Geneva Lab 3205, 3206 User Manual

GENEVA

HOT BEVERAGE

MERCHANDISER

OPERATOR

MANUAL

MODEL

3205 FRESH BREW

3206 FREEZE DRIED

JUN 2008 4214803 • C

TABLE OF CONTENTS

INTRODUCTION..................................................... 1

SPECIFICATIONS.................................................. 1

SAFETY WARNINGS............................................. 2

GENERAL DESCRIPTION..................................... 2

Cabinet Front ...................................................... 2

Cabinet Rear ....................................................... 2

MACHINE PARTS .................................................. 3

INSTALLATION...................................................... 4

SET-UP Requirements ....................................... 4

Electrical Supply .......................................................4

Water Supply............................................................ 4

Location............................................................... 4

Leveling ............................................................... 4

Connect Water .................................................... 5

Connect Electrical ............................................... 5

Checklist.............................................................. 5

FILL PRODUCT CANISTERS................................ 6

CHANGE MENU SELECTION LABELS................ 7

ADJUSTING CUP RING SETTING ........................ 8

SET PRICE FOR SINGLE CUP VOLUME

(LARGE) ................................................................. 9

SET PRICE FOR DUAL CUP VOLUMES

(LARGE AND REGULAR) ................................... 10

CUP SIZE ADJUSTMENT .................................... 11

FILL CUP COMPARTMENT ................................ 12

The Model and Serial numbers are needed for you to obtain quick service and parts information for your machine.

The numbers are listed on the identification plate located on the back side of the cabinet of the machine.

INGREDIENT VOLUME ADJUSTMENT ..............13

FLUSH HEATER TANK, BOWL & BREWER......14

Install Waste Containers.................................... 14

Flushing the machine ........................................ 14

Flush Mixing Bowls................................................. 14

Flush Coffee Brewer............................................... 15

DRIP CATCHER ................................................... 15

MERCHANDISER RECORD ................................15

CLEANING PROCEDURES .................................16

Hygiene.............................................................. 16

Safety................................................................. 16

Recommended items required ..........................16

Some Do’s & Don’ts: .........................................16

Daily/Weekly Routine ........................................ 17

Monthly Routine.................................................17

DISMANTLING COFFEE BREWER UNIT ...........18

FILTER BELT REMOVAL & REPLACEMENT ....20

REFITTING THE COFFEEE BREWER ................21

INTERNAL KEYPAD FUNCTIONS ......................22

USER KEYPAD..................................................... 24

TAKING A TEST VEND ........................................25

VIEWING COUNTER & EVENT RECORDS ........25

Heading Menu’s List:.........................................25

Available Sub-menu’s:....................................... 25

DIAGNOSTIC LOG ...............................................26

MODEL NUMBER: ___________________________________

SERIAL NUMBER: ___________________________________

ii

GENEVA - HOT BEVERAGE MERCHANDISER • 3205 • 3206 • 4214803

INTRODUCTION

1. The information contained in this service manual is applicable to the Hot Beverage Merchandiser. The Hot

Beverage Merchandiser line consists of two types of coin-operated, microprocessor controlled, Hot

Beverage Merchandisers that dispense a range of hot beverages in response to keypad selections.

2. Two versions of each model are available:

Freeze-dried (INST) - Freeze-dried Coffee and Tea

Fresh Brew (SFB) - Fresh Brew Coffee

3. This manual uses the SFB version as the basis for examples. Where significant differences between

versions exist this will be highlighted in the main body of the document. Due to customer requirements,

however, some features may vary from those described, e.g. extras fitted, variations in programming etc.

4. Cups from a cup drop mechanism are dispensed to contain the beverages.

5. Selections are made on a 12 button keypad and an LCD display panel indicates status and beverage

selection information.

6. The status of the machine may be monitored and the configuration altered by accessing a menu of program

options using both internal and external keypads. A number of sub-options are included under each option,

the settings of which can be altered.

7. A feature of the Hot Beverage Merchandiser is the mobile dispense head which moves to a parked position

away from the cup port after each beverage is vended, preventing the possibility of any residue from the

previous delivery cycle dripping into the next one.

8. Hot Beverage Merchandiser machines require a single-phase 120V electrical supply from a 12A outlet, and

a cold water supply. These services connect to the machine through the rear of the cabinet.

9. Maintenance of the coffee machine must be undertaken only by personnel who are authorized and

suitably qualified.

10. The contents of this publication are presented for informational purposes only, and while every effort has

been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use or applicability. The manufacturer

reserves the right to modify the designs or specifications of such products at any time without notice.

SPECIFICATIONS

DIMENSIONS

HEIGHT: 72 inches (1830 mm)

DEPTH: 26.8 inches (680 mm)

WIDTH: 27.6 inches (700 mm)

SHIPPING WEIGHT

360 lbs (163 kg) – Fresh Brew version

ELECTRICAL

120 Volts, 60 Hz, 9.2 Amps nominal

240 Volts, 50 Hz, 13 Amps

CUP CAPACITY

QUANTITY: Up to 400 (12 oz) cups

SIZES: 7 oz, 8 ¼ oz, 9 oz, 10 oz & 12 oz

OPERATING ENVIRONMENT

LOCATION:

SOUND LEVEL: Produces less than 70dBA

TEMPERATURE: 46°F (8°C) - 90°F (32°C)

For indoor use only

during normal operation

.

GENEVA - HOT BEVERAGE MERCHANDISER • 3205 • 3206 • 4214803

1

SAFETY WARNINGS

• DISCONNECT / UNPLUG POWER TO THE MACHINE BEFORE SERVICING. Lethal voltages are

exposed when any panel inside the cabinet is removed if power is supplied to the on/off switch.

• Installation and maintenance of the Hot Beverage Merchandiser is to be undertaken only by trained

personnel who are fully aware of the dangers involved and who have taken adequate precautions.

• The Hot Beverage Merchandiser must be grounded (earthed). Do not tamper, modify or remove

the ground pin from the power plug. Should the power cord or plug become damaged, a

trained person from an approved service agent must perform the replacement using only

factory approved parts. Do not ground (earth) the machine to the water supply pipe.

• Keep clear of the Brewer Unit when it is operating.

• The Hot Beverage Merchandiser is a heavy item. Ensure that sufficient personnel are available for

lifting and transporting the machine. Use proper lifting procedures and equipment.

• The water in the heater tank and the tank itself are hot enough to scald or burn even some time after

the machine has been switched off. The water tank must be drained, filled with cold water and drained

again before any attempt is made to handle it or any of its associated parts.

• The Controller Board is fitted with a lithium battery. Abuse of this type of battery can lead to

overheating, venting, explosion, release of potentially hazardous materials and spontaneous ignition.

The lithium battery must not be charged by, or connected to, any other source of power. The battery

must not be short-circuited or forced to discharge its stored energy. The battery must not be

subjected to physical damage or overheating. ONLY the Trained Technician should attempt

controller board replacement!

• Care must be taken to protect the Hot Beverage Merchandiser from frost. Do not attempt to operate

the machine if it becomes frozen.

machine to operation until it has been checked and approved for use by the service agent.

• Due to the risk of being scalded by hot beverages, young children, the aged and the infirm

should not be allowed to operate the Hot Beverage Merchandiser unsupervised.

IMPORTANT: Please refer to the safety manual (p/n 4206816) for additional safety

information.

Contact the nearest service agent immediately. Do not restore the

GENERAL DESCRIPTION

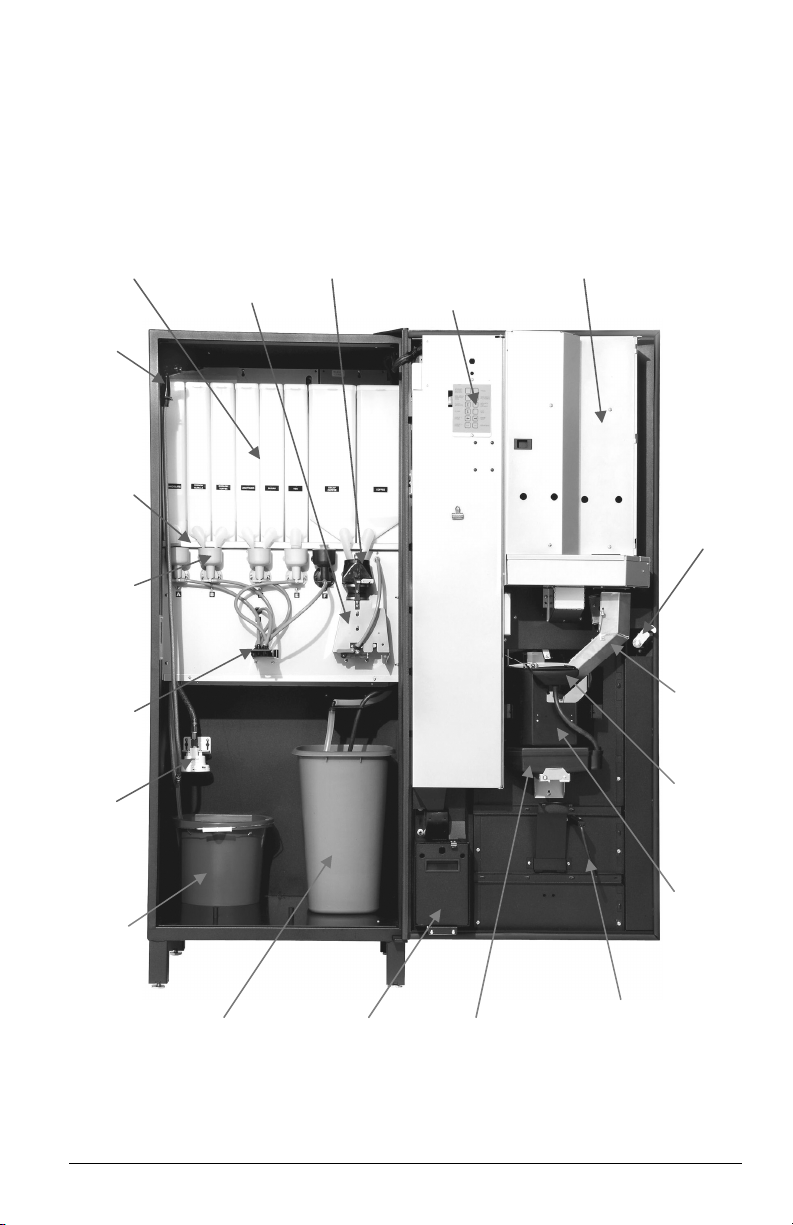

Opening the merchandiser door via the key operated lock allows access to its internal components. Equipment

inside the Hot Beverage Merchandiser is arranged in two sections: front and rear. When the merchandiser door is

open the Operator has immediate access to those items which he or she will be controlling or adjusting (Ingredient

Canisters, Cup Compartment, Coin Mechanism, Waste Buckets, etc.). The remaining equipment (Water Heater,

Valves, Electrical and electronics components, etc), access to which is limited to the Trained Technician, are

located behind the panel at the rear of the cabinet.

CABINET FRONT

The Cup Drop Assembly, Coin Mechanism, Controller Board and Cup Station are fitted to the rear of the door. The

Customer’s keypad is on the door front panel.

Ingredient canisters are located on a shelf within the cabinet above the mixing area. An extractor fan removes

excessive moisture from the mixing systems, helping assure that the systems function properly. The moving

dispense head keeps residue from previous dispensing cycles from dripping into the current dispensing cycle.

Level sensor probes assure that the waste buckets will not overflow. When a level-sensor probe is activated the

water supply is shut off and the machine is rendered inoperable until the waste container is emptied.

CABINET REAR

Access to the components and equipment in the rear section of the cabinet (behind the rear panel) is limited to the

Trained Technician.

2

GENEVA - HOT BEVERAGE MERCHANDISER • 3205 • 3206 • 4214803

r

Water for beverages travels through the inlet valve and into the water heater tank located at the top and back of

the cabinet. Solenoid dispensing valves direct the heated water to the appropriate mixing bowl. Excessively hot

water flowing from the tank activates a high temperature cut-out switch. When activated the cut-out switch cuts off

the electrical supply to the heater in the tank. The cut-out must then be reset to reactivate the heater

Level probes located in the cabinet door and waste container allows the unit’s control system to monitor the liquid

level in the waste containers and prevent overflow.

MACHINE PARTS

Ingredient Canisters

Rinse

Hose

Stainless

Steel

Canister

Shelf

Whipper

Chamber &

Station

Splash Guard

Coffee Brewer Unit Cup Storage Compartment

Internal Keypad

Door

Lock

Dispense

Arm

Wate

Filter

Liquid

Waste

Bucket

Coffee

Grounds

Waste Bucket

GENEVA - HOT BEVERAGE MERCHANDISER • 3205 • 3206 • 4214803

Cash Box Drain Tray

Safety Probe

Cup Station

Liquid Waste

Bucket

3

Cup

Delivery

Chute

Upper

Rinse

Funnel

Cup

Station

`

INSTALLATION

WARNING: Disconnect or unplug power to the machine before servicing.

1. Servicing personnel must be familiar with the SAFETY WARNINGS listed in this manual and the Safety

Manual (P/N 4206816) before undertaking any installation or maintenance procedure on the Hot Beverage

Merchandiser. Any procedure which is found to be impractical, inadequate or inaccurate should be reported

to the Management for further investigation.

2. The information given in this section covers installation and maintenance procedures for the Hot Beverage

Merchandiser. Only authorized personnel who have knowledge or experience with the equipment, and using

only the manufacturer’s approved parts should carry out these procedures.

3. The requirements of proper hygiene in respect of food products must be ensured at every level of contact

with the Hot Beverage Merchandiser and the ingredients associated with it.

IMPORTANT: You are required to be aware of and adhere to all Federal, State, and Local laws

regarding food handling and storage. NOTE: DO NOT use non-food safe lubricants or cleaners.

SET-UP REQUIREMENTS

ELECTRICAL SUPPLY

• 110V, 60Hz, 12A fused

• 240V, 50Hz, 13A fused

The electrical outlet and supply circuit must be dedicated and isolated before connecting power to the machine.

The electrical outlet must be within 6 ft (2 m) of the machine. Preferably, the switched outlet should be located

behind the machine to prevent accidental damage or misuse.

WATER SUPPLY

The main water supply must have 15-116 psi pressure. The water outlet must have a shutoff valve so that the

water supply to the merchandiser may be turned off during servicing. The water outlet should be located behind

the machine to prevent misuse.

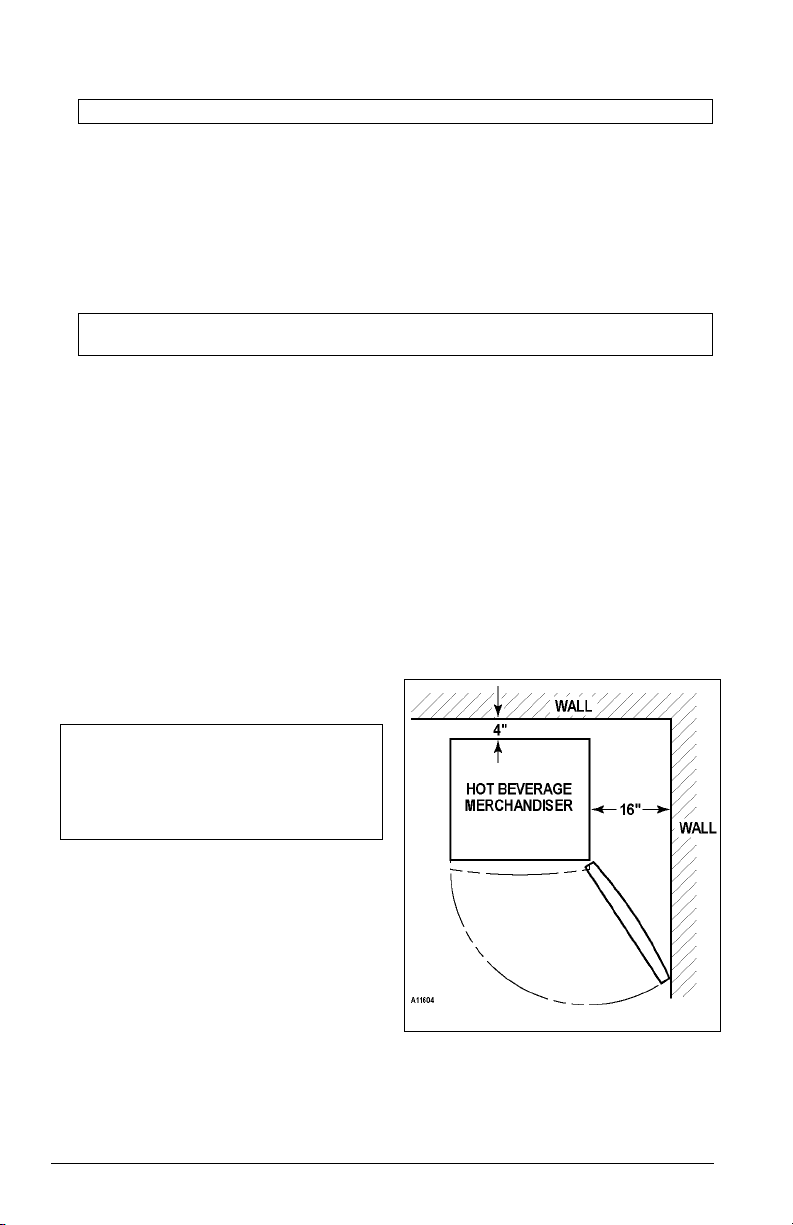

LOCATION

WARNING: The Hot Beverage Merchandiser

The Hot Beverage Merchandiser must be located close

to the appropriate electrical and water outlets.

There must be a minimum of 4 inches (100mm)

clearance between the rear of the cabinet and the wall

to allow adequate ventilation. See Figure 4a.

If placing in a corner location, there must be at least 16

inches (406mm) of space to the right hand wall to allow

the door to open properly.

is a heavy item. Ensure that

sufficient personnel are available

for lifting and transporting the

machine. Use proper lifting

procedures and equipment.

Figure 4a. Distance From Wall

LEVELING

The Hot Beverage Merchandiser must be level for proper operation. Using a level as a guide turn the machine’s

leg levelers as needed until all levelers are touching the floor. If it is properly leveled, the merchandiser should not

“rock” or “teeter” on any of the levelers.

4

GENEVA - HOT BEVERAGE MERCHANDISER • 3205 • 3206 • 4214803

When the machine is level, the door can be opened to any

position and not swing either way. Try the door at various open

positions before deciding that the machine is leveled.

CONNECT WATER

Before connecting the hose to the machine, flush the water

supply system via the shutoff valve to remove any impurities

which may have accumulated in the supply pipe or water hose.

The merchandiser’s water inlet - a standard ¼” NPT female

water hose connector - is located on the back of the machine.

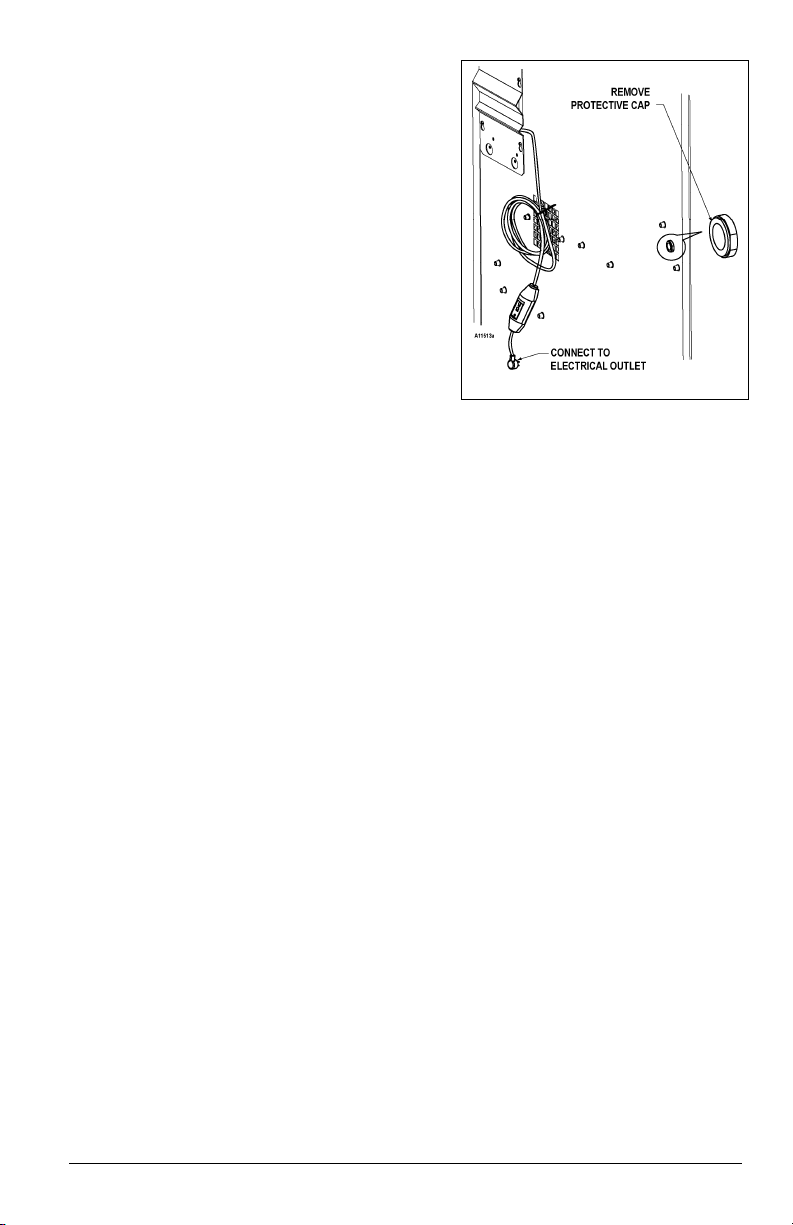

Remove the plastic protective cap. See Figure 4b. There is

also a 3/8” Flare Fitting supplied inside the waste bucket if this

is preferred.

Connect the water supply hose to machine water inlet and

ensure that all fittings are tight. Turn on the water supply at the

shutoff valve and check for leaks both outside and inside of the

machine.

Figure 4b. Power Cord & Water Inlet

CONNECT ELECTRICAL

Plug the Hot Beverage Merchandiser power cord into a 110V, 60Hz, 12A (240V, 50Hz, 13A) switch supply

socket. With the plug fitted to the socket, ensure that the cable is not stretched, distorted or hampered by any

object.

CHECKLIST

It is essential that the technician responsible for installing and commissioning the machine ensures the following:

1. All electrical and water supplies are correctly and safely connected and that the water heater overflow pipe

is not trapped or pinched (remove canisters to access and remove rear panel to check status of overflow

pipe.)

2. All covers, panels and access doors are in place and secured, and the machine is in a SAFE condition.

3. The Operator is familiar with the SAFETY PRECAUTIONS for the machine.

4. The Operator appreciates the importance of hygiene and regular cleaning of the merchandiser.

With water and electricity sources connected to the machine, check the water heater operation as follows:

1. Press merchandiser on/off switch (upper left side of interior back wall) to the ON position. Water will

flow into the water tank. Wait approx. 1 minute and the water will shut off (safety feature). Then turn

the power switch OFF, wait a few seconds and turn the power switch back ON. Water will continue to

fill the tank. When water reaches the probe level, the heater will turn on as indicated by the heater

indicator light (to the right of the on/off switch). There should be no water overflow into the waste

basket.

2. Ensure that the waste level probe is positioned in the waste basket.

3. Press the merchandiser on/off switch to the OFF position.

NOTE: Water tank MUST be allowed to preheat for 15 to 20 minutes before filling coin mechanism or

performing test vends because these will be automatically disabled if water temperature does not meet

standard.

GENEVA - HOT BEVERAGE MERCHANDISER • 3205 • 3206 • 4214803

5

FILL PRODUCT CANISTERS

WARNING: FILL PRODUCT CANISTERS WITH POWDERED INGREDIENTS ONLY.

DO NOT USE LIQUID INGREDIENTS.

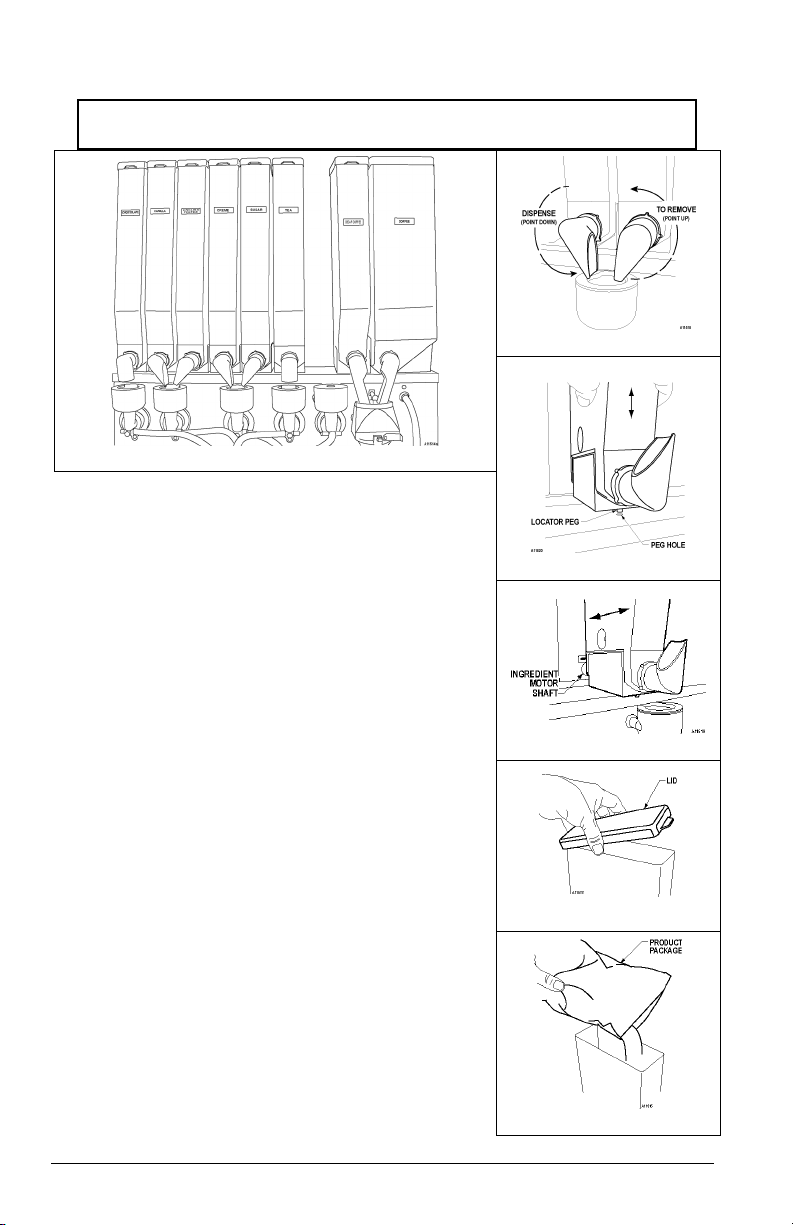

Figure 5a. Canister Lineup

1. Always remove the ingredient canisters in order to fill them. This

prevents spillage of foodstuffs which will encourage the ingress of

insects etc.

2. Prior to removing an ingredient canister, rotate the delivery chute in

an upward direction to prevent spillage of product onto internal

surfaces. See Figure 5b.

3. When removing each ingredient canisters, always give it a shake to

loosen-up any compacted product to keep it free-flowing.

4. When filling the canisters, hold the top and bottom of the canister

and slowly lift it up so that the locator peg clears the peg hole.

Figure 5c. Slide the canister forward until it is out of the ingredient

motor shaft. Figure 5d.

5. Place canister on a sheet of paper or on an easily cleaned surface.

6. Remove lid from the canister. Figure 5e.

7. Open product bag that matches the name on the Canister Label

(where applicable) according to the instructions on the bag.

8. Slowly pour the product into the canister. Figure 5f.

• Product must be loose for proper dispensing.

• DO NOT tap the sides of the canister.

• DO NOT compress or compact product into the canister.

• Leave a gap from the top of the product to the lip of the

canister. Figure 5g.

9. Replace canister lid. Figure 5e.

10. Review the canister arrangement as shown in Figure 5a. Hold the

canister carefully at the bottom and top to prevent spilling. Gently

place the filled canister back on the product shelf. Figure 5d.

11. Line up the hollow shaft in the back of the canister with the

ingredient motor shaft. See Figure 5d.

12. Slowly slide the canister toward and over motor shaft until locator

peg falls inside the hole on the product shelf. See Figure 5c.

Figure 5b. Product Chute

Figure 5c. Locator Peg

Figure 5d. Motor Shaft

Figure 5e. Canister Lid

Figure 5f. Fill Canister

6

GENEVA - HOT BEVERAGE MERCHANDISER • 3205 • 3206 • 4214803

13. Rotate the product chute so that it points down (dispense position)

to the whipper bowl. See Figure 5b.

14. Repeat above steps for other canisters.

Figure 5g. Do Not Pack

CHANGE MENU SELECTION LABELS

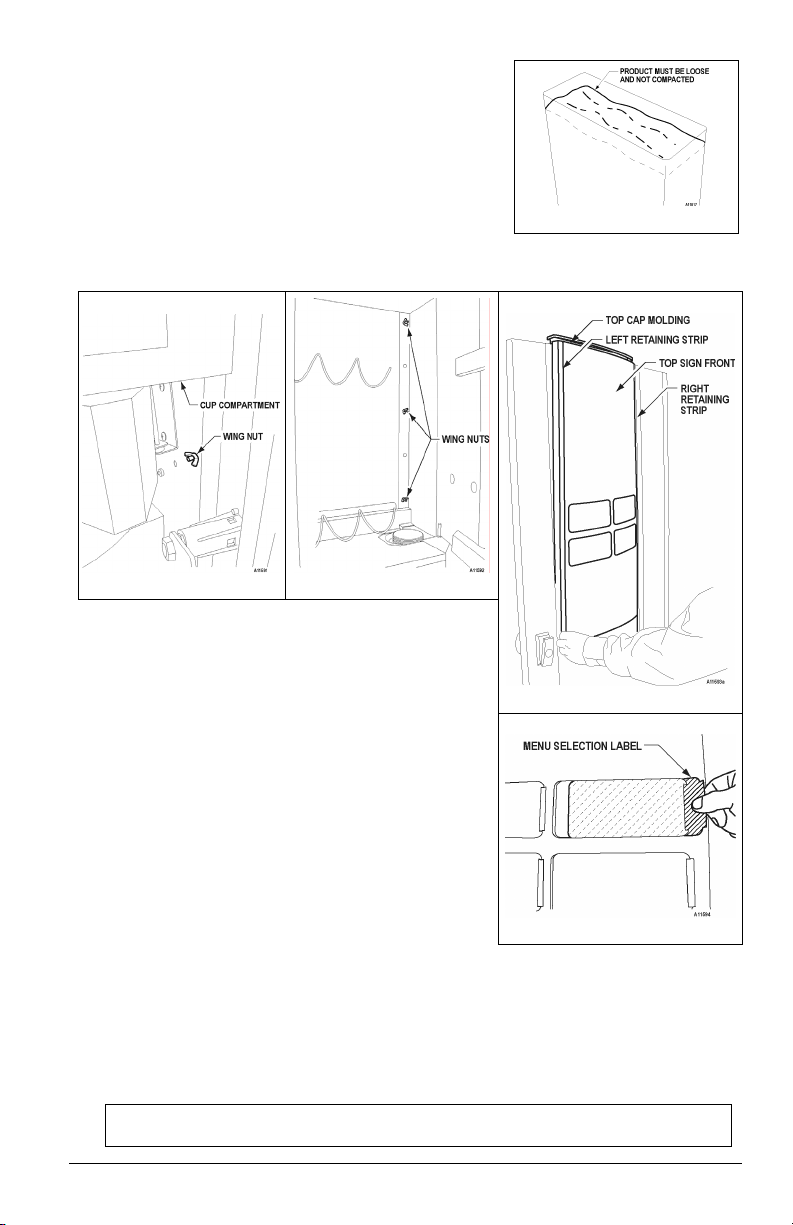

Figure 6a. Bottom Wing Nut Figure 6b. Inside Wing Nuts

1. Remove and save the wing nut located on the right side

below the cup compartment (as viewed from behind the

door). See Figure 6a.

2. Open the cup compartment door. Remove and save the 3

wing nuts located on the right side of the cup compartment.

Loosen 2 wing nuts holding the Top Cap Molding. See

Figure 6b.

3. Lift Top Cap Molding and loosen Retaining Strip on the left

side of the Top Sign Front (on the front of cabinet door).

Remove the Retaining Strip and Top Sign Front assembly.

See Figure 6c. (This is most easily done by applying

outward pressure on the wing nut screws on the inside of the

door.)

4. Place the Top Sign Front on a clean, non-abrasive surface.

5. Locate the menu selection label behind the Top Sign Front.

See Figure 6d. Carefully slide the menu selection label out

of its pocket.

6. Insert the new menu selection label through the slots. Check the

front of the Top Sign Front to make sure that the menu selection labels are correctly aligned.

7. Insert the right edge of the Top Sign Front into the slot of the right side Retaining Strip. See Figure 6c.

8. Slip the left side Retaining Strip over the left edge of the Top Sign Front. Push the Retaining Strip back into

place. See Figure 6c. (To accommodate the rounded front design, carefully bow the left edge of the

assembly to the right until you are able to press the three retaining screws back into position.)

9. Reinstall and tighten the wing nuts saved from steps 1 and 2. See Figure 6a and Figure 6b.

NOTE: These steps change only the beverage label. Only the Trained Technician may change

beverage type or content.

Figure 6c. Remove Top Sign Front

Figure 6d. Menu Selection Label

GENEVA - HOT BEVERAGE MERCHANDISER • 3205 • 3206 • 4214803

7

Loading...

Loading...