Page 1

MSV350D

USER’S MANUAL

DIGITAL 3-IN-1

STUD/VOLTAGE/METAL

DETECTOR

This digital 3-In-1 Stud/Volt/Metal Detector is

an unique instrument combining 3 tools in one

unit. It detects wood studs, metal studs, objects

carrying voltage, metal pipes and conduits

behind walls, floors and ceilings. By employing

the latest CPU technology, it will give an

accurate visual reading shown on the LCD

screen along with an audio signal. Ideal for the

Professional Technician, Handyman, Homeowner,

and Hobbyist.

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 1

Page 2

2

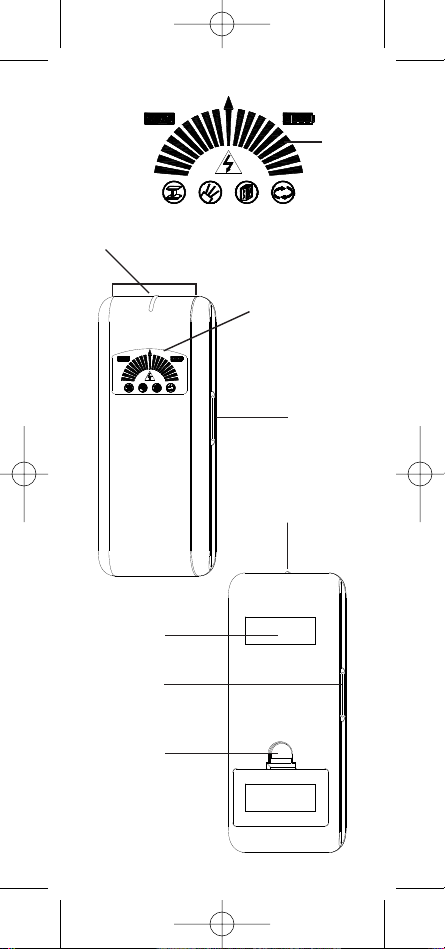

DESCRIPTION

1. Metal/Voltage Sensor Location

2. Marking Hole for Stud Edge

3. LCD Screen

4. Power & Function Selector Switch

5. Scan Switch

6. “SCAN” Symbol (This icon will appear when

calibration is completed)

7. Scanning Indicators (Full scale reading will

display when a target is being detected)

8. Battery Level Indicator

9. Metal Symbol (This icon will appear when

metal detector is being used or when metal

object is detected when auto mode is

selected)

10. Voltage Symbol & Warning Indicator (These

icons will appear when voltage detector is

being used or when voltage is detected

during auto mode)

11. Stud Symbol (This icon will appear when

stud detector is being used or when a stud

edge is detected during the auto mode

selection)

12. Auto Mode (This icon will appear when

performing metal, voltage and stud

detections simultaneously)

13. Stud Sensor Location

14. Battery Cover

OPERATING INSTRUCTIONS

BATTERY INSTALLATION

This unit is operated by one “9V” battery which is

not included.

• Slide open the battery cover on the back of the

instrument

• Attach the battery to the battery connector and

insert it into the battery compartment.

• Slide the battery cover back into place.

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 2

Page 3

3

9

10 11 12

6

8

7

2

3

5

13

14

4

FRONT

BACK

2

1

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 3

Page 4

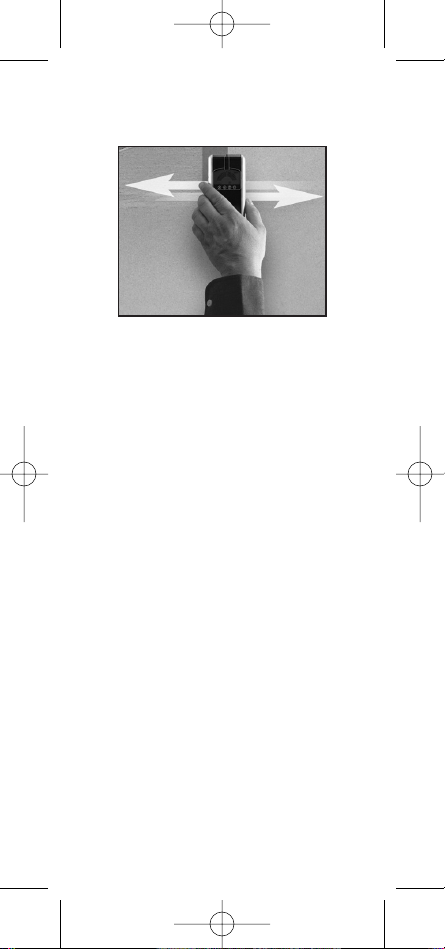

Hold down

the button

“STUD”

Figure 1

4

POWER

Power on the instrument by pressing the power

switch on the left side of the unit.

SET-UP

Hold the instrument against the wall surface in a

vertical position (see Figure 1). Press and release

selector switch until the stud icon appears on the

LCD screen.At this moment, auto calibration for

stud detection will start by displaying the

scanning bars from the bottom of the scanning

indicators. This procedure will be complete when

the scanning indicators show a full scale and

then disappear quickly. At the same time, the

scan symbol will display on the LCD screen with

a short “beep” tone. The instrument is now ready

for stud scanning. (See “Notes for Stud Seeking”)

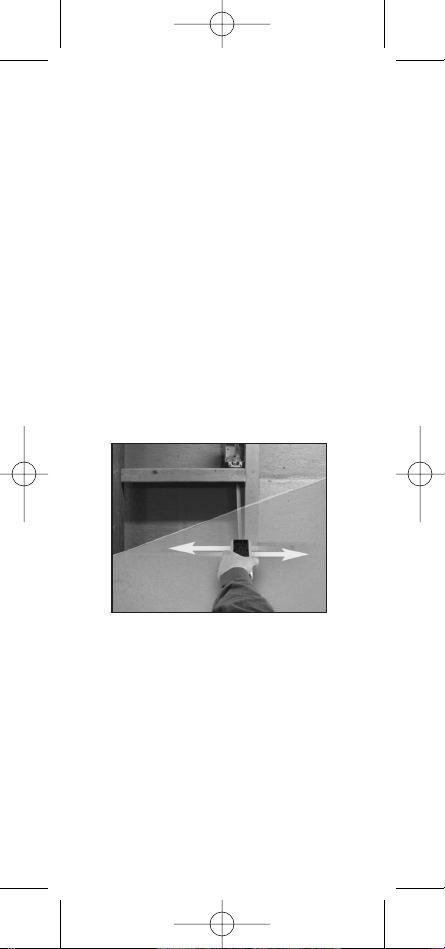

For locating a vertical batten or wall stud:

Place the instrument against the wall in a

vertical orientation (see Figure 1). Move the

instrument horizontally across the wall. As the

instrument moves towards a stud, the scanning

bars Icon will appear progressively from the

bottom. When the full scanning bars Icon with

steady tone sound appears, a stud edge has

been detected. Mark the first spot at the marking

position at the head of the instrument. Continue

moving the instrument in the same direction until

the arrow bar disappears and the sound ceases,

mark the second spot. The stud is now located

and the middle of stud is at the center between

the two marks.

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 4

Page 5

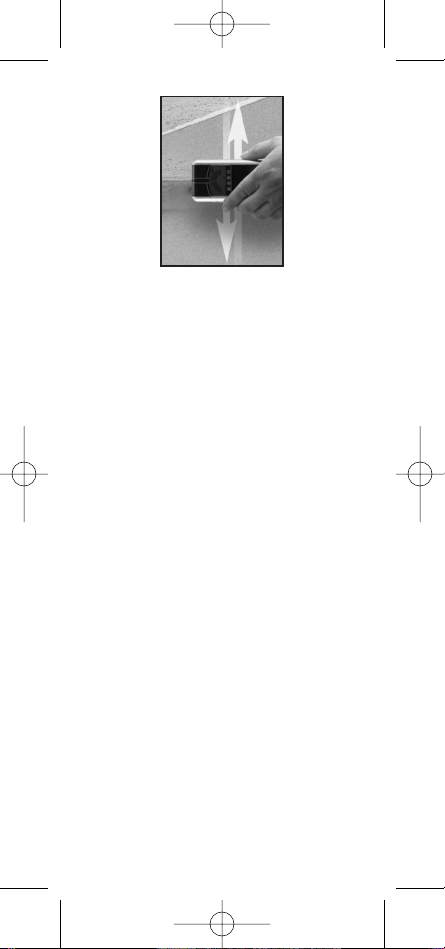

Figure 2

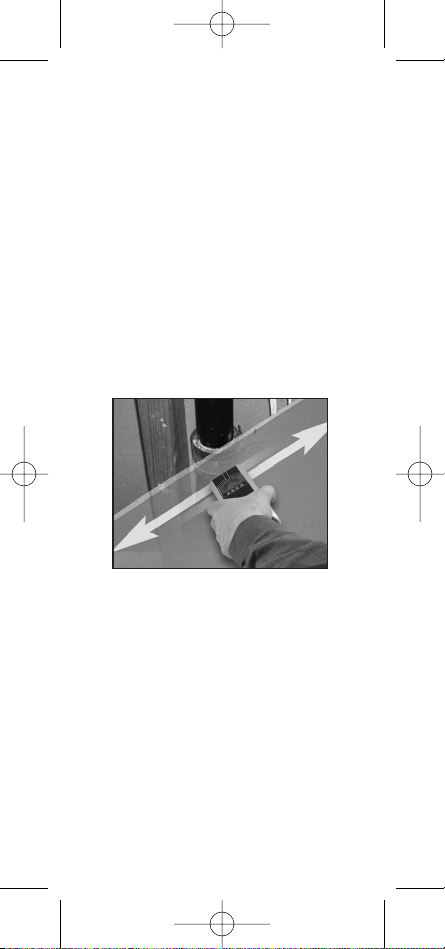

For locating the horizontal batten or wall stud:

Place the instrument against the wall in a

horizontal position (see Figure 2). Repeat the

same procedure for locating a vertical wall stud

but move the instrument in a vertical (top to

bottom) direction.

NOTES FOR STUD SEEKING

• In case of the instrument is placed over a

dense wall surface material, such as concrete

wall, during calibration procedure; the reading

only shows difference of wall density on the

surface. It is actually not a stud.

• If by chance the instrument is placed over the

wall batten or stud during calibration, the other

studs may be hard to detect. It is suggested

that you frequently re-calibrate on various

place on the same wall to avoid the false

readings. To do so, press Scan button once and

repeat the above procedures.

• The stud detection can be carried out normally

on wallpapered walls. However, it may not

function on some types of foil-backed or

metallic fabric surfaces.

• A double width of stud will be detected around

door or window frames as a double batten or

double stud is encountered.

• A solid wood header may exist in some doors.

The stud location will not be found if the

instrument is calibrated over the header.

However, if the unit is calibrated on a normal

wall first and then moved to the header area, it

will indicate the presence of the header.

• If the wall material is especially dense or thick,

the top arrow bar icon may not appear. Instead,

Hold down

the button

“STUD”

5

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 5

Page 6

Water Pipe

Figure 3

6

the other scanning bars might appear which

will actually be the “PEAK”.

• It is recommended to perform metal/voltage

detection to make sure the detected wood stud

or batten is not a metal pipe or energized

cable. Please note that some small securing

screws or nails may be detected.

METAL DETECTION

Check that there is no metal in the immediate

vicinity. Turn on the instrument by pressing the

Power Function selector button once which is

located on the left side of main body of the unit.

The icon will appear on the LCD screen.

At this moment, auto calibration for metal

detection will start by displaying the scanning

bars from the bottom of the scanning indicator.

This procedure will complete when the scanning

Indicator shows a full scale of reading and then

quickly disappears. At the same time, the scan

symbol will display on the LCD screen with a

short “beep” tone. The instrument is ready for

metal scanning now.

Metal Scanning

Hold the instrument horizontally with the sensor

head pointing towards the wall (see Figure 3) and

sweep systematically over the required area. If a

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 6

Page 7

7

metal object is detected, the scanning bars Icon

will appear from bottom. When the full scanning

bars Icon with steady tone sound appears, a

metal object is close to the sensor head. To

pinpoint the exact position after the metal has

been located, press the scan button once which

is located on the left side of main body of the

unit and repeat the above procedures.

VOLTAGE DETECTION

Check that there is no source of electricity in the

immediate vicinity. Then press and release

selector switch until icons appears on the LCD

screen. At this moment, auto calibration for

voltage detection will start by displaying the

scanning bars from bottom of the scanning

indicators. This procedure will complete when

the scanning Indicators show a full scale of

reading and disappear quickly. At the same time,

the scan symbol will display on the LCD screen

with a short “beep” tone. The instrument is now

ready for voltage scanning.

Voltage Scanning

Hold the instrument horizontally with the sensor

head pointing towards the wall (see Figure 4) and

sweep systematically over the required area. If a

source of voltage is detected, the scanning bars

Icon will appear from bottom. Once a full

scanning indicators icon with steady tone sound

appears. This represents a source of voltage is

close to the sensor head. To pinpoint the exact

position after a voltage carrying object has been

located, press the scan button once and repeat

the above procedures.

Electrical

Wire

Figure 4

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 7

Page 8

8

NOTES FOR VOLTAGE DETECTION

• Some walls may contain metallic fiber for

fireproofing; this will spread the area of voltage

pick-up. Placing your free hand on the wall

may cancel the effect.

• Rubbing or banging the instrument on the wall

may generate static electricity and cause a

false reading.

• Only a small amount of electricity will trigger

the detector and can cause false readings,

such as a badly insulated cable touching a

damp wall.

• When the instrument gives a “No Voltage”

reading, check the unit on a known voltage

source before touching any conductor.

• It will not detect shielded conductors (i.e. those

in metal conduct, the unit only shows presence

of METAL).

• Never take risks! If unsure, consult a qualified

electrician.

• The instrument can operate both Metal

Detecting and Stud Seeking simultaneously.

Since plumbing may exist at same location

inside the wall (see Figure 5), Metal as well

as Stud Indicators will come on together. If the

wiring that is carrying voltage is located at

the wall batten or stud inside the wall

(see Figure 5), Voltage as well as Stud

indicators will come on together.

In case of abnormal performance when

operating the unit, replace with a fresh battery.

Figure 5

Water Pipe

and Stud

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 8

Page 9

9

AUTO MODE

When this mode is selected, the instrument can

detect STUD, VOLTAGE & METAL simultaneously.

Press and release selector switch until icon

appears on the LCD screen. At this moment, auto

calibration will start by displaying the scanning

bars from bottom of the scanning indicators. This

procedure will complete when the scanning

indicators show a full scale of reading and

disappear quickly. At the same time, the scan

symbol will display on the LCD screen with a

short “beep” tone. The instrument is ready for

Auto Mode Scanning. For scanning procedure,

please refer to Sections 1, 2 & 3. In case of Stud,

Voltage and Metal being detected at the same

time, all four icons will show on the display.

BATTERY LEVEL INDICATOR

This shows current status of battery. Full

segments indicate battery in perfect condition.

Three segments indicate battery in good

condition and two segments indicate battery in

normal condition. When one segment or no

segment appears, replace battery immediately.

AUTO-POWER OFF

The instrument will turn off automatically when

not in use in about 3 minutes.

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 9

Page 10

MSV350D

MANUAL DEL USUARIO

DETECTOR DIGITAL

3 EN 1 DE VIGAS,

VOLTAJE, METALES

El detector digital 3 en 1 para Vigas/Voltaje y

Metal es un instrumento único que combina

3 herramientas en una sola. Detecta vigas de

madera o metal, objetos con voltaje y tuberías

o conductos metálicos dentro de paredes, pisos

o cielo rasos. Gracias al empleo de la última

tecnología CPU, ofrece lecturas visuales precisas

sobre la pantalla LCD en simultaneidad con

señales acústicas. Ideal para el técnico

profesional, aficionados, propietarios y operarios.

DESCRIPCIÓN

1. Ubicación del sensor de Metal/Voltaje

2. Orificio para marcar el borde de vigas

3. Pantalla LCD

4. Llave de encendido y selectora de funciones

5. Interruptor de exploración

6. Símbolo de “EXPLORACIÓN” - Aparecerá al

finalizar la calibración

7. Indicador de exploración - Una lectura a

plena escala indicará la detección del

objetivo

8. Indicador del nivel de la batería

9. Símbolo de Metal - Este icono aparecerá

cuando se emplee el aparato en modo

detección de metales o cuando se detecte

una masa metálica mientras el aparato

funciona en modo automático

10. Símbolo de Voltaje e Indicador de precaución

– Estos íconos aparecerán cuando se use el

detector de voltaje o cuando se detecte

voltaje mientras el aparato funciona en modo

automático

11. Símbolo de Viga – Este símbolo parecerá

cuando se use el detector de vigas o cuando

se detecte el borde de una viga mientras el

aparato funciona en modo automático

10

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 10

Page 11

11

12. Modo automático. Este icono aparecerá

cuando simultáneamente se realicen

detecciones de metal, voltaje y vigas

13. Ubicación del sensor de vigas

14. Tapa del receptáculo de la batería

9

10 11 12

6

8

7

2

3

5

13

14

4

FRENTE

ESPALDA

2

1

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 11

Page 12

INSTRUCCIONES DE OPERACIÓN

INSTALACIÓN DE LA BATERÍA

Esta unidad funciona con una batería de “9V” no

provista con el dispositivo.

• Deslice la tapa del receptáculo de batería, en la

parte de atrás del instrumento, para abrirlo.

• Conecte la batería al respectivo conector e

insértela dentro del receptáculo.

• Vuela a cerrar la tapa del receptáculo de la

batería.

ENCENDIDO

Encienda el instrumento presionando el

interruptor de encendido localizado en el costado

izquierdo de la unidad.

PREPARADO

Sostenga el instrumento en posición vertical y

contra la superficie de la pared (ver Figura 1).

Presione y suelte la llave selectora hasta que

aparezca el icono de ‘viga’ en la pantalla LCD.

En este momento comenzará la calibración

automática para la detección de vigas,

activándose las barras inferiores del indicador de

exploración. Este procedimiento estará completo

cuando el indicador de exploración de una

indicación de fondo de escala y se apague

rápidamente. Al mismo tiempo, se mostrará el

símbolo de exploración en la pantalla LCD y se

escuchará un breve pitido. En ese momento el

instrumento estará listo para comenzar la

exploración de vigas. (Refiérase“Comentarios

Sobre la Busqueda de Vigas”)

12

Mantenga

el botón

“STUD”

Figura 1

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 12

Page 13

Para localizar un listón o una viga vertical

en la pared:

Coloque el instrumento contra la pared en

posición vertical (ver Figura 1). Desplace el

instrumento horizontalmente a lo ancho de la

pared. A medida que el instrumento se acerque

a una viga, comenzará a incrementarse el

número de segmentos activos del indicador de

exploración. Se habrá detectado el borde de la

viga cuando se activen todos los segmentos del

indicador y se genere una indicación sonora.

Marque el primer punto de localización a través

del orificio que se encuentra a tal efecto en la

parte superior del instrumento. Continúe

desplazando el instrumento en la misma

dirección hasta que desaparezca la flecha de

segmentos y se extinga la indicación sonora.

Marque allí el segundo punto de localización. Se

habrá localizado la viga y su centro estará en el

punto intermedio entre las dos marcas realizadas.

Para localizar un listón o viga horizontal

en la pared:

Coloque el instrumento contra la pared en

posición horizontal (ver Figura 2). Repita el mismo

procedimiento que para encontrar una viga

vertical en la pared, pero ahora moviendo el

instrumento de arriba hacia abajo en dirección

vertical.

COMENTARIOS SOBRE LA BÚSQUEDA DE VIGAS

• En caso de que durante el procedimiento de

calibración el instrumento haya estado

apoyado sobre un sector de la pared de

material denso, tal como concreto, las lecturas

serán representativas de las diferencias de

densidad de dicha pared. Y no se estará

indicando realmente la presencia de una viga.

13

Figura 2

Mantenga

el botón

“STUD”

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 13

Page 14

• Si por casualidad el instrumento estaba

posicionado sobre un listón o una viga en el

momento de la calibración, podría ser difícil

detectar las otras vigas. Se sugiere que

recalibre frecuentemente el instrumento en

otras partes de la pared para evitar falsas

lecturas. Para hacerlo, presione el botón ‘Scan’

una vez y repita los procedimientos indicados

más arriba.

• La detección de vigas se puede realizar con

absoluta normalidad en paredes empapeladas.

Sin embargo, podría no funcionar sobre

algunos tipos de superficies con respaldos de

film o tejido metalizado.

• Se pueden detectar vigas del doble de ancho

alrededor de puertas y ventanas ya que allí se

suelen emplear listones o vigas dobles.

• En algunas puertas puede haber un travesaño

o dintel de madera maciza. No se detectará la

posición de las vigas si se calibró el

instrumento sobre dicho dintel. Sin embargo,

si la unidad se calibró primero en un sector

normal de la pared y luego se lo desplazó a la

zona del dintel, el mismo indicará la presencia

de dicho dintel con total normalidad.

• Si el material de la pared es particularmente

denso o grueso, podría no encenderse jamás el

segmento superior del icono. En su lugar, solo

se encenderán los segmentos restantes, lo que

pasará a constituirse en la indicación ‘pico’ de

la exploración.

• Se recomienda realizar la detección metal/

voltaje para asegurarse de que la viga o listón

detectado no es en realidad una tubería

metálica o un cable con energía eléctrica. Por

favor note que podrían detectarse algunos

clavos o tornillos de fijación.

DETECCIÓN DE METALES

Verifique que no haya metal inmediatamente al

lado del instrumento. Encienda el instrumento

presionando una vez el botón de Encendido,

ubicado sobre el costado izquierdo del cuerpo

principal de la unidad. Aparecerá el icono

respectivo en la pantalla LCD.

14

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 14

Page 15

En este momento comenzará la calibración

automática para la detección de metales,

activándose las barras inferiores del indicador de

exploración. Este procedimiento habrá finalizado

cuando el indicador de exploración provea una

breve indicación de fondo de escala y luego se

apague totalmente. Al mismo tiempo, se

mostrará el símbolo de exploración en la pantalla

LCD y se escuchará un breve pitido. En ese

momento el instrumento estará listo para

comenzar la exploración.

BÚSQUEDA DE METALES

Mantenga el instrumento horizontal, con su

cabeza apuntando hacia la pared (ver Figura 3)

y barra sistemáticamente sobre el área

seleccionada. Si se detecta un objeto metálico se

comenzarán a encender, comenzando por los

inferiores, los distintos segmentos del indicador

de exploración. El cabezal del instrumento estará

cerca de un objeto metálico cuando se prendan

todos los segmentos del icono y se genere una

indicación sonora permanente. Para localizar

exactamente la posición de dicho metal, presione

una vez el botón ‘Scan’, en el costado izquierdo

de la unidad, y repita el procedimiento anterior.

15

Pipa de aqua

Figura 3

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 15

Page 16

DETECCIÓN DE VOLTAJE

Verifique que no haya ningún dispositivo eléctrico

inmediatamente al lado del instrumento. Luego

presione y suelte la llave selectora hasta que

aparezca el icono en la pantalla LCD. En este

momento comenzará la calibración automática

para la detección de voltaje, activándose las

barras inferiores del indicador de exploración.

Este procedimiento habrá finalizado cuando el

indicador de exploración provea una breve

indicación a fondo de escala y luego se apague

totalmente. Al mismo tiempo, se mostrará el

símbolo de exploración en la pantalla LCD y se

escuchará un breve pitido. En ese momento el

instrumento estará listo para comenzar la

exploración de voltaje.

Exploración de voltajes

Mantenga el instrumento horizontal, con su

cabeza apuntando hacia la pared (ver Figura 4)

y barra sistemáticamente sobre el área

seleccionada. Si se detecta una fuente de voltaje

se comenzarán a encender, comenzando desde

abajo, los segmentos del indicador de

exploración. Luego el indicador de exploración

dará una lectura a fondo de escala y se

escuchará una señal sonora continua. Esto

quiere decir que un objeto con voltaje está cerca

del cabezal del instrumento. Para localizar la

posición exacta del objeto con voltaje aplicado,

presione una vez el botón de ‘Scan’ y repita los

procedimientos de más arriba.

COMENTARIOS SOBRE LA DETECCIÓN

DE VOLTAJE

• Algunas paredes, para hacerlas a prueba de

incendios, pueden contener fibras metálicas.

16

Alambre

Eléctrico

Figura 4

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 16

Page 17

Esto agrandará las áreas donde se indique

voltaje. El colocar su mano libre sobre la pared

puede ayudar a cancelar dicho efecto.

• Frotar o golpear el cabezal del instrumento

contra la pared puede generar electricidad

estática y provocar una falsa lectura.

• Apenas una pequeña cantidad de electricidad

disparará el detector, pudiendo provocar falsas

lecturas, como en el caso de que exista un

cable con problemas de aislamiento tocando

la pared húmeda.

• Cuando el instrumento dé una lectura de ‘No

voltaje’, antes de tocar ningún conductor

pruebe la unidad sobre una fuente de voltaje

conocida.

• No se detectarán conductores blindados (p. ej.

Aquellos dentro de un conducto metálico, en

cuyo caso la unidad solo reportará la presencia

de METAL).

• ¡Nunca tome riesgos! Si está inseguro,

consulte con un electricista calificado.

• El instrumento puede operar simultáneamente

detectando metales y buscando vigas. Desde

el momento en que puede haber cañerías

dentro de la pared (ver la Figura 5), pueden

encenderse simultáneamente los indicadores

de Viga y de Metal. Si el cableado que tiene

voltaje aplicado está junto a un listón o viga

dentro de la pared (ver la Figura 5), pueden

encenderse simultáneamente los indicadores

de Viga y de Voltaje.

En caso de que note un desempeño anormal del

instrumento durante su operación, colóquele una

batería nueva.

17

Figura 5

Pipa de

aqua

y Viga

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 17

Page 18

MODO AUTOMÁTICO

Cuando se seleccione el modo automático, el

instrumento simultáneamente podrá detectar

VIGAS, VOLTAJES y METALES. Presione y suelte la

llave selectora hasta que aparezca el icono en la

pantalla LCD. En este momento comenzará la

calibración automática, activándose las barras

inferiores del indicador de exploración. Este

procedimiento habrá finalizado cuando el

indicador de exploración provea una breve

lectura a fondo de escala y luego se apague

totalmente. Al mismo tiempo, se mostrará el

símbolo de exploración en la pantalla LCD y se

escuchará un breve pitido. En ese momento el

instrumento estará listo para comenzar la

exploración en modo automático. Respecto al

procedimiento de exploración, por favor refiérase

a las Secciones 1, 2 & 3. En caso de detectarse

al mismo tiempo una viga, voltaje y metal, se

activarán los cuatro iconos de la pantalla.

INDICADOR DE NIVEL DE BATERÍA

Indica el estado actual de la batería. Todos las

barritas encendidas indican que la batería está

en perfecto estado. Tres líneas indican que la

batería está en buen estado y dos líneas que la

misma está ‘normal’. Cuando no aparezca ningún

segmento o solo uno de ellos, reemplace

inmediatamente la batería.

AUTO APAGADO

El instrumento se apagará automáticamente

después de 3 minutos de inactividad.

18

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 18

Page 19

MSV350D

Manuel de utilisateur

DÉTECTEUR

NUMÉRIQUE DE

MONTANT/TEN-

SION/METAUX 3 en 1

Le détecteur numérique de montant/tension/

métaux 3 en 1 est un instrument unique qui

combine 3 outils dans un même appareil. Il

détecte des montants en bois, en métal, les

objets portant de la tension, et même les tuyaux

en métal et les conduits derrière les murs, les

planchers et les plafonds. En utilisant la dernière

technologie de CPU, il donnera une lecture

visuelle précise affichée sur l’écran à cristaux

liquides avec un avertisseur sonore. Idéal pour

les Techniciens, les Bricoleurs, les Propriétaires

et les Amateurs professionnels.

DESCRIPTION

1. Détecteur de tension/métal

2. Trou de marquage pour le bord des montants

3. Écran à cristaux liquides

4.

Interrupteur sélecteur d’Alimentation et Fonction

5. Interrupteur de balayage

6. Symbole « SCAN » (balayage) (Ce symbole

s’affichera lorsque le calibrage est complet)

7. Indicateurs de balayage (L'échelle de lecture

complète s'affichera lorsqu’une cible est

détectée)

8. Indicateur de l’état des piles

9. Symbole de métal (Ce symbole s’affichera

lorsque le détecteur de métaux est en

fonctionnement ou lorsqu’un objet métallique

est détecté quand le mode automatique est

sélectionné)

11. Symbole de tension et Indicateur

d’avertissement (Ces symboles s’afficheront

lorsque le détecteur de tension est en

fonctionnement ou lorsque la tension est

détectée avec le mode automatique)

12. Symbole de montant (Ce symbole s’affichera

lorsque le détecteur de montant est en

19

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 19

Page 20

fonctionnement ou lorsque le bord des

montants est détecté avec la sélection de

mode automatique)

13. Mode automatique (Ce symbole s’affichera

lorsque vous faites de détections de

montant/tension/métaux tout en même temps)

14. Détecteur de montant

15. Couvercle de pile

20

9

10 11 12

6

8

7

2

3

5

13

14

4

DEVANT

DOS

2

1

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 20

Page 21

CONSIGNES D’UTILISATION

MISE EN PLACE DES PILES

Cet appareil fonctionne avec une pile de 9 volts

qui n’est pas incluse.

• Ouvrez en glissant le couvercle de la pile à

l’arrière de l’instrument

• Attachez la pile au connecteur et insérez-la

dans le compartiment de la pile.

• Mettez la couverture de la pile en place.

PUISSANCE

Mettez l’instrument en marche en appuyant sur

l’interrupteur d’alimentation sur le côté gauche

de l’appareil.

PRÉPARATION

Tenez l’instrument contre la surface murale en

position verticale (voir Figure 1). Appuyez et

relâchez l’interrupteur sélecteur jusqu’à ce que

le symbole de montant s’affiche sur l’écran à

cristaux liquides. À ce moment-ci, le calibrage

automatique de détection de montant

commencera par afficher les barres de balayage

dans le coin inférieur des indicateurs de

balayage. Cette procédure sera complétée

lorsque les indicateurs de balayage afficheront

une échelle complète puis disparaîtront

rapidement. En même temps, le symbole de

balayage s’affichera sur l'écran à cristaux

liquides avec court bip. L’instrument est

maintenant prêt pour commencer le balayage

de montant. (Référez-vous “Remarques Pour

Rechercher un Montant”)

21

Maintenez

le bouton

“STUD”

Figure 1

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 21

Page 22

Pour localiser une plinthe verticale ou un

poteau de cloison :

Placez l’instrument contre la surface murale en

position verticale (voir Figure 1). Déplacez

l’instrument de manière horizontale sur le mur.

Lorsque l’instrument se déplace vers le montant,

le symbole des barres de balayage s'affichera

progressivement dans le coin inférieur. Lorsque

l’ensemble des barres de balayage s’affiche avec

un ton régulier, un bord des montants a été

détecté. Marquez le premier endroit sur les

endroits déterminés dans le coin supérieur de

l’instrument. Continuez à déplacer l’instrument

dans la même direction jusqu’à ce que la barre

en flèche s’affiche et le son s’arrête, marquez

donc le deuxième endroit. Le montant est

maintenant localisé et le milieu du montant est

au centre entre les deux marques.

Pour localiser une plinthe horizontale ou un

poteau de cloison :

Placez l’instrument contre la surface murale en

position horizontale (voir Figure 2). Suivez la

même procédure pour localiser un poteau de

cloison vertical, mais déplacez l’instrument en

position verticale (du haut vers le bas).

REMARQUES POUR RECHERCHER UN MONTANT

• Dans le cas où l’instrument est placé sur un

matériel dense de la surface murale, comme

un mur de béton, au cours d'une procédure de

calibrage, la lecture ne montrera que la

différence de densité du mur dans la surface.

Ce n’est pas exactement un montant.

• Si par hasard l’instrument est placé sur une

plinthe de mur ou un poteau de cloison lors du

calibrage, il peut être difficile de trouver les

22

Figure 2

Maintenez

le bouton

“STUD”

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 22

Page 23

autres montants. Il est suggéré que vous

recalibriez souvent dans les différents endroits

sur le même mur pour éviter les fausses

lectures. Pour le faire, appuyez sur le bouton

Scan (balayer) une fois et suivez les

instructions ci-dessus.

• La détection de montant peut se faire

normalement sur les murs avec du papier

peint. Cependant, il ne fonctionnera pas sur

certains types de surfaces métalliques ou

recouvertes de feuilles d'aluminium à l'endos.

• Une largeur double de montant sera détectée

autour de la porte ou des cadres de la fenêtre

lorsque vous rencontrez une double plinthe ou

un double montant.

• Un en-tête en bois solide peut exister sur

certaines portes. L’emplacement du montant ne

sera pas trouvé si l'instrument est réglé sur l’entête. Toutefois, si l’appareil est réglé sur un mur

normal d’abord et ensuite déplacé vers la zone

d’en-tête, il indiquera la présence de l’en-tête.

• Si le matériel du mur est particulièrement

dense ou épais, la barre de la flèche vers le

haut pourrait ne pas apparaître. À sa place, les

autres barres de balayage pourraient

apparaître, qui seront effectivement le sommet.

• Il est suggéré de faire une détection de

tension/métal pour vous assurer que le

montant ou la plinthe en bois détecté ne soit

pas un tuyau de métal ou un câble sous

tension. Veuillez remarquer que certains petits

clous ou vis peuvent être détectés.

DÉTECTION DE MÉTAUX

Vérifiez qu’il n’y a pas du métal dans les

environs immédiats. Allumez l'instrument en

appuyant sur le bouton sélecteur Power (fonction

d'alimentation) une seule fois. Ce bouton se

trouve sur le côté gauche du corps principal de

23

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 23

Page 24

l’appareil. Le symbole s’affichera sur l’écran à

cristaux liquides.

À ce moment-ci, le calibrage automatique de

détection de métaux commencera par afficher

les barres de balayage dans le coin inférieur de

l’indicateur de balayage. Cette procédure sera

complétée lorsque l’indicateur de balayage

affichera une échelle complète de la lecture puis

disparaîtra rapidement. En même temps, le

symbole de balayage s’affichera sur l'écran à

cristaux liquides avec court bip. L’instrument est

maintenant prêt pour commencer le balayage de

métaux.

Balayage de métaux

Maintenez l'instrument horizontalement avec la

tête du détecteur vers le mur (voir Figure 3) et

balayez systématiquement sur l’endroit requis.

Si un objet de métal est détecté, le symbole des

barres de balayage s’affichera au bas. Lorsque

l’ensemble des barres de balayage s’affiche avec

le ton régulier, un objet de métal est proche de la

tête du détecteur. Pour indiquer la position

exacte après avoir localisé le métal, appuyez sur

le bouton de balayage une seule fois. Ce bouton

se trouve sur le côté gauche du corps principal

de l’appareil. Ensuite, suivez les indications cidessus.

DÉTECTION DE TENSION

Vérifiez qu’il n’y a aucune source d’électricité

dans les environs immédiats. Ensuite, appuyez et

relâchez l’interrupteur sélecteur jusqu’à ce que

le symbole s’affiche sur l’écran à cristaux

liquides. À ce moment-ci, le calibrage

automatique de détection de tension

commencera par afficher les barres de balayage

24

Conduite

d’eau

Figure 3

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 24

Page 25

dans le coin inférieur des indicateurs de

balayage. Cette procédure sera complétée

lorsque les indicateurs de balayage afficheront

une échelle complète de la lecture puis

disparaîtront rapidement. En même temps, le

symbole de balayage s’affichera sur l'écran à

cristaux liquides avec court bip. L’instrument est

maintenant prêt pour commencer le balayage

de tension.

Balayage de tension

Maintenez l'instrument horizontalement avec

la tête du senseur vers le mur (voir Figure 4) et

balayez systématiquement sur l’endroit requis.

Si une source d’électricité est détectée, le

symbole des barres de balayage s’affichera au

bas. Le symbole de l’indicateur de balayage

complet avec un son régulier s’afficha une seule

fois. Ceci signifie qu'une source de tension est à

proximité de la tête du détecteur. Pour indiquer

la position exacte après avoir localisé un objet

ayant de la tension, appuyez sur le bouton de

balayage une seule fois et suivez les instructions

ci-dessus.

REMARQUES POUR LA DÉTECTION DE TENSION

• Certains murs peuvent contenir des fibres

métalliques résistantes au feu ; ce qui répartira

la zone de détection de tension. En plaçant

votre main libre sur le mur, vous pouvez éviter

cet effet.

• Frotter ou cogner l’instrument sur le mur peut

générer de l’électricité statique et provoquer

une fausse lecture.

• Seulement une petite quantité d’électricité

déclenchera le détecteur et peut provoquer des

25

Fil Éléctrique

Figure 4

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 25

Page 26

erreurs de lecture, comme un câble mal isolé

touchant un mur humide.

• Lorsque l’instrument donne une lecture

« No Voltage » (sans tension), vérifiez l’appareil

sur une source de tension connue avant de

toucher un autre conducteur.

• Il ne détectera pas les conducteurs blindés (par

exemple, ceux qui sont en conduite de métal,

l’appareil montre seulement la présence du

METAL).

• Ne prenez jamais des risques ! En cas de

doute, consultez un électricien qualifié.

• L’instrument peut fonctionner simultanément

en fonction Détection de Métaux et Recherche

de montants. Puisqu’il peut exister une

tuyauterie dans le même endroit dans le mur

(voir Figure 5), les indicateurs de métaux et de

montants s’afficheront ensemble. Si le câblage

qui est en tension est situé dans la plinthe de

mur ou un poteau de cloison dans le mur (voir

Figure 5), les indicateurs de tension et de

montants s’afficheront ensemble.

En cas de résultats anormaux pendant le

fonctionnement de l’appareil, remplacez avec

une nouvelle pile.

MODE AUTOMATIQUE

Lorsque ce mode est sélectionné, l’instrument

peut détecter du MONTANT (STUD),TENSION

(VOLTAGE) et MÉTAL simultanément. Appuyez et

relâchez l’interrupteur sélecteur jusqu’à ce que

les symboles s’affichent sur l’écran à cristaux

liquides. À ce moment-ci, le calibrage

automatique commencera par afficher les barres

de balayage dans le coin inférieur des

indicateurs de balayage. Cette procédure sera

26

Figure 5

Conduite

d’eau et

Montant

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 26

Page 27

complétée lorsque les indicateurs de balayage

afficheront une échelle complète de la lecture

puis disparaîtront rapidement. En même temps,

le symbole de balayage s’affichera sur l'écran à

cristaux liquides avec court bip. L’instrument est

prêt pour commencer le balayage en mode

automatique. Pour une procédure de balayage,

veuillez vous référer aux Sections 1, 2 et 3. En

cas de détection de montant, tension ou métal en

même temps, les quatre symboles s'afficheront

sur l'écran.

INDICATEUR DE L’ÉTAT DES PILES

Ceci montre l’état actuel de la pile. L’ensemble

des barres indique que la pile est en parfait état.

Trios barres indiquent que la pile est bon état et

deux barres indiquent que la pile est en condition

normale. Lorsqu’une seule barre ou aucune ne

s’affiche, remplacez la pile immédiatement.

ARRÊT AUTOMATIQUE

L’instrument s’arrêtera automatiquement lorsqu’il

n’est pas en fonctionnement environ 3 minutes.

27

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 27

Page 28

28

GENERAL TOOLS & INSTRUMENTS

™

80 White Street,

New York,NY10013-3567

PHONE (212) 431-6100

FAX (212) 431-6499

TOLL FREE (800) 697-8665

e-mail: sales@generaltools.com

www.generaltools.com

MSV350D User’s Manual

Specifications subject to change without notice

©2009 GENERAL TOOLS & INSTRUMENTS

™

NOTICE - WE ARE NOT RESPONSIBLE FOR TYPOGRAPHICAL ERRORS.

MAN#MSV350D 4/09

MSV350D-FINAL- 033009:Layout 1 3/30/09 9:36 AM Page 28

Loading...

Loading...