Page 1

RLD382P

USER’S MANUAL

Thank you for purchasing this Refrigerant Leak Detector.

Read through the instruction manual before operation for correct and safe

usage. Please store and retain this instruction manual for future reference.

Refrigerant

Leak Detector

w/Pump

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 1

Page 2

FEATURES:

This Refrigerant Leak Detector is the perfect tool for maintaining airconditioning, or cooling systems with a compressor and refrigerant. This unit

uses a newly developed semi-conductor sensor, which is extremely sensitive

to a wide variety of general refrigerants.

• Microprocessor control with advanced digital signal processing

• Multi-color visual display

• High, Medium, Low - leak sensitivity selector

• Low battery indication

• Semiconductor gas sensor

• Detection of R-134a, R-404A, R-410A, R-407C, R-22 (Freon gas)

• Carrying case included

• 15.5" Flexible stainless probe (394mm)

• Reference leak source included

• Ambient concentration reset

• Long Life, DC Brushless fan

• Automatic Zero and background compensation

SPECIFICATIONS:

DETECTABLE GASES:

• R-134a, R-404A, R-410A, R-407C,R-22 (Freon gas)

SENSITIVITY:

Hi Med Lo

134a, R-22, 3g/year 15g/year 30g/year

R-404A, 407C, 410A 4g/year 20g/year 40g/year

ALARM METHOD:

Buzzer, Tricolor LED bar Indicator

POWER SOURCE:

4 “AA” batteries

FLEXIBLE PROBE LENGTH:

15.5" (394mm)

DIMENSION / WEIGHT:

6.8" H x 2.6" W x 2.2" D (173 x 66 x 56 mm)

Approximately 14.1 oz (400 g)

ACCESSORIES:

4 “AA” batteries, User Manual, Leak Check bottle, carry case

BATTERY LIFE:

Approximately 7 hours normal use

AUTO POWER OFF: 10 minutes

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 2

Page 3

DISABLE AUTO POWER OFF: Press and Hold “Hi” button then power on the

meter.

Warm-Up TIME: Approximately 45 seconds

Operating Temperature & Humidity: 32° to 104°F (0° to 40°C), < 80% RH

STORAGE TEMPERATURE & HUMIDITY:

14° to 140°F (-10° to 60°C), < 70% RH

ALTITUDE:

< 6500' (2000m)

OPERATING GUIDE:

1. The refrigerant leak detector unit is not equipped with anti-explosive

designs and measures. Do not use this unit in the environment with any

burnable gases

2. There are some environmental conditions that might cause error

readings:

• Pollutant places

• Large temperature variation

• Places with high wind velocity

• Organic solvent, adhesive vapor, fuel gas and vesicant will cause an

abnormal response from the sensor. Try to avoid environments affected

by these substances

• Places filled with too much Freon gas

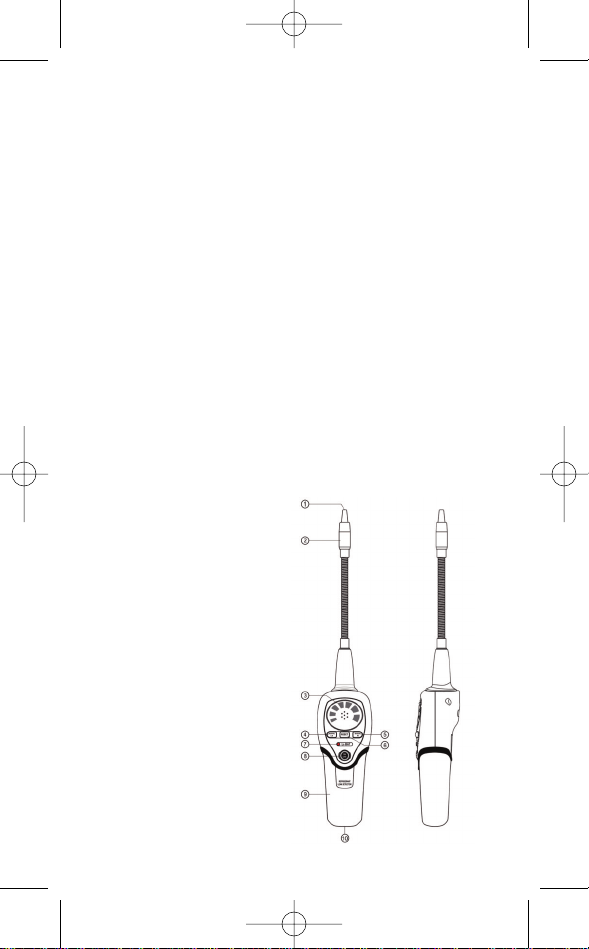

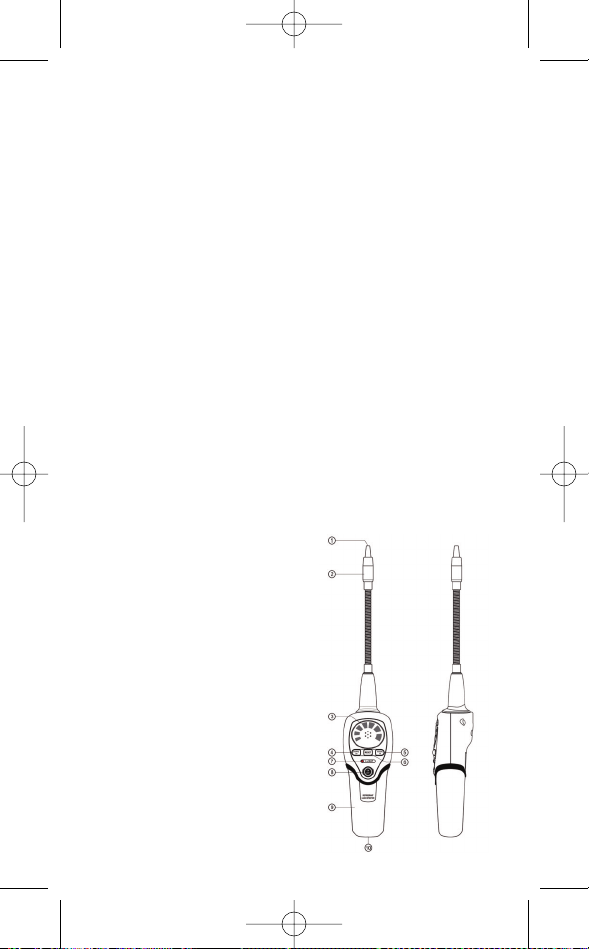

PARTS & CONTROLS:

PANEL DESCRIPTION

1. Sensor Protector

2. Sensor

3. LED Leak Indicators

4. Sensitivity Lo Button

5. Sensitivity Hi Button

6. Reset Button

7. Low Battery Indicator

8. Power ON/OFF

9. Battery Cover

10. Battery Cover Screw

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 3

Page 4

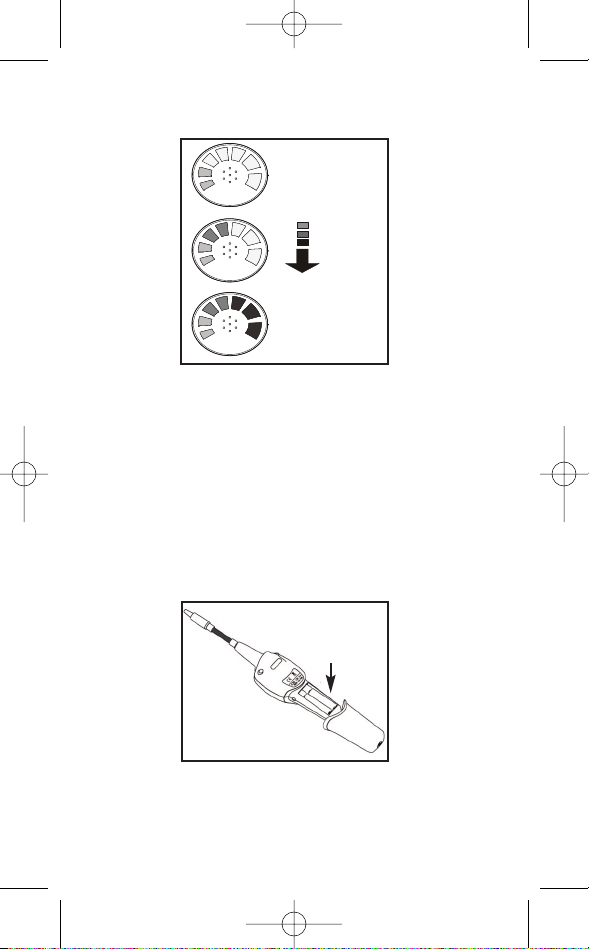

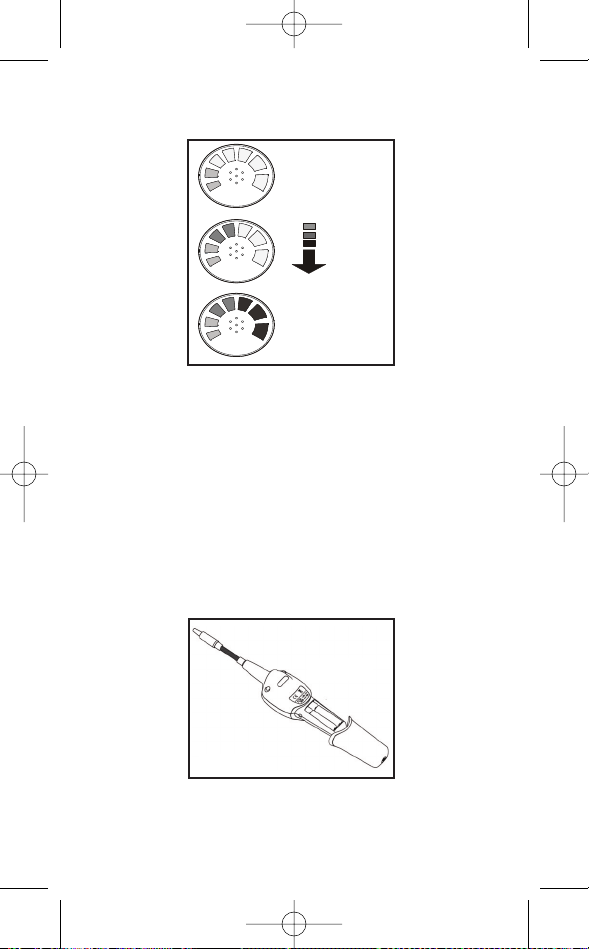

LED LEAK INDICATOR DEFINITION:

GETTING STARTED:

INSTALLING BATTERIES

• Loosen the screw and remove the battery compartment door located on

the bottom of the instrument as shown below (Fig.1).

• Install 4 “AA” batteries.

• Reinstall the battery cover by aligning it with the handle.

When the batteries are nearing the end of their useful life, the Red LED Low

Battery indicator will illuminate. The batteries should be replaced as quickly

as possible.

Base

Concentration

Indication

More

Highest

Concentration

Indication

4 “AA”

batteries

Fig. 1

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 4

Page 5

AUTOMATIC AMBIENT RESET FEATURE:

The Refrigerant leak detector features an Automatic Ambient Reset function

that sets the unit to ignore ambient concentrations of refrigerant.

• Automatic Ambient Setup - Upon initial power on, the unit automatically

sets itself to ignore the level of refrigerant present at the tip. Only a

level, or concentration greater than this will cause an alarm.

CAUTION!

Be aware that this feature will cause the unit to ignore any refrigerant

present at turn on. In other words, with the unit off if you place the tip up to a

known leak and switch the unit on, no leak will be indicated!

• Ambient Reset Feature - Resetting the unit during operation performs a

similar function, it programs the circuit to ignore the level of refrigerant

present at the tip. This allows the user to “home-in” on the source of the

leak (higher concentration). Similarly, the unit can be moved to fresh air

and reset for maximum sensitivity. Resetting the unit with no refrigerant

present (fresh air) causes any level above zero to be detected.

• After the unit is warmed up, the default sensitivity level is set at “High”

and Auto Reset function is “ON”.

• Auto Reset function is best used initially when user is moving around

trying to identify leakage source. Once the leak source is determined,

cancel the Auto Detect function to proceed with leakage measurement.

• Auto Reset function should be turned OFF when use in fixed position

leakage detection.

FEATURE SENSITIVITY ADJUSTMENT:

The instrument provides two levels of sensitivity. When the unit is switched

on, it is set to the high sensitivity level.

• To change the sensitivity, press the “Lo” key. When this key is pressed,

the visual display will momentarily show the two left LED’s (green)

indicating low sensitivity level is selected.

• To switch back to high sensitivity, press the “Hi” key. The two right LED’s

(red) will light momentarily indicating high sensitivity level is selected.

Low Sensitivity Level

(Green LED)

Medium Sensitivity Level

(Orange LED)

High Sensitivity Level

(Red LED)

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 5

Page 6

OPERATING PROCEDURE:

WARNING!

Do not operate this instrument in the presence of gasoline, natural gas,

propane, or in other combustible atmospheres.

• HOW TO FIND LEAKS

NOTE: A sudden whipping of the leak detector probe or “blowing” into the

sensor tip will affect the air flow over the sensor and cause the

instrument to alarm.

(1) POWER-UP KEY:

The “ON/OFF” key turns the Refrigerant Leak Detector instrument ON or OFF

and is also the reset function.

• Press it once to turn on the Refrigerant Leak Detector. The display will

illuminate with flashing for 45 seconds to heat up the sensor.

• Press and hold this button for 5 seconds to turn OFF the power.

(2) AUTO RESET & RESET FUNCTION KEY

When the Auto Reset function is turned ON, the meter will monitor

background status and fine tune itself. When Reset LED light is on, it

indicates it is in ON mode. Press Reset button and hold for 2 seconds the

Reset light will turn off and Auto Reset function is in OFF mode. When the

Reset light is off,it indicates the Reset function is in manual mode. Press the

Reset button once to enable manual Reset function.

(3) VERIFY THE CONDITION OF THE UNIT AND SENSOR:

• Set the sensitivity level to “Hi”.

• Open the Leak Check bottle cover and slowly move it closer to the

flexible stainless probe nozzle.

• The indication should move up to high from low. Then move the check

bottle away and the LED should go off again. This shows that the unit is

in working condition.

• If the unit does not perform as expected, order a new sensor and

batteries from your local supply office.

(4) ENTER THE MEASURING MODE:

• Place the tip of the leak detector probe as close as possible to the site

of the suspected leak. Try to position the probe within 1/4"

(6mm) of the possible leak source.

• Slowly move the probe past each possible leakage point.

• When the instrument detects a leak source, the audible tone will alarm.

Additionally, the visual indicators will light from left to right, Green LED,

then Orange LED, then Red LED (highest concentration) as increase in

level indicates that the location is close to the source.

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 6

Page 7

• When the instrument signals a leakage, pull the probe away from the

leak for a moment, then bring it back to pinpoint the location. If the

refrigerant leak is large, setting the sensitivity switch to “Lo” will make

it easier to find the exact site of the leak.

• Return the sensitivity switch to “Hi” before searching for additional

leaks.

• When you've finished leak-testing, turn OFF the instrument and store it

in a clean place to protect the leak detector from possible damage.

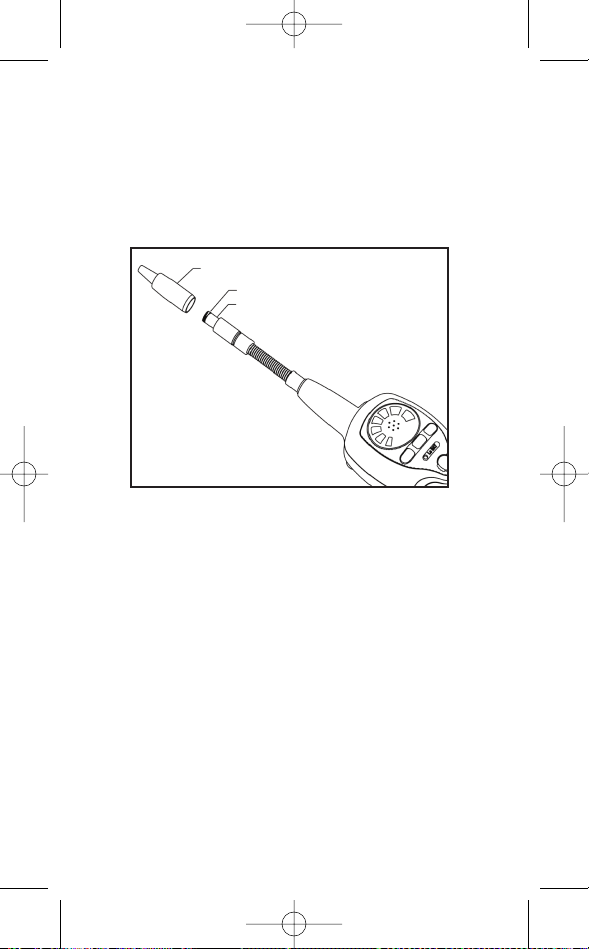

REPLACING A NEW SENSOR:

Under normal operation, the sensor should work for more than one year.

Though, the sensor may experience a limited operative period. Exposing the

sensor to high densities of coolant (>30000ppm) will shorten its life cycle

rapidly. It is important to ensure that the sensor surface is free from water

droplets, vapor, oil, grease, dust and any or all other forms of contaminant.

Furthermore, to ensure good working condition of the unit, a sensor must be

replaced periodically when it’s operative life is over.

WARNING! When replacing a new sensor, the worn-out sensor may be HOT!

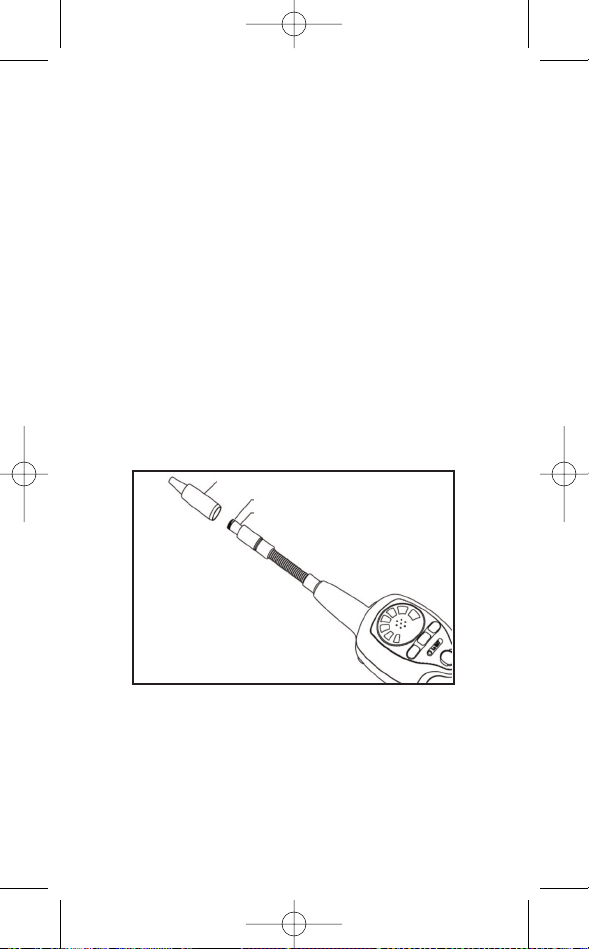

(1) Remove cone cap cover from the tip of flexible probe.

(2) Pull out the old sensor and insert the new sensor into the plug

(see below fig. 2).

(3) Seal the cap cover over the plug.

CLEANING:

The instruments plastic housing can be cleaned with standard household

detergent or isopropyl alcohol. Care should be taken to prevent the cleaner

from entering the instrument. Gasoline and other solvents may damage the

plastic and should be avoided.

WARNING!

Detergent or isopropyl alcohol may damage the sensor. Please avoid contact

with the sensor at all times.

Sensor Protector

Sensor

Fig. 2

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 7

Page 8

RLD382P

MANUAL DEL PROPIETARIO

DETECTOR DE PÉRDIDAS DE REFRIGERANTE CON BOMBA

INFORMACIÓN GENERAL

Gracias por comprar este detector de fugas de refrigerante.

Lea cuidadosamente el manual de instrucciones antes de la operación para

lograr un uso seguro y correcto. Guarde y conserve este manual de

instrucciones para consultarlo en el futuro.

CARACTERÍSTICAS:

Este detector de fugas de refrigerante es la herramienta perfecta para dar

mantenimiento a sistemas de aire acondicionado o refrigeración con

compresor y refrigerante. La unidad usa un sensor semiconductor creado

recientemente, que es extremadamente sensible a una amplia variedad de

refrigerantes de uso general.

• Control por microprocesador con procesamiento de señal digital

• Visualización a colores

• Selector de sensibilidad de pérdida alta, media, baja

• Indicación de pila baja • Sensor de gas con semiconductor

• Detección de R-134a, R-404A, R-410A, R-407C, R-22 (gas freón)

• Estuche incluido • Sonda flexible de acero inoxidable de 394mm (15.5")

• Se incluye fuente de fuga de referencia

• Restablecimiento de concentración ambiental

• Ventilador de CC sin escobillas, de larga vida

• Compensación automática de cero y de fondo

ESPECIFICACIONES:

GASES DETECTABLES:

• R-134a, R-404A, R-410A, R-407C, R-22 (gas freón)

SENSIBILIDAD:

Alta Media Baja

134a, R-22, 3 g/año 15 g/año 30 g/año

R-404A, 407C, 410A 4 g/año 20 g/año 40 g/año

MÉTODO DE ALARMA

Zumbador, indicador de barra LED de tres colores

CONSUMO DE ENERGÍA

4 pilas tamaño “AA” (6V CD)

Longitud de la sonda flexible: 394mm (15.5")

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 8

Page 9

DIMENSIONES / PESO:

6.8" alto x 2.6" ancho x 2.2" profundidad. Aproximadamente 14.1 onzas

(173 x 66 x 56 mm) aproximadamente (400 g)

ACCESORIOS: 4 pilas “AA”, manual del usuario, botella de comprobación

de fugas, estuche

VIDA DE LA PILA: Aproximadamente 7 horas de uso normal

APAGADO AUTOMÁTICO: 10 minutos

DESACTIVACIÓN DEL APAGADO AUTOMÁTICO: Mantenga presionado el botón

“Hi” cuando enciende el medidor.

TIEMPO DE CALENTAMIENTO:Aproximadamente 45 segundos

TEMPERATURA Y HUMEDAD DE OPERACIÓN:

32° a 104°F (0° a 40°C), < 80% HR

TEMPERATURA Y HUMEDAD DE ALMACENAMIENTO:

14° a 140°F (-10° a 60°C), < 70% HR

ALTURA SOBRE EL NIVEL DEL MAR: < 6500 pies (2000 m)

GUÍA DE OPERACIÓN

(1) La unidad del detector de fugas de refrigerante no está equipada con

diseños y medidas contra explosión. No use esta unidad si en el

ambiente hay gases combustibles.

(2) Hay ciertas condiciones ambientales que podrían causar lecturas

erróneas:

• Lugares con contaminantes.

• Grandes variaciones de temperatura.

• Lugares con alta velocidad del viento.

• Los disolventes orgánicos, el vapor adhesivo, el gas combustible y los

agentes vesicantes causarán una respuesta anormal del sensor. Trate de

evitar los entornos afectados por estas sustancias.

• Lugares llenos con exceso de gas freón.

PIEZAS Y CONTROLES:

DIBUJOS Y CONTROL

DESCRIPCIÓN DEL PANEL

1. Protector del sensor

2. Sensor

3. LEDs indicadores de pérdida

4. Botón de sensibilidad baja

5. Botón de sensibilidad alta

6. Botón de reajuste

7. Indicador de pila baja

8. Botón de ENCENDIDO/APAGADO

9. Cubierta para las pilas

10. Tornillo para la cubierta de las pilas

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 9

Page 10

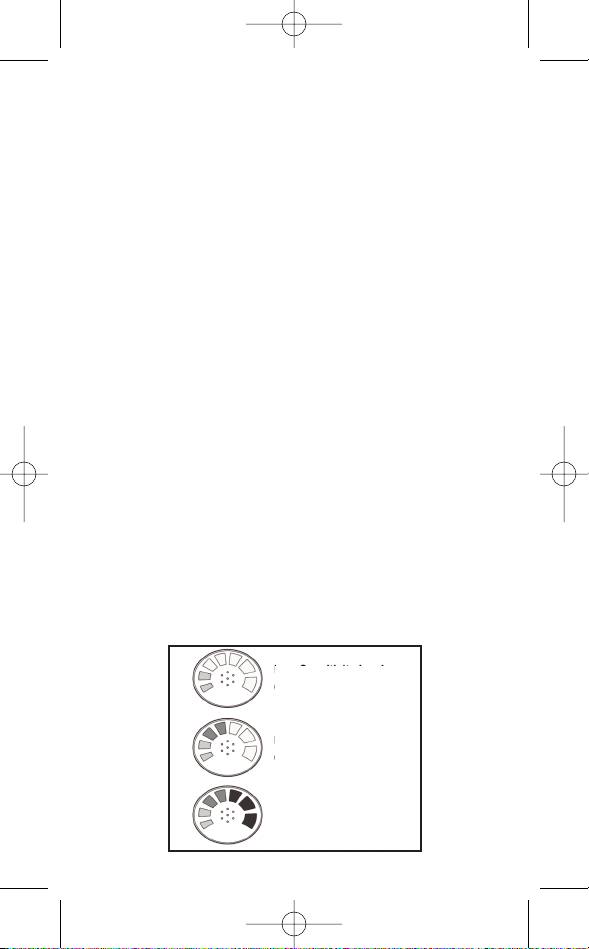

DEFINICIÓN DEL INDICADOR LED DE FUGA:

PARA EMPEZAR:

CÓMO INSTALAR LAS PILAS

• Afloje el tornillo y retire la puerta del compartimiento de las pilas

ubicado en la parte inferior del instrumento como se muestra a

continuación (figura 1).

• Instale 4 pilas “AA”.

• Vuelva a instalar la cubierta de las pilas y alinéela con el mango.

Cuando las pilas se están acercando al final de su vida útil el LED rojo que

funciona como Indicador de pila baja se iluminará. Se deberá reemplazar las

pilas tan pronto como sea posible.

Indicación de

concentración

base

Más

Indicación de

concentración

más alta

4 pilas “AA”

Fig. 1

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 10

Page 11

FUNCIÓN DE RESTABLECIMIENTO AMBIENTAL AUTOMÁTICO:

El detector de fugas de refrigerante presenta una función de restablecimiento

ambiental automático que ajusta la unidad para que ignore las

concentraciones ambientales de refrigerante.

• Ajuste ambiental automático - Al encender el detector, la unidad se

ajusta automáticamente para ignorar el nivel de refrigerante presente

en la punta. Sólo un nivel o concentración mayor desencadenarán una

alarma.

¡PRECAUCIÓN!

Tenga en mente que esta función hará que la unidad ignore el refrigerante

presente al encenderse. En otras palabras, con la unidad apagada si se

acerca la punta a una fuga conocida y se enciende el interruptor, no se

indicará una fuga.

• Función de restablecimiento ambiental - Restablecer la unidad mientras

está funcionado ejecuta una función similar: programa el circuito para

ignorar el nivel de refrigerante presente en la punta. Esto permite al

usuario encontrar más fácilmente la fuente de la fuga (una

concentración mayor). De manera semejante, la unidad se puede mover

a un sitio con aire fresco y restablecerse ahí para lograr la máxima

sensibilidad. Al restablecer la unidad sin que haya refrigerante presente

(aire fresco) hace que se detecte cualquier nivel por encima de cero.

• Luego de que la unidad se haya calentado, el nivel inicial de sensibilidad

será “High” (alto) y la función de reinicio automático estará activada.

• La función de reinicio automático se aprovecha mejor al principio,

cuando el usuario se mueve tratando de identificar el origen de la

pérdida. Una vez que se haya determinado el origen de la pérdida,

desactive la función de detección automática y proceda con la medición

de la pérdida.

• La función de reinicio automático debe desactivarse al usarlo en una

posición fija para detectar pérdidas.

FUNCIÓN DE AJUSTE DE SENSIBILIDAD:

El instrumento ofrece dos niveles de sensibilidad. Cuando la unidad se

enciende, se ajusta al nivel de sensibilidad alto.

• Para cambiar la sensibilidad, oprima la tecla “Lo” (bajo). Cuando se

oprime esta tecla, se encenderán momentáneamente los dos LED de la

izquierda (verdes), indicando que se seleccionó el nivel de sensibilidad

bajo.

• Para volver a la sensibilidad alta, oprima la tecla “Hi” (alto). Los dos LED

de la derecha (rojos) se encenderán momentáneamente para indicar que

se seleccionó el nivel de sensibilidad alto.

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 11

Page 12

PROCEDIMIENTO DE OPERACIÓN:

¡ADVERTENCIA!

No opere este instrumento en presencia de gasolina, gas natural, propano,

u otras atmósferas combustibles.

• CÓMO ENCONTRAR FUGAS

NOTA: Si se hace un movimiento repentino de la sonda del detector de fugas

o se “sopla” en la punta del sensor se alterará el flujo de aire sobre el sensor

y provocará que el instrumento emita una alarma.

(1) TECLA DE ENCENDIDO:

La tecla “ON/OFF” enciende o apaga el detector de fugas de refrigerante y es

también la función de restablecimiento.

• Oprímala una vez para encender el detector de fugas de refrigerante.

Los LED se encenderán y destellarán durante 45 segundos y medio para

calentar el sensor.

• Oprima y sostenga este botón durante 5 segundos para apagar.

(2) TECLA DE REINICIO AUTOMÁTICO Y FUNCIÓN DE

REINICIO

Cuando se activa la función de reinicio automático, el medidor comenzará a

monitorear el estado de fondo y se ajustará automáticamente para

compensarlo. Cuando el LED de reinicio está encendido, indica que está

activado. Mantenga presionado el botón de reinicio durante 2 segundos y la

luz de reinicio se apagará indicando que la función de reinicio automático

está desactivada. Cuando la luz de reinicio está apagada, indica que la

función de reinicio se encuentra en modo manual. Presione una vez el botón

de reinicio para activar la función de reinicio manual.

Nivel de sensibilidad

bajo (LED verde)

Nivel de sensibilidad

medio (LED naranja)

Nivel de sensibilidad

alto (LED rojo)

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 12

Page 13

3) VERIFIQUE EL ESTADO DE LA UNIDAD Y DEL SENSOR:

• Ajuste el nivel de sensibilidad a “Hi” (Alto).

• Destape la botella de comprobación de fugas y acérquela lentamente

a la boquilla de la sonda de acero inoxidable.

• La indicación deberá subir de bajo a alto. Luego aleje la botella de

comprobación y el LED deberá volver a apagarse. Esto demuestra que

la unidad está funcionando.

• Si la unidad no está funcionando de forma esperada, pida a su

proveedor local un nuevo sensor y pilas. .

(4) ENTRE AL MODO DE MEDICIÓN:

• Ponga la punta de la sonda detectora de fugas tan cerca como sea

posible de la posible fuga. Trate de colocar la sonda a menos de 1/4"

(6 mm) de la posible fuente de fuga.

• Mueva lentamente la sonda junto a cada posible punto de fuga.

• Cuando el instrumento detecte una fuente de fuga, sonará una alarma.

Además, los indicadores visuales se encenderán de izquierda a derecha,

el LED verde, luego el naranja, después el rojo (concentración más alta),

ya que un aumento en el nivel indica la cercanía a la fuente.

• Cuando el instrumento indique una fuga, retire la sonda de la fuga un

momento y luego devuélvala para encontrar la ubicación exacta. Si la

fuga de refrigerante es grande, mover el interruptor de sensibilidad a

“Lo” (bajo) hará que sea más fácil encontrar el sitio exacto de la fuga.

• Devuelva el interruptor de sensibilidad a “Hi” (alto) antes de buscar

fugas adicionales.

• Cuando haya terminado de buscar fugas, apague el instrumento y

guárdelo en un sitio limpio para proteger el detector de fugas de

posibles daños.

CÓMO INSTALAR UN SENSOR NUEVO:

En condiciones de operación normales, el sensor funcionará más de un año.

Sin embargo, el sensor puede tener un periodo de operación limitado.

Exponer el sensor a altas densidades de refrigerante (>30000 ppm) acortará

su ciclo de vida más rápidamente. Es importante asegurarse de que la

superficie del sensor no tenga gotas de agua, vapor, aceite, grasa, polvo o

cualquier otra forma de contaminación. Además, para garantizar un buen

funcionamiento de la unidad, se debe reemplazar el sensor cuando termine

su vida útil.

¡ADVERTENCIA! ¡Cuando instale un sensor nuevo, puede que el sensor usado

esté CALIENTE!

(1) Retire la cubierta de la tapa cónica de la punta de la sonda flexible.

(2) Retire el sensor viejo e inserte el sensor nuevo en el enchufe (ver

figura 2, abajo).

(3) Selle la cubierta de la tapa sobre el enchufe.

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 13

Page 14

LIMPIEZA:

La caja de plástico del instrumento se puede limpiar con detergente

doméstico estándar o con alcohol isopropílico. Se deberá tener cuidado para

evitar que el limpiador entre al instrumento. La gasolina y otros disolventes

pueden dañar el plástico, por lo tanto se deberán evitar.

¡ADVERTENCIA!

El detergente o el alcohol isopropílico pueden dañar el sensor. Evite en todo

momento el contacto con el sensor.

Protector del sensor

Sensor

Fig. 2

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 14

Page 15

RLD380L

MODE D’EMPLOI

DÉTECTEUR DE FUITE DE FLUIDE FRIGORIGÈNE AVEC

POMPE

GÉNÉRALITÉS

Merci d’avoir acheté ce détecteur de fuite de réfrigérant.

Pour assurer un usage correct et sans danger, lire tout le mode d’emploi

avant utilisation. Veiller à conserver ce manuel pour toute consultation

ultérieure.

FONCTIONS :

Ce détecteur de fuite de réfrigérant est l’outil idéal pour l’entretien de

systèmes de climatisation ou de réfrigération à compresseur et fluide

réfrigérant. Cet appareil comporte un capteur à semi-conducteur de

conception nouvelle qui est extrêmement sensible à une grande variété de

fluides réfrigérants courants.

• Commande par microprocesseur avec traitement de signal numérique

évolué

• Affichage visuel couleur

• Sélecteur de sensibilité aux fuites élevé, moyen ou faible

• Indication de décharge des piles • Capteur de gaz à semi-conducteur

• Détection de R-134a, R-404A, R-410A, R-407C, R-22 (Fréon gazeux)

• Fourni avec étui de transport

• Sonde inoxydable souple de 394mm (15.5 po)

• Fourni avec une source de fuite de référence

• Réinitialisation de la concentration ambiante

• Ventilateur sans balai CD de longue durée

• Zéro automatique et compensation de l’arrière-plan

CARACTÉRISTIQUES :

GAZ DÉTECTABLES :

• R-134a, R-404A, R-410A, R-407C, R-22 (Fréon gazeux)

SENSIBILITÉ :

Haute Milieu Basse

134a, R-22, 3 g/an 15 g/an 30 g/an

R-404A, 407C, 410A 4 g/an 20 g/an 40 g/an

MÉTHODE D’ALARME :

Ronfleur, indicateur à voyants tricolores

ALIMENTATION ÉLECTRIQUE :

4 piles de format « AA » (6 V DC)

Longueur de la sonde flexible : 394mm (15.5 po)

DIMENSIONS / POIDS : (HxLxP) 173 mm x 66 mm x 56 mm. 400 g environ

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 15

Page 16

ACCESSOIRES :

4 piles AA, Mode d’emploi, flacon de contrôle de fuite, étui de transport

AUTONOMIE DES PILES : 7 heures d’utilisation normale environ

ARRÊT AUTO : 10 minutes

DÉSACTIVER LA FERMETURE AUTOMATIQUE Appuyez et tenez enfoncé le

bouton d'alimentation « Hi » sur l’instrument de mesure.

DURÉE DE PRÉCHAUFFAGE : 45 secondes environ

TEMPÉRATURE ET HUMIDITÉ D’EXPLOITATION :

0 à 40°C (32 à 104°F), < 80% HR

TEMPÉRATURE ET HUMIDITÉ D’ENTREPOSAGE :

-10 à 60°C (14 à 140°F), < 70% HR

ALTITUDE : < 2000 m

GUIDE D’UTILISATION :

(1) Le détecteur de fuite de réfrigérant n’est pas conçu ni équipé pour être

antidéflagrant. Ne pas utiliser cet appareil dans un milieu contenant

des gaz combustibles.

(2) Diverses conditions ambiantes peuvent causer des erreurs de mesure :

• Présence de polluants.

• Grande variation de température.

• Présence de vent fort.

• Les solvants organiques, vapeurs d’adhésif, carburants gazeux et

vésicants produisent une réponse anormale du capteur. Veiller à éviter

les milieux présentant de telles substances.

• Milieux présentant une teneur élevée en Fréon gazeux.

PIÈCES ET COMMANDES :

DESCRIPTION DE LA FAÇADE

1. Protège-capteur

2. Capteur

3. Indicateurs de fuite à DEL

4. Bouton basse sensibilité

5. Bouton haute sensibilité

6. Bouton de remise

7. Indicateur de décharge des piles

8. Bouton de marche/arrêt

9. Couvercle des piles

10. Vis du couvercle des piles

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 16

Page 17

INDICATIONS DES VOYANTS DE FUITE :

POUR DÉMARRER :

MISE EN PLACE DES PILES

• Desserrer la vis et enlever le couvercle du compartiment des piles situé

au bas de l'appareil, comme représenté ci-dessous (Fig.1).

• Placer 4 piles AA.

• Remettre le couvercle des piles en place en l’alignant avec la poignée.

Lorsque les piles arrivent à la fin de leur durée utile, le voyant de décharge

des piles rouge s’allume. Les piles doivent alors être changées dans les plus

brefs délais.

Indication de la

concentration

de base

Plus

Indication de la

concentration la

plus élevée

4 piles AA

Fig. 1

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 17

Page 18

FONCTION DE RÉINITIALISATION AMBIANTE

AUTOMATIQUE :

Le détecteur de fuite de réfrigérant comporte une fonction de réinitialisation

ambiante automatique, qui règle l’appareil de manière à ignorer les

concentrations ambiantes de réfrigérant.

• Configuration de la fonction ambiante automatique – Lors de la mise

sous tension, l’appareil se règle automatiquement pour ignorer la

concentration en réfrigérant au niveau de l’embout. Seul une teneur ou

concentration plus élevée déclenchera une alarme.

ATTENTION !

Garder à l’esprit que cette fonction amène l’appareil à ignorer tout réfrigérant

présent à la mise sous tension. En d’autres termes, si l’embout de l’appareil

éteint est placé à côté d’une fuite connue puis que l’appareil est mis en

marche, aucune fuite ne sera signalée !

• Fonction de réinitialisation ambiante – La réinitialisation de l’appareil

durant la marche remplit une fonction semblable, en programmant le

système pour qu’il ignore la concentration de réfrigérant présente au

niveau de l’embout. Ceci permet de se diriger progressivement jusqu’à

la source de la fuite (concentration plus élevée). Pareillement, l’appareil

peut être amené à l’air frais et réinitialisé pour offrir une sensibilité

maximum. La réinitialisation de l’appareil en l’absence de tout

réfrigérant (air frais) permet la détection de toute concentration audessus de zéro.

• Après que l’unité soit réchauffée, le niveau de sensibilité par défaut est

réglé à « Élevé » et la fonction de réinitialisation automatique est en

marche.

• La fonction de réinitialisation automatique est utilisée initialement

lorsque l'utilisateur se déplace et tente de localiser la source de la fuite.

Une fois que la source de la fuite est déterminée, annulez la fonction de

réinitialisation automatique afin de procéder à la mesure de la fuite.

• La fonction de réinitialisation automatique devrait être arrêtée lors de la

détection d’une fuite à un emplacement fixe.

RÉGLAGE DE LA SENSIBILITÉ :

Cet appareil offre deux niveaux de sensibilité. À la mise en marche, il se règle

sur le niveau de sensibilité élevé.

• Pour changer la sensibilité, appuyer sur la touche « Lo ». Lorsque cette

touche est enfoncée, les deux voyants de gauche (verts) s’allument

brièvement pour indiquer que la basse sensibilité est sélectionnée.

• Pour revenir à la haute sensibilité, appuyer sur la touche « Hi ». Les deux

voyants de droite (rouges) s’allument brièvement pour indiquer que la

haute sensibilité est sélectionnée.

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 18

Page 19

PROCÉDURE D’UTILISATION :

AVERTISSEMENT !

Ne pas utiliser cet appareil en présence d’essence, de gaz naturel, de

propane ou autre atmosphère combustible.

• COMMENT DÉTECTER DES FUITES

REMARQUE : Le fouettement soudain de la sonde de détection de fuite ou le

fait de souffler dans l’embout du capteur modifie l’écoulement d’air sur le

capteur et peut déclencher l’alarme de l’appareil.

(1) TOUCHE D’ALIMENTATION :

La touche « ON/OFF » commande la mise en marche et d'arrêt du détecteur

de fuite de réfrigérant, ainsi que la fonction de réinitialisation.

• Appuyer une fois pour mettre le détecteur de fuite de réfrigérant en

marche. L’afficheur clignote pendant 45 seconds et demi durant le

préchauffage du capteur.

• Tenir la touche enfoncée pendant 5 secondes pour éteindre l’appareil.

(2) TOUCHE DE RÉINITIALISATION AUTOMATIQUE ET DE

RÉINITIALISATION

Lorsque la fonction de réinitialisation automatique est mise en marche,

l’appareil de mesure va surveiller l’état de l’arrière-plan et s’ajustera luimême. Lorsque la lumière DEL de réinitialisation est en marche, ceci indique

qu’elle est en mode de fonctionnement. Appuyez sur le bouton de

réinitialisation et tenez-le enfoncé pendant 2 secondes et la lumière de

réinitialisation va se fermer et le mode de réinitialisation automatique sera

arrêté. Lorsque la lumière de réinitialisation est arrêtée, ceci indique que la

fonction de réinitialisation est en mode manuel. Appuyez sur le bouton de

réinitialisation une fois afin d'activer la fonction de réinitialisation.

Niveau de sensibilité

faible (DEL verte)

Niveau de sensibilité

moyen (DEL orange)

Niveau de sensibilité

élevé (DEL rouge)

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 19

Page 20

(3) VÉRIFIER L’ÉTAT DE L’APPAREIL ET DU CAPTEUR :

• Régler le niveau de sensibilité sur « Hi ».

• Ouvrir le capuchon du flacon de contrôle de fuite et le rapprocher

lentement de l’embout de la sonde flexible.

• L’affichage doit passer du niveau faible au niveau élevé. Éloigner ensuite

le flacon de contrôle et l’affichage doit revenir à zéro. Ceci montre que

l’appareil est en bon état de marche.

• Si l’appareil ne fonctionne pas comme prévu, commander un capteur

neuf et des piles auprès du fournisseur local.

(4) PASSER EN MODE DE MESURE :

• Placer l’embout de la sonde de détection de fuite aussi près que

possible de l’emplacement de la fuite supposée. Essayer de placer la

sonde à moins de 6 mm de la source de fuite potentielle.

• Passer lentement la sonde devant chaque point de fuite possible.

• Lorsque l’appareil détecte une source de fuite, l’alarme sonore se

déclenche. Par ailleurs, les indicateurs visuels s’allument de la gauche

vers la droite, les voyants verts, puis les voyants orange et enfin les

voyants rouges (concentration la plus élevée), à mesure de

l’augmentation de niveau pour indiquer que l’appareil se rapproche de la

source.

• Lorsque l’appareil signale une fuite, éloigner la sonde de la fuite

pendant quelques instants, puis la ramener pour repérer l’emplacement

exact. Si la fuite de réfrigérant est importante, régler la sensibilité sur «

Lo » pour faciliter la localisation exact de la fuite.

• Remettre la sensibilité sur « Hi » avant de rechercher d’autres fuites.

• Une fois le contrôle de fuites terminé, éteindre l’appareil et le ranger

dans un endroit propre de manière à protéger le détecteur contre les

dommages potentiels.

REMPLACEMENT DU CAPTEUR NEUF :

Dans des conditions normales d’utilisation, le capteur doit fonctionner

pendant plus d’un an. Toutefois, il est possible que sa durée utile soit plus

limitée. L’exposition du capteur à de fortes densités de réfrigérant (> 30000

ppm) réduit rapidement sa durée utile. Il est important de s’assurer que la

surface du capteur soit exempte de gouttelettes d’eau, vapeur, huile, graisse,

poussière et autres contaminants. De plus, pour assurer un bon état de

marche de l’appareil, le capteur doit être changé régulièrement, à l’expiration

de sa durée utile.

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 20

Page 21

AVERTISSEMENT ! Lors du remplacement du capteur neuf, le capteur usagé

peut être CHAUD !!

(1) Déposer le capuchon conique de l’embout de la sonde flexible.

(2) Extraire le capteur usagé et introduire le capteur neuf dans la fiche

(voir Fig. 2 ci-dessous).

(3) Remettre le capuchon sur l’embout.

NETTOYAGE :

Le boîtier en plastique de cet appareil se nettoie avec un détergent ménager

courant ou avec de l’alcool isopropylique. Prendre soin de ne pas laisser de

produit nettoyant pénétrer dans l’appareil. L’essence et autres solvants

peuvent endommager le plastique et doivent être évités.

AVERTISSEMENT !

Les détergents et l’alcool isopropylique peuvent endommager le capteur.

Veiller à éviter tout contact avec le capteur.

Protège-capteur

Capteur

Fig. 2

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 21

Page 22

NOTES

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 22

Page 23

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 23

Page 24

GENERAL TOOLS & INSTRUMENTS

™

80 White Street, New York,NY10013

-

3567

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

RLD382P User’s Manual

Specifications subject to change without notice

©2008 GENERAL TOOLS & INSTRUMENTS

™

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

MAN#RLD382P 7/08

RLD382P Manual -6P-071008:RLD382P 7/10/08 11:32 AM Page 24

Loading...

Loading...