Page 1

3531835447

_BLE OF (IION]_ENT$

Safety Information ...................... 2

Important Installation Instructions ...... 2

Safety Features ......................... 2

Pre-installation Checklist ................ 3

Garage Door Opener Assembly ......... 9

Record Data (for Service) .............. 11

Garage Door Opener Installation ....... 12

Accessories ........................... 22

Maintenance .......................... 25

Troubleshooting ...................... 26

Wiring Diagram ....................... 29

Warranty information .................. 30

wm-I IB_]:ELLIC I .....' .... ,.Os_E

BI_:0o0o0,.o1_:t0BOLy..,.o°0.s,SEI/_:::_

For 7' 6" Doors, Extension Kit isavailable for 8' Doors

included Wall Control MUST be installed prior to Operation

of this Garage Door Operator,

Safe-T-Beam ® Safety Reverse System Must be installed and

the Force Controls MUST be Properly Set to close door.

This Equipment meets or exceeds all Federal, State and UL325

Safety Requirements.

Will not operate twice as fast on a one-piece door,

Please call us: 1-800-35-GENiE (354-3643)

www.geniecompany, com

Please have Model information ready when calling.

Page 2

GarageDoorsareheavyobjectsthatmovewiththehelpofsprings

underhightensionandelectricopeningequipment.Sincemoving

objects,springsundertension,andelectricopeningequipment

maycauseinjuries,yoursafetyandthesafetyofothersdependon

youreadingandunderstandingtheinformationinthismanual.

Ifyouhavegaragedoorrelatedquestionsordonotunderstandthe

informationpresented,callyournearestGenieFactoryAuthorized

Dealerlistedatwww.geniecompany.com,orcustomerServiceat

1-800-35-GENIE..

WARNING:

Can Cause Serious

Injury or Death

oKeep people clear of opening while door is moving.

oDo Not allow children to play with the door operator.

oDo Not operate a door thatjams or one that has a broken spring.

MOVINGDOOR

WARNING:

Can Cause Serious

Injury or Death

ELECTRICALSHOCK

WARNING:

Can Cause Serious

Injury or Death

HIGHSPRINGTENSION

oTurn off power before removing operator cover.

oWhen replacing cover, make sure wires are not pinched or near

moving parts.

oOperator must be properly grounded.

oDo Not try to remove, repair or adjust springs or anythinqto

which door sprinq parts are tastened, such as,woodl blocks,

steel brackets, cables or other like items.

oRepairs and adjustments must be made by a trained service

person using proper tools and instructions.

.& WARNING;

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH:

1 READAND FOLLOW ALL SAFETY,INSTALLATIONAND

OPERATIONINSTRUCTIONS.If you have any

questions or do not understand an instruction, call

your service representative.

2 Do Not install operator on an improperly balanced

door. An improperly balanced door could cause

severe injury. Repairs and adjustments to cables,

spring assembly, and other hardware must be made

by a trained service person using proper tools and

instructions.

3 Remove all ropes, and disable all locks connected to

the door before installing operator.

4 Install door operator 7 feet or more above the floor.

Mount the emergency release knob 6 feet above

the floor.

5 Do Not connect the operator to the source of power

until instructed to do so.

6 Locatethe control button:

• Within sight of door.

• At a minimum height of 5 feet, so small children

cannot reach it.

• Away from all moving parts of the door.

7 Install the entrapment WARNING label next to the

wall button or console. Install the emergency release

tag on, or next to, the emergency release

8 The operator must reverse when the door contacts a

1-1/2 inch high object on the floor at the center of

the doorway.This is about the size ofa 2"x 4" board

laid flat.

Safe-T-Beam ® (STB) Non-Contact Reversing System

Places an invisible beam across door opening, that reverses

the door during down travel to the fully open position if

anything passes through beam.

Safe-T-Reverse ® Contact Reversing System

Automatically stops and reverses a closing door within 2

seconds of contact with an object.

Safe-T-Stop ® Timed Reversed System

Automatically opens a closing door, if door does not close

within 30 seconds.

Force Guard ® Control

Used to set the force required for opening and closing

door. For maximum safety, set the minimum force required

to fully open and close door.

Automatic Lighting System

Two light bulbs up to 60 Watts max. each, are used for safer

entries and exits.The light turns on when door is activated

and automatically turns off 4.5 minutes later.

Manual Emergency Release

Allows the garage door to be opened or closed manually

for emergencies or maintenance.

Page 3

This Opener includes parts and supplies needed to install in most garages and

connect to most garage doors. There are many variations of garages and garage

doors. A few additional parts and supplies may be needed to install Opener into

your garage and connect to your garage door. While checking items listed

below, note any additional items you will need.

TOol ued _ t_i ectio_s

• 12'+ Tape Measure . Pencil . Ladder . Level

Check condition of vertical stile in center of door, and its connection to door's

top and bottom beams.

A If door frame is nailed together and not a solid connection, door frame

must be braced or reinforced before installing Opener.

B If door is"lightweight" (made with frame and skin - not solid), door

(including door frame) must be braced or reinforced before

installing Opener.

C A door opener reinforcement bracket may also be needed to connect

garage door to Opener's Door Bracket. This Opener is designed for

installation on a properly braced sectional door or solidly braced

one-piece door.

D Contact your Genie Factory Authorized Dealer or dealer of your garage

door for any necessary bracing and a door opener reinforcement

bracket (if needed) before proceeding.

E If you have a wooden door, measure door's thickness. (1/4" x 2") Lag

Screws are included for installing Door Bracket onto door. If your door

is less than 2"thick, brace door or use shorter Door Bracket Lag

Screws (1/4" x 11/4"- not included)

WARNING:

Ifyour door sticks,binds,or is out of

balance,haveit adjusted by aGenieFactory

Authorized Dealer.Door springs,cables,

pulleys,bracketsand associatedhardware

are under extreme tension and can cause

seriousinjury ordeath.

NOTE

The Excelerator Opener is equipped with

an automatic Garage Door Balance

Detection System. SeeTroubleshooting

Guide on page 27.

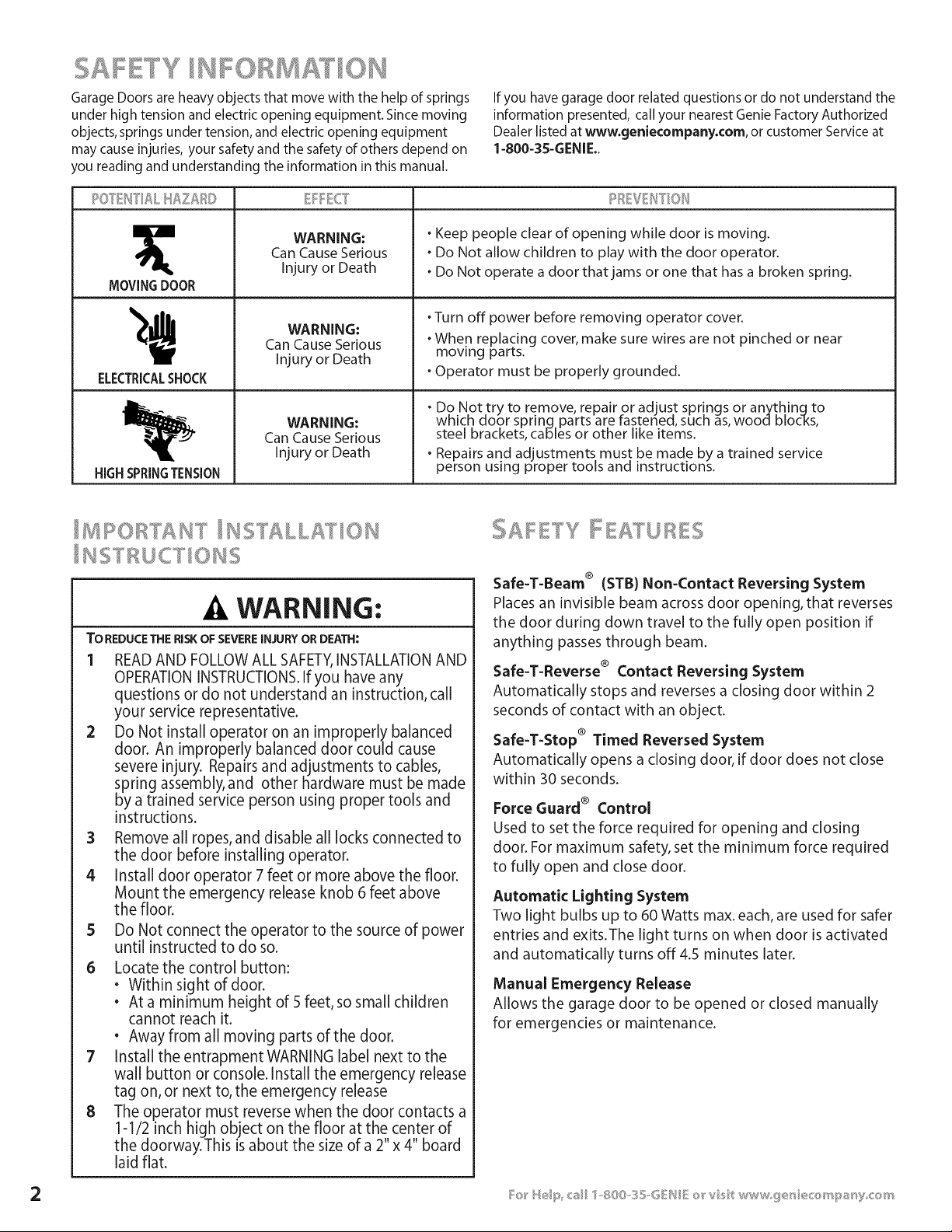

KEEPFEETCLEAR OF DOOR

Sectional Door

CHCK G£_£6 ©oo_

ALIGH _EIU I")OPEB£T 01%

A

Raise door, check alignment and see if it moves freely (Figure 1). If door

appears out of alignment, binds, or does not move smoothly, contact a

Genie Factory Authorized Dealer or dealer of your garage door for repairs

and adjustments to door mechanism.

Raise door to 3' - 4' above ground and carefully let go. Door should stay

stationary. Slight movement is acceptable. More than slight movement

means door is out of balance. Contact a Genie Factory Authorized Dealer

or dealer of your garage door

for repairs and adjustments SECTIONAL ._cj_DOOR'TORSION SPRINGS SECTIONAL DOOR, EXTENSION SPRINGS

to door mechanism. I_ Torsion Springs

C

Check door type. Make _/_-_411-_. "J

a note of whether it is a __ __-__, _

sectional or a one-piece __- _:_' -

door (Figure 2). _........e ............

.............::]--+........

Figure 2 Note Door Type

One-Piece Door

Figure 1 Checking door balance

ONE-PIECE DOOR, TRACKLESS

Header Area

_ Center Stile

Page 4

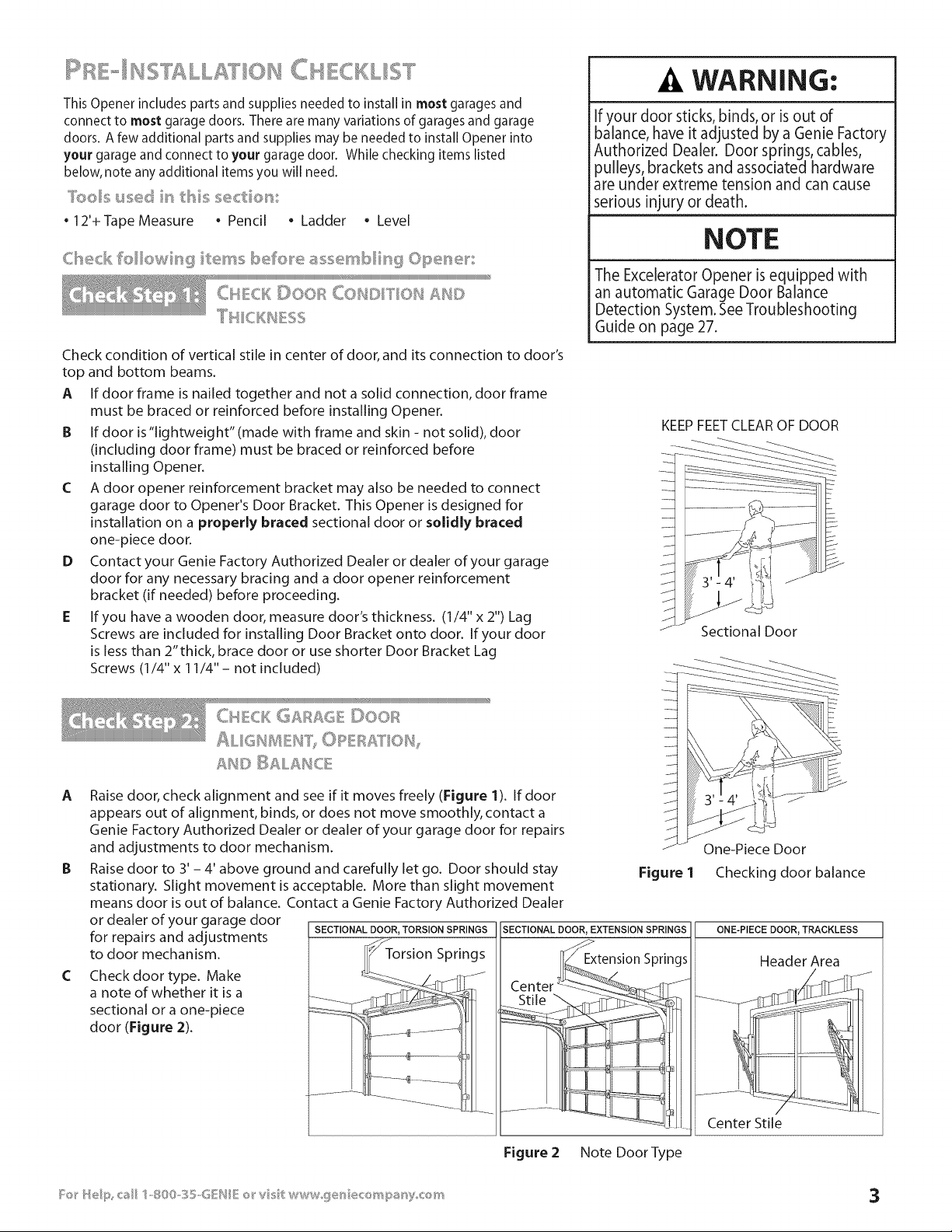

Measure garage door height (7'-6", 8'-0", or taller) with

tape measure.

A If door height is 7'-6" or less,continue with Check Step 4.

B If your door height isabove 7'-6%make sure your rail is long

enough to open the garage door. If there isany question

contact your Customer Service Representative at

1-800-3S-GENIE.

CH CKDOOR t_ AD R

NOTE

The header is a heavily reinforced section of the wall just

above the top of the garage door opening.

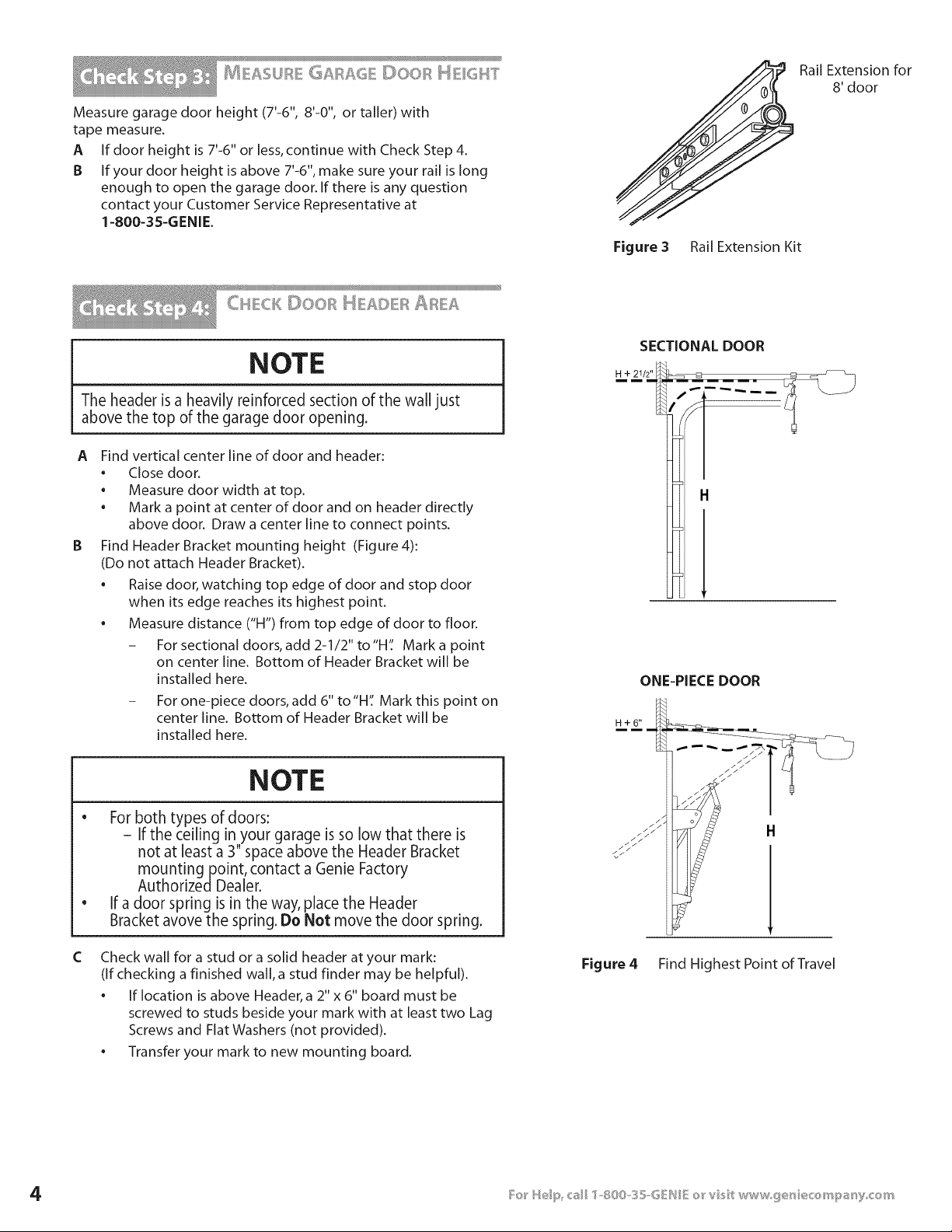

ABFind vertical center line of door and header:

• Close door.

• Measure door width at top.

• Mark a point at center of door and on header directly

above door. Draw a center line to connect points.

Find Header Bracket mounting height (Figure 4):

(Do not attach Header Bracket).

• Raise door, watching top edge of door and stop door

when its edge reaches its highest point.

• Measure distance ('H") from top edge of door to floor.

- For sectional doors, add 2-1/2" to"H': Mark a point

on center line. Bottom of Header Bracket will be

installed here.

- For one-piece doors, add 6" to"H': Mark this point on

center line. Bottom of Header Bracket will be

installed here.

RailExtension for

8' door

Figure 3 Rail Extension Kit

SECTIONAL DOOR

ONE-PIECE DOOR

H+6"

NOTE

e

For both types of doors:

i If the ceiling in your garage is so low that there is

not at least a 3" space above the Header Bracket

mountingpoint, contact a Genie Factory

AuthorizedDealer.

If a door spring is in the way, place the Header

Bracket avove the spring. Do Not move the door spring.

C

Check wall for a stud or a solid header at your mark:

(if checking a finished wall, a stud finder may be helpful).

• If location is above Header, a 2" x 6" board must be

screwed to studs beside your mark with at least two Lag

Screws and Flat Washers (not provided).

• Transfer your mark to new mounting board.

H

Figure 4 Find Highest Point of Travel

Page 5

120 Volt grounded outlet

4_ or wiring box within 3 feet of

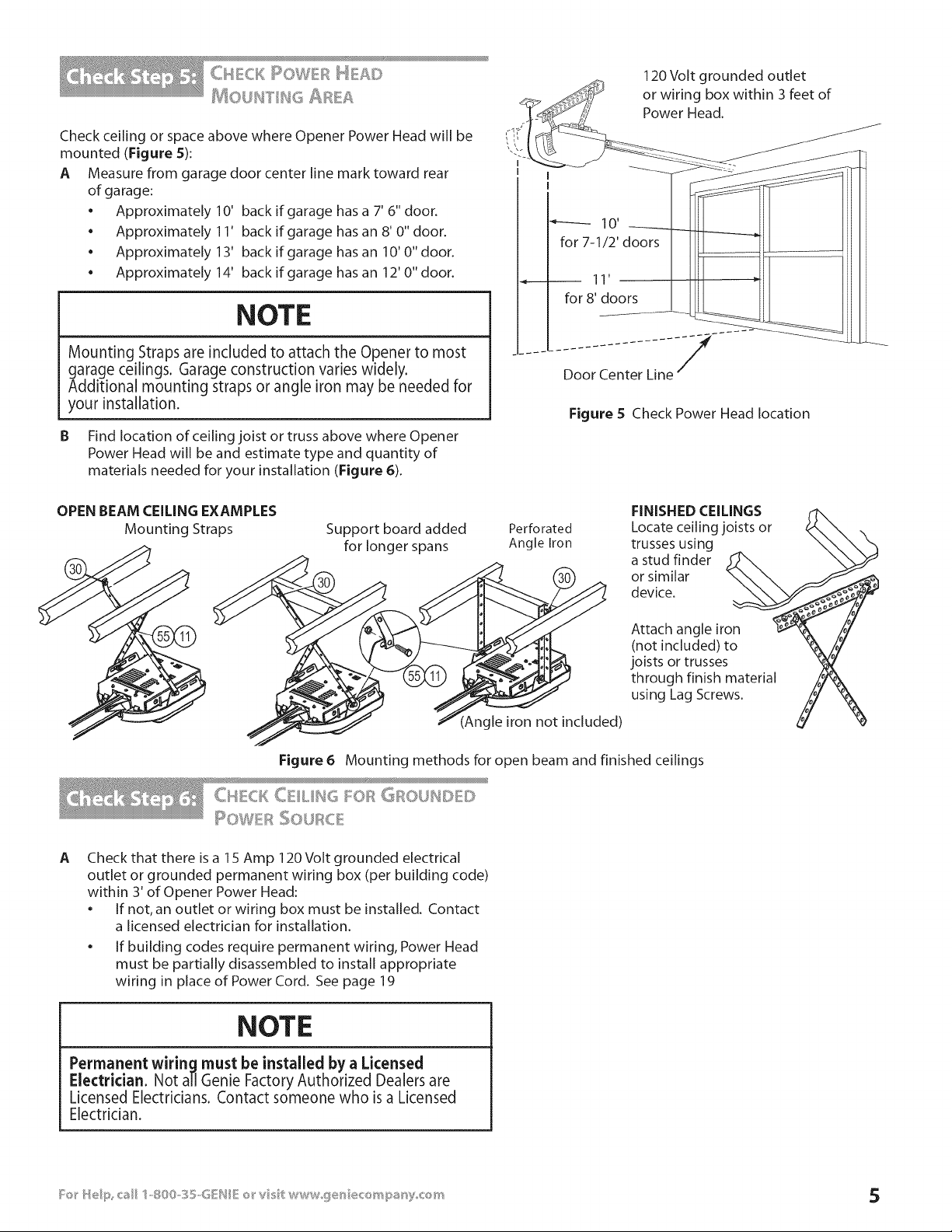

Check ceiling or space above where Opener Power Head will be

mounted (Figure S):

A Measure from garage door center line mark toward rear

of garage:

• Approximately 10' back if garage hasa 7' 6" door.

• Approximately 11' back if garage hasan 8' 0" door.

• Approximately 13' back if garage hasan 10'0"door.

• Approximately 14' back if garage hasan 12'0"door.

NOTE

Mounting Straps are included to attach the Opener to most

garage ceilings. Garage construction varies widely.

Additional mounting straps or angle iron may be needed for

your installation.

B Find location of ceiling joist or truss above where Opener

Power Head will be and estimate type and quantity of

materials needed for your installation (Figure 6).

OPEN BEAMCEILINGEXAMPLES

Mounting Straps

Support board added

for longer spans

°"f_ Power Head.

I IIIi "1 II

- - Door Center Line--

Figure S Check Power Head location

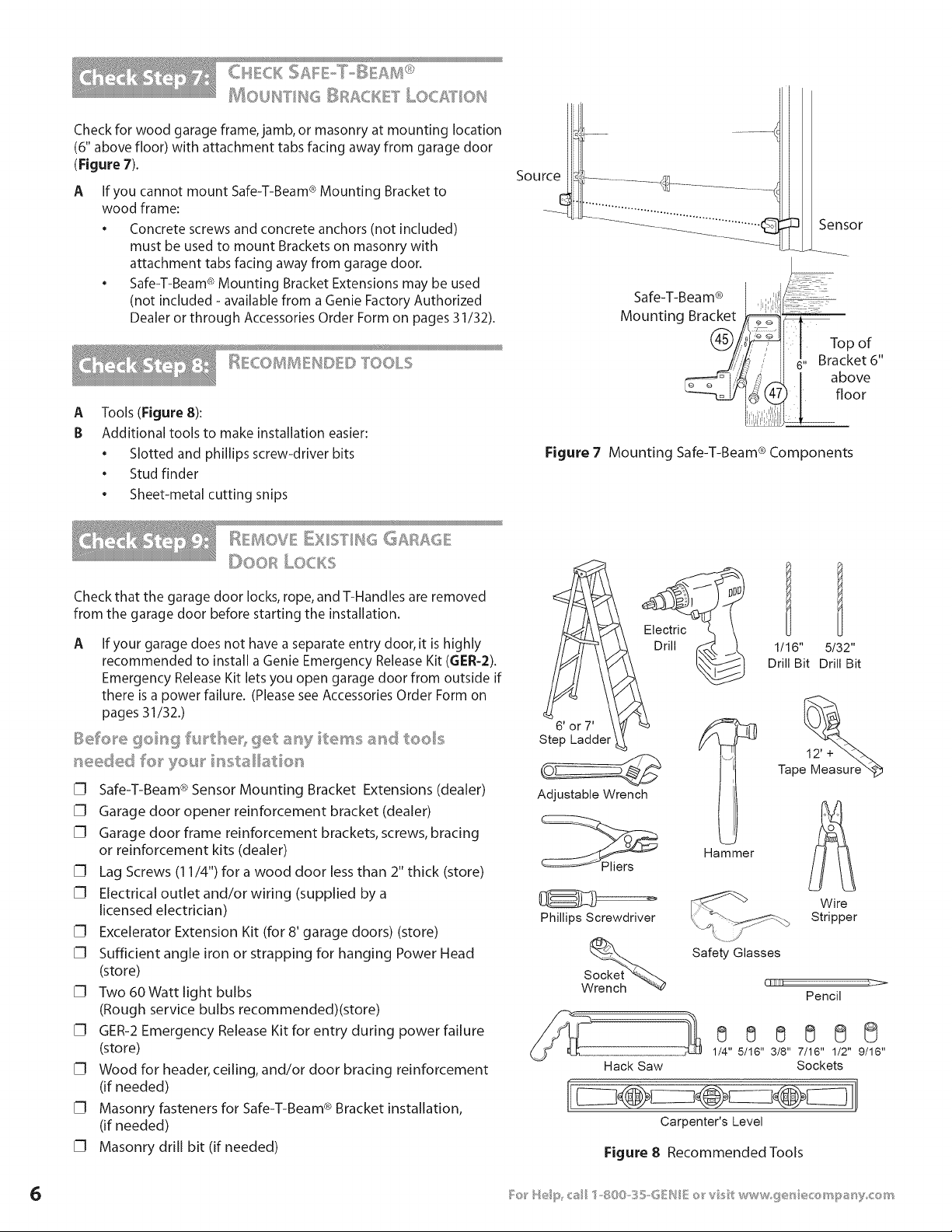

FINISHED CEILINGS

Perforated

Angle Iron

Locate ceiling joists or

trusses using

a stud finder

or similar

device.

Figure 6 Mounting methods for open beam and finished ceilings

CtICK C iI.iI_16 l::_,._Fl'_"6FlOUl_I[l [)

I OWER _:'_: '=°'°

A

Check that there is a 1S Amp 120 Volt grounded electrical

outlet or grounded permanent wiring box (per building code)

within 3' of Opener Power Head:

• If not, an outlet or wiring box must be installed. Contact

a licensed electrician for installation.

• If building codes require permanent wiring, Power Head

must be partially disassembled to install appropriate

wiring in place of Power Cord. See page 19

,:;:_0JR_. £

NOTE

Permanent wiring must be installed by a Licensed

Electrician. Not all Genie Factory Authorized Dealers are

Licensed Electricians. Contact someone who is a Licensed

Electrician.

Attach angle iron

(not included) to

joists or trusses

through finish material

using Lag Screws.

(Angle iron not included)

Page 6

MOUF_ FIF_G _}RACiKE I" LOC£T OIU

Check for wood garage frame, jamb, or masonry at mounting location

(6" above floor) with attachment tabs facing away from garage door

(Figure 7).

A

Ifyou cannot mount Safe-T-Beam ®Mounting Bracket to

wood frame:

• Concrete screws and concrete anchors (not included)

must be used to mount Brackets on masonry with

attachment tabs facing away from garage door.

• Safe-T-Beam ®Mounting Bracket Extensions may be used

(not included - available from a Genie Factory Authorized

Dealer or through Accessories Order Form on pages 31/32).

_3 Sensor

Safe-T-Beam ® i,_,

Mounting Bracket •__

_ COBRSREIU[3E[)TOOLS

A

Tools (Figure 8):

B

Additional tools to make installation easier:

* Slotted and phillips screw-driver bits

. Stud finder

. Sheet-metal cutting snips

i_ 140V" =......... ¢: . . ." E l!×l:JYlt< ,,:_GAFbS,QE

L;,RLOClS

Check that the garage door locks, rope, and T-Handles are removed

from the garage door before starting the installation.

A If your garage does not have a separate entry door, it is highly

recommended to install a Genie Emergency Release Kit (6ER-2).

Emergency Release Kit lets you open garage door from outside if

there is a power failure. (Please see Accessories Order Form on

pages 31/32.)

[] Safe-T-Beam ® Sensor Mounting Bracket Extensions (dealer)

[] Garage door opener reinforcement bracket (dealer)

[] Garage door frame reinforcement brackets, screws, bracing

or reinforcement kits (dealer)

[] Lag Screws (11/4") for a wood door less than 2" thick (store)

[] Electrical outlet and/or wiring (supplied by a

licensed electrician)

[] Excelerator Extension Kit (for 8' garage doors) (store)

[] Sufficient angle iron or strapping for hanging Power Head

(store)

[] Two 60 Watt light bulbs

(Rough service bulbs recommended)(store)

[] GER-2 Emergency Release Kit for entry during power failure

(store)

[] Wood for header, ceiling, and/or door bracing reinforcement

(if needed)

[] Masonry fasteners for Safe-T-Beam ® Bracket installation,

(if needed)

[] Masonry drill bit (if needed)

Figure 7

6' or 7'

Step Ladder

Adjustable Wrench

Phillips Screwdriver

Mounting Safe-T-Beam ® Components

Hack Saw

Figure 8 Recommended TooLs

Drill 1_

Hammer

.......I

Safety Glasses

888888

1/4" 5/16" 3/8" 7/16" 1/2" 9/16"

Carpenter's Level

i , H 6" Bracket6

/4_ I above

Top of ,,

8 floor

1/16" 5/32"

Drill Bit Drill Bit

12' +

Tape

Wire

Stripper

Pencil

Sockets

Page 7

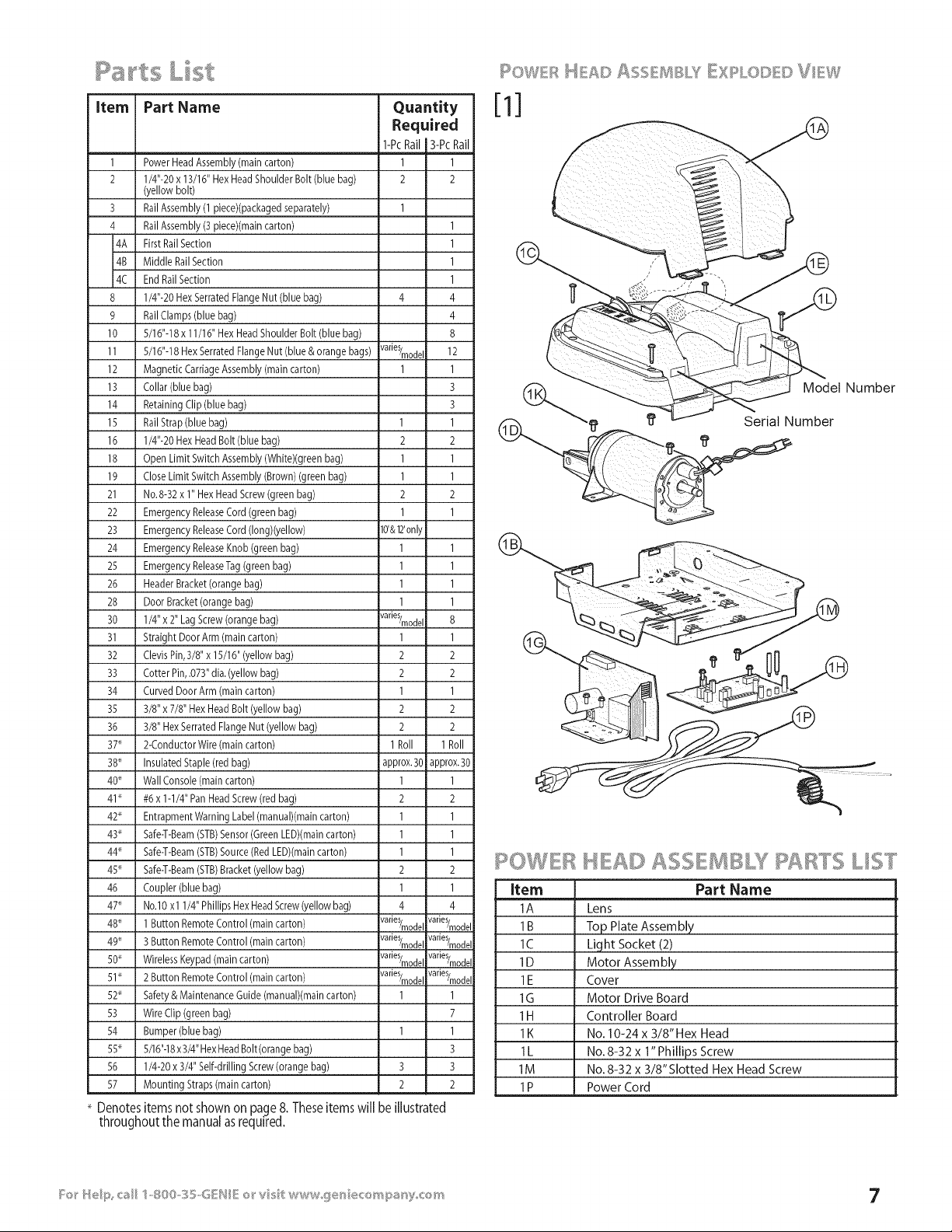

L st

item Part Name Quantity

Required

1-Pc Rail 13-Pc Rail

1 PowerHead Assembly (main carton) 1 1

2 1/4"-20 x 13/16" HexHead Shoulder Bolt (blue bag) 2 2

(yellow bolt)

3 RailAssembly (1 piece#packaged separately) 1

4 RailAssembly(3 piece)(main carton) 1

4A First RailSection 1

4B Middle RailSection 1

4C End RailSection 1

8 1/4"-20 Hex Serrated FlangeNut (blue bag) 4 4

9 RailClamps(blue bag) 4

10 5/16"-18 x 11/16" Hex HeadShoulder Bolt (blue bag) 8

11 5/16"-18 Hex SerratedFlange Nut (blue &orange bags) varieS/modeI 12

12 Magnetic CarriageAssembly (maincarton) 1 1

13 Collar (blue bag) 3

14 Retaining Clip (blue bag) 3

15 RailStrap (blue bag) 1 1

16 1/4"-20 Hex HeadBolt (blue bag) 2 2

18 Open Limit Switch Assembly (White)(green bag) 1 1

19 CloseLimit Switch Assembly(Brown) (green bag) 1 1

21 No.8-32x 1" HexHead Screw (green bag) 2 2

22 Emergency ReleaseCord (green bag) 1 1

23 Emergency ReleaseCord (Iong)(yellow) 10'&12'only

24 Emergency ReleaseKnob (green bag) 1 1

25 Emergency ReleaseTag(green bag) 1 1

26 Header Bracket(orange bag) 1 1

28 Door Bracket(orange bag) 1 1

30 1/4" x 2" LagScrew(orange bag) varieS/modeI 8

31 Straight Door Arm (main carton) 1 1

32 ClevisPin,3/8" x 15/16" (yellow bag) 2 2

33 Cotter Pin,.073" dia.(yellow bag) 2 2

34 Curved Door Arm (main carton) 1 1

35 3/8" x 7/8" HexHead Bolt (yellow bag) 2 2

36 3/8" HexSerratedFlange Nut (yellow bag) 2 2

37_ 2-ConductorWire (maincarton) 1 Roll 1 Roll

38_ Insulated Staple (red bag) approx.30 approx.30

40* Wall Console (maincarton) 1 1

41" #6 x 1-1/4" Pan HeadScrew (red bag) 2 2

42* Entrapment Warning Label (manual)(main carton) 1 1

43* Safe-T-Beam(STB)Sensor(GreenLED)(maincarton) 1 1

44* Safe-T-Beam(STB)Source(RedLED#maincarton) 1 1

45* Safe-T-Beam(STB)Bracket (yellow bag) 2 2

46 Coupler (blue bag) 1 1

47_ No.lO x l 1/4" Phillips HexHeadScrew(yellow bag) 4 4

48_ 1 Button RemoteControl (main carton) varieS/modeI varieS/modeI

49* 3 Button Remote Control (main carton) varieS/modeI varieS/modeI

SO* Wireless Keypad(main carton) varieS/modeI varieS/modeI

51" 2 Button Remote Control (main carton) varieS/modeI varieS/modeI

52* Safety&Maintenance Guide (manual)(main carton) 1 1

53 Wire Clip (green bag) 7

54 Bumper (blue bag) 1 1

SS* 5/16"-18x 3/4" HexHeadBolt(orange bag) 3

56 1/4-20 x3/4" Self-drilling Screw(orange bag) 3 3

57 Mounting Straps(main carton) 2 2

Denotesitems not shownon page8.Theseitemswill beillustrated

throughout the manualasrequired.

I_ f}' Serial Number

Model Number

ROWER HEAD c ....,, BTs L/ST

Item

1A

1B

lC

1D

1E

1G

1H

1K

1L

1M

1P

Lens

Top Plate Assembly

Light Socket (2)

Motor Assembly

Cover

Motor Drive Board

Controller Board

No. 10-24 x 3/8" Hex Head

No.8-32 x 1" Phillips Screw

No. 8-32 x 3/8" Slotted Hex Head Screw

Power Cord

Part Name

Page 8

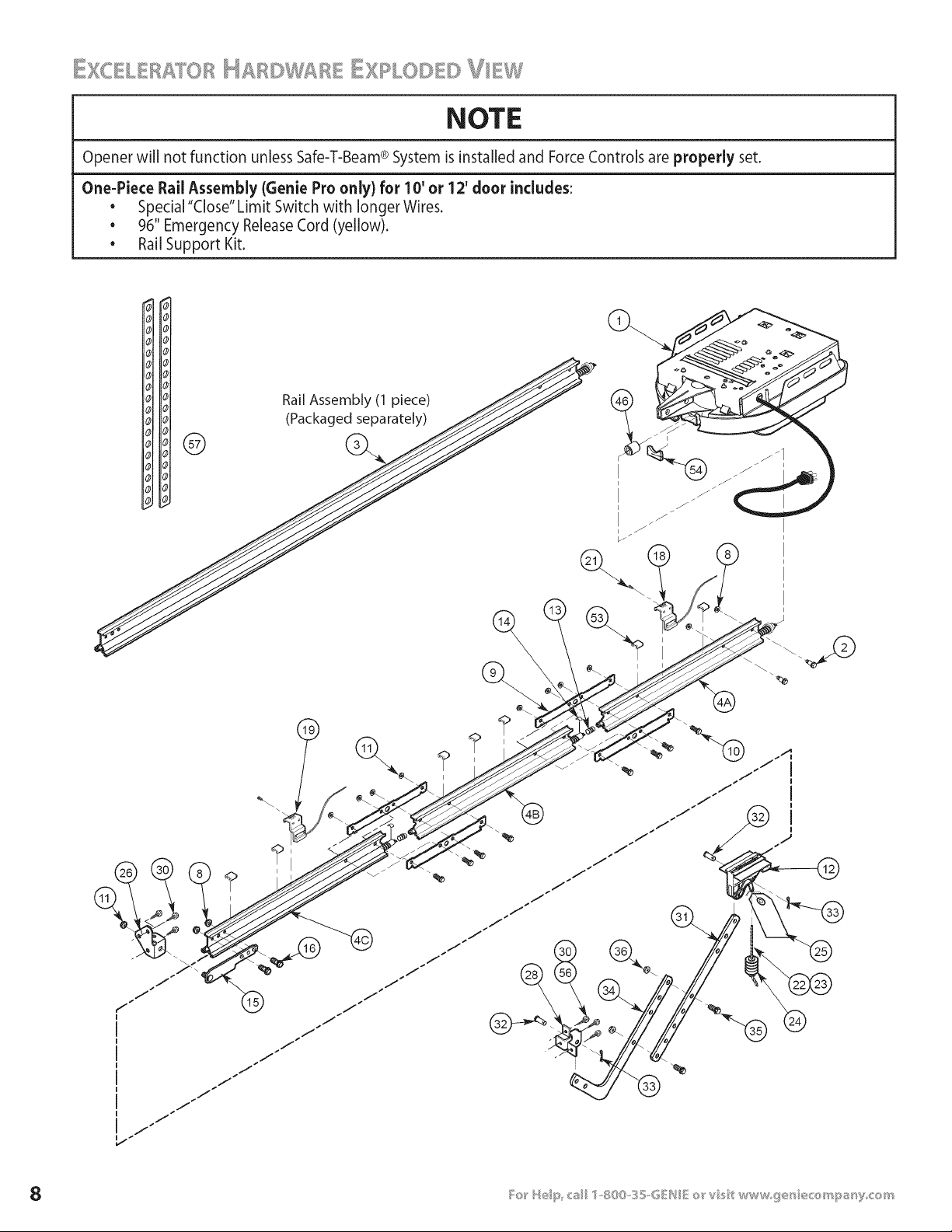

NOTE

Opener will not function unless Safe-T-Beam®System isinstalledand ForceControls are properly set.

One-Piece Rail Assembly {Genie Pro only) for 10' or 12' door includes:

• Special"Close" Limit Switch with longer Wires.

• 96" Emergency Release Cord (yellow).

• Rail Support Kit.

Rail Assembly (1 piece)

H Hol (Packaged separately) /_/ \ _

\

i

®

Page 9

RailStrap

COIl CT RAIL TO I ©WEF_

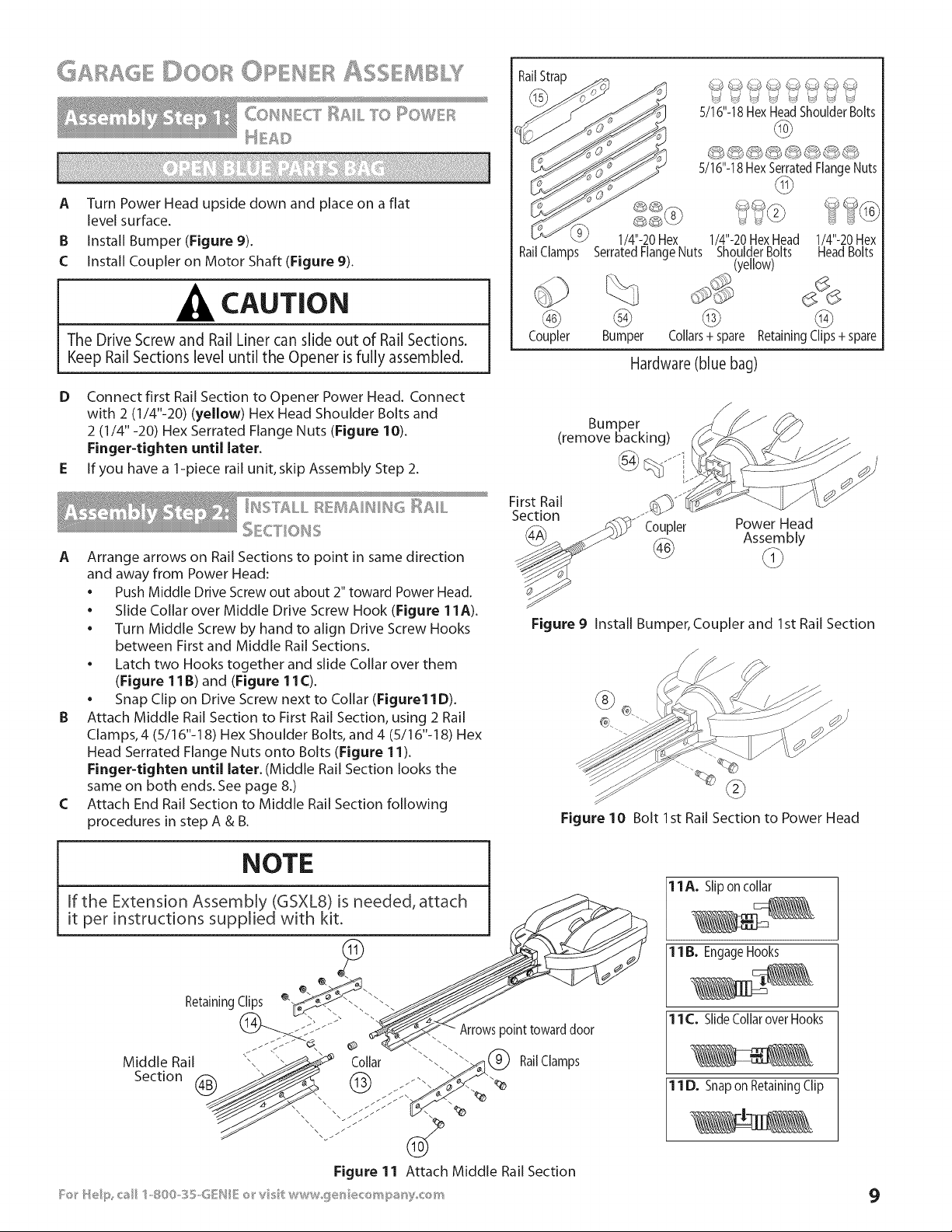

A

Turn Power Head upside down and place on a flat

level surface.

B

Install Bumper (Figure 9).

C

Install Coupler on Motor Shaft (Figure 9).

CAUTION

The Drive Screw and Rail Liner can slide out of Rail Sections.

Keep RailSections level until the Opener is fully assembled.

D Connect first Rail Section to Opener Power Head. Connect

with 2 (1/4"-20) (yellow) Hex Head Shoulder Bolts and

2 (1/4"-20) Hex Serrated Flange Nuts (Figure 10).

Finger-tighten until later.

E If you have a 1-piece rail unit, skip Assembly Step 2.

A Arrange arrows on Rail Sections to point in same direction

and away from Power Head:

• Push Middle Drive Screw out about 2" toward Power Head,

• Slide Collar over Middle Drive Screw Hook (Figure 11A).

• Turn Middle Screw by hand to align Drive Screw Hooks

between First and Middle Rail Sections.

• Latch two Hooks together and slide Collar over them

(Figure 11B) and (Figure 11C).

• Snap Clip on Drive Screw next to Collar (Figure11D).

B Attach Middle Rail Section to First Rail Section, using 2 Rail

Clamps, 4 (5/16"-18) Hex Shoulder Bolts, and 4 (5/16"-18) Hex

Head Serrated Flange Nuts onto Bolts (Figure 11).

Finger-tighten until later. (Middle Rail Section looks the

same on both ends. See page 8.)

C Attach End Rail Section to Middle Rail Section following

procedures in step A & B.

S/16"-18HexHeadShoulderBolts

@

5/16"-18HexSerratedFlangeNuts

@

RailClamps

1/4"-20 Hex

SerratedFlangeNuts

1/4"-20HexHead 1/4"-20Hex

ShoulderBolts HeadBolts

(yellow)

%

@

Coupler

(remove backing)

First Rail

Section

Figure 9 Install Bumper, Coupler and 1st Rail Section

Figure 10 Bolt 1st Rail Section to Power Head

@

Bumper

Hardware (blue bag)

Bumper

@ Jfi

Coupler Power Head

@ @

Collars+ spare Retaining Clips+ spare

Assembly

11A. Slipon collar

1B. EngageHooks

11 C._Slide Collarover Hooks

11 D._Snap on Retaining Clip

9

Page 10

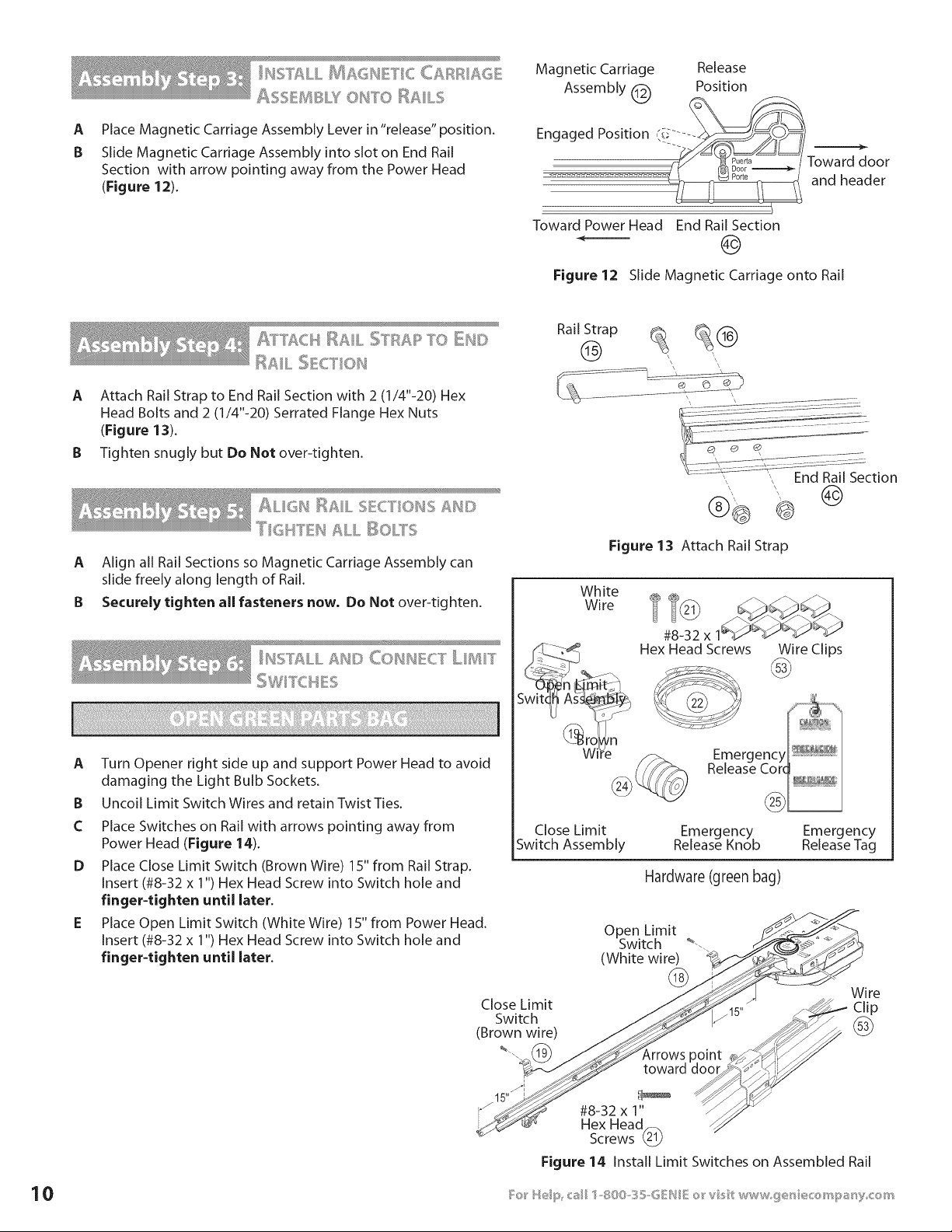

Magnetic Carriage Release

Assembly _ Position

A

Place Magnetic Carriage Assembly Lever in "release" position.

B

Slide Magnetic Carriage Assembly into slot on End Rail

Section with arrow pointing away from the Power Head

(Figure 12).

A]_]'ACH RAIL STRAR TO DU©

RAIL :_E_._[l,N

A Attach Rail Strap to End Rail Section with 2 (1/4"-20) Hex

Head Bolts and 2 (1/4"-20) Serrated Flange Hex Nuts

(Figure 13).

B Tighten snugly but Do Not over-tighten.

'I? I & I "

ALIGH I_AIL SECTIONS ;_N©

A Align all Rail Sections so Magnetic Carriage Assembly can

slide freely along length of Rail.

B Securely tighten all fasteners now, Do Not over-tighten.

Engaged Position (i_.... -__/_/

kCC/

To.o=

.................................. _ andheader

Toward Power Head End Rail Section

Figure 12 Slide Magnetic Carriage onto Rail

RailStrap _@

Figure 13 Attach Rail Strap

White

Wire

I¢2 = =_'_ & I "=S,>%, LL _S[} CONNECT LIIIIT

A

Turn Opener right side up and support Power Head to avoid

damaging the Light Bulb Sockets.

B

Uncoil Limit Switch Wires and retain Twist Ties.

C

Place Switches on Rail with arrows pointing away from

Power Head (Figure 14).

D

Place Close Limit Switch (Brown Wire) 15" from Rail Strap.

Insert (#8-32 x 1") Hex Head Screw into Switch hole and

finger-tighten until later.

Place Open Limit Switch (White Wire) 15" from Power Head.

Insert (#8-32 x 1") Hex Head Screw into Switch hole and

finger-tighten until later.

#8-32 x

Hex Head Screws

Close Limit Emergency Emergency

Switch Assembly Release Knob Release Tag

Wire Clips

Hardware (green bag)

Open Limit

Switch _--.

(White wire)

@

Close Limit

Switch

(Brown wire)

%.

i

15"

,rro..t

toward I_o_#i_

#8-32 x 1" --_"_

Hex Head_

Screws

Figure 14 Install Limit Switches on Assembled Rail

_15" j_- Clip

Wire

Page 11

NOTE

o Loosen (Do Not Remove) Terminal Block Screws_

o Limit Switch adjustments and securing the Wires

will be done later.

F Lay Wires in channel on top of Rail and secure with Wire Clips

(Figure 14).

G Coil and bundle excess Limit Switch Wires on top of Power

Head with Twist Ties. Leave just enough Wire to reach

Terminals on back of Power Head (Figure 14).

H Turn Opener upside down, and connect Limit Switch Wires to

Power Head Terminal Block (Figure lS):

• Terminal 4: OPEN Limit Switch Wire (white).

• Terminal 5: OPEN Limit Switch Wire (white) and

CLOSE Limit Switch Wire (brown).

• Terminal 6: CLOSE Limit Switch Wire (brown).

_ffT'£Ck¢ _D4 F_G _SCY_ L AS

A Tie overhand knot at one end of Emergency Release Cord.

B Thread opposite end of Cord through Knob and hole in

Magnetic Carriage Assembly Release Lever (Figure 16).

C Tie overhand knot at this end of Emergency Release Cord.

D Attach Emergency Release Tag to Magnetic Carriage

Assembly Release Lever.

Antenna

Terminal White Limit Brown Limit

Block Switch wires Switch wires

Figure 15 Connect Limit Switch Wires to Power

HeadTerminal Block

Please note the following information so it is available if you need

to call us:

Date purchased: / /

Serial number (Figure 17):

Model number (Figure 17):

Dealer Name:

Dealer Address:

City:

State:

Zip:

Phone:

NOTE

Please keep original or photocopy of your sales receipt with

this manual for future reference should service ever be

required.

Figure 16

Emergency

Release Knob

®

Attach Emergency Release Cord/Knob

and Tag

Model

Number

Serial

Number

(example)

WK YR PI

01 02 4E

Figure 17 Model and Serial Numbers

Page 12

NOTE

Mount directly

into header

_--____ .___ ',

Use of Header Bracket

support board

Center Line of door

I

Forlightweight garage doors, make sure you have installed

the proper reinforcement (SeeCheck Door Condition and

Thickness on page 3).

CAUTION

o

The Header Bracket must be fastened to the garage

framing. Do Not fasten the Header Bracket to drywall,

particle board, plaster, or other such material.

• It may be necessary to attach a 2" x 6" board across the

wall studs above the door header to serve as a

mounting plate for the Header Bracket. The Bracket can

then be mounted at the proper location and have

sufficient support.

• Ifa door spring isin the way, place the Header Bracket

above the spring. Do Not move the door spring.

A If needed, attach a 2" x 6" board (Figure 18) (also see page 4)

with at least two (four is recommended) Lag Screws and Flat

Washers (not supplied).

7::?: : .....

Bottom of

bracket flange

Alternative Header Bracket orientations

\

Highest Point of door travel

+ 2-1/2" (sectional door) or

+ 6" (one-piece door)

Figure 18 Attach Header Bracket above Garage Door

'\. j _ _-_

5/16-18 x 3/4"

Header

Bracket

Hex Head Bolts

B Attach Header Bracket to header at mark above door.

NOTE

Mounting variations are shown in Figure 18. Any of these

may be used depending on space. However, it iscritical that

the point where the Rail attaches to the Header Bracket be

on the center line of the door.

• Mark 3 hole positions.

• Drill 3 (5/32") pilot holes.

• Attach Header Bracket with 3 (1/4" x 2") Lag Screws.

1/4"x 2"

Lag Screws

Door Bracket

5/16-18 x 3/4"

Hex Serrated Flange Nuts

1/4"-20 x 3/4"

Self-Drilling Screws

Hardware (orange bag)

Page 13

CAUTION

Doors made of masonite, lightweight wood, fiberglass, metal,

or other lightweight materials must be properly braced

before mounting door Opener.

_o_ _'e<:tier_al doo_'_x

A Place Door Bracket on door center line, no lower than top

roller, and mark holes (Figure 19).

B Attach Door Bracket:

• For metal doors, use 3 (1/4" -20 x 3/4") Self-Drilling

Screws (provided).

• For wood doors, use 3 (1/4" x 2") Lag Screws or

3 (1/4" x 11/4") Lag Screws (not provided).

NOTE

Before installing,check length of the included Lag Screws vs.

the thickness of your garage door. For doors thinner than 2%

use 11/4" Lag Screws. Check door condition and thickness.

See page 3.

SECTIONAL DOORS

Center Line of door

i I

Optional Door Operator Bracket (not included)

Figure 19 Attach Door Bracket

I®

ONE-PIECE DOORS

Center Line of door

_e} _ etxe_,}::} ece doe}_5

A Position Door Bracket on door's center line, as high as

possible or on top of door.

B Attach Door Bracket:

• For metal doors, use 3 (1/4" -20 x 3/4") Self-Drilling

Screws.

. For wood doors, use 3 (1/4" x 2") Lag Screws.

A While supporting the Power Head, place threaded end of Rail

Strap Bolt through Header Bracket hole (Figure 20).

B Attach (5/16"-18) Flange Nut to Rail Strap Bolt.

Finger-tighten until later,

Rail Strap Bolt

Rail

®

Header Bracket

Figure 20 Attach Rail Strap to Header Bracket

Page 14

SECTIONAL DOORS

Rail Should be level or dip down slightly.

A RaiseandsupportOpenerPowerHead(alongdoorcenter

line)higherthanhighestpointofdoortravel(usingstep

ladder,etc.)(Figure21).

B Measure distance from Opener to garage ceiling.

CAUTION

Mounting Brackets must be fastened to garage framing.

Do Not fasten to drywall, particle board, plaster, or other

such materials.

NOTE

• Make sure the rail of your supported Power Head is

slightly higher than the highest point of door travel

by raising the door to check. Adjust as needed.

e

Materials needed for mounting Opener Power Head

to garage may vary. Read all instructions completely.

e

Garage constructions differ. Extra material may be

needed. See Check Power Head Mounting Area on

page 5.

C Install Mounting Straps and/or support brackets (angle iron

not included) to joists or trusses and to mounting slots in

Opener. Use (5/16"-18 x 3/4") Hex Head Bolt, (5/16"-18)

Serrated Flanged Nut, and (1/4" x 2") Lag Screws as needed

(Figure 22).

D Securely tighten all fasteners now. Do Not over-tighten.

Check for clearance.

H

ONE-PIECE DOORS

Set clearance at 1"-11/2"between Rail and door at

highest point of travel.

H

OPEN BEAM CEILING EXAMPLES

Mounting Straps Support board added

Figure 22 Mounting methods for open beam and finished ceilings

for longer spans

Figure 21 Checking Power Head position

Perforated

Angle Iron

(Angle iron not included)

FINISHED CEILINGS

Locate ceiling joists or

trusses using

a stud finder

or similar

device.

Attach angle iron

(not included) to

joists or trusses

through finish material

using Lag Screws.

Page 15

I:o_ _'sectio_al doo_'s:

A Attach Curved Door Arm to Door Bracket with Clevis Pin and

Cotter Pin (Figure 23).

B Attach Straight Door Arm to Magnetic Carriage Assembly.

C Attach both Arms together with 2 (3/8" x 7/8") Hex Head

Bolts and 2 (3/8") Serrated Flange Hex Serial Number

Nuts so overall length isas short as pos-

sible. Securely tighten fasteners.

D Adjust height of Emergency Release Cord Knob to 6' above

floor:

• Pull Cord through Magnetic Carriage Assembly Lever

until Knob is 6' from floor.

• Tie a new overhand knot in Cord at Magnetic Carriage

Assembly Lever.

I:o_ _'o_'_e-piece doo_'s

A Attach Straight Arm to Door Bracket with Clevis Pin and

Cotter Pin (Figure 24).

B Attach Curved Arm to Magnetic Carriage Assembly.

C Attach both Arms together with 2 (3/8" x 7/8") Hex Head

Bolts and 2 (3/8") Serrated Flange Hex Nuts so overall length

isas long as possible. Securely tighten fasteners.

D Adjust height of Emergency Release Cord Knob to 6' above

floor:

• Pull Cord through Magnetic Carriage Assembly Lever

until Knob is 6' from floor.

• Tie a new overhand knot in Cord at Magnetic Carriage

Assembly Lever.

Safe-T-Beam ® (STB) Brackets

#10-16 x 11/4'.

Phillips Hex Head Screw

Hardware (yellow bag)

As short as

Clevis Pins Cotter Pins

3/8" x 7/8"

Hex Head Bolts

3/8" Hex Serrated

Flange Nuts

WARNING

Do Not skip Step D above!

Failure to comply may leave Emergency Release Knob within

reach of children. If the Knob is pulled with garage door fully

or partially open, garage door may close without warning!

Figure 23 Assemble Arms (SECTIONAL)

As long as

possible

(_ Doo'r'Arm

_!.(_ Straight

.... Door Arm

Figure 24 Assemble Arms (ONE-PIECE)

Page 16

ELECTRICALWARNING

Ensure there is No power to the Opener before installing

Safe-T-Beam®System Wires. If Opener is plugged into outlet,

Unplug it now.

Safe-T-Beam ® Sensor

(Green LED)

Safe-T-Beam ® Source

(Red LED)

NOTE

The Opener will not close the door automatically unless the

Safe-T-Beam®System is installed.

A Install Safe-T-Beam ® Source and Sensor (Figure 25):

• Mark both sides of garage door frame or wall 6"

above floor.

Hold Bracket against door frame or wall. Check if Bracket

extends out from wall far enough so tongue of Bracket is

beyond door, tracks, or any door hardware. If not, Safe-T-

Beam ® Mounting Bracket Extensions are available from a

Genie Factory Authorized Dealer or through the

Accessories Order Form.

- Blocks of wood, etc. may be substituted

for extensions.

Position top of Mounting Bracket at 6" mark and fasten

with 2 (#10-16 x 1-1/4") Phillips Hex Head Screws

per Bracket.

NOTE

Mounting Brackets can be attached to brick walls or concrete

floor using masonry anchors (not included).

ONE DOOR

GARAGE

Slide onto

tongue of

Bracket until._. J i:_1

it clicks into 4_//

place !/i}i _. Bracket 6"

Figure 25 Install Safe-T-Beams ®

TWO DOOR

GARAGE

Top

I above

[floor

of

B Attach Safe-T-Beam ® Source (Red LED) and Sensor (Green

LED) to Brackets (Figure 2S):

For single-door garages.

- Determine which side of garage receives the most

direct sunlight, and place Source (Red LED) on this

side whenever possible.

For multiple-door garages see (Figure 26).

- Preventing crossed signals is critical.

- Place Source and Sensor modules on adjacent doors

facing in opposite directions.

NOTE

To help prevent interference from the sun, the Safe-T-Beam®

Sensor (Green LED) may be placed further away from the

door opening, where it will spend more time in the shadows.

• ®

Slide the Safe-T-Beam Source and Sensor onto the

tongues of the Brackets until they click into place.

• Check final height of Lens (Figure 27).

THREEDOOR

GARAGE

Figure 26 Source/sensor Locations

Figure 27 Final Check Safe-T-Beams ®

Top edge of Lens

5" - 6" above floor

Page 17

CAUTION

;taples which are too tight may cut or pinch Wires.Cut or

)inched Wires can cause the Safe-T-Beam®System to stop

working. When installing the Insulated Staples, make sure

_oufasten them only astightly asneeded to hold the

Wire securely.

®

Insulated Staples

(approximately 30 parts)

©

#6-11/4"

Pan Head Screws

C

Install Safe-T-Beam ®Wiring (Figure 28):

• Route Wire and Insulated Staples

(Figure 29 and Figure 30).

- Securely fasten Wires with Insulated Staples as

you go. Staples should be snug only.

- Wires between garage wall and Power Head should

be run on top of Rail and underneath Wire Clips.

Attach Wires to Safe-T-Beam ®Sensors.

- Split and strip Wire ends to be connected as shown.

- Loosen Terminal Screws.

- Insert each Wire under flat plate and tighten Screw.

It does not matter which Wire, white or striped, goes

on which Terminal.

• Attach Wires at Power Head.

- Wires are connected to Terminals #2 and #3 on

Power Head Terminal Block. It does not matter which

Wire, white or striped, goes on which Terminal.

Check the following.

- Ensure that no part of door or its hardware is in path

between Source or Sensor Lenses.

• Ensure that tops of Lenses are between S" - 6" above

floor. Brackets are flexible and can be adjusted slightly

if needed.

Hardware (red bag)

Approxi112

Wire

@

Figure 28 Wire the Safe-T-Beam ® System

X,

NOTE

The Safe-T-Beam®alignment check will be performed

following connection to electrical power.

Do Not plug in yet!

Figure 29 Wiring Method A

Wire Clips (_

STB j

i

Terminal

attach ments

at Power Head

Figure 30 Wiring Method A

at Safe-T-Beam ®

at Safe-T-Beam® J

Leave slack for

adjustment

Insulated

Staples

@

Leave slack for

adjustment

Page 18

WF_LL C©BSS©L

Security

Vacation

Lock Switch

WARNING

Verify there is no power to the Opener before installing Wall

Console Wires.

NOTE

More than one lighted Wall Control per Opener will cause

a malfunction.

A Wall Console (Figure 31):

• Has a Security Vacation Lock Switch which disables

all controls.

• LED Indicator shows whether system is powered, locked,

or unlocked. Makes Console easy to find in dark.

• Controls door Opener from inside garage.

• Independent Light Control allows convenient manual

control of Opener Lighting System.

B Find a convenient mounting location:

• Within direct sight of garage door.

• At least 5' above floor (to prevent small children from

operating garage door).

• Away from any moving garage door or Opener parts (you

should not be able to reach door while standing at

Wall Console).

C Ensure Vacation Lock Switch is in UNLOCKED position.

D Wire Wall Console to Opener (Figure 32):

• On Power Head, connect Striped Wire to Terminal #1 and

White Wire to Terminal #2.

• On back of Wall Console, connect Striped Wire to

terminal "B" and White Wire to Terminal "W'[

E Attach Wall Console onto wall at location found above with 2

(#6 x 11/4") Pan Head Screws.

F Remove protective backing from Entrapment Warning Label,

and attach it to wall near Wall Console.

CAUTION

e

Use of any wall consoles other than the type included

will prevent the light from working properly and could

cause the door to operate on its own.

Cut or pinched Wires can cause the Wall Console to stop

working. When using the Insulated Staples, be sure to

only tap them in asfar as needed to hold the

Wire snugly.

Independent

Light Control

Figure 31 Wall Console

Terminal

Attachment

at Power Head

White Wire

to

Terminal 2

Striped Wire

to

Terminal 1

Terminal

Attachment

at Wall Console

White Wire

to

Terminal "W"

Striped Wire

to

Terminal "B"

[ I

©

Wall Console

@

®®@

1

Garage Door

J Control

Allow

slack

®

Figure 32 Install Wall Console with

Entrapment Warning Label

Page 19

Co_s_scs__sG_ovv_

ELECTRICALWARNING

e

To reduce the risk of electrical shock, this equipment has

a grounding type Plug that has a third (grounding) Pin.

This Plug will only fit into a grounding type outlet. If the

Plug does not fit into the outlet, contact a qualified

electrician to install the proper outlet. Do Not change

the Plug in any way.The door Opener must be properly

grounded to prevent personal injury and damage to the

components.

The electrical power to the door Opener Must Be removed

when the Motor Cover is removed. Electrical power must

remain off while making electrical connections.

A

Check building codes:

• If building code requires Opener be permanently wired

to building, have a licensed electrician perform step B.

• If you are not installing permanent wiring, go to step C.

Instructions for licensed electrician - connecting power

with permanent wiring (Figure 33):

• Remove power from circuit.

• Remove Motor Cover.

• Remove and discard Power Cord.

- Cut off Power Cord inside Power Head as near Strain

Relief as possible.

- Remove Knock-Out Plug, Strain Relief, and Power

Cord. (Cut Ground Wire on line side of Toroid).

- Dispose of Plug, Strain Relief, and Power Cord.

• Install required entrance bushing.

• Connect permanent wiring to Power Head Wires.

- White supply line to Opener White Wire.

- Black supply line to Opener Black Wire.

- Ground to Opener Green Wire.

- Replace Motor Cover.

Knockout

Cut

Wires

here

Two

tabs

slide

out

NOTE

e

Use only Underwriters Laboratories, Inc. (U.L.)

recognized wire nuts.

The Circuit Boards are light sensitive. Ensure the

Motor Cover is installed before energizing

the Opener.

- Restore Power to circuit.

C

Connecting Power with Plug:

• Plug Opener into a grounded outlet as stated in previous

electrical warning.

D

Perform Safe-T-Beam ®alignment check:

• Check if Safe-T-Beam ®Source Red LED is glowing

continuously (OK) or blinking (problem).

• If Red LED is blinking twice, adjust Sensor Brackets as

needed to make Red LED glow continuously. (Refer to

page 26.)

I

Four screws hold

Motor Cover

Figure 33 Connecting power with permanent wiring

Page 20

5elX@_{_of Limt 5w t@_®s

A Setting Close Limit Switch (Figure 34):

• Check that Magnetic Carriage Assembly is disengaged.

• With garage door fully closed, slide Close Limit Switch

until it is aligned with Carriage Assembly Magnet.

• Tighten Set Screw. Do Not over-tighten.

B Setting Open Limit Switch:

• Manually open garage door to full open position.

• Slide Open Limit Switch until it is aligned with Carriage

Assembly Magnet.

• Tighten Set Screw. Do not over-tighten.

. Re-engage Magnetic Carriage Assembly.

NOTE

o

Little effort isrequired to turn the Force

Adjusting Knobs.

• If the door stops moving while opening or

closing, adjust the Open Force or Close Force

Controls slightly clockwise (to slightly

increase the force) and retry the step.

• The Open Force and Close Force Controls are to

be set to the minimum force necessary to

ensure the door smoothly opens fully and

closes completely.

• The garage door will move slowly the first

time it runs, until the Opener"learns"the

type of door.

• Ensure the Magnetic Carriage Assembly is

engaged and is between the two Limit

Switches before operating the Opener.

WARNING

• The garage door opens rapidly, and can cause serious

injury or death.

• Keep the path clear.

• Position the ladder to the side of the Power Head so it is

clear of all moving parts of the Opener and the door.

• Set the door Opener to use the minimum force needed

to open the door.

A Pre-set Force Controls to midpoint between fully counter

clockwise and fully clockwise (Figure 35).

B Adjust the Close Limit Switch:

* Press Wall Console to close garage door.

- If door does not close completely, measure distance

from bottom of door to floor. Move Limit Switch

same amount toward door and try again.

- If door reverses after contacting floor, move Limit

Switch toward Power Head and try again.

- If door reverses before contacting floor, increase

Close force and try again.

- If door fails to move, check Safe-T-Beam ® System. See

Safe-T-Beam ®Troubleshooting Guide on pg. 26, and

Opener System Self-diagnostic Troubleshooting

on pg. 27.

. Tighten Limit Switch Set Screw. Do not over-tighten

{strip) Limit Switch Set Screw.

C Adjust Open Limit Switch:

. Press Wall Console to open garage door.

- If door does not open completely, move Limit Switch

toward Power Head.

- If door opens completely, but motor continues to

run, move Limit Switch toward door.

. Tighten Limit Switch Set Screw. Do not over-tighten

{strip) Limit Switch Set Screw.

Close Limit Switch

(door fully closed)

Carriage _'_ Switch

(disengaged) I% _ Magnet

Open Limit Switch Switch

(door fully open)/

Carriage

(disengaged) IC\\ "\ ....J

_ " Magnet

Figure 34 Setting Limit Switches

Force Controls

HI LO

OPEN CLOSE X.._

FORCE FORCE

Figure 35 Making Force Adjustments

Page 21

NOTE

NOTE

e

To protect your new investment, your Excelerator ® is

equipped with a Timer and Cycle Counter which work

together to prevent any chance of heat damage to

electrical circuits caused by too many cycles in too short

a time. If your Opener suddenly stops responding to the

Wall Console- Do Not Unplug the Unit- simply wait

10 minutes for the Timer/Cycle Counter to reset itself

and try again.

Unplugging the unit will prevent the Timer/Cycle

Counter from resetting.

D Test Door Opener:

• Run door up and down a few times using Wall Console

and observe door travel.

• Repeat steps above as needed to set Limit

Switch positions.

E Adjust Open Force to minimum needed:

• Place door in closed position using Wall Console.

• Gently adjust Open Force fully counterclockwise

(minimum force).

• Run Opener using Wall Console.

• Observe that door runs to Open Limit Switch.

- If not, adjust Open Force Control slightly clockwise,

close garage door, and open it again.

• Repeat steps above until garage door runs smoothly

from Close Limit Switch to Open Limit Switch.

F Adjust Close Force to minimum needed:

• Place door in open position using Wall Console.

• Gently adjust Close Force fully counterclockwise

(minimum force).

• Run Opener using Wall Console.

• Observe that door runs to Close Limit Switch.

- If not, adjust Close Force Control slightly clockwise,

open garage door, and close it again.

. Repeat steps above until garage door runs smoothly

from Open Limit Switch to Close Limit Switch.

The door must contact the 2"x 4" board before the

Carriage activates the Close Limit Switch. If not,

readjust the Close Limit Switch.

2" x 4" board

laid flat

Figure 36 Checking Contact Reverse

c _°-= _ =_¢_=_c =_

NOTE

Limit Switch and Force Adjustments must be completed

before checking the contact reverse function (Figure 38).

A Open garage door using Wall Console.

B Lay a 2" x 4" board flat in center of doorway.

C Close door using Wall Console.

D Check that door stops and reverses within 2 seconds after it

contacts board:

o If door does not reverse, decrease Close Force until

door reverses.

o If door still does not reverse, move Limit Switch

toward door.

E Check Safe-T-Beam ® System operation:

o If beam is blocked, door will not close.

Page 22

_ _OY _ COH]'ROL

A To program one Button of a Remote Control (Figure 37):

• Locate Learn Button and Learn Indicator Light near

Terminal Block on Power Head (Figure 38).

• Press and release Learn Button. Red Learn Indicator Light

will blink 2 times per second.

• Press Remote Control Button once within 30 seconds.

Red Learn Indicator Light will stay lit.

• Press Remote Control Button again. Red Learn Indicator

Light will go out, indicating that memory is stored.

B Program each additional Remote using step A above.

7b E_'ase Ail .......... _,,

A Press and hold Learn Button on Power Head for 10 seconds or

until Learn Indicator Light goes out. Memory is erased:

. Program Remotes again as needed.

_essetes frown Re e_" Mea_t BJ]e_'_'_ery

NOTE

e

Each Remote Control must be programmed

separately.

• The Remote Controls will not cause the door

Opener to close the garage door if the Safe-T-

Beam®System is malfunctioning.

• When programming the Remote Controls, they

must be at least 24" from the Antenna Wire.

• Ifthe red Learn Indicator Light blinks

approximately 4 times per second,

programming has stopped. If programming

has stopped, repeat the above steps.

Each Button on a 2 or 3 Button Remote Control

is for a different Opener. You cannot use more

than one Button per Remote, per Opener.

• A maximum of seven Remote Controls or

Wireless Keypads can be stored into the

Receiver at one time. If a Remote Control

becomes lost, or if you want to delete a Remote

Control or Wireless Keypad, see "To EraseAll

Receiver Memory."

A Push in on Battery Cover Latch at base of Remote Control

(Figure 39):

Use coin, pen, screwdriver or any similar device.

- Cover snaps open.

Replace old Battery with new _EI/_'RE/ID_, A23,

12 Volt Battery.

B Snap Battery Cover closed.

WARNING

A moving garage door may cause serious injury or death.

• Keep people clear of opening while door ismoving.

• Do not allow children to play with the Remote Controls.

If the Safety Reverse does not work properly:

• Close the door and disconnect the Opener using the

Emergency Release Cord.

• Do not use the door Opener, Remote Controls, or

Wireless Keypad.

• Referto the door and door Opener Owner's Manuals

before attempting any repairs.

A Press Button on Remote Control. Garage door will move.

B Press Button again. Garage door will stop:

• The door automatically stops at the end of the open or

close cycle.

C Press Button again. Garage door will reverse.

@@@

1 Button 2 Button 3 Button

Remote Remote Remote

® ® ®

Figure 37 Genie Remote Controls

Learn Code Button

J

LEARN INDICATOR LIGHT

Figure 38 Learn Code Button and Indicator Light

Visor Clip

Push to open

Battery Cover

Model

Number

\\

Figure 39 Remote Control Battery Replacement

Page 23

WARNING

A Moving door can cause serious injury or death.

1 Keep people clear of opening while door is moving.

2 Do Not allow children to play with Wireless Keypad.

3 During programming, the door opener couldbegin

to run, so stay away from the moving door and its

parts.To keep the door from moving, dose the door

and disconnect it from the Openerby pulling the

Emergency Release.

If Safety Reverse does not work properly

1 Close door and disconnect the Opener using

Emergency Release Cord.

2 Do not use door Opener, Remote Controls, or

Wireless Keypad.

3 Refer to Door and Door Opener Owner's Manuals

before attempting any repairs.

NOTE

FOR CONVENIENCE-- Program Keypad BEFOREmounting.

NOTE

e

If the door does not move, check the red LED on

Keypad. If the LEDisblinking rapidly,the PINwas

entered incorrectly. After the LEDstops blinking,

re-enter your PINand try again.

Any keypad button will control the door for

30 seconds after the door starts moving.

Rapid Blinking of the red LEDindicates an error.

After afew secondsthe LEDwill turn off. Start over.

A Set Wireless Keypad PIN (Personal ID Number):

Activate programming mode.

- Press(in order) )).

- RedLEDblinks -once per second.

• Enteryour PIN (3to 8 characters).

• Press )).

- RedLEDblinks- twice per second and turns off.

B Programming the Keypad for Multiple Door openers:

A Set Wireless Keypad PIN (Personal ID Number):

• Activate programming mode.

- Press (in order)

- RedLEDblinks -once per second.

o

Enteryour PIN(3to 8characters).

o

Press

RedLEDblinks-twice persecondandturnsoff.

Programming One Door Operator:

• Findthe LearnCode Button and Learn Code

Indicator LEDon your door opener.

- Ifyour door opener has a blackantenna

wire,the LearnCode Button and Indicator

LEDare located near the antenna.

(Thelight lens may need to be opened)

- Ifyour door opener doesnot have an

antenna, you have an external receiver.

The external receivercover must be

removed to accessthe LearnCode

Button and Indicator LED.

• Pressthe LearnCode Button.

- LearnCode Indicator LED(onOpener)

will blink.

Enteryour PINand press _.

- Learn Code Indicator LEDstays on.

• Press_

- Learn Code Indicator LEDturns off.

C

Operating One Door Operator:

• To move the garage door:

- Enteryour PIN.

again.

Figure 1

Indicator

Learnj_

Code--

Button

• Enteryour PIN and press }.

- RedLEDblinks - once per second.

• Press again.

- RedLEDblinks -twice per second.

• Pressthe number of doors (total) you wish

to control (@ or @).

• Press ).

- RedLEDblinks severaltimes and turns off.

C Programming Door Openers:

Decide which door will be door #1,#2 and #3.

Pressthe LearnCode Button (see Figure 1).

- Learn Code Indicator LED(on Opener) blinks.

• Enteryour PIN and press _.

- Learn Code Indicator LEDstayson.

Pressthe number you have picked for this

door Opener(@ or @ or @).

- Learn Code Indicator LEDstayson.

" Press _.

- Learn Code Indicator LEDturns off,

B Repeatstep A above for each door opener,

Eachdoor opener must be programmed to receive the

signal from the Wireless Keypad,

oi _ ;5 0

- PressC@.

Page 24

P_'eg_a_ss'@_¢_ fe_' 2 o__3 Doe_ _Ope_e_'s (Continued)

A Operating 2 or 3 Door Openers:

• Tomoveoneof the doors.

• Enteryour PIN.

• Press

• Pressdoor openernumber (@ or @ or@ ).

Figure 3

Red LED

t&_OUHTH6 HSW_U('?_OHS

T_seI_ypad m_S be mo_,_ted _ssght _£'the _:_00(s st/(}ast 5 feet

above tB®g_ouhd _hd c/e_'__d _r%zmevhg doo_' pats,,

A Mount Keypad.(Mounting screwslocated inside

battery compartment.)

• Remove Battery Cover. See Figure 3.

• Drill a1/16"pilot hole for the top mounting screw.

• install a screw into the drilled hole,

leaving a 1/8" gap between the

screw head and the wall.

SeeFigure2.

• Hook the Keypad over the screw.

Mark,drill pilot hole and fasten

bottom screw.

ReinstallBattery Cover.

Figure 2

1"

screw head gap

Bottom

X/Mounting

Presshere Screw

NOTE

. DO NOT reprogram the Door Opener(s).

. Temporary PINremains active until the next time your

normal PIN isentered.

_ _ _ _ _%_c_ _c

A Eraseold PIN:

• Pressand hold in order @_--_

- RedLEDwill blink once and turn off.

• Releaseall buttons.

Programming Door Opener(s).

• Return to"Programming for 1Door Opener"or

"Programming for2 or 3 Door Openers."

Page 25

Snap Lens Hinges into

slots on back of Motor Cover

60 Watts

Lens

maximum

@

close Lens

Figure 41 Install Lens Cover and Light Bulbs

A Install two 60 Watt light bulbs (not included) into Light

Sockets (Figure 41):

• Rough service, 130 Volt bulbs are recommended.

IB Install Lens into slots in Motor Cover.

£ Install Genie Emergency Release Kit (GER-2) accessory,

if purchased.

D

Installation is now complete.

f

Transmitters comply with all United States and Canadian legal requirements

asof the date of manufacture. No warranty is made that they comply with all

legal requirements of any other jurisdiction. Iftransmitters are to be used in

another country, the importer must determine compliance with any local

laws and regulations which may differ from United States and Canadian

requirements prior to use.

Los transmisores cumplen con todas las reglamentaciones legales de los

Estados Unidos y del Canad& en la fecha de fabricaci6n. Ninguna garantia

se da que cumpJan con todas as reglamentaciones legaJesde ninguna otra

jurisdicci6n. Si los transmisores se van a utilizar en otro pais, el importador

debe determinar si cumplen con las reglamentaciones y byes locales que

puedan ser diferentes alas reglamentaciones de los Estados Unidos y del

Canad4, antes de usar los mismos.

Les e_metteurssont conformes &la re_glementation am_ricaine et canadienne

compter de leur date de fabrication. Aucune garantie n'est stipul@

indiquant qu'iJssont conformes _ toutes les prescriptions juridiques d'autres

autorit_s. Si les _metteurs sont utilis@sdans d'autres pays, ilincombe

I'importateur d'en d_terminer leur conformit_ aux loiset r@gleslocales

pouvant diff@rerde celles des Etats-Unis et du Canada avant toute

utiJisation desdits _metteurs.

Sendeger_ite entsprechen allen gesetzlichen Bestimmungen in den USA und

Kanada zum Zeitpunkt der Herstellung.Wir ubemehmen keine

Gew_ihrleistung for die Einhaltung alJergesetzlichen Bestimmungen in

anderen L_ndern. SolJenSendeger_te inanderen L_inderneingesetzt werden,

so muss der Importeur vor dem Gebrauch sicherstellen, dassdie Sendeger_ite

auch solchen Iokalen Bestimmungen entsprechen, welche von den

Bestimmungen der USAund Kanadasabweichen.

Push in

Latches

to

A Monthly:

Door springs and door hardware:

- Oil door roller, bearings, and hinges using silicone

lubricant or light oil.

WARNING

Do not operate door automatically or manually if springs

are broken. Contact a Genie Factory Authorized Dealer for

service or call Customer Service at 1-800-35-GENIE.

• Balance Door.

- Closedoor.

- ReleaseMagnetic Carriage Assembly from RailAssembly

bypulling down on EmergencyReleaseKnob.

- Raisedoor manually 3'- 4' and verify that door stays at

that position. See Check Step 2 on page 3.

NOTE

When the door is3'- 4' above the ground, the door

should stay open. Slight movement is acceptable. If

the door moves too much, contact a Genie Factory

Authorized Dealer for service or call Customer Service at

1-800-35-GENIE.

- Reattach Magnetic Carriage Assembly to Rail Assembly:

a. Pull the Emergency Release Knob toward Power Head.

b. Close door.

Contact ReverseTest.

- Perform Installation Step 10 on page 21.

WARNING

If the door fails to reverse on contact with the board,

adjust the Close Force Control asspecified in Set Limit

Switches and Force Controls on page 20. If the Opener

still fails, contact a Genie Factory Authorized Dealer for

service or call Customer Service at 1-800-35-GENIE.

IB Yearly:

• Wipe off old excess lubricant from Drive Screw.

• Lubricate Drive Screw with Genie Lubricant (GLU-3)

NOTE

Use ONLY Genie Lubricant (GLU=3). Other lubricants

may damage the Opener.

_igb £_:d-,td,g:£_ b • 1-I_,o

GLU-3

Lubricant

FCCAND IC CERTIFIED

All devices comply with Part lS of the FCCRules.

Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2)

this device must accept any interference received, includ-

J

ing interference that may cause undesired operation.

Page 26

.41LWARNING

TO

1 READAND FOLLOW ALL INSTRUCTIONS.

2 Never let children operate or play with the Door Controls. Keep the Remote Control away from children.

3 Always keep the moving door in sight and away from people and objects until the door is completely closed.

NO ONE SHOULD CROSSTHE PATHOF THE MOVING DOOR.

4 NEVERGO UNDER A STOPPED,PARTIALLYOPEN DOOR.

5 Test Opener monthly'. The door MUST reverse on contact with a 1-1/2" high object (or a 2" x 4" board laid flat)

at the center of the doorway on the floor. After adjusting either the Force or the Limit of travel, retest the Door

Opener. Failure to adjust the Opener properly may cause severe injury or death.

6 When possible use the Emergency Release only when the door is closed. Use caution when using this Release

with the door open. Weak or broken springs are capable of increasing the rate of door closure and increasing

the risk of severe injury or death.

7 KEEPGARAGE DOORS PROPERLYBALANCED. See Owner's Manual. An improperly balanced door increases the

risk of severe injury or death. Have a Genie Factory Authorized Dealer make repairs to cables, spring

assemblies, and other hardware.

REDUCETHE RiSK OF SEVEREiNJURY OR DEATH

8 SAVETHESEINSTRUCTIONS.

. WARNING

Usethe Wall Console includedwith Opener. Any other wall console can cause the Opener to operate unexpectedly and

the light to stop working.

TI!;,IOUBLESHOOTI ' ....

Source (Red LED) Sensor (Green LED) Possible Problem Solution

ON ON Normal operation None required

OFF OFF

OFF ON

2 BLINKS, Pause

(Repeat)

2 BLINKS, Pause

(Repeat)

3 BLINKS, Pause

(Repeat)

4 BLINKS, Pause

(Repeat)

ON

OFF

ON

ON • Source defective • Contact Customer Service

- Power Head not powered - Check breakers, fuses, plugs

• Wiring from Power Head bad • Check wiring for obvious shorts

- Wiring to Source missing or bad

• Power has been interrupted

- Beam not aligned

• Beam obstructed

• Sensor defective

- Wire to Sensor missing or bad

• Sensor defective

• Sensor receiving interference - Determine source of interference

- Source not sending pulses - Contact Customer Service

- Check wiring

• Remove power and reapply

- Check Source, Sensor alignment

- Check for obstruction

• Contact Customer Service

- Check wiring

• Contact Customer Service

• Contact Customer Service

Page 27

• See Status Light on Figure38, page 22)

You See

1 BLINK,

Pause

(Repeat)

2 BLINKS,

Pause

(Repeat)

3 BLINKS,

Pause

(Repeat)

Problem

Motor Drive

Board

Normal

operation

restored

If the problem

recurs

Operation not

restored

Controller

Board

Interrupt

Opener

Overheated

or

What to Do

. Reset Opener--unplug (or disconnect power), wait 5 seconds, plug

back in (reapply power), and activate from Wall Console.

. First Cycle will run at slow speed.

. Check door condition. NOTE:This Opener is equipped with an

automatic garage door balance detection system. An improperly

balanced door, damaged or worn counter-balance spring, binding

door hardware or rollers may result in a "ONE-BLINK" signal,

• Contact Customer Service for further assistance.

. Checkdoor condition.

. Have a Genie Factory Authorized Dealer check:

- Fuse on Motor Drive Board.

- Ribbon Cable on Motor Drive Board is properly inserted into

Connector on Controller Board.

. Contact Customer service for further service.

. Reset Opener -- unplug (or disconnect power), wait S seconds, plug

back in (reapply power), and activate from Wall Console.

. Have a Genie Factory Authorized Dealer check that Ribbon Cable on

Motor Board is properly inserted into connector on Controller Board.

. Contact Customer Service for further assistance.

. Do not unplug or disconnect power from Opener.Wait 10 minutes

for internal clock to provide additional cycles. Cycles are restored

at a rate of S cycles per 10 minutes of rest.

Reference

See Door

Safety Guide

1. See page 3.

2. See door

Safety Guide

4 BLINKS,

Pause

(Repeat)

SBLINKS,

Pause

6 BLINKS,

Pause

7 BLINKS,

Pause

8 BLINKS, Wall Console See page 18

Pause locked

(Repeat)

Force Settings

Incorrect

Safe-T-Beam ®

Malfunction

Wall Console

does not work

Limit Switches

not working

. Check Force Settings. NOTE: Force Settings are not pre-set at factory.

. Checkdoor condition.

. Contact Customer service for further assistance.

. Check Safe-T-Beam ® Self-diagnostic System. NOTE: Safe-T-Beam ®

System must be installed and operational to enable door to close,

• Contact Customer Service for further assistance.

. Check Wall Console Wiring for shorts, tight Staples, or pinched Wires.

. Check Wiring Connections at Power Head and Wall Console.

Contact Customer Service for further assistance

. Check Limit Switch Wire connections to Terminals on Power Head.

. Check for shorted or pinched Wires under Limit Switch Brackets.

. Contact Customer Service for further assistance.

. Vacation Locking Switch on Wall Control is in"Lock" mode.

Unlock switch.

. Contact Customer Service for further assistance.

1. See page 20.

2. See Door

See page 16.

See page 18.

See page 20.

NOTE

• The status LEDIndicator Light is located under the LensCover.The Green LEDlight will turn ON, then OFF when

power is applied to the Opener. If LED stays ON, have a Genie Factory Authorized Dealer check the Controller

Board, or call Customer Service at 1-800-35-GENIE.

• If Safe-T-Beam®problems exists, the door can be closed electrically by holding the Wall Console Button down

until door is fully closed.

• The Remote Controls and Wireless Keypad will not work without a working Safe-T-Beam®System.

Page 28

Problem What To Do

Opener does not run 1. Check power source.

from Remote Control A. If Opener isconnected to an outlet:

• Plug a working lamp into outlet used for Power Head.

• If lamp glows, power source and outlet are OK.

. If not, check fuse or circuit breaker or non-compatible GFCl.

NOTE:A licensed electrician must replace non-compatible GFCI's.

B. If Opener is connected to a wiring box:

. Check fuse is not blown, or circuit breaker is"Closed" (not tripped).

. If still no power, have a licensed electrician check circuit and wiring.

2. If power is OK:

. Check connections at Power HeadTerminals (seeWall Console Installation page 18), tightening any

loose connections.

Havea Genie Factory Authorized Dealer check that Ribbon Cable between Controller Board and Motor Drive

Board is properly connected to Connectors on Circuit Boards,or call Customer Service at 1-800-3S-GENIE.

Door Opener starts . CheckWires to ensure that they are not cut (Stapes can cut insulation and short Wires).

for no apparent reason Replace any shorting Staples and shorted Wires.

. Was Remote Control lost or stolen? If so,eraseall Remote Control codes from Receiver's memory

and reprogram for remaining remote controls. (SeeErase All ReceiverMemory on page 22).

,x ,,

Door starts down, then . Check Close Limit Switch setting (seeSet Limit Switches and Force Controls on page 20).

stops before it is Adjust as needed.

completely closed . Check for shorted Wires.

. Check garage door for binding.

Door starts down, then • If anew installation, check Door Arm position.

stops and goes backup • Check operation of Contact Reversefunction.

• Check Safe-T-Beam®Systemfor beam obstruction or misalignment of Lenses.

• CheckSafe-T-Beam Systemdiagnostic code.

®

• Check CloseForceadjustment (seeSetLimit Switchesand ForceControls on page 20). Adjust as needed.

. Checkgaragedoor for binding.

Door will only run closed • CheckOpen Limit Switchfor ashort circuit and for proper wiring.

. CheckOpen Forceadjustment (seeSetLimit Switchesand ForceControls on page 20). Adjust asneeded.

. Checkcondition ofgarage door and door spring(s).

. J:_R __}6.Ifyou suspect a problem with the garage door hardware or springs,contact a Genie

FactoryAuthorized De aler for service,or contact Customer Serviceat 1-800-3S-GENIE.

Door will only run open • CheckSafe-T-Beam Systemasdetailed in the Safe-T-Beam®SystemSelf-diagnosticTroubleshooting Chart

(seeSafe-T-Beam SystemSelf-diagnosticTroubleshooting Sectionon page 26).

®

®

. CheckCloseLimit Switch for a short circuit and for proper wiring.

. CheckCloseForceadjustment (seeSetLimit Switchesand ForceControls on page 20). Adjust as needed.

Lightswill not turn off . DisconnectWires connecting Wall Console to Power Head(seeWallConsole Installationon page 18).

Checktheir condition andeither replace or reconnect.

. Until a replacement Wall Consolecan be obtained, disconnectWall Consoleand use only Remote Controls

or WirelessKeypadto operate Opener.

Door starts up, but stops • Check (ensure) that garage door and Opener are in good repair,properly lubricated, and properly

before it is balanced as detailed in Maintenance Section.

cornpletely open . W _ H' : If you suspecta problem with the garage door hardware or springs,contactaGenie

FactoryAuthorized De aler for service,or contact Customer Serviceat 1-800-3S-GENIE.

. CheckOpen Limit Switchfor ashort circuit and for proper wiring.

. CheckOpen Forceadjustment (seeSet Limit Switchesand ForceControls on page20). Adjust as needed.

Operator runs,but door • EnsureMagnetic CarriageAssembly is engaged to RailDrive Screw(seeInstall Magnetic CarriageAssembly

doesnot move onto Railson page 10).

. CheckForceadjustment (seeSet Limit Switchesand ForceControls on page 20).Adjust asneeded.

. Checkthat all sectionsof RailDriveScrewareturning when Motor runs. If not:

- Checkcondition (not cracked,split,or broken) and placement of Coupler. Replaceasneeded.

- Checkcondition (not cracked,split,or broken) and placement of Collarand Clip. Replacethem

asneeded.

WallConsoleVacation . EnsureMagnetic CarriageAssembly isin contact with Close Limit Switch.

Lockfunction does . Checkwhen door isfully closed,that Carriageactivates Close Limit Switch. If not,adjust position of Close

not work Limit Switch(Seepage 19).

Page 29

Problem What To Do

Remote Control hasless , Relocate Remote Control inside car.

than 2S'operating range • Ensure Remote Control is pointing toward garage door when pressing Control Button.

, Replace Remote Control Battery _'I/ER_'/ID_ type"A23." (See page 22).

Reposition Opener Antenna Wire.

Do Not attempt to retune Remote Controls or Receiver.

Opener works from Wall • Program code for each Remote Control into Receiver memory (See Programming the Remote

Control, but not from Control on page 22.

Remote Control , Replace Remote Control Battery _B/ERBID_ type"A23." (See page 22).

Check Safe-T-Beam®System for beam obstruction or misalignment of Lenses.

Check Safe-T-Beam®System for any diagnostic codes. If present, troubleshoot as detailed in

Safe-T-Beam®System Self-Diagnostic Troubleshooting Chart (See page 26).

Noisy operation • Ensure all fasteners are tightened.

Check that the garage door and Opener are in good repair, properly lubricated, and properly

balanced. (SeeMaintenance page 25).

W_:n_//_s. If you suspect a problem with garage door hardware or springs, contact a Genie

Factory Authorized Dealer for service, or contact Customer Service at 1-800-35-GENIE.

Safe-T-Beam®System , If an operational problem exists,Opener will not run closed.

CheckSafe-T-Beam®System for beam obstruction or misalignment of Lenses.

• CheckSafe-T-Beam Systemforany diagnostic codes. Ifpresent, troubleshootas detailed in Safe-T-Beam®

®

SystemSelf-DiagnosticTroubleshooting Chart (Seepage 26).

Door closes,andOpener , Check position of Wall ConsoleVacation LockSwitch. It must be in UNLOCKEDposition for Opener to

shuts down open door.

WARNING Opening Cover May Cause Electric Shock I

I OPEN LIMIT

WALLCONTROL

_b- lal

&

k-

- -_

-@

WHITE (_)

WHITE

i

i

i

I '

1

1

1

i

CONTROLLER BOARD

@

PRIMARYGROUND

MOTOR DRIVE BOARD

----111t

19k

13f

GREEN

_T LINE

BLUE

BLACK

WHITE

WHITE

_AX.

I CLOSE LIMIT

GREEN

_L

SECONDARYGROUND

Page 30

" HE GssH/E C'OM NY LM ['psD

Wl_at is Cove_®d

Any defect in material and workmanship from personal, normal

household use in accordance with the Owner's Manual.

Fo__'How Lo_g

H8000D Series -- Lifetime* on motor, on parts and service.

ISD990 Series -- Lifetime* on motor, 5 years* on parts.

ISD990-2 Series -- Lifetime* on motor and all parts.

ISD995 Series -- Lifetime* on motor and all parts.

ISD995-2WKM Series -- Lifetime* on motor and all parts.

ISD1000 Series -- Lifetime* on motor, all parts and service.

CMD9900 Series -- Lifetime* on motor, S years* on parts.

PRO99 Series -- Lifetime* on motor and all parts.

* for as long as you own your home.This warranty is non-transferable.

W_'_oGet b .......

Thiswarrantyapplies only to the consumer who originally purchased

the product.

Cieog_'a,,.# _:>BR::,,.Scopes

This warranty applies only to Genie products purchased in the United

States and Canada.

If your Genie product is defective, we will send replacement parts or, at

our option, a replacement unit at no charge to you, excluding shipping,

handling and labor costs. If we send replacement parts for your Genie

product, we may use new or reconditioned parts. If we choose to send

a replacement unit, we may use a new or reconditioned one of the

same or similar design.

IMPLIED WARRANTIES, INCLUDING THOSE OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY (AN UNWRITTEN

WARRANTY THATTHE PRODUCT IS FIT FOR ORDINARY USE) ARE

LIMITED TO ONE YEAR FROM DATE OF PURCHASE. GENIE WILL NOT PAY

FOR: LOSS OF USE OF YOUR GENIE PRODUCT OR PROPERTY DAMAGE

CAUSED BY YOUR GENIE PRODUCT OR ITS FAILURETO WORK; ANY

SPECIAL INCIDENTAL OR CONSEQUENTIAL DAMAGES; ANY DAMAGES

RESULTING FROM MISUSE OR MODIFICATION OF YOUR GENIE PRODUCT.

Some states and provinces do not allow limitations on how long an

implied warranty lasts or the exclusion of incidental or consequential

damages, so the above exclusions and limitations may not apply.

This warranty is the only one we wil give on your Genie product, and

it sets forth all our responsibilities regarding your Genie product.

There are no other expressed warranties.

State and Province Rights: This warranty gives you specific legal rights,

and you may also have other rights that vary from state to state and

province to province.

How to Get Wa_'_'a_ty ......

To get warranty service for your Genie product, you must

provide proof of date, and place of purchase of the product.

....@ , ¢;:@_.

], ©o- t,,-Vou_self ge_'vk;es

Call Genie Customer Service toll free at 1-800-354-3643, or visit

our website at www.geniecompany.com.Trained Genie

representatives will assist in diagnosing the problem and will

arrange to supply you with the required parts for do-it-yourself

repairs.Trained service representatives are available Monday -

Friday, 8:00 AM - 11:00 PM, and on Saturday, 11:00 AM - 8:00 PM

Eastern Time (subject to holidays).

You can obtain the name of a Genie Factory Authorized Dealer

by calling the Genie Dealer Locator Service at 1-800-654-3643.

If an Authorized dealer provides warranty service, Genie will not

reimburse you or otherwise be responsible for any labor

charges. Your choice of one of the above described service

options is your remedy under this warranty.

. Batteries (which are considered replacement parts)

, Installation

, Commercial use

, Defects resulting from accidents

, Damage while in transit to our service location or damage

from alterations

Misuse or Abuse

Lack of proper maintenance

Unauthorized repairs or modifications of the product

Affixing of any attachment not provided with the product

Programming of Remote Control Devices

Programming of Keypads

Safe-T-Beam ®adjustment/cleaning

Staples through wiring

Pinched or broken wires

Carriage disengaged

Force Control adjustments

Door out of balance