Course 13041.20D

Rear Wheel Steering

™

(QUADRASTEER

Service Technical College

)

Participant Guide Revised: 10/16/06

Caution

In order to reduce the risk of personal injury or property damage, carefully

observe the following information:

The service manuals of General Motors Corporation are intended for use

by professional, qualified technicians. Attempting service procedures

without the appropriate training, tools, and equipment could cause

personal injury, vehicle damage, or improper vehicle operation. Proper

vehicle service is important to the safety of the service technician and to

the safe, reliable operation of all motor vehicles. If a replacement part is

needed, use the same part number or an equivalent part. Do not use a

replacement part of lesser quality.

The service manuals contain effective methods for performing service

procedures. Some of the procedures require the use of tools that are

designed for specific purposes.

Accordingly, any person who intends to use a replacement part, a service

procedure, or a tool that is not recommended by General Motors, must

first establish that there is no jeopardy to personal safety or the safe

operation of the vehicle.

The service manuals contain Cautions and Notices that must be

observed carefully in order to reduce the risk of personal injury. Improper

service may cause vehicle damage or render the vehicle unsafe. The

Cautions and Notices are not all-inclusive. General Motors can not

possibly warn of all the potentially hazardous consequences that may

result by not following the proper service procedures.

The service manuals cover service procedures for vehicles that are

equipped with Supplemental Inflatable Restraints (SIR). Failure to observe

all SIR Cautions and Notices could cause air bag deployment, personal

injury, or otherwise unneeded SIR repairs. Refer to the SIR component

and wiring location views in Restraints before performing a service on or

around SIR components or wiring.

If multiple vehicle systems are in need of repair, including SIR, repair the

SIR system first to reduce the risk of accidental air bag deployment and

personal injury.

January 2002

© 2006 General Motors Corporation

All Rights Reserved

Table of Contents

Welcome and System Instructions .......................................................................i

Introduction ....................................................................................................... i-1

Module 1: Rear Wheel Steering System Introduction .....................................1-1

Module 2: Rear Wheel Steering System Operation ........................................2-1

Module 3: Four Wheel Steering Alignment......................................................3-1

Appendix..........................................................................................................A-1

Evaluation.........................................................................................................E-1

Instructor:

This manual contains information about service for the Rear Wheel Steering System. Always refer to applicable vehicle service information

and appropriate Dealer Technical Service Bulletins for additional information regarding system operation and diagnostic/repair procedures.

When this manual refers to a brand name, a number, or a specific tool, you may use an equivalent product in place of the recommended

item.

All information, illustrations and specifications in this manual are based on the latest product information available at the time of publication

approval. General Motors reserves the right to make changes at any time without notice.

No part of this book may be reproduced, stored in any retrieval system, or transmitted in any form or by any means (including but not

limited to electronic, mechanical, photocopying, and recording) without prior written permission of General Motors Corporation. This applies to

all text, illustrations, tables and charts.

© 2001, 2002, 2003, 2004, 2005, 2006

QUADRASTEER

TM

is a registered treademark of Delphi Automotive Systems, Inc.

© 2006 General Motors Corporation

All Rights Reserved

i Rear Wheel Steering (QUADRASTEERTM)

Welcome to Rear Wheel Steering

(QUADRASTEERTM)

Before the broadcast begins, please read the following information which will

help you understand the One Touch site controller and keypad — your links to

the instructor and the other course participants.

Using One Touch

1) Logging in to the system

To log in to the system, follow these steps:

1. Verify correct HOST number for your session by referring to the Host number

that appears in the lower, right corner of the TV screen during the broadcast.

2. Check the Host Number that appears on your OneTouch site controller,

which is the large black box located near your TV equipment. If necessary , use the

Plus (+) or Minus (-) key on the site controller's display to change the host to the

correct number, and then press the Enter Key (↵) to log onto the host.

3. Once the keypad asks for you ID, enter your student identification number.

(U.S. Social Security, Canadian EIN or Mexican IMSS or Person ID, effective

January 2005) on your OneTouch keypad, and then press the Enter Key. The

message "Validating" appears on the keypad for a few seconds. Next, your name

appears. this confirms that you have logged onto a host.

NOTE: If you have already logged in to your keypad and you determine that our site

controller is NOT set to the correct host number , you must first log off the site controller

by pressing the Esc key on the site controller's display. W ait until the sytem logs you

off, and then follow the steps above for logging back into the system.

Finally , if you are experiencing any technical difficulties and are unable to log in on both

the keypad and the site controller, please call the GM T raining Help Desk at 1-888-

748-2687 and press prompt 1.

2) Speaking to the Instructor

For best results while speaking to the instructor, follow these tips:

1. Place the keypad near the front of your desk. Put your class materials

between you and the keypad.

Speak directly into the microphone on the keyp ad. The microphone is located just

2.

below the row of five function keys. Speak in a normal tone from your standard

seated position. You will be heard by all of the other course participants and the

instructor.

© 2006 General Motors Corporation

All Rights Reserved

System Instructions ii

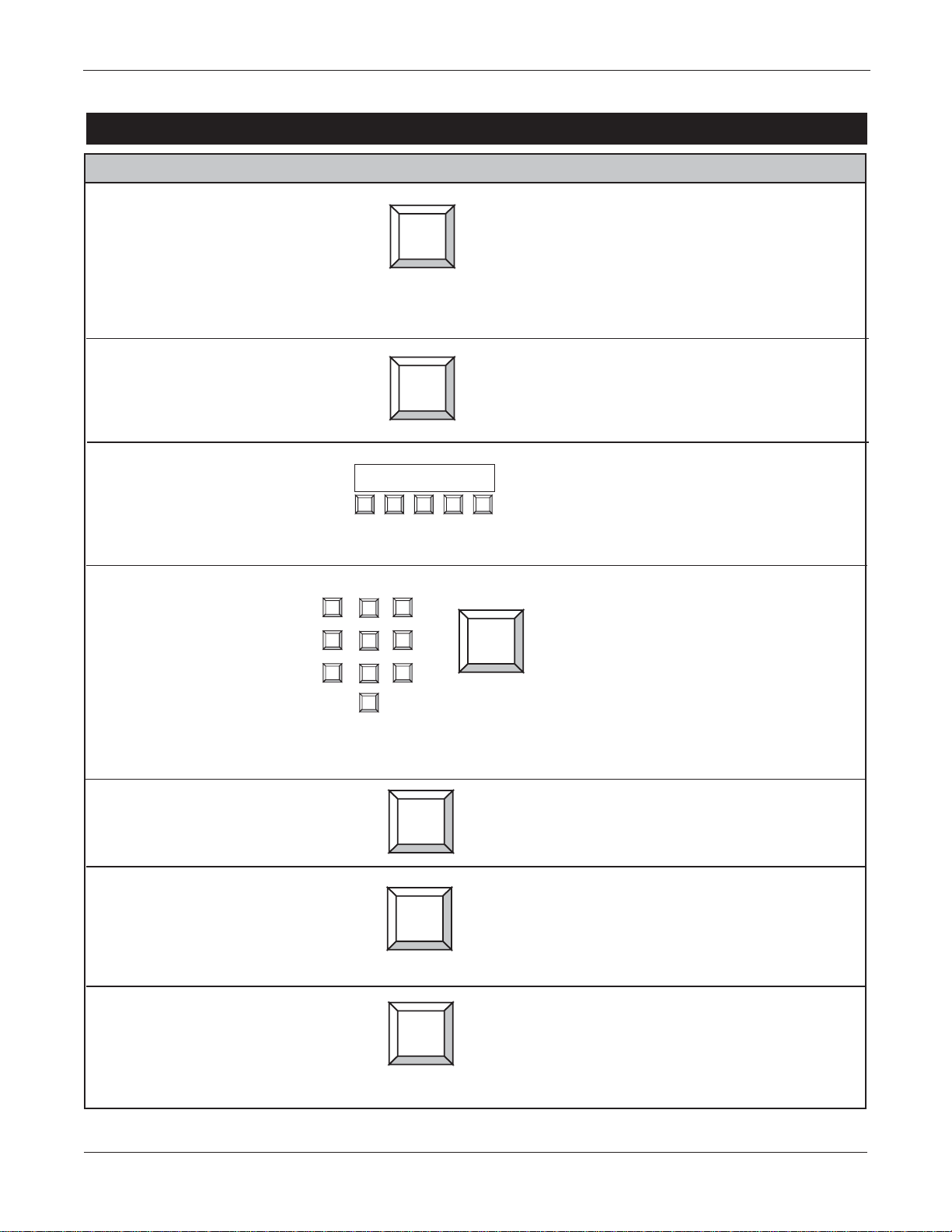

Using the Keypad

If you want to...

Ask a question, make a

comment, enter a

discussion, or cancel a call

to the instructor.

Signal the instructor

anonymously that you do

not understand.

Answer a multiple-choice

question.

Answer a question with a

numeric answer.

press: and this will happen...

Your WAIT light will be turned on and your

Call

Flag

A

BCDE

+

Enter

name will be added to the queue. Your

SPEAK light will come on when it is your

turn to speak. If you press the CALL key a

second time, your WAIT light will go off, and

your call will be canceled.

The percentage of students signaling the

instructor is displayed on the instructors

monitor. The instructor may adjust the

lecture accordingly.

If you are taking a multiple question quiz, the

answer is stored until you answer the last

question. On single questions the answer is

transmitted to the host site when you press

the ANSWER key.

If you are taking a multiple questions quiz

the answer is stored until you answer the

last question. On single questions,the

answer is transmitted to the host site when

you press the ENTER key.

Erase a numeric answer.

See the next quiz

questions answer set, and

any response you may

have entered for that

question.

See the previous quiz

questions answer set, and

any response you may

have entered for that

question

GM Training Help Desk 1-888-748-2687

Clear

Next

Quest

Prev

Ques

NOTE: To confirm that your response has been

received by the system, your letter or number

choice will be found in brackets in the upper

right-hand corner of the keypad display.

The answer in the window will be erased. On

single questions, you must press CLEAR

before you press ENTER.

The next questions ID and answer character

set will appear on the keypad display. If you

have already answered the question, your

answer will also display.

The previous questions ID and answer

character set will appear on the keypad

display. If you have already answered the

question, your answer will also display.

© 2006 General Motors Corporation

All Rights Reserved

Rear Wheel Steering

(QUADRASTEER

Introduction

TM

)

Introduction i-1

Welcome

Welcome to Rear Wheel Steering

(QUADRASTEERTM)

One Touch Familiarization

• Press the red call button to ask a question

• Wait for a green light before speaking

• Anticipate a momentary delay when

speaking

• Contact the Technical help desk at

1-888-748-2687, prompt 1, if necessary

Question 1

In which of the following regions is your

dealership located?

Course Goal

Upon successful completion of this course, you

will be able to identify the Rear Wheel Steering

System, associated components and apply

concepts and procedures to diagnose the

system operation.

Session Objectives

Identify the Rear Wheel Steering

System and its benefits

Identify system components and their

roles in operation

Identify unique system features

Identify diagnostic procedures

A. Atlanta

B. Chicago

C. Dallas

D. Los Angeles

E. New York

Question 2

Which of the following best

describes your experience level

at GM dealerships?

A . Greater than 10 years

B. Between 5-10 years

C. Between 2-5 years

D. Less than 2 years

Strategy Based Diagnostics

Step 1. Verify customer concern

Step 2. Make quick checks

Step 3. Follow diagnostic system checks

Step 4. Check service bulletins

Step 5. Diagnostics

Step 6. Decision on cause isolation

Step 7. Repair and verification

Special Instructions

The diagnostic charts in this courseware

are for reference only. Refer to Service

Information when servicing Rear Wheel

Steering Systems.

© 2006 General Motors Corporation Introduction

All Rights Reserved

i- 2 Rear Wheel Steering (QUADRASTEERTM)

STC T raining Courses*

Video CBT IDL Hands-On

1–Component Course

2–Component Course

3–Component Course

* Sample course component combinations

X

X

X

X

XX

*Course Components

•A 1-component course has no recommended prerequisite(s) or follow-up component

•A 2-component course has a recommended prerequisite(s) CBT or Video component

which you should complete before attending the IDL

(or)

it consists of an IDL or CBT followed by a Hands-On component which you will need to take in

order to complete the course

•A 3-component course has a recommended prerequisite(s) CBT or Video component

which should be completed before attending the IDL. You will need to take the follow-up

Hands-On component in order to complete the entire course

The dealership STS Report is credited when all components of the course are completed.

NOTICE: You’ll see your Training Record and Individual Training Plan change as each

course component is successfully completed. Just visit www.gmtraining.com and check

TMS.

To purchase authentic GM Service Training Materials,

contact the GM Training Materials Headquarters at 800-393-4831.

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All Rights Reserved

Rear Wheel Steering

(QUADRASTEER™)

Module 1

Rear Wheel Steering Introduction

Rear Wheel Steering System Introduction 1-1

Module 1 Objectives

Identify the benefits of the Rear Wheel

Steering System

Describe the three phases of

operation

Describe the three modes of operation

Identify system components and

operation

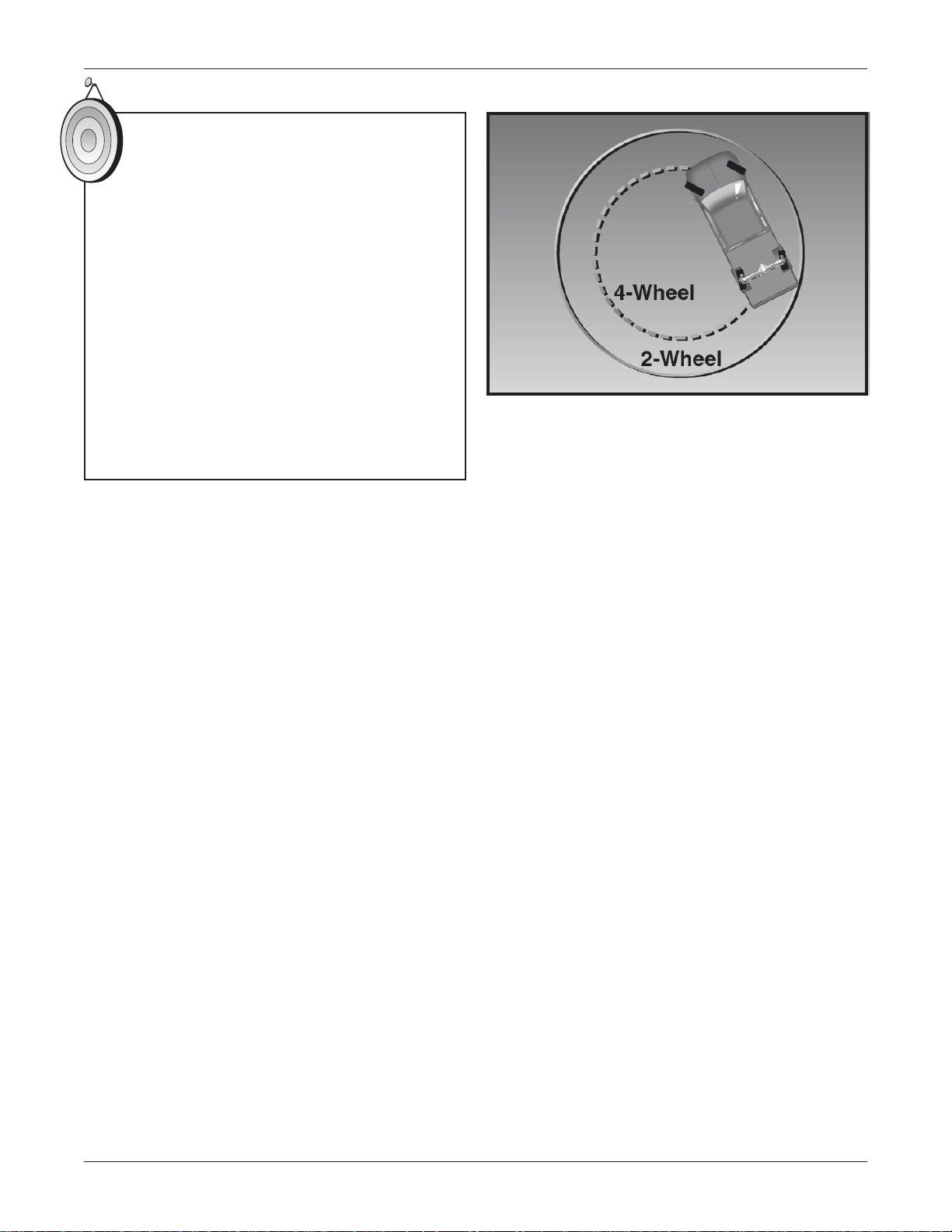

Turning Radius

Identify the cautions associated with

using in-ground hoist/jack stand

Rear Wheel Steering System

Benefits

The Rear Wheel Steering System, in

combination with the front steering system,

offers several benefits over typical non-rear

steering systems:

• Reduced turning radius

• Increased stability during high-speed

maneuvers such as passing and lane

changes

• Increased maneuverability when towing a

trailer

• Better maneuverability during low-speed

maneuvers such as parking

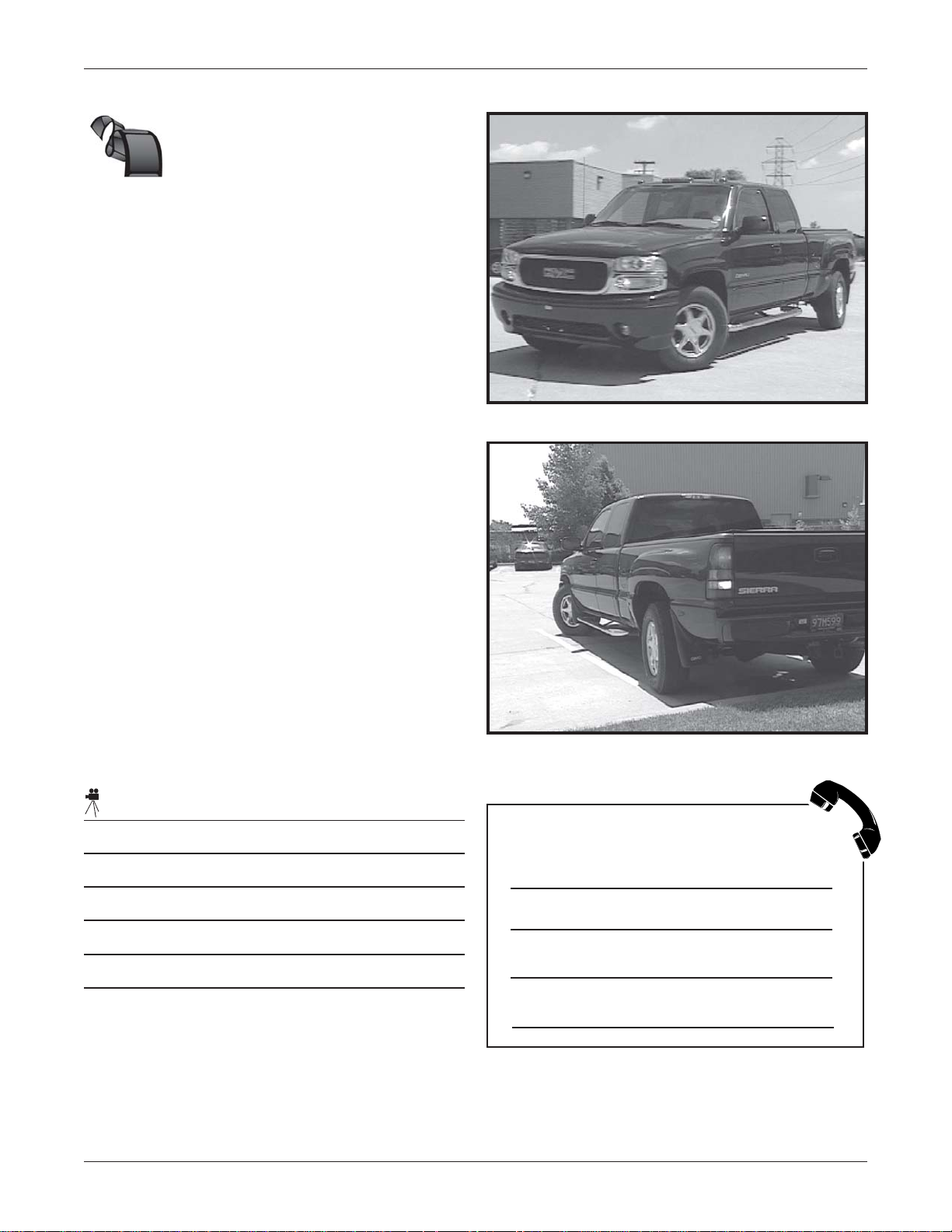

T urning Radius

The turning radius of a vehicle is significantly

enhanced with Rear Wheel Steering.

The turning radius of the GMC Sierra with

Rear Wheel Steering can be compared to

the turning radius of a Saturn Sedan

© 2006 General Motors Corporation Module 1

All rights reserved

1-2 Rear Wheel Steering (QUADRASTEER™)

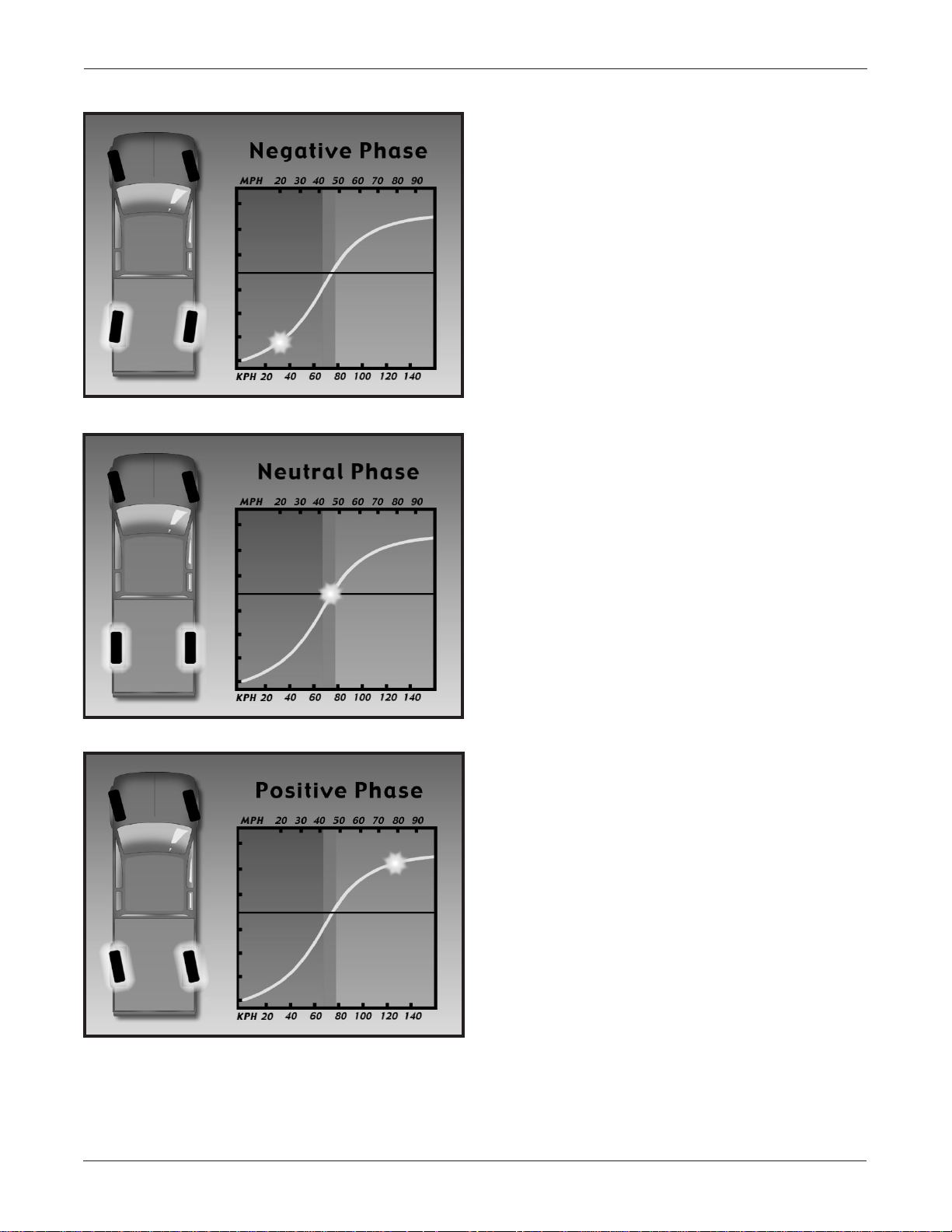

Driving Phases

Depending on the various inputs

communicated to the controller, the system

operates in one of three phases:

Negative Phase

• Used during low-speed maneuvers for

increased maneuverability

• Steers the wheels in the opposite direction

of the front wheels

Negative Phase

Neutral Phase

• Between zero and 45 mph

(approximately)

Neutral Phase

• Used during front-wheel only steering

• Rear wheels remain in a straight ahead

position no matter what direction the front

wheels turn

• It is the fail-safe phase of operation

• 45 mph (approximately)

Positive Phase

• Used during high-speed maneuvers and

when towing a trailer at high speeds for

increased stability

• Steers the rear wheels in the same

direction as the front wheels

• 45 mph and above (approximately)

The changes between the phases are subtle,

gradual changes.

Positive Phase

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Introduction 1-3

High-Speed St ability , T railering

Maneuverability , and Low-S peed

Maneuverability

These videos demonstrate how the combined

steering of the front and rear wheels improves

the truck’s maneuverability. These three video

segments will show high speed stability,

enhanced trailering and improved

maneuverability during parking.

Video Outline –

High-Speed Stability

• The Rear Wheel Steering System helps

improve stability during high-speed lane

changes

Front and Rear Wheels Turned in Same

Direction

• With the Mode Select Switch in the

4-wheel steer position, the front and rear

wheels turn in the same direction during

high-speed maneuvers

• When both the front and rear wheels turn in

the same direction, the system is operating

in the positive phase

• Positive phase Rear Wheel Steering

improves stability during higher-speed

maneuvers

Video Notes:

Lateral Motion Affected by Direction

Changes in Wheel Angle

© 2006 General Motors Corporation Module 1

All rights reserved

1-4 Rear Wheel Steering (QUADRASTEER™)

Video Outline cont. –

Trailering Maneuverability

• Stability of Rear Wheel Steering continues

with a trailer attached

• System continues operating in positive

phase, allowing the trailer to track the truck

more directly

• With Rear Wheel Steering, backing and

parking a trailer becomes easier,

particularly when additional maneuvering

Lane-Change when Towing a Trailer

space isn’t available

• When operating at slow speeds in the tow

mode, the rear wheels turn in the opposite

direction of the front wheels

Vehicle Parking with a Trailer Attached

• Allows for much easier maneuvering of the

trailer, particularly in tight spots

Video Notes:

Front Wheel and Rear Wheel Turning in

Opposite Directions

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Introduction 1-5

Video Outline cont. –

Low-Speed

Maneuverability

• Normal vehicle parking, especially in

tight parking spaces, also becomes

much easier with Rear Wheel Steering

• With the Mode Select Switch in the

4-wheel steer position, the front and rear

wheels turn in the opposite direction during

low-speed maneuvers, such as parking

• When the front and rear wheels turn in the

opposite direction, the system is operating

in the negative phase

• Negative phase Rear Wheel Steering

improves maneuverability while operating at

low speeds

Video Notes:

Vehicle Pulling into Parking Spot

Front and Rear Wheels Turning in Opposite

Directions

Why do we use a 5º positive phase

steering vs. a 12º negative phase?

© 2006 General Motors Corporation Module 1

All rights reserved

1-6 Rear Wheel Steering (QUADRASTEER™)

Modes of Operation

Video Outline –

The modes of operation steer by using the

driving phases.

2-Wheel Steer

• Steering Wheel Position Sensor – base of

steering column

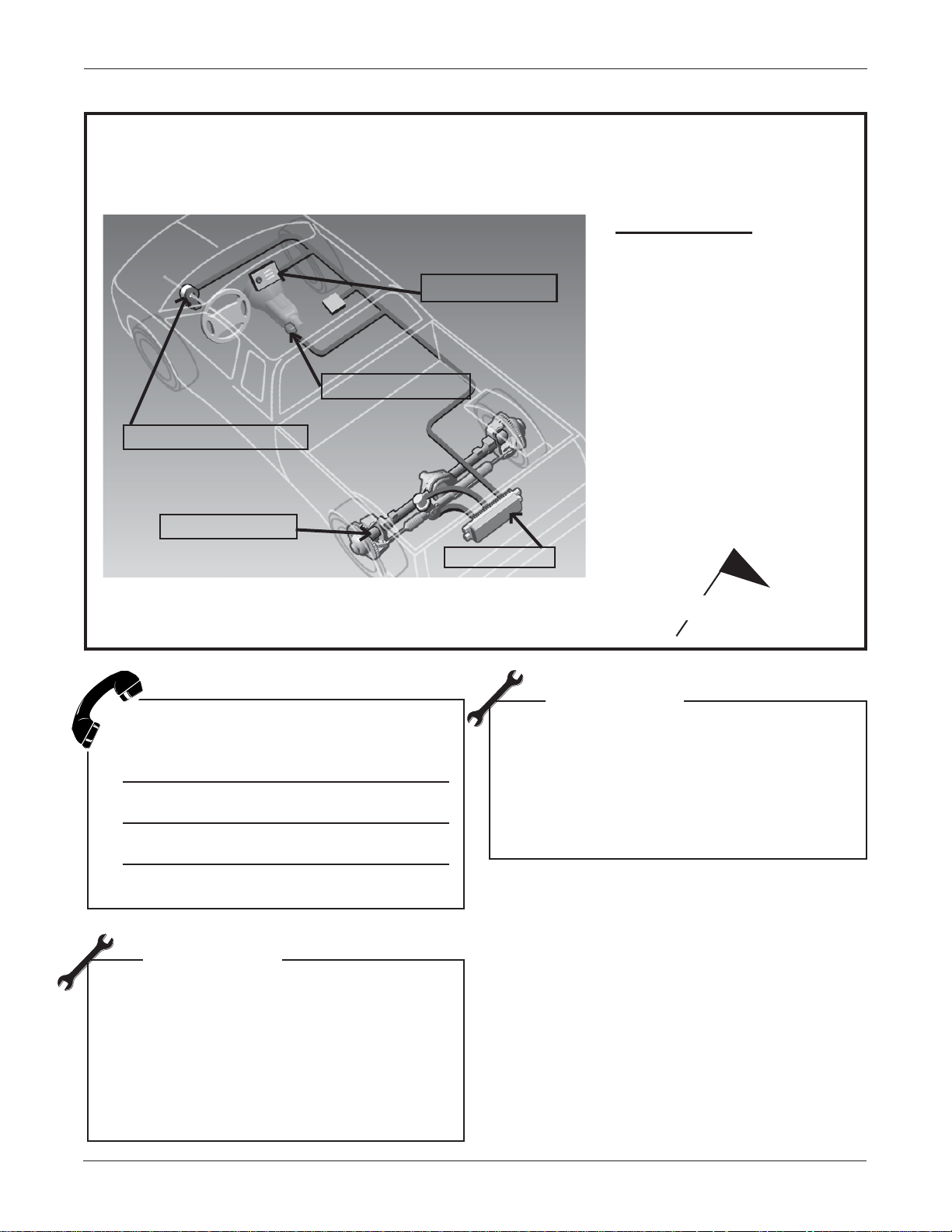

Component Locations

– Conventional front steering

4-Wheel Steer

– Conventional front steering with rear

wheel steer

4-Wheel Steer Tow

– Conventional front steering with rear

wheel steering optimized for towing

Rear steering angle is determined based on:

• Mode selection by the driver

• Speed of the vehicle

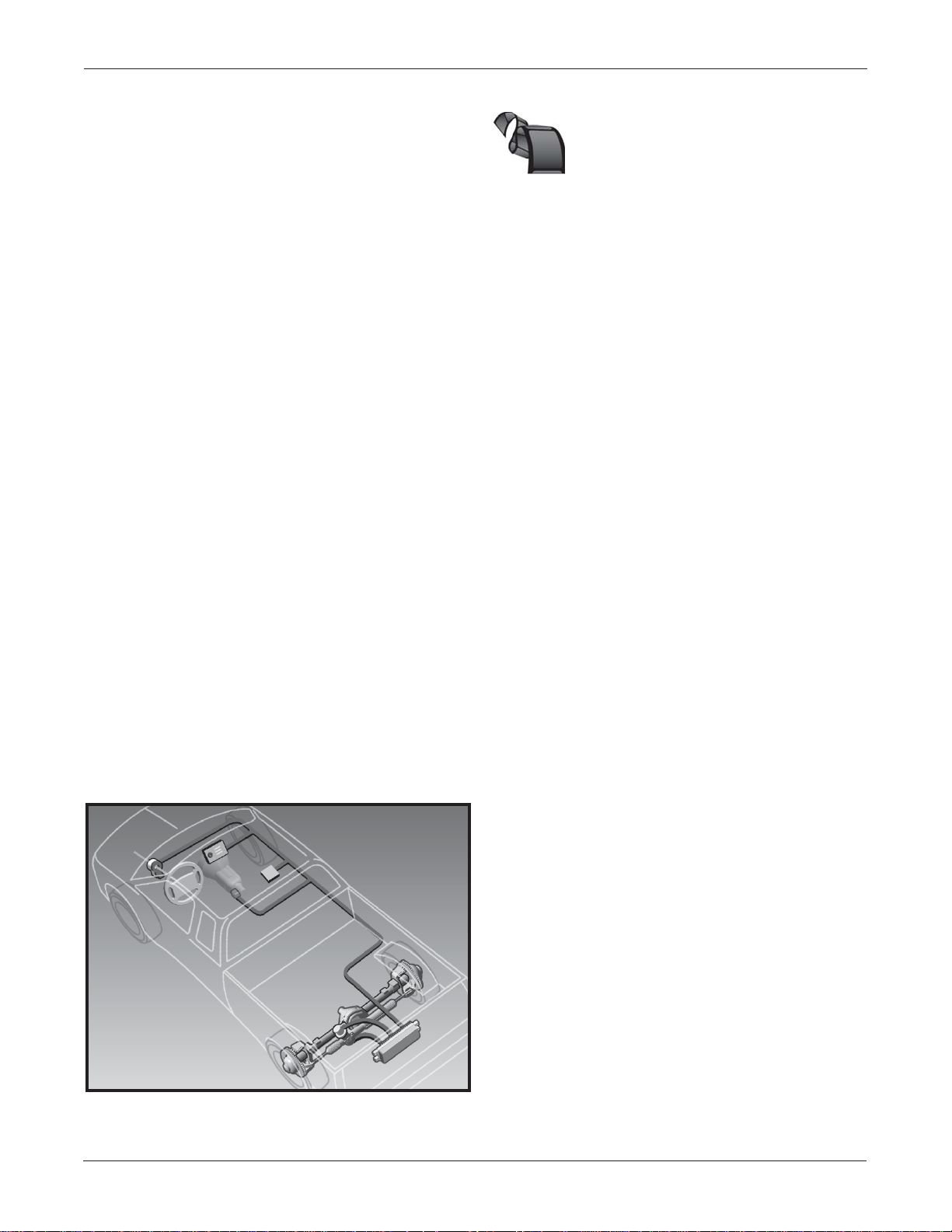

Component Locations

The video on component locations

demonstrates the visual placement of each

component in the system.

• Mode Select Switch – instrument panel

• Yaw Rate and Lateral Accelerometer –

beneath front passenger seat (Removed in

MY04)

• Vehicle Speed Sensor – transmission

housing

• Steerable Rear Axle – normal rear axle

position

• Difference is steerable rear axle includes

quarter shafts with steering components on

ends of quarter shafts

• Rear Wheel Steering Control Module –

frame mounted on rear undercarriage of

vehicle

• Rear Actuator – positioned on rear axle and

consists of:

- Inner and outer tie rods

- Rear Position Sensor

- Steering gear motor

- Rack and pinion assembly with boots

• Wiring Harness – subsystem of the vehicle

harness

Component Locations

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Introduction 1-7

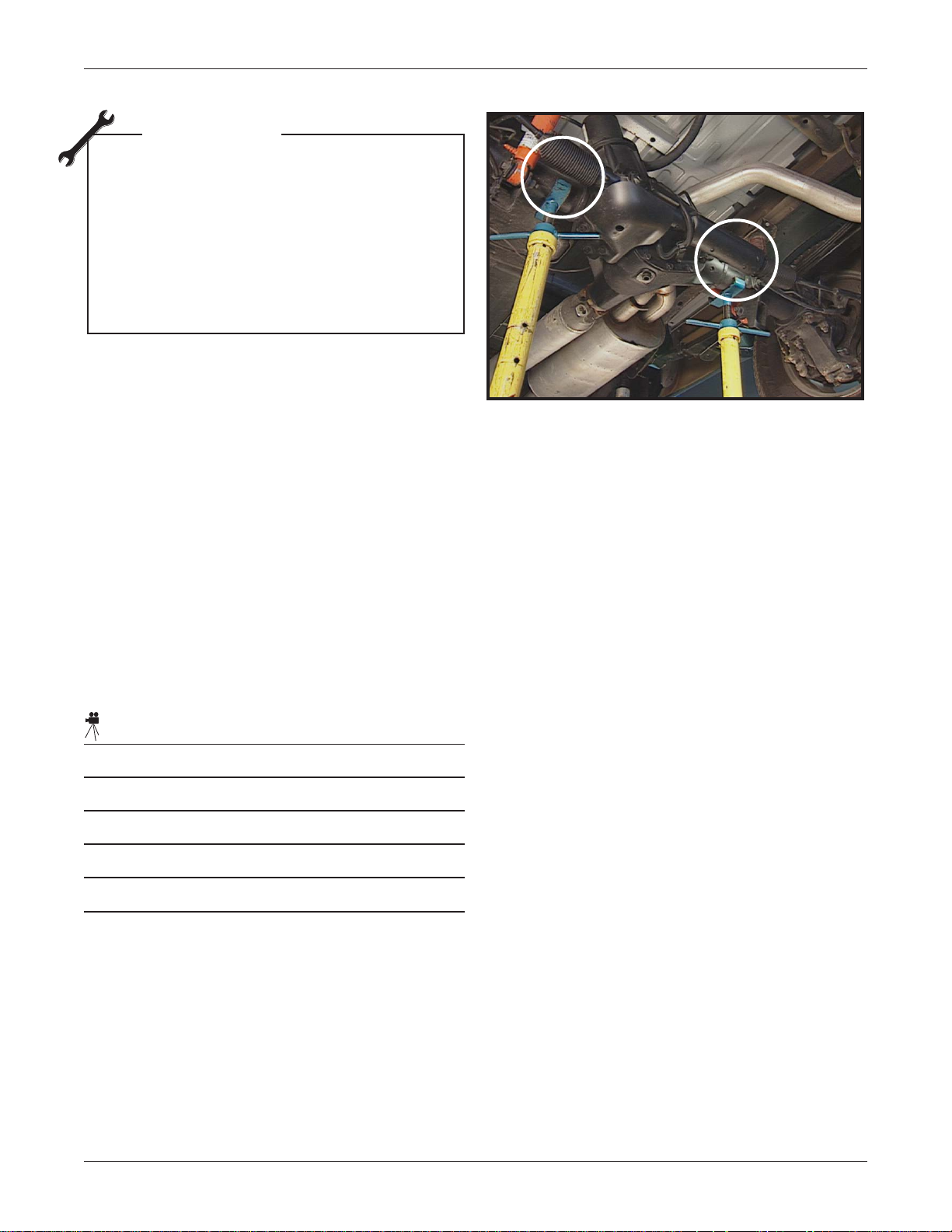

TECH TIP

Caution

When lifting the vehicle using an in-

ground hoist or supporting the axle

with jack stands, it’s very important that

the hoist is positioned at the correct

lifting points on the vehicle. If not, boot

damage may occur.

• Notice how close the lift point is to the boots

• Use caution when lifting this vehicle

Correct Lift Points (Circled)

• The recommended method to lift the vehicle

is using an above ground hoist

• Use current Service Information for details:

– Select "General Information" and then

"General Information " again. Next select

"Introduction". Finally select "Lifting and

Jacking the Vehicle".

Video Notes:

© 2006 General Motors Corporation Module 1

All rights reserved

1-8 Rear Wheel Steering (QUADRASTEER™)

Fill in the blanks on the illustration below with the letter for each component shown in

the list.

Exercise: Component Locations

Components

A. Steering Wheel Position

Sensor

B. Vehicle Speed Sensor

C. Mode Select Switch

D. Control Module

E. Steerable Rear Axle

Identify any one of the three inputs and

its purpose.

TECH TIP

GM recommends you do not use tire

chains with the Rear Wheel Steering

System. The chains could hit the

wheel housing when the wheels are

turning left or right. If you must use

chains, keep the vehicle in 2WS mode.

Hit your flag key when finished.

TECH TIP

Do NOT change the tire size. This may

cause interference with the wheel

housing and calibration concerns

with the ABS, PCM and the Rear

Wheel Steering Module.

Module 1 Summary

Benefits of System

Three Phases of Operation

Three Modes of Operation

System Components and Operation

Caution When Using In-Ground Hoist/Jack

Stand

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering

(QUADRASTEER™)

Module 2

Rear Wheel Steering System Operation

Rear Wheel Steering System Operation 2- 1

Module 2 Objectives

Identify individual system components

and their operation

Identify unique system features

Identifiy diagnostic information as it

relates to component operation

Video Outline – Rear

Wheel Steering System

Operation

• With the Mode Select Switch in the

4-wheel steer position, the Rear Wheel

Steering Control Module identifies inputs

from:

– Steering Wheel Position Sensor

– Vehicle Speed Sensor

• Based on information from those sensors,

the control module will react either:

– in the negative phase, turning the rear

wheels in the opposite direction of the

front wheels

– in the positive phase, turning the rear

wheels in the same direction as the

front

• The amount rear wheels are steered in

either direction is based on an algorithm

programmed into the control module

Front and Rear Tires in Same Direction

Front and Rear Tires in Opposite Direction

• Algorithm takes into consideration mode of

operation selected, position of the steering

wheel and vehicle’s speed

• Control module then processes this

information and turns the rear wheels

• At a slow speed the wheels turn in the

opposite direction, or in negative phase

• At a higher speed the wheels turn in the

same direction, or in positive phase

© 2006 General Motors Corporation Module 2

All rights reserved

Algorithm Chart

2- 2 Rear Wheel Steering (QUADRASTEER™)

Steering Wheel Position Sensor

The Steering Wheel Position Sensor

determines the driver’s steering input.

• Pin can only be installed in one position due

to sensor cap alignment

• Not the same sensor used on earlier trucks

for EVO

• Similar to that used on Corvette (active

handling) or Cadillac's Stabilitrac

Steering Wheel Position Sensor

Steering Wheel Position Sensor Location

TECH TIP

The Steering Wheel Position Sensor is

pre-indexed and should NOT be rotated

after pulling the shipping pin. If the

shipping pin gets removed, or if you are

reassembling a column and reusing the

original sensor, you can center the

sensor by plugging it into the harness

and installing a scan tool. Navigate to

the rear wheel data screen and view the

steering wheel sensor analog voltage

signal. Rotate the inner portion of the

sensor to obtain 2.5 volts. This is the

centered position. The sensor can now

be mounted onto the column with the

wheels in the straight ahead position.

• Located at base of steering column

• Identifies position of the steering wheel

– Identifies direction that front wheels are

pointed

– Indicates how far the steering wheel is

turned

Steering Wheel Position Sensor

Signals (Outputs)

Unlike most two-wheel-steer trucks with this

type of sensor, the Steering Wheel Position

Sensor generates four output signals. One

signal is analog and three signals are digital.

Analog signal

– Sensor Signal

Digital signals – all high/low output

– Phase A

– Phase B

– Index Pulse

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Operation 2- 3

Analog signals:

• 5-volt reference

• Signal out

• Sensor return

• Reports to BCM for MY2003 and above

• Vary between near 0 or near 5 volts for all

Quadrasteer vehicles

• Indicate when steering wheel is furthest

turning capacity of either direction (+/- 225

degrees from center)

Steering Wheel Position Sensor Analog

• Indicate position of the steering wheel

• When the steering wheel is at 0

degrees,

the analog sensor voltage will be about 2.5

volts

Digital signals:

• Phase A and Phase B signals indicate the

direction and range of motion of the front

wheels

– Digital signals have a 12 volt reference

and vary from approximately 11.49 to

0.25 volts (for MY03 and newer)

Output to Control Module

5

4

3

2

1

0

0 100-100 200 300-200-300

Steering Angle (deg)

– MY02 uses a 5 volt reference circuit

• Index pulse marker signal indicates:

– When the steering wheel is in the

centered position

– When the front wheels are

positioned straight ahead

– Used for mode change

– Sensor must indicate steering wheel

has moved ±10º for change to occur

© 2006 General Motors Corporation Module 2

Steering Wheel Analog Signal

Steering Wheel Digital Signal

All rights reserved

2-4 Rear Wheel Steering

Steering Wheel Position Sensor Digital Output to Control Module

Notes:

Participant Guide Revised 10/16/06

Rear Wheel Steering System Operation 2- 5

CENTER

A

B

COUNTERCLOCKWISE

ROTATION

INDEX

DEGREES ROTATION

20 DEGREES

CLOCKWISE

ROTATION

0

Sensor Malfunction

These three bulletins are related to steering

wheel position sensor malfunction: PI01736,

PIT3057c, PI00196.

• For PI01736 - Ground fastening interior

issue

– G203: Left side of IP near A pillar is

loose

– G107 & G104: Braided ground from

strap cowl to engine block is loose ensure it is tight

• For PIT3057c, C0455 code - Specific

wheel

– Caused by steering wheel turned

within first few seconds of engine start

– BCM and RWS control module

compare SWP data over Class 2

– Class 2 bus is busy, message is

delayed

– Refer to bulletin

• For PI00196 - Underhood megafuse

– Inspect megafuse; 125 amp at

underhood fuse holder wire; may be

loose

– Check circuit 1042, red wire

© 2006 General Motors Corporation Module 2

All rights reserved

2- 6 Rear Wheel Steering (QUADRASTEER™)

Question 3

What assists with Steering Wheel

Position Sensor installation?

A . Sensor molds to installation

B. Sensor is pre-indexed

C. Sensor is color-coded to

mounting

D. Alignment of screw holes

Steering Modes

Mode Select Switch Circuit

The Mode Select Switch Circuit provides an

input to the module for the driver’s request on

steering mode.

• Resistance of the momentary contact switch

is:

– 1.8k ohms to 2.2k ohms when switch is

released

– 450 ohms to 550 ohms when depressed

• Reference voltage is 5 volts

• Normal voltage range is 0.49v to 4.2v

– DTC B3593 sets when voltage is

outside this range

• Module is looking for specific voltage drop,

depending on if the switch is pressed or

released

Mode Select Switch Circuit

Mode Select Switch

The position of the Mode Select Switch

determines the steering mode selected by the

driver.

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Operation 2- 7

Video Outline – Steering

Modes

• With the Mode Select Switch in the 2-wheel

steer position:

– the rear wheels are locked in the

straight ahead position

– the vehicle steers and operates in the

same manner as a normal, 2-wheel

steering vehicle.

• 2-wheel steering is also called neutral

phase. Rear wheels do not move relative to

the front wheels

• With the Mode Select Switch in the

4-wheel steer position:

2-Wheel Steer - Wheels Remain Straight

– system will operate in the negative

hase at low speeds, turning the rear

wheels in the opposite direction of the

front wheels

– or in positive phase at high speeds,

turning rear wheels in same direction

as front wheels

• Both negative phase and positive phase

are determined by control module and are

based on position of steering wheel and

speed of vehicle

• Resulting amount or degrees the rear

wheels are turned determined by the

algorithm programmed into the control

module

• In the positive phase, this amount could be

as high as five degrees with the vehicle

traveling at higher speeds or as low as

twelve degrees when the system is being

controlled by the Tech 2 in the shop

4-Wheel Steer - Positive/Negative Phase

• With the Mode Select Switch in 4-wheel

steer tow mode, system works essentially

the same as in 4-wheel steer, except that

system is optimized for towing a trailer

© 2006 General Motors Corporation Module 2

All rights reserved

4-Wheel Steer Tow - Positive/Negative Phase

2- 8 Rear Wheel Steering (QUADRASTEER™)

Mode Lamps

What is the main difference between

4-Wheel Steer Mode and 4-Wheel

Steer in Tow Mode?

If all mode lamps are illuminated, the vehicle

requires wheel alignment. A learn alignment

procedure is also required. Replacing the

module without reprogramming will illuminate

all the mode lamps.

TECH TIP

After performing an alignment procedure,

confirm all mode lamps are NOT

illuminated. If all the mode lamps are

illuminated, this would indicate an

incomplete learn electrical alignment

procedure.

Transitions

To change modes, press the desired mode

switch on the dash.

• Indicator lamp of selected mode flashes

until steering wheel passes through center

– passing through ±10 degrees

• Once steering wheel passes through center,

indicator lamp of selected mode remains

illuminated

Mode Lamps

With the vehicle in Neutral for 4 seconds, the

system will default to 2-wheel steer and flash

the previous mode until the transmission is

place in gear.

• This is to accommodate automatic car

wash requirements and is normal. It is

something you may notice in your

diagnosis.

• With the vehicle in the park or reverse

position, Rear Wheel Steering is limited to

±5 degrees.

• PRNDL info is pulled from Class 2 data

If the system has a malfunction, the system will

Steering Wheel Centers

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

default to 2-wheel steer mode.

Rear Wheel Steering System Operation 2- 9

Y aw Rate and Lateral

Question 4

If the Mode Select Switch lamps

are all illuminated, ______.

A. replace the indicator

B. the vehicle is in 4-wheel tow

mode

C. the mode is changing

D. perform a learn alignment

procedure

Accelerometer Sensor

The Yaw Rate and Lateral Accelerometer

Sensor is one combined component rather

than two individual components as on some

other systems. It was eliminated in MY04.

• Voltage range for the sensor is 0 to 5 volts

• Sensor reports to rear steer module: uses

special functions under rear steer to center

the lateral accelerometer portion of the

sensor

– This zeros out the sensor settings and

it learns center position

YAW RATE

RTN

SIGNAL

5V

Yaw Rate/Lateral Accelerometer Circuit

YAW RATE/

LATERAL

ACCELEROMETER

SENSOR

LATERAL

ACCELEROMETER

SIGNAL

REAR

WHEEL

STEERING

CONTROL

MODULE

© 2006 General Motors Corporation Module 2

All rights reserved

2-10 Rear Wheel Steering (QUADRASTEER™)

V ehicle Speed Sensor

The Vehicle Speed Sensor (VSS), also used

for the Instrument Panel Cluster (IPC) is used

as a discrete input to the Rear Wheel Steering

Control Module. If this signal is not present, the

system will default to 2 wheel steer.

• The rear wheel steering module also

receives a Class 2 VSS signal as a

comparative signal

• If Class 2 and discrete signal vary by more

than

> 9 mph (15 kph), DTC C000 sets

• Located on the transmission/transfer case

output housing

• Signal is processed by the Powertrain

Control Module (PCM)

• Signals are then sent to the Instrument

Panel Cluster and the Rear Wheel Steering

Control Module

Steerable Rear Axle

The steerable rear axle consists of:

• Ball joints

• Tie rods

• CV joints on quarter shaft

• Rear actuator

• DANA 9

• Rear actuator assembly bolts in place of

rear differential cover and serves as both

differential cover and actuator mount

– Axle fluid service does not require

– Axle fluid contains a friction modifier

– No recommended service interval

¾ in. limited slip differential

removal of the acutator, utilizes drain

plug

Steerable Rear Axle

TECH TIP

• Rear axle fill capacities

– Oil capacity: approximately 3 L

Vehicle Speed Sensor Schematic

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

• No friction modifer for locker

equipped axles

Rear Wheel Steering System Operation 2-11

The video on the rear axle quarter shaft

operation demonstrates the basic function of

the quarter shafts.

Video Outline – Quarter

Shaft Operation

• Quarter shaft operation parallels what you

have seen on other axle shafts that are a

constant velocity or CV joint

• The rear axle quarter shaft knuckle joints

are able to move independent of one

another

• Due to mechanical constraints only normal

axle rotation and steering of the wheels at

the CV joint is allowed

Rear Axle Quarter Shafts

• There is no camber or caster adjustment.

The only adjustment is for toe

Video Notes:

Diaphram Seal

© 2006 General Motors Corporation Module 2

All rights reserved

2-12 Rear Wheel Steering (QUADRASTEER™)

Steerable Rear Axle Handling

Precautions

1. Diaphragm seal must be rolled onto cardan

joint to prevent damage

2. When inserting the axle shaft into the

housing, be sure to avoid damaging the

axle shaft oil seal

What components were added to

make the rear axle steerable?

Rear Wheel Steering Control

Module

The Rear Wheel Steering Control Module

monitors and controls the actuator.

Pinch Point between Ball Joint housing area

of the Rear Axle and the Steering Knuckle OPEN

Pinch Point between Ball Joint housing area

of the Rear Axle and the Steering Knuckle CLOSED

The module is mounted in the rear underbody

near the spare tire on a bracket connected to

the frame.

• The Control Module determines the correct

amount of rear wheel steering needed at

the rear wheels

• Based on the inputs received, the module

energizes the steering motor to turn the rear

wheels either left or right

• Watch for the pinch point between the ball

joint housing area of the rear axle and

and the steering knuckle

Rear Wheel Steering Control Module

• The pinion angle should not be shimmed

or changed

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Operation 2-13

Control Module Inputs/Outputs

TECH TIP

Control Module Inputs and Outputs

Inputs:

• Vehicle Speed Sensor

Any time a controller is replaced, the

truck requires a learn alignment due to

calibration.

• Class 2 Serial data

• Mode Select Switch

• Steering Wheel Position Sensor

• Phase 1

• HWP Phase A, B

• HWP Absolute

• HWP Index Pulse

• Rear Position Sensor

• Hall Sensor A, B, C

Outputs:

• Mode Select Switch

• Steering gear motor assembly - Motor

phase 1, 2 & 3

• Service 4-Wheel Steer

Control Module Unique Features

• Calibrations are unique to each vehicle for

MY02 only

• There are three different part numbers for

the control module, each with an individual

calibration

• For MY03 and later there is one part

number and it is programmable through TIS

Control Module Features

There are two DTCs related to the operation of

the module. They are C0550 and U1305.

C0550 will set with any internal failure in the

rear wheel steering control module.

If normal Class 2 communication is interrupted

or disabled, a DTC U1305 may set.

• Class 2 serial data

• Shorting Relay

© 2006 General Motors Corporation Module 2

All rights reserved

2-14 Rear Wheel Steering (QUADRASTEER™)

Question 5

Which of the following is a true

statement about the 2002 Control

Module?

A . There is only one software

calibration.

B. A DTC C0550 can be set only

one way.

C. It has three part numbers with

three software calibrations.

D. There are three part numbers

for the module with one

calibration.

Rear Actuator

The Rear Actuator controls the direction of the

rear wheels and consists of the following

components:

• Inner tie rods

Operational Characteristics

The video on operational characteristics of the

actuator includes the normal operating sound

the actuator makes.

Video Outline –

Operational

Characteristics

• During normal vehicle operation, no

operating noise from the rear wheel

steering actuator should be audible

• When commanded by the Tech 2, sound

can be heard from the actuator during

operation, which is normal

TECH TIP

A mechanical binding condition in the

actuator could generate an electrical

DTC (C0543).

• Outer tie rods

• Rack and pinion unit with boots

• Steering motor

Actuator

Rear Actuator

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Operation 2-15

Inner Tie Rods

The inner tie rods are attached to the steering

rack and turn the rear wheels as the motor

rotates.

• Support clamp has right hand threads

– To remove the support clamp, turn it

counterclockwise

• Support nut has left hand threads

• Check for tie rod wear by physical

inspection

Inner Tie Rod Special T ools

Inner Tie Rods

Two special tools are required when servicing

the inner tie rods:

• J 44665-1 – Inner tie rod wrench

• J 44665-2 – Inner tie rod wrench (2-sided

wrench)

© 2006 General Motors Corporation Module 2

All rights reserved

2-16 Rear Wheel Steering (QUADRASTEER™)

Outer Tie Rods

The Outer Tie Rods are attached to the

steering knuckles at the ends of each axle

shaft. The tie rods use an overlaying bracket on

each side.

TECH TIP

When servicing the system, only

puller J 24319-B should be used to

disengage the outer tie rod from the

steering knuckle.

Outer Tie Rods

Tie Rod Bracket

• Prevents complete disengagement of the

tie rod from the steering knuckle

Tie Rod Bracket

• Bracket maintains tie rod operation, even

if nut malfunctions

TECH TIP

If the rear of the vehicle drifts or

wanders, a malfunctioning tie rod

may exist.

An important part near the Inner Tie Rods is

the Return To Center Spring. This spring is an

internal component of the actuator assembly

and is non-serviceable.

• Spring is very powerful and no

disassembly is allowed

• With the ignition OFF, the Return To

Center Spring returns the wheels to the

straight ahead position

Return to Center Spring

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Operation 2-17

Question 6

What should you suspect if you

notice a slight whining noise from the

actuator while operating the system?

A . The actuator should be replaced.

B. The inner tie rod is worn.

C. The actuator is working normally.

D. The rear position sensor is out of

alignment.

Rack and Pinion Boot

Rack and Pinion Boots

The Rear Rack and Pinion Boots function

similarly to the Front Rack and Pinion Boots.

Differences from the front boots include:

• Rear boots are more robust, stiffer and

thicker

• Rear boots may possibly be more exposed

to damage by road debris

• When replacing boots, make sure they are

in actuator and inner tie rod grooves

Boot Check

The video on checking boots demonstrates how

to check boots for damage.

TECH TIPS

• Rack and Pinion Boots can be

damaged by an in-ground hoist

• If boots are damaged on the hoist,

replace the boots with boot kit

• If damage to boots occurs while

driving, replace the entire

actuator assembly

– Damage could be due to water

intrusion which would cause

repeated failure of the rear

position sensor

© 2006 General Motors Corporation Module 2

All rights reserved

2-18 Rear Wheel Steering (QUADRASTEER™)

Rear Position Sensor Unique Features

What steering components could

cause the vehicle to drift?

Rear Position Sensor

• Skid plate must be removed to access

cover and the cover needs to be removed to

gain access to sensor

• Do not rotate sensor; it cannot be relocated

• Use Blue LocTite 242

• Properly torque bolt when reinstalling to

35 in/lbs

The Rear Position Sensor is located in the

bottom of the rack and pinion unit on the

Actuator Motor Assembly.

Rear Position Sensor with Cover Installed

• Provides rear wheel steer control module

with actuator position

Rear Position Sensor Additional Information

• O-ring in the actuator is green to be more

visible and housing is black

– Replace O-ring if sensor is removed/

replaced

– Retaining fingers in actuator housing

hold O-ring in place

– If oil or water is present when servicing

Rear Position Sensor, replace

actuator assembly

• If sensor is replaced, perform the learn

alignment procedure

• With wiring or connection malfunction,

replace motor assembly

– Do not attempt to repair harness or

terminals as they are integral part of

motor assembly

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Operation 2-19

Rear Position Sensor Activation

Video Outline – Rear

The video on Rear Position Sensor Operation

demonstrates the operation of the sensor as it

picks up movement of the rack.

Planetary Gear Activated

• Once the Mode Select Switch is placed in

one of the mode selections, the rear wheel

steering control module sends a signal to

the motor assembly

• The motor then activates the planetary gear

sets inside the motor housing

• The pinion gear drives the steering rack

along its teeth and the rear position steering

sensor through its center

• As the rack steers the rear wheels in the

commanded direction, the rear position

sensor sends a corresponding signal back

to the control module indicating the position

of the rear wheels

Position Sensor Operation

Pinion Gear

• The sequence continues constantly while

the Mode Select Switch is in one of the fourwheel steer positions

© 2006 General Motors Corporation Module 2

All rights reserved

2-20 Rear Wheel Steering (QUADRASTEER™)

REAR

WHEEL

STEERING

5 VOLT

REFERENCE

POSITION 1

SIGNAL

SENSOR

GROUND

POSITION 2

SIGNAL

CONTROL

MODULE

REAR

POSITION

SENSOR

Rear Position Sensor Circuit

There are several inputs and outputs for the

Rear Position Sensor.

• 5 volt reference

• Ground

• Position 1 signal

• Position 2 signal

Question 7

Does the Rear Position Sensor

obtain its data from circuits internal

to the steering motor?

Yes

No

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Operation 2-21

Rear Wheel Position Sensor Diagnostic Information

º

300

Rear Wheel Sensor Data

The two signals, when utilized together, provide

very accurate position signals.

• Position 1 signal (300 degrees either side

of center) - approximate signal

– provides module with approximate

rack location

Question 8

º

300

• Position 2 signal - refined signal

– provides module with refined location

depending on approximate signal

• At 2.5 volts, actuator is in the straight ahead

position

• If voltage is too close to 0 volts or 5 volts, it

indicates a circuit fault

Which of the following is important

to check when replacing the Rear

Position Sensor?

A. O-ring lubrication

B. Bolt torque

C. Pinion aligment

D. Sensor cover index marks

© 2006 General Motors Corporation Module 2

All rights reserved

2-22 Rear Wheel Steering (QUADRASTEER™)

Steering Gear Motor

The Steering Gear Motor is inside the Rear

Rack and Pinion Steering Gear. It:

• Mounts to top of Actuator Assembly

• Operates through planetary gear set at 45:1

ratio

Steering Gear Motor Unique Features

• If motor replaced, make sure O-ring

installed and seated properly

• Motor removal exposes planetary gear set

which must be protected from

contamination (clean undercarriage before

removal)

– fluid not replaceable/not serviceable

– if the fluid is contaminated, replace the

entire actuator assembly

• Motor installation requires engaging sun

gear with planetary gears

• Harness must be oriented properly during

motor installation

• Motor replacement does not require learn

alignment

Steering Gear Motor

• Ground straps must be connected

– one for the motor and two for the

controller

If the motor is not operating properly it could

generate an electronic-related DTC, which is

C0538.

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Operation 2-23

The Steering Gear Motor inputs control selfpositioning motor circuitry.

• Hall sensor 12v reference

• Hall sensor ground

• Actuator Hall A signal, Actuator Hall B

signal, Actuator Hall C signal

– used to determine which motor phase

to energize

• Hall sensor malfunction only repaired by

actuator motor replacement

The Steering Gear Motor outputs control motor

operation.

• Actuator Phase A control, Actuator Phase B

control, Actuator Phase C control

– control module energizes phases

• The shorting relay shorts all 3 phases

together, causing the motor to act as an

electromagnetic brake whenever the

module removes power, slowing the rear

wheel return to center

• Relay shorts all of these phases together

• Relay slows vehicle with a controlled return;

doesn't "snap" back

• Motor shorting relay power and ground

• 3 phase brushless DC motor

ACTUATOR

HALL A

SIGNAL

ACTUATOR

HALL B

SIGNAL

ACTUATOR

HALL C

SIGNAL

HALL

SENSOR

12 V

REFERENCE

C1

Steering Gear Motor Inputs/Outputs

HALL

SENSOR

GROUND

ACTUATOR

PHASE A

CONTROL

C2

ACTUATOR

PHASE B

CONTROL

MOTOR

M

3 Ω

ACTUATOR

PHASE C

CONTROL

SHORTING

RELAY

VO LTAGE

C1

SHORTING

RELAY

GROUND

SHORTING

RELAY

REAR

WHEEL

STEERING

CONTROL

MODULE

STEERING

GEAR

MOTOR

ASSEMBLY

© 2006 General Motors Corporation Module 2

All rights reserved

2-24 Rear Wheel Steering (QUADRASTEER™)

Question 9

When the motor is serviced, you

should ______.

A . replace the lubricant

B. perform an alignment

C. re-calibrate the control module

D. protect the gearset from

contamination

Exercise

Draw a line to match the component in the left column with its function in the right column.

Component

Steering Wheel

Position Sensor

Rear Wheel

Steering Control

Module

Rear Actuator

Function

Commands Rear

Actuator

Controller Input

Positions Wheels

Hit your flag key when finished.

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering System Operation 2-25

System Operation

The video on system operation demonstrates

how the components all work together.

Video Outline – System

Operation

• Explain system operation by looking at its

sensor data

• Steering Wheel Postion Sensor

continuously monitors the position of the

steering wheel and tells the control module

the number of degrees from center the

steering wheel has been turned in either

direction

Steering Wheel Speed Sensor Activation

• Mode Select Switch provides a driverselectable input to the control module of the

desired steering mode

• Vehicle Speed Sensor is multi-purpose

sensor that continuously monitors the

vehicle’s speed so it can determine rear

wheel steering phase and amount rear

wheels will be turned

• Yaw Rate and Lateral Accelerometer

Sensor only records history information

• Rear Wheel Steering Control Module output

consists of three voltage phases applied to

the Rear Wheel Seering Gear Motor

• Last rear wheel steering input comes from

the Rear Position Sensor

• This information, along with other inputs, is

used to determine rear wheel steering

phase and amount the rear wheels will be

turned

Vehicle Speed Sensor Activation

Module 2 Summary

System Components

System Operation

Unique System Features

Diagnostic Information

© 2006 General Motors Corporation Module 2

All rights reserved

Rear Wheel Steering

(QUADRASTEER™)

Module 3

Four-Wheel Steering Alignment

Four-Wheel Steering Alignment 3-1

Mechanical Alignment Procedure

Module 3 Objectives

Identify Tech 2 Learn Alignment

Procedure

Identify Tech 2 Special Functions

TECH TIP

Replacement of any serviceable

component, other than the rear wheel

steering motor, requires a learn

alignment procedure, which in turn

requires a four-wheel alignment

Alignment Guidelines

Alignment with the Rear Wheel Steering

System consists of four major steps:

1. Repair concerns and clear DTCs from the

RWS system

2. Clear the learned alignment parameters:

The steering wheel position sensor and rear

wheel position sensor straight ahead info

– connect Tech 2 and follow Special

Function instructions

1. Repair concerns and clear DTCs from the

RWS system

2. Clear the learned alignment parameters

3. Perform the mechanical alignment

4. Perform learn alignment procedure

Clear Alignment Information

© 2006 General Motors Corporation Module 3

All rights reserved

3- 2 Rear Wheel Steering (QUADRASTEER™)

Mechanical Alignment Procedure

cont.

3. Perform the mechanical alignment

• Tech 2 instructs you to turn the ignition

OFF and perform mechanical adjustments

as necessary

– press CONTINUE when done

Perform Mechanical Adjustments

4. Perform learn alignment procedure

• START engine

– check to be sure the rear wheels

are centered (lift rear wheels)

– if OK, press CONTINUE

Start Engine

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Four-Wheel Steering Alignment 3-3

The Tech 2 directs you to turn the steering

wheel 90 degrees (or a quarter turn) to the left,

followed by turning to 90 degrees past center to

the right.

• System “learns” front and rear sensor

positions

• Tech 2 verifies “Learn Alignment

procedure has been successfully

completed”

Upon completion, the system defaults to

2-Wheel Steer mode. Drive the vehicle with all

Learn Alignment

modes to verify proper 4-Wheel Steer

operation.

If the Learn Alignment Procedure didn't function

as expected, several things will happen to

indicate that this has occurred.

Unsuccessful Alignment

Question 10

Before clearing the controller

learned parameters, it is important to

______.

A . turn the igniton OFF

B. run the engine for five minutes

C. diagnose and repair any DTCs

Upon completion of learning the front and rear

sensor positions:

• If Tech 2 screen displays “Learn

Alignment unsuccessful,” then retry learn

alignment procedure up to 2 additional

times

– Tech 2 identifies whether front or

rear sensor is out of range

– Follow Service Information to repair

it

Alignment Procedure Wrap-Up

A test drive using all modes is required after an

alignment is completed.

When in the four-wheel steering tow mode, the

steering wheel may be slightly offset from

center, up to but no more than five degrees.

D. learn sensor positions

© 2006 General Motors Corporation Module 3

All rights reserved

3- 4 Rear Wheel Steering (QUADRASTEER™)

Tech 2 Special Functions

The video on Tech 2 Special Functions

demonstrates the operation of the following:

• Lamps

• Motor control

• Steering commands

Video Outline – Tech 2

Special Functions

• Rear wheel steering system offers

bi-directional interface for scan tools, such

as Tech 2. Functional output tests allow

verification of proper operation

Tech 2 Special Functions Submenu

• Functional output tests are listed by

pressing F2 from the Chassis menu

• After F0, “Learn Alignment," other nine

selections allow activation of system

functions

• F1 through F5 command specific system

actions. F6 through F9 operate system

indicator lamps

• Using “Command Rear Steer” left or right

actuates system to commanded position

• When ON is selected, rear wheels are

steered to commanded position

• When OFF is selected, wheels return to

normal straight ahead position

• Changing data parameters can be noted…

most notably rear position sensor

• Selecting one of three mode commands

allows system to be placed into that mode

Tech 2 Data Parameters

• Selected parameter should be displayed

until OFF is selected

• Four separate mode lamp tests possible to

verify operation

• Each can be operated individually as well

as all ON at once

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Tech 2 with Mode ON

Four-Wheel Steering Alignment 3-5

Notes:

Module 3 Summary

Tech 2 Learn Alignment Procedure

Tech 2 Special Functions

Evaluation Instructions

Turn to the Evaluation at the end of this session in your workbook; remove and

complete the course evaluation as instructed

Use the keypad to answer the multiple choice questions

Press the "Next Quest" key after answering each question

Press "Yes" when completed

Fill out the back of the evaluation form

Include today's date, time and time zone

Fax your written evaluation to the Detroit Training Center at (586) 576-3319

© 2006 General Motors Corporation Module 3

All rights reserved

Rear Wheel Steering

(QUADRASTEER™)

Appendix

Appendix A-1

**** QUADRASTEERTM Service Update ****

Features of normal QUADRASTEERTM operation

· Rear angle is limited to 5 degrees in park (w/ no vehicle speed) - once vehicle speed is

present the system is capable of 12 degrees.

· Rear angle is limited to 5 degrees when driving in reverse

· Neutral operation - system defaults to 2WS if in neutral for more than 4 seconds. The 2ws

mode light will be illuminated and the previous mode will be flashing. When shifted out of

neutral the system will automatically go back to the previous mode.

· Mode changes - QUADRASTEER

TM

will only change modes when the steering wheel passes

through center, until then the requested mode will be flashing. ('03 and newer models will

switch modes immediately if speed=0)

Vehicle requirements for QUADRASTEERTM to operate

· Engine must be running

· Alternator / Charging system must be functional. If a fault is detected by the Alternator/

Charging system, the QUADRASTEERTM system will become inoperable to minimize battery

drain.

· System voltage must be within a 9 - 16 volt range.

· System voltage is supplied by 1 high-current connection, 1 low-current connection, & 1 ignition

line.

· Valid vehicle speed information from the PCM (hard-wired & class II message) and ABS

(class II message) must all correlate.

· Valid hand wheel position information must be received. Analog information from the Truck

Body Controller (TBC) via Class II and digital information is obtained from phase A, phase B,

& Marker pulse of the position sensor wired directly to the QUADRASTEERTM control module.

· Valid signals from rear position sensor.

© 2006 General Motors Corporation Appendix

All rights reserved

A-2 Rear Wheel Steering (QUADRASTEER™)

Most common mis-diagnosed QUADRASTEER

TM

issues

· QUADRASTEERTM does not operate and all three mode lights illuminated solidly

May be caused by

– Service control modules need to be programmed (03 MY and above) and/or needs tech II

alignment to be performed. No class II information is available until module is

programmed.

· QUADRASTEERTM does not operate and blinking mode lights

May be caused by

– Vehicle in Neutral. QUADRASTEERTM will return to normal operation when shifted out of

Neutral and steered through straight ahead.

· C0550 DTC - internal controller fault

May be caused by

– A loose 125 Amp Mega-fuse.

– Shorted Lat / Yaw combo sensor

– Water intrusion into rear position sensor

· C0522 DTC and/or C0532 DTC - Rear Wheel Sensor and Rear Sensor to Hall Comparison

May be caused by

– Shorted Lat / Yaw combo sensor

– Water intrusion into rear position sensor

· C0455 DTC - Handwheel Position Sensor (HWPS)

May be caused by

– Improper terminal tension at HWPS connector

– Loose or damaged ground at circuit G203 (03 MY and above).

– Damaged harness between C201 and HWPS connector

· QUADRASTEERTM inoperable with no DTC's present

May be caused by

– Missing required vehicle signals such as Ignition (541), Batt2 (2640), Engine Run message

(Class II) or faulted Charging System. See Vehicle Requirements for

QUADRASTEERTM Operation above.

Note: Clearing History DTCs from the controller is NOT required to restore normal operation

during troubleshooting. PLEASE LEAVE CODES STORED IN THE MODULE. This will aid in

root cause analysis.

Participant Guide © 2006 General Motors Corporation Revised 10/16/06

All rights reserved

Rear Wheel Steering

(QUADRASTEER

Evaluation

TM

)

Service T echnical Level 1 Evaluation E-3

Rear Wheel Steering (QUADRASTEERTM) Course #13041.20D

Customer Satisfaction Survey

Interactive Distance Learning

We value your opinion regarding this course. Please take a few minutes to complete this evaluation,

including your suggestions for course improvements.

If a statement does not apply , leave it blank.

Strongly Disagree

Disagree

Somewhat Agree

Relevance / Value

1. This course provides knowledge/skills useful to me now and/or in the future. A B C D E

2. This course met the stated objectives. A B C D E

Agree

Strongly Agree

3. I will recommend this course to others. A B C D E

Design

4. The amount of material presented in this course is just right. A B C D E

5. The content is realistic and practical. A B C D E

6. The content is sequenced so that it is easily understood. A B C D E

7. The participant materials support the instructor’s presentation. A B C D E

Instructor

8. The instructor appeared well-prepared and organized. A B C D E

9. The instructor demonstrated a thorough understanding of the subject matter. A B C D E

10. The instructor presented course material at a comfortable pace. A B C D E

11. The instructor responded effectively to questions. A B C D E

Delivery

12. There were no technical (equipment) problems during this course. A B C D E

13. Handouts, workbook, visuals and/or other aids are clear, effective, and understandable. A B C D E

14. The activities / exercises helped me better understand the information presented. A B C D E

Version 1.0 © 2006 General Motors Corporation

All rights reserved

E-4 Service T echnical Level 1 Evaluation

Course #13041.20D Rear Wheel Steering (QUADRASTEERTM)

Customer Satisfaction Survey

Interactive Distance Learning

We value your opinion regarding this course. Please take a few minutes to complete this evaluation, including

your suggestions for course improvements.

Course Date: _____/_____/_____ Time: _________________ Time Zone: AT ET CT MT PT

Instructor's Name:__________________________________________________

Additional Comments

Please share any additional comments you may have to improve the relevance of this training.

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Please share any additional comments you may have to improve the design of this training.

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Please share any additional comments you may have regarding the instructor conducting this training.

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Please share any additional comments you may have to improve the delivery of this training.

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Please share any additional comments, positive or negative, you may have regarding course improvements.

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Thank you for taking the time to help us build an effective GM Distance Learning Program.

Please fax to: Detroit IDL Center at 586-576-3319

Version 1.0 © 2006 General Motors Corporation

All rights reserved

Loading...

Loading...