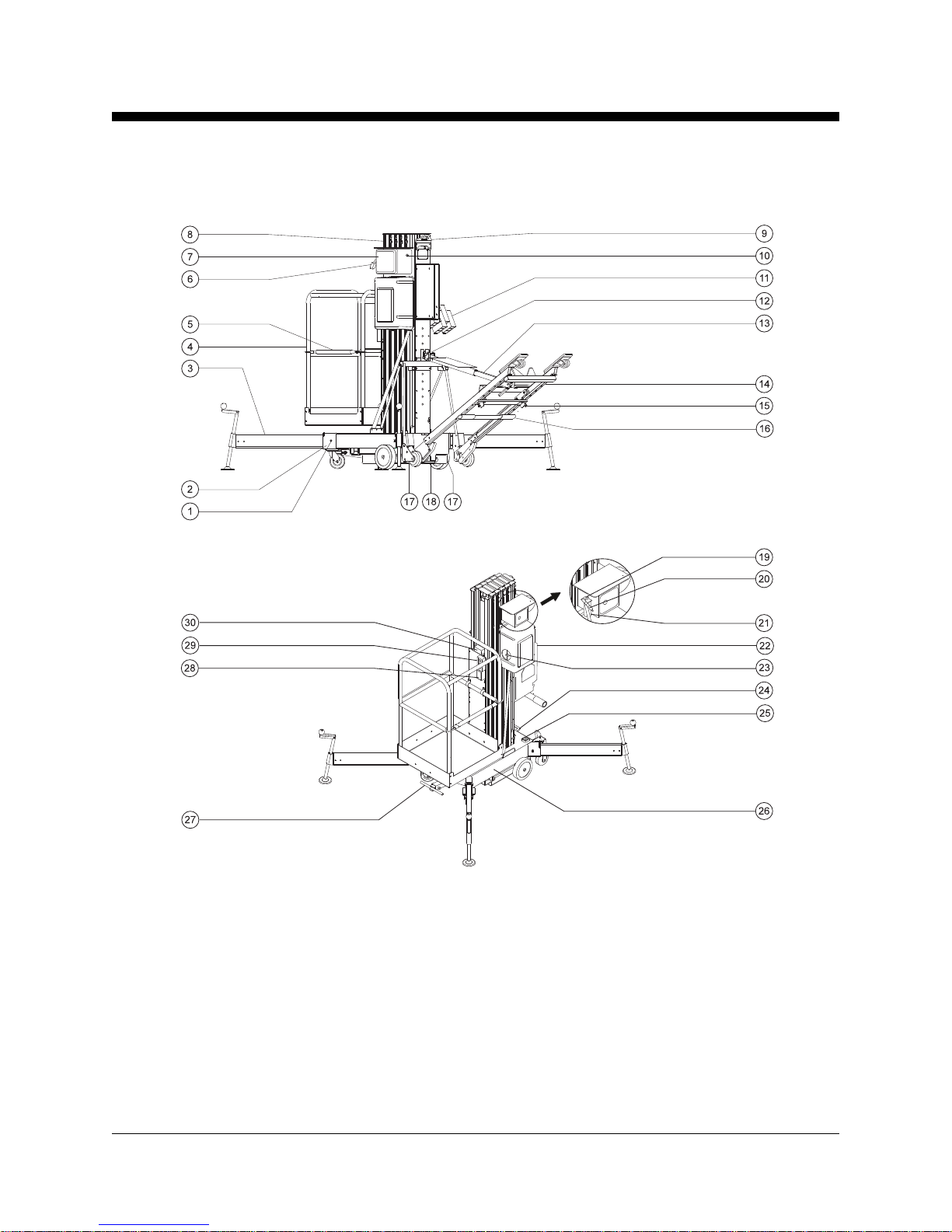

Legend

1 Outrigger lock pin

2 Base outrigger

socket

3 Outrigger with

leveling jack

4 Platform

5 Platform entry mid-

rail or gate

6 AC models: Power

supply for machine

DC models: Power

to platform

Part No. 37168 Genie AWP Super Series 9

7 Ground controls

8 Mast

9 Lifting eye

1 0 AC models: Circuit

11 Outrigger storage

1 2 Tilt-back frame

1 3 Tilt-back strut

1 4 Tilt-back frame

15 Loading stop

breaker

socket

retaining pin

bracket

1 6 Loading pivot bar

17 Forklift pocket

18 Manual lowering

valve (under

machine)

19 Airline lubricator

adjustment knob

2 0 Air supply for

machine

21 Airline lubricator

2 2 DC models: Battery

pack with charger

23 Hydraulic power unit

24 Winching/tie-down

point

2 5 Bubble level

26 Base

27 Sliding T-handle

2 8 AC outlet

2 9 Platform controls

30 Operator's manual

storage container

Page 12

Operator’s Manual First Edition • Ninth Printing

Pre-operation Inspection

Fundamentals

It is the responsibility of the operator to perform a

Pre-operation Inspection and routine maintenance.

The Pre-operation Inspection is a visual inspection

performed by the operator prior to each work shift.

The inspection is designed to discover if anything

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

Know and understand the pre-operation

inspection before going on to the next

section.

3 Always perform the function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Breather Cap - AC & DC Models

is apparently wrong with a machine before the

operator performs the function tests.

The Pre-operation inspection also serves to

determine if routine maintenance procedures are

required. Only routine maintenance items specified

in this manual may be performed by the operator.

Refer to the list on the next page and check each

of the items and locations for modifications,

damage or loose or missing parts.

A damaged or modified machine must never be

used. If damage or any variation from factory

delivered condition is discovered, the machine

must be tagged and removed from service.

Repairs to the machine may only be made by a

qualified service technician, according to the

manufacturer's specifications. After repairs are

completed, the operator must perform a

pre-operation inspection again before going on to

the function tests.

Component damage will occur if the machine

is operated without a breather cap. Check to make

sure the breather cap is in place in the hydraulic

reservoir.

AWP-36 & AWP-40: The

first time these machines

are set up for use, the pipe

plug in the hydraulic

reservoir should be

removed and permanently

replaced with a breather

cap.

A breather cap is supplied and can be found

in an envelope taped to the mast near the

platform controls.

10 Genie AWP Super Series Part No. 37168

Scheduled maintenance inspections shall be

performed by qualified service technicians,

according to the manufacturer's specifications and

the requirements listed in the responsibilities

manual.

Page 13

Pre-operation Inspection

Operator’s ManualFirst Edition • Ninth Printing

PRE-OPERATION INSPECTION

Be sure that the operator’s, safety and

responsibilities manuals are complete, legible

and in the storage container located on the

platform.

Be sure that all decals are legible and in place.

See Decals section.

Check for battery fluid leaks and proper fluid

level. Add distilled water if needed. See

Maintenance section.

AC & DC models: Check for hydraulic oil leaks

and proper oil level. Add oil if needed. See

Maintenance section.

RT base models: Check for proper tire pressure.

Add air to tires if needed. See Maintenance

section.

Air models: Check the oil level of the airline

lubricator. See Maintenance section.

Air models: Check the oil lubricator canister drip

rate. Adjust as needed. See Maintenance

section.

Air models: Check the air filter/regulator

canister. Drain water as needed. See

Maintenance section.

Sequencing cables and pulleys

Lifting chains and idler wheels

Nuts, bolts and other fasteners

Mast columns and counterweight

Breather cap

Outriggers, leveling jacks and footpads

Adjustable glide pads

Check entire machine for:

Dents or damage

Corrosion or oxidation

Cracks in welds or structural components

Inspect and clean battery terminals and all

battery cable connections.

Be sure that all structural and other critical

components are present and all associated

fasteners and pins are in place and properly

tightened.

Check the following components or areas for

damage, modifications and improperly installed or

missing parts:

Electrical components, wiring and

electrical cables

AC & DC models: Hydraulic power unit,

hoses, fittings and cylinder

Air models: Air power unit, airlines, fittings

and cylinder

Platform entry mid-rail or gate

Part No. 37168 Genie AWP Super Series 11

Page 14

Operator’s Manual First Edition • Ninth Printing

Maintenance

Check the Battery - DC Models

Proper battery condition is essential to good

machine performance and safe operation. Improper

fluid levels or damaged cables and connections can

result in engine component damage and hazardous

Observe and Obey:

Only routine maintenance items specified in this

manual shall be performed by the operator.

Scheduled maintenance inspections shall be

completed by qualified service technicians,

according to the manufacturer's specifications

and the requirements specified in the

responsibilities manual.

conditions.

Electrocution hazard. Contact with

hot or live circuits could result in

death or serious injury. Remove all

rings, watches and other jewelry.

Bodily injury hazard. Batteries

contain acid. Avoid spilling or

contacting battery acid. Neutralize

battery acid spills with baking soda

and water.

Maintenance Symbols Legend

The following symbols have been

used in this manual to help

communicate the intent of the

instructions. When one or more of

the symbols appear at the

beginning of a maintenance

procedure, it conveys the meaning

below.

Indicates that tools will be required to

perform this procedure.

Indicates that new parts will be required

to perform this procedure.

Perform this test after fully

charging the battery.

1 Put on protective clothing and eye wear.

2 Remove the battery vent caps.

3 Check the battery acid level. If needed,

replenish with distilled water to the bottom of the

battery fill tube. Do not overfill.

4 Install the vent caps.

12 Genie AWP Super Series Part No. 37168

Page 15

Operator’s ManualFirst Edition • Ninth Printing

MAINTENANCE

Check the Hydraulic Oil Level

Maintaining the hydraulic oil at the proper level is

essential to machine operation. Improper hydraulic

oil levels can damage hydraulic components. Daily

checks allow the inspector to identify changes in oil

level that might indicate the presence of hydraulic

system problems.

1 Be sure the platform is fully lowered.

2 Check the sight gauge on the side of the

hydraulic reservoir.

Result: The hydraulic oil level should be visible

in the middle of the sight gauge. Do not overfill.

Hydraulic oil specifications

Hydraulic oil type Dexron equivalent

Check the Air Line Lubricator Oil

Level - Air Models

Maintaining the proper oil level in the lubricator

canister is essential to safe operation and good

machine performance. Failure to keep the lubricator

canister at the proper oil level could result in unsafe

operating conditions and possible component

damage.

1 Be sure the platform is fully lowered.

2 Inspect the lubricator canister for the proper oil

level.

Result: The oil level must be within 1/2 inch /

12.7 mm from the top of the lubricator canister.

3 To add oil, remove the oil lubricator canister

from the lubricator base and fill with oil. Install

the canister back onto the lubricator base.

Oil Specifications

Check the Tire Pressure - RT

Base Models

It is essential to maintain proper pressure in all airfilled tires. Improperly inflated tires can affect

machine handling.

1 Check each tire with an air pressure gauge. Add

air as needed. The proper air pressure is

stamped on the tire.

Oil Type 10W automotive engine oil

Part No. 37168 Genie AWP Super Series 13

Page 16

Operator’s Manual First Edition • Ninth Printing

MAINTENANCE

Check the Oil Lubricator

Canister Drip Rate - Air Models

Maintaining the proper oil drip rate into the lubricator

canister is essential to safe operation and good

machine performance. Failure to maintain the

proper drip rate could result in machine component

damage.

1 While raising the platform, visually inspect the

oil lubricator sight gauge.

Result: There should be a maximum of 1 to 2

drops of oil visible in the sight gauge.

2 To adjust the drip rate, turn the oil flow control

valve clockwise to decrease the flow or

counterclockwise to increase the flow.

3 Repeat this procedure until the proper oil drip

rate is achieved.

Scheduled Maintenance

Maintenance performed quarterly, annually and

every two years must be completed by a person

trained and qualified to perform maintenance on this

machine according to the procedures found in the

service manual for this machine.

Machines that have been out of service for more

than three months must receive the quarterly

inspection before they are put back into service.

Check the Air Filter/Regulator

Canister - Air Models

It is essential to drain the air filter/regulator canister

of water to ensure good air motor performance and

service life. A water-filled canister could cause the

air motor to perform poorly and continued use could

cause component damage.

1 Check the air filter/regulator canister for any

water accumulation.

2 If water is visible, loosen the drain plug at the

bottom of the canister and allow the water to

drain out.

3 Tighten the drain plug.

14 Genie AWP Super Series Part No. 37168

Page 17

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation inspection.

Operator’s ManualFirst Edition • Ninth Printing

Function Tests

Fundamentals

The Function Tests are designed to discover any

malfunctions before the machine is put into service.

The operator must follow the step-by-step

instructions to test all machine functions.

A malfunctioning machine must never be used. If

malfunctions are discovered, the machine must be

tagged and removed from service. Repairs to the

machine may only be made by a qualified service

technician, according to the manufacturers

specifications.

After repairs are completed, the operator must

perform a pre-operation inspection and function

tests before putting the machine into service.

3 Always perform the function tests prior to

use.

Know and understand the function tests

before going on to the next section.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Part No. 37168 Genie AWP Super Series 15

Page 18

Operator’s Manual First Edition • Ninth Printing

FUNCTION TESTS

Function Tests

Setup

1 Position the machine directly below the desired

work area.

2 Connect to the appropriate power source:

DC models: Connect battery pack.

AC models: Connect to a grounded 15A AC

power supply. Use a 12 gauge / 3.3mm2 3-wire

grounded extension cord no longer than

50 feet / 13 m.

Air models: Connect the airline.

3 Insert the key and turn to the ON position OR

turn to platform control.

4 Pull out the red Emergency Stop button to the

ON position at the ground controls.

5 Twist to release the red Emergency Stop button

at the platform controls.

Result: AC & DC models: The power light should

come on.

Air models: The air

pressure gauge should

read 80-110 psi /5.5 -

7.8 bar.

7 Check the interlock display lights at the ground

controls. Confirm that the corresponding light is

on.

8 Repeat this procedure for each of the remaining

outriggers.

9 Use the bubble level and adjust the leveling

jacks until the machine base is level.

Test Emergency Stop

1 0 Push in the red Emergency Stop button at the

ground controls to the OFF position.

1 1 Push in the control activate button and rotate

the up/down switch in the direction of intended

travel.

ANSI & CSA CE

6 Select an outrigger and

slide it into a base

socket until the

outrigger lock pin snaps

into place. Adjust the

outrigger to level the

a b a b

machine and raise the

base casters slightly off

the ground. Level the

machine using only the

outriggers. Do not use

chocks, blocks or shims

Result: The up/down function should not

operate.

a control activate button

b up/down switch

to level the machine.

16 Genie AWP Super Series Part No. 37168

Page 19

Operator’s ManualFirst Edition • Ninth Printing

FUNCTION TESTS

1 2 Push in the red Emergency Stop button at the

platform controls to the OFF position.

1 3 Pull out the red Emergency Stop button at the

ground controls to the ON position.

1 4 Push in the control activate button and rotate

the up/down switch in the direction of intended

travel.

Result: The up/down function should not

operate.

Test Outrigger Interlock

1 5 Twist to release the red Emergency Stop button

at the platform controls.

Result: The up/down functions should operate.

1 6 Unscrew one leveling jack until the

corresponding interlock display light turns off.

Result: The up/down function should not

operate.

1 7 Return the leveling jack to the previous setting

and check the bubble level.

23 Connect the power source to the machine.

2 4 Turn the key switch to platform control

(if equipped).

2 5 Raise the platform slightly.

2 6 Disconnect the power source from the machine.

2 7 Push in the control activate button and rotate

the up/down switch in the down direction.

Result: The platform should lower.

2 8 Connect the power source to the machine.

Test Manual Lowering

2 9 Raise the platform slightly.

3 0 Activate the manual

lowering valve located

at the bottom of the

hydraulic cylinder.

Result: The

platform should

lower.

1 8 Repeat this procedure for each outrigger.

Test Auxiliary Platform Lowering

- AC & DC Models

1 9 Raise the platform slightly.

2 0 Disconnect the power source from the machine.

2 1 Turn the key switch to ground control

(if equipped).

2 2 Push in the auxiliary platform lowering button at

the ground controls.

Result: The platform should lower.

Part No. 37168 Genie AWP Super Series 17

Page 20

Operator’s Manual First Edition • Ninth Printing

Workplace Inspection

Workplace Inspection

Be aware of and avoid the following hazardous

situations:

· drop-offs or holes

· bumps, floor obstructions or debris

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

Know and understand the work place

inspection before going on to the next

section.

5 Only use the machine as it was intended.

Fundamentals

· overhead obstructions and high voltage

conductors

· hazardous locations

· inadequate surface support to withstand all load

forces imposed by the machine

· wind and weather conditions

· the presence of unauthorized personnel

· other possible unsafe conditions

The Workplace Inspection helps the operator

determine if the work place is suitable for safe

machine operation. It should be performed by the

operator prior to moving the machine to the work

place.

It is the operator’s responsibility to read and

remember the work place hazards, then watch for

and avoid them while moving, setting up and

operating the machine.

18 Genie AWP Super Series Part No. 37168

Page 21

Do Not Operate Unless:

You learn and practice the principles of safe

machine operation contained in this operator’s

manual.

1 Avoid hazardous situations.

2 Always perform a pre-operation

inspection.

3 Always perform function tests prior to use.

4 Inspect the workplace.

5 Only use the machine as it was intended.

Operator’s ManualFirst Edition • Ninth Printing

Operating Instructions

Setup

1 Position the machine directly below the desired

work area.

2 Connect to the appropriate power source:

DC models: Connect battery pack.

AC models: Connect to a grounded 15A AC

power supply. Use a 12 gauge / 3.3mm

grounded extension cord no longer than

50 feet / 13 m.

Air models: Connect the airline.

3 Insert the key and turn to the ON position OR

turn to platform control.

4 Pull out the red Emergency Stop button at the

ground controls and twist to release the red

Emergency Stop at the platform controls. Be

sure the power light is on or the air pressure

gauge reads 80-110 psi / 5.5 - 7.8 bar.

5 Install the outriggers and adjust to level the

machine and raise the base casters slightly off

the ground.

2

3-wire

Fundamentals

Using the machine for anything other than lifting

personnel and tools to an aerial work site is unsafe.

If more than one operator is expected to use a

machine at different times in the same work shift,

each operator is expected to follow all safety rules

and instructions in the operator’s manual. That

means every new operator should perform a preoperation inspection, function tests and a work

place inspection before using the machine.

Part No. 37168 Genie AWP Super Series 19

6 Check the interlock

display. Be sure all four

interlock display lights are

on and all four outriggers

are in firm contact with the ground.

7 Use the bubble level to make sure the machine

is level.

Note: If adjustment is necessary, check the bubble

level and interlock display again to make sure the

machine is level and all four interlock display lights

are on.

Page 22

Operator’s Manual First Edition • Ninth Printing

OPERATING INSTRUCTIONS

Emergency Stop

Push in the red Emergency Stop button at the

platform controls or at the ground controls to stop

the up function.

Platform Raise and Lower

1 Twist to release the red Emergency Stop button

at the platform controls.

2 Push in the control activate button and rotate

the up/down switch in the desired direction of

travel.

ANSI & CSA CE

a b a b

Auxiliary Platform Lowering

- AC & DC Models

1 Turn the key switch to the ON position OR turn to

ground control. Pull out the red Emergency Stop

button to the ON position.

2 Activate the auxiliary platform lowering button at

the ground controls.

After Each Use

1 Select a safe storage location—firm, level

surface, weather protected, clear of obstruction

and traffic.

2 Chock the wheels to prevent the machine from

rolling.

3 Remove the key to secure from unauthorized

use.

4 DC models: Recharge the battery.

a control activate button

b up/down switch

Manual Lowering

1 Activate the manual

lowering valve located

at the bottom of the

hydraulic cylinder.

20 Genie AWP Super Series Part No. 37168

Page 23

Battery and Charger Instructions

Operator’s ManualFirst Edition • Ninth Printing

OPERATING INSTRUCTIONS

8 Monitor the ampere meter for the correct charge

rate. The initial charge rate should be

approximately 10A. The charge rate will

decrease as the battery reaches full charge.

9 The charger will turn off automatically when the

battery is fully charged. Set the power switch to

the OFF position, then disconnect from the AC

supply.

Observe and Obey:

Do not use an external charger or booster

battery.

Charge the battery in a well-ventilated area.

Use proper AC input voltage for charging as

indicated on the charger.

Use only Genie authorized battery and charger.

To Charge Battery

1 Open the battery pack lid to access the battery.

2 Remove the battery vent caps and check the

battery acid level. If necessary, add only

enough distilled water to cover the plates. Do

not overfill prior to the charge cycle.

3 Replace the battery vent caps.

4 Set the power switch to the OFF position. Be sure

that the DC output cord is properly connected to

the battery.

Black to negative, red to positive.

1 0 Check the battery acid level when the charge

cycle is complete. Replenish with distilled water

to the bottom of the fill tube. Do not overfill.

Dry Battery Filling and

Charging Instructions

1 Remove the battery vent caps and permanently

remove the plastic seal from the battery vent

openings.

2 Fill each cell with battery acid (electrolyte) until

the level is sufficient to cover the plates.

Do not fill to maximum level until the battery charge

cycle is complete. Overfilling can cause the battery

acid to overflow during charging. Neutralize battery

acid spills with baking soda and water.

3 Install the battery vent caps.

4 Charge the battery.

5 Check the battery acid level when the charging

cycle is complete. Replenish with distilled water

to the bottom of the fill tube. Do not overfill.

5 Connect the battery charger to a grounded AC

circuit.

6 If equipped: Set the AC Selector switch to the

proper voltage.

7 Set the power switch to the AUTO position.

Part No. 37168 Genie AWP Super Series 21

Page 24

Operator’s Manual First Edition • Ninth Printing

OPERATING INSTRUCTIONS

Lifting Instructions

The number of people required to load and unload a

machine is dependent on a number of factors,

including but not limited to:

Transport Instructions

Observe and Obey:

Be sure the transport vehicle capacity and

loading surfaces are sufficient to support the

machine weight. See Specifications section.

Some pick-up truck tailgates are not strong

enough to support the weight of the machine

and may require reinforcement.

Do not load the machine onto a transport vehicle

unless it is parked on a level surface.

The transport vehicle must be secured to

prevent rolling while the machine is being

loaded.

The machine must be securely fastened to the

transport vehicle.

Be sure to lock both swivel casters on the

tilt-back frame.

Do not transport with the machine resting on the

tilt-back frame.

· the physical condition, strength and

disabilities or prior injuries of the people

involved

· the vertical and horizontal distances the

machine has to be moved

· the number of times the machine will be

loaded or unloaded

· the stance, posture and grip used by the

people involved

· the lifting techniques used

· the site conditions and weather in which the

activity is being performed (i.e., slippery, icy,

raining)

The appropriate number of people and proper lifting

techniques must be used to prevent physical injury.

22 Genie AWP Super Series Part No. 37168

Page 25

Operator’s ManualFirst Edition • Ninth Printing

OPERATING INSTRUCTIONS

Loading for Transport

1 Fully lower the platform.

2 Push in the red Emergency Stop buttons, turn

the key switch to the OFF position and remove

the key.

3 Remove the outriggers from the base and place

them in the storage sockets.

4 DC models: Disconnect the battery cable and

remove the battery pack.

5 Inspect the entire machine for loose or

unsecured items.

6 Slide the stop bracket to the top lock position.

a

b

a stop bracket

b loading pivot

7 Hook the loading pivot to the stop bracket.

8 Position the machine

flush against the

loading surface.

Lower and lock the

stop bracket to the

lowest lock pin

position above the

loading surface.

9 All models with tilt-back frame:

Be sure both stop bracket lock pins are fully

locked.

Be sure both tilt-back frame swivel casters are

locked.

1 0 Slide out the T-handle until the lock pin snaps

into place.

1 1 Lift the T-handle to

tilt the machine

onto the loading

surface. Use the

appropriate number

of people and

proper lifting

techniques.

All models without tilt-back frame

12 Carefully push

the machine into

the transport

position.

a

1 3 Return the sliding

T-handle to the

b

stowed position.

1 4 Secure the machine base and mast to the

transport vehicle. Use chains or straps of ample

load capacity.

1 5 Reverse this procedure to unload the machine.

a stop bracket

b loading pivot

All models with tilt-back frame

Part No. 37168 Genie AWP Super Series 23

Page 26

Operator’s Manual First Edition • Ninth Printing

OPERATING INSTRUCTIONS

Winching the Machine onto a

Flatbed Truck

1 Fully lower the platform.

2 Push in the red Emergency Stop buttons, turn

the key switch to the OFF position and remove

the key.

3 Remove the outriggers from the base and place

them in the storage sockets.

4 Inspect the entire machine for loose or

unsecured items.

5 Connect the cable to the winching point located

at the rear of the base.

6 Carefully winch the machine onto the truck.

7 Secure the machine base and mast to the

transport vehicle. Use chains or straps of ample

load capacity.

Loading the Machine With

a Crane

Use the lifting eye mounted on the rear mast

column.

The battery pack must be removed before lifting the

machine with a crane.

Be sure to inspect the machine and remove any

loose or unsecured items.

Always place the lifting hook

through the lifting eye so that

it points away from the

machine.

24 Genie AWP Super Series Part No. 37168

Page 27

Operator’s ManualFirst Edition • Ninth Printing

OPERATING INSTRUCTIONS

Lifting Instructions

The number of people required to load and unload a

machine is dependent on a number of factors,

including but not limited to:

Tilt-back Operation Instructions

Observe and obey:

The retaining pin must be inserted to prevent the

spring loaded tilt-back frame from dropping.

Do not tilt the machine back unless the area is

clear of personnel and obstructions.

Do not stand behind or under the tilt-back frame

when raising or lowering it.

Tilt-back Frame

The Genie AWP Super

Series has a tilt-back

frame which allows the

machine to roll through a

standard doorway. The

tilt-back frame is

standard equipment on

standard base AWP-36S

and 40S models, and

optional on standard base

AWP-15S, 20S, 25S and

30S models. The tilt-back

frame is not available on

narrow base machines or

rough terrain base machines.

· the physical condition, strength and

disabilities or prior injuries of the people

involved

· the vertical and horizontal distances the

machine has to be moved

· the number of times the machine will be

loaded or unloaded

· the stance, posture and grip used by the

people involved

· the lifting techniques used

· the site conditions and weather in which the

activity is being performed (i.e., slippery, icy,

raining)

The appropriate number of people and proper lifting

techniques must be used to prevent physical injury.

Part No. 37168 Genie AWP Super Series 25

Page 28

Operator’s Manual First Edition • Ninth Printing

OPERATING INSTRUCTIONS

Lowering the Tilt-back Assembly

1 Be sure the area behind the machine and under

the tilt-back frame is clear of personnel and

obstructions.

2 Fully lower the platform.

3 Remove the outriggers from the base and place

them in the storage sockets.

The tilt-back frame is spring loaded and will

immediately fall

outward when the

retaining pin is

removed.

Maintain a firm

grasp on the tiltback frame and

remove the

retaining pin.

4 Lower the tilt-

back frame

and guide the

tilt-back strut into the strut socket.

Tilting Back the Machine

1 Slide out the T-

handle until the lock

pin snaps into

place.

2 Lift the machine

with the T-handle to

mid-tilt position—

casters on the tilt-back frame are in contact with

the floor, and the machine is supported by the

extended tilt-back strut. Use the appropriate

number of people and proper lifting techniques.

3 Continue lifting until the telescoping tilt-back

strut is completely compressed.

5 Insert the retaining pin into the strut socket.

4 Return the sliding T-handle to the stowed

position.

26 Genie AWP Super Series Part No. 37168

Page 29

Operator’s ManualFirst Edition • Ninth Printing

OPERATING INSTRUCTIONS

Returning the Machine to

Standing Position

1 Be sure the area below the machine base and

T-handle is clear of personnel and obstructions.

2 Slide out the T-handle

untl the lock pin snaps

into place.

3 Carefully pull down the

T-handle until the

machine rests at mid-

tilt position.

4 Lower the machine with

the T-handle until the base casters are in

contact with the ground. Use the appropriate

number of people and proper lifting techniques.

5 Return the sliding T-handle to the stowed

position.

Stowing the Tilt-back Assembly

1 Remove the retaining pin.

2 Firmly grasp the tilt-back frame and remove the

tilt-back strut from the strut socket.

3 Lift the tilt-back

frame, hold in an

upright position

against the spring

and secure with

the retaining pin.

Part No. 37168 Genie AWP Super Series 27

Page 30

Operator’s Manual First Edition • Ninth Printing

Decals

Decal Inspection

Use the pictures on the next two pages to verify

that all decals are legible and in place. Below is a

numerical list with quantities and descriptions.

Part No. Description Quantity

27838 Warning - Tilt-back Hazards/Instructions 1

27839 Label - Sliding T-handle 1

27840 Retaining Pin 1

27841 Label - Stop Bracket 1

27842 Label - Loading Pivot 1

27843 Label - Tilt-back Strut 1

27844 Label - Strut Socket 1

27857 Caution - Pipe Plug 1

27863 Caution - Component Damage Hazard 3

27864 Notice - Lower Stop Bracket Before . . . 1

27865 Label - Bubble Level 1

27867 Label - Swivel Lock 1

27868 Danger - Relief Valve 1

27872 Danger - Tip-over Hazard, Outriggers 1

27873 Notice - Maintain Firm Grasp 1

27874 Label - Insert Retaining Pin 1

28157 Label - Dexron 1

28372 Caution - Quick Disconnect 1

31068 Danger - Battery Charger Safety 1

31070 Danger - Tip-over Hazard, Moving 1

31071 Warning - Failure to Read 1

31076 Caution - 8A Maximum, 115V AC 1

31077 Caution - Collision Hazard 1

31245 Warning - Collision Hazard 1

33550 Safety Tape, CE --37133 Label - Interlock Display 1

37141 Notice - Manual Lowering Instructions 1

37142 Notice - Operating Instructions 1

37143 Notice - Max Capacity 300 lbs / 136 kg 1

37144 Notice - Max Capacity 350 lbs / 159 kg 1

Part No. Description Quantity

37145 Label - Manual Lowering Valve 1

38122 Label - Manual Storage Container 1

38142 Label - Circuit Breaker 1

38143 Label - Interlock Display 1

38149 Label - Patents 1

41266 Label - Interlock Display 1

41268 Label - Interlock Display 1

44999 Label - Control Activate 1

46203 Notice - 20 inch Outrigger, CE 4

46204 Notice - 26 inch Outrigger, CE 4

46205 Notice - 30.5 inch Outrigger, CE 4

46206 Notice - 36 inch Outrigger, CE 4

46207 Notice - 40 inch Outrigger, CE 4

46211 Notice - 85 inch Outrigger, CE 4

46218 Notice - Side Force, Wind Speed 1

52996 Cosmetic - Genie Logo 1

52998 Cosmetic - AWP-15S 2

52999 Cosmetic - AWP-20S 2

62992 Cosmetic - AWP-25S 2

62993 Cosmetic - AWP-30S 2

62994 Cosmetic - AWP-36S 2

62995 Cosmetic - AWP-40S 2

65198 Serial Plate, CSA 1

72086 Label - Lifting Eye 1

72843 Danger - General Safety 1

72856 Label - Interlock Display 1

72857 Label - Interlock Display 1

1257853 Notice - 75 inch Outrigger, CE 4

1257854 Notice - 60 inch Outrigger, CE 4

1260610 Notice - 46 inch Outrigger, CE 4

28 Genie AWP Super Series Part No. 37168

Page 31

Operator’s ManualFirst Edition • Ninth Printing

DECALS

Note: Platform decals may

be in diffferent locations on

optional fiberglass basket.

Models

without

Tilt-back

Frame

or 1257853 or 1257854 or 1260610 or 46211

Part No. 37168 Genie AWP Super Series 29

Page 32

Operator’s Manual First Edition • Ninth Printing

DECALS

Note: Platform decals may

be in diffferent locations on

optional fiberglass basket.

Models with

Tilt-back

Frame

or 1257853 or 1257854 or 1260610 or 46211

30 Genie AWP Super Series Part No. 37168

Page 33

Operator’s ManualFirst Edition • Ninth Printing

Specifications

Machine Specifications

Height, working maximum

AWP-15S 21 ft 4 in 6.5 m

AWP-20S 26 ft 1 in 8.0 m

AWP-25S 30 ft 9 in 9.4 m

AWP-30S 35 ft 6 in 10.8 m

AWP-36S 42 ft 5 in 12.9 m

AWP-40S 46 ft 3 in 14.1 m

Height, platform maximum

AWP-15S 15 ft 4 in 4.7 m

AWP-20S 20 ft 1 in 6.1 m

AWP-25S 24 ft 9 in 7.6 m

AWP-30S 29 ft 6 in 9.0 m

AWP-36S 36 ft 6 in 11.1 m

AWP-40S 40 ft 3 in 12.3 m

Lift capacity - AWP-15S, 20S, 25S, 350 lbs

30S & 36S models except Canada 159 kg

Lift capacity - AWP-40S 300 lbs

models except Canada 136 kg

Lift capacity 300 lbs

models sold in Canada only 136 kg

Power source

DC model 12V

AC model 110V or 220V

Air motor 100 psi / 6.9 bar @ 80 cfm / 37760 cc/sec

Ambient operating -20°F to 135°F

temperature -29°C to 57°C

Airborne noise emissions 80 dB

Maximum sound level at normal operating workstations

(A-weighted)

Standard Base Specifications

Machine weight (DC / AC models)

AWP-15S 718 / 628 lbs 326 / 285 kg

AWP-20S 767 / 677 lbs 348 / 307 kg

AWP-25S 817 / 727 lbs 371 / 330 kg

AWP-30S 867 / 777 lbs 393 / 352 kg

AWP-36S 1107 / 1017 lbs 502 / 461 kg

AWP-40S 1130 / 1040 lbs 513 / 472 kg

Height, stowed

AWP-15S, 20S, 25S, 30S 78 in 2.0 m

AWP-36S, 40S 1091/2 in 2.8 m

Width 29 in

73.6 cm

Length

AWP-15S, 20S, 25S, 30S 46 in 1.2 m

AWP-36S, 40S 55 in 1.4 m

Platform dimensions - all models

(length x width x height)

Standard platform 27 x 26 x 443/4 in

gated or sliding mid-rail 69 cm x 66 cm x 1.1 m

Gated ultra-narrow platform 22 x 18 x 443/4 in

56 cm x 46 cm x 1.1 m

Gated narrow platform 26 x 20 x 443/4 in

66 cm x 51 cm x 1.1 m

Standard fiberglass platform 29 x 261/2 x 431/2 in

74 cm x 67 cm x 1.1 m

Narrow fiberglass platform 26 x 22 x 431/2 in

66 cm x 56 cm x 1.1 m

Front entry gated narrow platform 20 x 26 x 443/4 in

51cm x 66 cm x 1.1 m

Extra large front and side entry 30 x 28 x 443/4 in

platform 76 cm x 71 cm x 1.1 m

Continuous improvement of our products is a Genie

policy. Product specifications are subject to change

without notice or obligation.

Part No. 37168 Genie AWP Super Series 31

Page 34

Operator’s Manual First Edition • Ninth Printing

SPECIFICATIONS

Standard Base Specifications AWP-15S AWP-20S AWP-25S

Outrigger footprint 603/4 x 523/4 in 603/4 x 523/4 in 603/4 x 523/4 in

(l x w) ANSI 1.5 x 1.3 m 1.5 x 1.3 m 1.5 x 1.3 m

Outrigger footprint 603/4 x 523/4 in 691/4 x 611/4 in 831/2 x 751/2 in

(l x w) CSA 1.5 x 1.3 m 1.8 x 1.6 m 2.1 x 1.9 m

Outrigger footprint 603/4 x 523/4 in 603/4 x 523/4 in 691/4 x 611/4 in

(l x w) CE Indoor 1.5 x 1.3 m 1.5 x 1.3 m 1.8 x 1.6 m

Outrigger footprint 691/4 x 611/4 in 831/4 x 751/4 in 89 x 81 in

(l x w) CE Outdoor 1.8 x 1.6 m 2.1 x 1.9 m 2.3 x 2.1 m

Corner access/wall access* 153/4 / 8 in 141/2 / 51/2 in 14 / 3 in

ANSI 39.7 / 20.3 cm 36.9 / 7.4 cm 35.1 / 7.4 cm

Corner access/wall access* 153/4 / 8 in 201/4 / 93/4 in 283/4 / 141/4 in

CSA 39.7 / 20.3 cm 51.2 / 24.5 cm 72.6 / 36.2 cm

Corner access/wall access* 153/4 / 8 in 141/2 / 51/2 in 191/4 / 71/4 in

CE Indoor 39.7 / 20.3 cm 36.9 / 7.4 cm 48.6 / 18.2 cm

Corner access/wall access* 211/2 / 121/4 in 30 / 163/4 in 321/2 / 17 in

CE Outdoor 54.6 / 30.8 cm 76 / 42.4 cm 82.5 / 43.4 cm

AWP-30S AWP-36S AWP-40S

Outrigger footprint 691/4 x 611/4 in 831/4 x 751/4 in 89 x 81 in

(l x w) ANSI 1.8 x 1.6 m 2.1 x 1.9 m 2.3 x 2.0 m

Outrigger footprint 971/2 x 891/2 in 1171/4 x 1091/4 in 1171/4 x 1091/4 in

(l x w) CSA 2.5 x 2.3 m 3.0 x 2.8 m 3.0 x 2.8 m

Outrigger footprint 751/2 x 671/2 in 831/4 x 751/4 in 89 x 81 in

(l x w) CE Indoor 1.9 x 1.7 m 2.1 x 1.9 m 2.3 x 2.0 m

Outrigger footprint 1171/4 x 1091/2 in 1171/4 x 1091/2 in 1171/4 x 1091/2 in

(l x w) CE Outdoor 3.0 x 2.8 m 3.0 x 2.8 m 3.0 x 2.8 m

Corner access/wall access* 181/2 / 43/4 in 281/2 / 141/4 in 311/4 / 141/2 in

ANSI 46.6 / 11.9 cm 72.7 / 36.2 cm 79.4 / 37.1 cm

Corner access/wall access* 37 / 183/4 in 52 / 311/4 in 503/4 / 283/4 in

CSA 94.1 / 47.8 cm 1.3 m / 79.3 cm 1.3 m / 73 cm

Corner access/wall access* 221/4 / 8 in 281/2 / 141/4 in 311/4 / 141/2 in

CE Indoor 56.5 / 20.3 cm 72.7 / 36.2 cm 79.4 / 37.1 cm

Corner access/wall access* 503/4 / 283/4 in 52 / 311/4 in 503/4 / 283/4 in

CE Outdoor 1.3 m / 73 cm 1.3 m / 79.3 cm 1.3 m / 73 cm

* Corner of platform top rail to corner of wall with ability to rotate leveling jack.

32 Genie AWP Super Series Part No. 37168

Page 35

Operator’s ManualFirst Edition • Ninth Printing

SPECIFICATIONS

Machine Specifications

Height, working maximum

AWP-15S 21 ft 4 in 6.5 m

AWP-20S 26 ft 1 in 8.0 m

AWP-25S 30 ft 9 in 9.4 m

AWP-30S 35 ft 6 in 10.8 m

Height, platform maximum

AWP-15S 15 ft 4 in 4.7 m

AWP-20S 20 ft 1 in 6.1 m

AWP-25S 24 ft 9 in 7.6 m

AWP-30S 29 ft 6 in 9.0 m

Lift capacity - AWP-15S, 20S, 25S & 350 lbs

30S models except Canada 159 kg

Lift capacity 300 lbs

models sold in Canada only 136 kg

Power source

DC model 12V

AC model 110V or 220V

Air motor 100 psi / 6.9 bar @ 80 cfm / 37760 cc/sec

Ambient Operating -20°F to 135°F

Temperature -29°C to 57°C

Airborne noise emissions 80 dB

Maximum sound level at normal operating workstations

(A-weighted)

Narrow Base Specifications

Machine weight (DC / AC models)

AWP-15S 711 / 621 lbs 323 / 282kg

AWP-20S 750 / 660 lbs 340 / 299kg

AWP-25S 784 / 694 lbs 356 / 315 kg

AWP-30S 819 / 729 lbs 371 / 330 kg

Height, stowed 78 in 2.0 m

Width 22 in 55.8 cm

Length 491/2 in 1.3 m

Platform dimensions

Gated ultra-narrow platform 22 x 18 x 443/4 in

(l x w x h) 56 cm x 46 cm x 1.1 m

Gated narrow platform 26 x 20 x 443/4 in

(l x w x h) 66 cm x 51 cm x 1.1 m

Narrow fiberglass platform 26 x 22 x 431/2 in

(l x w x h) 66 cm x 56 cm x 1.1 m

Outrigger Specifications

Narrow Base AWP-15S AWP-20S AWP-25S AWP-30S

Outrigger footprint 64 x 481/4 in 64 x 481/4 in 64 x 481/4 in 711/2 x 58 in

(l x w) ANSI 1.6 x 1.2 m 1.6 x 1.2 m 1.6 x 1.2 m 1.8 x 1.5 m

Outrigger footprint 711/2 x 58 in 741/2 x 651/2 in 831/4 x 74 in 951/4 x 893/4 in

(l x w) CSA 1.8 x 1.5 m 1.9 x 1.6 m 2.1 x 1.9 m 2.4 x 2.3 m

Outrigger footprint 64 x 481/4 in 711/4 x 58 in 711/4 x 58 in 741/2 x 651/2 in

(l x w) CE Indoor 1.6 x 1.2 m 1.8 x 1.5 m 1.8 x 1.5 m 1.9 x 1.6 m

CE/AUS Narrow Base or Rough Terrain base machines are Indoor Use Only, even with longer outriggers.

Corner access/wall access* 16 / 11 in 141/4 / 81/2 in 13 / 6 in 181/2 / 71/4 in

ANSI 40.6 / 27.9 cm 36.2 / 21.6 cm 33 / 15.2 cm 47 / 18.4 cm

Corner access/wall access* 221/2 / 143/4 in 241/2 / 14 in 283/4 / 15 in 371/2 / 181/2 in

CSA 57.1 / 37.5 cm 62.2 / 35.5 cm 73 / 38.1 cm 95.2 / 47 cm

Corner access/wall access* 16 / 11 in 21 / 121/4 in 191/2 / 93/4 in 22 / 9 in

CE Indoor 40.6 / 27.9 cm 53.3 / 31.1 cm 49.5 / 24.7cm 55.8 / 22.8 cm

* Corner of platform top rail to corner of wall with ability to rotate leveling jack.

Continuous improvement of our products is a Genie policy. Product specifications are subject to change without

notice or obligation.

Part No. 37168 Genie AWP Super Series 33

Page 36

Operator’s Manual First Edition • Ninth Printing

SPECIFICATIONS

Machine Specifications

Height, working maximum

AWP-15S 21 ft 4 in 6.5 m

AWP-20S 26 ft 1 in 8.0 m

AWP-25S 30 ft 9 in 9.4 m

AWP-30S 35 ft 6 in 10.8 m

Height, platform maximum

AWP-15S 15 ft 4 in 4.7 m

AWP-20S 20 ft 1 in 6.1 m

AWP-25S 24 ft 9 in 7.6 m

AWP-30S 29 ft 6 in 9.0 m

Lift capacity - AWP-15S, 20S, 25S & 350 lbs

30S models except Canada 159 kg

Lift capacity 300 lbs

models sold in Canada only 136 kg

Power source

DC model 12V

AC model 110V or 220V

Air motor 100 psi / 6.9 bar @ 80 cfm / 37760 cc/sec

Ambient Operating -20°F to 135°F

Temperature -29°C to 57°C

Airborne noise emissions 80 dB

Maximum sound level at normal operating workstations

(A-weighted)

Rough Terrain Base Specifications

Machine weight (DC / AC models)

AWP-15S 715 / 625 lbs 324 / 283 kg

AWP-20S 750 / 660 lbs 340 / 299 kg

AWP-25S 784 / 694 lbs 356 / 315 kg

AWP-30S 819 / 729 lbs 371 / 330 kg

Height, stowed 79 in 2.0 m

Width 291/2 in 75 cm

Length 58 in 1.5 m

Platform dimensions

(length x width x height)

Standard platform 27 x 26 x 443/4 in

gated or sliding mid-rail 69 cm x 66 cm x 1.1 m

Gated ultra-narrow platform 22 x 18 x 443/4 in

56 cm x 46 cm x 1.1 m

Gated narrow platform 26 x 20 x 443/4 in

66 cm x 51 cm x 1.1 m

Standard fiberglass platform 29 x 261/2 x 431/2 in

74 cm x 67 cm x 1.1 m

Narrow fiberglass platform 26 x 22 x 431/2 in

66 cm x 56 cm x 1.1 m

Front entry gated narrow platform 20 x 26 x 443/4 in

51 cm x 66 cm x 1.1 m

Extra large front and side entry 30 x 28 x 443/4 in

platform 76 cm x 71 cm x 1.1 m

Continuous improvement of our products is a Genie

policy. Product specifications are subject to change

without notice or obligation.

Outrigger Specifications

Rough Terrain Base AWP-15S AWP-20S AWP-25S AWP-30S

Outrigger footprint 64 x 481/4 in 64 x 481/4 in 64 x 481/4 in 711/2 x 58 in

(l x w) ANSI 1.6 x 1.2 m 1.6 x 1.2 m 1.6 x 1.2 m 1.8 x 1.5 m

Outrigger footprint 711/2 x 58 in 741/2 x 651/2 in 831/4 x 74 in 951/4 x 893/4 in

(l x w) CSA 1.8 x 1.5 m 1.9 x 1.6 m 2.1 x 1.9 m 2.4 x 2.2 m

Outrigger footprint 64 x 481/4 in 711/4 x 58 in 711/4 x 58 in 741/2 x 651/2 in

(l x w) CE Indoor 1.6 x 1.2 m 1.8 x 1.5 m 1.8 x 1.5 m 1.9 x 1.6 m

CE/AUS Narrow Base or Rough Terrain base machines are Indoor Use Only, even with longer outriggers.

Corner access/wall access* 16 / 11 in 141/4 / 81/2 in 13 / 6 in 181/2 / 71/4 in

ANSI 40.6 / 27.9 cm 36.2 / 21.6 cm 33 / 15.2 cm 47 / 18.4 cm

Corner access/wall access* 221/2 / 143/4 in 241/2 / 14 in 283/4 / 15 in 371/2 / 181/2 in

CSA 57.1 / 37.5 cm 62.2 / 35.5 cm 73 / 38.1 cm 95.2 / 47 cm

Corner access/wall access* 16 / 11 in 21 / 121/4 in 191/2 / 93/4 in 22 / 9 in

CE Indoor 40.6 / 27.9 cm 53.3 / 31.1 cm 49.5 / 24.7cm 55.8 / 22.8 cm

* Corner of platform top rail to corner of wall with ability to rotate leveling jack.

34 Genie AWP Super Series Part No. 37168

Page 37

Loading...

Loading...