General Motors DTC U1002 Specifications

3/8/2021 Direct-Hit -- Search

https://dh.identifix.com/SearchFixes/Index?ROID=280669408&VID=2417566&VSM=2&LocationId=2&WorkflowPath=1&SearchTerm=u1002#KW=u10

…

DTC U1002 (DATA COMMUNICATION...

DTC U1002 (DATA COMMUNICATIONS) Document ID# 3972437

DTC U1002 (DATA COMMUNICATIONS)

Diagnostic Instructions

Perform the Diagnostic System Check - Vehicle prior to using this diagnostic procedure.

Review Strategy Based Diagnosis for an overview of the diagnostic approach.

Diagnostic Procedure Instructions provides an overview of each diagnostic category.

DTC Descriptor

DTC U1002 : System Comm (CAN)

For symptom byte information, refer to Symptom Byte List .

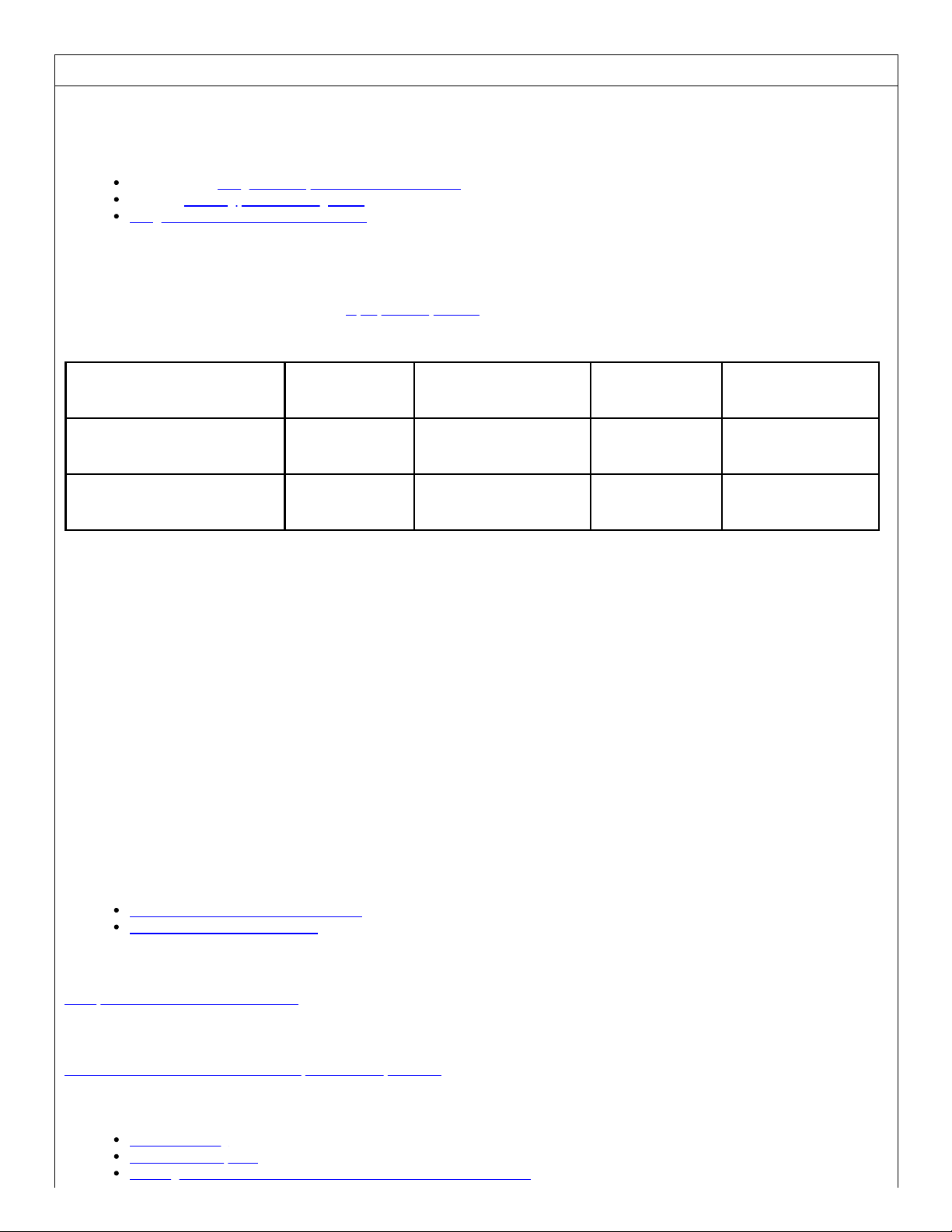

Diagnostic Fault Information

Circuit

Short to

Ground

Open/High

Resistance

Short to

Voltage

Signal

Performance

High Speed LAN Serial Data

(+)

U1000, U1002 U1002 U1000, U1002 —

High Speed LAN Serial Data

(−)

U1000, U1002 U1002 U1000, U1002 —

Circuit/System Description

CAN (Controller Area Network) is a serial communication line for real-time application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction detection ability. Many

electronic control units are equipped onto a vehicle, and each electronic control unit shares information and links

with other electronic control units during operation (not independently). In CAN communication, electronic control

units are connected with 2 communication lines (CAN-H line, CAN-L line) allowing a high rate of information

transmission with less wiring. Each electronic control unit transmits/receives data but selectively reads required

data only.

Conditions for Running the DTC

The system voltage is between 9–16 V.

Conditions for Setting the DTC

The device is not transmitting or receiving CAN communication signal for 2 s or more.

Reference Information

Schematic Reference

Data Communication Schematics

Control Module References

Connector End View Reference

Component Connector End Views

Description and Operation

Data Link Communications Description and Operation

Electrical Information Reference

Circuit Testing

Connector Repairs

Testing for Intermittent Conditions and Poor Connections

1/3

3/8/2021 Direct-Hit -- Search

https://dh.identifix.com/SearchFixes/Index?ROID=280669408&VID=2417566&VSM=2&LocationId=2&WorkflowPath=1&SearchTerm=u1002#KW=u10

…

Wiring Repairs

Scan Tool Reference

Control Module References for scan tool information

Circuit/System Verification

1. Ignition ON.

2. Verify DTC U1000 is not set.

⇒ If DTC U1000 is set

Refer to Scan Tool Does Not Communicate with High Speed GMLAN Device .

⇓ If DTC U1000 is not set

3. Refer to Circuit/System Testing.

Circuit/System Testing

Note:

Inspect the connectors and terminals for damage and loose connection.

Use the schematics and connector end views to identify the control module's ground, B+, ignition, and

serial data circuit terminals.

1. Ignition OFF, all access doors closed, all vehicle systems OFF, and all keys at least 3 m (9.8 ft) away from

vehicle. It may take up to 2 min for all vehicle systems to power down. Disconnect all the harness connectors

at the K17 Electronic Brake Control Module.

2. Test for less than 10 Ω between each ground circuit terminal and ground.

⇒ If 10 Ω or greater

2.1. Ignition OFF.

2.2. Test for less than 2 Ω in the ground circuit end to end.

⇒ If 2 Ω or greater, repair the open/high resistance in the circuit.

⇒ If less than 2 Ω, repair the open/high resistance in the ground connection.

⇓ If less than 10 Ω

3. Ignition ON.

4. If equipped, verify a test lamp illuminates between each B+ circuit terminal and ground.

⇒ If the test lamp does not illuminate and the circuit fuse is good

4.1. Ignition OFF, remove the test lamp.

4.2. Test for less than 2 Ω in the B+ circuit end to end.

⇒ If 2 Ω or greater, repair the open/high resistance in the circuit.

⇒ If less than 2 Ω, verify the fuse is not open and there is voltage at the fuse.

⇒ If the test lamp does not illuminate and the circuit fuse is open

4.1. Ignition OFF, remove the test lamp.

4.2. Test for infinite resistance between the B+ circuit and ground.

⇒ If less than infinite resistance, repair the short to ground on the circuit.

⇒ If infinite resistance, replace the K17 Electronic Brake Control Module.

⇓ If the test lamp illuminates

5. If equipped, verify a test lamp illuminates between each ignition circuit terminal and ground.

⇒ If the test lamp does not illuminate and the circuit fuse is good

5.1. Ignition OFF, remove the test lamp.

5.2. Test for less than 2 Ω in the ignition circuit end to end.

⇒ If 2 Ω or greater, repair the open/high resistance in the circuit.

⇒ If less than 2 Ω, verify the fuse is OK and there is voltage at the fuse.

⇒ If the test lamp does not illuminate and the circuit fuse is open

2/3

Loading...

Loading...