Genie 36255W, 1042, 1024, 1022 Owner’s Manual

OVERVl F POTENTIALHAZARDS

READTHISSAFETYINFORMATI N

Garage doors are large, heavy objectsthat movewiththe help of springs under high tension and electric motors.Since moving

objects, springs under tension, and electric motorscan cause injuries, your safetyandthe safety of others depend on the owner or

user of this system to read, understandand implementthe informationinthis manual. Ifyou havequestions or do NOT

understandthe information presented,contact The Genie Companyor an authorized Genie®Dealer.

The safety alert symbolandfollowing signalwords DANGER,WARNING, and CAUTIONare used throughout this manualto call

attentionto and identifydifferent levels of hazard and special instructions.

,& This is the safety alert symbol. This symbol isplaced next to signalwords and messagesto help you identify

importantsafety information

Theword:

,& DANGERindicates an imminently hazardoussituation which, if NOT avoided,will result in death or serious injury.

,& WARNING indicatesa potentially hazardoussituation which, if NOT avoided, could result in death or serious injury.

,& CAUTION indicatesa potentially hazardoussituationwhich, if NOTavoided, may result in injury or property damage.

Theword ,_0 is used to indicateimportantstepsto be followed, importantconsiderations,or location of parts.

IMPORTANTSAFETYINSTRUCTIONS

READAND FOLLOWALL INSTRUCTIONS

POTENTIAL

HAZARD

MOVINGDOOR

ELECTRICAL

SHOCK

SAVETHESEINSTRUCTIONS

PREVENTION

Keep people clear of openingwhile door is moving.

Do NOTallow children to play with the dooroperator.

Do NOToperate a door that jams or onethat hasa brokenspring.

Turn OFF power before removingoperator cover.

When replacing cover, make sure wires are not pinchedor near

moving parts.

Operator must be properlygrounded.

Do NOTtry to remove,install,repair or adjustsprings or anythingto

which door springparts arefastened, suchas, wood blocks,steel

brackets,cablesor other like items.

HIGH

SPRING

TENSION

Installations,repairsand adjustmentsmustbe done by a traineddoor

systemtechnicianusingpropertools and instructions.

PN# 3642036534, 02/26/2010 REV, 1

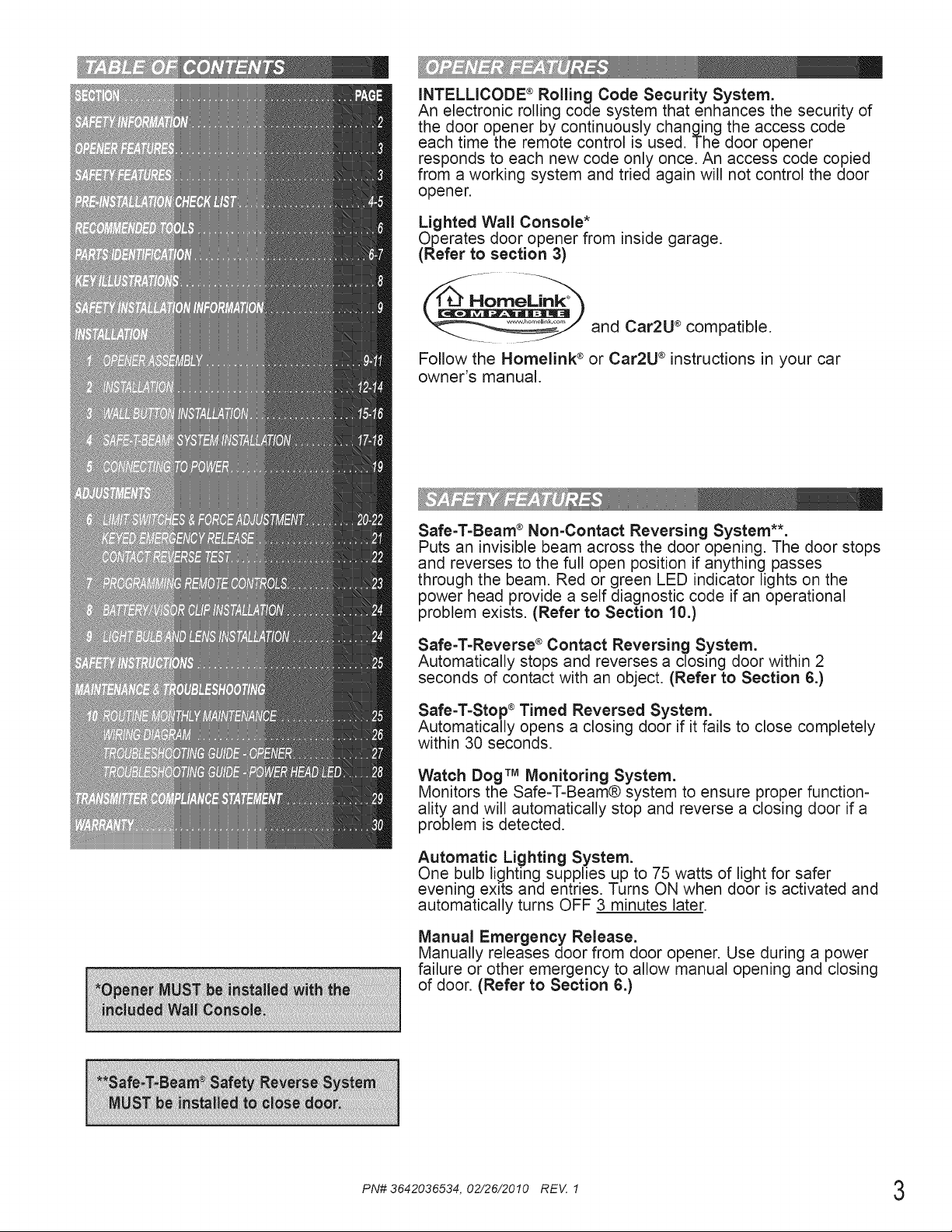

INTELLICODE ®Rolling Code Security System.

An electronic rolling code system that enhances the security of

the door opener by continuously changing the access code

each time the remote control is used. The door opener

responds to each new code only once. An access code copied

from a working system and tried again will not control the door

opener.

Lighted Wall Console*

Operates door opener from inside garage.

(Refer to section 3)

and Car2U ®compatible.

Follow the Homelink ®or Car2U ®instructions in your car

owner's manual.

Safe-T-Beam ®Non-Contact Reversing System**.

Puts an invisible beam across the door opening. The door stops

and reverses to the full open position if anything passes

through the beam. Red or green LED indicator lights on the

power head provide a self diagnostic code if an operational

problem exists. (Refer to Section 10.)

Safe-T-Reverse ®Contact Reversing System.

Automatically stops and reverses a closing door within 2

seconds of contact with an object. (Refer to Section 6.)

Safe-T-Stop ®Timed Reversed System.

Automatically opens a closing door if it fails to close completely

within 30 seconds.

Watch DogTM Monitoring System.

Monitors the Safe=T-Beam@ system to ensure proper function=

ality and will automatically stop and reverse a closing door if a

problem is detected.

Automatic Lighting System.

One bulb lighting supplies up to 75 watts of light for safer

evening exits and entries. Turns ON when door is activated and

automatically turns OFF 3 minutes later.

Manual Emergency Release.

Manually releases door from door opener. Use during a power

failure or other emergency to allow manual opening and closing

of door. (Refer to Section 6.)

PN# 3642036534, 02/26/2010 REV. 1 3

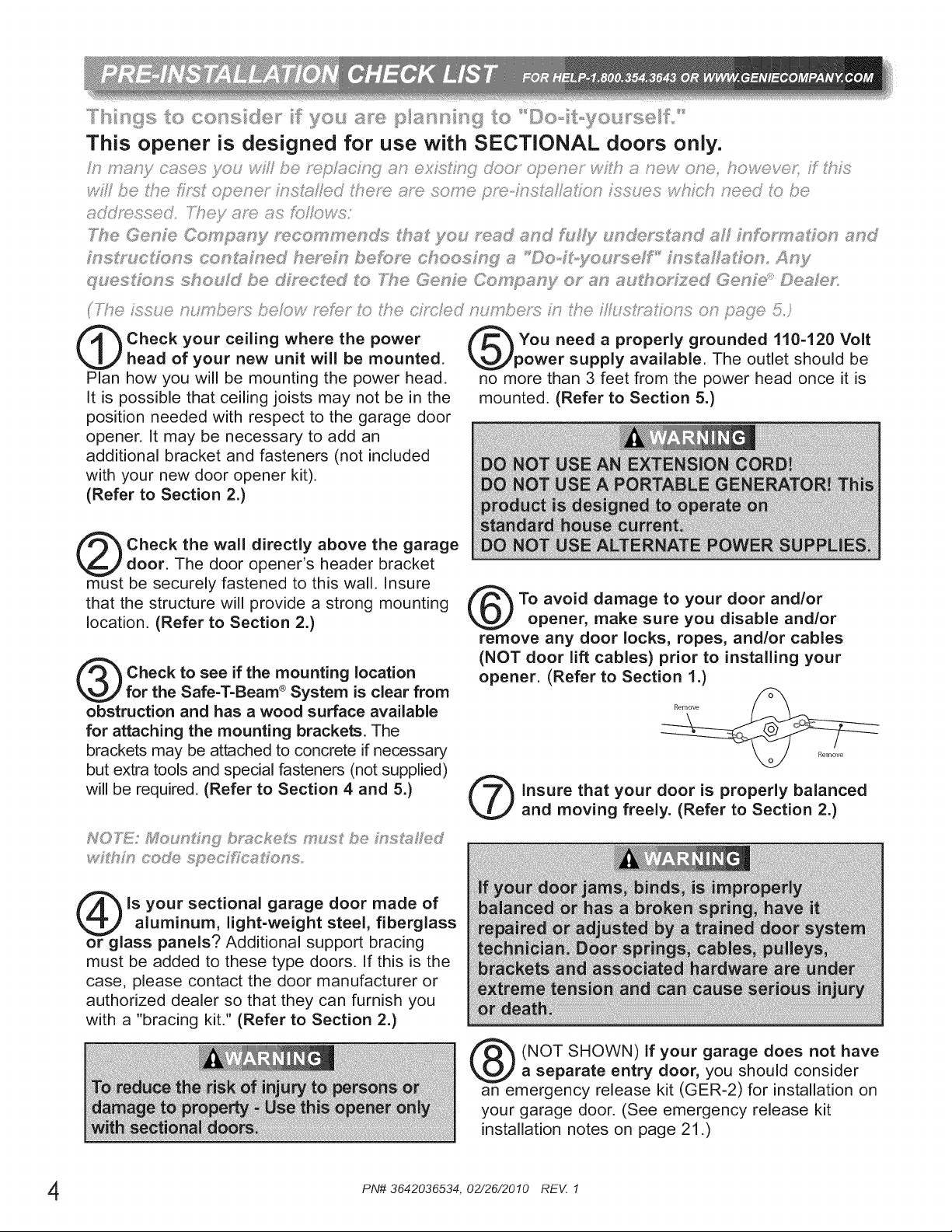

Check your ceiling where the power

head of your new unit will be mounted.

Plan how you will be mounting the power head.

It is possible that ceiling joists may not be in the

position needed with respect to the garage door

opener. It may be necessary to add an

additional bracket and fasteners (not included

with your new door opener kit).

(Refer to Section 2.)

Check the wall directly above the garage

door. The door opener's header bracket

must be securely fastened to this wall. Insure

that the structure will provide a strong mounting

location. (Refer to Section 2.)

Check to see if the mounting location

for the Safe-T-Beam ®System is clear from

obstruction and has a wood surface available

for attaching the mounting brackets. The

brackets may be attached to concrete if necessary

but extra tools and special fasteners (not supplied)

will be required. (Refer to Section 4 and 5.)

You need a properly grounded 110-120 Volt

power supply available. The outlet should be

no more than 3 feet from the power head once it is

mounted. (Refer to Section 5.)

To avoid damage to your door and/or

opener, make sure you disable and/or

remove any door locks, ropes, and/or cables

(NOT door lift cables) prior to installing your

opener. (Refer to Section 1.)

insure that your door is properly balanced

and moving freely. (Refer to Section 2.)

_z_t_,:_ code specifications

is your sectional garage door made of

aluminum, light-weight steel, fiberglass

or glass panels? Additional support bracing

must be added to these type doors. If this is the

case, please contact the door manufacturer or

authorized dealer so that they can furnish you

with a "bracing kit." (Refer to Section 2.)

PN# 3642036534, 02/26/2010 REV. 1

(NOT SHOWN) If your garage does not have

a separate entry door, you should consider

an emergency release kit (GER-2) for installation on

your garage door. (See emergency release kit

installation notes on page 21.)

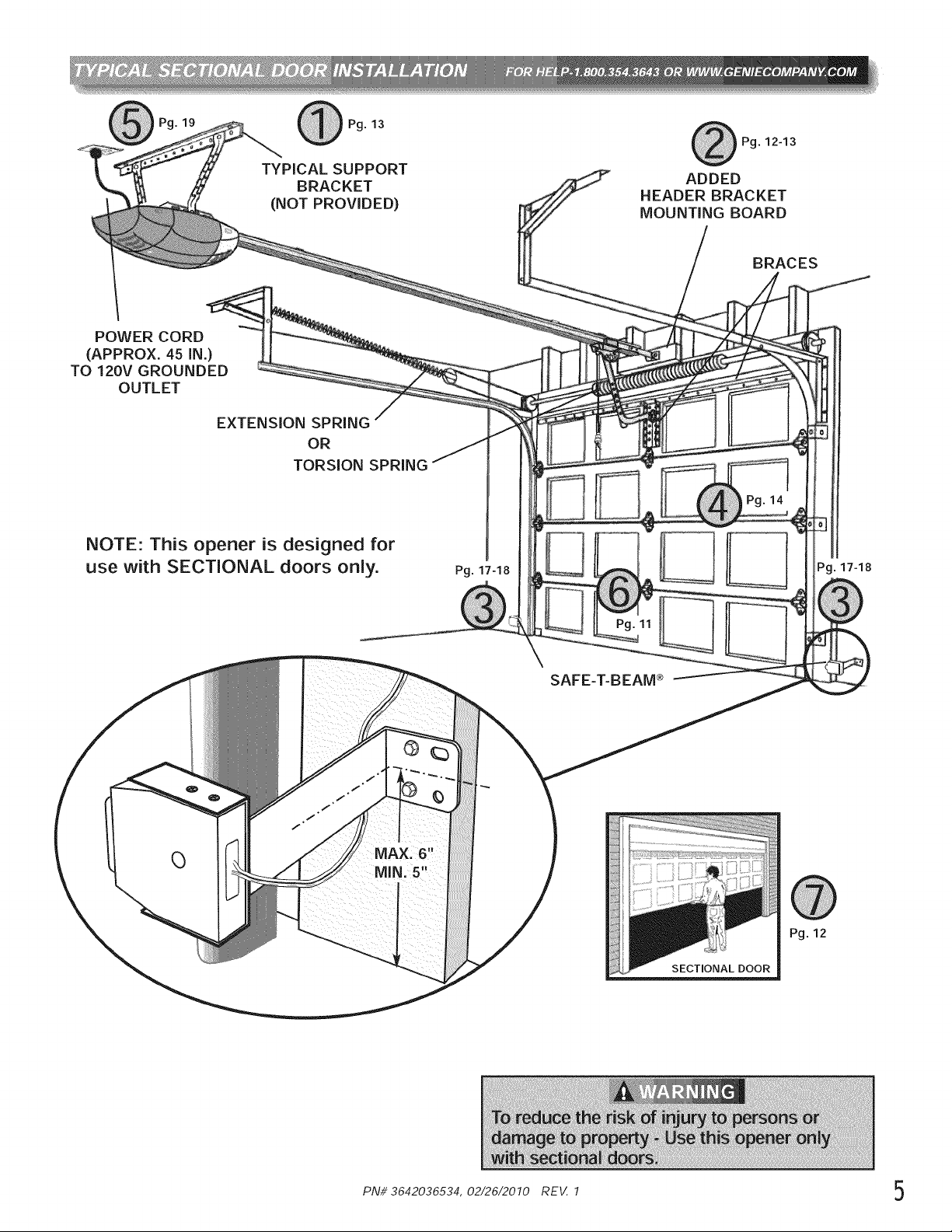

TYPICAL SUPPORT

BRACKET

(NOT PROVIDED)

POWER CORD

(APPROX. 45 IN.)

TO 120V GROUNDED

OUTLET

EXTENSION SPRING

OR

TORSION SPRING

NOTE: This opener is designed for

use with SECTIONAL doors only.

Pg. 13

Pg. 17-18

Pg. 12-13

ADDED

HEADER BRACKET

MOUNTING BOARD

BRACES

Pg. 17-18

MIN. 5

SAFE-T-BEAM _

Pg. 12

SECTIONAL DOOR

PN# 3642036534, 02/26/2010 REV. 1 5

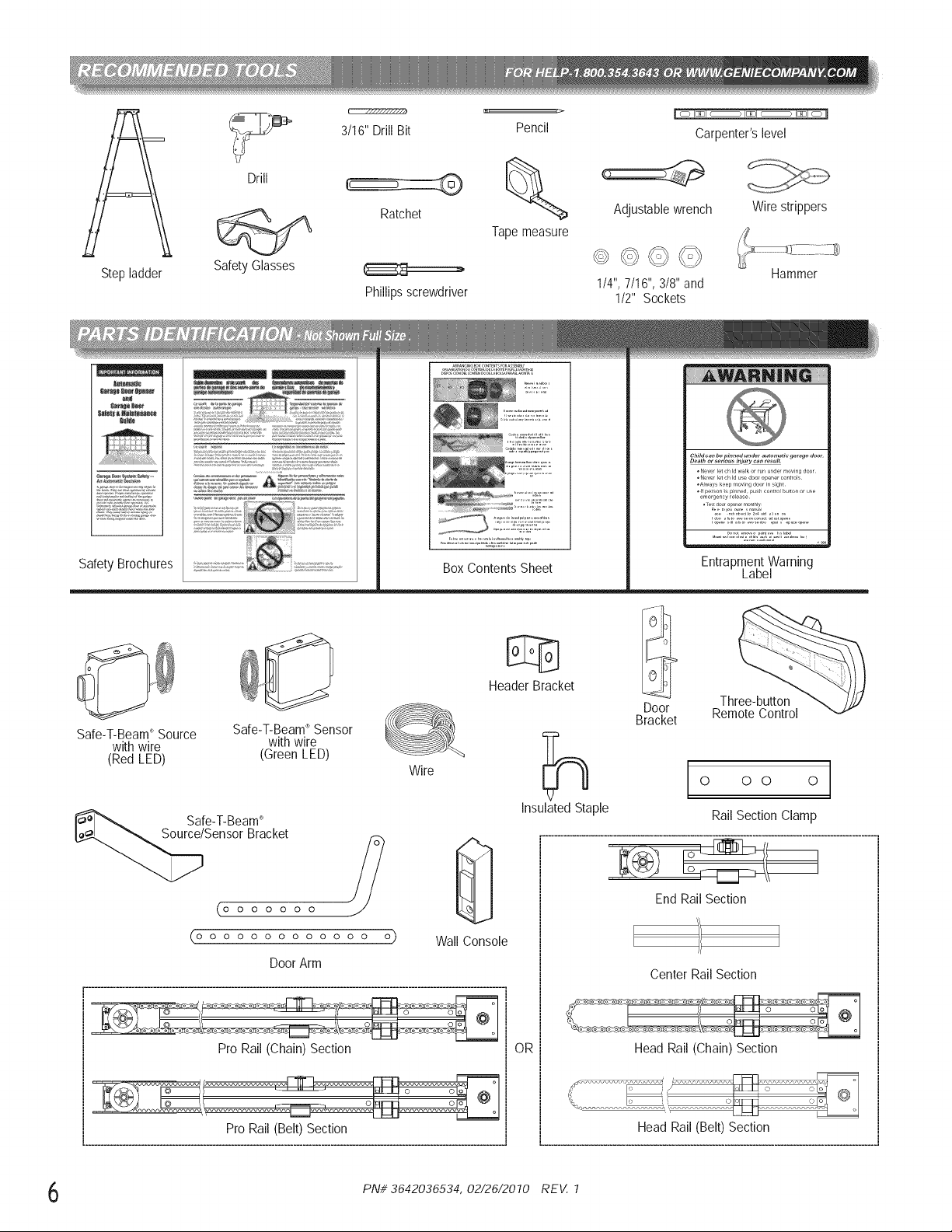

Drill

3/16" Drill Bit

Pencil

Carpenter'slevel

Stepladder

Safety Brochures

Safety Glasses

AN

Ratchet

Phillipsscrewdriver

ARRA.GI.G_×CO.TE.TSrORASSe,,B_

Tapemeasure

Adjustablewrench

1/4",7/16", 3/8"and

1/2" Sockets

Child can be pinned under automatic 9arage door

Dea*hor _eriou_ injury can re_ul_

Wire strippers

Hammer

°Neverle_chId walkor,un undermovingdoor¸

°Newt le_chIdus_ doo,openercontTol_

°AIway_ke_pmovingdoor_n_ght

°. pe,son_sp_n_d pushcontrolbu_onorus_

_mergency,e_ease

Te_,_oorol,_n_rmonthly¸

_o _ ................. _o_o_

..........°:n::::'X_,::':r:i:,__o_o.__'r4.........

Entrapment Warning

Label

Safe-T-Beam_Source Safe-T-Beam_ Sensor

with wire with wire

(Red LED) (Green LED)

Safe-T-Beam_

Sensor Bracket

0000000

0000000000000

DoorArm

,-.......................................................................................................................................

Pro Rail (Chain) Section

Header Bracket

Wire

o) WallConsole

OR

Door RemoteControl

Bracket

Three-button

Center Rail Section

,/

Head Rail (Chain) Section

PNi/3642036534, 02/26/2010 REV. 1

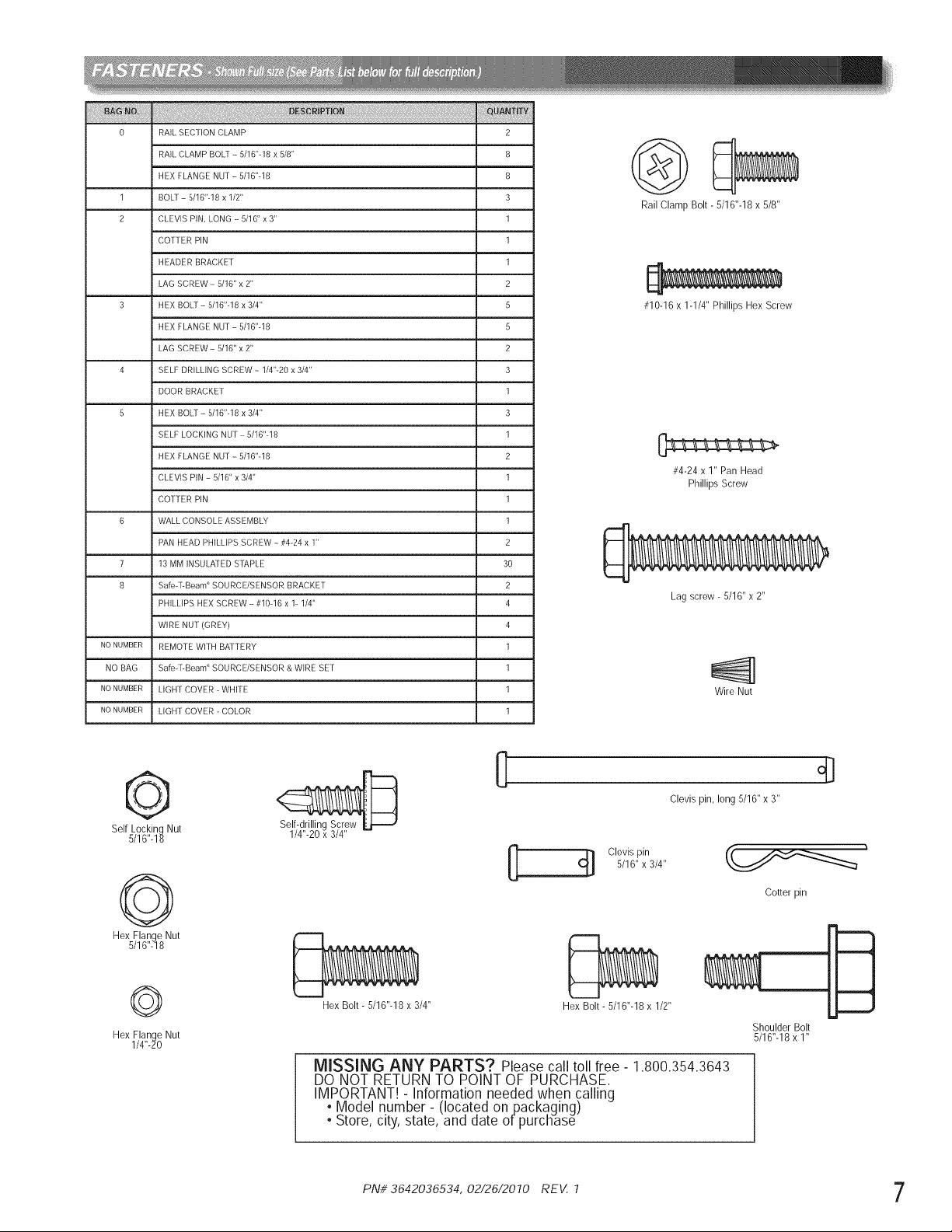

0 RAIL SECIlON CLAMP 2

RAILCLAMP BOLT - 5/16"-18 x 5/8" 8

HEX FLANGE NU1- 5/16"-18 8

1 BOLl - 5/16"-18 x 1/2" 3

2 CLEVIS PiN, LONG ---5/16" x 3" 1

COI1ER PiN 1

L

HEADER BRACKE 1 1

LAG SCREW - 5/16" x 2" 2

3 HEX BOLt - 5/16".18 x 3/4" 5

HEX FLANGE NUi - 5/16"-18 5

LAG SCREW - 5/16" x 2" 2

4 SELF DRILLING SCREW - 1/4"-20 x 3/4" 3

DOOR BRACKE1 1

5 HEX BOLt - 5/16".18 x 3/4" 3

SELF LOCKING NUi - 5/16".18 1

HEX FLANGE NUi - 5/16".18 2

CLEVIS PIN - 5/16" x 3/4" 1

COTiER PIN 1

6 WALL CONSOLE ASSEMBLY 1

PAN HEAD PHILLIPS SCREW - #4.24 x 1" 2

7 13 MM INSULATED STAPLE 30

8 Safe r-Beam_ SOURCE/SENSOR BRACKE 1 2

PHILLIPS HEX SCREW ---#10-16 x 1- 1/4" 4

WIRE NDI (GREY) 4

NONUMBER REMOTE WITH BATTERY 1

NO BAG Safe r-Beam_ SOURCE/SENSOR & WIRE BE1 1

NONUMBER LIGHi COVER - WHITE 1

NONUMBER LIGH1 COVER - COLOR 1

Rail Clamp Bolt - 5/16"-18 x 5/8"

#10-16 x 1-1/4" Phillips Hex Screw

#4-24 x 1" Pan Head

Phillips Screw

Lag screw - 5/16" x 2"

Wire Nut

©

Self Locking Nut

5/16"-18

©

Hex Flange Nut

5/16"-18

©

Hex Flange Nut

1/4"-20

Self-drilling Screw

1/4"-20 x 3/4"

5/16" x 3/4"

0

Hex Bolt - 5/16"-18 x 3/4" Hex Bolt - 5/16"-18 x 1/2"

C[] Clevis pin

MISSING ANY PARTS? Please call toll free- 1.800.354.3643

DO NOT RETURNTO POINT OF PURCHASE.

IMPORTANT!- Information needed when calling

, Model number- (located onpackaging)

• Store, city, state, and date ofpurcHase

PNi/ 3642036534, 02/26/2010 REV. 1 7

Clevis pin, long 5/16" x 3"

Cotter pin

mml

Shoulder Bolt

5/16"-18 x 1"

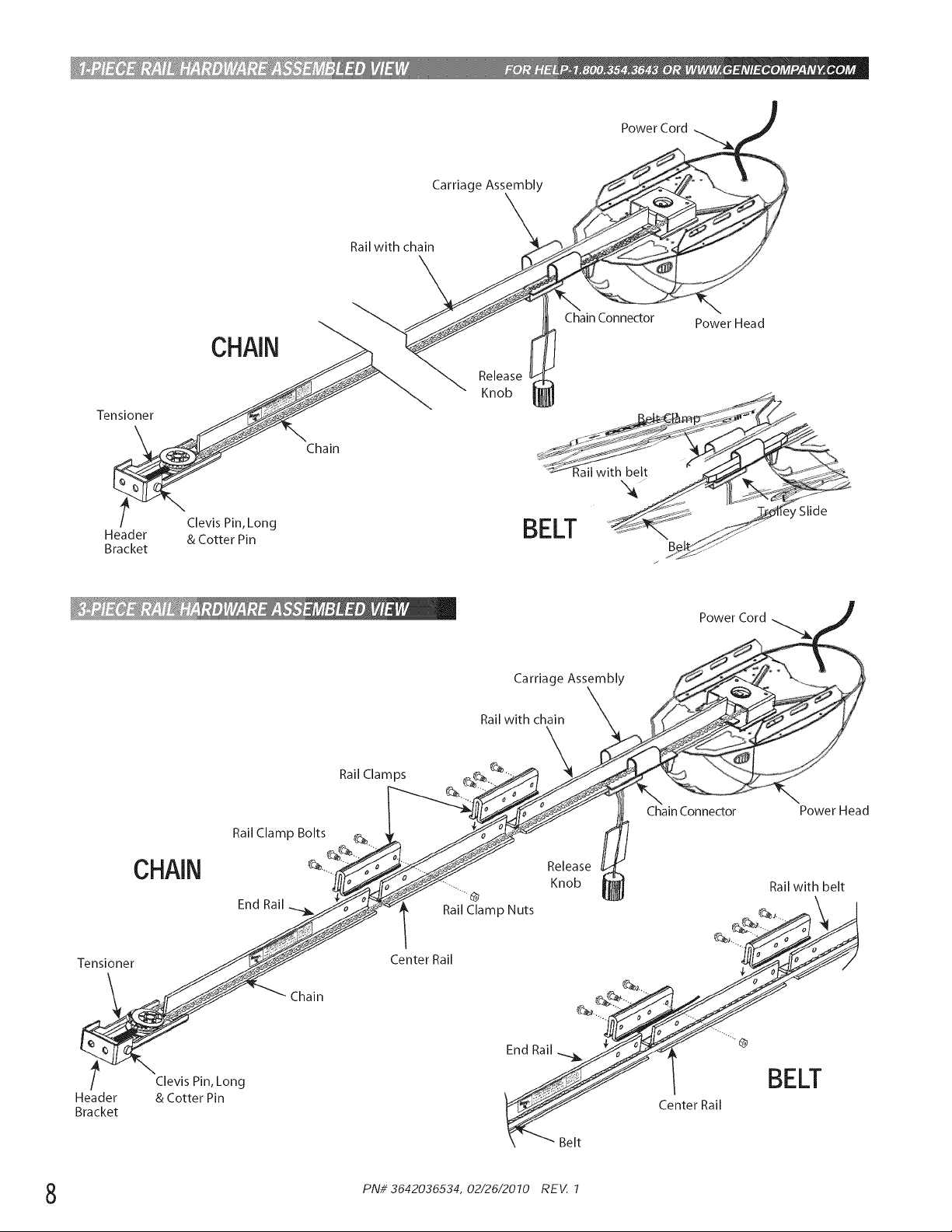

Tensioner

Power Cord

Carriage Assembly

Rail with chain

Chain Connector Power Head

CHAIN

Chain

Header

Bracket

Tensioner

t

CHAIN

Clevis Pin, Long

& Cotter Pin

Rail Clamp Bolts

End Rail

Rail Clamps

Center Rail

Carriage Assembly

Rail with chain

--...

Rail Clamp Nuts

Power Cord

\

Chain Connector Power Head

Release

Knob Rail with belt

_ _,. __

Header

Bracket

Clevis Pin, Long

& Cotter Pin

Chain

S

BELT

_Belt Center Rail

PNi/3642036534, 02/26/2010 REV. 1

IMPORTANTiNSTALLATiONiNSTRUCTiONS

I

1. READAND FOLLOW ALL SAFETY, INSTALLATION 5.

AND OPERATION INSTRUCTIONS.f v:_

d n_i nd_)nd_n 6.

,:: ,::....... , >' ........ ,:: <) D:,

2. Installonly on a properly balancedsectional garage door.

An improperly balanced door could cause severe injury.

Have a trained door system technician make repairs or

adjustments to cables, spring assemblies, and other 7.

hardware before installing the opener.

3. Removeall ropesand removeor makeinoperativeall

locksconnectedtothe garagedoor beforeinstallingopener.

4. Wherepossible,installthe dooropener7 feet or more 8.

above the floor.Forproductshavingan emergency

release, mount the emergency releasewithin reach, but at

least6 feet abovethe floorandavoiding contactwith

vehiclesto avoid accidental release.

Do NOT connect the opener to source of power

until instructedto do so.

Locate the control button:

. Within sight of door,

. At minimum height of 5 feet so small children are not

able to reach it, and

. Away from all moving parts of the door.

Installthe Entrapment WARNING Label next to the Wall

Control button in a prominentlocation. Install the

Emergency Release Tag on or next to the emergency

release.

After installing the opener,the door must reverse within

2 seconds when it contacts a 1-1/2 inch high object (or a

2 x 4 board laid flat) on the floor.

1oo_h}£Jhdoos

Cleara workspaceareatounpackand organizebox

and contentsforassembly.

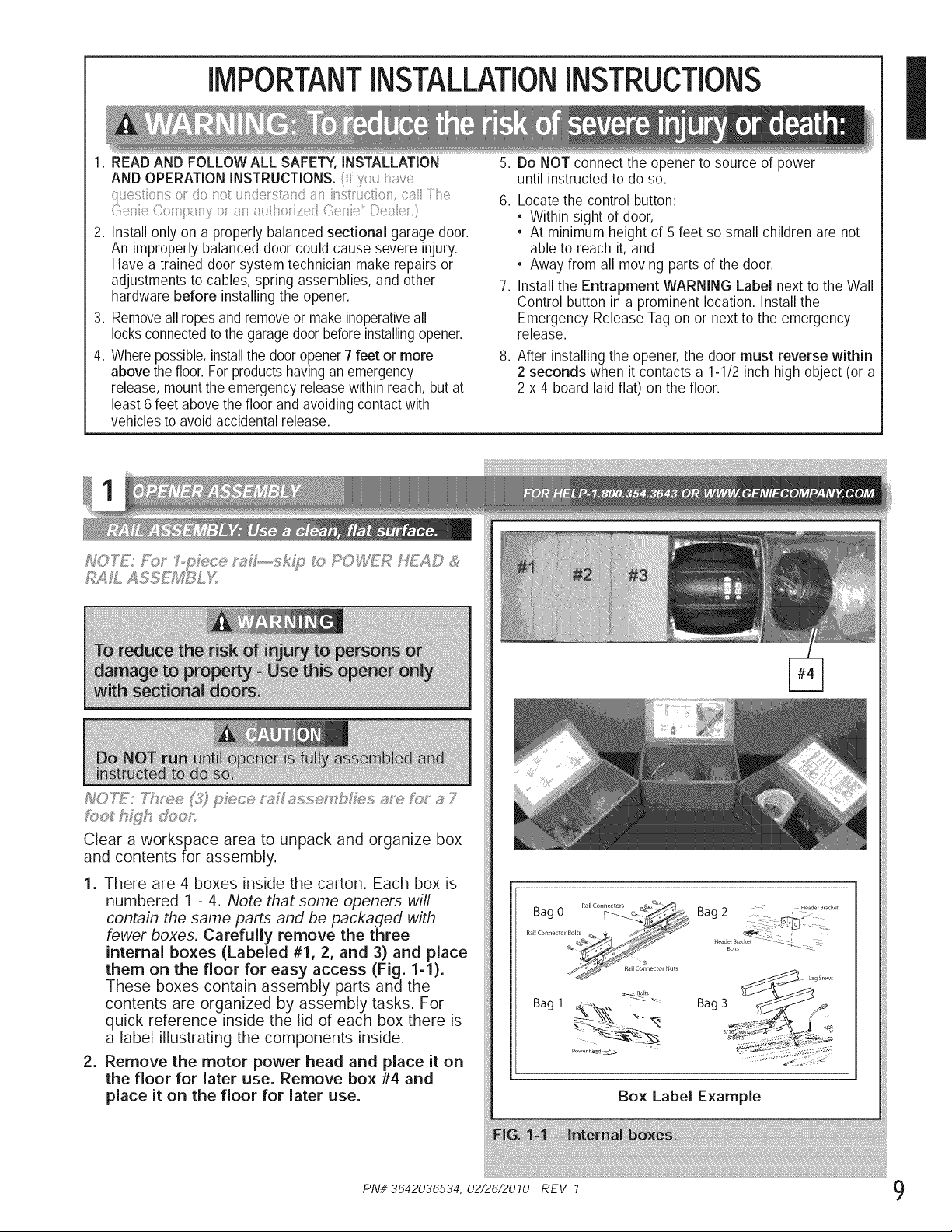

1. There are 4 boxes inside the carton. Each box is

numbered 1 - 4. Note that some openers will

contain the same parts and be packaged with

fewer boxes. Carefully remove the three

internal boxes (Labeled #1, 2, and 3) and place

them on the floor for easy access (Fig. 1-1).

These boxes contain assembly parts and the

contents are organized by assembly tasks. For

quick reference inside the lid of each box there is

a label illustrating the components inside.

2. Remove the motor power head and place it on

the floor for later use. Remove box #4 and

place it on the floor for later use.

PN# 3642036534, 02/26/2010 REV. 1 9

Bag 1

Lag Srews

Bag 3 _/

P_w_r h£ad _

Box Label Example

Loading...

Loading...