SBLF1030CT AND SBLF1040CT

SCHOTTKY ISOLATED PLASTIC RECTIFIER

Reverse Voltage - 30 and 40 Volts Forward Current - 10.0 Amperes

FEATURES

¨ Isolated plastic package has Underwriters Laboratory

Flammability Classifications 94V-0

¨ Metal silicon junction, majority carrier conduction

¨ Low power loss,high efficiency

¨ High current capability,

low forward voltage drop

¨ High surge capacity

¨ For use in low voltage, high frequency inverters,

free wheeling, and polarity protection applications

¨ Guardring for overvoltage protection

¨ High temperature soldering guaranteed:

250¡C/10 seconds, 0.25" (6.35mm) from case

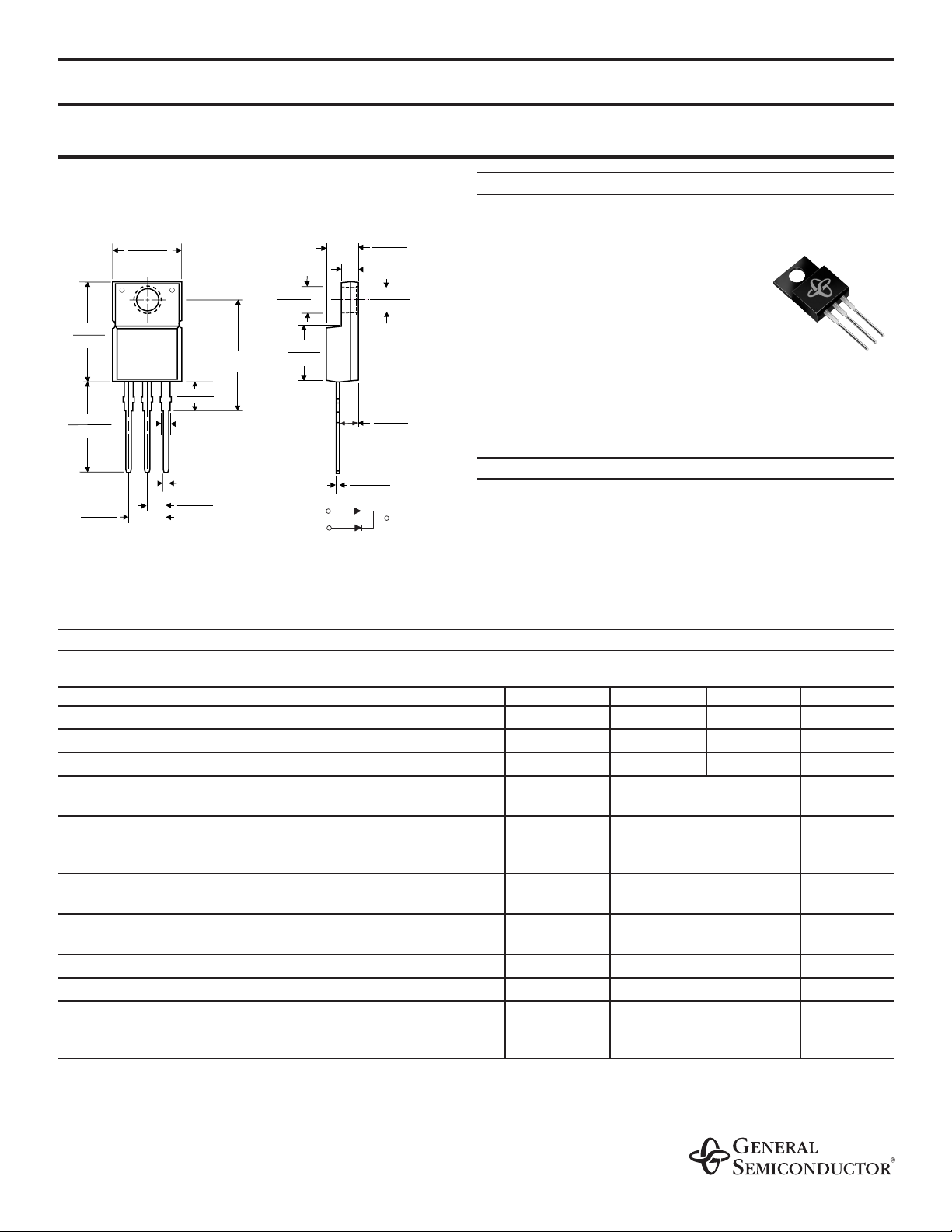

MECHANICAL DATA

Case: JEDEC ITO-220AB fully overmolded plastic body

Terminals: Lead solderable per MIL-STD-750,

Method 2026

Polarity: As marked

Mounting Position: Any

Mounting Torque: 5 in. - lbs max.

Weight: 0.08 ounce, 2.24 grams

MAXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS

Ratings at 25¡C ambient temperature unless otherwise specified.

SYMBOLS SBLF1030CT SBLF1040CT UNITS

Maximum repetitive peak reverse voltage V

RRM

30 40 Volts

Maximum RMS voltage V

RMS

21 28 Volts

Maximum DC blocking voltage V

DC

30 40 Volts

Maximum average forward rectified current

at TC=95¡C

I

(AV)

10.0 Amps

Peak forward surge current, 8.3ms single

half sine-wave superimposed on rated load

(JEDEC Method)

I

FSM

175.0 Amps

Maximum instantaneous forward voltage

per leg at 5.0A

(NOTE 1)

V

F

0.55 Volts

Maximum instantaneous reverse current at T

C

=25¡C 0.5

rated DC blocking voltage

(NOTE 1)

TC=100¡C

I

R

50.0

mA

Typical thermal resistance

(NOTE 2)

R

QJC

5.0 ¡C/W

Operating and storage temperature range TJ, T

STG

-40 to +125 ¡C

RMS Isolation voltage from terminals to heatsink 4500

(NOTE 3)

with RH ² 30% V

ISOL

3500

(NOTE 4)

Volts

1500

(NOTE 5)

NOTES:

(1) Pulse test: 300ms pulse width, 1% duty cycle

(2) Thermal resistance from junction to case per leg

(3) Clip mounting (on case), where lead does not overlap heatsink with 0.110Ó offset.

(4) Clip mounting (on case), where leads do overlap heatsink.

(5) Screw mounting with 4-40 screw, where washer diameter is £ 4.9 mm (0.19Ó).

ITO-220AB

Dimensions in inches and (millimeters)

NEW PRODUCT NEW PRODUCT NEW PRODUCT

2/17/99

0.600 (15.5)

0.580 (14.5)

0.560 (14.22)

0.530 (13.46)

0.205 (5.20)

0.195 (4.95)

0.405 (10.27)

0.383 (9.72)

0.191 (4.85)

0.171 (4.35)

0.060 (1.52)

0.037 (0.94)

0.027 (0.69)

0.105 (2.67)

0.095 (2.41)

0.676 (17.2)

0.646 (16.4)

PIN

3

2

1

0.140 (3.56)

0.130 (3.30)

0.350 (8.89)

0.330 (8.38)

PIN 1

PIN 3

0.188 (4.77)

0.172 (4.36)

0.110 (2.80)

0.100 (2.54)

0.131 (3.39)

DIA.

0.022 (0.55)

0.014 (0.36)

0.122 (3.08)

0.110 (2.80)

0.100 (2.54)

PIN 2

DIA.

FIG. 1 - FORWARD CURRENT DERATING CURVE

CASE TEMPERATURE, ¡C

AVERAGE FORWARD CURRENT,

AMPERES

FIG. 2 - MAXIMUM NON-REPETITIVE PEAK FORWARD SURGE

CURRENT

NUMBER OF CYCLES AT 60 H

Z

PEAK FORWARD SURGE CURRENT,

AMPERES

FIG. 3 - TYPICAL INSTANTANEOUS FORWARD

CHARACTERISTICS PER LEG

FIG. 4 - TYPICAL REVERSE

CHARACTERISTICS PER LEG

INSTANTANEOUS FORWARD CURRENT,

AMPERES

INSTANTANEOUS REVERSE CURRENT,

MILLIAMPERES

INSTANTANEOUS FORWARD VOLTAGE,

VOLTS

PERCENT OF RATED PEAK REVERSE

VOLTAGE, %

FIG. 5 - TYPICAL JUNCTION CAPACITANCE PER LEG

JUNCTION CAPACITANCE, pF

REVERSE VOLTAGE, VOLTS

t, PULSE DURATION, sec.

TJ=75¡C

TJ=25¡C

TJ=25¡C

TJ=125¡C

TJ = 25¡C

f=1.0 MHz

Vsig=50mVp-p

PULSE WIDTH = 300ms

1% DUTY CYCLE

RESISTIVE OR INDUCTIVE LOAD

TJ=125¡C

FIG. 6 - TYPICAL TRANSIENT THERMAL IMPEDANCE PER LEG

TRANSICENTTHERMAL IMPEDANCE, °C/W

TJ=TJmax.

8.3ms SINGLE HALF SINE-WAVE

(JEDEC Method)

1.0

1

RATINGS AND CHARACTERISTIC CURVES SBLF1030CT AND SBLF1040CT

12.5

10

7.5

5

2.5

0

0

50

50

10

100

150

300

250

200

150

100

50

0

1

10

50

10

100

4,000

1,000

1

0.1

0.01

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

1

0.1

0.01

0.001

0

20

40

60

80

100

10.0

100

100

0.1

1.0

10

100

1.0

0.1

0.01

0.1

1

10.0

100

Loading...

Loading...