Page 1

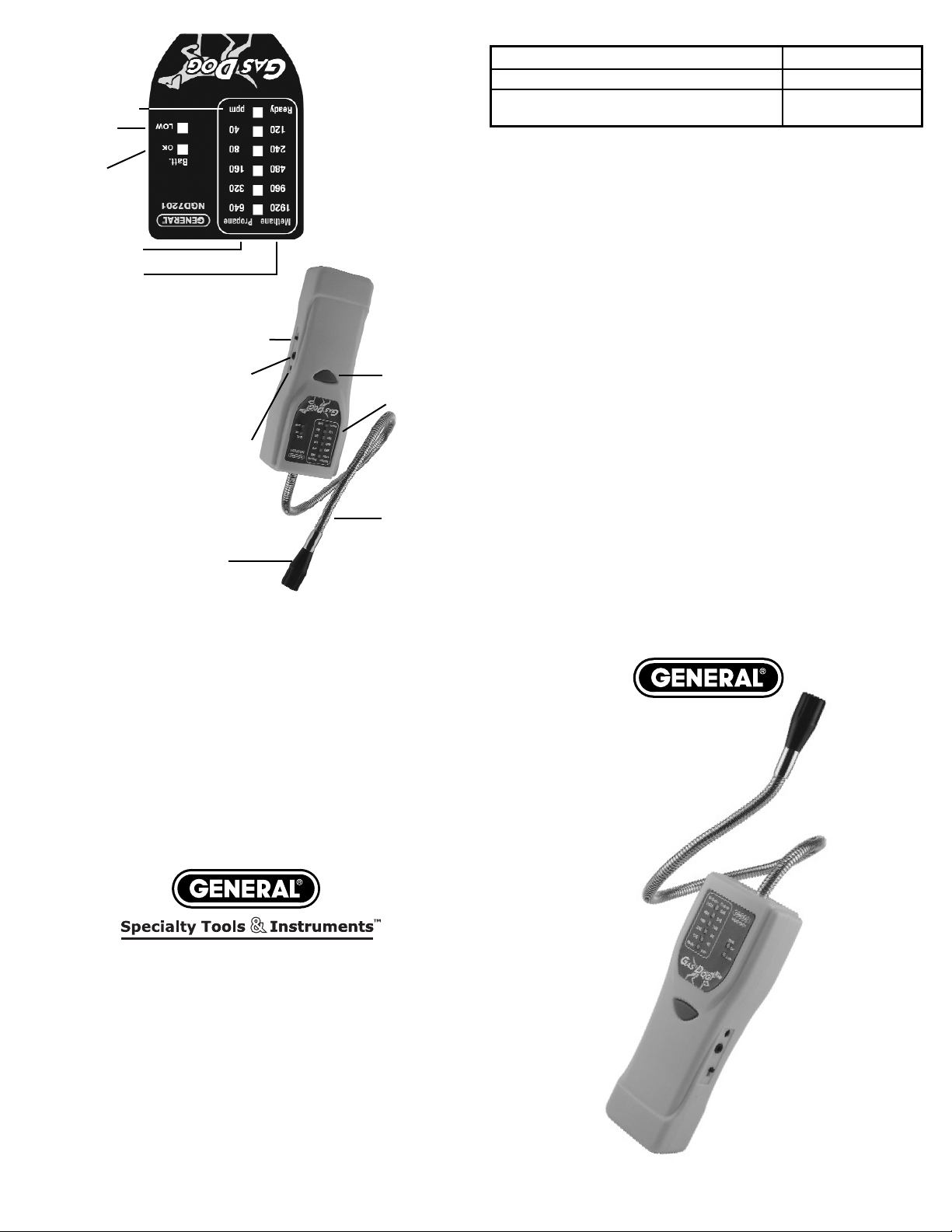

Sensor Cap

Flexible Probe

Indicator LED

“ON/OFF” Key

Earphone Jack

(Dia.: 3.5 mm)

Adaptor Jack

(Dia. outer: 4 mm/

inner: 1.3 mm)

Mute Slide Switch

Propane 5 level LED

Power “ON” &

Batt. “OK” LED

Batt. “LOW” LED

Sensor “Ready” LED

Methane 5 level LED

NGD7201

USER’S MANUAL

GAS LEAK DETECTOR

GENERAL TOOLS & INSTRUMENTS

™

80 White Street

New York, NY 10013-3567

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

NGD7201 User’s Manual

Specifications subject to change

without notice

©2008 GENERAL TOOLS & INSTRUMENTS

™

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

MAN#NGD7201 05/08

This latest handheld gas leak detector features the following functions:

FFEEAATTUURREESS::

• Detects methane and propane gas

• Quickly pinpoint gas leaks

• Automatically calibrate when power is on

• Auto power off to save battery life

• 60 seconds warm-up time

• Response Time less than 10 seconds

• 5 level LED leak alarm

• Over 440 mm long flexible probe

• Built in earphone jack

• Mute function

SS PPEECCIIFFIICCAATTII OONNSS::

• Sensor: Semiconductor

• Response Time: < 10 seconds

• Warm-up Time: < 60 seconds

• Operation Temp. Range: -5° to 45°C

• Power OFF: 10 minutes from power on

• Power Source: 4 “AA” batteries (alkaline suggested) or “9V” adaptor

• Battery Life: 14 hours (continuous)

• Minimum battery voltage: 4.8V

• Probe Length: 17.5" (447 mm)

• Size: 6.9" x 2.8" x 1.5" (175 x 70 x 38 mm)

• Indicator: Intermittent beep (Acoustic) / LED (Visual)

SS PPEECCIIFFIICCAATTIIOONN TTAABBLLEE::

DDIIAAGGRRAAMM::

IINNDDIICCAATTOORR::

Please be reminded

that the left methane

number isn't equal

to the right propane

number.

So, make sure what

gas you measured,

then read the correct

corresponding

side value.

Range

Sensitivity

Advantage

Methane: 120 to 1920 ppm

Propane: 40 to 640 ppm

40 ppm (Propane)

Filter included for high discrimination

Page 2

MMEEAASSUURREEMM EE NNTT OOPPEERR AATTIIOONN::

1.

Power ON/OFF

Press the “ON/OFF” key for more than 0.2 second to turn

the meter on. While the meter is on and there is enough

electrical power the Batt. “OK” LED will stay on.

To ensure the accuracy, users must perform the

warm-up period in clean air.

Press the “ON/OFF” key again to turn the meter off.

The meter automatically turns off in 10 minutes.

2.

Warm-up Status

While the meter is powered on but “Ready” LED is off,

it means the sensor is under warm-up process. The warm-up

time is less than 60 seconds. While “Ready” LED is on,

it means the meter is ready to measure.

During this phase, a special compensating circuit automatically

limits the effect of environmental change.

Even when you turn the meter off for a short time and turn it

back on again, it always needs 60 seconds to warm up.

3.

Mute function

The meter beeps every one second to ensure the meter is

in normal working status. The “beep” frequency will speed up

as the detected gas concentration becomes higher.

When the user uses the earphone, the meter will

automatically mute, but the user can hear the

beeping through the earphone.

When the user is not using the earphone, the user can mute the

beeping by switching the mute to the “ON” position.

4.

Leakage Checking

Move the sensor toward the pipe, slowly sliding the sensor

along the pipe. Repeat the procedure on the other side

of the pipe. When the sensor is near a leak, the LED

will light up and the beep frequency will increase.

It takes at least 2 minutes of waiting for the sensor to recover

after removing the sensor from the leak point.

BBAATTTTEERRYY RREEPPLLAACCEEMMEENNTT::

When the battery “LOW” LED is on, it is suggested to change

the batteries to ensure the units accuracy. Open the battery

compartment of the meter on the rear side and replace

with 4 “AA” batteries.

TTRROOUUBBLLEESSHHOOOO TTIINNGG ::

Meter does not turn on

a)

Make sure the time of pressing the “ON/OFF” key

is more than 200 mS.

b)

Check that the batteries are in place,

with good contact and correct polarity.

c)

Replace with a new battery and try again.

“Ready”LED isn’t on after 60 seconds warm-up

a)

Check that the sensor is making good contact.

MMAAIINNTT EE NNAANNCCEE::

1.

If silicone vapors settle onto the sensor’s surface,

the sensor will be coated. So, avoid exposure where

silicone adhesives, hair grooming materials and silicone

rubber/putty may be present.

2.

High-density exposure to corrosive materials such as

H2S, SOx, Cl2, HCl, etc. may cause corrosion or

breakage of the lead wires or heater material.

3.

Sensor drift may occur when the sensor is contaminated

by alkaline metals, especially salt water sprays.

4.

Sensor drift may occur due to soaking or splashing

the sensor with water.

5.

If water freezes on the sensing surface, the sensor

may crack and alter characteristics.

6.

This meter is required to operate under around 21%

ambient oxygen environment in order to function

properly. This meter cannot work well in a zero

or low oxygen atmosphere.

Situations which must be avoided

1.

Light condensation under indoor usage should

not be a problem for the sensor. However, if water

condenses on the sensor’s surface for a while,

the sensor characteristics may still drift.

2.

Sensor performance may be also affected if exposed

to a high density gas for a long time, regardless

of the powering condition.

3.

When meter is off for a long time, the sensor

may show a drift in resistance according to

the storage environment. So, the meter should

be stored in a sealed bag with clean air.

NOTE:

While the unpowered time becomes longer,

a longer warm-up period is required to stabilize

the sensor before usage. Turn on the meter occasionally

to make the accumulative warm-up time shorter.

4.

Regardless of the powering condition, if the sensor

is exposed to extreme conditions such as very

high humidity, extreme temperatures or high

contamination levels for a long period of time,

the sensor performance will be adversely affected.

Loading...

Loading...