Page 1

VM8205SD

USER’S MANUAL

VIBRATION METER

WITH DATALOGGING SD CARD

Please read this manual carefully and thoroughly before using this product.

Page 2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating Instructions . . . . . . . . . . . . . . . . . . . . . 4 – 10

What’s in the case . . . . . . . . . . . . . . . . . . . . . . . 4

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 –6

Normal Operation . . . . . . . . . . . . . . . . . . . . . 6 –8

Holding and Storing Measurements

(RMS values only) . . . . . . . . . . . . . . . . . . . . . 8

Automatic vs. Manual Datalogging . . . . . . . . . . 9

Transferring Data from the SD Card

to a Computer . . . . . . . . . . . . . . . . . . . . . . . 10

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance & Troubleshooting Tips . . . . . . . . . . . . 12

Optional Accessories. . . . . . . . . . . . . . . . . . . . . . . . . 12

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . 12

Return for Repair Policy . . . . . . . . . . . . . . . . . . . . . . 13

2

Page 3

INTRODUCTION

Thank you for purchasing General Tools & Instruments’ VM8205SD Vibration Meter with

Datalogging SD Card. Please read this user’s manual carefully and thoroughly before using

the meter.

The VM8205SD is a general-purpose handheld instrument that can measure the

acceleration or velocity of a machine as an indicator of its vibration level. All industrial

machinery vibrates, and a machine’s vibration level can serve as a proxy for its condition.

Imbalance, misalignment or loose bolts will cause the vibration level to increase, indicating

the need for maintenance.

The meter is a professional-quality instrument that comes with a vibration probe as well as

a magnetic base for attaching the probe to any metal part of a machine or its housing. The

meter’s sensitivity and frequency spectrum of 10 Hz to 1 kHz comply with ISO 2954, the

standard for measuring mechanical vibration of rotating and reciprocating machinery.

Measurements made by the probe can be displayed in either of two metric units or one

English unit. Vibration inputs can be displayed in the preferred way: as root mean square

(RMS) values. The meter also can measure, hold and update the RMS peak value in a series

of measurements.

Because it is microprocessor-based, the VM8205SD can make full use of the portability,

reliability and large storage capacities that SD memory cards offer. Measurements can be

made automatically at any sampling rate between one second and one hour. After timestamping and storing the measurements on an SD card plugged into the meter (a process

called datalogging), the user can remove the card and plug it into to a laptop or desktop

computer either directly or via a USB card reader. The data logs are stored on the card as

files with the .xls extension, which can be opened by Microsoft’s Excel application.

The VM8205SD has a backlit 2-1/2 in. diagonal display and is powered by six “AA” Alkaline

batteries or an optional 9-VDC AC adapter.

KEY FEATURES

• Vibration probe measures acceleration or velocity

• Included magnetic base facilitates attachment of probe to metal parts or

machine housing

• Big (2.5 in. diagonal) front-panel green backlit LCD is easy to read

• Displays maximum and minimum readings and holds any RMS reading

• Automatically logs measurements at sampling time settable from one second

to one hour

• Also supports manual datalogging and changing of SD card storage location

• Outputs Excel-compatible data logs

• Accepts SD memory cards of up to 16 GB capacity

• Powered by six “AA” batteries or optional 9V AC/DC adapter

3

Page 4

OPERATING INSTRUCTIONS

WHAT’S IN THE CASE

The VM8205SD comes fully assembled in a carrying case along with a vibration sensing

probe, a magnetic base, a 2 GB SD memory card and this user’s manual.

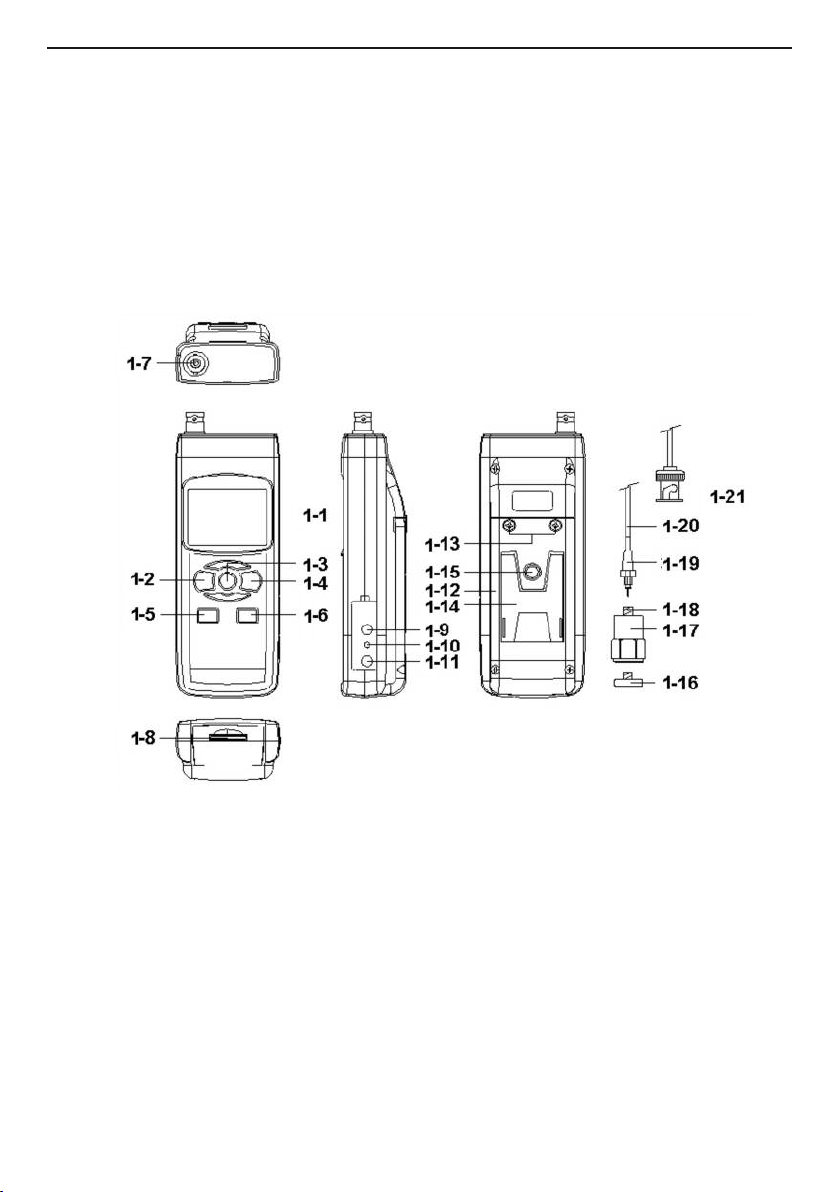

Figure 1 shows all of the controls and indicators on the front, right side, back, top and

bottom of the VM8205SD. The drawing also shows the components of the included

vibration probe. Familiarize yourself with the positions and functions of these controls,

indicators and connectors before moving on to the setup procedure.

TOP

FRONT

BOTTOM

RIGHT

SIDE

BACK

VIBRATION

PROBE

1. The VM8205SD’s controls and indicators and other physical features

1-1 Liquid-crystal display

1-2 POWER/ESC button

1-3 FUNC./HOLD/NEXT

button

1-4 REC/ENTER button

1-5 SET ▼ button

1-6 LOGGER ▲ button

1-7 Socket for vibration

probe BNC plug

1-8 SD card socket

4

1-9 RS-232 output jack

1-10 RESET button

1-11 Socket for 9VDC AC

adapter

1-12 Battery compartment

cover

1-13 Battery compartment

cover screws

1-14 Kickstand

1-15 Tripod attachment nut

1-16 Magnetic base

1-17 Vibration sensor

1-18 Vibration sensor input

socket

1-19 Vibration probe mini-

plug

1-20 Vibration probe cable

1-21 Vibration probe BNC

plug

Page 5

SETUP

1. Choose the power source. Before using the VM8205SD, make sure it is powered by

fresh batteries or an optional 9VDC AC adapter plugged into the bottom jack on its right

side (callout 1-12).

To remove the battery compartment cover (callout 1-13), remove the two screws holding

it in place (callout 1-14). Then install six “AA” batteries in the correct orientation, using the

polarity marks on the inside of the compartment as a guide. Replace the cover by replacing

the two screws.

2. Install an SD card. To prepare for setup, also install the supplied 2 GB SD memory card

or another card with a capacity from 1 GB to 16 GB in the socket on the bottom of the

meter (callout 1-9). When installing the card, make sure its gold contacts are facing front

and push the card into the socket until you hear a click. To remove the card, push it in

until you hear a click and the card pops out.

Now power on the instrument by pressing the POWER/ESC button (callout 1-2) to generate

a short beep. (To power off the VM8205SD, press the POWER/ESC button and hold it until

the instrument responds with a long beep.)

When the meter powers on, a series of transient startup screens will briefly appear. Once

the display has stabilized, perform the following six setup steps in the order presented.

3. Set the date and time. Press the SET ▼ button (callout 1-5) and hold it for at least five

seconds, until the word “dAtE” appears in the center of the display, along with the

flashing value “00.00.00” at the lower left, above “yy.mm.dd”.

Set the current year by pressing the SET ▼ or LOGGER ▲ button repeatedly until the

correct value appears above “yy”. Quickly (within three seconds), press the REC/ENTER

button to store the setting. The next screen that appears will have the value above “mm”

flashing. Use the SET ▼ or LOGGER ▲ button to navigate to the current month and press

the REC/ENTER button to store the setting. When the next screen flashes the value above

“dd”, again use the SET ▼ or LOGGER ▲ button to navigate to the current day and press

the REC/ENTER button to store the setting.

(If you press buttons too slowly in setup mode, the screen will revert to the normal display.

To return to the setup sequence, press and hold the SET ▼ button again. To move ahead to

the next field in the sequence or to the next parameter, press the FUNC./HOLD/NEXT

button.)

Once you have set the date, the display will prompt you to set the hour, minute and second

of the current time. Again use the SET ▼ or LOGGER ▲ buttons to navigate to the correct

values, and the REC/ENTER button to store the settings.

4. Choose a decimal point or comma to represent the decimal division between integers

and fractions (for example, American-style 20.88 vs. European-style 20,88). Once you

have set the date and time, the display will show the word “bASIC” above the phrase

“dEC”. Press the SET ▼ button to make “bASIC” (American style) or “Euro” appear in

the upper display, as desired. Press the REC/ENTER button to store the selection as

the default.

5

Page 6

5. Enable or disable auto power off. Once the format of decimal point divisions has been

set and stored, the display will show the word “yES’ over the term “PoFF”. Press the

SET ▼ button until the desired automatic power off management scheme (“yES” for

enable; “no” for disable) is displayed. Press the REC/ENTER button to store the selection.

If enabled, the power off function shuts off the VM8205SD after a period of inactivity

of ten minutes.

6. Enable or disable the beeper. Once the auto power off scheme has been chosen and

stored, the display will show the word “yES” over the word “bEEP”. Press the SET ▼

button until the desired setting (“yES” or “no”) is displayed, and then press the

REC/ENTER button to store the selection as the default.

7. Set the datalogging sampling time. Once the beeper has been enabled or disabled, the

display will show a value above the letters “SP-t”. Press the SET ▼ or LOGGER ▲ button

to decrease or increase the value until the desired sampling time appears above “SP-t”.

The options are 0, 1, 2, 5, 10, 30, 60, 120, 300, 600, 1800 and 3600 seconds (0 seconds

to 1 hour).

8. Format the SD card. Once the sampling time has been set and stored, the term “Sd-F”

will appear in the lower half of the display. Press the REC/ENTER button.

Pressing the REC/ENTER button causes the word “no” or “yES” to appear over the term

“Sd-F”. Press the ▼ button to make a selection. Choose “yES” whenever a new SD card is

being used, or when a used card is being repurposed (from use with another SD card

instrument or a camera, for example) and all data on it is to be erased. Choose “no” to

preserve any data on a card previously used with this instrument.

If you choose “yES”, after you press the REC/ENTER button the instrument will prompt you

to confirm that decision by displaying the term “Ent” below “yES” and sounding three

beeps. To confirm that you want to begin the erasure/formatting procedure, press the

REC/ENTER button. “Ent” will then flash several times and the instrument will sound

another three beeps to confirm that the SD card has been erased and formatted.

Once the SD card has been formatted (or not), the display will then either return to the first

of the six steps in the setup sequence—setting the current date and time—or show the

term “ESC”. If “ESC” appears, press the POWER/ESC button to exit the setup procedure and

enter normal operating mode.

NORMAL OPERATION

1. To prepare to make vibration measurements, power on the VM8205SD and make sure

an SD card is firmly seated in the socket on the bottom of the meter. Seat the vibration

probe BNC plug (callout 1-21 of Fig. 1) in the socket on the top of the meter. Then seat

the vibration probe mini-plug (callout 1-19) in the vibration sensor input socket

(callout 1-18).

2. If the surface of the machine being measured is a non-ferrous material, hold the

vibration sensor (callout 1-17) in your hand and touch its end to the machine.

3. If the surface material is ferrous, plug the sensor into the magnetic base (callout 1-16)

and attach the base to the machine’s surface. In both cases, avoid touching the vibration

probe cable (callout 1-20) with your finger or hand.

6

Page 7

The meter can measure two vibration-related parameters (acceleration and velocity) and

show readings of each one in any of three units. Acceleration can be measured and

2

displayed (using the term “ACC”) in the metric unit m/s

2

force) or the English unit ft/s

. Velocity can be measured and displayed (using the term

, the metric unit “g” (gravitational

“VEL”) the in the metric unit mm/s, the metric unit cm/s or the English unit inch/s.

4. To select the measurement parameter and its units, press the REC/ENTER button

(which has the word “Unit” stenciled below it). Doing so cycles through the six

parameters and units in the following order:

• ACC in m/s

2

• VEL in cm/s • ACC in ft/s

• ACC in g • VEL in mm/s

2

• VEL in inch/s

Pressing the REC/ENTER button when VEL in inch/s is displayed returns the display to

2

ACC in m/s

. Releasing the button saves the displayed parameter/unit as the default.

For most industrial vibration measurement applications, use an acceleration setting.

Pressing the FUNC./HOLD/NEXT button repeatedly cycles through the three functions that

can be performed on measured values. The meter can:

• Show the root mean square (RMS) value of measured acceleration or velocity readings

(this is the typical function performed on acceleration and velocity measurements)

• Measure the peak value in a series of measurements (the display shows “PEAK”)

• Update and hold the peak value (the display shows “Max HOLD”). To clear a previously

stored peak value, press the LOGGER ▲ button and hold it for at least five seconds.

5. To choose the function to be applied to measured values, press the

FUNC./HOLD/NEXT button until the text corresponding to the desired function appears on

the display. Then release the button. Doing so makes the selected function the default

until the FUNC./HOLD/NEXT button is pressed again.

The following tables correlate the severity of a machine’s vibration (good, acceptable,

still permissible and dangerous) with a range of values for each of the four machinery

classifications recognized by ISO2372 and VDI 2056.

Small machines, especially production

electrical motors of up to 15 kW

(Group K)

Good 0 to 0.71 mm/s

Acceptable 0.72 to 1.80 mm/s

Still permissible 1.81 to 4.5 mm/s

Dangerous > 4.5 mm/s

Medium sized machines, especially

electrical motors with 15 up to 75 kW

output, without special foundations

( Group M )

Good 0 to 1.12 mm/s

Acceptable 1.13 to 2.80 mm/s

Still permissible 2.81 to 7.1 mm/s

Dangerous > 7.1 mm/s

7

Page 8

Large machines on heavy foundations

(Group G)

Good 0 to 1.80 mm/s

Acceptable 1.81 to 4.50 mm/s

Still permissible 4.51 to 11.2 mm/s

Dangerous > 11.2 mm/s

Largest machines and turbo machines

with a special foundations (Group T)

Good 0 to 2.80 mm/s

Acceptable 2.81 to 7.10 mm/s

Still permissible 7.11 to 18.0 mm/s

Dangerous > 18 mm/s

For any of several reasons (e.g., temperature changes, weak or new batteries, infrequent

use of the meter), the display may show a small, non-zero value after the vibration sensor

is plugged in but before it is placed in contact with a machine. In most cases, those residual

readings will be dwarfed by vibration inputs.

6. To eliminate residual readings, perform the following procedure. With the vibration

probe BNC plug seated in the socket on the top of the meter, use the REC/ENTER button

to select any of the three acceleration (“ACC”) settings. Keeping the vibration sensor

away from machinery and as motionless as possible, press the LOGGER ▲ button and

hold it for at least five seconds, until the display reads zero.

Whenever the meter is in any measurement mode, you can turn off the backlight (which is

on by default) by briefly pressing (but not holding) the POWER/ESC button. To reactivate the

backlight, briefly press the button again.

Whenever the instrument is in any measurement mode, you also can check the current

date and time by briefly pressing the SET ▼ button (which has the words “Time check”

stenciled below it). Doing so causes both values to appear briefly at the lower left of the

display.

HOLDING AND STORING MEASUREMENTS (RMS VALUES ONLY)

1. To hold a measured value, press the FUNC./HOLD/NEXT button during the

measurement. Doing so will cause the word “HOLD” to appear at the top of the display.

Pressing the FUNC./HOLD/NEXT button again releases the hold.

2. To record and recall readings, press the REC/ENTER button while making

measurements. This will make the term “REC” appear at the top of the display. Pressing

the REC/ENTER button again, briefly, will make the term “MAX” appear to the right of

“REC” and switch the display to the maximum value stored in memory during the last

recording session. Pressing the REC/ENTER button again, briefly, will make the term

“MIN” appear to the right of “REC” and switch the display to the minimum value stored

during the last session.

3. To exit recording mode, press the REC/ENTER button and hold it for at least three

seconds, until the term “REC” disappears from the top line of the display. The display will

then revert to showing the current reading.

8

Page 9

AUTOMATIC VS. MANUAL DATALOGGING

The VM8205SD can automatically log data at a user-selected sampling period from

1 second 3,600 seconds (one hour). To view the sampling time that the instrument has

been set up to use, press the LOGGER ▲ button (which has the words “Sampling check”

stenciled below it) once. To change the sampling time, perform Step 7 of the setup

procedure.

1. To start automatic datalogging, press the REC/ENTER button once. The top line of the

display will then show the term “REC”. Pressing the LOGGER ▲ button at this point will

make REC flash and add the flashing term “LOGGER” at the top right of the display. This

indicates that the instrument is currently storing measured values and their time stamps

in memory.

2. To pause automatic datalogging, press the LOGGER ▲ button once; this action makes

the flashing term “LOGGER” disappear from the top right of the display and changes the

term “REC” from flashing to constant. Pressing the LOGGER ▲ button again resumes

automatic datalogging.

3. To end automatic datalogging, press the REC/ENTER button and hold it for at least two

seconds. This action causes the “REC” message to disappear.

4. To log data manually, set the sampling time to zero using Step 7 of the setup

procedure. Then press the REC/ENTER button once. The display will show the term “REC”

on the top line, a value in the middle, and below it the letter “P” on the left and a number

from 1 to 99 on the same line to the right. The number indicates the position on the SD

card that will be used to store manually logged data.

Now press the LOGGER ▲ button. This will cause the beeper to sound and the term

“LOGGER” to briefly appear at the upper right of the display. As in automatic datalogging

mode, in this mode the instrument is storing measurements and their time stamps on the

SD card.

In manual datalogging mode, however, measurements are being stored continuously

(with a sampling time of zero), and their locations on the card can be changed.

5. To change the storage location of manually logged data, press the SET ▼ button

once; this causes the “P” to disappear from the left side of the display and the value on

its line to begin flashing. Once the flashing begins, you can use the SET ▼ and LOGGER

▲ buttons to change the flashing value to any number between 1 and 99. Once you have

chosen the storage location, press the REC/ENTER button to save the setting. This causes

the value to stop flashing and the “P” to return.

6. To end manual datalogging, press the REC/ENTER button and hold it for at least three

seconds. This action causes the “REC” message to disappear from the top line of the

display.

9

Page 10

TRANSFERRING DATA FROM THE SD CARD TO A COMPUTER

After automatic or manual datalogging of measurements, remove the SD card from the

meter and plug it into your computer either directly (if it has an SD card slot) or through an

SD card reader.

Because the files containing time-stamped data logs have the file extension .xls, they open

in Microsoft’s Excel application. Figures 2 and 3 show two kinds of Excel presentations: a

data-only screen and a graphics-only screen.

10

Fig. 2. Typical Excel data-only screen

Fig. 3. Typical Excel graphics-only screen

Page 11

SPECIFICATIONS

Embedded microcontroller Custom one-chip LSI device

Display type Liquid-crystal with green backlight

Display size 2.05 x 1.5 in. (52 x 38mm)

Parameters measured Acceleration, velocity

Units For acceleration: m/sec

for velocity: mm/sec, cm/sec or inches/sec.

Displayed value options Root mean square (RMS), peak, max hold

Input frequency range 10 Hz to 1 kHz

Measurement range For acceleration: 0.5 to 199.9 m/sec

2

2 to 656 ft/sec

; for velocity: 0.5 to 199.9 mm/sec,

0.05 to 19.99 cm/s, 0.02 to 7.87 inch/s

Measurement accuracy For acceleration and velocity: ± (5 % of reading + 2 digits)

Measurement resolution For acceleration: 0.1 m/sec

0.1m/sec, 0.01 inches/sec

Calibration point For acceleration: 50 m/sec

50 mm/sec @ 160 Hz

Sampling time options 0, 1, 2, 5, 10, 30, 60, 120, 300, 600, 1800 or 3600 seconds

(0 seconds to 1 hour)

Settable parameters Date, time, decimal point or comma decimal division,

auto power off, beep sound, sampling time

Storable/recallable readings Maximum, minimum, peak (RMS values only)

SD card capacity 1 GB to 16 GB

Operating temperature 32º to 122ºF (0º to 50ºC)

Operating relative humidity 0 to 85%

Power source 6 Alkaline “AA” batteries or optional 9-VDC AC adapter

Power consumption 15 mADC (normal operation, with backlight off and SD card

not saving data); 36 mADC with backlight on and card saving

data; 48 mADC with backlight on and card saving data

Dimensions of meter 7.99 x 2.99 x 1.50 in. (203 x 76 x 38mm)

Weight of meter 1.13 lb. (515g)

Dimensions of probe 1.46 (length) x 0.63 (diameter) in. (37 x 16mm)

Length of probe cable 47.24 in. (1.2m)

2

, g (gravitational force) or ft/sec2;

2

, 0.05 to 20.39 g,

2

, 0.01 g, 1 ft/sec2; for velocity:

2

@ 160 Hz; for velocity:

11

Page 12

MAINTENANCE & TROUBLESHOOTING TIPS

Keep the vibration probe and cable and the magnetic base clean. Store them in the carrying

case when you are not using the meter.

When the icon appears in the left corner of the display, it’s time to replace the

six “AA” batteries that power the instrument (although measurements will remain valid for

several hours after the low-battery indicator first appears). Replacing the batteries requires

removing the two screws that hold the battery compartment cover in place, as explained in

Step 1 of the setup procedure. After inserting fresh batteries in the correct orientation,

tighten the screws to secure the cover.

If the meter “freezes” (like a computer) and buttons become unresponsive, try resetting the

instrument by pushing the RESET button on its right side (callout 1-11 of Fig. 1) with the

end of a paper clip.

Remove the batteries when storing the meter for an extended period of time.

Do not drop or disassemble the meter or immerse it in water.

OPTIONAL ACCESSORIES

The only optional accessory for the VM8205SD available from General Tools & Instruments

is a 9VDC adapter for a 110V power supply

WARRANTY INFORMATION

General Tools & Instruments’ (General’s) VM8205SD Vibration Meter with Datalogging

SD Card is warranted to the original purchaser to be free from defects in material and

workmanship. Subject to certain restrictions, General will repair or replace this instrument

if, after examination, the company determines it to be defective in material or workmanship

for a period of one year.

This warranty does not apply to damages that General determines to be from an attempted

repair by non-authorized personnel or misuse, alterations, normal wear and tear, or

accidental damage. The defective unit must be returned to General Tools & Instruments or

to a General authorized service center, freight prepaid and insured.

Acceptance of the exclusive repair and replacement remedies described herein is a

condition of the contract for purchase of this product. In no event shall General be liable for

any incidental, special, consequential or punitive damages, or for any cost, attorneys’ fees,

expenses, or losses alleged to be a consequence of any damage due to failure of, or defect

in any product including, but not limited to, any claims for loss of profits.

12

Page 13

RETURN FOR REPAIR POLICY

Every effort has been made to provide you with a reliable product of superior quality.

However, in the event your instrument requires repair, please contact our Customer Service

to obtain an RGA (Return Goods Authorization) number before forwarding the unit via

prepaid freight to the attention of our Service Center at this address:

General Tools & Instruments

80 White Street

New York, NY 10013

212-431-6100

Remember to include a copy of your proof of purchase, your return address, and your

phone number and/or e-mail address.

13

Page 14

NOTES

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

14

Page 15

NOTES

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

15

Page 16

GENERAL TOOLS & INSTRUMENTS

80 White Street

New York, NY 10013-3567

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

VM8205SD User’s Manual

Specifications subject to change without notice

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

©2010 GENERAL TOOLS & INSTRUMENTS

MAN#VM8205SD 12/03/10

Loading...

Loading...