Page 1

A L WAY S A T Y O U R C O M M A N D

Installer:

Leave this manual

with homeowner.

Homelink® is a registered trademark of

Johnson Controls Technology Company.

®

is a registered trademark of

Car2U

Lear Corporation.

© The Genie Company 2010. X900-786

PN# 37026500123, 2/26/2010 REV.1

Models 2022/2024/2042

GARAGE DOOR OPENERS

Includes: 2-Bulb Light System

Wall Console

Includes INTELLICODE® Remote Control

Safe-T-Beam

®

System must be installed to close door.

For use only with sectional doors.

Homelink® and Car2U® compatible

For Answers and Assistance:

1.800.354.3643

or visit www.geniecompany.com

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

PN# 37026500123 02/26/2010 REV. 1

2

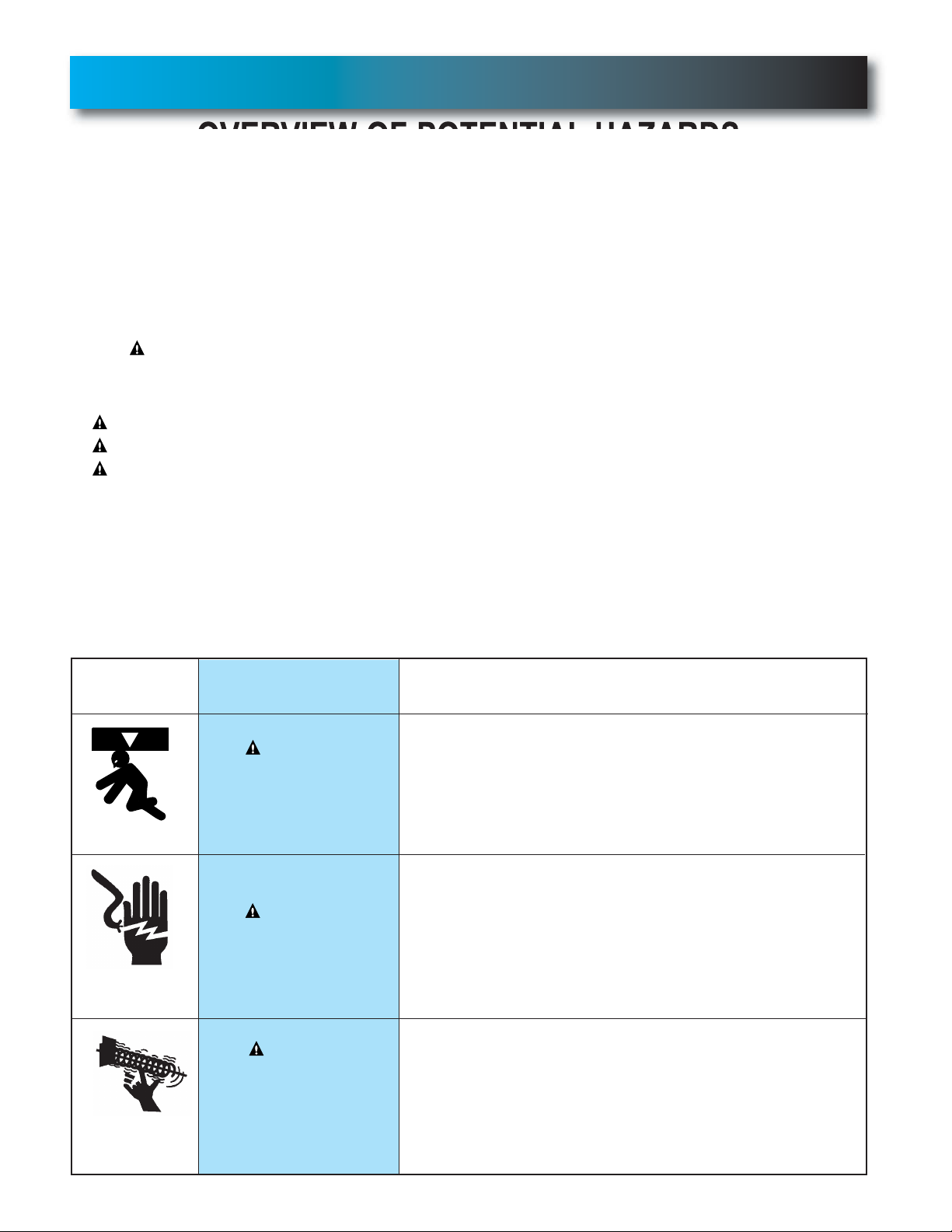

OVERVIEW OF POTENTIAL HAZARDS

READ THIS SAFETY INFORMATION

Garage doors are large, heavy objects that move with the help of springs under high tension and electric motors. Since moving

objects, springs under tension, and electric motors can cause injuries, your safety and the safety of others depend on the owner or

user of this system to read, understand and implement the information in this manual. If you have questions or do NOT

understand the information presented, contact The Genie Company or an authorized Genie

®

Dealer.

The safety alert symbol and following signal words DANGER, WARNING, and CAUTION are used throughout this manual to call

attention to and identify different levels of hazard and special instructions.

This is the safety alert symbol. This symbol is placed next to signal words and messages to help you identify

important safety information

The word:

DANGER indicates an imminently hazardous situation which, if NOT avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if NOT avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if NOT avoided, may result in injury or property damage.

The word

NOTE is used to indicate important steps to be followed, important considerations, or location of parts.

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

SAFETY INFORMATION

POTENTIAL

HAZARD

EFFECT PREVENTION

Keep people clear of opening while door is moving.

Do NOT allow children to play with the door operator.

Do NOT operate a door that jams or one that has a broken spring.

MOVING DOOR

WARNING:

Could result in Death

or Serious Injury

Turn OFF power before removing operator cover.

When replacing cover, make sure wires are not pinched or near

moving parts.

Operator must be properly grounded.

ELECTRICAL

SHOCK

WARNING:

Could result in Death

or Serious Injury

Do NOT try to remove, install, repair or adjust springs or anything to

which door spring parts are fastened, such as, wood blocks, steel

brackets, cables or other like items.

Installations, repairs and adjustments must be done by a trained door

system technician using proper tools and instructions.

HIGH

SPRING

TENSION

WARNING:

Could result in Death

or Serious Injury

Page 3

PN# 37026500123 02/26/2010 REV. 1

3

TABLE OF CONTENTS

OPENER FEATURES

INTELLICODE®Rolling Code Security System.

An electronic rolling code system that enhances the security of

the door opener by continuously changing the access code

each time the remote control is used. The door opener

responds to each new code only once. An access code copied

from a working system and tried again will not control the door

opener.

Lighted Wall Control*

Operates door opener from inside garage.

(Refer to section 3)

and Car2U®compatible.

Follow the Homelink

®

or Car2U®instructions in your car

owner’s manual.

*Opener MUST be installed with the

included Wall Control.

SAFETY FEATURES

Safe-T-Beam®Non-Contact Reversing System**.

Puts an invisible beam across the door opening. The door stops

and reverses to the full open position if anything passes

through the beam. Red or green LED indicator lights on the

power head provide a self diagnostic code if an operational

problem exists. (Refer to Section 10.)

Safe-T-Reverse

®

Contact Reversing System.

Automatically stops and reverses a closing door within 2

seconds of contact with an object. (Refer to Section 6.)

Safe-T-Stop

®

Timed Reversed System.

Automatically opens a closing door if it fails to close completely

within 30 seconds.

Watch Dog

™

Monitoring System.

Monitors the Safe-T-Beam® system to ensure proper functionality and will automatically stop and reverse a closing door if a

problem is detected.

Automatic Lighting System.

Twin bulb lighting supplies up to 120 watts of light for safer

evening exits and entries. Turns ON when door is activated and

automatically turns OFF 3 minutes later.

Manual Emergency Release.

Manually releases door from door opener. Use during a power

failure or other emergency to allow manual opening and closing

of door. (Refer to Section 6.)

**Safe-T-Beam®Safety Reverse System

MUST be installed to close door.

SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

OPENER FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SAFETY FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PRE-INSTALLATION CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . 4-5

RECOMMENDED TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

KEY ILLUSTRATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SAFETY INSTALLATION INFORMATION . . . . . . . . . . . . . . . . . . . . 9

INSTALLATION

1 OPENER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

2 OPENER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 12-14

3 WALL CONTROL INSTALLATION . . . . . . . . . . . . . . . . . 15-16

4 SAFE-T-BEAM

®

SYSTEM INSTALLATION . . . . . . . . . . . 17-18

5 CONNECTING TO POWER . . . . . . . . . . . . . . . . . . . . . . . . . 19

ADJUSTMENTS

6 LIMIT SWITCHES & FORCE ADJUSTMENT . . . . . . . . . 20-22

KEYED EMERGENCY RELEASE . . . . . . . . . . . . . . . . . . . . 21

CONTACT REVERSE TEST . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 PROGRAMMING REMOTE CONTROLS. . . . . . . . . . . . . . . 23

8 BATTERY/ VISOR CLIP INSTALLATION . . . . . . . . . . . . . . . 24

9 LIGHT BULB AND LENS INSTALLATION . . . . . . . . . . . . . . 24

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

MAINTENANCE & TROUBLESHOOTING

10 ROUTINE MONTHLY MAINTENANCE . . . . . . . . . . . . . . . . 25

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

TROUBLESHOOTING GUIDE - OPENER. . . . . . . . . . . . . . 27

TROUBLESHOOTING GUIDE - POWER HEAD LED . . . . . 28

TRANSMITTER COMPLIANCE STATEMENT . . . . . . . . . . . . . . . 29

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page 4

PN# 37026500123 02/26/2010 REV. 1

6

To avoid damage to your door and/or

opener, make sure you disable and/or

remove any door locks, ropes, and/or cables

(NOT door lift cables) prior to installing your

opener

. (

Refer to Section 1.)

4

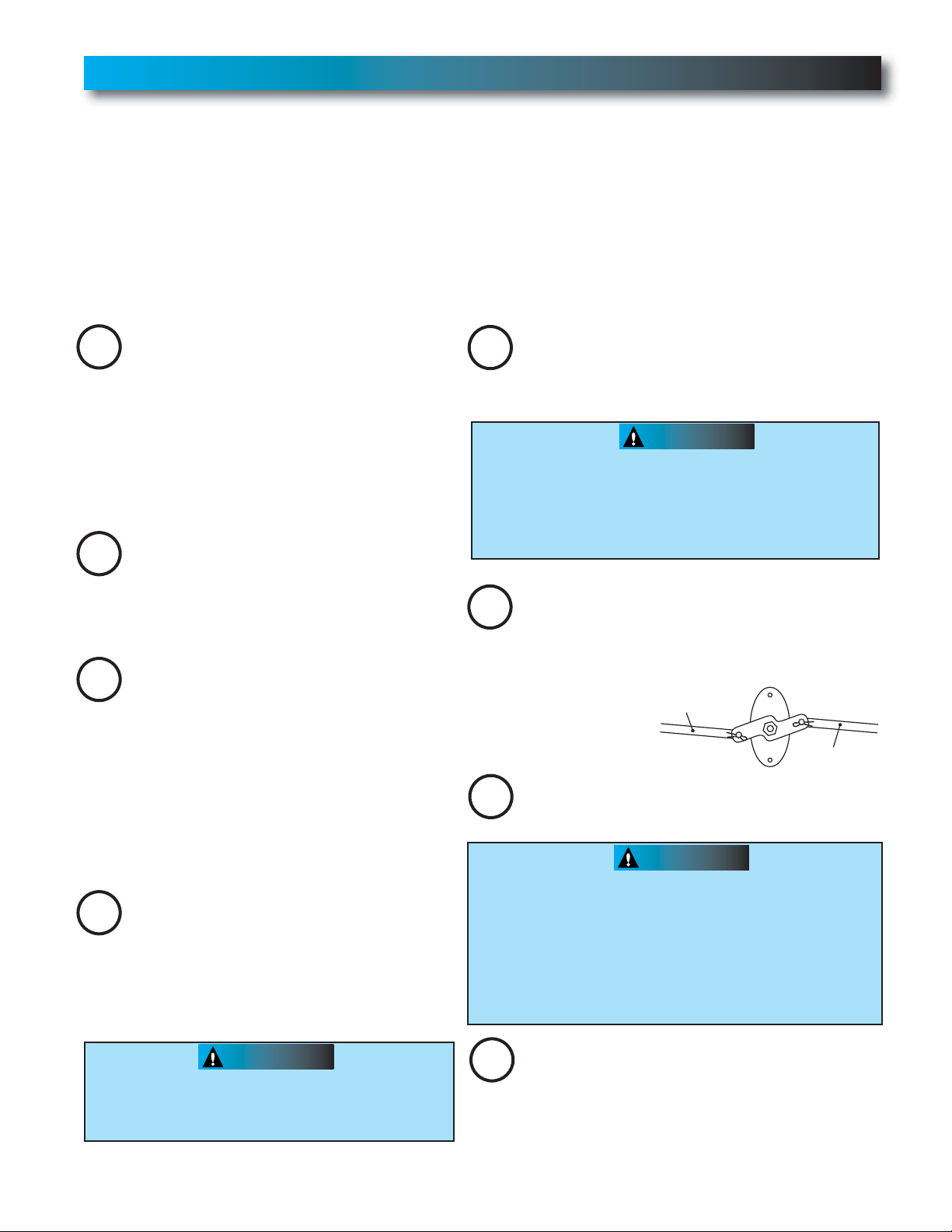

PRE-INSTALLATION CHECK LIST

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

Things to consider if you are planning to "Do-it-yourself."

This opener is designed for use with SECTIONAL doors only.

In many cases you will be replacing an existing door opener with a new one, however, if this

will be the first opener installed there are some pre-installation issues which need to be

addressed. They are as follows:

The Genie Company recommends that you read and fully understand all information and

instructions contained herein before choosing a "Do-it-yourself" installation. Any

questions should be directed to The Genie Company or an authorized Genie

®

Dealer.

1

Check your ceiling where the power

head of your new unit will be mounted.

Plan how you will be mounting the power head.

It is possible that ceiling joists may not be in the

position needed with respect to the garage door

opener. It may be necessary to add an

additional bracket and

fasteners (not included

with your new door opener kit).

(Refer to Section 2.)

2

Check the wall directly above the garage

door

. The door opener’s header bracket

must be securely fastened to this wall. Insure

that the structure will provide a strong mounting

location. (

Refer to Section 2.)

3

Check to see if the mounting location

for the Safe-T-Beam

®

System is clear from

obstruction and has a wood surface available

for attaching the mounting brackets

. The

brackets may be attached to concrete if necessary

but extra tools and special fasteners (not supplied)

will be required.

(Refer to Section 4 and 5.)

NOTE: Mounting brackets must be installed

within code specifications.

4

Is your sectional garage door made of

aluminum, light-weight steel, fiberglass

or glass panels

? Additional support bracing

must be added to these type doors. If this is the

case, please contact the door manufacturer or

authorized dealer so that they can furnish you

with a "bracing kit."

(Refer to Section 2.)

7

Insure that your door is properly balanced

and moving freely. (

Refer to Section 10.)

If your door jams, binds, is improperly

balanced or has a broken spring, have it

repaired or adjusted by a trained door system

technician. Door springs, cables, pulleys,

brackets and associated hardware are under

extreme tension and can cause serious injury

or death.

WARNING

(

The issue numbers below refer to the circled numbers in the illustrations on page 5.

)

8

(NOT SHOWN) If your garage does not have

a separate entry door, you should consider

an emergency release kit (GER-2)for installation on

your garage door.

DO NOT USE AN EXTENSION CORD!

DO NOT USE A PORTABLE GENERATOR! This

product is designed to operate on

standard house current.

DO NOT USE ALTERNATE POWER SUPPLIES.

WARNING

5

You need a properly grounded 110-120 Volt

power supply available

. The outlet should be

no more than 3 feet from the power head once it is

mounted.

(Refer to Section 5.)

Remove

Remove

To reduce the risk of injury to persons or

damage to property - Use this opener only

with sectional doors.

WARNING

Page 5

PN# 37026500123 02/26/2010 REV. 1

5

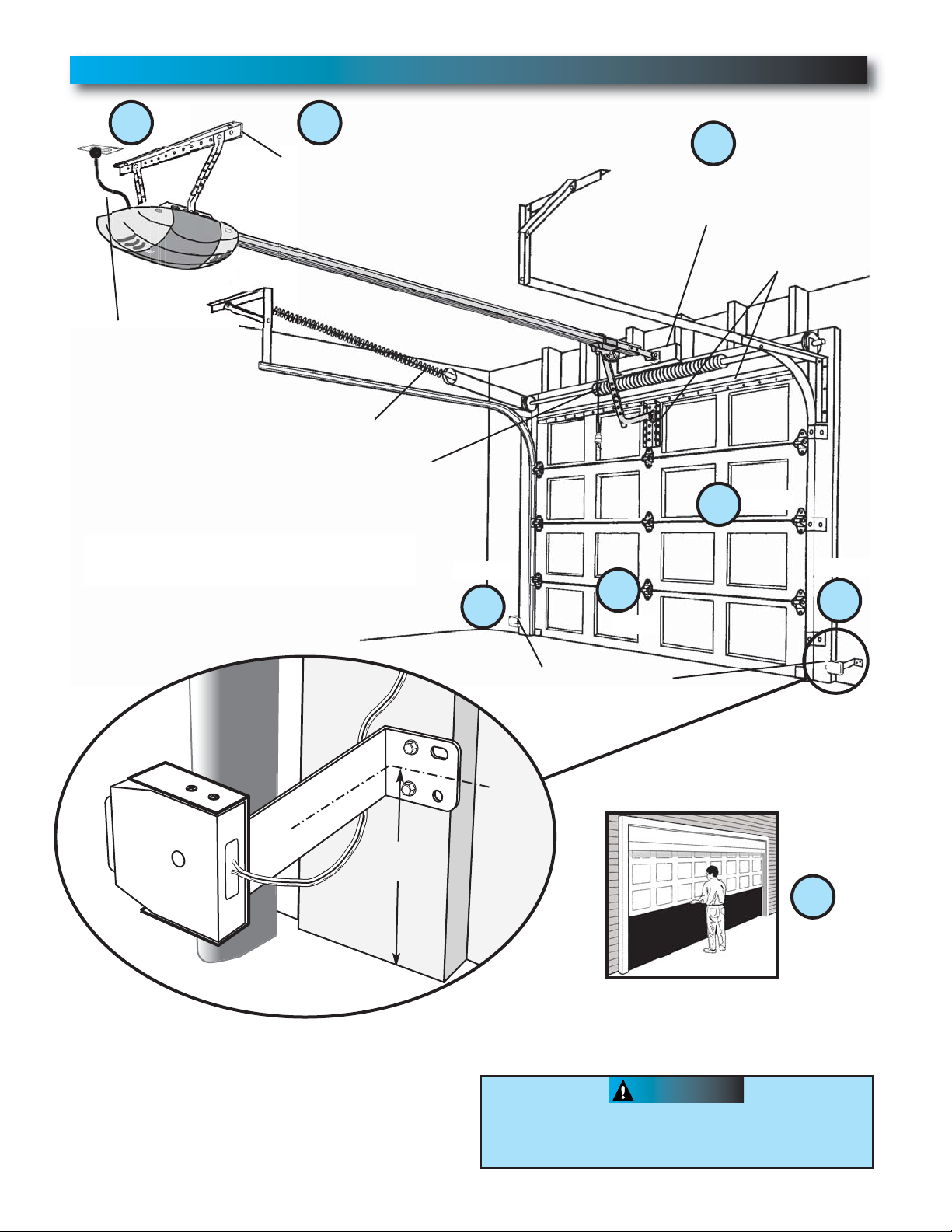

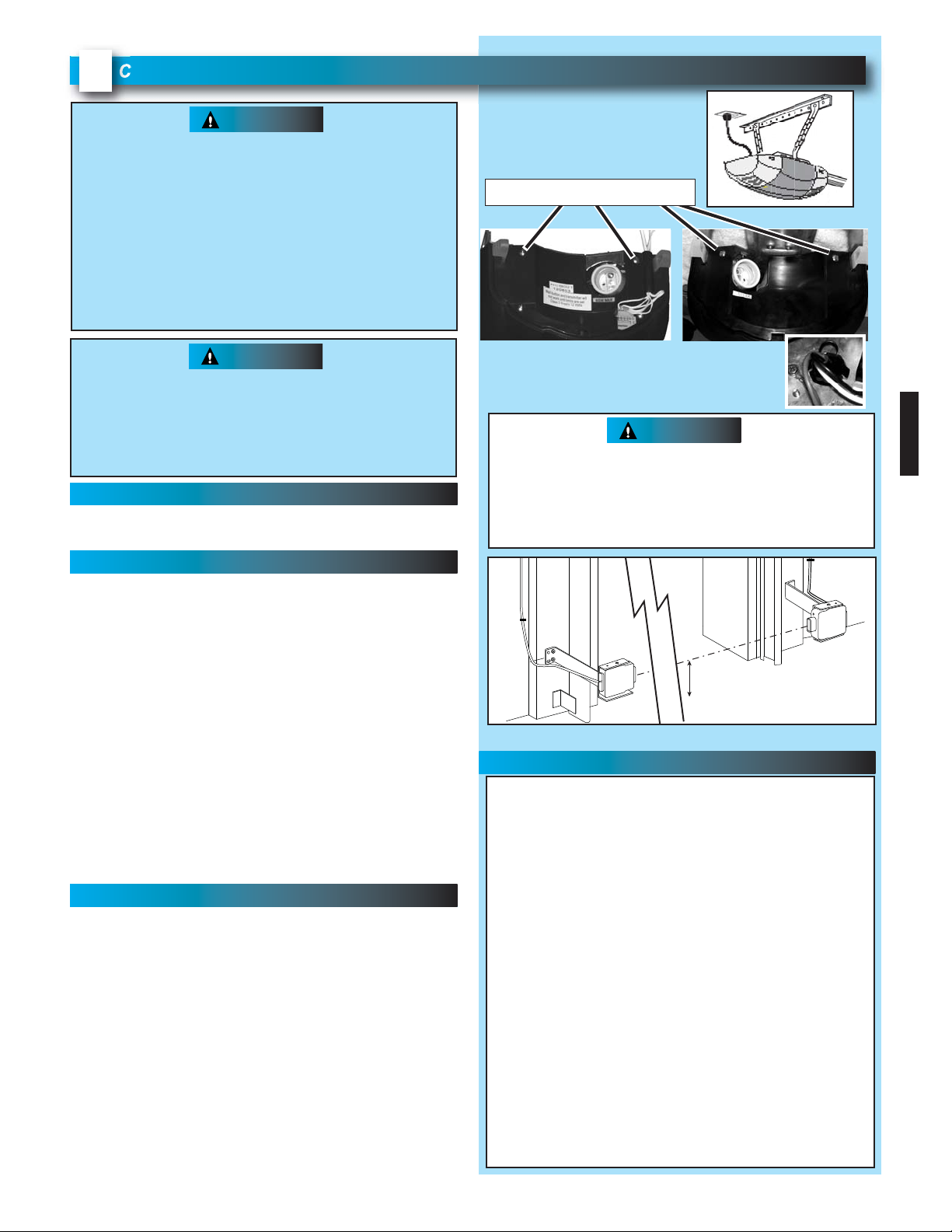

TYPICAL SECTIONAL DOOR INSTALLATION

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

TYPICAL SUPPORT

BRACKET

(NOT PROVIDED)

EXTENSION SPRING

OR

TORSION SPRING

SAFE-T-BEAM

®

SENSORS

BRACES

ADDED

HEADER BRACKET

MOUNTING BOARD

POWER CORD

(APPROX. 45 IN.)

TO 120V GROUNDED

OUTLET

4

1

3

6

2

3

5

SECTIONAL DOOR

Pg. 19

Pg. 13

Pg. 12-13

Pg. 14

Pg. 11

Pg. 17-18

Pg. 17-18

MAX. 6"

MIN. 5"

Pg. 25

To reduce the risk of injury to persons or

damage to property - Use this opener only

with sectional doors.

WARNING

7

NOTE: This opener is designed for

use with SECTIONAL doors only.

Page 6

PN# 37026500123 02/26/2010 REV. 1

6

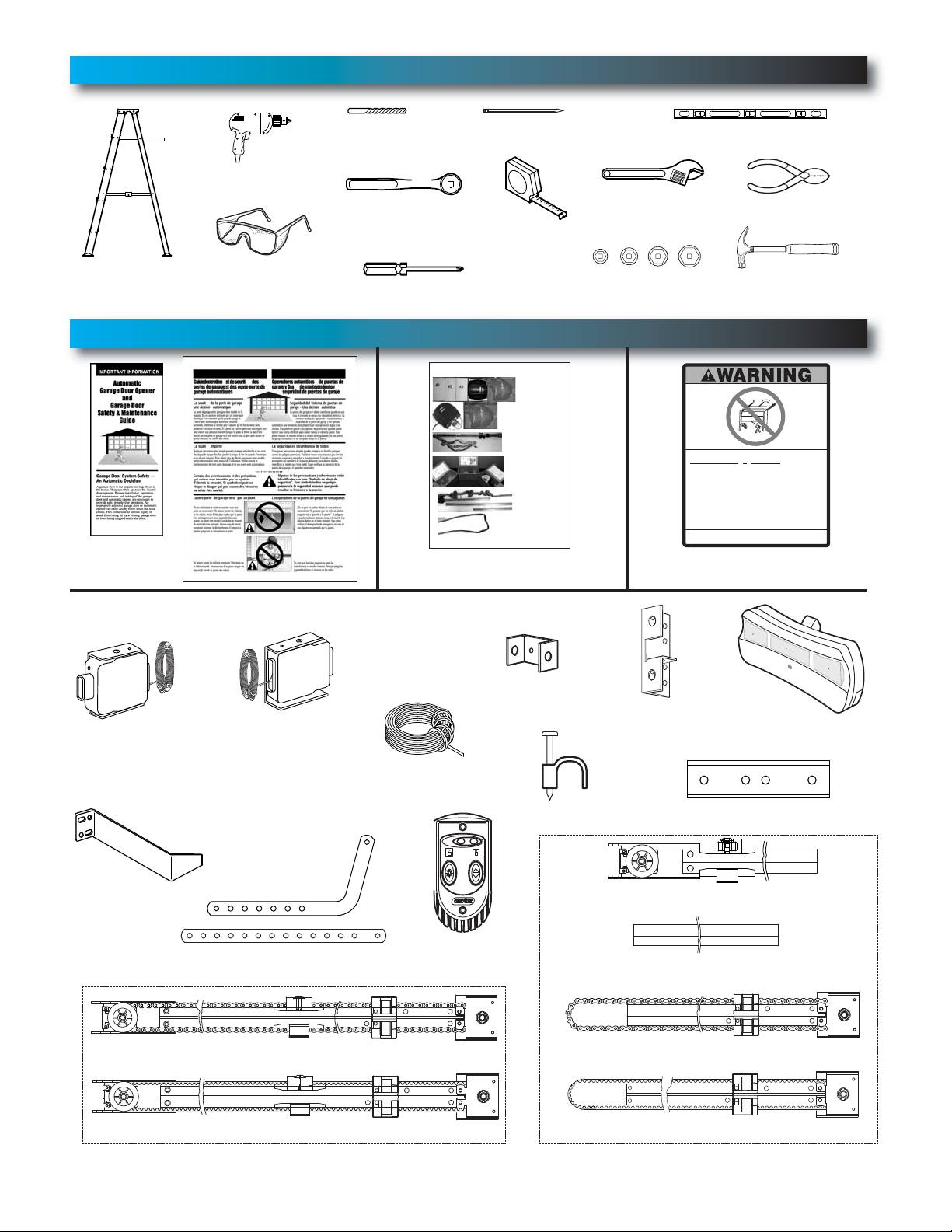

RECOMMENDED TOOLS

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

3/16" Drill Bit

1/4", 7/16", 3/8" and

1/2" Sockets

Step ladder

Drill

Ratchet

Carpenter’s level

Pencil

Tape measure

Wire strippers

Phillips screwdriver

Adjustable wrench

PARTS IDENTIFICATION

-

Not Shown Full Size .

Three-button

Remote Control

Safety Brochures

Entrapment Warning

Label

Safe-T-Beam

®

Source

with wire

(Red LED)

Safe-T-Beam

®

Sensor

with wire

(Green LED)

Wire

Insulated Staple

Door

Bracket

Header Bracket

Rail Section Clamp

Safe-T-Beam

®

Source/Sensor Bracket

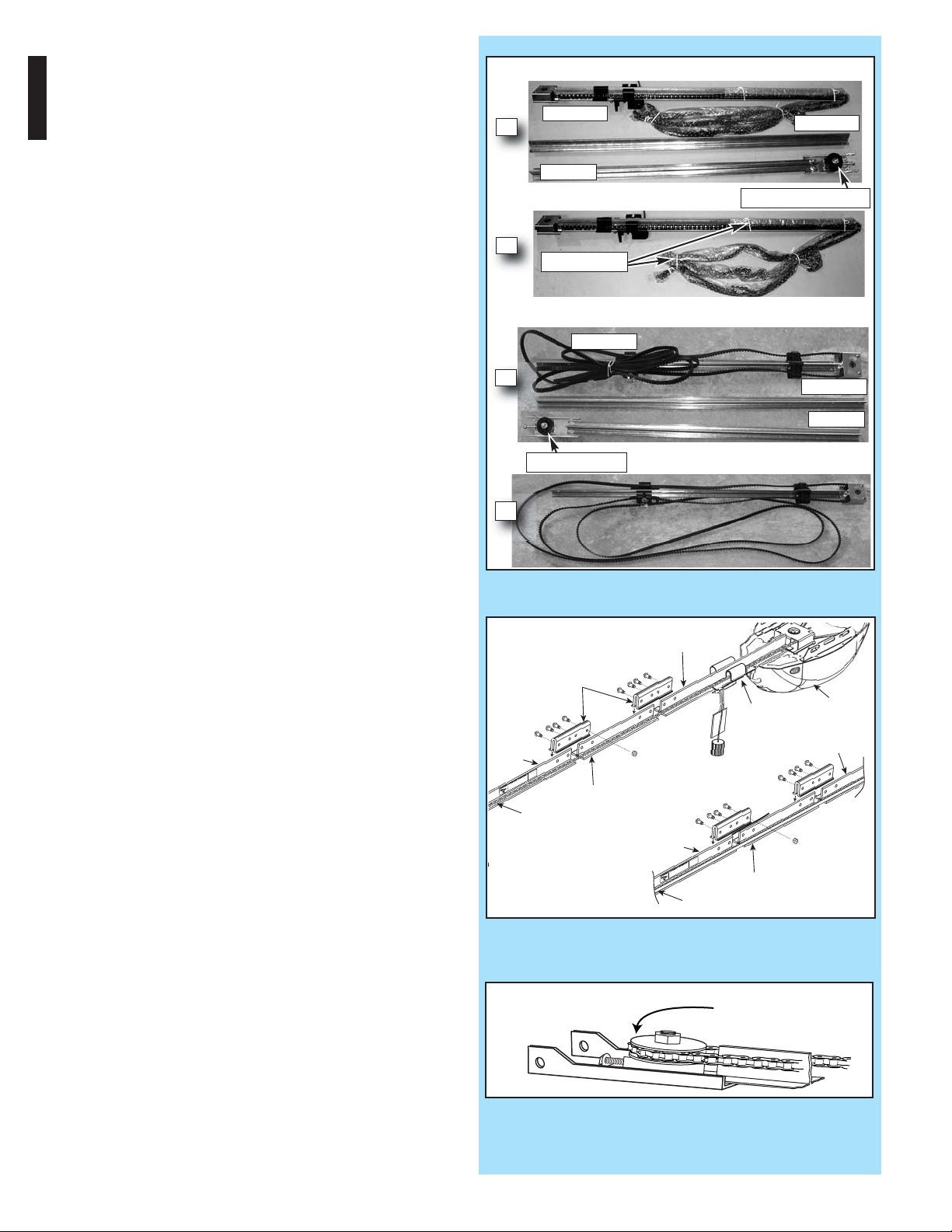

ARRANGING BOX CONTENTS FOR ASSEMBLY

ORGANISATION DU CONTENU DE LA BOÎTE POUR LE MONTAGE

DISPOSICIÓN DEL CONTENIDO DE LA BOLSA PARA EL MONTAJE

Remove internal boxes.

Enlever les boîtes internes.

Quite las cajas internas.

Arrange three small boxes for easy access.

Arranger les trois petites boîtes de manière à

pouvoir y accéder facilement.

Disponga las tres cajas pequeñas para tener

acceso fácil.

Arrange rails in line and pull plastic sleeve off chain

or plastic tie off belt.

Arranger les rails en ligne et tirer sur le manchon en plastique

pour le dégager de la chaîne ou cravate en plastique

outre de courroie.

Disponga los rieles en línea y estire la camisa de plástico fuera

de la cadena o lazo plástico de la correa.

Remove lens Box and motor power head.

Enlever la boîte des lentilles et la tête motorisée.

Quite la caja de la lente y el motor de la caja de control.

Carefully remove third rail (with chain or belt

attached) and place on floor.

Enlever soigneusement le troisième rail (avec la

chaîne ou courroie attachée) et le placer sur le sol.

Cuidadosamente quite el tercer riel (con la

cadena o correa acoplada) y ponga en el

piso.

Remove rail sections not connected

to chain or belt.

Enlever les sections de rail non connectées

à la chaîne ou courroie.

Quite las secciones de riel no conectadas a

la cadena o correa.

Follow instructions in the Installation Manual for assembly steps.

Procéder selon les instructions stipulées dans le manuel d'installation pour les étapes de

©Overhead Door Corporation 02/2009

Box Contents Sheet

Head Rail (Chain) Section

Center Rail Section

End Rail Section

Door Arm

Hammer

Safety Glasses

Head Rail (Belt) Section

Pro Rail (Chain) Section

Pro Rail (Belt) Section

OR

Wall Control

(varies with model)

Child canbe pinned under automatic garage

Death or serious injury can result.

Never let child walk or run under moving door.

•

Never let child use door opener controls.

•

Always keep moving door in sight.

•

If person is pinned, push control button or use

•

emergency release.

Test door opener monthly:

•

Refer to your owner'’s manual.

1

Place 1

/2-inch object (or 2x4 laid flat) on floor.

If door fails to reverse on contact, adjust opener.

If opener still fails to reverse door, repair or replace opener.

Do not remove or paint over this label.

Mount wall control out of child's reach

Place next to wall control.

(at least 5 feet above floor).

door.

.

©1999

Page 7

PN# 37026500123 02/26/2010 REV. 1

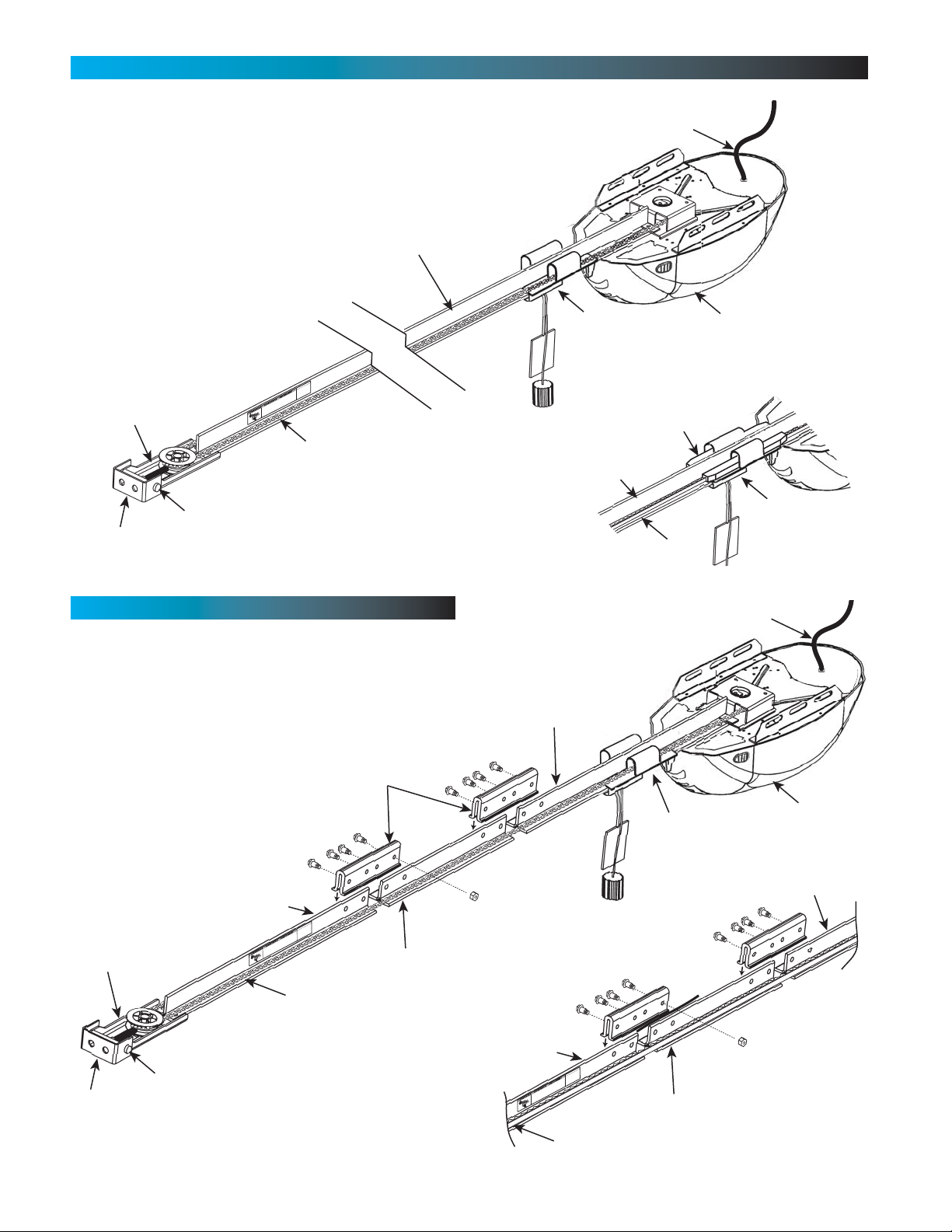

FASTENERS

-

Shown Full size (

See Parts List below for full description.)

Lag screw - 5/16" x 2"

Self-drilling Screw

1/4 -20 x 3/4"

Hex Flange Nut

1/4 -20

Cotter pin

Clevis pin

5/16" x 3/4"

Hex Bolt - 5/16 -18 x 3/4"

Hex Flange Nut

5/16 -18

Rail Clamp Bolt - 5/16 -18 x 5/8"

#10-16 x 1-1/4" Phillips Hex Screw

Hex Bolt - 5/16 -18 x 1/2"

#4-24 x 1" Pan Head

Phillips Screw

Clevis pin, long 5/16" x 3"

7

BAG NO. DESCRIPTION QUANTITY

0 RAIL SECTION CLAMP 2

RAIL CLAMP BOLT – 5/16 -18 x 5/8'' 8

HEX FLANGE NUT – 5/16 -18 8

1 BOLT – 5/16 -18 x 1/2'' 3

2 CLEVIS PIN, LONG – 5/16" x 3" 1

COTTER PIN 1

HEADER BRACKET 1

LAG SCREW – 5/16'' x 2'' 2

3 HEX BOLT – 5/16 -18 x 3/4'' 5

HEX FLANGE NUT – 5/16 -18 5

LAG SCREW – 5/16'' x 2'' 2

4 SELF DRILLING SCREW – 1/4 -20 x 3/4'' 3

DOOR BRACKET 1

5 HEX BOLT – 5/16 -18 x 3/4'' 3

SELF LOCKING NUT – 5/16 -18 1

HEX FLANGE NUT – 5/16 -18 2

CLEVIS PIN – 5/16" x 3/4" 1

COTTER PIN 1

6 WALL CONTROL ASSEMBLY 1

PAN HEAD PHILLIPS SCREW – #4-24 x 1'' 2

7 13 MM INSULATED STAPLE 30

8 Safe-T-Beam®SOURCE/SENSOR BRACKET 2

PHILLIPS HEX SCREW – #10-16 x 1- 1/4'' 4

WIRE NUT (GREY) 4

NO NUMBER

REMOTE WITH BATTERY 1

NO BAG Safe-T-Beam®SOURCE/SENSOR & WIRE SET 1

NO NUMBER

LIGHT COVER - WHITE 2

Self Locking Nut

5/16 -18

Wire Nut

MISSING ANY PARTS?

Please call toll free - 1.800.354.3643

DO NOT RETURN TO POINT OF PURCHASE.

IMPORTANT! - Information needed when calling

• Model number - (located on packaging)

• Store, city, state, and date of purchase

Shoulder Bolt

5/16 -18 x 1"

Page 8

PN# 37026500123 02/26/2010 REV. 1

8

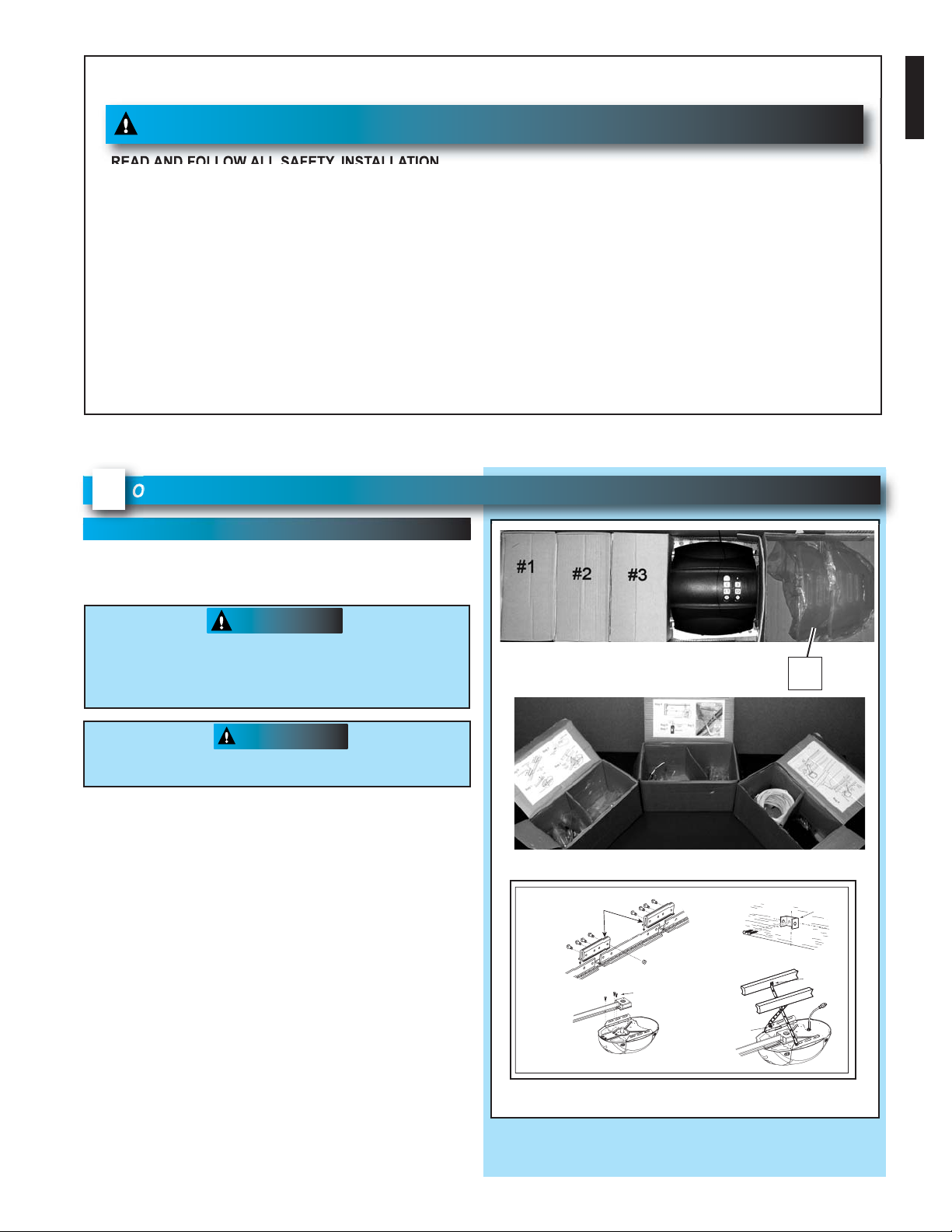

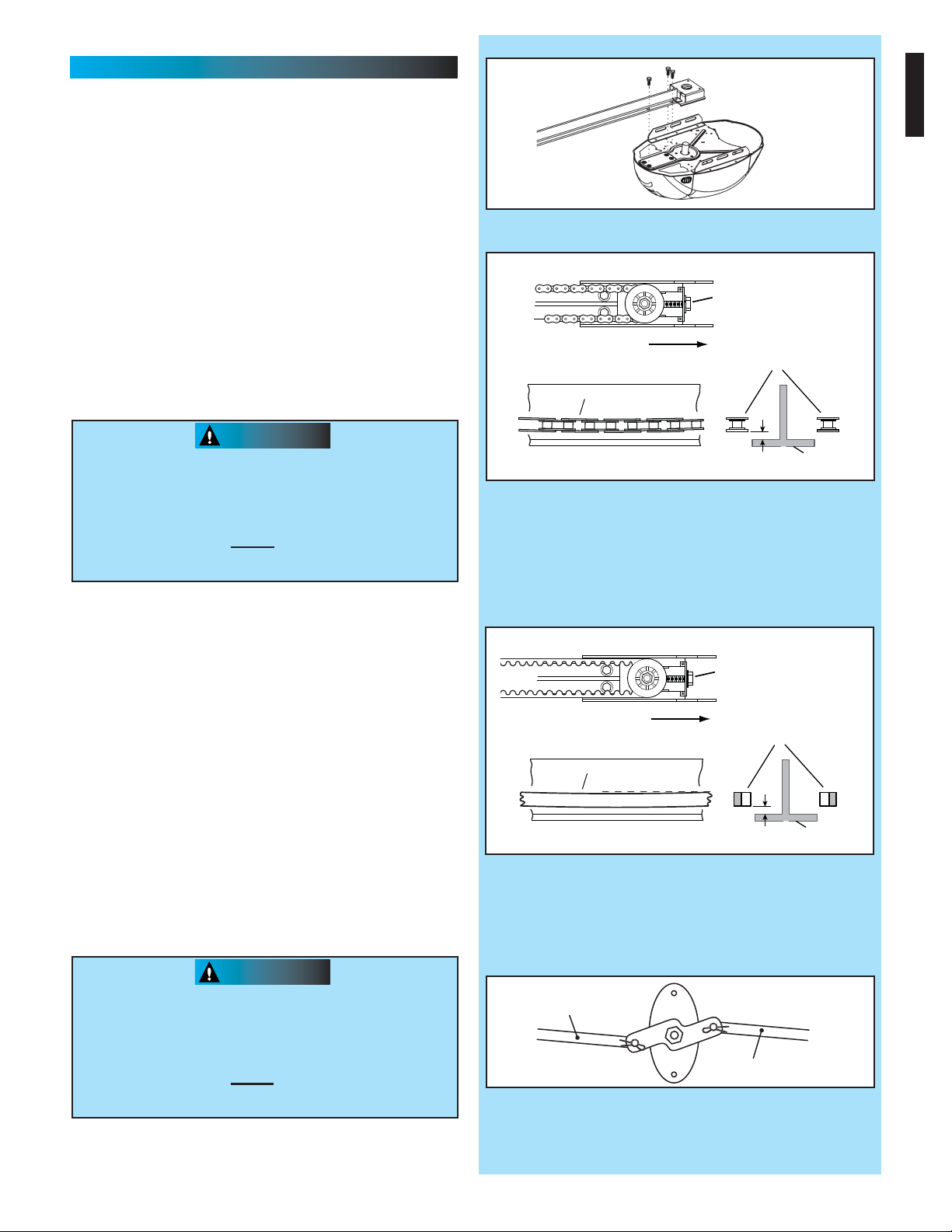

1-PIECE RAIL HARDWARE ASSEMBLED VIEW

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

3-PIECE RAIL HARDWARE ASSEMBLED VIEW

Tensioner

Rail with chain

Chain

Carriage Slide

Release

Knob

Header

Bracket

Power Head

Power Cord

Clevis Pin, Long

& Cotter Pin

N

O

T

E

Some do

ors need

b

ra

cin

g. Con

tac

t

doo

r distributor or

manufactur

er

for

instructions.

HIGH SPRING TENSION

C

an

C

ause

Seriou

s I

n

ju

r

y

o

r D

e

ath

R

e

p

a

i

r

s

o

r

a

d

j

u

s

t

m

e

n

t

s

m

u

s

t

b

e

m

a

d

e

b

y

a

t

r

a

i

n

e

d

s

e

r

v

ic

e

p

e

r

s

o

n

u

s

i

n

g

p

r

o

p

e

r

t

o

o

l

s

a

n

d

i

n

s

t

r

u

c

t

i

o

n

s

Rail with belt

Belt

Carriage Slide

Belt Clamp

Rail Clamps

Rail Clamp Bolts

Rail Clamp Nuts

Tensioner

Rail with chain

Center Rail

End Rail

Chain

Carriage Slide

Release

Knob

Header

Bracket

Clevis Pin, Long

& Cotter Pin

Power Head

Power Cord

N

O

T

E

Som

e doors

need

bracing.

Con

tac

t

doo

r distr

ibutor or

manufac

turer

for

instr

uct

ions

.

H

IG

H

S

P

R

ING

TEN

SI

O

N

Can

Cau

se Se

rio

u

s Inju

r

y o

r Death

Rep

airs

or

ad

jus

tme

nts

mu

st be

made by a t

rai

ned

service

per

son using

p

rop

er too

ls

and i

nstr

uct

ion

s

Rail with belt

Center Rail

End Rail

Belt

Release

Knob

N

O

T

E

Som

e do

ors need

bracing.

Con

tac

t

door distr

ibut

or or

manufac

turer

for

instr

uct

ions

.

HIG

H

S

PR

ING

TEN

SI

O

N

C

an

Cause Se

rio

u

s Inju

r

y or Death

Rep

airs

or adjustme

nts

mu

st be

made

by

a t

rai

ned

service per

son using

p

rop

er too

ls

and i

nstr

uct

ion

s

CHAIN

CHAIN

BELT

BELT

Page 9

PN# 37026500123 02/26/2010 REV. 1

9

OPENER ASSEMBLY

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

1

NOTE: Three (3) piece rail assemblies are for a 7

foot high sectional door.

Clear a workspace area to unpack and organize box

and contents for assembly.

1. There are 4 boxes inside the carton. Each box is

numbered 1 - 4. Note that some openers will

contain the same parts and be packaged with

fewer boxes. Carefully remove the three

internal boxes (Labeled #1, 2, and 3) and place

them on the floor for easy access (Fig. 1-1).

These boxes contain assembly parts and the

contents are organized by assembly tasks. For

quick reference inside the lid of each box there is

a label illustrating the components inside.

2. Remove the motor power head and place it on

the floor for later use. Remove box #4 and

place it on the floor for later use.

Do NOT run until opener is fully assembled and

instructed to do so.

CAUTION

FIG. 1-1 Internal boxes.

RAIL ASSEMBLY: Use a clean, flat surface.

Rail Connectors

Rail Connector Bolts

Rail Connector Nuts

Box Label Example

#4

1.

READ AND FOLLOW ALL SAFETY, INSTALLATION

AND OPERATION INSTRUCTIONS.

(If you have

questions or do not understand an instruction, call The

Genie Company or an authorized Genie

®

Dealer.)

2. Install only on a properly balanced sectional garage door.

An improperly balanced door could cause severe injury.

Have a trained door system technician make repairs or

adjustments to cables, spring assemblies, and other

hardware before installing the opener.

3. Remove all ropes and remove or make inoperative all

locks connected to the garage door before installing opener.

4. Where possible, install the door opener 7 feet or more

above the floor. For products having an emergency

release, mount the emergency release 6 feet above the floor.

IMPORTANT INSTALLATION INSTRUCTIONS

WARNING:

To reduce the risk of severe injury or death:

5. Do NOT connect the opener to source of power

until instructed to do so.

6. Locate the Wall Control:

• Within sight of door,

• At minimum height of 5 feet so small children are not

able to reach it, and

• Away from all moving parts of the door.

7. Install the Entrapment WARNING Label next to the Wall

Control in a prominent location. Install the Emergency

Release Tag on or next to the emergency release.

8. After installing the opener, the door must reverse within

2 seconds when it contacts a 1-1/2 inch high object (or a

2 x 4 board laid flat) on the floor.

To reduce the risk of injury to persons or

damage to property - Use this opener only

with sectional doors.

WARNING

NOTE: For 1-piece rail—skip to POWER HEAD &

RAIL ASSEMBLY.

NOTE: Please follow ALL instructions in their NUMBERED sequence. Use wall control and safety sensors

provided with this unit. Do NOT substitute wall control or safety sensors.

Bag 0

Rail

Bolts

Power head

Bag 2

Header Bracket

Bag 3Bag 1

Bolts

5/16" Nuts

& Bolts

Header Bracket

Lag Srews

Page 10

10

FIG. 1-2 Split Rail sections.

FIG. 1-3 Split Rail assembly.

A

B

Chain Rail

Center Rail

End Rail

Wire Tie(s)

Rail Assembly for CHAIN DRIVE OPENER

NOTE: For split rail clamps, nuts, and bolts

locate Bag 0 from Box 1.

3. Remove the two rail sections that are not

connected to the chain and place them on

floor (Fig. 1-2, A).

4. Carefully remove the third rail section with

chain and plastic sleeve. Place rail section on

floor and extend chain straight out

(Fig. 1-2, B). Chain and rail should extend

approximately 7 feet.

5. Remove wire ties and plastic bag from chain.

Leave chain extended straight out on floor.

Avoid kinks in the chain by careful handling and

keeping chain flat on the floor.

6. Align the three rail sections by pulling the

chain straight and wrapping it around the

chain tensioner pulley (Fig. 1-3 & 1-4).

7. Attach the two rail clamps to the rail section

joints with (4) bolts and nuts. After both rail

clamps have been assembled to the rail sections,

securely tighten the bolts and nuts.

PN# 37026500123 02/26/2010 REV. 1

Rail Clamps

Rail Clamp Bolts

Rail Clamp Nuts

Rail with chain

Center Rail

End Rail

Chain

Carriage Slide

Release

Knob

Power Head

N

O

T

E

S

o

m

e

do

o

rs

n

e

e

d

b

ra

c

in

g

.

C

o

n

ta

c

t

d

oor d

istrib

u

t

o

r o

r

m

a

nu

fa

ct

ur

er

for

ins

tr

uc

t

io

n

s

.

H

I

G

H

S

P

R

IN

G

T

E

N

S

I

O

N

C

a

n

C

a

u

s

e S

e

r

i

o

u

s

I

n

ju

ry o

r

De

a

t

h

R

e

p

a

i

r

s

o

r

a

d

j

u

s

t

m

e

n

t

s

m

u

s

t

b

e

m

a

d

e

b

y

a

tr

a

i

n

e

d

s

e

r

v

i

c

e

p

e

r

s

o

n

u

s

i

n

g

p

r

o

p

e

r

t

o

o

l

s

a

n

d

i

n

s

t

r

u

c

t

i

o

n

s

Rail with belt

Center Rail

End Rail

Belt

Release

Knob

N

O

TE

So

m

e

d

o

or

s

n

e

e

d

br

a

cin

g

.

C

o

n

ta

c

t

d

o

or distrib

u

t

o

r o

r

m

a

nu

fa

c

t

ur

e

r

fo

r

instr

u

ct

io

n

s.

H

I

G

H

S

P

R

I

N

G

T

E

N

S

I

O

N

C

a

n

C

a

u

s

e

S

e

r

io

u

s

I

n

ju

r

y

or

D

e

a

t

h

R

e

p

a

i

r

s o

r

a

d

j

u

s

t

m

e

n

t

s

m

u

s

t

b

e

m

a

d

e

b

y

a

tr

a

i

n

e

d

s

e

r

v

i

c

e

p

e

r

s

o

n

u

s

in

g

p

r

o

p

e

r

t

o

o

l

s

a

n

d

i

n

s

t

r

u

c

t

i

o

n

s

Rail Assembly for BELT DRIVE OPENER

NOTE: For split rail clamps, nuts, and bolts

locate Bag 0 from Box 1.

3. Remove the two rail sections that are not

connected to the belt and place them on floor

(Fig. 1-2, A).

4. Carefully remove the third rail section with

belt. Place rail section on floor, remove ties on

belt and extend belt straight out (Fig. 1-2, B).

Avoid twists and kinks in the belt by careful

handling and keeping belt flat on the floor. Belt

and rail should extend approximately 7 feet.

5. Align the three rail sections by pulling the belt

straight and wrapping it around the tensioner

pulley (Fig. 1-3 & 1-4).

6. Attach the two rail clamps to the rail section

joints with (4) bolts and nuts. After both rail

clamps have been assembled to the rail sections,

securely tighten the bolts and nuts.

Belt Rail

Center Rail

End Rail

CHAIN DRIVE RAILS

BELT DRIVE RAILS

FIG. 1-4 Mount chain/belt to tensioner pulley.

Wrap around tensioner pulley

CHAIN

BELT

A

B

Chain Tensioner Pulley

Tensioner Pulley

Page 11

POWER HEAD & RAIL ASSEMBLY

Assembly for CHAIN DRIVE OPENER

NOTE: Handle carefully! Drive chain can slide out

of rail.

NOTE: For power head and rail assembly locate

Bag 1 from Box 1.

NOTE: Copy serial number from power head

frame and record it on warranty page.

1. Attach rail assembly to power head by aligning

the sprocket onto the motor shaft. Use (3)

bolts, 5/16 -18 x 1/2" (Fig. 1-5).

2. Tighten the chain by turning the adjustment

nut clockwise. The chain adjustment nut is

located in the Chain Pulley Bracket (opposite rail

end from the power head) (Fig. 1-6).

3. Tighten chain until chain is approximately 1/8

inch above the base of the rail at midpoint on

the rail (Fig. 1-6). Do NOT over tighten chain.

Set assembled power head and rail aside. Begin with

Section 2 INSTALLATION.

PN# 37026500123 02/26/2010 REV. 1

11

FIG. 1-6 Chain adjustment.

FIG. 1-5 Rail - Power head assembly.

Chain Pulley Bracket (at wall end of rail)

Chain

T-Rail at center of rail assembly

1/8"

T-Rail

Chain

Tighten nut to move pulley this direction

Use 1/2" socket

on adjustment nut

Use

5/16"-18 x 1/2"

Bolts

FIG. 1-8 Disable garage door lock.

Remove

Remove

FIG. 1-7 Belt adjustment.

Belt Pulley Bracket (at wall end of rail)

Belt

T-Rail at center of rail assembly

1/8"

T-Rail

Belt

Tighten nut to move pulley this direction

Use 1/2" socket

on adjustment nut

Assembly for BELT DRIVE OPENER

NOTE: For power head and rail assembly locate

Bag 1 from Box 1.

NOTE: Copy serial number from power head

frame and record it on warranty page.

1. Attach rail assembly to power head by aligning

the sprocket onto the motor shaft. Use (3)

bolts, 5/16 -18 x 1/2" (Fig. 1-5).

2. Tighten the belt by turning the adjustment nut

clockwise. The belt adjustment nut is located in

the Belt Pulley Bracket (opposite rail end from the

power head) (Fig. 1-7).

3. Tighten belt until belt is approximately 1/8 inch

above the base of the rail at midpoint on the

rail (Fig. 1-7). Do NOT over tighten belt.

Set assembled power head and rail aside. Begin with

Section 2 INSTALLATION.

You should have removed all ropes and/or

cables (NOT door lift cables) and disabled

the door lock already. If you have not,

remove all ropes and/or cables and disable

garage door lock NOW before continuing

with installation (Fig. 1-8).

CAUTION

You should have removed all ropes and/or

cables (NOT door lift cables) and disabled

the door lock already. If you have not,

remove all ropes and/or cables and disable

garage door lock NOW

before continuing

with installation (Fig. 1-8).

CAUTION

Page 12

12

PN# 37026500123 02/26/2010 REV. 1

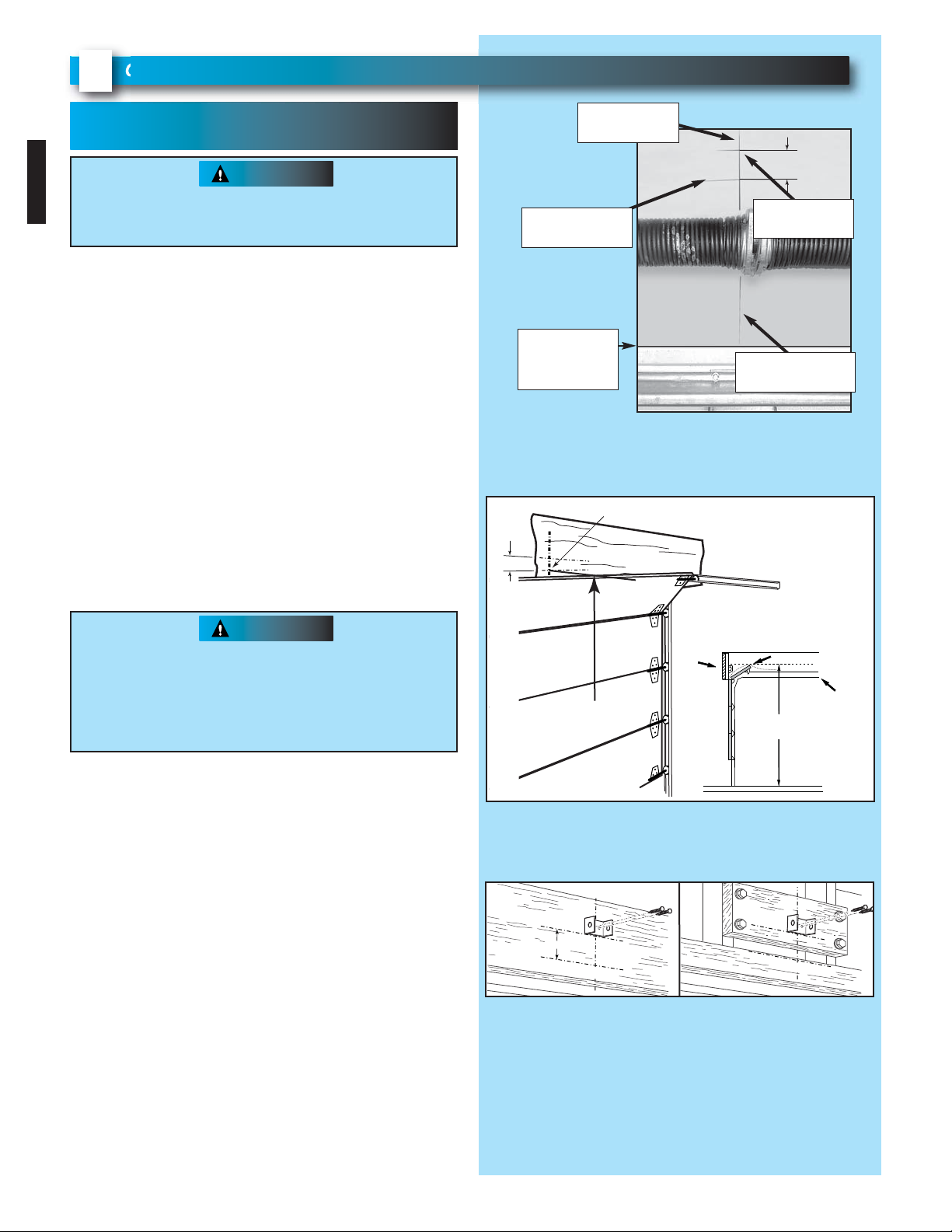

FIG. 2-2 Finding highest point of travel.

OPENER INSTALLATION

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

2

HEADER AND DOOR

MOUNTING BRACKETS:

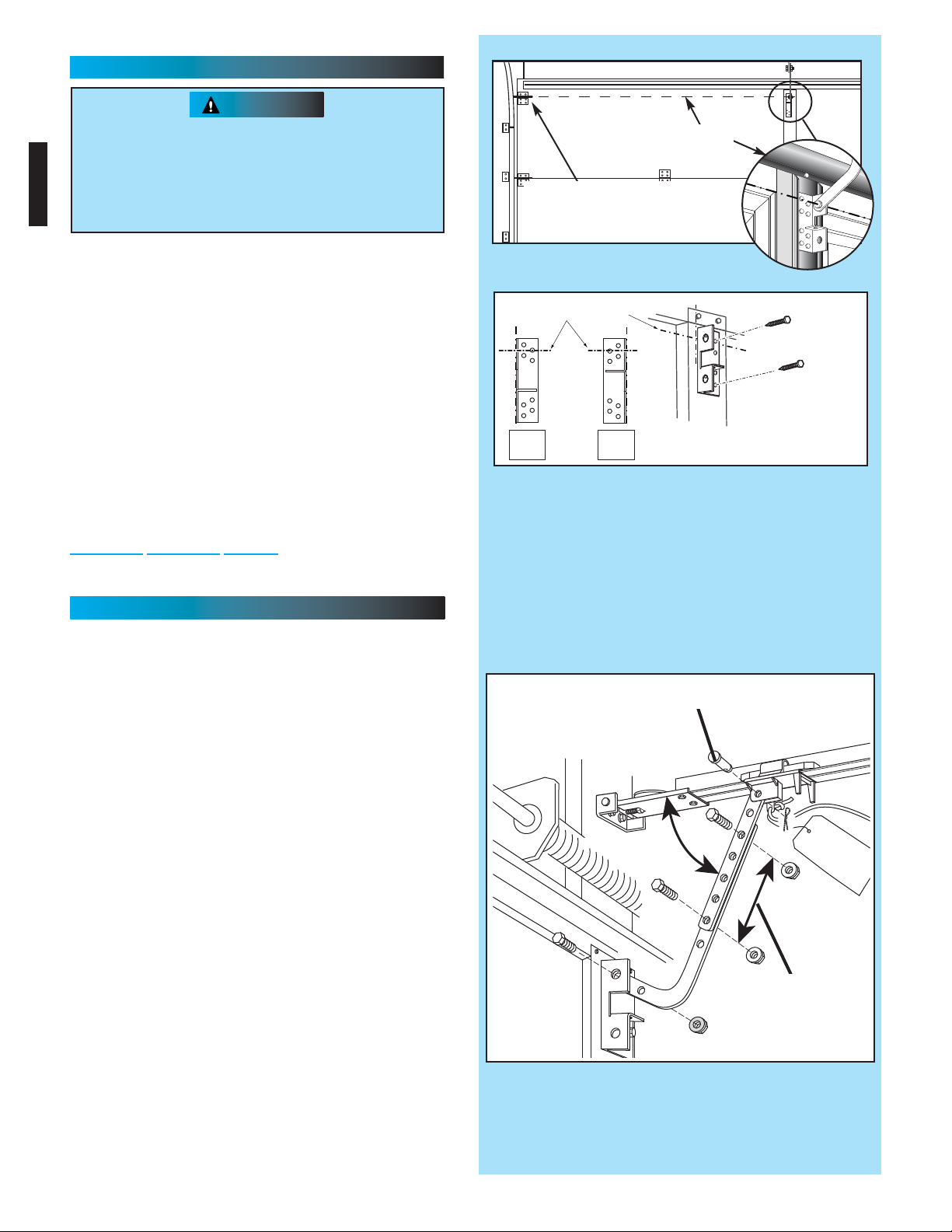

1. Finding header bracket mounting location.

• Close garage door.

– Use a pencil and level.

a) Mark center of garage door (one-half overall

width) on the wall with 6" vertical line at top

edge of door.

b) Continue this line on wall above door for

about 12" (Fig. 2-1, a).

• Raise garage door until top edge of door

reaches its maximum height

(Fig. 2-2)

.

• With door at highest point.

–

Measure height from top edge of door to floor

(Fig. 2-2).

• Close door again.

• Mark height measurement on wall above door

(Fig. 2-1, c)

.

– Make your mark across vertical line made earlier.

• Add 2-1/2" to height mark just made on

wall. This

is location for header bracket (Fig. 2-1, d).

NOTE: If header bracket location needs to be

above header for garage door opening, you need

to add a "mounting surface." A 2" x 6" board

securely attached (board and fasteners not

included) to wall studs on either side of your mark

is sufficient (Fig. 2-3).

NOTE: For header bracket and bolts locate Bag 2

from Box 1.

NOTE: The bolts supplied in Bag 2 are designed

to be used on pressure treated lumber.

2. Mounting the header bracket.

• Hold header bracket against wall

(Fig. 2-3).

• Position bracket as shown.

–

Place center on vertical line,

–

Bottom edge on final height line.

•

Mark screw hole locations on wall.

• Drill 3/16" pilot holes at each screw hole mark.

–

Fasten header bracket with 2 lag screws

(provided) (Fig. 2-3).

FIG. 2-1 Final height mark.

Header bracket must be fastened to garage

framing. Do NOT fasten to drywall, particle

board, plaster or other such materials.

WARNING

2-1/2"

top of door

in closed

position

d) - final

height mark

HIGHEST POINT OF TRAVEL

TRACK

SECTIONAL

DOOR

HEADER

FROM HERE

TO FLOOR

2-1/2"

HIGHEST POINT OF TRAVEL

TRACK

SECTIONAL

DOOR

HEADER

FROM HERE

TO FLOOR

a) - 6" vertical

line

b) - extend

vertical line

c) - door at

highest point

door at highest point

door at highest point

final height mark

final height

mark

2-1/2"

FIG. 2-3

Header bracket mounting (on header &

above header)

.

Door springs are under high tension. If spring or

its shaft is in the way, measure 2-1/2" above

spring or shaft on the garage door centerline and

mark this height as your location for header

bracket.

Do NOT move door spring!

WARNING

Page 13

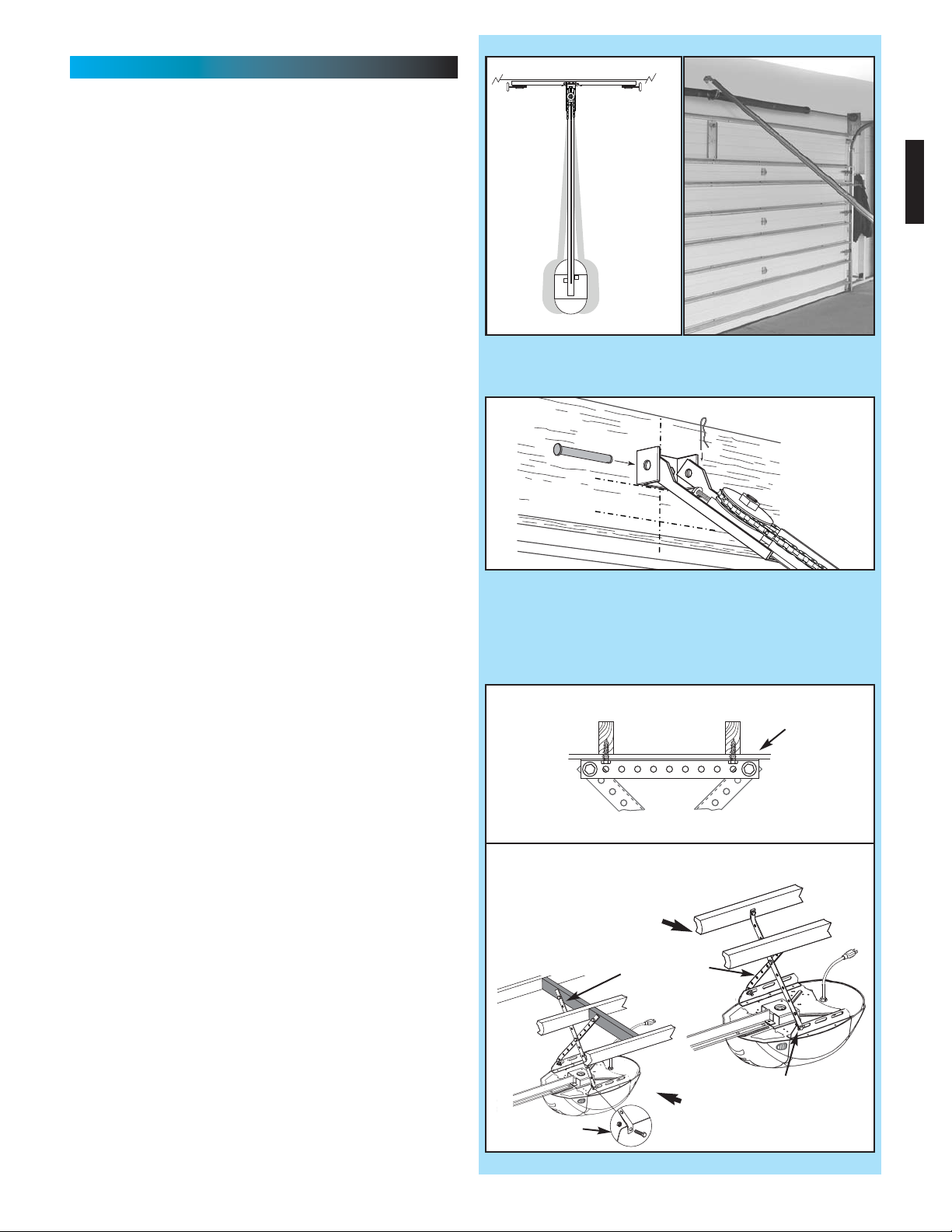

MOUNTING THE OPENER:

1. Getting started.

• Position assembled rail

on wall next to header

bracket

(Fig. 2-4).

– Place material on floor under power head to

protect from scratching. (A box, stool, or

similar device may be needed to clear a

torsion spring.)

NOTE: For header bracket pins locate Bag 2 from

Box 1.

2. Mounting the assembly.

• Attach rail to header bracket using clevis pin

and cotter pin (Fig. 2-5).

• Support power head on step-ladder to prevent

interference with header mounted (torsion)

spring.

NOTE: Before final attachment to ceiling, insure

that assembly is in proper alignment (Fig. 2-4).

NOTE: For nuts, bolts, and lag screws locate Bag

3 from Box 1.

• On finished ceilings, locate ceiling joists or

trusses using a stud finder or similar device.

Attach angle iron (not provided) to joists or

trusses through finish material using (provided)

lag screws (Fig. 2-6).

• On unfinished ceilings or open ceilings, straps

may attach directly to joists or trusses.

Depending on the garage construction, extra

framing material (not provided) which may be

required should be installed using appropriate

construction techniques (Fig. 2-6).

NOTE: Refer to your local building codes for

appropriate construction techniques.

• Attach mounting straps (not provided) to ceiling

using lag bolts (Fig. 2-6).

• Set height of power head to following

(Fig. 2-6).

a)

Rail must clear door at door’s highest point

of travel.

b)

Rail must b

e level or at power head end

slightly below level.

• Securely tighten power head mounting bolts

and nuts.

• Carefully raise and lower door manually.

Ensure door does not contact any section of

power head or rail.

• Check that rail clamp bolts and nuts are tight.

• DO NOT PLUG OPENER IN YET!

FIG. 2-4 Position assembly and align.

VIEW

FROM ABOVE

(not to scale)

HEADER BRACKET

Mounting Straps

(not provided)

FIG. 2-6 Mounting the power head.

ANGLE IRON ON FINISHED CEILING

Attach angle iron to beams

UNFINISHED OR OPEN BEAM

Extra framing

not needed

Extra framing

NEEDED

DRYWALL

bolts & nuts

bolts & nuts

FIG. 2-5

Rail mounting to header bracket

.

COTTER PIN

CLEVIS PIN

(Chain drive

shown)

PN# 37026500123 02/26/2010 REV. 1

13

N

O

YES / SÍ / OUI

O

N

Page 14

14

PN# 37026500123 02/26/2010 REV. 1

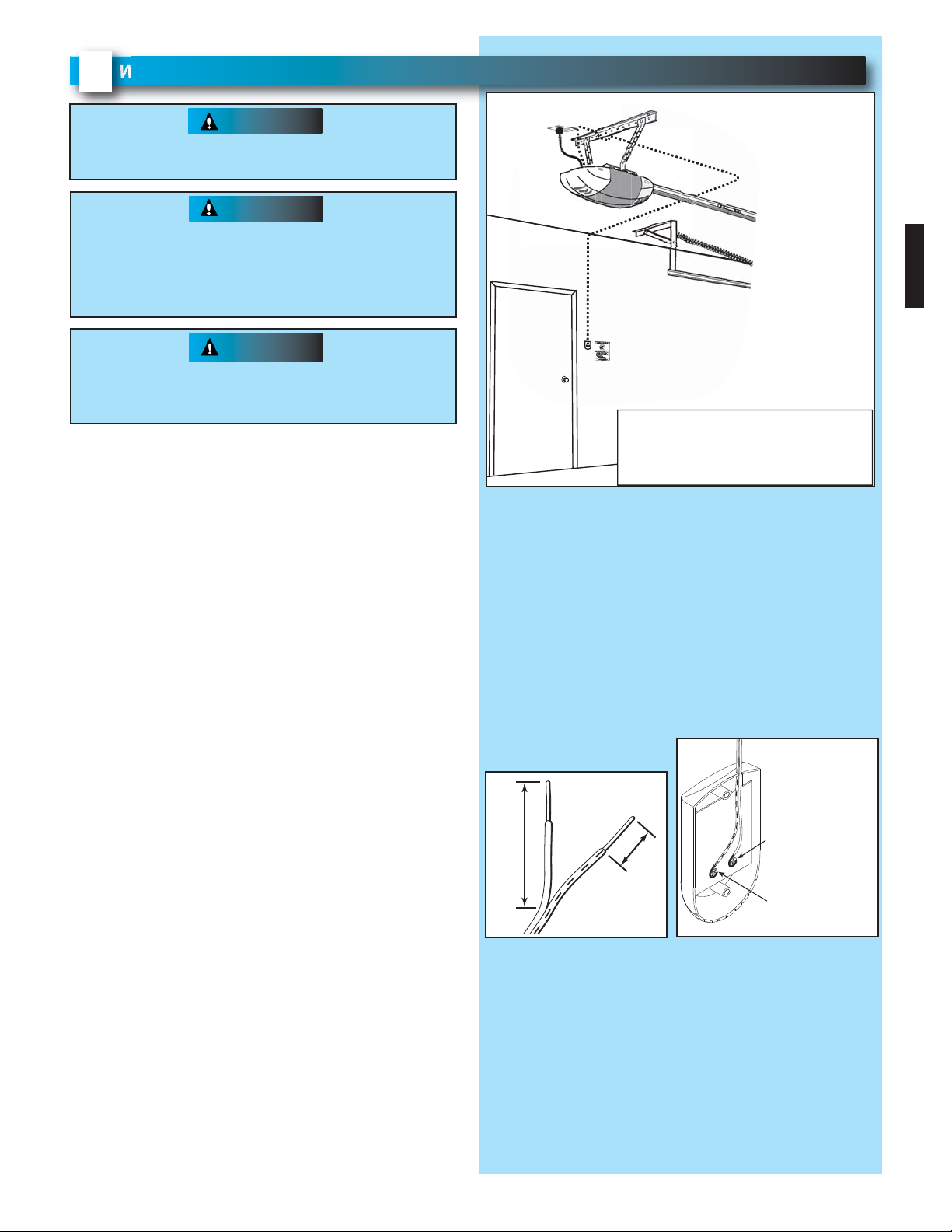

DOOR BRACKET:

NOTE: For door bracket and bolts locate Bag 4

from Box 2.

1. Finding door bracket mounting location.

• Door bracket is mounted as high on

door as

possible along vertical centerline and NO LOWER

THAN top set of rollers (Fig. 2-7).

2. Mounting the door bracket.

• Proper bracing should be verified at this point.

–

Align door bracket centered on your vertical

centerline (Fig. 2-8).

–

Attach using 3 self-drilling screws for sheet

metal or other light weight material.

–

Use lag screws (not provided) for solid

wooden sectional doors.

NOTE: For solid wood doors, carriage bolts

WITHOUT SLOTTED HEADS (not included) may

also be used for attaching door bracket.

INSTALL DOOR ARMS

NOTE: For door arm nuts and bolts, clevis and

cotter pins locate Bag 5 from Box 2.

1. Attach the arms.

• Fasten short branch of curved door arm to door

bracket using bolt and locking nut (Fig. 2-9).

• Fasten straight arm to carriage using clevis pin

and cotter pin (Fig. 2-9).

2. Connecting the arms.

•

Slide carriage back and forth to adjust arm length.

– Position the straight arm 50º down from the

rail.

• With the arms arranged in this position, fasten

arms together using bolts and nuts spaced as

far apart as possible (Fig. 2-9).

Doors made of masonite, lightweight wood,

fiberglass, and sheet metal must be properly

braced before mounting door opener. Contact

door manufacturer or distributor for a bracing kit.

The Genie Company is not responsible for

damage caused due to improperly braced door.

CAUTION

FIG. 2-7 Mounting door Bracket

.

centerline

even with or

above top roller

FIG. 2-9 Attaching door arms.

FIG. 2-8 Examples of door bracket positioning.

A B

centerline

50°

short clevis pin & cotter pin

bolts as far

apart as

possible

centerline of top roller

Page 15

PN# 37026500123 02/26/2010 REV. 1

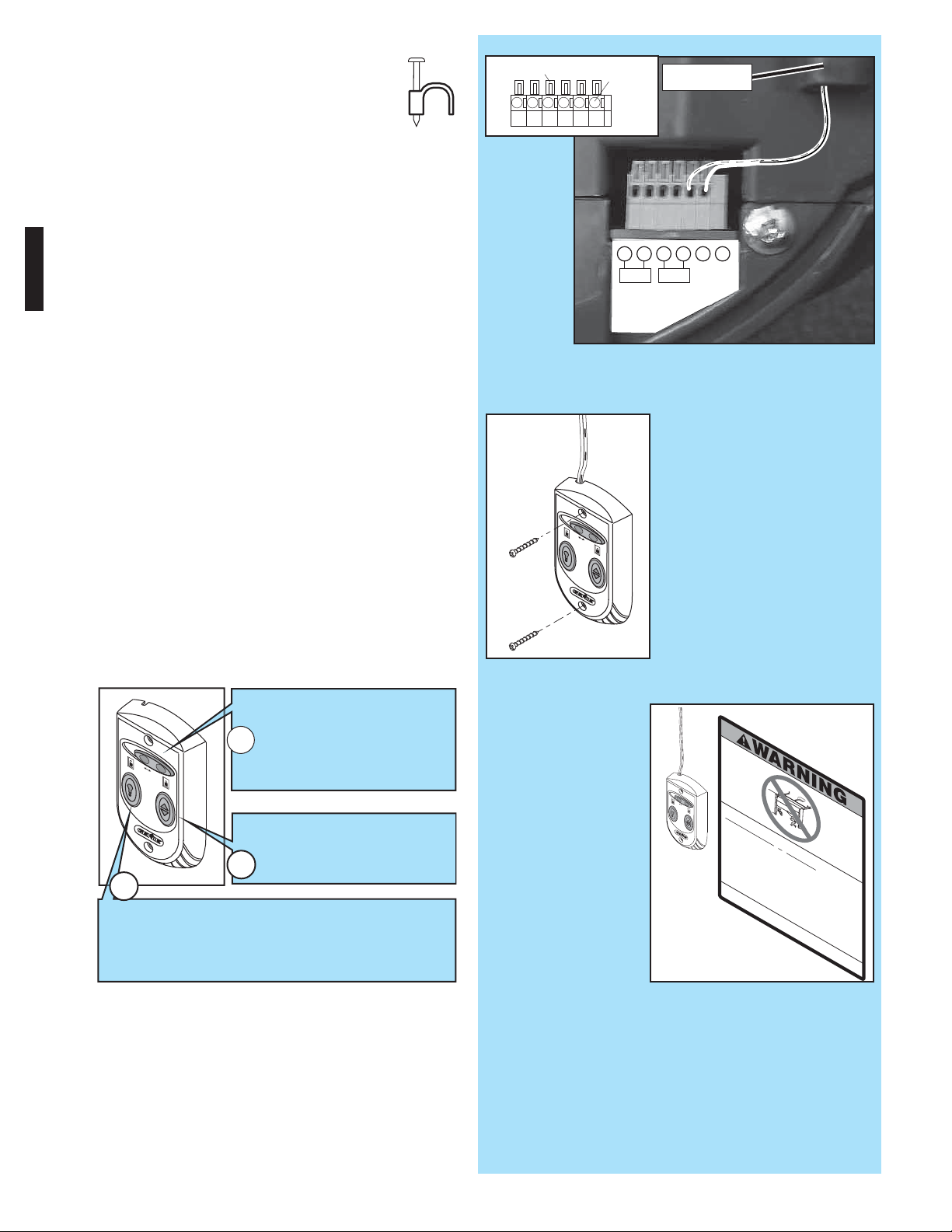

NOTE: Wall control will not operate until limits

are set.

NOTE: For Wall Control, wire and insulated

staples locate Bags 6 and 7 from Box 2.

1. Wall Control location.

• Wall Control location should be in direct sight

of door.

• It should be at least five feet (5') above floor to

prevent small children from operating door.

• It must be away from any moving parts. (You

should NOT be able to reach the garage door

while standing at Wall Control.)

• Wall Control board screw connections are

polarized, (+) positive and (-) negative.

2a. Wiring (If pre-wired).

• Locate Wall Control pre-wired wire ends

(Fig. 3-1). (They should be located within the

guidelines mentioned above.)

• Split and strip ends of wire (Fig. 3-2).

• Fasten wire to Wall Control board screws on

back of Wall Control.

– Striped wire to the + (plus) terminal.

– White wire to the - (minus) terminal.

2b. Wiring (If NOT pre-wired).

• Pick a convenient location for mounting

Wall Control using the guidelines mentioned

above (Fig. 3-1).

• Run wire from power head to Wall Control

(Fig. 3-1).

• Split and strip ends of wire (Fig. 3-2).

• Fasten wire to Wall Control board screws on

back of Wall Control.

– Striped wire to the + (plus) terminal.

– White wire to the - (minus) terminal.

WALL CONTROL INSTALLATION

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

3

Verify there is NO power to the opener before

installing Wall Control wires and Wall Control.

WARNING

Staples which are too tight can cut or pinch wires.

Cut or pinched wires can cause the Wall Control to

stop working. When using the insulated staples,

make sure you fasten them only as tightly as

needed to hold the wire snugly.

CAUTION

FIG. 3-2 Splitting and stripping

.

FIG. 3-1 Wall Control wire routing

Wire from

power head

to Wall Control

Wall

Control

"Entrapment"

warning label

Separate

entry door

EXAMPLE ONLY!

This is an example of wire routing

when NOT pre-wired. Your wire

routing may be different.

1/2"

2"

15

Black

Striped

White

+

–

or

or

Use of any other wall control can cause the door to

operate unexpectedly and the light not to work.

Use only the included Wall Control.

WARNING

Page 16

PN# 37026500123 02/26/2010 REV. 1

16

3. Securely fasten wires.

• Securely fasten wires to ceiling and

wall using insulated staples provided.

– Use insulated staples.

– Staples should be snug only.

• If rear cover is attached to power head,

remove it.

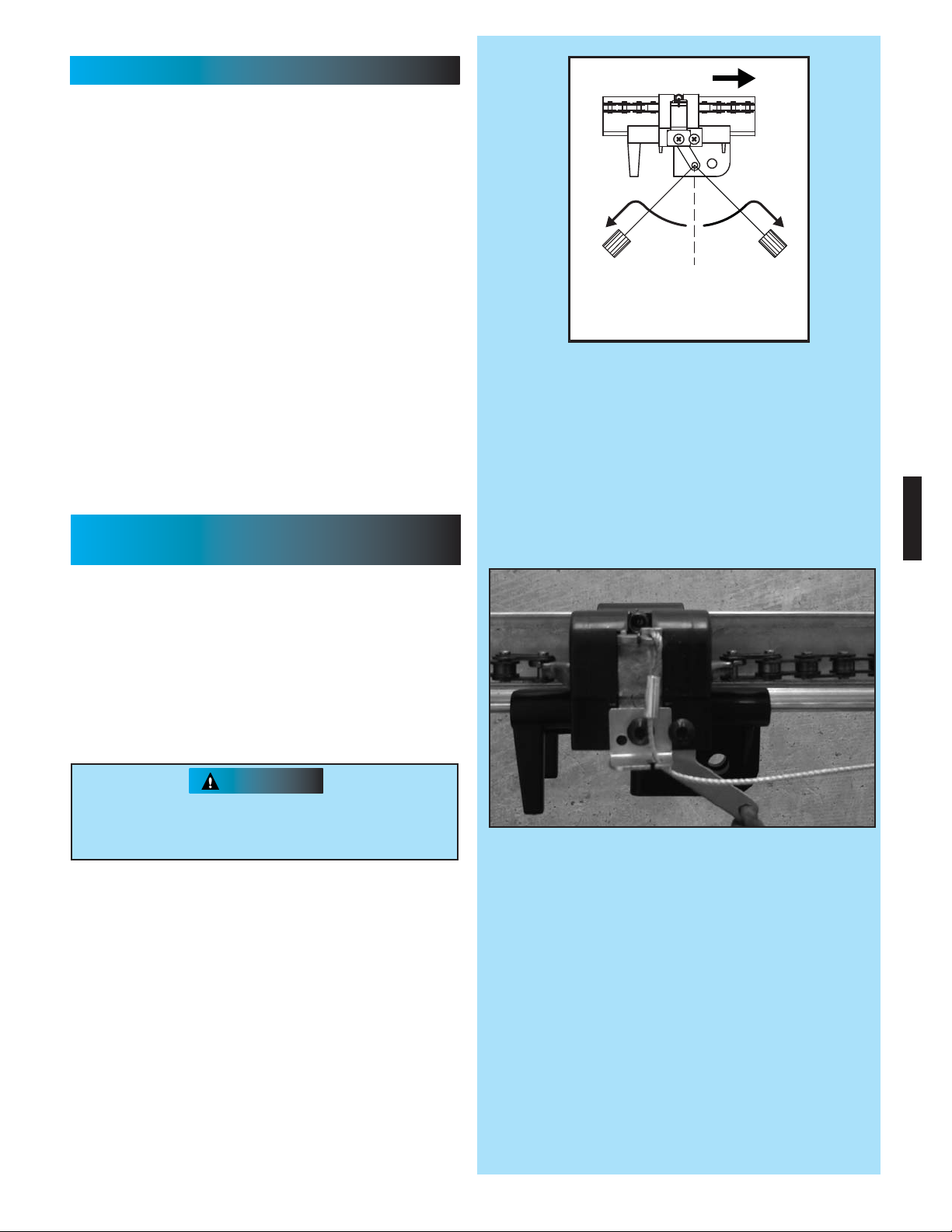

• On power head:

– Route Wall Control wires through wire guide

on power head.

– Split and strip ends of wire (Fig. 3-2 on

previous page).

– Insert wire into terminal holes and lightly press in

the orange locking clips above each terminal

hole. (You can use a pencil or small screwdriver

to comfortably press in locking clips.) The white

wire into #1 terminal hole and striped wire into

the #2 terminal hole.

– Confirm wire lock by lightly tugging on the wire.

The wire should remain in the terminal hole.

• Do NOT install rear cover yet.

4. Mounting.

• Fasten Wall Control to wall with 2 screws

(provided) (Fig. 3-4).

• Remove protective backing from "Entrapment"

warning label (Fig. 3-5). The "Entrapment" label

is located in the center of this manual.

– Stick label on wall near Wall Control.

FIG. 3-4 Mounting Wall Control.

Insulated

Staple

+–

PB

Infared Sensor

123456

FIG. 3-3 Insert wires

.

(Power Head With Rear Cover Removed)

FIG. 3-5 Mounting Entrapment warning label.

3

2

1

Independent Light Control

–

Controls door opener lights from inside garage

–

Energy-Saver shut-off turns OFF lights 3 minutes after

door activation

Vacation Locking Switch

– LOCK disables controls after

door is completely closed

– UNLOCK allows controls to

work normally

Door Control "Open/Close" Button

–

Open and closes door from

inside garage

wire guide

Locking

Clips

56

1234

Terminal

Holes

Childcanbe p

D

ea

th or serio

•

N

e

v

•

er let ch

N

e

v

•

e

A

r let

lw

a

•

If p

ys

em

er

son is pin

er

ge

•

Test door opener

R

e

P

la

If do

If op

M

ou

inn

u

s injury can resu

i

ld w

ch

ke

i

ld u

e

p m

nc

y re

fer to you

c

e

1

1

/

r

2

ow

o

-inch o

’

r

f

a

e

ils to reverse

n

er still fails to rev

nt wall control out

D

o not

ed u

o

n

le

a

ner'

b

nd

a

l

k or ru

se

d

v

in

g

e

d

, pu

se.

m

on

sm

jec

t (or 2x

on co

re

move o

of child's reach

Place next to wal

er autom

o

o

r op

do

o

s

h co

thly:

a

n

ua

l

4

la

n

erse d

ta

r

p

ain

n

u

n

en

r in sight.

n

.

i

d flat) on floor

ct,

ad

o

o

r

,

repa

t

o

ve

(at least

l

control.

a

t

ic

lt.

garage

de

r

m

doo

e

o

r co

v

r.

ing d

n

trols.

o

.

tro

or

.

l

b

u

tto

n

or use

j

ust o

.

p

e

ir

ne

or rep

r.

la

r

ce ope

th

is

la

n

be

5

er

feet

l

.

.

abov

e floor).

©1999

Page 17

PN# 37026500123 02/26/2010 REV. 1

17

SAFE-T-BEAM®SYSTEM INSTALLATION

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

4

NOTE: The opener will not close the door

automatically unless the Safe-T-Beam

®

System is

installed.

NOTE: For Sensors, screws, wire, and insulated

staples locate items and Bag 8 from Box 3.

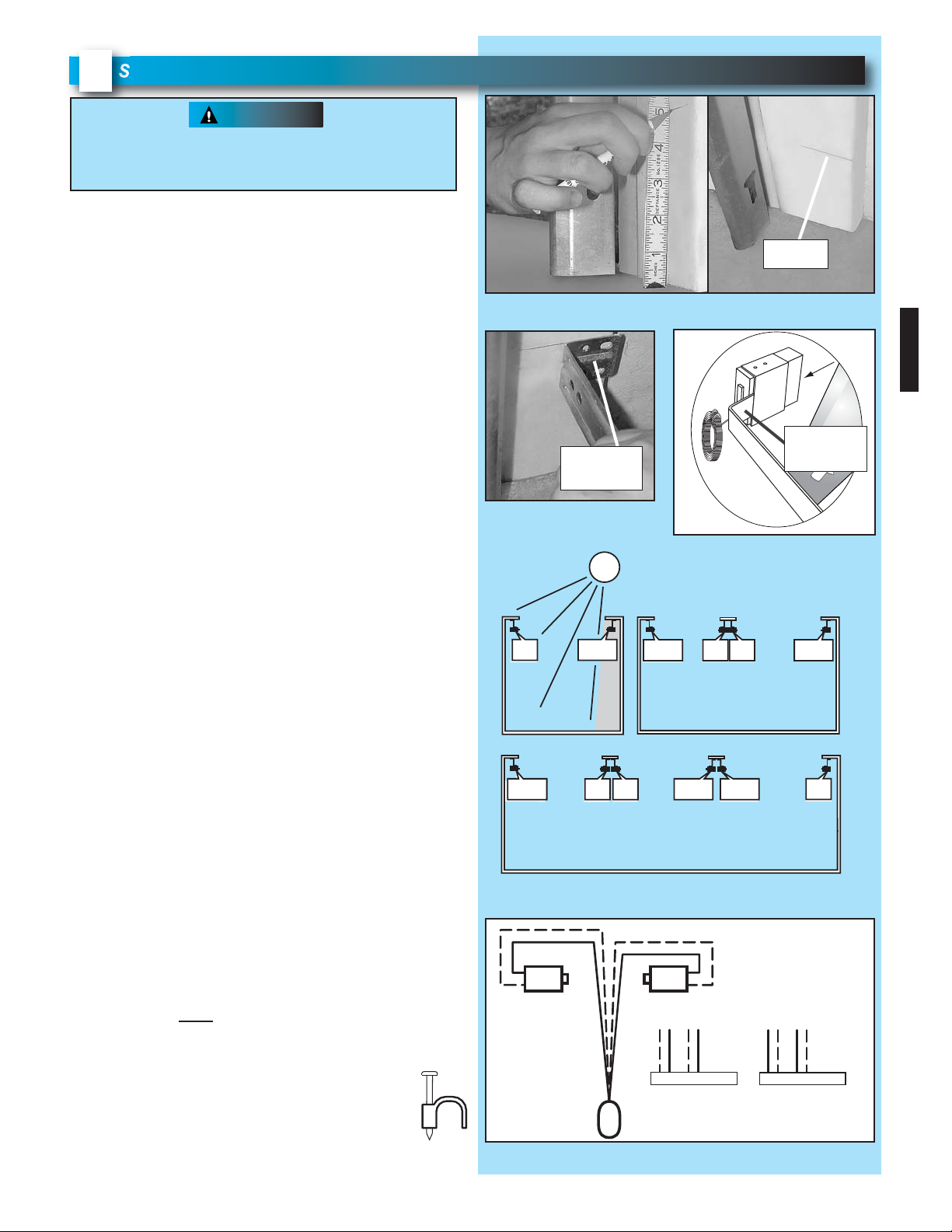

1. Mounting brackets.

• Mark both sides of garage door frame or wall no

higher than 6" and no lower than 5" above floor

(Fig. 4-1)

.

• Hold bracket against door frame or wall.

– Check if brackets extend out from wall far

enough, so tongue of bracket is beyond door,

tracks or any door hardware.

– If not:

a) Mounting bracket extensions are available

through an authorized Genie

®

Dealer.

b) Blocks of wood, etc. may be substituted for

extensions.

• Locate top of bracket on your mark (Fig. 4-2).

• Fasten each with 2 screws (Fig. 4-2).

NOTE: Mounting brackets can be attached to the

floor or concrete rim using concrete anchors

(not provided) obey manufacturer’s instructions.

2. Mounting Safe-T-Beam®Source (Red LED) and

Sensor (Green LED).

• If garage has only one garage door.

– Determine which side of garage receives most

direct sunlight (Fig. 4-4).

– Red LED should always be on sunny side

whenever possible (Fig. 4-4).

• For multiple doors.

– Preventing crossed signals is critical.

– Place source and sensor modules on adjacent

doors facing in opposite directions (Fig. 4-4).

NOTE: To help prevent interference from sun,

Safe-T-Beam

®

sensor with Green LED may be

placed further away from the door opening,

though extended no further out from the wall,

where it will spend more time in shadow.

• Slide source/sensor onto tongue of bracket until

it clicks into place (Fig. 4-3).

3a. Wiring (If NOT

pre-wired).

• Route wire from Safe-T-Beam

®

sensors to power

head using method shown in (Fig. 4-5a).

• Securely fasten wires to wall and ceiling

as you go (Fig. 4-6 on next page).

– Use insulated staples.

– Staples should be snug only.

There should be no electrical power to the opener

while installing Safe-T-Beam

®

wires. If you have

plugged in the power cord—UNPLUG IT NOW!

WARNING

FIG. 4-1 Mark door frame

.

FIG. 4-2

Mounting brackets

.

FIG. 4-3 Attach

sensors to brackets

.

bracket

tongue

mark

FIG. 4-4 Safe-T-Beam

®

source and sensor

locations

.

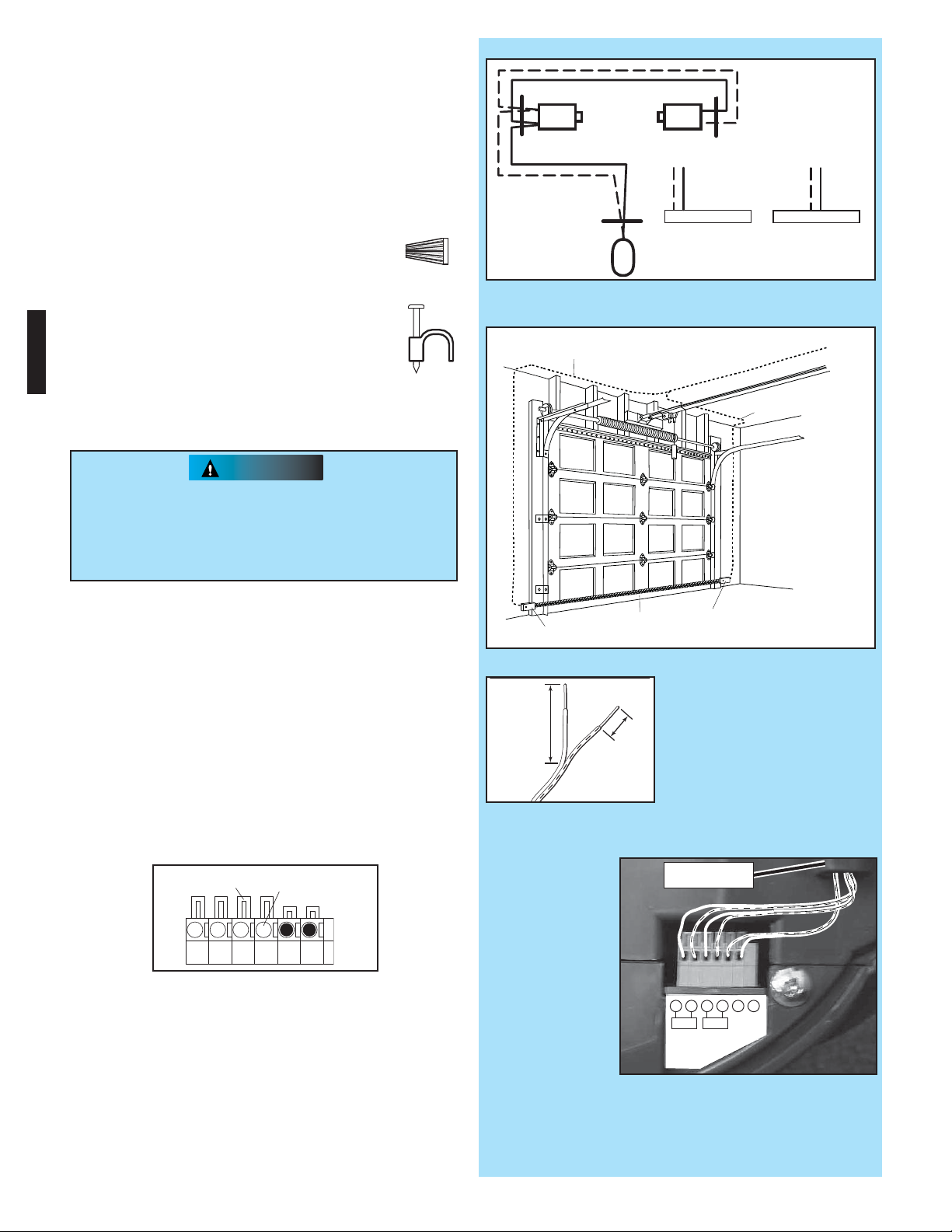

FIG. 4-5a Source and sensor wiring methods

.

SensorSource

Red Green

Power

Head

Dashed Line = striped wire

Solid Line = white wire

Insulated

Staple

center of

bracket

SUN

RED

LED

ONE DOOR

GARAGE

GREEN

LED

THREE DOOR

GARAGE

GREEN

LED

RED

LED

RED

LED

RED

GREEN

LED

TWO DOOR

GARAGE

RED

LED

LED

GREEN

GREEN

LED

LED

6 5 4 3 2 1

or

GREEN

LED

6 5 4 3 2 1

id

l

s

RED

LED

e

Page 18

PN# 37026500123 02/26/2010 REV. 1

18

3b. Wiring (pre-wired).

• Route wire from wall to Safe-T-Beam

®

sensors

(Fig. 4-5b).

• Splice pre-wiring to shortened sensor wire,

match wire pairs dash-to-dash (striped-to-

striped) and plain-to-plain (white-to-white).

- Trim sensor wire to approximately one foot

(1 ft) from sensor.

- Split and strip ends of sensor wires and

pre-wired wires (Fig. 4-7).

- Splice wires together with (provided)

wire nuts.

• Route wire from ceiling to power head

(Fig. 4-5b).

• Securely fasten wires where they exit

wall and ceiling as you go.

– Use insulated staples.

– Staples should be snug only.

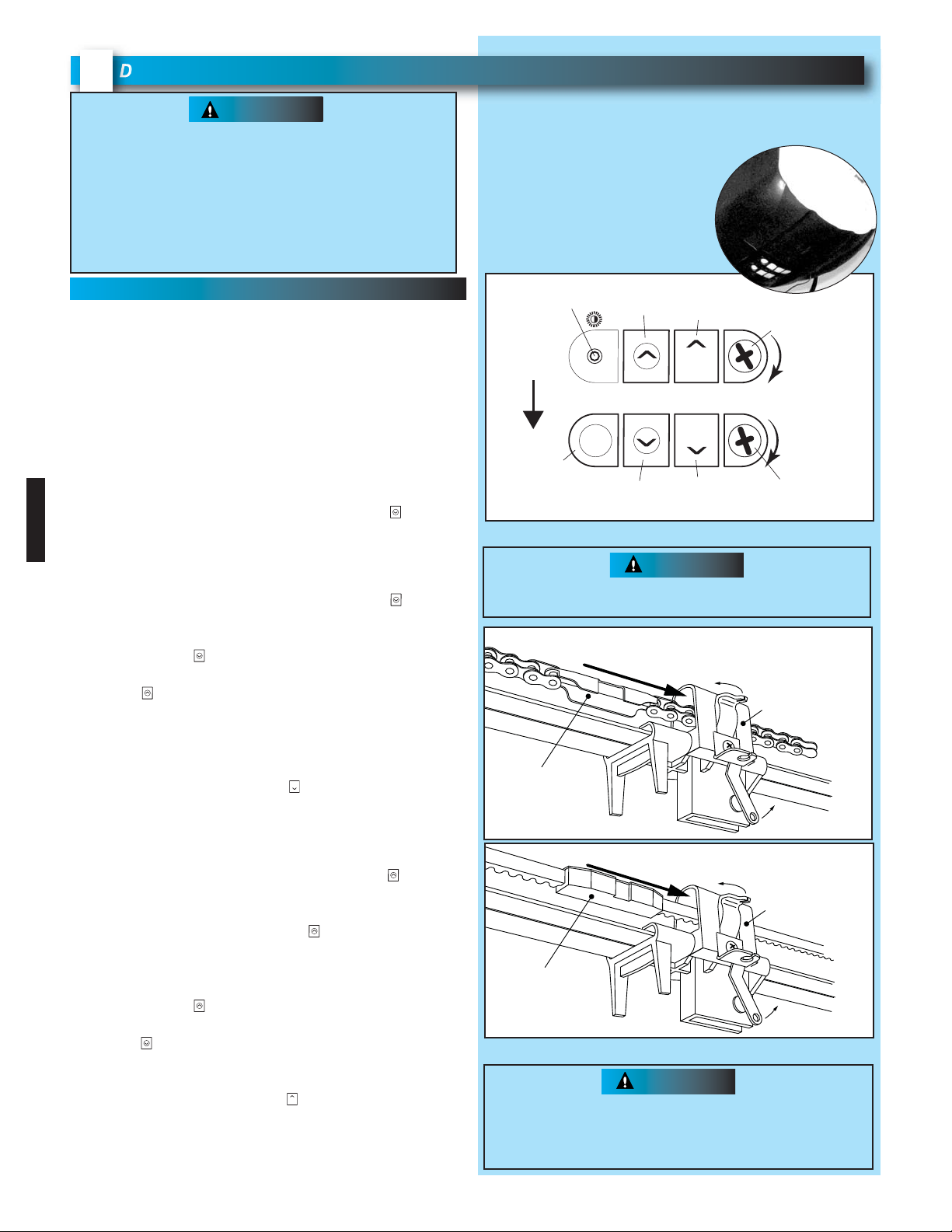

4. Split and strip ends of sensor wires (Fig. 4-7).

NOTE: For rear cover locate Box 4.

5. Attach Safe-T-Beam®wire to power head wire

terminal.

• Route Safe-T-Beam

®

wires through wire guide

on power head.

– Insert wire into terminal holes and lightly press

in the orange locking clips above each terminal

hole. (You can use a pencil or small

screwdriver to comfortably reach in and lightly

press down locking clips.) Insert white wires to

'even' numbered terminal holes and striped

wires into 'odd' terminal holes (Fig. 4-8).

– Confirm wire lock by lightly tugging on the wire.

The wire should remain in the terminal hole.

• Do not install the white (lamp) cover at this time.

NOTE: Safe-T-Beam®alignment check must be

performed following connection to electrical

power (see page 19). DO NOT PLUG IN YET!

Staples which are too tight can cut or pinch wires.

Cut or pinched wires can cause the Safe-T-Beam

®

System to stop working. When using the insulated

staples, make sure you fasten them only as tightly

as needed to hold the wire snugly.

CAUTION

FIG. 4-7 Splitting and stripping

.

FIG. 4-6 Wire routing

.

+–

PB

Infared Sensor

123456

FIG. 4-8

Insert wires

.

(Power Head With Rear Cover Removed)

FIG. 4-5b Pre-Wired source and sensor wiring

methods

.

SensorSource

Red Green

Power

Head

Dashed Line = striped wire

Solid Line = white wire

Wall Wall

Ceiling

1/2"

2"

Insulated

Staple

Wire Nut

wire guide

6 5 4 3 2 1

or

6 5 4 3 2 1

Wire

Insert Wire

Into Connector

Wire

Locking

Clips

Terminal

Holes

Invisible Light Beam

Sensor

Protection Area

Sensor

Use this

wire routing

if NOT pre-wired

56

1234

Page 19

PN# 37026500123 02/26/2010 REV. 1

19

CONNECTING TO POWER

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

5

Plug the opener into a properly grounded

electrical outlet (Fig. 5-1).

• To reduce the risk of electrical shock, this equipment

has a grounded type plug that includes a third

(grounding) pin. This plug will only fit a grounded type

outlet. If you do not have a grounded outlet, contact

a qualified licensed electrician to install one. DO NOT

alter the plug in any way. The door opener must be

properly grounded in order to prevent personal injury

and damage to the components.

• DO NOT remove motor cover. All work performed

on motor must be done by a trained door system

technician.

WARNING

• Check local building codes to make sure that you

are not required to have your garage door opener

permanently wired, with circuit breaker protection.

If building codes require door opener to be

permanently wired have a qualified licensed

electrician connect power with permanent wiring.

CAUTION

WITH GROUNDED PLUG:

5

" m

in

f

r

om

fl

o

o

r

6

" m

ax

f

r

o

m f

l

o

o

r

FIG. 5-4 Check Safe-T-Beam®alignment

.

FIG. 5-1 Connect to power

.

INFRARED PROTECTION FUNCTION

1. When the garage door is opening, its movement

will not be influenced if the Safe-T-Beam®is

obstructed.

2. If the Safe-T-Beam

®

is obstructed before the

garage door fully closes, the door will not close.

3. When the garage door is closing, if Safe-T-Beam

®

is cut off by people or obstacle, the garage door

will reverse automatically to its fully opened position.

(Meanwhile, the opener light will keep blinking until

door moves to its fully opened position.)

4. If the Safe-T-Beam

®

System fails, loses power,

or is installed improperly, press and hold the

Wall Control "open/close" button until the door

reaches its fully closed position. The LED

indicator light on the power head will be green

and blink twice (Pattern: ☼☼ pause ☼☼ pause)

to inform you to eliminate the problem first.

If you release the "open/close" button on the

Wall Control during the closing movement the

door will reverse automatically to its fully

opened position.

FIG. 5-2 Remove motor cover.

(Electrican ONLY)

WITH PERMANENT WIRING:

Instructions for Electrician.

• Remove power from circuit.

• Remove rear cover and motor cover.

– Remove four motor cover screws (Fig. 5-2).

• Remove existing power cord and strain relief

from the 7/8" dia. hole and discard (Fig. 5-3).

• Connect permanent wiring to power head using

7/8" diameter hole.

– White to white/black to black/ground to green.

– Use only UL recognized wire nuts.

• Wires inside the power head must be at least 6"

in length.

• Replace motor cover and rear cover and

re-energize the circuit.

NOTE: The Genie Company is not responsible for

charges resulting from work performed by an

independent electrician.

Check Safe-T-Beam®alignment (Fig. 5-4).

• Insure that no part of door or its hardware is

in path between lenses of source and sensor.

• Insure that tops of lenses are between 5" - 6"

above the floor (Fig. 5-4). The brackets are

flexible, and can be adjusted slightly if needed.

• Adjust the Red LED transmitter by aiming the

unit directly at the Green LED receiver. Use the

adjustment screw located on the top of the

transmitter housing to make adjustments.

• The Red LED transmitter will blink if there is a

misalignment. When the LED units are aligned

the Red LED will remain ON continuously.

• After the alignment is finished tighten the

adjustment screws on both sensors.

Motor Cover Screws

FIG. 5-3 Power cord strain relief.

• Do NOT use an extension cord.

• Do NOT use a portable generator. This product

is designed to operate using standard

household current.

• Do NOT use alternate power supplies.

CAUTION

WITH POWER SUPPLIED:

Page 20

PN# 37026500123 02/26/2010 REV. 1

20

DOOR LIMITS

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

6

The OPEN (UP) and CLOSE (DOWN) door positions

are controlled by making the adjustments on the

panel located on the bottom of the power head. The

adjustments that can be made are:

• Close Travel Limit,

• Open Travel Limit,

Adjust Closing Force

Adjust Opening Force

Transmitter Programming

SETTING & TESTING OPEN/CLOSE LIMITS

FIG. 6-1 Limit controls.

• Severe injury or death can result if the door

closing force is set too high.

• Never increase the door closing force above the

minimum required to move the door.

• Never adjust force to compensate for a sticking

or binding door.

• Perform monthly CONTACT REVERSE TEST as

described on page 22 and in Section 10.

WARNING

Limit Controls location

on power head.

B) CLOSE TRAVEL LIMIT

1. Press and hold the "Close Travel Limit" button

until the door is fully closed.

2. You can quickly press and release the "Close

Travel Limit" button to move the door in small

increments. You can also use the "Open Travel

Limit" button to move the door slightly in the

UP direction.

3. Door is fully closed when the bottom edge of door

presses firmly onto the ground.

4. Once the door is in the desired position, press and

hold the "Close SET Limit" button for 5 seconds.

The LED indicator light will blink green once. This

stores the closed position in memory.

C) OPEN TRAVEL LIMIT

1. Press and hold the "Open Travel Limit" button

to move the door to its fully opened position. This

starts the opener moving in the UP direction.

2. Hold the "Open Travel Limit" button until the

door is in the fully opened position that you desire,

then release this button.

3. You can quickly press and release the "Open

Travel Limit" button to move the door in small

increments. You can also use the "Close Travel

Limit" button to move the door slightly in the

DOWN direction.

4. Once the door is in the desired position, press and

hold the "Open SET Limit" button for 5 seconds.

The LED indicator light will blink green twice. This

stores the opened position in memory.

SET

SET

Carriage Assembly

Chain Connector

Latch

Movement

Latch

Movement

Move in this direction

Carriage Assembly

Belt Connector

Latch

Movement

Latch

Movement

M

ove in this directi on

FIG. 6-2 Engage Chain/Belt Connector to Carriage.

Operation of the opener without the Chain or Belt

Connector engaged to the Carriage Assembly will

result in damage to rail components including the

rail pulley.

CAUTION

A) ENGAGE CHAIN/BELT CONNECTOR

TO CARRIAGE

1. Press and hold the "Close Travel Limit" button

until the chain or belt connector advances and

engages to the Carriage Assembly (Fig. 6-2).

Failure to verify the engagement of the belt/chain

connector will result in damage to rail components.

CAUTION

NOTE: Set Close Travel Limit

before setting Open Travel

Limit for unit to operate

normally.

Unless limits are being reset

do not press set limit buttons.

Open

Set Limit

Button

SET

SET

Close

Set Limit

Button

OPEN

FORCE

CLOSECODE

Up Force

Control

Adjustment

Down Force

Control

Adjustment

To

Garage Door

LED

Indicator Light

LEARN LIMITMANUAL

Learn

Code

Button

Open

Travel Limit

Close

Travel Limit

Page 21

21

FIG. 6-3 Engage/Disengage Carriage Lock.

CARRIAGE LOCK

The Carriage Lock can be manually engaged or

disengaged.

• To disengage Carriage Lock

– Pull handle downward opener power head.

• To engage Carriage Lock

– Pull handle towards door.

Obtain standard emergency release kit and remove

S-hook from the cable end that attaches to the

opener carriage.

1. Attach the emergency release cable loop end to

the opener carriage as shown (FIG 6-4).

Properly connecting the release cable to the

carriage fitting will enable the correct carriage

release action for the opener.

KEYED EMERGENCY RELEASE

(PURCHASED SEPARATELY)

FIG. 6-4 Emergency release cable to carriage.

Improper connection of the emergency release cable

to the opener carriage will result in a failure of the

emergency release.

WARNING

2. Follow the remaining installation instructions for

the standard emergency release kit.

3. Test for correct operation of emergency release kit.

Keyed Emergency Release Operation Instructions

• Place key in slot.

• Rotate and hold key while lifting garage door 1 to

2 inches.

• Release key and continue opening garage door.

NOTE: The next normal operation of the opener or

fully closing garage door manually will re-engage

the emergency release mechanism.

DOOR

UNLOCK

TO RELEASE

PULL TOWARD

THE OPENER

LOCK

TO RECONNECT

PULL TOWARD

DOOR

Page 22

PN# 37026500123 02/26/2010 REV. 1

22

FIG. 6-6 2 x 4 under center of door opening.

CONTACT REVERSE TEST

The force adjustments and limit switch settings

MUST BE COMPLETED before testing.

1. Testing.

• Open garage door using Wall Control.

– Place a 2" x 4" board (laid flat) under center

of garage door opening (FIG. 6-6).

• Close door using Wall Control.

• When door contacts board, the door must stop

(within 2 seconds) and reverse direction

returning to open position.

2. Adjustment.

• If the door does not properly reverse.

– Check to see if door has "close" limit

programmed. It should not have reached its

"close" limit before hitting board.

– If the door STOPS but does not reverse,

decrease "CLOSE FORCE" control

setting slightly (turn it counter-clockwise).

• Test again. Repeat as necessary until door

reverses upon contacting board.

CLOSE

1. Press and hold both of the "SET" buttons

( & ) together until the green indicator

light blinks (about 5 seconds).

2. All close and open travel limit settings are

erased. Then follow the steps above to

reprogram close and open travel limits.

NOTE: The opener will not close the door

automatically unless the Safe-T-Beam®System is

installed.

ERASE - OPEN/CLOSE TRAVEL LIMIT

1. By turning the "Close Force Control" clockwise, the DOWN force can be increased. By

turning the "Close Force Control" counterclockwise, the DOWN force can be decreased.

Set the DOWN force level at the minimum force

required to close door without reversing.

2. Once the desired level is selected, this stores the

necessary force level for the DOWN direction in memory.

3. By turning the "Open Force Control" clockwise,

the UP force can be increased. By turning the

"Open Force Control" counter-clockwise, the UP

force can be decreased. Set the UP force level at

the minimum force required to open door without

stopping.

4. Once the desired level is selected, this stores

the necessary force level for the UP direction

in memory.

OPEN

CLOSE

OPEN

CLOSE

UP/DOWN FORCE

FIG. 6-5 Force Control Adjustment.

SET

SET

Up Force

Control

OPEN

Adjustment

(Increasing Force)

FORCE

CLOSE

Down Force

Control

Adjustment

ROTATE

CLOCKWISE

(Decreasing Force)

ROTATE

COUNTER-CLOCKWISE

Page 23

PN# 37026500123 02/26/2010 REV. 1

23

FCC and IC CERTIFIED

FIG. 7-1 Learn code button and LED

This device complies with FCC Part 15 and RSS 210

of Industry Canada. This equipment has been tested

and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may

cause harmful interference to radio communications.

However, there is no guarantee that interference will

not occur in a particular installation. If this equipment

does cause harmful interference to radio or television

reception, which may be determined by turning the

equipment OFF and ON, the user is encouraged to

try to correct the interference by one or more of the

following measures:

• Re-orient or relocate the receiver antenna.

• Increase the separation between the opener

and receiver.

• Connect the opener into an outlet on a circuit

different from that to which the receiver is

connected.

• Consult your local dealer.

PROGRAMMING REMOTE CONTROLS

7

NOTE: For remote control locate Box 3.

1a. Single Button Remote Programming.

NOTE: This opener can learn up to 7 transmitter

buttons.

• Locate "Learn Code" button and indicator

LED on the power head (Fig. 7-1).

• Press and release "Learn Code" button.

– Indicator LED will blink RED at a rate of twice

per second.

• Within 30 seconds, push remote control

button once.

– Indicator LED will stop blinking and stay ON.

• Press remote control button again.

– Red LED will go out. Remote is now programmed

and ready for use.

1b. Multi Button Remote Programming.

NOTE: Each button on a multi-button remote is

designed for use with 1 door. You cannot

program 2 buttons to operate the same door, nor

can you program 1 button to operate 2 doors.

You can program a maximum of 7 different

transmitters or wireless devices.

NOTE: Pushing two buttons on power head

simultaneously will erase programmed memory and

limits must be reset.

• For each button

.

– Program each button separately using the

Single Button Remote Programming steps.

2. Operating.

• Press remote button once.

– Door will move.

• Press button again.

– Door will stop.

• Press button again.

– Door will move in opposite direction.

NOTE: The door will stop automatically at the

fully open or fully closed position.

LEARN

A moving door can cause serious injury or death.

1. Keep people clear of opening while door is

moving.

2. Do NOT allow children to play with opener,

including Wall Control, remote control, or

Wireless Keypad.

3. During programming, the door opener could

begin to run, so keep people and objects away

from the moving door and its parts. To keep the

door from moving, close the door and

disconnect it from the Opener by pulling the

Emergency Release.

WARNING

LOST OR STOLEN REMOTE

1. Clear memory.

• Press and hold "Learn Code" button (on

power head) for 10 seconds or until the red

blinking indicator LED goes out.

• Program remaining or new remote controls as

done previously. Your door opener will no

longer recognize any signal received from the

missing remote control, or any other which has

not been reprogrammed.

LEARN

NOTE: To program a

Homelink

®

and Car2U

®

device follow the Homelink®or Car2U

®

instructions in your car owner’s manual.

Limit controls location

on power head.

NOTE: Wall control will

not operate until limits

are set.

Open

Set Limit

Button

SET

SET

Close

Set Limit

Button

OPEN

FORCE

CLOSECODE

Up Force

Control

Adjustment

Down Force

Control

Adjustment

To

Garage Door

LED

Indicator Light

LEARN LIMITMANUAL

Learn

Code

Button

Open

Travel Limit

Close

Travel Limit

Page 24

REMOTE CONTROL

BATTERY REPLACEMENT AND VISOR CLIP INSTALLATION

8

FIG. 8-1 Open battery cover.

1. Battery replacement.

• To open, gently push straight out on battery

cover lock tab as shown. (Fig. 8-1).

• Slide open battery cover.

– Remove old battery.

• Make sure new battery is facing proper direction

(Match battery polarity with symbols inside

battery housing) (Fig. 8-2).

– Recommended replacement battery type:

Alkaline A23, 12 volt.

NOTE: Batteries differ in care and maintenance.

Follow the manufacturer’s directions for battery

maintenance, replacement, and use.

• Slip new battery into place.

– Slide battery cover until it clicks shut.

• Operate remote to make sure it is working

properly. (No re-programming is needed.)

2. Visor clip.

(The visor clip may come already installed.)You

will have to install the visor clip if you choose to

attach your remote to the car visor.

• Slide visor clip into back of remote control.

– It will snap into place (Fig. 8-3).

FIG. 8-3

Attach visor clip.

FIG. 8-2 Match battery polarity.

LIGHT BULB/ LENS INSTALLATION

9

FIG. 9-2

Fasten lens.

NOTE: For lens covers locate Box 4.

1. Light bulb.

• Recommendations.

– Do NOT use a short neck bulb.

– Light bulbs should be no more than 60 Watts.

– Use a heavy duty service bulb for longer life.

• Screw 1 bulb into each socket.

2. Lens.

• Select a white (lamp) cover.

• On the power head end nearest the garage

door, line up lamp lens tabs on power head with

corresponding slots in lens (Fig. 9-1).

• Slide lens onto power head. Make sure the tabs

are fully engaged into lens slots (Fig. 9-2).

• Repeat for rear lens on power head.

• Plug power cord back into electrical outlet.

• Test lamp operation.

– and + polarity marks

FIG. 9-1 Slide each lens onto motor cover.

Light bulb socket

Slide out

PN# 37026500123 02/26/2010 REV. 1

24

For added safety and protection please unplug

opener before installing light bulb.

WARNING

Lens tabs

Light bulb socket

Page 25

PN# 37026500123 02/26/2010 REV. 1

25

Use Wall Control supplied with opener. Any other Wall Control can cause

the opener to operate unexpectedly.

WARNING

If you have any questions, please do not hesitate to contact Genie®customer service at:

1.800.354.3643

IMPORTANT SAFETY INSTRUCTIONS

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with the door controls. Keep the remote control away from children.

3. Always keep the moving door in sight and away from people and objects until the door is completely

closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

4. NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR.

5. Test opener monthly. The door MUST reverse on contact with a 1-1/2" high object (or a 2" x 4" board

laid flat) at the center of the doorway on the floor. After adjusting either the force or the limit of travel,

retest the door opener. Failure to adjust the opener properly may cause severe injury or death.

6. When possible, use the emergency release only when the door is closed. Use caution when using this

release with the door open. Weak or broken springs are capable of increasing the rate of door closure

and increasing the risk of severe injury or death.

7. KEEP DOORS PROPERLY BALANCED. See your garage door Owner’s Manual. An improperly

balanced door increases the risk of severe injury or death. Have a trained door system technician make

repairs to cables, spring assemblies, and other hardware.

8.

SAVE THESE INSTRUCTIONS.

WARNING:

To reduce the risk of severe injury or death:

MAINTENANCE

1. Door balance.

• With the door closed, pull emergency release

knob (Carriage Lock) towards the opener to

release door from carriage assembly.

• Raise door manually approximately 3'- 4' and

release.

–

Door should remain stationary or move very

slightly.

–

If door moves quickly, CONTACT A TRAINED

DOOR SYSTEM TECHNICIAN.

• Close the door.

• Pull emergency release knob towards door to

engage carriage.

–

Operate door using remote.

–

Door will re-attach itself to carriage assembly.

ROUTINE MONTHLY MAINTENANCE

2. Contact reverse.

• Place a 2

"

x 4"board laid flat on floor.

–

In center of garage door opening.

• Close door by using wall control or remote control.

–

Door fails to reverse on contact with board

(See section "CONTACT REVERSE

.

")

–

Opener still fails

CONTACT THE GENIE COMPANY OR AN

AUTHORIZED GENIE

®

DEALER.

3. Safe-T-Beam

®

System.

• Red LED blinks.

–

check alignment (See section ).

6

5

10

•

Garage door hardware (springs, cables,

brackets, pulleys, etc.) are under extreme

pressure and tension.

• DO NOT attempt to repair or adjust door springs

or any hardware, and DO NOT OPERATE garage

door automatically or manually if door is

improperly balanced or springs are broken.

–

CONTACT A TRAINED DOOR SYSTEM

TECHNICIAN.

WARNING

Page 26

PN# 37026500123 02/26/2010 REV. 1

26

CIRCUIT WIRING DIAGRAM

FOR HELP-1.800.354.3643 OR WWW.GENIECOMPANY.COM

Opener circuit wiring diagram. This wiring diagram is for reference only.

Diagrama del circuito del abrelatas. Este diagrama es sólo para referencia.

Schéma de câblage de l’ouvreur. Ce schéma de câblage est indiqué à titre de référence uniquement.

Opening Cover May Cause Electric Shock.

Abrir la tapa puede causar choques eléctricos.

L’ouverture du couvercle peut entraîner des chocs électriques.

Disconnect power from opener prior to removing cover.