Page 1

GE Home Generator Systems

Not

for

Reproduction

Home Generator System

Installation and

Start-Up Manual

Page 2

Thank you for purchasing this quality-built GE home generator. We’re pleased that you’ve placed your confidence in the

Not

for

Reproduction

GE brand. When operated and maintained according to the instructions in the operator’s manual, your home generator

will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with residential

generator systems and how to avoid them. This generator system is designed and intended only for use as an

optional home standby system that provides an alternate source of electric power and to serve loads such as heating,

refrigeration systems, and communication systems that, when stopped during any power outage, could cause

discomfort or inconvenience. Save these original instructions for future reference.

This generator requires professional installation before use. The installer should follow the instructions completely.

Where to Find Us

You never have to look far to find support and service for your generator. For quick service when you need it most

fill out the information below and keep your original receipt with this manual. You may contact Customer Service at

(888) 575-8226, or click on SERVICE & SUPPORT at www.homestandbygeneratorsystems.com, which provides a list of

authorized dealers.

For Future Reference

Please fill out the information below and keep with your receipt to assist in unit identification for future purchase issues.

DATE OF PURCHASE

GENERATOR

Model Number

Model Revision

Serial Number

ENGINE

Model Number

2

Page 3

Table of Contents

Not

for

Reproduction

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Important Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Home Owner Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing Dealer/Contractor Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cold Weather Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpacking Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Delivery Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shipment Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Generator Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Placement of Standby Generator to Reduce the Risk of Carbon Monoxide Poisoning . . . 10

Placement of Standby Generator to Reduce the Risk of Fire . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Other General Location Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

National Fire Protection Association (NFPA) Standard NFPA 37

Requirements and Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

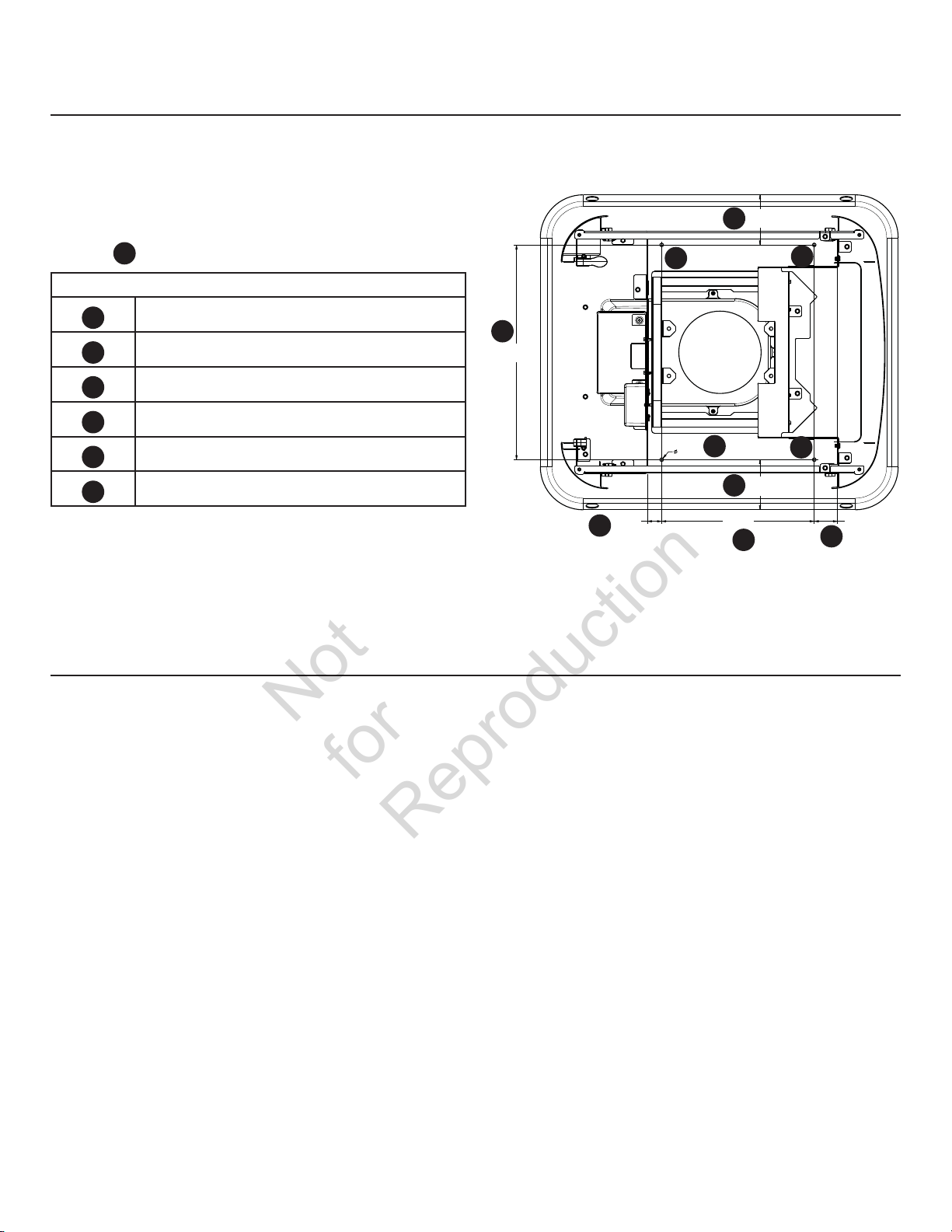

Electrical and Fuel Inlet Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Lifting the Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Access Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The Gaseous Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

System Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Generator AC Connection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Grounding the Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Utility Circuit Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Transfer Switch Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Fault Detection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

System Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Concrete Slab (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Final Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Initial Start-up (No Load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Engine Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Schematic / Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Automatic Operation Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting Exercise Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3

Page 4

Safety Rules

Not

for

Reproduction

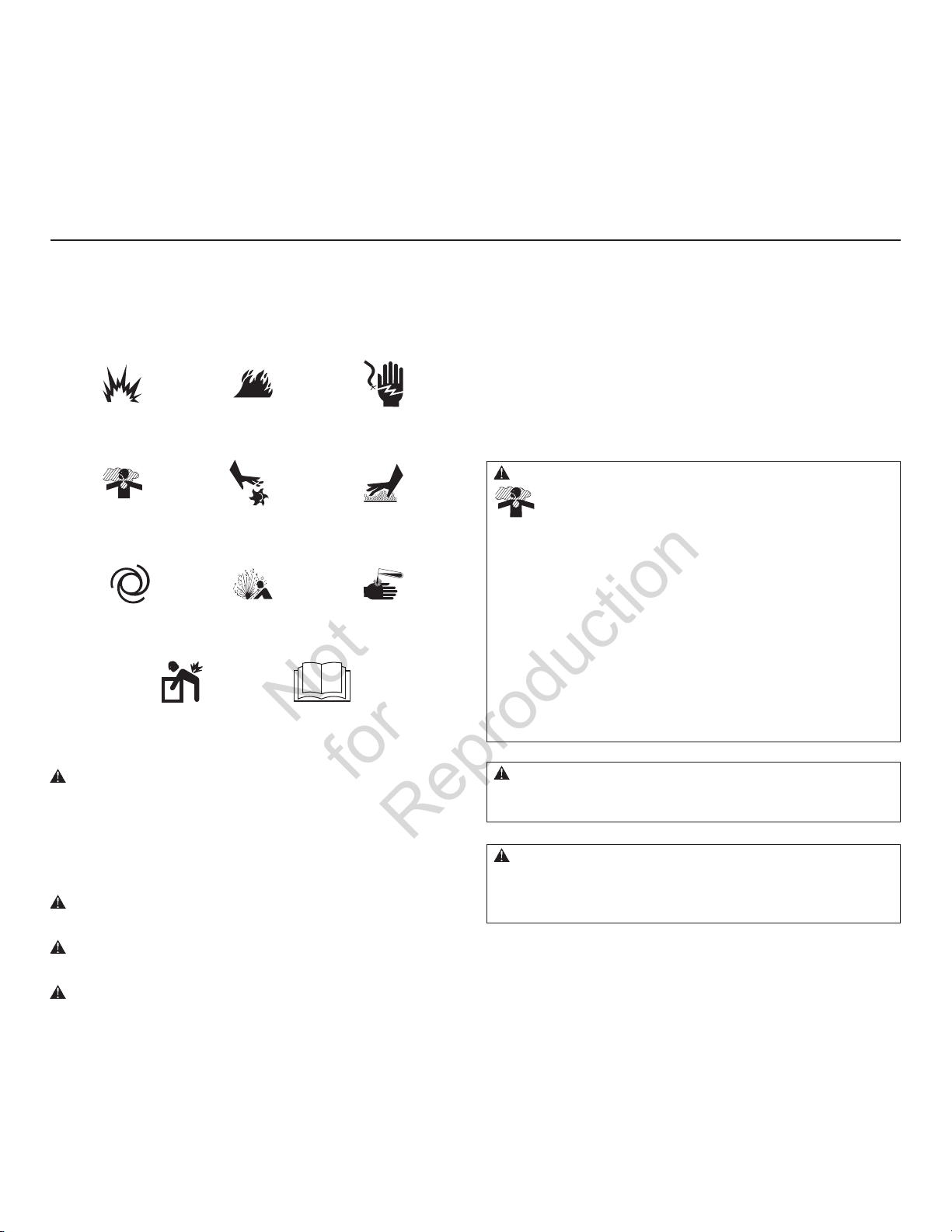

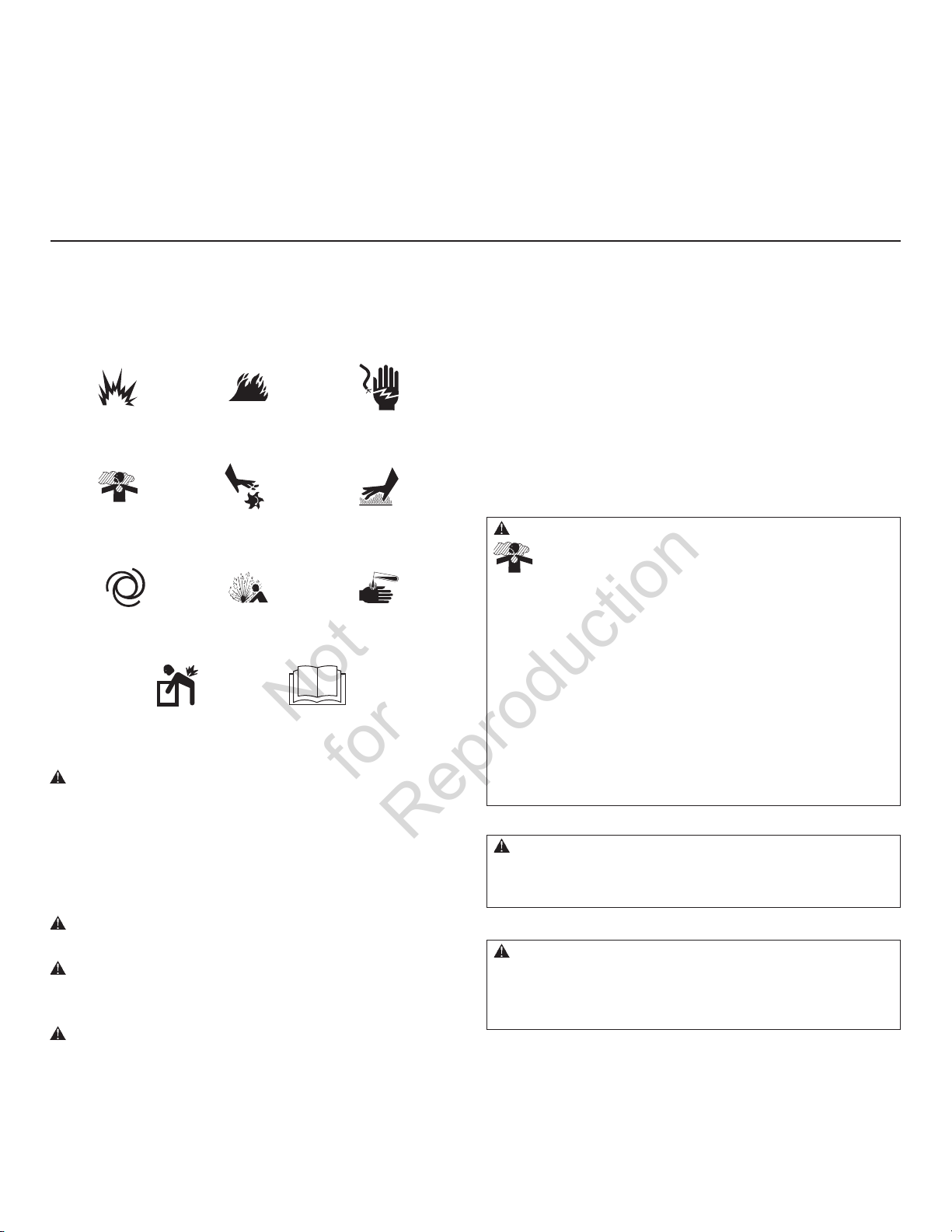

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation and maintenance of the generator and batteries.

Safety Symbols and Meanings

Explosion

Toxic Fumes

Lift Hazard

Fire

Rotating Parts

Read Manual

Electrical Shock

Hot Surface

Chemical BurnExplosive PressureAuto Start

The manufacturer cannot possibly anticipate every possible

circumstance that might involve a hazard. The warnings

in this manual, and the tags and decals affixed to the unit

are, therefore, not all-inclusive. If you use a procedure, work

method or operating technique that the manufacturer does

not specifically recommend, you must satisfy yourself that it

is safe for you and others. You must also make sure that the

procedure, work method or operating technique that you

choose does not render the generator system unsafe.

WARNING Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide could result in death, serious

injury, headache, fatigue, dizziness, vomiting, confusion,

seizures, nausea or fainting.

• Operate this product ONLY outdoors in an area that will not

accumulate deadly exhaust gas.

• Keep exhaust gas away from any windows, doors, ventilation

intakes, soffit vents, crawl spaces, open garage doors or other

openings that can allow exhaust gas to enter inside or be drawn

into a potentially occupied building or structure.

• Carbon monoxide detector(s) MUST be installed and maintained

indoors according to the manufacturer’s instructions/

recommendations. Smoke alarms cannot detect carbon

monoxide gas.

The safety alert symbol indicates a potential personal

injury hazard. A signal word (DANGER, WARNING, or

CAUTION) is used with the alert symbol to designate a degree

or level of hazard seriousness. A safety symbol may be used

to represent the type of hazard. The signal word NOTICE is

used to address practices not related to personal injury.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

4

WARNING The engine exhaust from this product contains

chemicals known to the State of California to cause cancer, birth

defects, or other reproductive harm.

WARNING Certain components in this product and related

accessories contain chemicals known to the State of California

to cause cancer, birth defects, or other reproductive harm. Wash

hands after handling.

Page 5

WARNING Storage batteries give off explosive hydrogen gas

Not

for

Reproduction

during recharging.

Slightest spark will ignite hydrogen and

cause explosion, resulting in death, serious

injury and/or property damage.

Battery electrolyte fluid contains acid and is extremely caustic.

Contact with battery contents could cause severe chemical burns.

A battery presents a risk of electrical shock and high short

circuit current.

• DO NOT dispose of battery in a fire. Recycle battery.

• DO NOT allow any open flame, spark, heat, or lit cigarette during

and for several minutes after charging a battery.

• DO NOT open or mutilate the battery.

• Wear protective goggles, rubber apron, rubber boots and

rubber gloves.

• Remove watches, rings, or other metal objects.

• Use tools having insulated handles.

WARNING Propane and Natural Gas are extremely flammable

and explosive, which could cause burns, fire or

explosion resulting in death, serious injury and/or

property damage.

• Install the fuel supply system according to NFPA 37 and other

applicable fuel-gas codes.

• Before placing the generator into service, the fuel system lines

must be properly purged and leak tested.

• After the generator is installed, you should inspect the fuel

system periodically.

• NO leakage is permitted.

• DO NOT operate engine if smell of fuel is present or other

explosive conditions exist.

• DO NOT smoke around the generator. Wipe up any oil spills

immediately. Ensure that no combustible materials are left in the

generator compartment. Keep the area near the generator clean

and free of debris.

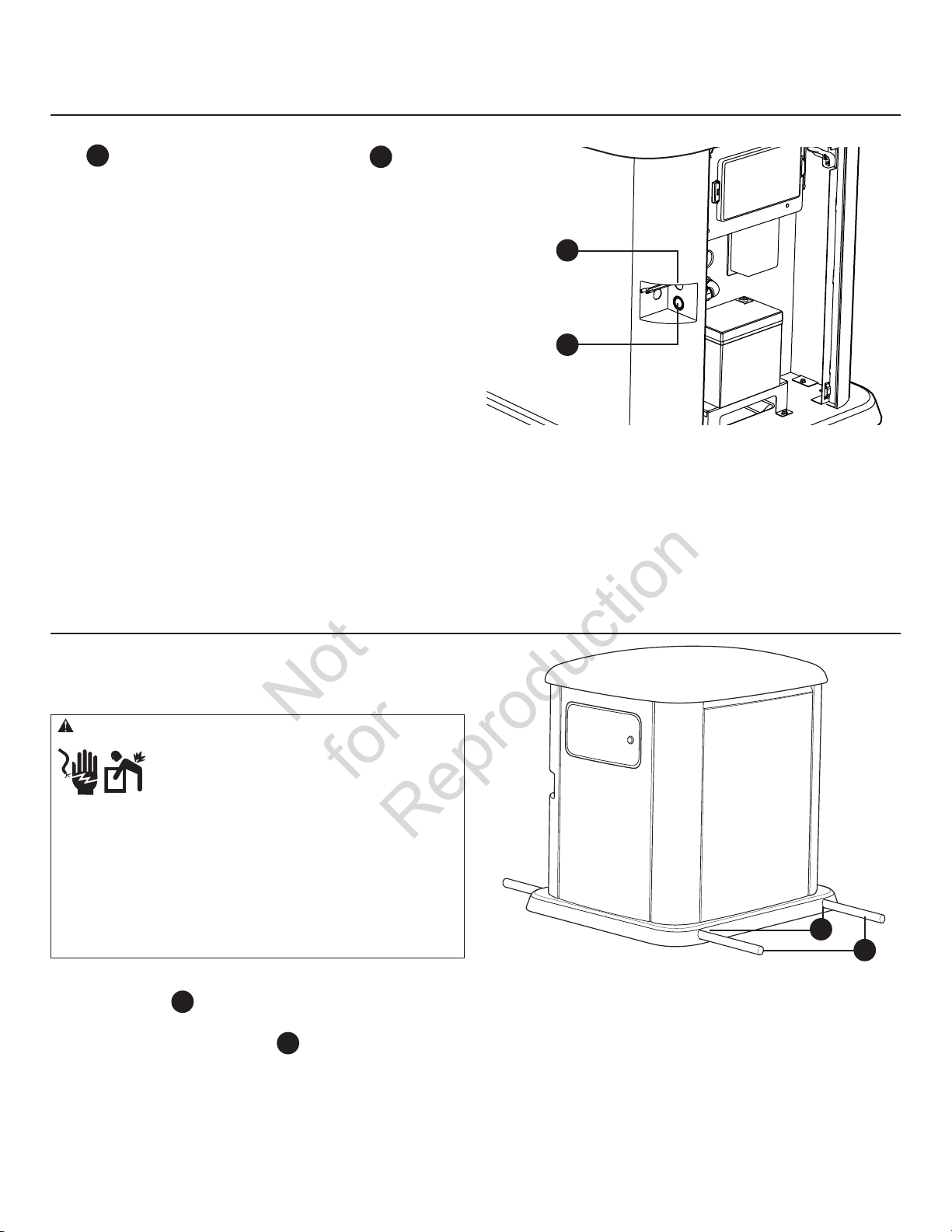

WARNING Hazardous Voltage - Contact with power lines could

cause electric shock or burn, resulting in death or

serious injury.

Lifting Hazard / Heavy Object - Could result in

serious injury.

• If lifting or hoisting equipment is used, DO NOT contact any

power lines.

• DO NOT lift or move generator without assistance.

• Use lifting pipes as described in Lifting the Generator.

• DO NOT lift unit by roof as damage to generator will occur.

WARNING Generator produces hazardous voltage.

Failure to properly ground generator could result

in electrocution.

Failure to isolate generator from utility power could result

in death or serious injury to electric utility workers due to

backfeed of electrical energy.

• When using generator for backup power, notify utility company.

• DO NOT touch bare wires or bare receptacles.

• DO NOT use generator with electrical cords which are worn,

frayed, bare or otherwise damaged.

• DO NOT handle generator or electrical cords while standing in

water, while barefoot, or while hands or feet are wet.

• If you must work around a unit while it is operating, stand on an

insulated dry surface to reduce the risk of a shock hazard.

• DO NOT allow unqualified persons or children to operate or

service generator.

• In case of an accident caused by electrical shock, immediately

shut down the source of electrical power and contact the local

authorities. Avoid direct contact with the victim.

• Despite the safe design of the residential generator, operating

this equipment imprudently, neglecting its maintenance or being

careless could cause possible injury or death.

• Remain alert at all times while working on this equipment.

Never work on the equipment when you are physically or

mentally fatigued.

• Before performing any maintenance on the generator, disconnect

the battery cable indicated by a NEGATIVE, NEG or (-) first. When

finished, reconnect that cable last.

• After your system is installed, the generator may crank and start

without warning any time there is a power failure. To prevent

possible injury, always set the generator’s system switch to OFF,

remove the service disconnect from the disconnect box AND

remove the 15 Amp fuse BEFORE working on the equipment.

5

Page 6

WARNING Exhaust heat/gases could ignite combustibles or

Not

for

Reproduction

structures resulting in death, serious injury and/or

property damage.

Contact with muffler area could cause burns

resulting in serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• DO NOT place weatherproof enclosure opposite exhaust side closer

than 18 inches (0.5 m) from any structure.

• Exhaust outlet side of weatherproof enclosure must have at least

5 ft (1.5 m) minimum clearance from any structure, shrubs, trees or

any kind of vegetation.

• Standby generator weatherproof enclosure must be at least 5 ft

from windows, doors, any wall opening, shrubs or vegetation over

12 inches (30.5 cm) in height.

• Standby generator weatherproof enclosure must have a minimum

of 4 feet (1.2 m) overhead clearance from any structure, overhang

or trees.

• DO NOT place weatherproof enclosure under a deck or other type

of structure that may confine airflow.

• USE ONLY flexible steel fuel line provided. Connect provided fuel

line to generator, DO NOT use with or substitute any other flexible

fuel line.

• Smoke detector(s) MUST be installed and maintained indoors

according to the manufacturer’s instructions/ recommendations.

Carbon monoxide alarms cannot detect smoke.

• Keep at least minimum distances shown in Generator Placement

to insure for proper generator cooling and maintenance

clearances.

• It is a violation of California Public Resource Code, Section 4442,

to use or operate the engine on any forest-covered, brushcovered, or grass-covered land unless the exhaust system is

equipped with a spark arrester, as defined in Section 4442,

maintained in effective working order. Other states or federal

jurisdictions may have similar laws.

Contact the original equipment manufacturer, retailer, or dealer to

obtain a spark arrester designed for the exhaust system installed

on this engine.

• Replacement parts must be the same and installed in the same

position as the original parts.

WARNING Starter and other rotating parts could entangle

hands, hair, clothing, or accessories resulting in

serious injury.

CAUTION Installing the 15A fuse could cause the engine

to start at any time without warning resulting in minor or

moderate injury.

• Observe that the 15 Amp fuse has been removed from the control

panel for shipping.

• DO NOT install this fuse until all plumbing and wiring has been

completed and inspected.

CAUTION Excessively high operating speeds could result in

minor injury and/or equipment damage.

Excessively low speeds impose a heavy load on generator.

• DO NOT tamper with governed speed. Generator supplies correct

rated frequency and voltage when running at governed speed.

• DO NOT modify generator in any way.

NOTICE Improper treatment of generator could damage it and

shorten its life.

• Use generator only for intended uses.

• If you have questions about intended use, contact your

authorized dealer.

• Operate generator only on level surfaces.

• Adequate, unobstructed flow of cooling and ventilating air is

critical for correct generator operation.

• The access panels/door must be installed whenever the unit

is running.

• DO NOT expose generator to excessive moisture, dust, dirt, or

corrosive vapors.

• Remain alert at all times while working on this equipment.

Never work on the equipment when you are physically or

mentally fatigued.

• DO NOT start engine with air cleaner or air cleaner cover removed.

• DO NOT insert any objects through cooling slots.

• DO NOT use the generator or any of its parts as a step. Stepping

on the unit could cause stress and break parts. This may result in

dangerous operating conditions from leaking exhaust gases, fuel

leakage, oil leakage, etc.

• If connected devices overheat, turn them off and disconnect them

from generator.

• Shut off generator if:

-electrical output is lost;

-equipment sparks, smokes, or emits flames;

-unit vibrates excessively;

-unit makes unusual noises.

• NEVER operate generator without protective housings, covers, or

guards in place.

• DO NOT wear loose clothing, jewelry or anything that could be

caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

• Before servicing, remove 15 Amp fuse from control panel and

disconnect Negative (NEG or -) battery cable.

6

Page 7

Installation

Not

for

Reproduction

This product is intended for use as an optional home

generator system which provides an alternate source

of electric power and to serve loads such as heating,

refrigeration systems, and communication systems that,

when stopped during any power outage, could cause

discomfort or inconvenience. This product does not qualify

for emergency standby as defined by NFPA 70 (NEC).

Home Owner Responsibilities

• Read and follow the instructions given in the

operator’s manual.

• Follow a regular schedule in maintaining, caring for

and using your home generator, as specified in the

operator’s manual.

Installing Dealer/Contractor Responsibilities

Every effort has been made to ensure that information in this

manual is accurate and current. However, we reserve the

right to change, alter, or otherwise improve the product and

this document at any time without prior notice.

Only current licensed electrical and plumbing professionals

should attempt home generator system installations.

Installations must strictly comply with all applicable codes,

industry standards, laws and regulations.

• Carbon monoxide detector(s) MUST be installed and

maintained indoors according to the manufacturer’s

instructions/ recommendations. Smoke alarms

cannot detect carbon monoxide gas.

• Read and observe the safety rules.

• Install only an UL approved transfer switch that is

compatible with the generator.

• Read and follow the instructions given in this

installation and start-up manual.

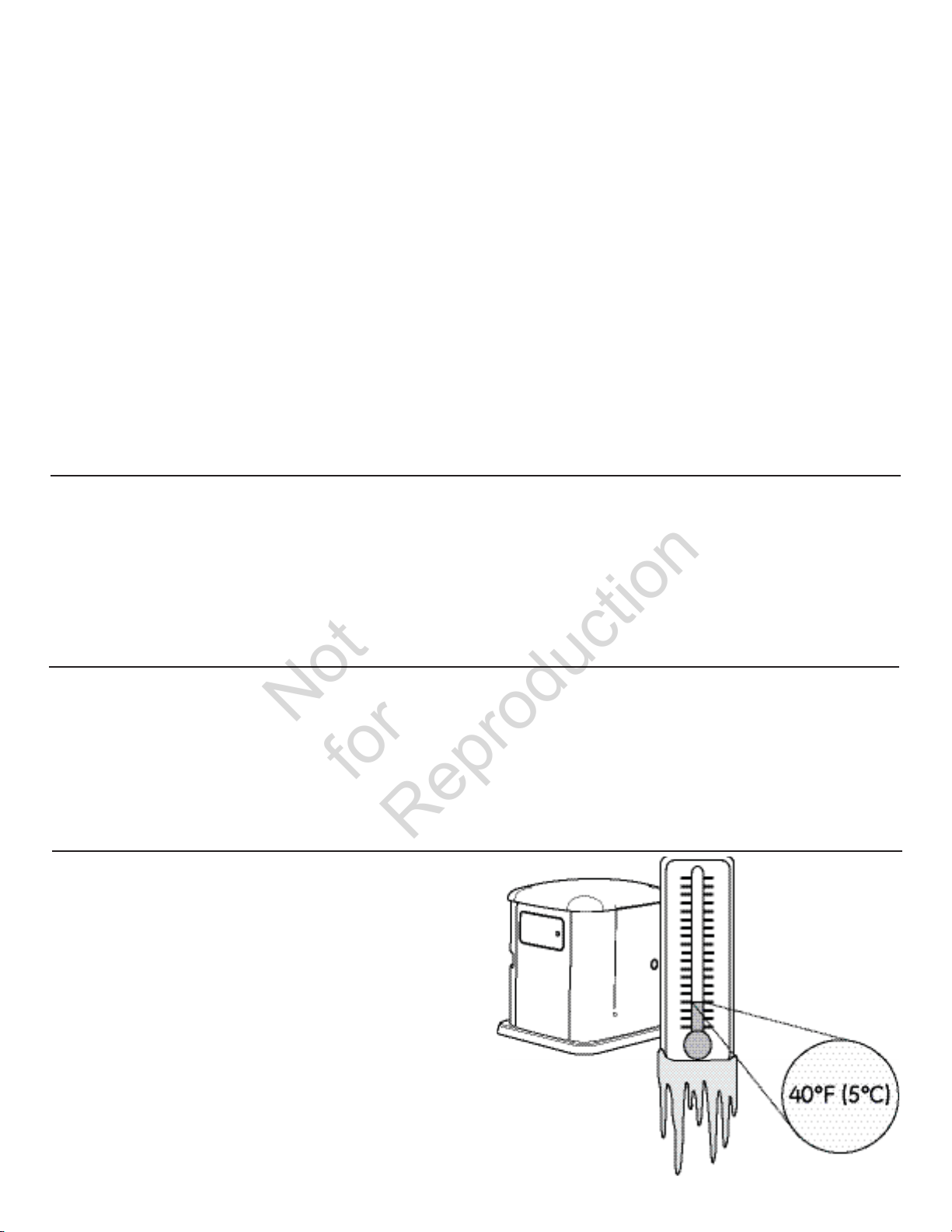

Cold Weather Kit

If operating the generator below 40°F (5°C), it is HIGHLY

RECOMMENDED that a Model 6030 Cold Weather Kit

(includes oil warmer and battery warmer) be installed.

These items are available at your local servicing dealer.

If you need more information on this matter, please call

(888) 575-8226, between 8:00 AM and 5:00 PM CT.

• Installation must strictly comply with all applicable

codes, industry standards, laws, and regulations.

• Allow sufficient room on all sides of the generator for

maintenance and servicing.

7

Page 8

Unpacking Precautions

Not

for

Reproduction

Avoid damage from dropping, bumping, collision, etc. Store

and unpack carton with the proper side up, as noted on the

shipping carton.

Delivery Inspection

After removing the carton, carefully inspect the generator for

any damage that may have occurred during shipment.

If loss or damage is noted at time of delivery, have the

person(s) making delivery note all damage on the freight bill

and affix his signature under the consignor’s memo of loss or

damage. If loss or damage is noted after delivery, separate

the damaged materials and contact the carrier for claim

procedures. Missing or damaged parts are not warranted.

Shipment Contents

The home generator system is supplied with:

• Fully-serviced oil/lubricating system

• Flexible steel fuel line

• Installation and start-up manual

• Operator’s manual

• Spare access door keys

• Spare 15 Amp ATO-type fuse

• Two pin control panel connector

• Ten pin control panel connector

• Lifting hole plugs (4)

• LP conversion jet

Not included:

• Carbon monoxide detector(s)

• Starting battery

• Connecting wire and conduit

• Fuel supply valves/plumbing

• Crane, lifting straps, chains or cables

• Two 48” lengths of 1” pipe (NOT conduit)

• Torque screwdriver, 5 to 50 inch-pound range

• Voltage/frequency meter

8

Page 9

Installation Checklist

Not

for

Reproduction

Proper installation of the home generator requires the

completion of the following tasks:

Carbon Monoxide (CO) Detector

Carbon Monoxide (CO) detector in working order.

Placement

Required permits have been obtained.

Generator placed in a Carbon Monoxide (CO) safe

zone. See Placement of Standby Generator to

Reduce the Risk of Carbon Monoxide Poisoning.

Generator placed in a fire safe zone. See Placement

of Standby Generator to Reduce the Risk of Fire.

Generator placed in a water damage safe zone. See

Other General Location Guidelines.

Generator placed in a utility safe zone. See Other

General Location Guidelines.

Generator placed in a debris free zone. See Other

General Location Guidelines.

Fuel

Generator is connected to fuel source with flexible

fuel line, has no fuel leaks and conforms to local

codes. See The Gaseous Fuel System.

Proper fuel pressure has been measured with all gas

appliances operating. See The Gaseous Fuel System.

Fuel system has been configured for the proper fuel

supply: Natural gas (NG) or liquefied petroleum ( LP)..

See Fuel Conversion.

Electrical

Generator neutral is connected to Automatic

Transfer Switch. See Generator AC Connection

System.

Generator is grounded. See Grounding the

Generator is connected to the transfer switch with

Dipswitches in most transfer switches must be set

Operation

Cold weather kit is installed, if required. See Cold

Correct battery type is installed and fully charged.

Generator engine oil level is at full mark. See Final

Utility was shut off to test the operation of generator

Generator.

Generator is connected to the transfer switch with

the specified wiring. See Utility Circuit Connection

and Transfer Switch Communication.

the specified wiring. #18AWG twisted pair wiring

from the generator control panel to the transfer

switch is installed in a separate conduit from

high voltage wires unless the insulation rating on

all wiring is rated for 600V See Transfer Switch

Communication.

to correspond to the wattage of the generator. See

Transfer Switch Operator/Installation Manual.

Weather Kit.

See Final Installation Considerations.

Installation Considerations.

and transfer switch. Note any fault codes and make

corrections as required.

Generator Placement

Before installing the generator, consult with the homeowner

and convey the following requirements, which must be

satisfied before the installation is complete.

There are two equally important safety concerns in regards

to carbon monoxide poisoning and fire. There are also

several general location guidelines that must all be met

before the installation is considered complete.

WARNING Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide could result in death, serious

injury, headache, fatigue, dizziness, vomiting, confusion,

seizures, nausea or fainting.

• Operate this product ONLY outdoors in an area that will not

accumulate deadly exhaust gas.

• Keep exhaust gas away from any windows, doors, ventilation

intakes, soffit vents, crawl spaces, open garage doors or other

openings that can allow exhaust gas to enter inside or be drawn

into a potentially occupied building or structure.

• Carbon monoxide detector(s) MUST be installed and maintained

indoors according to the manufacturer’s instructions/

recommendations. Smoke alarms cannot detect carbon

monoxide gas.

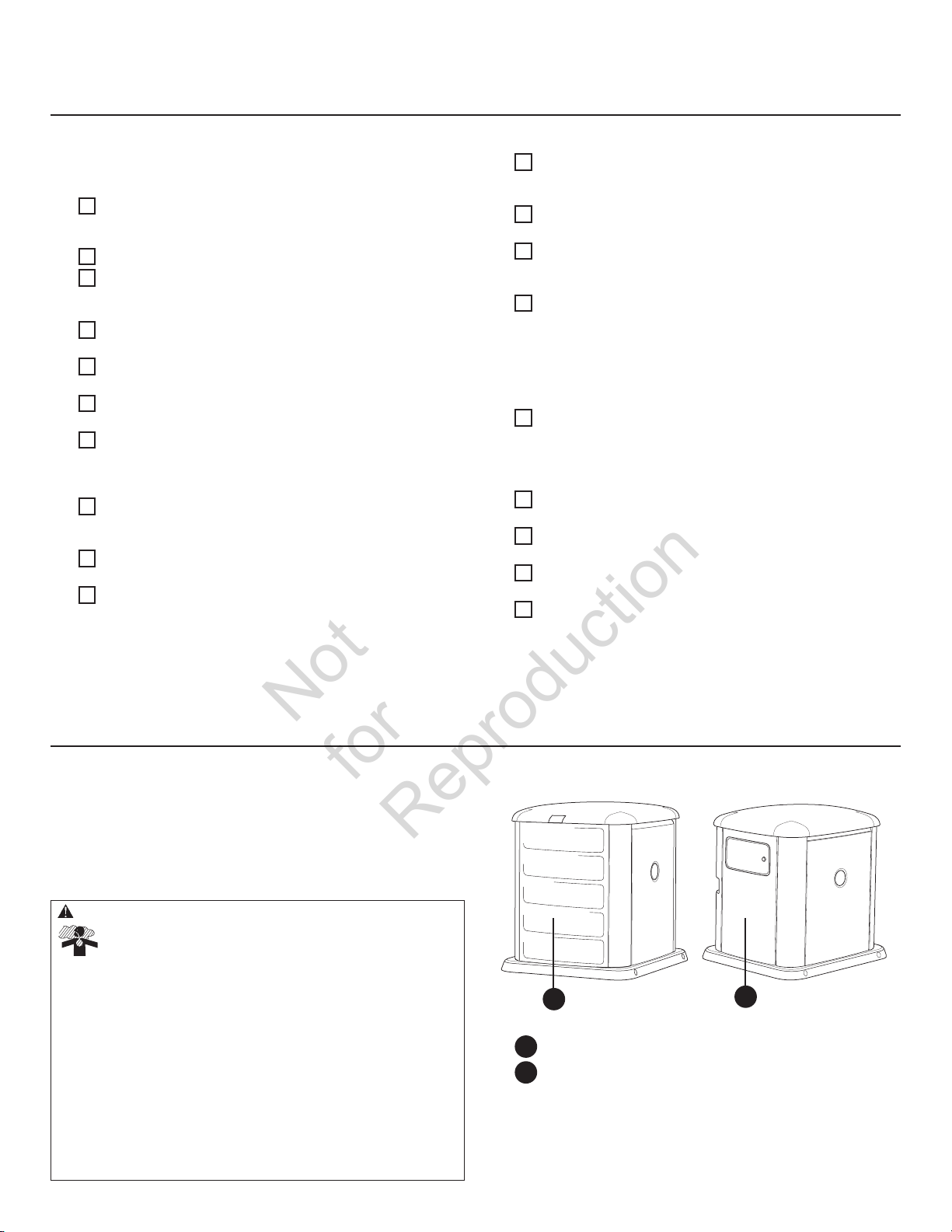

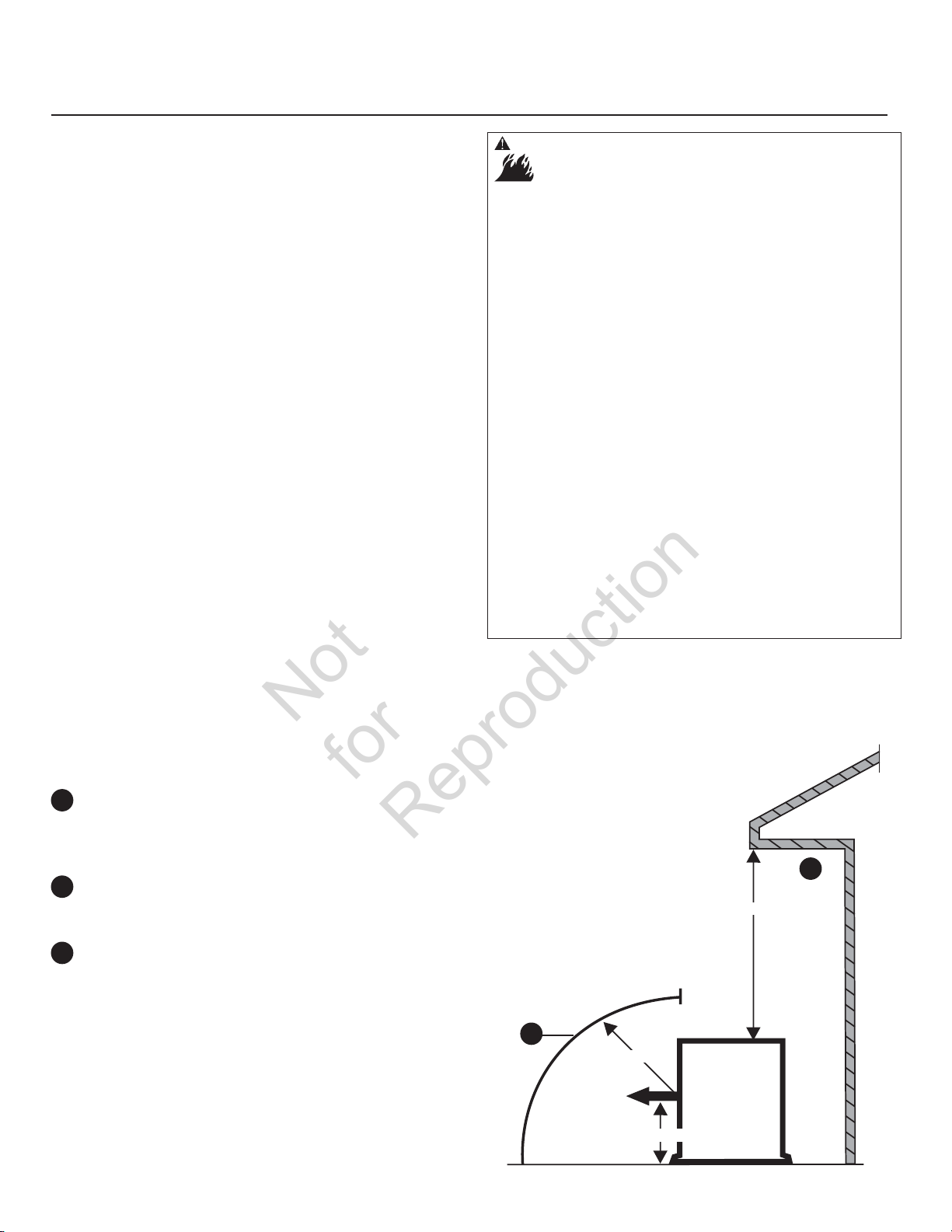

Exhaust Side of the Generator

A

Exhaust outlet side of weatherproof enclosure.

A

Weatherproof enclosure opposite exhaust side.

B

B

9

Page 10

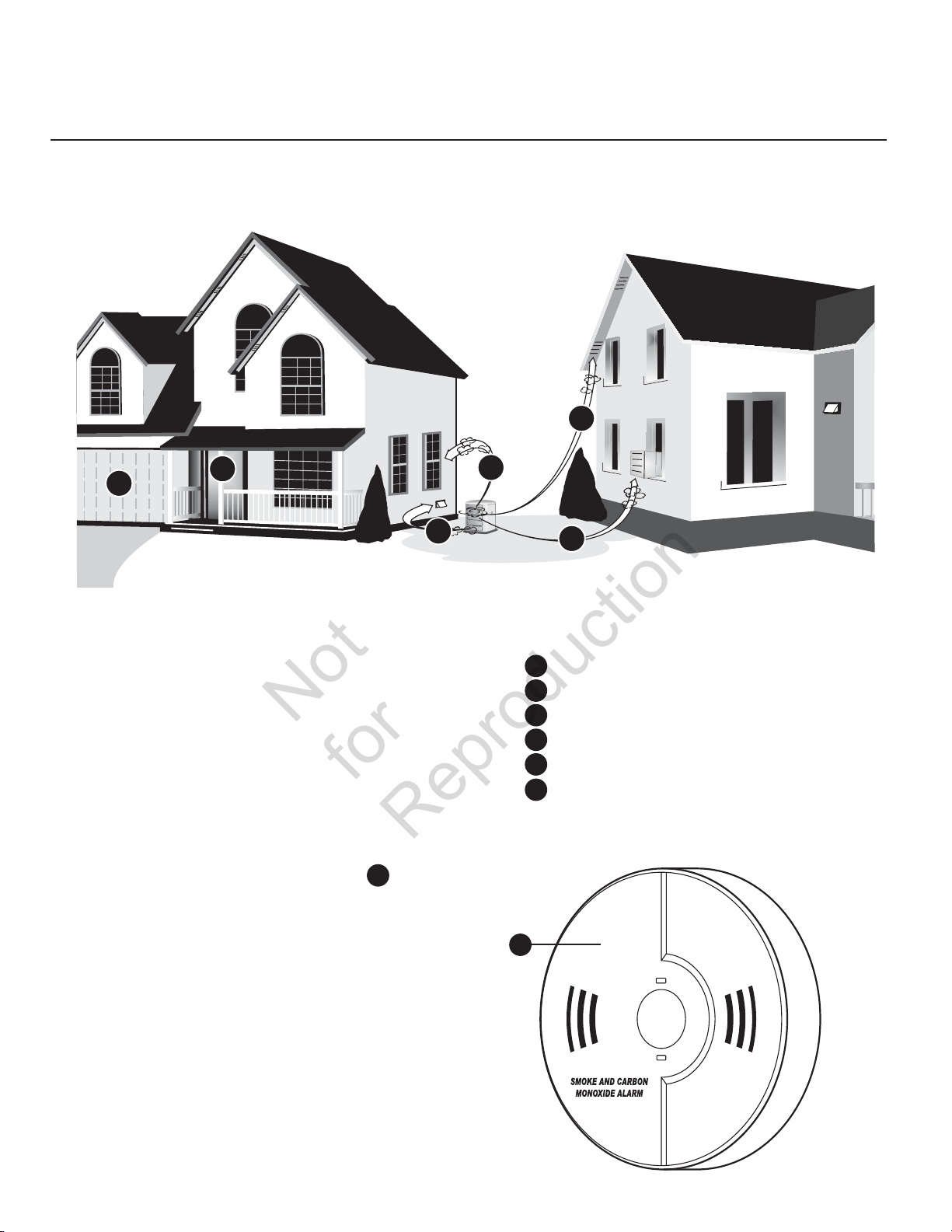

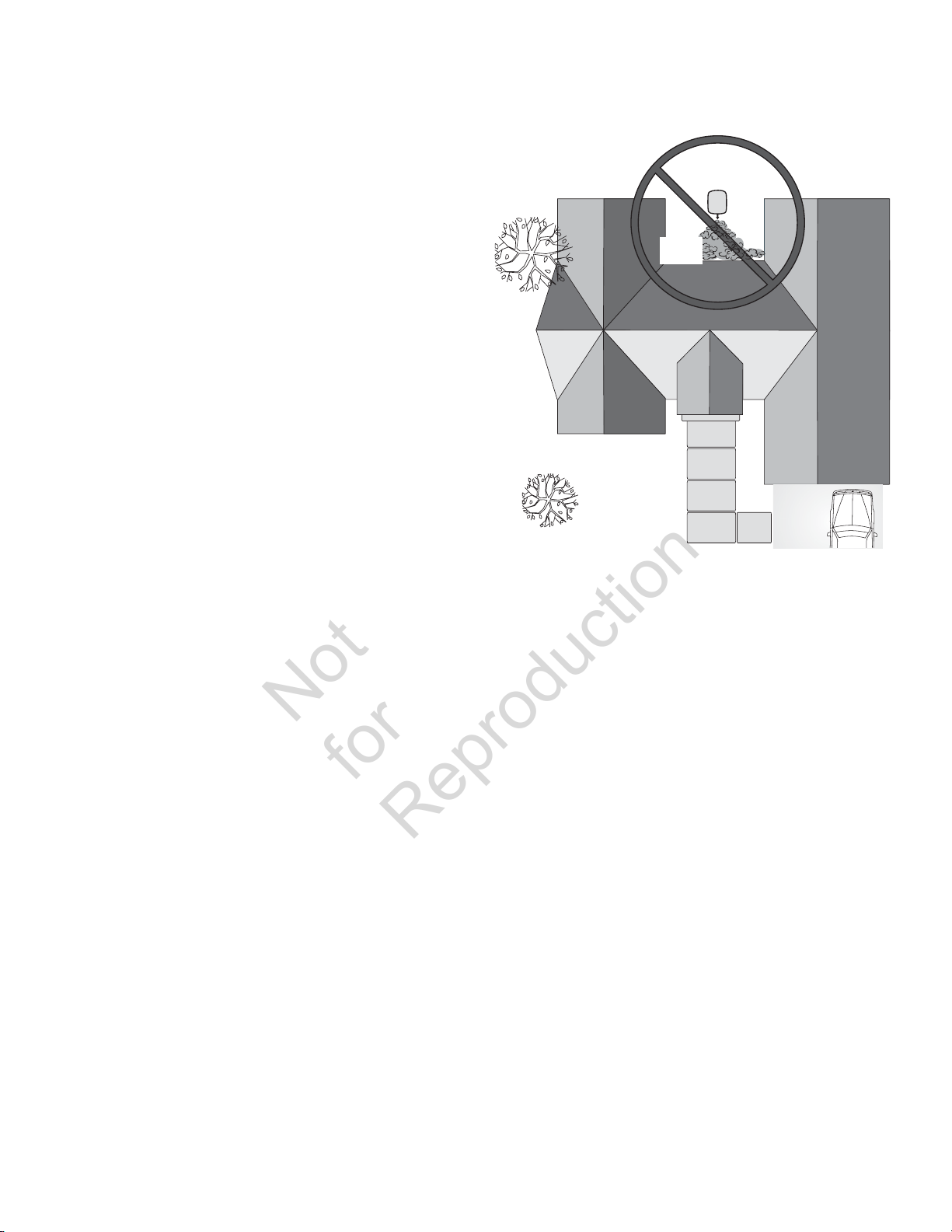

Placement of Standby Generator to

B

D

E

F

G

C

Not

for

Reproduction

REDUCE THE RISK OF CARBON MONOXIDE POISONING

The arrows in the figure below point to POTENTIAL points of entry for Carbon Monoxide Gas.

B

All fossil fuel burning equipment, such as standby

generators, contains carbon monoxide (CO) gas in the engine

exhaust. CO gas is odorless, colorless and tasteless and is

unlikely to be noticed until a person is overcome. CO gas can

kill you so it is required that the following is included as part

of the installation:

• Install generator outdoors in an area that will not

accumulate deadly exhaust gas.

• DO NOT install generator where exhaust gas could

accumulate and enter inside or be drawn into a

potentially occupied building or structure.

• By law it is required in many states to have a Carbon

Monoxide (CO) detector in operating condition in

your home. Carbon monoxide detector(s)

be installed and maintained indoors according to

the manufacturer’s instructions/ recommendations.

A CO monitor is an electronic device that detects

hazardous levels of CO. When there is a buildup of

CO, the monitor will alert the occupants by flashing

visual indicator light and alarm. Smoke alarms cannot

detect CO gas.

• Your neighbor(s) home may be exposed to the engine

exhaust from your standby generator and must be

considered when installing your standby generator.

A

MUST

• Ensure exhaust gas is kept away from:

windows

B

doors

C

ventilation intakes

D

E

soffit vents

F

garage doors

G

crawl spaces or other openings that can allow

exhaust gas to enter inside or be drawn into a

potentially occupied building or structure.

A

10

Page 11

• Direct the standby generator exhaust away from or

Not

for

Reproduction

parallel to the building or structure. DO NOT direct the

generator exhaust towards a potentially occupied

building, structure, windows, doors, ventilation intakes,

soffit vents, crawl spaces, open garage doors or other

openings where exhaust gas could accumulate and

enter inside or be drawn into a potentially occupied

building or structure.

• DO NOT place standby generator in any area where

leaves or debris normally accumulates. Position

standby generator in an area where winds will carry

the exhaust gas away from any potentially occupied

building or structure.

Standby

Generator

Exhaust

Gas

11

Page 12

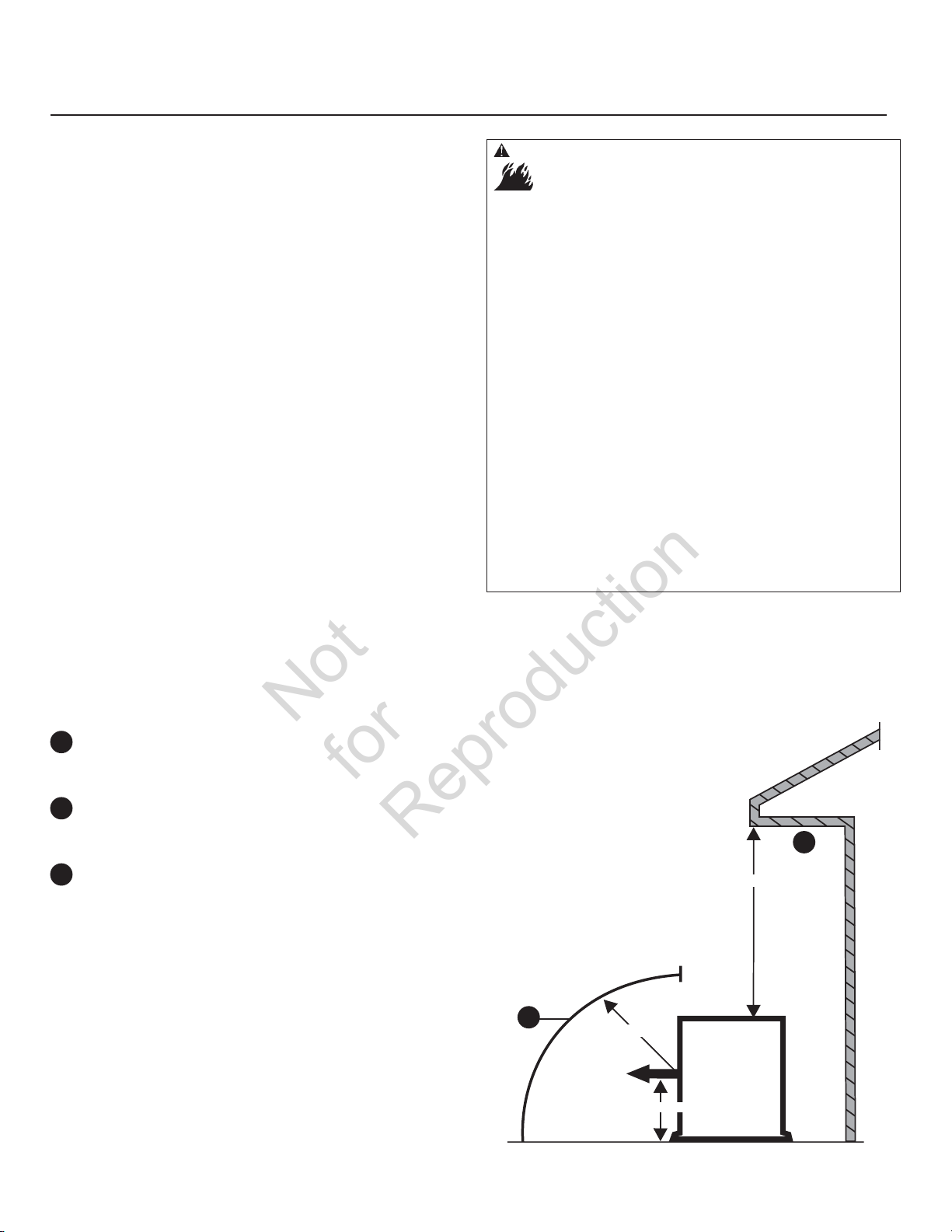

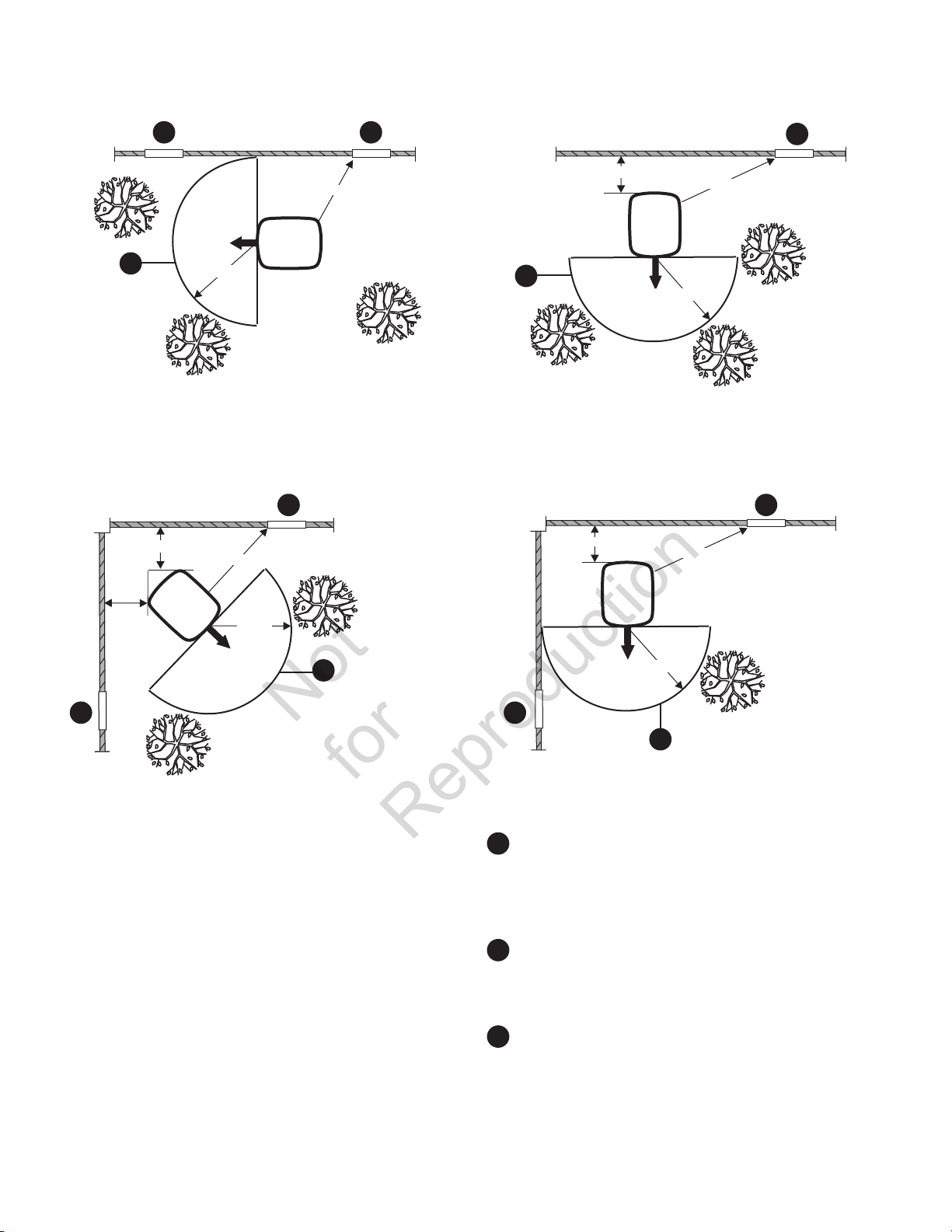

Placement of Standby Generator to REDUCE THE RISK OF FIRE

Not

for

Reproduction

The National Fire Protection Association (NFPA) standard

NFPA 37 establishes criteria for minimizing the hazard

of fire during the installation and operation of stationary

combustion engines. NFPA 37 limits the spacing of an

enclosed generator from openings in walls, structures and

combustible materials outside the enclosure.

The placement requirements provided are based on

compliance to NFPA 37 2010 section 4.1.4 and a full-scale

demonstration fire test. Details of compliance testing can be

found in section National Fire Protection Association (NFPA)

standard NFPA 37 requirements and testing.

WARNING Exhaust heat/gases could ignite combustibles or

structures resulting in death, serious injury and/or property

damage.

• DO NOT place weatherproof enclosure opposite exhaust side closer

than 18 inches (0.5 m) from any structure.

• Exhaust outlet side of weatherproof enclosure must have at least

5 ft (1.5 m) minimum clearance from any structure, shrubs, trees or

any kind of vegetation.

• Standby generator weatherproof enclosure must be at least

5 ft (1.5 m) from windows, doors, any wall opening, shrubs or

vegetation over 12 inches (30.5 cm) in height.

• Standby generator weatherproof enclosure must have a minimum

of 4 feet (1.2 m) overhead clearance from any structure, overhang

or trees.

• DO NOT place weatherproof enclosure under a deck or other type

of structure that may confine airflow.

• USE ONLY flexible steel fuel line provided. Connect provided fuel

line to generator, DO NOT use with or substitute any other flexible

fuel line.

• Smoke detector(s) MUST be installed and maintained indoors

according to the manufacturer’s instructions/ recommendations.

Carbon monoxide alarms cannot detect smoke.

• DO NOT place weatherproof enclosure in manner other than shown

in illustrations.

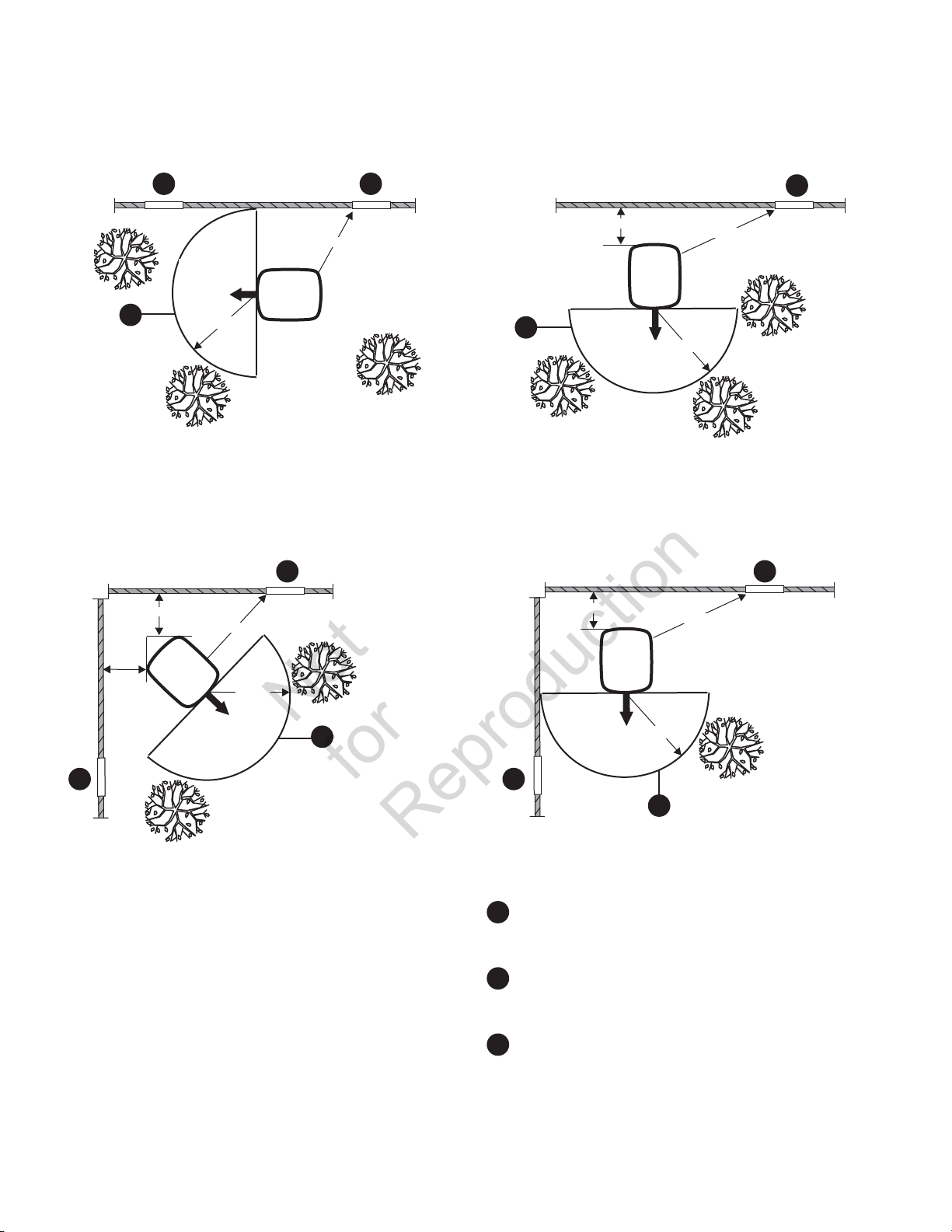

Examples of standby generator locations to reduce the

risk of fire:

Legend for Generator Locations to reduce the risk of fire.

Standby weatherproof enclosure must be at least 5 ft

A

(1.5 m) from windows, doors, any wall opening, shrubs

or vegetation over 12 inches (30.5 cm) in height.

Exhaust outlet side of weatherproof enclosure must

B

have at least 5 ft (1.5 m) minimum clearance from any

structure, shrubs, trees or any kind of vegetation.

Standby weatherproof enclosure must have a

C

minimum of 4 feet (1.2 m) overhead clearance from

any structure, overhang or trees.

NOTICE DO NOT place weatherproof enclosure under a deck

or other type of covered structure that may confine airflow.

Vertical Clearances

B

Exhaust

Direction

Center of Exhaust Panel

5 ft (1.5 m)

Structure

C

4 ft (1.2 m)

Standby

12

Page 13

Single Structure Installations

Not

for

Reproduction

A A

Exhaust

Direction

B

Two Structure Installations

18 in (45.7 cm) min

5 ft (1.5 m)

Structure

5 ft (1.5 m) min

Structure

5 ft (1.5 m) min

Standby

A

Shrubs, Tree or

Vegitation

18 in (45.7 cm) min

B

18 in (45.7 cm) min

Standby

Exhaust

Direction

Structure

5 ft (1.5 m) min

5 ft (1.5 m)

Structure

5 ft (1.5 m) min

A

A

Standby

A

Exhaust

Direction

5 ft

(1.5 m)

Standby

Exhaust

B

A

Legend for Generator Locations to reduce the risk of fire.

Standby weatherproof enclosure must be at least 5 ft

A

Exhaust outlet side of weatherproof enclosure must

B

Standby weatherproof enclosure must have a

C

NOTICE DO NOT place weatherproof enclosure under a deck

or other type of covered structure that may confine airflow.

Direction

(1.5 m) from windows, doors, any wall opening, shrubs

or vegetation over 12 inches (30.5 cm) in height.

have at least 5 ft (1.5 m) minimum clearance from any

structure, shrubs, trees or any kind of vegetation.

minimum of 4 feet (1.2 m) overhead clearance from

any structure, overhang or trees.

5 ft (1.5 m)

B

13

Page 14

Other General Location Guidelines

Not

for

Reproduction

• Place the standby generator in a prepared location

that is flat and has provisions for water drainage.

• Install the standby generator in a location where

sump pump discharge, rain gutter down spouts, roof

run-off, landscape irrigation, or water sprinklers will

not flood the unit or spray the enclosure and enter

any air inlet or outlet openings.

• Install the standby generator where it will not affect or

obstruct any services (including covered, concealed

and underground), such as telephone, electric, fuel

(natural gas / LPG vapor), irrigation, air conditioning,

cable, septic, sewer, well and so forth.

• Install the standby generator where leaves, grass,

snow, etc will not obstruct air inlet and outlet

openings. If prevailing winds will cause blowing or

drifting, you may need to construct a windbreak to

protect the unit.

National Fire Protection Association (NFPA) Standard NFPA 37 Requirements and Testing

Requirements:

NFPA 37 2010, section 4. 1. 4, Engines Located Outdoors.

Engines, and their weatherproof housings if provided, that

are installed outdoors shall be located at least 1.5m (5 ft)

from openings in walls and at least 1.5 m (5 ft) from structures

having combustible walls. A minimum separation shall not be

required where either of the following conditions exist:

1. The adjacent wall of the structure has a fire resistance

rating of at least 1 hour.

2. The weatherproof enclosure is constructed

of noncombustible materials and it has been

demonstrated that a fire within the enclosure will not

ignite combustible materials outside the enclosure. *

* Annex A Explanatory Material

A.4.1.4 (2) Means of demonstrating compliance are by means

of full-scale fire tests or by calculation procedures, such as

those given in NFPA 555, Guide on Methods for Evaluating

Potential for Room Flashover.

To comply with condition 2 above the weatherproof

enclosure has been constructed completely of noncombustible materials and full-scale fire tests have been

conducted to demonstrate that a fire within the enclosure

will not ignite combustible materials outside the enclosure.

A U.S. Department of Labor Occupational Safety & Health

Administration (OSHA) Nationally Recognized Testing

Laboratory (NRTL) performed full scale fire demonstration

testing. This 3rd party independent NRTL evaluated

many worst-case ignition scenarios. The results of the

demonstration testing concluded that a fire within the

enclosure would not ignite combustible materials outside the

enclosure.

14

Page 15

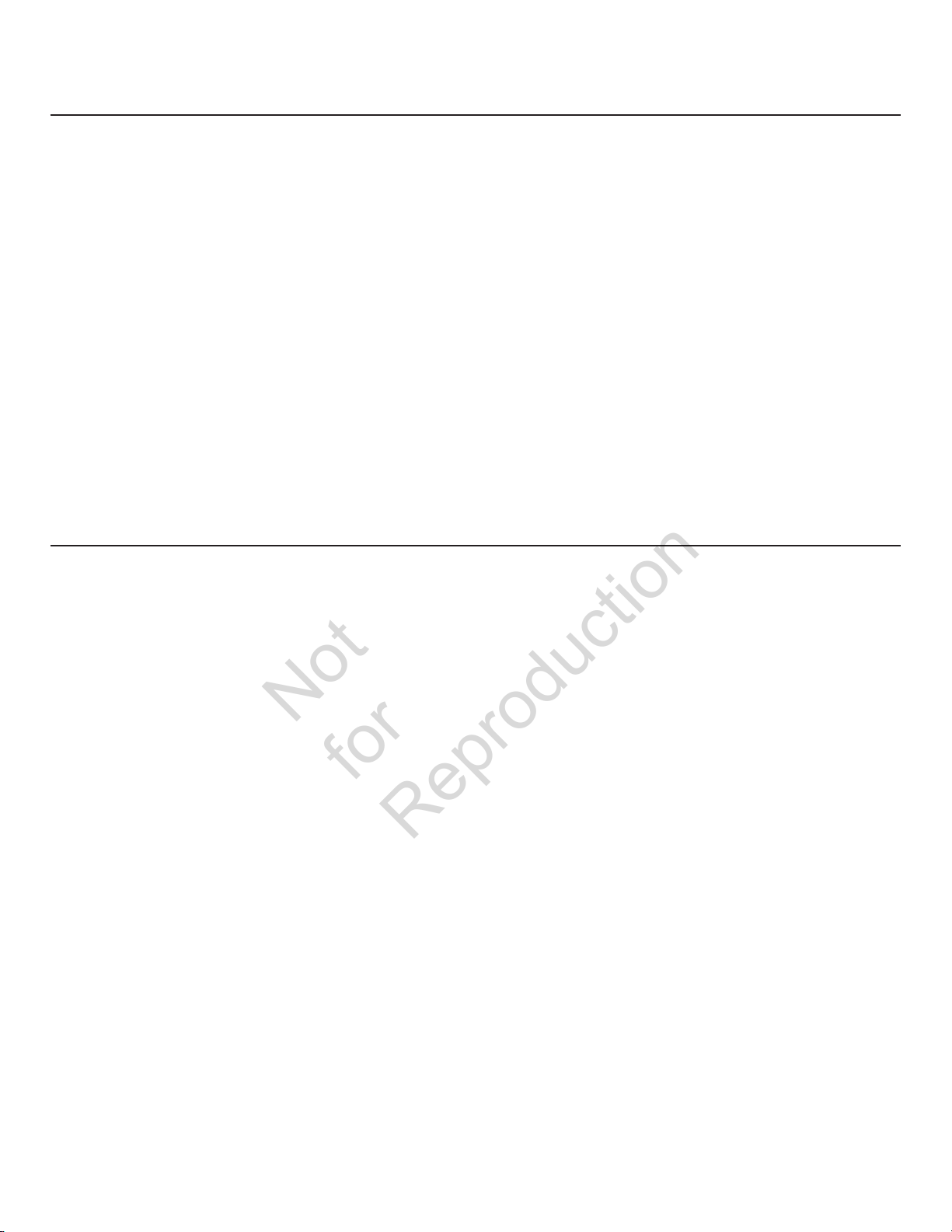

Electrical and Fuel Inlet Locations

Not

for

Reproduction

The 3/4 inch N.P.T. fuel inlet connector

location

The home generator is shipped alr

mounting pad. Unless mandated by local code, a concrete

slab is not required.

B

is shown at right.

A

and electrical inlet

eady attached to its

Lifting the Generator

B

A

The generator weighs more than 240 kg (530 pounds). Proper

tools, equipment and qualified personnel should be used in

all phases of handling and moving the generator.

WARNING Hazardous Voltage - Contact with power lines could

cause electric shock or burn, resulting in death or

serious injury.

Lifting Hazard / Heavy Object - Could result in

serious injury.

• If lifting or hoisting equipment is used, DO NOT contact any

power lines.

• DO NOT lift or move generator without assistance.

• Use lifting pipes as described in Lifting the Generator.

• DO NOT lift unit by roof as damage to generator will occur.

Two 48” lengths of 1” pipe

required to lift the generator manually. Insert pipes through

the lifting holes D located near the unit’s base.

You may also lift the unit using a “hook and hoist” method

attached to the lifting pipes, provided that you use a

spreader bar to ensure that the chains or cables DO NOT

touch the generator’s roof.

C

, supplied by the installer, are

D

C

After unit is in place, fill the lifting holes with the supplied

lifting hole plugs.

15

Page 16

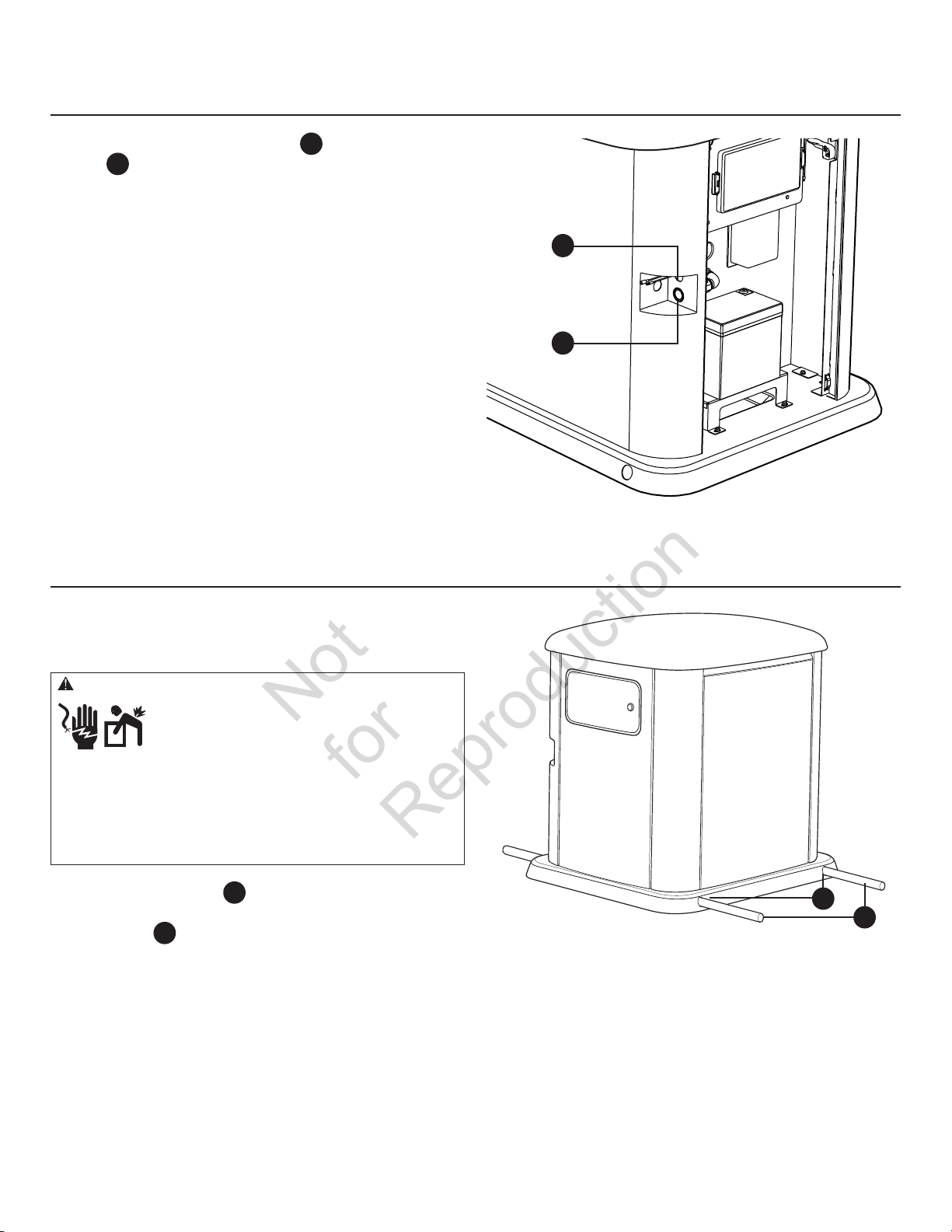

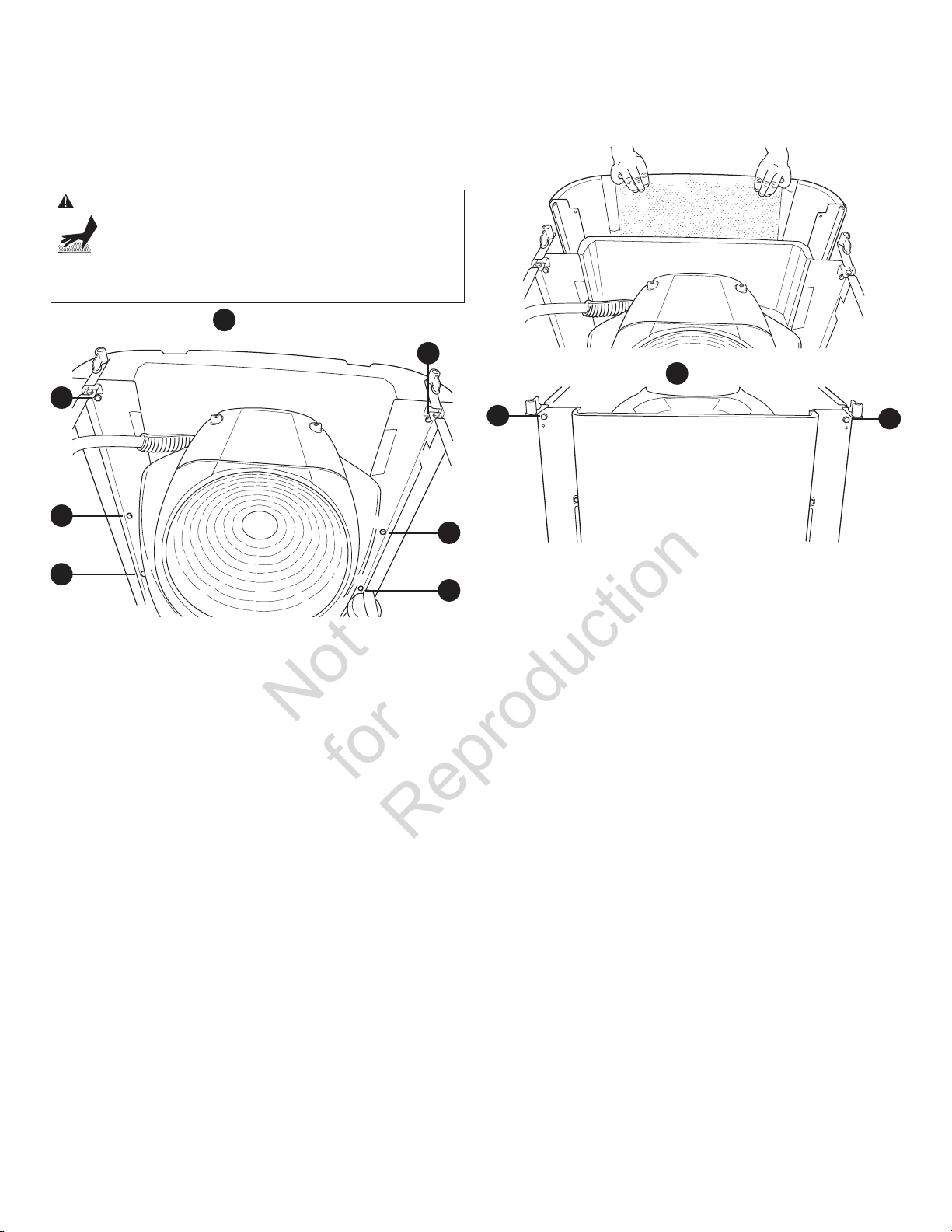

Access Ports

Not

for

Reproduction

Each home generator is suppied with a set of identical keys.

These keys fit the lock that secures the control panel access

door.

To open access door:

1. Insert key into lock of access door and turn key one

quarter turn counterclockwise.

2. Remove key.

To close access door:

1. Close control panel door and insert key into lock and

turn key one quarter turn clockwise.

2. Remove key.

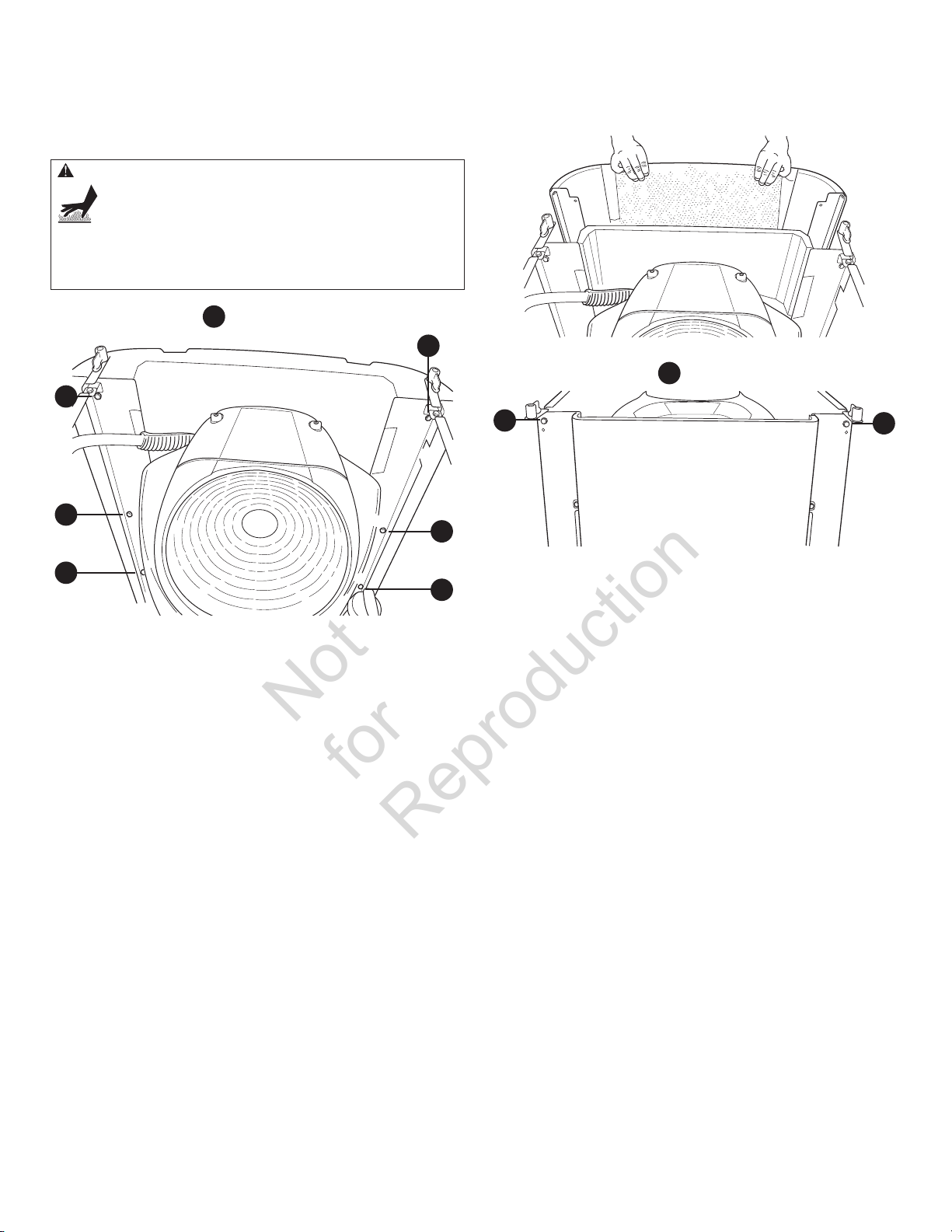

The home generator is equipped with a removable roof and

removable side panels to permit simple servicing.

To remove roof and divider:

1. Open the control panel access door.

2. Set generator’s circuit breaker to OFF position.

3. Set control panel system switch to OFF.

4. Remove 15 Amp fuse from control panel.

5. Move roof latch to the left until roof pops up slightly.

7. Rotate 4 knobs 1/4 turn and lift divider off.

8. Replace divider and roof in reverse order.

To remove side panels:

1. Open the control panel access door.

2. Set generator’s circuit breaker to OFF position.

3. Set control panel system switch to OFF.

4. Remove 15 Amp fuse from control panel.

5. Remove roof and divider.

6. Lift latches

A

up on both sides of panel to release.

6. Lift roof off of generator.

A

7. Pull panel upward and out of grooves.

16

Page 17

To remove exhaust panel:

Not

for

Reproduction

1. Remove roof and divider.

2. Remove side panels.

WARNING Contact with muffler area could cause burns

resulting in serious injury.

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

4. Pull exhaust panel up and out of base.

3. Remove 6 screws

A

A

A

A

from exhaust panel.

A

5. Remove two screws

B

A

6. Replace muffler cover and exhaust panel in reverse order.

A

To install side panels:

1. Place panel in grooves and slide down in place.

2. Push latches down on both sides of panel to lock into place.

3. Replace divider and roof.

and pull muffler cover off.

B

B

17

Page 18

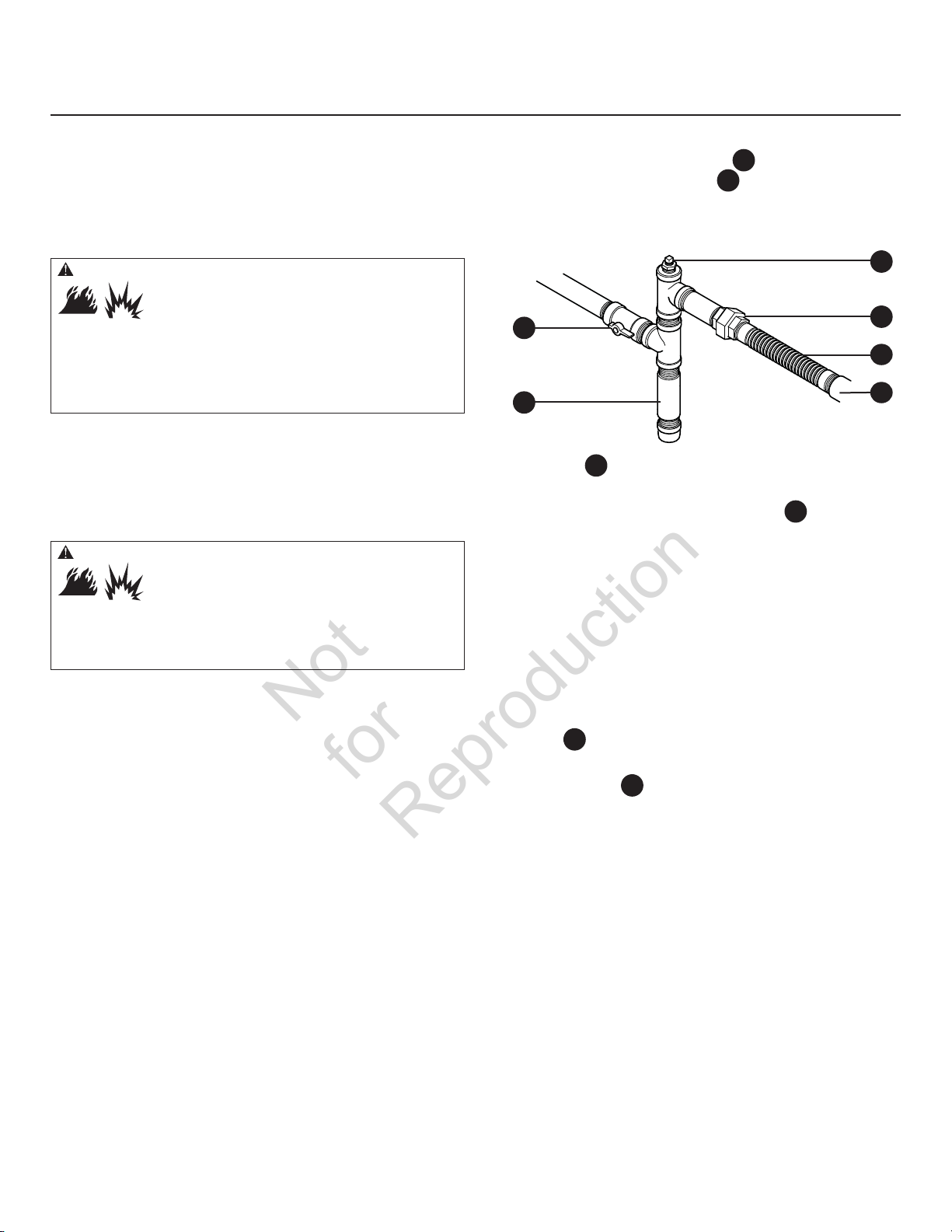

The Gaseous Fuel System

Not

for

Reproduction

The information below is provided to assist gaseous fuel

system technicians in planning installations. In no way

should this information be interpreted to conflict with

applicable fuel gas codes. Consult with your local fuel

supplier or Fire Marshall if questions or problems arise.

WARNING Propane and Natural Gas are extremely flammable

and explosive, which could cause burns, fire or

explosion resulting in death, serious injury and/or

property damage.

• LP gas is heavier than air and will settle in low areas.

• Natural gas is lighter than air and will collect in high areas.

• The slightest spark could ignite these fuels and cause an explosion.

• DO NOT light a cigarette or smoke.

TO THE INSTALLER: Consult with the generator owner(s) and

convey any technical considerations that might affect their

installation plans before applying these general guidelines.

The following general rules apply to gaseous fuel

system piping:

WARNING Propane and Natural Gas are extremely flammable

and explosive, which could cause burns, fire or

explosion resulting in death, serious injury and/or

property damage.

• Before placing the generator into service, the fuel system lines

must be properly purged and leak tested.

• No leakage is permitted.

NOTICE The supplied flexible

underground or in contact with the ground.

• The entire

periodic inspection and must not be concealed within

nor contact nor run through any wall, floor, or partition.

• The piping should be of a material that conforms

to federal and local codes, rigidly mounted and

protected against vibration.

• Piping should be protected from physical damage

where it passes through flower beds, shrub beds, and

other cultivated areas where damage could occur.

flexible

steel fuel line

steel fuel line must be visible for

is not to be installed

• Install the

the generator fuel inlet port A and rigid piping

to prevent thermal expansion or contraction from

causing excessive stress on the piping material.

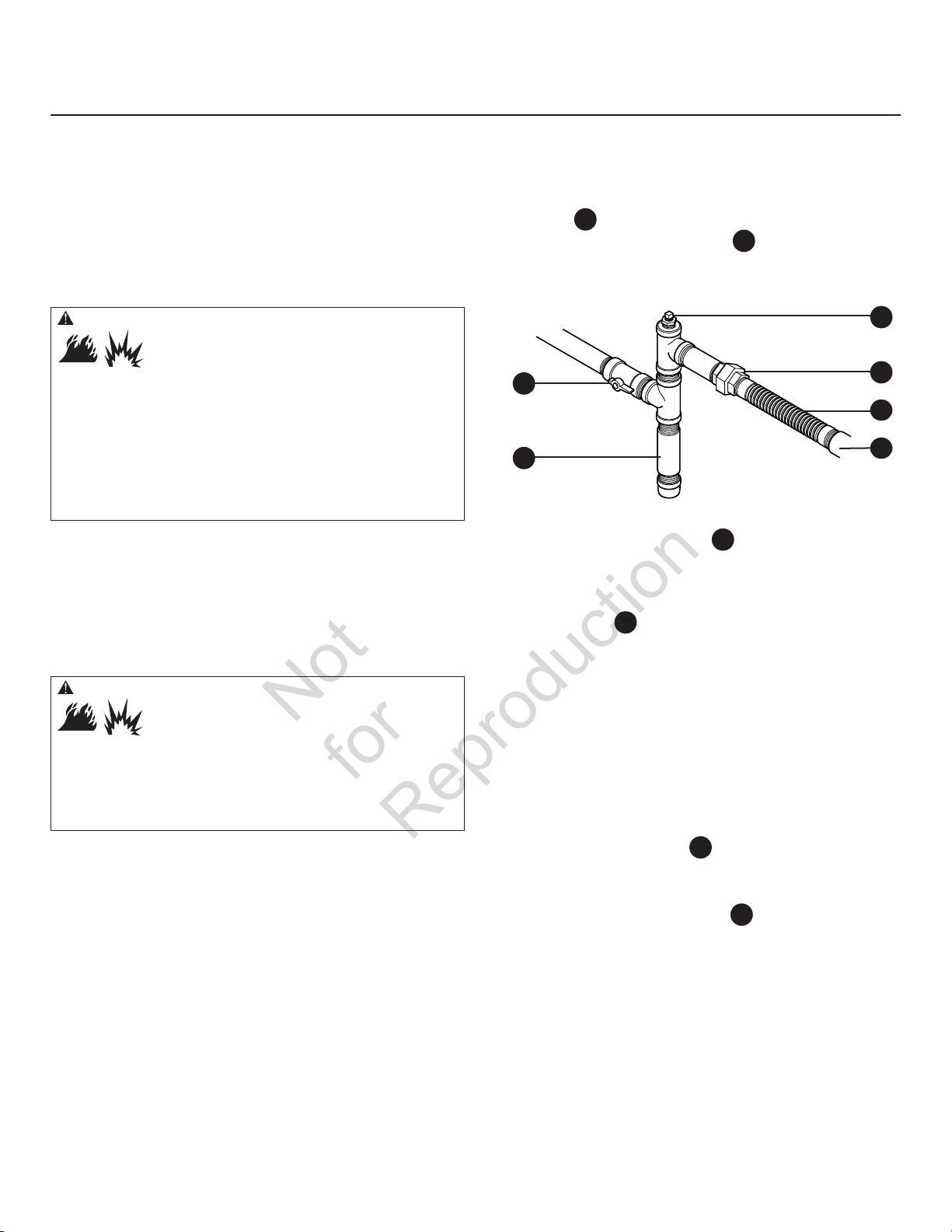

E

F

• A union C or flanged connection shall be provided

downstream to permit removal of controls.

• A manometer port should be provided D. A digital

manometer, P/N 19495, is available at your Briggs &

Stratton service center. When the initial test runs are

completed, the manometer is removed and the port

is plugged. The manometer port permits temporary

installation of a manometer to ensure that the

engine receives the correct fuel pressure to operate

efficiently throughout its operating range.

• Where the formation of hydrates or ice is known to

occur, piping should be protected against freezing. The

termination of hard piping should include a sediment

trap F where condensate is not likely to freeze.

• A minimum of one accessible, approved manual

shutoff valve E shall be installed in the fuel supply

line within 6 ft (180 cm) of the home generator.

• A minimum 10 ft. (3 m) section of gas pipe between

the primary fuel regulator and the generator fuel inlet

connection (acts as accumulator for high block loads).

• A manual fuel shut-off valve located in the interior of

the building.

• Where local conditions include earthquake,

tornado, unstable ground, or flood hazards, special

consideration shall be given to increase strength and

flexibility of piping supports and connections.

flexible

steel fuel line B (supplied) between

D

C

B

A

18

Page 19

• Piping must be of the correct size to maintain the

Not

for

Reproduction

r

equired supply pressures and volume flow under

varying generator load conditions with all gas

appliances connected to the fuel system turned on

and operating.

• Use a pipe sealant or joint compound approved for

use with NG/LPG on all threaded fittings to reduce the

possibility of leakage.

• Installed piping must be properly purged and

leak tested, in accordance with applicable codes

and standards.

Fuel Pressure

Both LP vapor and natural gas fuel supply pressure at the

generator’s fuel inlet port should be between the following levels

at full load with all gas appliances turned on and operating.

• NG is 5-7” W.C.

• LP is 11-14” W.C.

Ensur

e that all gas line shutoff valves are OPEN and that

adequate fuel pressure is available whenever automatic

operation is desired.

Power Loss

Air density is less at high altitudes, resulting in less available

engine power. Specifically, engine power will decrease 3.5%

for each 1,000 feet (300 m) above sea level and 1% for each

10° F (5.6°C) above 77°F (25°C). Generators located in these

conditions must have their transfer switch programmed

appropriately for this power decrease.

Fuel Pipe Sizing

There are numerous on-line or otherwise-published

references for fuel pipe sizing. For example, NFPA 54 National Fuel Gas Code, 2006 (Item #: 320-6031-06) is a

common resource.

The installer should consider the specific gravity of gas

and compensate for a nominal amount of restriction from

bends, fittings, etc. If an unusual number of fittings, bends, or

other restrictions are used, refer to federal and local codes

for guidance.

19

Page 20

Fuel Conversion

Not

for

Reproduction

The engine of your home generator system is factory

calibrated to run on natural gas (NG). It may also be operated

on liquefied petroleum (LP) vapor. The LP Conversion Kit

(supplied) is required to convert the unit to LP vapor fuel.

LP fuel inlet pressure must be between 11 and 14 inches

water column at full load with all gas appliances turned on

and operating.

To configure the fuel system for LP use:

1. Set generator’s system switch to OFF.

2. Remove 15 Amp fuse from control panel.

3. Remove roof, divider, side panels, exhaust panel and

muffler cover.

4. Change main jet in fuel mixer following instructions

provided in LP Conversion Kit.

5. Reinstall muffler cover, exhaust panel, side panels,

divider and roof.

6. Reinstall 15 Amp fuse in control panel.

7. Set generator’s system switch to AUTO.

The system is now ready to operate automatically using

LP vapor fuel.

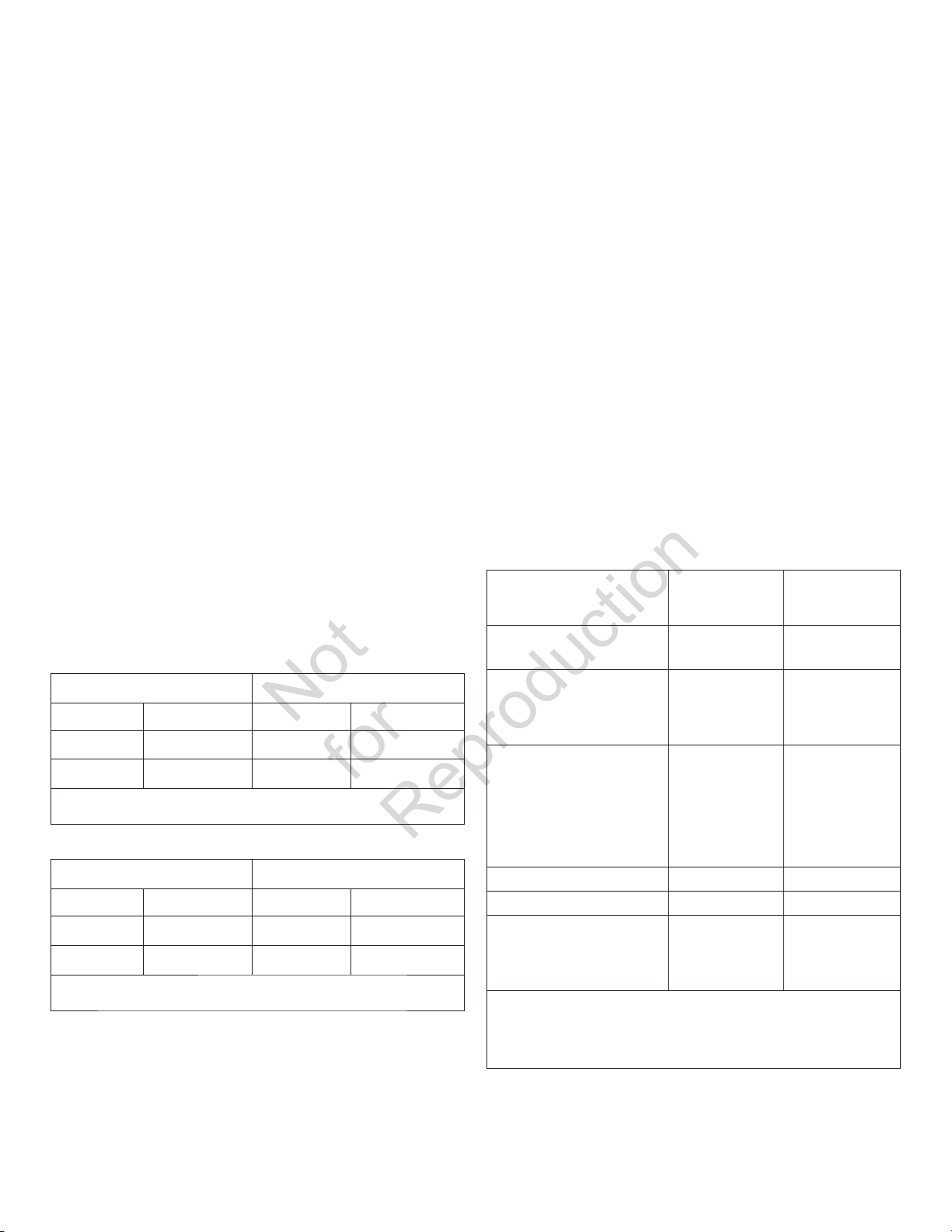

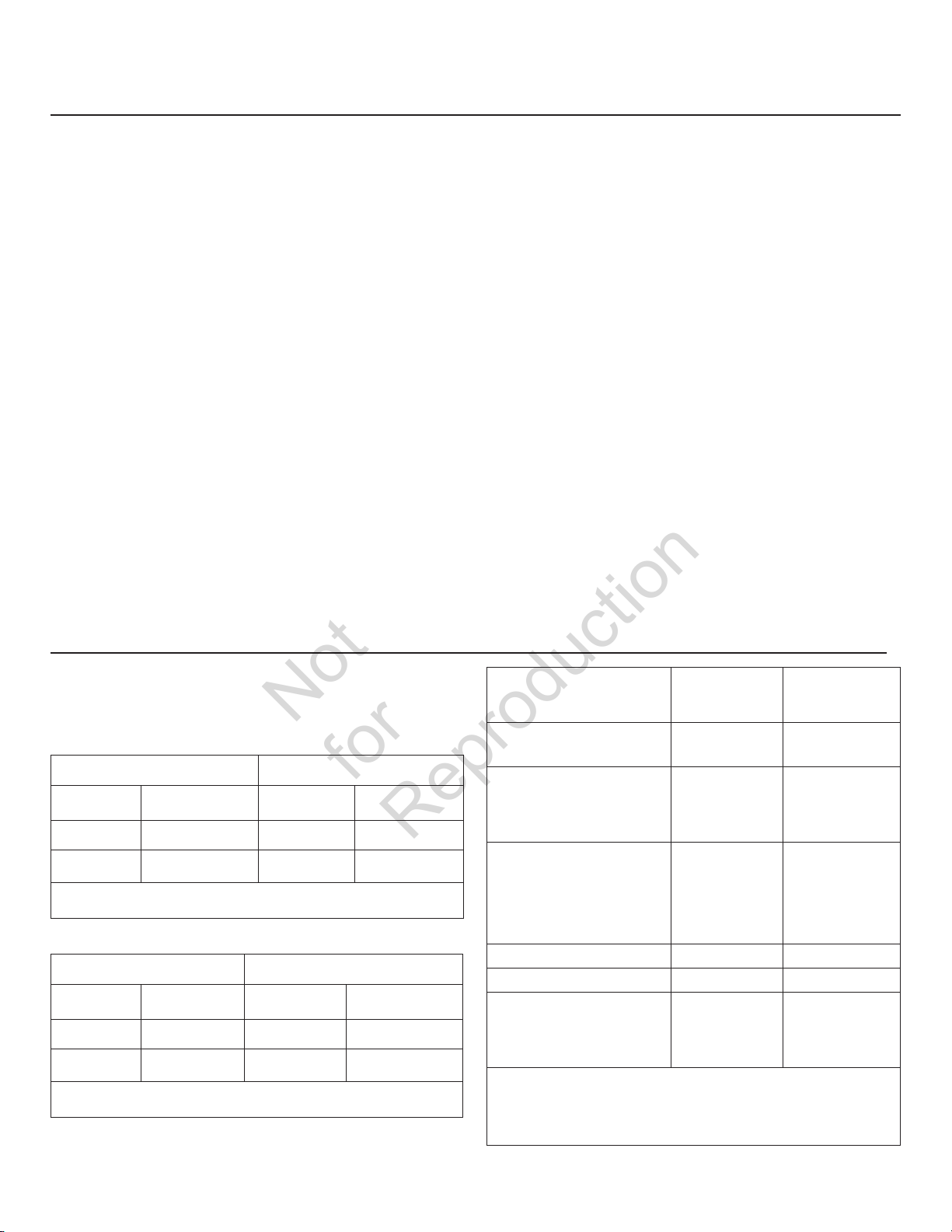

Fuel Consumption

Estimated fuel supply requirements at half and full load for

natural gas and LP vapor fuels are shown here.

11K Watt

Natural Gas LP Vapor

1/2 Load Full Load 1/2 Load Full Load

82 C 143 C 44 C 73 C

82,000 B 143,000 B 108,350 B 181,200 B

C = Cubic feet per hour

B = BTU’s per hour

13K Watt

Natural Gas LP Vapor

1/2 Load Full Load 1/2 Load Full Load

93 C 164 C 49 C 83 C

93,000 B 164,400 B 121,600 B 207,699 B

C = Cubic feet per hour

B = BTU’s per hour

Physical

Properties

Normal Atmospheric

State

Boiling Point (in °F):

Initial

End

Heating Value:

BTU per gallon (Net

LHV*)

BTU per gallon (gross**)

Cubic feet (gas)

Density*** 36.39 57.75

Weight† 4.24 2.65

Octane Number:

Research

Motor

* LHV (Low Heat Value) is the more realistic rating.

** Gross heat value does not consider heat lost in the form of water during

combustion.

*** Density is given in “Cubic Feet of Gas per Gallon of Liquid”.

† Weight is given in “Pounds per Gallon of Liquid”.

LP Vapor Natural

Gas

Gas Gas

-44

-44

83,340

91,547

2,500

110+

97

-259

-259

63,310

1,000

110+

20

Page 21

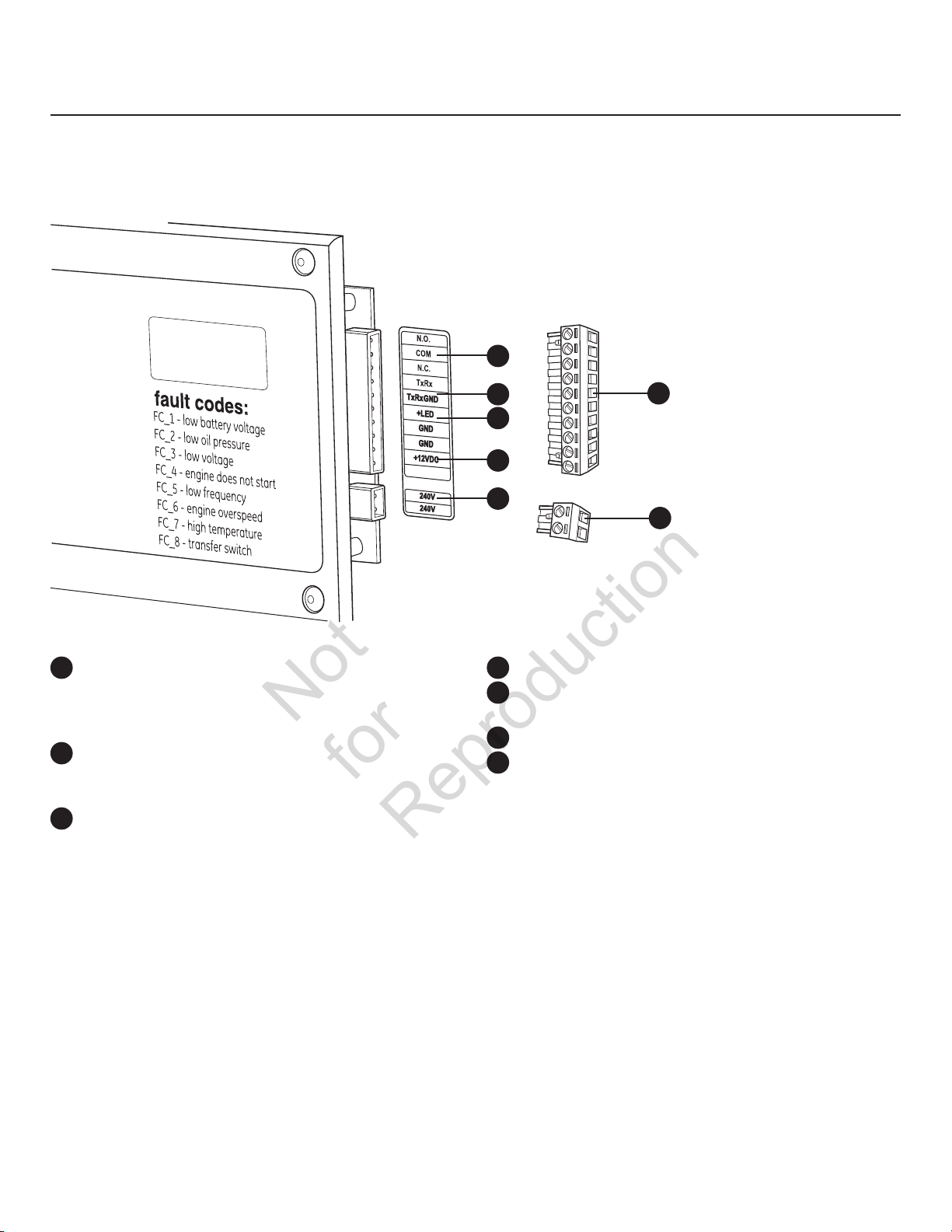

System Connectors

Not

for

Reproduction

Low Voltage connections to signal fault contacts, transfer switch communication, remote LED and auxiliary 12VDC power are

made via a removable ten-pin connector plug. Compare this illustration with your generator to familiarize yourself with the

location of these connections. Count down to the proper pin location on the control board since visual alignment with the decal

can be misleading:

A

A

- Fault Contacts ― Use NO, COM and NC to hook up a

siren, light, etc. to alert you in case of a fault. Contacts

reverse state (NO goes to NC and vice versa) upon a

fault condition.

B

- Transfer Switch Communication ― Connect to transfer

switch control board for communication interface using

18AWG copper twisted pair wire.

C

– LED ― Not Used.

B

C

D

E

D

- +12 Volt DC, .5 Amp Output ― Internal power supply.

E

- 240 Volt Utility ― Use to hook up the 240V utility leads

from the transfer switch to the generator.

F

– Ten-pin Connector Plug

G

– Two-pin Connector Plug

F

G

• For power output connection, use #6 AWG minimum 300 volt 90°C copper wire, (ref. NEC Table 310.16, 100 ft.

Use National Electric Code for correction factors and wire size calculations).

• For utility circuit connection use #14 AWG minimum 300 volt 90°C copper wire.

• For transfer switch communication use #18 AWG twisted pair conductors, no greater than 200 ft in length, 300 volt 90°C

copper wire.

• When connecting to the connector plugs, fasten only one wire to each connector screw.

• Torque connector plug screws to 7 in-lb (7.9 Newton meter).

21

Page 22

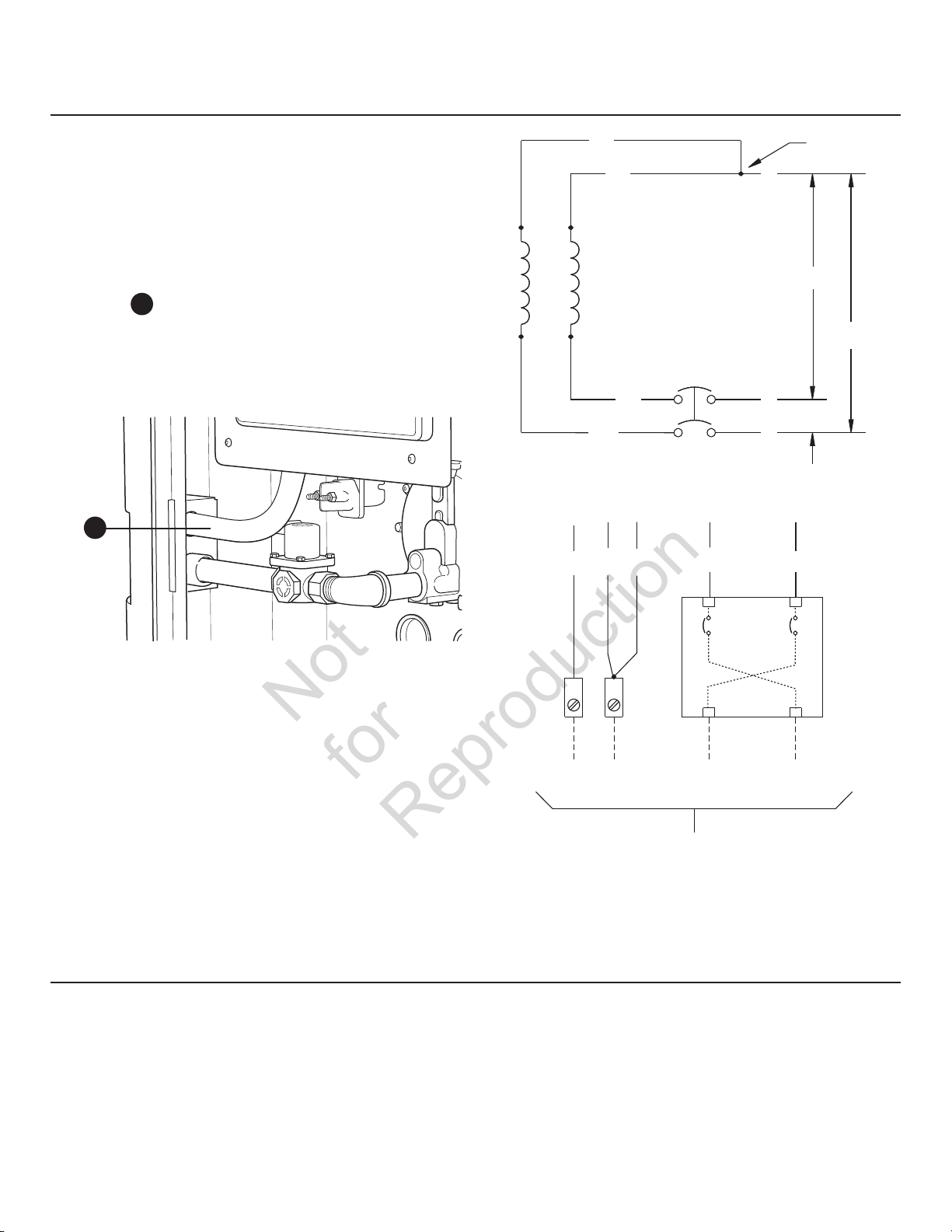

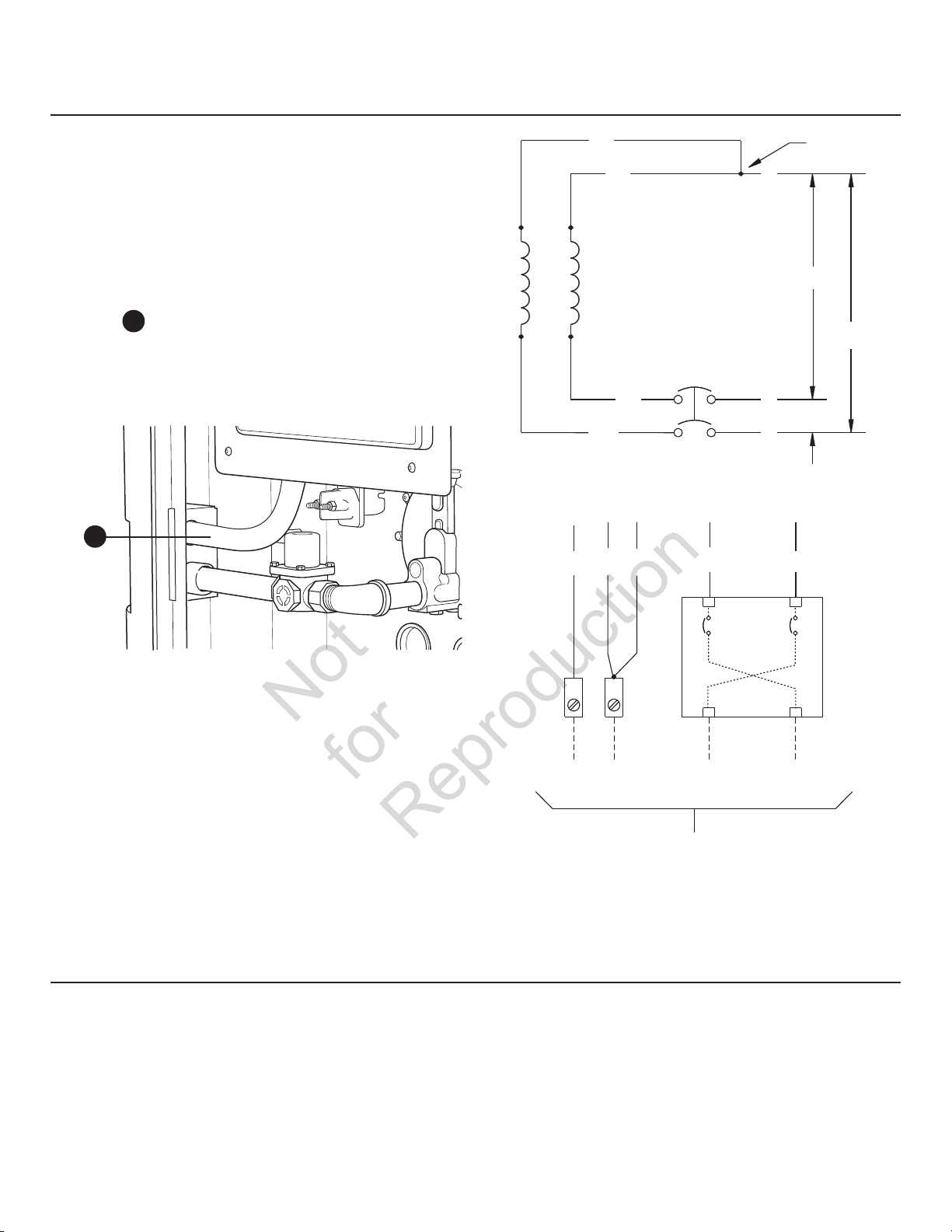

Generator AC Connection System

Not

for

Reproduction

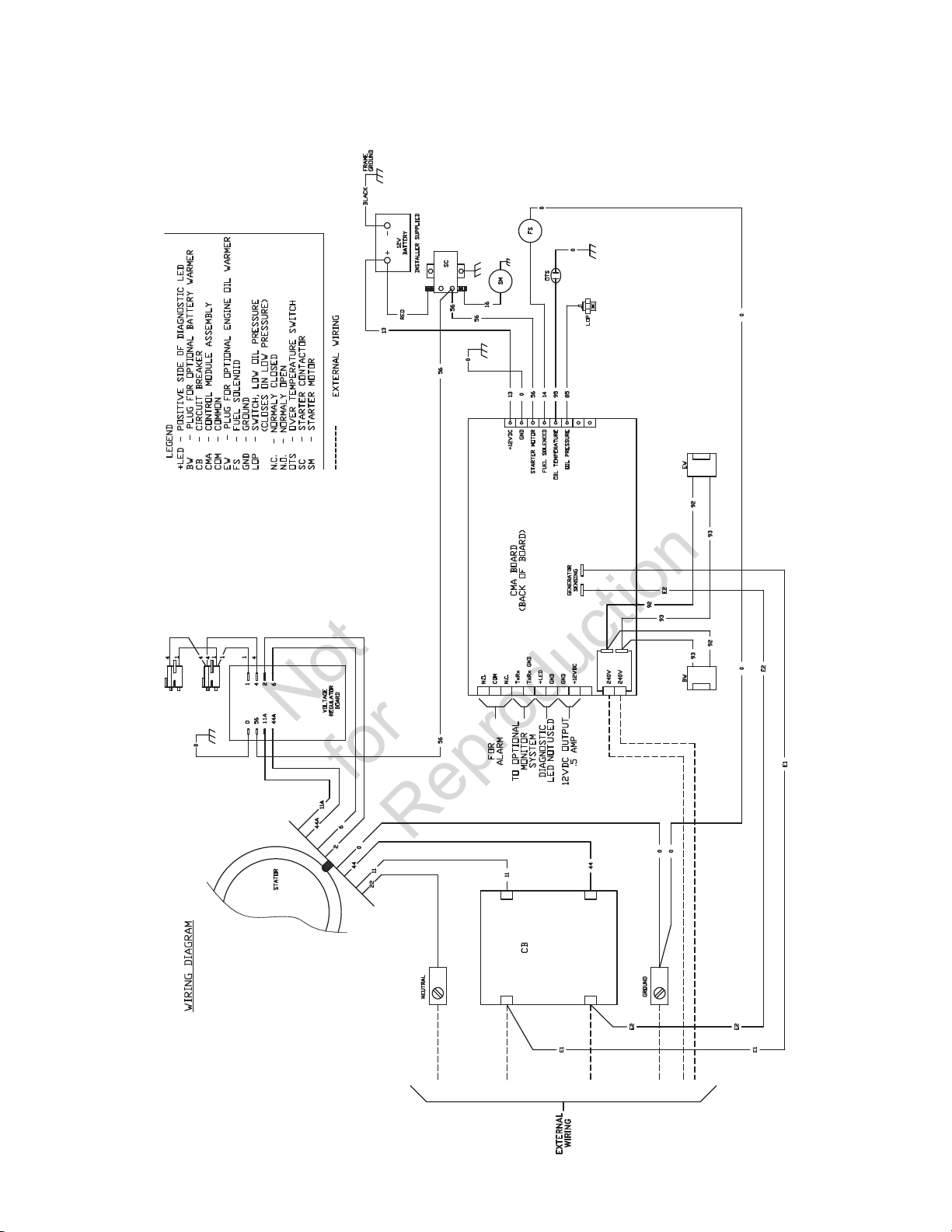

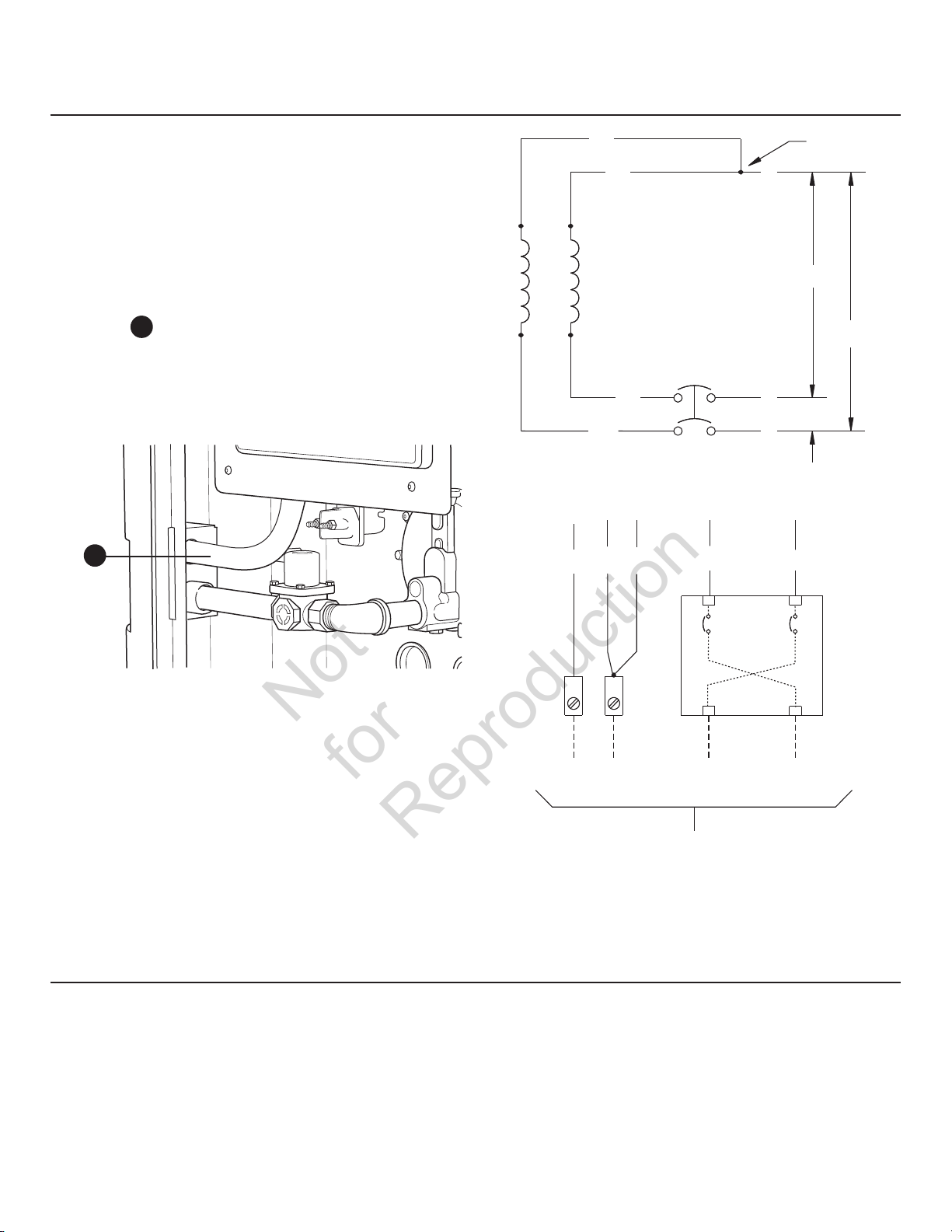

A single-phase, three-wire AC connection system is used in

the home generator. The stator assembly consists of a pair

of stationary windings with two leads brought out of each

winding. The junction of leads 22 and 33 forms the neutral

lead, as shown schematically and as a wiring diagram. A

complete schematic and wiring diagram can be found later

in this manual.

NOTICE

Neutral is not bonded to ground at generator.

The conduit

control panel is a UL requirement. If removed, it must be

replaced with similar conduit.

A

A

between the corner electrical inlet and the

Power Winding

33

44

Neutral

22

120V

120V

Circuit

Breaker

11

240V

1122 33 440

Grounding the Generator

Ground the home generator per applicable codes, standards,

and regulations. The generator GND lug is located inside the

control panel box.

Neutral

Circuit

Breaker

Line 2Ground

To Transfer Switch

Line 1

22

Page 23

Utility Circuit Connection

Not

for

Reproduction

“240V Utility” leads must be routed in conduit. The “240V

Utility” leads deliver power to the generator’s circuit board,

optional battery warmer and optional oil warmer. This power

also charges the battery. When power on these leads is lost,

the generator will start.

Using provided 2 pin connector plug and installer-supplied

minimum 300V, 14 AWG copper wire, connect each control

circuit terminal in the generator to the two-amp fuse

terminals in the automatic transfer switch.

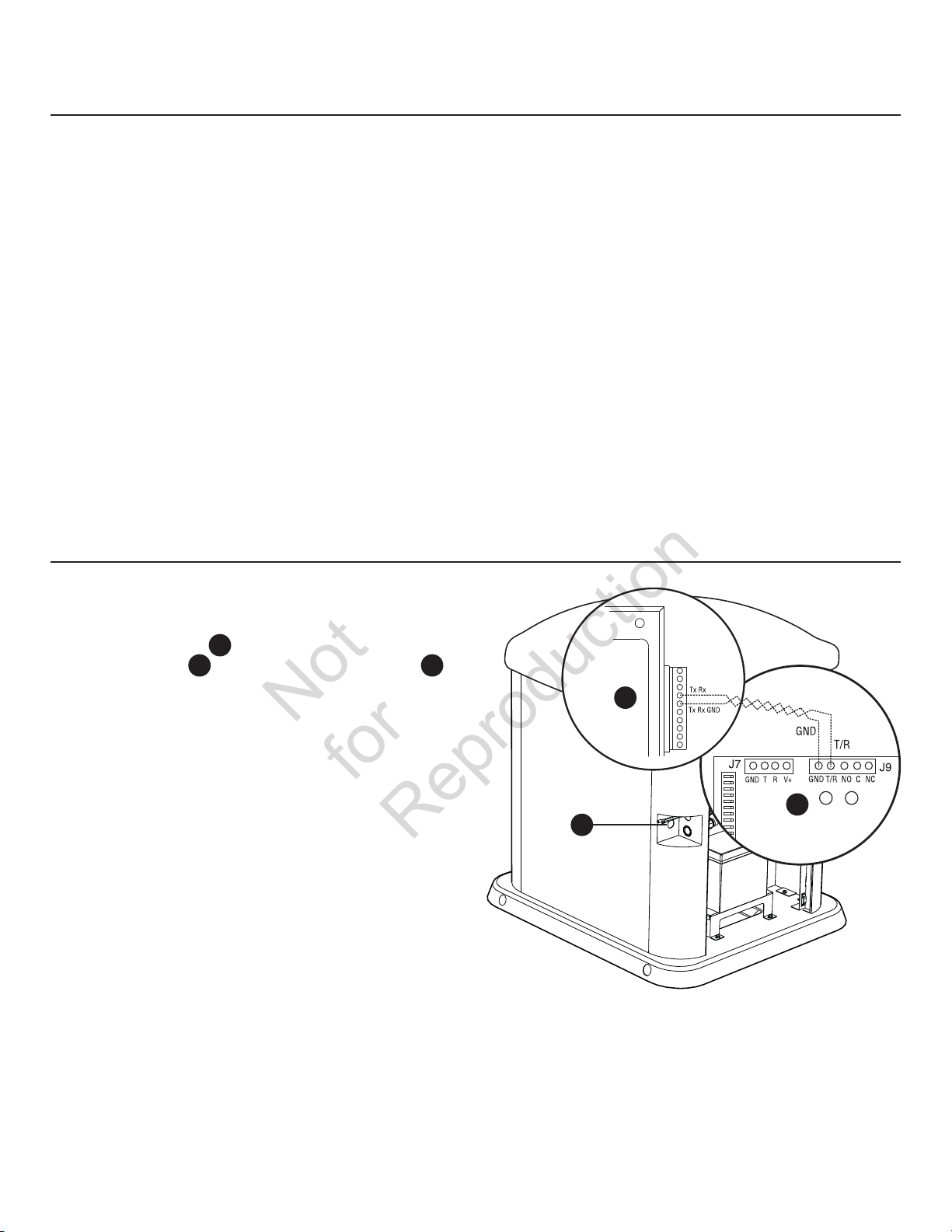

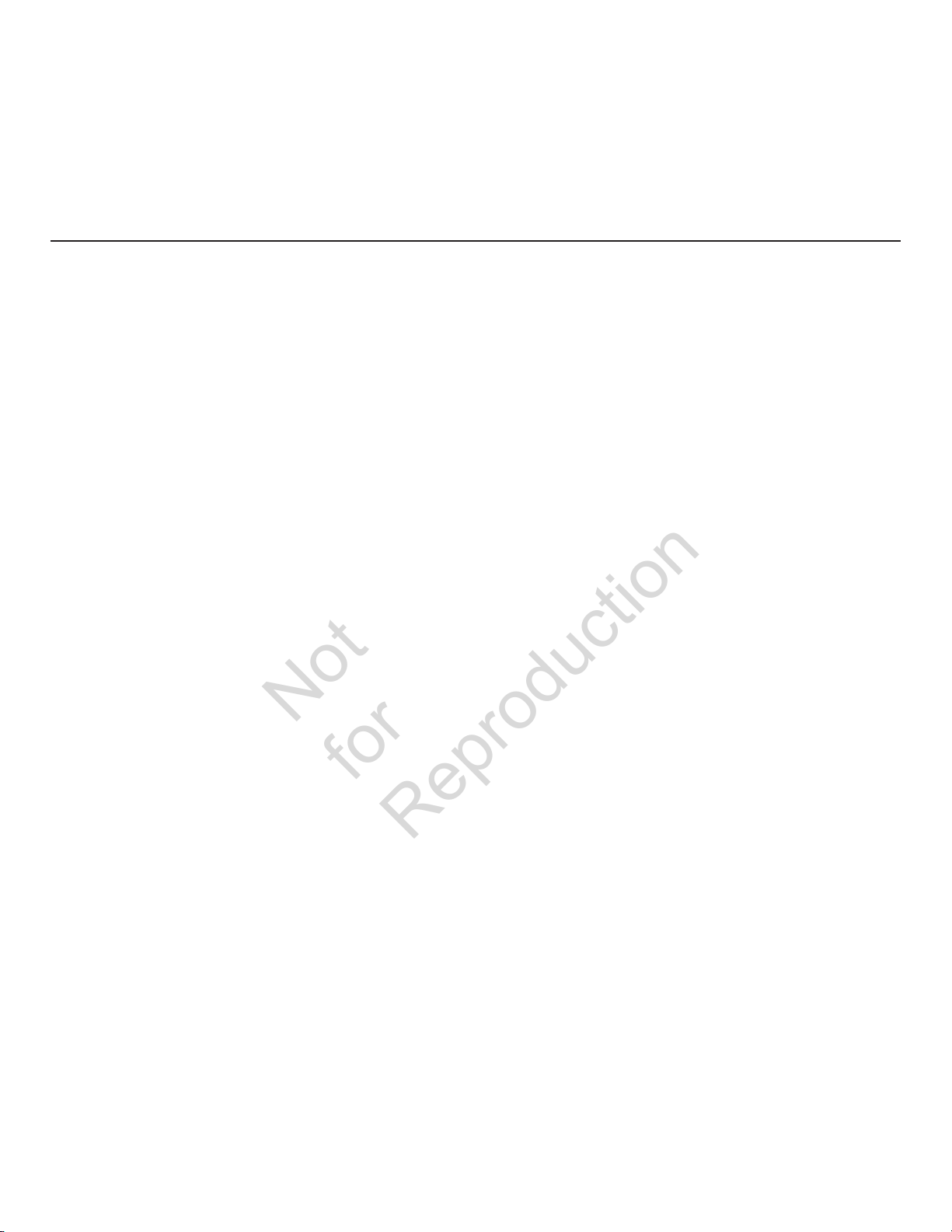

Transfer Switch Communication

(Units with ACCM II or later transfer switch only)

Using #18 AWG twisted pair conductors, no greater than

200 ft in length, connect Tx Rx and Tx Rx GND from the

generator control panel

switch control board B via the low voltage access hole C.

A

to T/R and GND on the transfer

When making connections, obey wire type and torque

specifications printed on the circuit breaker and neutral/

ground connector.

A

B

C

23

Page 24

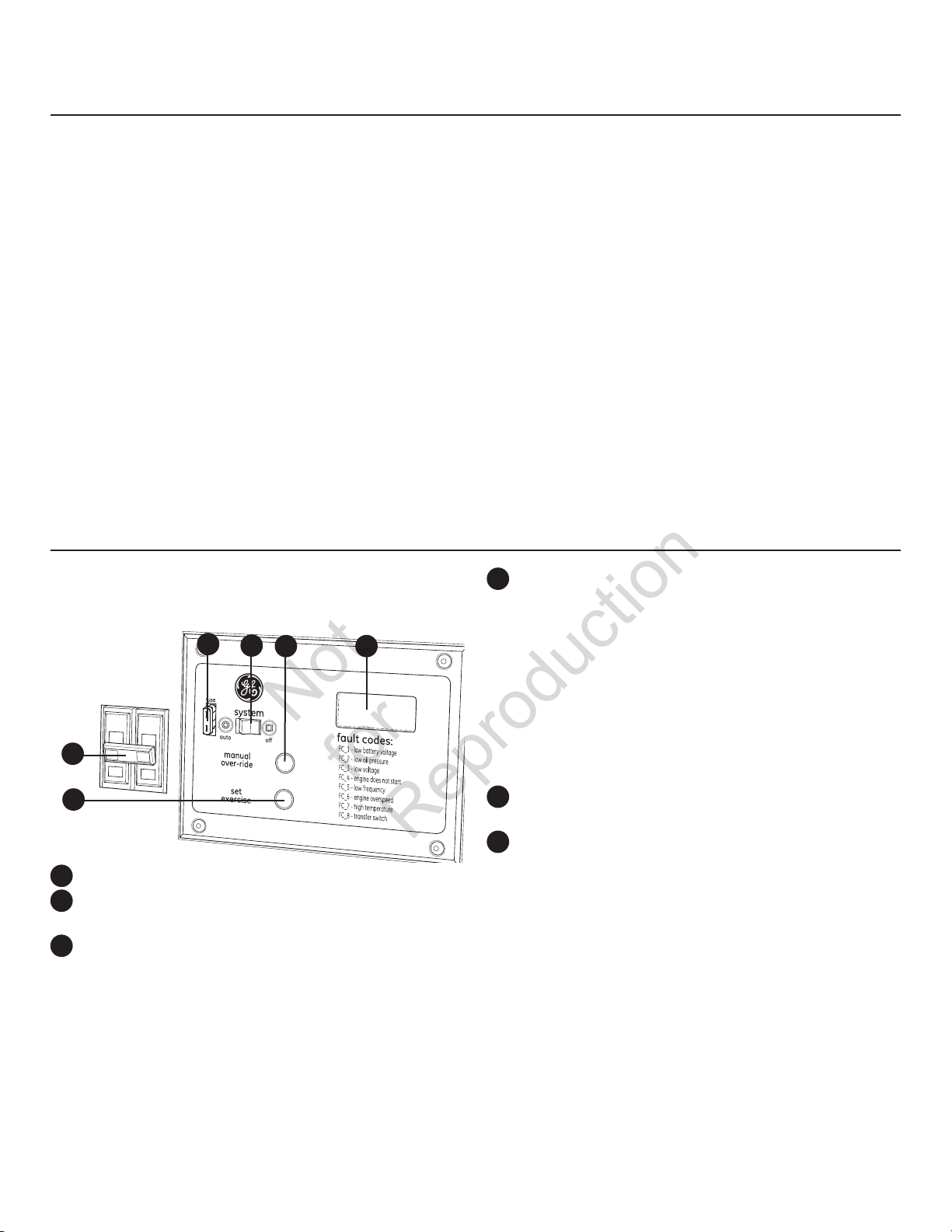

Fault Detection System

Not

for

Reproduction

The generator may have to run for long periods of time with

no operator present. For that reason, the system is equipped

with sensors that automatically shut down the generator

in the event of potentially damaging conditions, such as

low oil pressure, high temperature, over speed, and other

conditions. Refer to Fault Detection System in the operator’s

manual for more detailed information.

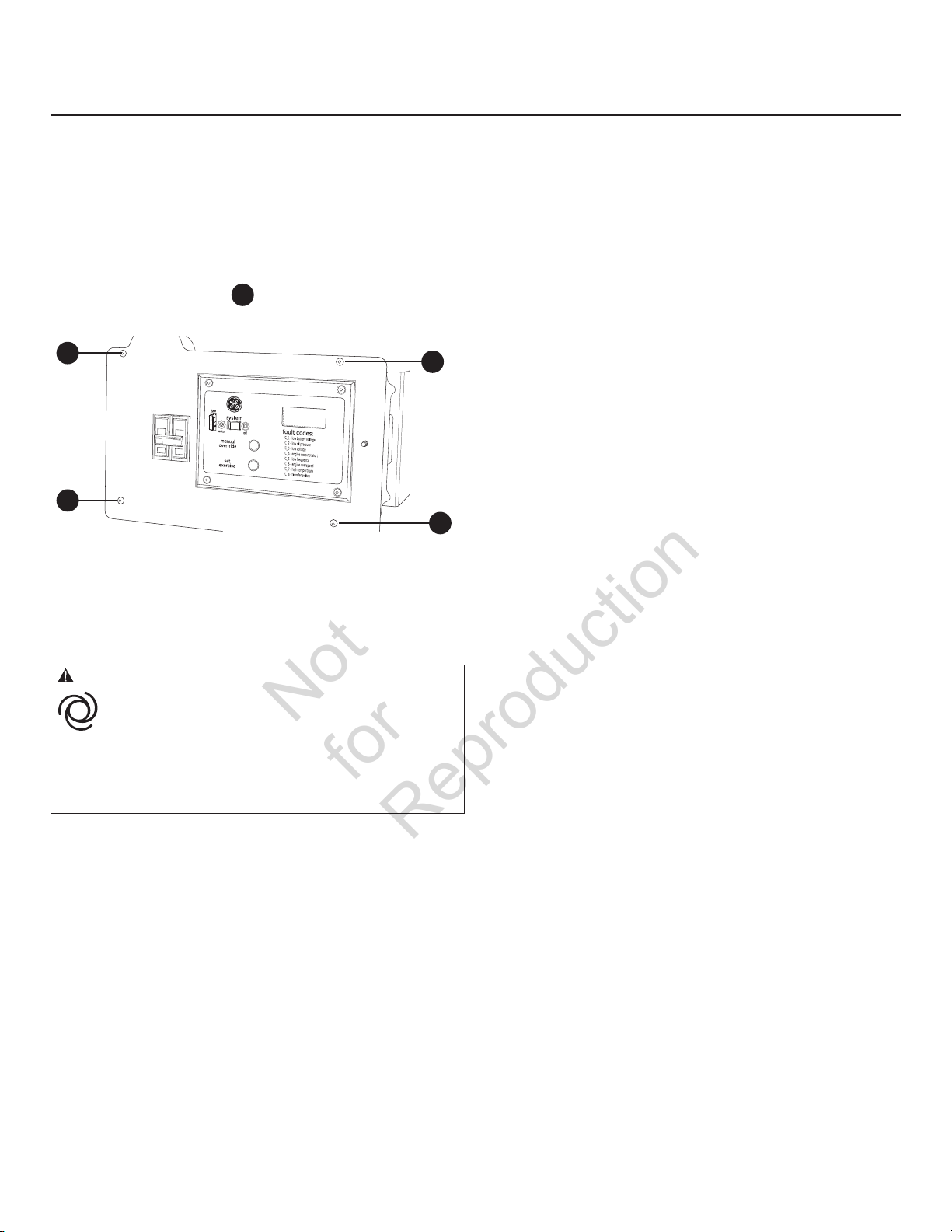

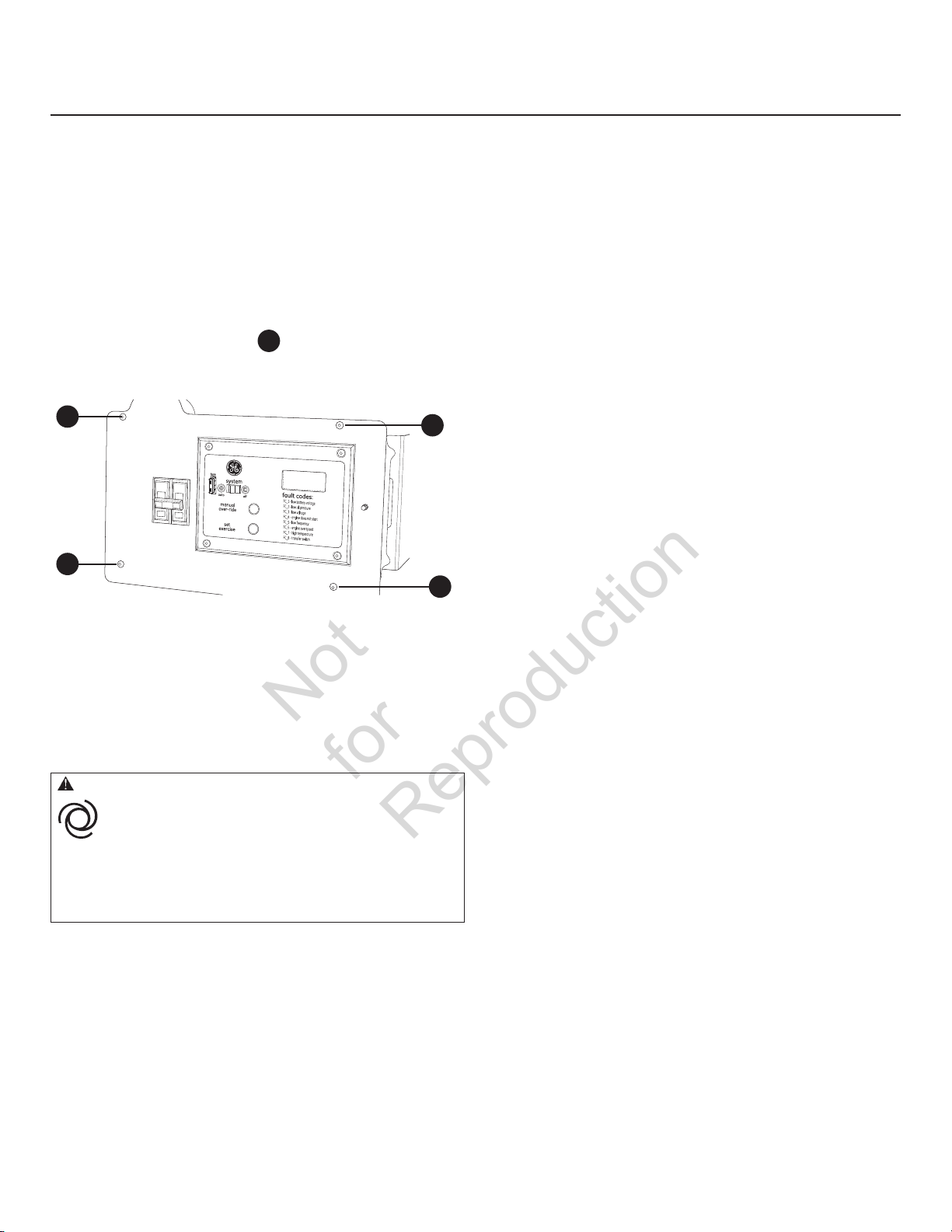

System Control Panel

The home generator control panel, located inside the

generator housing, is shown below. Brief descriptions of the

controls used during installation are:

C

D

E F

B

A

A

- Set Exercise ― Used to set the exercise cycle.

B

- Circuit Breaker ― Must be ON to supply power to the

transfer switch.

C

- 15 Amp Fuse ― Protects the home generator DC

control circuits. If the fuse has ‘blown’ (melted open) or

was removed, the engine cannot crank or start. Replace

the fuse using only an identical ATO 15A fuse. One

spare fuse is supplied with the unit. If fuse was blown or

removed, you will need to reset the exercise timer (see

Setting Exercise Timer).

D

- System Switch ― This two-position switch is the most

important control on the home generator and is used as

follows:

•“AUTO” position is the normal operating position. If a

utility power outage is sensed, the system will start the

generator. When utility power is restored, lets the engine

stabilize internal temperatures, shuts off the generator,

and waits for the next utility power outage.

•“OFF” position turns off running generator, prevents unit

from starting and resets any detected faults.

E

– MANUAL OVER-RIDE ― Used to manually start and

stop the generator.

F

- Digital Display ― Displays running time in hours or

fault codes.

e information may be found in Controls in the

Mor

operator’s manual.

24

Page 25

Concrete Slab (Optional)

Not

for

Reproduction

If mandated by local code, construct a concrete slab at least

3 in (76 mm) thick and 6 in (152 mm) longer and wider than

the unit (34.6 in (880 mm) x 39.4 in (1000 mm)). Attach unit to

slab with 1/4” (6 mm) diameter (minimum) masonry anchor

bolts long enough to retain the unit.

Drill anchor bolt holes into the unit base at the four ideal

locations

Anchor Bolt Drill Location Measurements

F

indicated.

5.51 in

140

A

(140mm)

F

F

A

B

C

D

E

F

5.51 in (140 mm)

23.62 in (600 mm)

16.78 in (426.4 mm)

2.55 in (65 mm)

1.57 in (40 mm)

1/4 in (6 mm) holes

Gravel Base (Optional)

If mandated by local code, clear an area approximately five

inches deep and about six inches wider that the foot print

of the standby generator. Line the area with polyurethane

film and fill with pea gravel or crushed stone. Compact and

level the stone. If concrete slab is required, see Concrete Slab

section in this manual.

B

23.62 in

(600mm)

1/4 in

F

(6mm)

5.51 in

A

(140mm)

1.57 in

40

(40mm)

E

16.78 in

426.4

(426.4mm)

C

F

140

2.55 in

(65mm)

D

25

Page 26

Final Installation Considerations

Not

for

Reproduction

Engine Oil

NOTICE Any attempt to crank or start the engine before it has

been properly serviced with the recommended oil will result in

equipment failure.

• Refer to Maintenance in the operator’s manual for oil fill

information.

• Damage to equipment resulting from failure to follow this

instruction will void engine and generator warranty.

This engine is shipped from the factory pre-run and filled

with synthetic oil (API SJ/CF 5W-30). This allows for system

operation in a wide range of temperature and climate

conditions. Before starting the engine, check oil level as

described in Maintenance of the Operator’s Manual.

The use of synthetic oil does not alter the required oil change

intervals described in the Operator’s Manual.

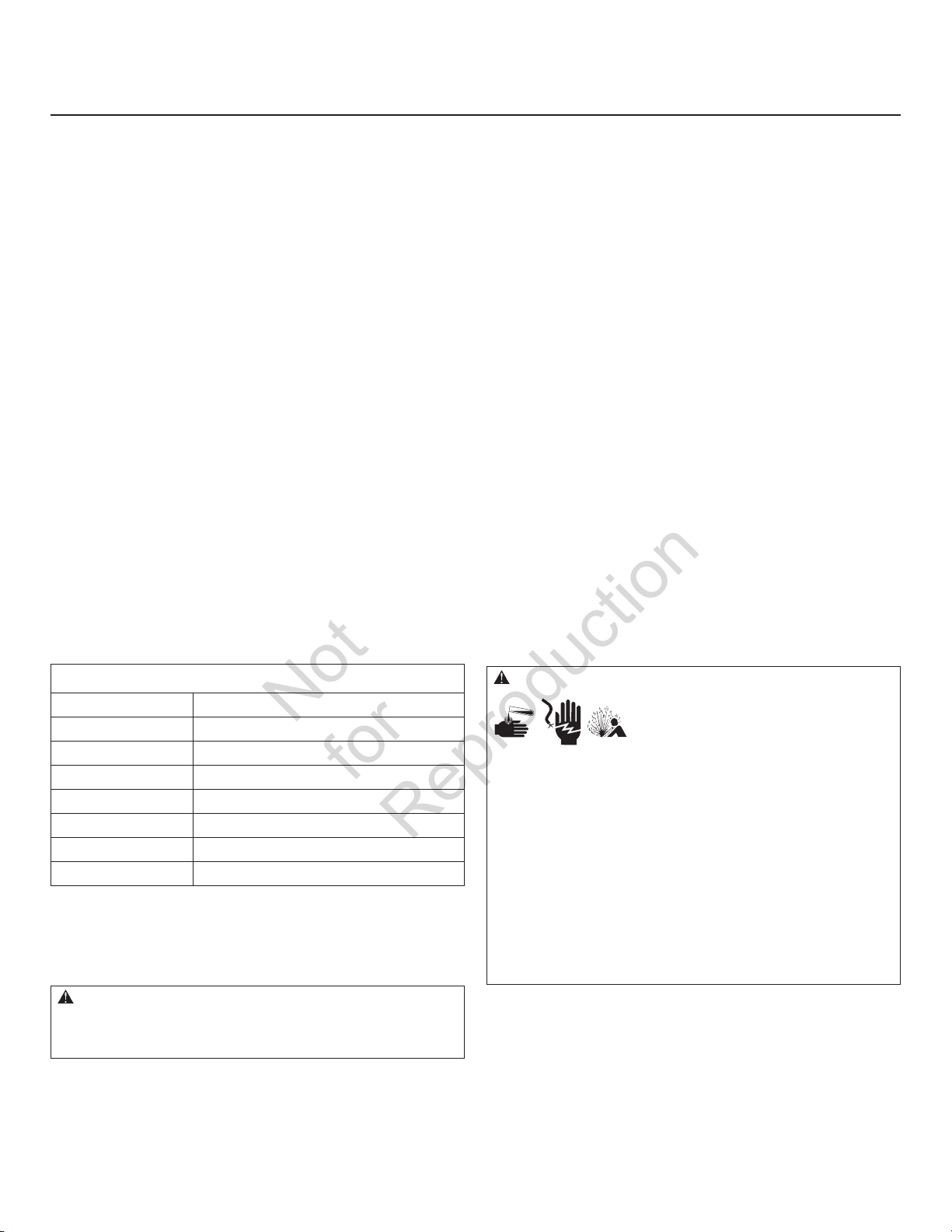

Battery

The installer must supply and install a valve-regulated

rechargeable 12 volt starting battery. The starting battery

MUST conform to the specifications shown in this chart.

Battery Specifications

Volts 12 Volt DC

Amps (MIN) 600 CCA (cold cranking amps)

Type AGM (absorbent glass mat)

Terminal Hardware M6

Dimensions (MAX):

Width 5.5 inches (140 mm)

Length 9.0 inches (230 mm)

Height 8.25 inches (210 mm)

Install the battery as described in Servicing the Battery in

the Maintenance section of the operator’s manual. Always

make sure the NEGATIVE cable is connected last and that

the red POSITIVE terminal insulator is fully in place.

WARNING Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals known to the State

of California to cause cancer and reproductive harm. Wash hands

after handling.

WARNING Storage batteries give off explosive hydrogen gas

during recharging.

Slightest spark will ignite hydrogen and

cause explosion, resulting in death, serious

injury and/or property damage.

Battery electrolyte fluid contains acid and is extremely caustic.

Contact with battery contents could cause severe chemical burns.

A battery presents a risk of electrical shock and high short

circuit current.

• DO NOT dispose of battery in a fire. Recycle battery.

• DO NOT allow any open flame, spark, heat, or lit cigarette during

and for several minutes after charging a battery.

• DO NOT open or mutilate the battery.

• Wear protective goggles, rubber apron, rubber boots and

rubber gloves.

• Remove watches, rings, or other metal objects.

• Use tools having insulated handles.

26

Page 27

Initial Start-up (No Load)

Not

for

Reproduction

Unit has been set-up for NG operation at the factory. Fuel

conversion, if needed, must be completed prior to performing

these steps. See Fuel Conversion.

Before operating the home generator or placing it into

service, inspect the entire installation carefully. Then begin

testing the system without any electrical loads connected,

as follows:

1. Remove four screws

to enclosure to expose unit’s circuit breaker.

A

A

2. Connect an accurate frequency meter to line side of

generator’s main circuit breaker.

3. Set generator’s main circuit breaker to ON

(closed) position.

4. Set generator’s system switch to OFF.

CAUTION Installing the 15A fuse could cause the engine

to start at any time without warning resulting in minor or

moderate injury.

A

that secure control box front

A

A

When the generator is started for the very first time, it will

require that air in the gaseous fuel lines be purged. This may

take a few minutes.

8. Listen for unusual noises, vibration or other

indications of abnormal operation. Check for oil leaks

while engine runs.

9. Let engine warm up for about five minutes to allow

internal temperatures to stabilize.

10. Check generator output at load side of circuit breaker.

Voltage should be 239 - 262 Volts, frequency should

be 62.0 - 62.5 Hz.

If either parameter is outside these ranges, perform Engine

Adjustment described later in this section.

11. Check generator output between one generator

connection lug and neutral lug, then between

other generator connection lug and neutral lug.

In both cases, voltage reading should be between

119 and 131 Volts.

DO NOT proceed until you are certain that generator AC

voltage and frequency are correct and within the stated

limits. To obtain the proper generator frequency, see

Engine Adjustment.

12. Push and hold MANUAL OVER-RIDE button on control

panel until engine stops.

13. Reinstall control panel into enclosure.

• Observe that the 15 Amp fuse has been removed from the control

panel for shipping.

• DO NOT install this fuse until all plumbing and wiring has been

completed and inspected.

5. Install 15 Amp fuse in control panel.

6. Set generator’s system switch to AUTO.

7. Push and hold MANUAL OVER-RIDE button on control

panel for about six seconds. Engine will start.

27

Page 28

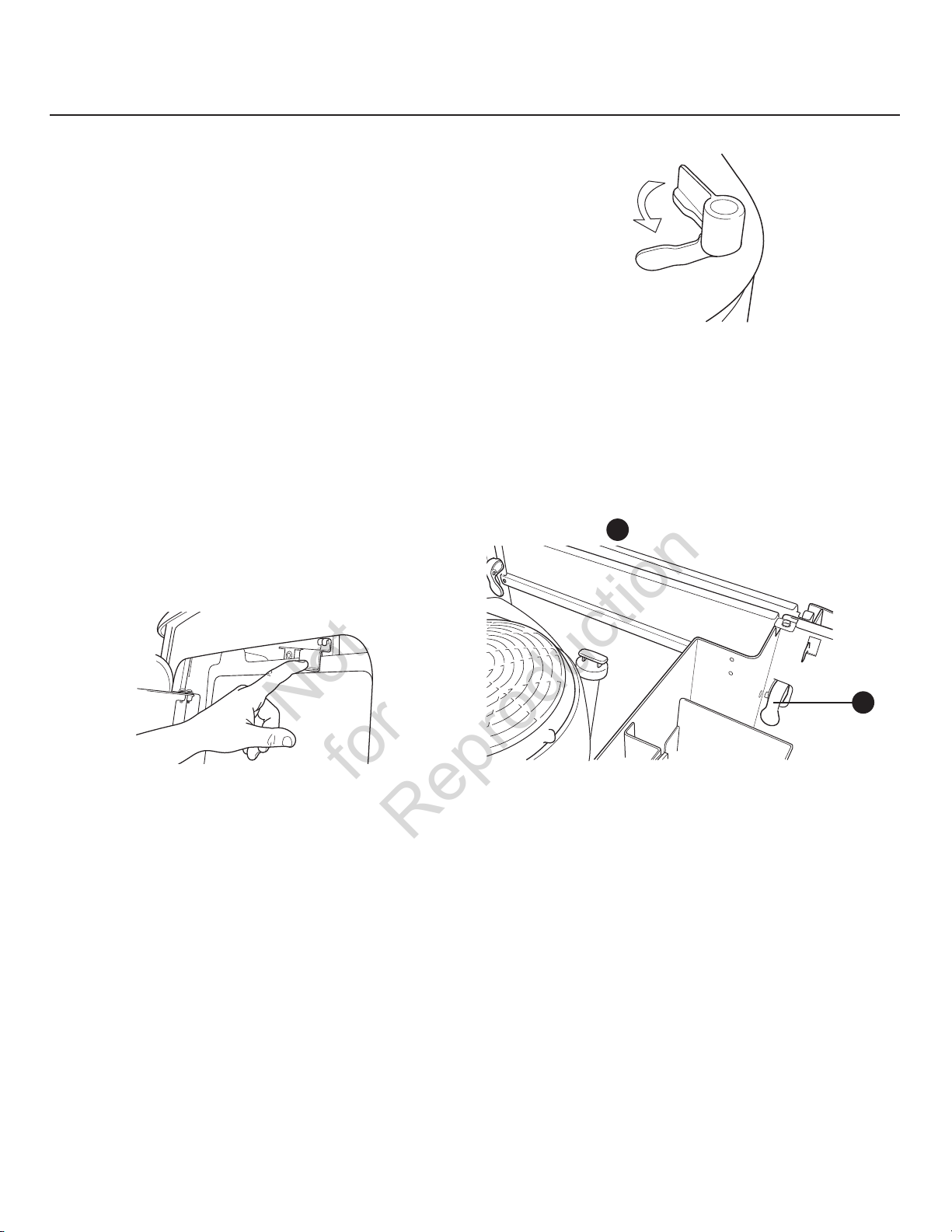

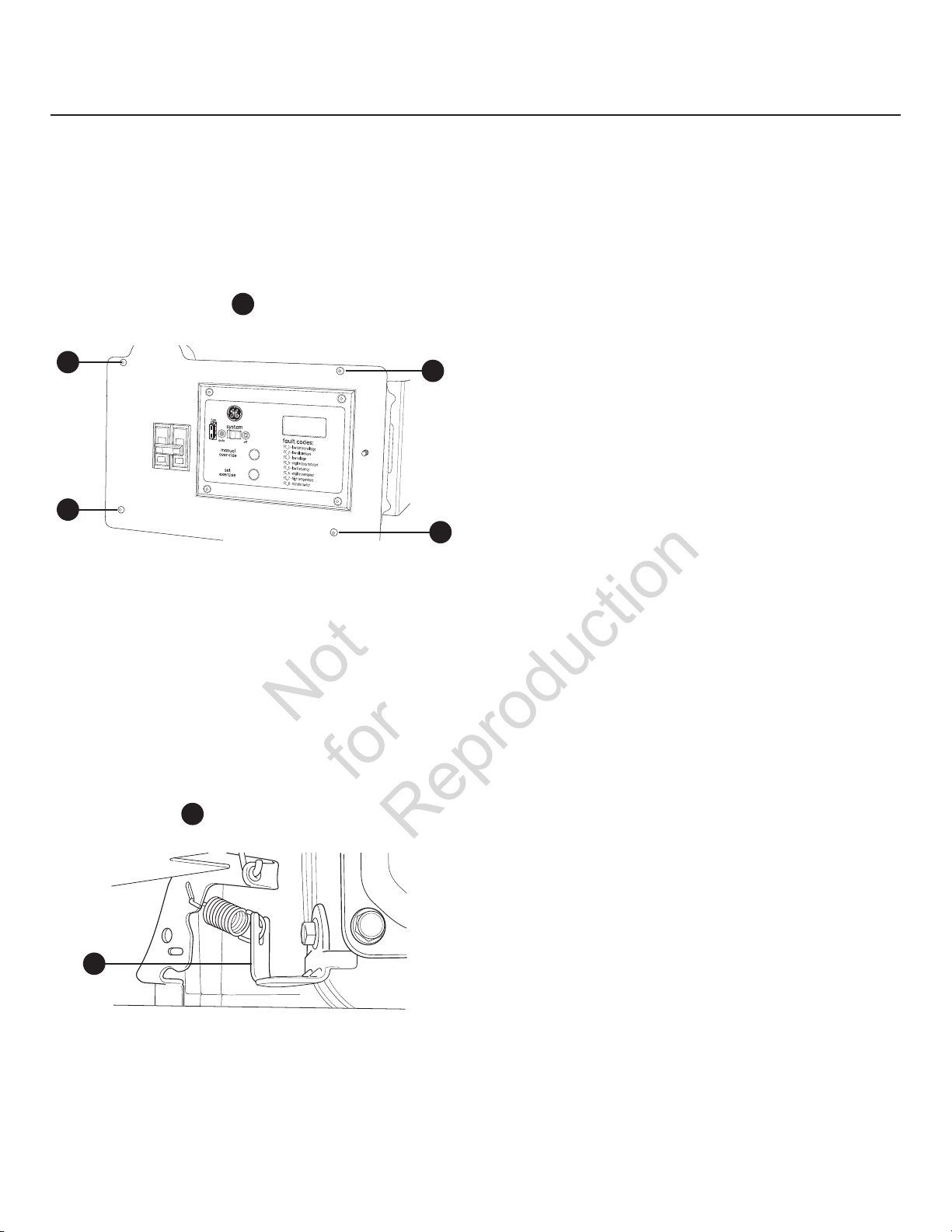

Engine Adjustment

Not

for

Reproduction

There are regional variances in the composition of natural

gas. Each home generator unit leaves the factory set for

NG operation. If the generator output voltage or frequency

measured during Initial Start-Up is outside the listed ranges,

the combustibility of the gas supplied at the installation

site may be substantially different from the fuel used at

the factory.

To adjust the engine for this difference, proceed as follows:

1. Remove four screws

to enclosure to expose unit’s circuit breaker.

A

A

2. Connect an accurate frequency meter to line side of

generator’s main circuit breaker.

3. Ensure that the 15 Amp fuse is installed.

4. Set the generator’s main circuit breaker ON.

5. Set the generator’s system switch to AUTO.

6. Push MANUAL OVER-RIDE button on control panel.

When the engine starts, allow it to warm up for

five minutes.

7. Normal no load frequency is 62.0 to 62.5 Hz. If

adjustment is needed at no load, remove unit

side panels. Using needle nose pliers, bend spring

anchor tang B slowly up or down until frequency is

62.0 to 62.5 Hz.

A

that secure control box front

A

8. Turn utility service disconnect to transfer switch OFF.

After a short time delay, transfer switch will connect

to generator.

9. Load generator to full load.

10. After load stabilizes, frequency should be

above 57.0 Hz.

11. If frequency is below 57.0 Hz, slowly adjust the

governor until frequency is above 57.0 Hz.

12. Turn service disconnect to transfer switch ON.

Transfer switch will connect to utility power after

five minutes.

13. Push and hold MANUAL OVER-RIDE button on control

panel until engine stops.

14. After the engine has stopped:

• If an adjustment was made in step 11, repeat steps

2 through 7.

• If an adjustment was not made in step 11, proceed

A

If no load frequency falls out of the no load range shown

in step 7 after full load adjustment is made, contact an

authorized service center.

15. Reinstall control panel into enclosure.

to step 15.

B

28

Page 29

Not

for

Reproduction

29

Page 30

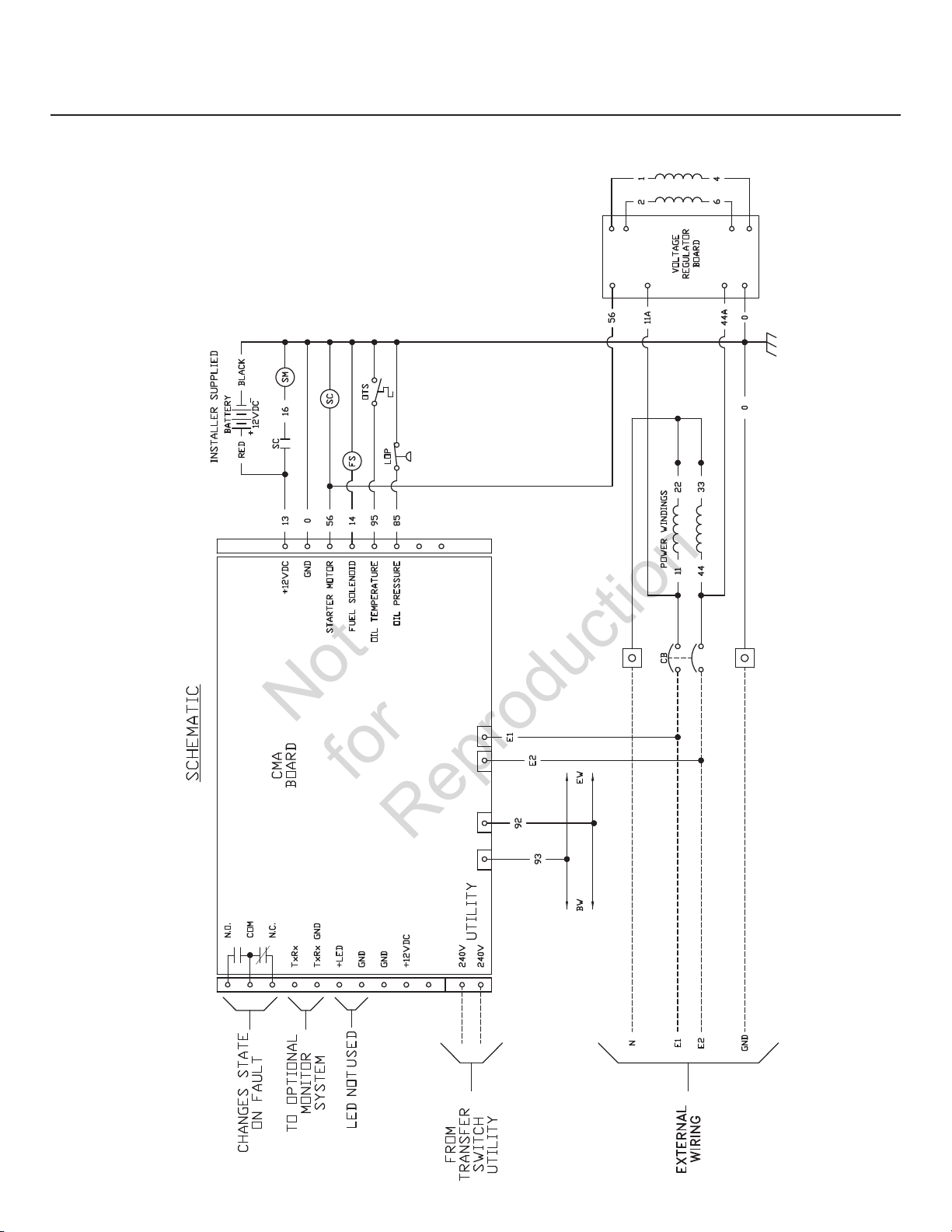

Schematic / Wiring Diagrams

Not

for

Reproduction

Schematic Diagram 11,000 Watt

30

Page 31

Wiring Diagram 11,000 Watt

Not

for

Reproduction

31

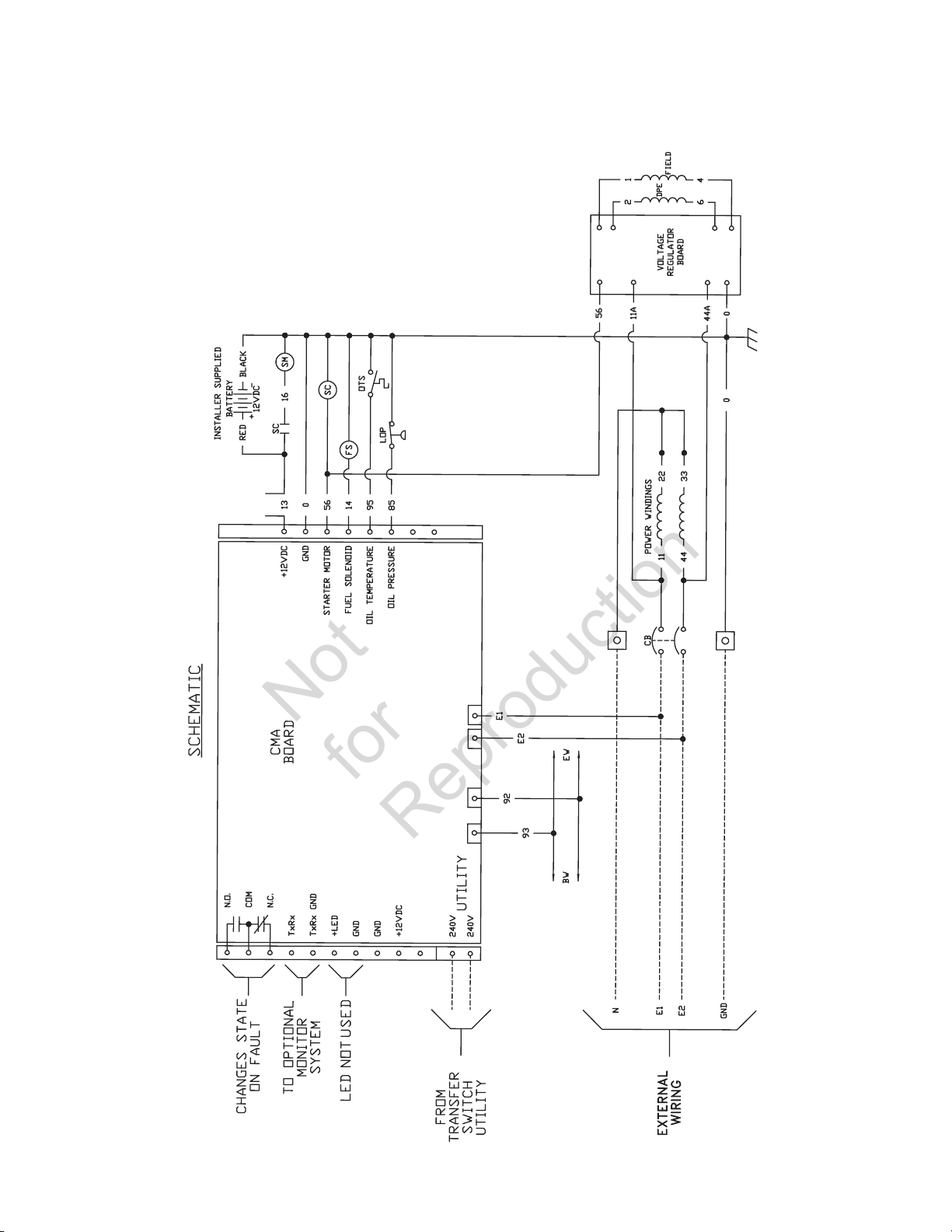

Page 32

Schematic Diagram 13,000 Watt

Not

for

Reproduction

32

Page 33

Wiring Diagram 13,000 Watt

Not

for

Reproduction

33

Page 34

Operation

Not

for

Reproduction

Automatic Operation Sequence

The generator’s control panel houses a logic control circuit

board. This control board constantly monitors utility power

source voltage. Should that voltage drop below a preset

level, control board action will signal the engine to crank

and start.

When utility source voltage is restored above a preset

voltage level, the engine is signaled to shut down.

The actual system operation is not adjustable and is

sequenced by sensors and timers on the control board,

as follows:

Utility Voltage Dropout Sensor

• This sensor monitors utility source voltage.

• If utility source voltage drops below about 70 percent

of the nominal supply voltage, the sensor energizes

a 10 second timer. The timer is used to ‘sense’

brown-outs.

• Once the timer has expired, the engine will crank

and start.

Utility Voltage Pickup Sensor

This sensor monitors utility power supply voltage. When that

voltage is restored above 80 percent of the nominal source

voltage, a time delay starts timing and the engine will go to

engine cool-down.

Engine Cool-down Timer

• When the load is transferred back to the utility power

source, the engine cool-down timer starts timing.

• The timer will run for about one minute, then the

generator will stop.

• Minimum engine run time is 5 minutes.

34

Page 35

Setting Exercise Timer

Not

for

Reproduction

The home generator is equipped with an exercise timer that

will start and exercise the system once every seven days.

During this exercise period, the unit runs for approximately

20 minutes and then shuts down. Electrical load transfer

DOES NOT occur during the exercise cycle (unless an utility

power outage occurs).

A button on the control panel is labeled “SET EXERCISE” (see

System Control Panel). The specific day and the specific

time of day this button is pressed is programmed into the

control board memory. This date and time is then used to

automatically initiate the system exercise cycle. The “SET

EXERCISE” legend on the control panel will flash until the set

exercise cycle is set.

To perform the Set Exercise procedure:

1. Choose the day and time you want your home

generator to exercise.

2. On that day and time, press and hold “SET EXERCISE”

for three seconds.

The “Set Exercise” display will illuminate then turn off

to confirm that the exercise timer has been set. Then

release the button.

The unit will crank and run the exercise cycle. During

the cycle, “Set Exercise” will illuminate.

Once the exercise cycle is complete, the unit will turn

off and “Set Exercise” will no longer be displayed.

The exercise cycle may be discontinued at anytime by

turning the System Switch to OFF.

3. The unit will then start and run it’s 20 minute exercise

cycle.

For example, if you press SET EXERCISE on Sunday morning

at 10:00 AM, the unit will run an immediate exercise cycle

and an exercise cycle every following Sunday at 10:00 AM

(+/- 1/2 hour).

“Set Exercise” will only work if the unit is in the AUTO mode

and this exact procedure is followed. The exerciser will need

to be re-set if the 15 Amp fuse is removed or changed, or if

the starting battery is disconnected.

If you want to change the day and time the unit exercises,

simply perform the “Set Exercise” procedure at the exact

weekday and time you want it to take place.

Generator will not exercise if timer is not set.

35

Page 36

Installation Inspection

Not

for

Reproduction

Before placing the generator system into service, inspect the

entire installation carefully.

This completes the installation and start-up instructions.

The operator’s manual provides full details on Operation,

Maintenance and Troubleshooting for this generator system.

is a trademark of General Electric Company

and is under license by Briggs & Stratton

Power Products Group, LLC.

36

Copyright © 2011. All rights reserved. No part of this material may

be reproduced or transmitted in any form without the express

written permission of Briggs & Stratton Power Products Group, LLC.

Page 37

GE Home Generator Systems

Not

for

Reproduction

Sistema generador doméstico

Manual de instalación

y arranque

Page 38

Gracias por aduirir este generador doméstico de reserva GE de alta calidad. Nos complace ue haya depositado su

Not

for

Reproduction

confianza en la marca GE. Si se utiliza y mantiene conforme a las instrucciones de este manual, el generador GE le

ofrecerá muchos años de servicio fiable.

Este manual contiene información de seguridad para que usted conozca los peligros y riesgos propios de los sistemas

generadores domésticos y cómo evitarlos. Este sistema generador doméstico está diseñado y pensado para utilizarlo

únicamente como un sistema de reserva doméstico opcional que proporciona una fuente alternativa de energía

eléctrica con capacidad para alimentar cargas tales como sistemas de calefacción y refrigeración y sistemas de

comunicaciones, que cuando dejan de funcionar a causa de una interrupción de la alimentación eléctrica de la red

pueden producir incomodidades o problemas. Guarde estas instrucciones originales para futuras consultas.

Este generador de reserva doméstico debe ser instalado por un profesional antes de ser utilizado. El instalador

debe seguir las instrucciones por completo.

Dónde encontrarnos

No tiene que buscar mucho para obtener ayuda y servicio de mantenimiento para su generador. Consulte las Páginas

Amarillas. Existen muchos distribuidores de servicio autorizados de GE que brindan servicio de calidad. También

puede comunicarse por teléfono al número 888 575-8226. entre 08:00 a. m. y 5:00 p. m., hora del centro de los EE.

UU; o haga clic en SERVICE & SUPPORT en www.homestandbygeneratorsystems.com para que aparezca una lista de

distribuidores autorizados.

Para la referencia futura

Complete por favor la información abajo y guarde con su recibo para asistir a la identificación de la unidad para las

ediciones futuras de la compra.

Fecha de compra

Generador

Número de modelo

Revisión

Número de serie

Motor

Número de modelo

38

Page 39

Tabla de contenido

Not

for

Reproduction

Instrucciones de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Instrucciones importantes de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Responsabilidades del propietario. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Responsabilidades del distribuidor/técnico instalador. . . . . . . . . . . . . . . . . . . . . . . . 44

Juego para climas fríos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Precauciones al momento del desempaque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Inspección al momento de la entrega. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Contenido de la caja . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Lista de control de la instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Colocación del generador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Colocación de un generador de reserva para

reducir el riesgo de envenenamiento por monóxido de carbono . . . . . . . . . . . . . . 47

Colocación de un generador de reserva para reducir el riesgo de incendio . . . . . 49

OTRAS directrices generales de ubicación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Requisitos y pruebas de la norma NFPA 37 de National Fire Protection Association (NFPA) 51

Ubicación de las entradas eléctricas y de combustible . . . . . . . . . . . . . . . . . . . . . . . 52

Elevación del generador. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Puertas de acceso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Sistema de combustible gaseoso. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

44

Conversión de combustible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Consumo de combustible. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Conexiones de sistema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Sistema de conexión de c.a. del generador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Conexión a tierra del generador. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Interconexiones del circuito de control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Comunicación del conectador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Sistema de detección de fallas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Panel de control del sistema . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Solera de concreto (opcional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Consideraciones finales para la instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Arranque inicial (sin carga) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Ajuste del motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Utilización . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Secuencia de operación automática . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Configuración del temporizador de práctica. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Inspección posterior a la instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

39

Page 40

Instrucciones de seguridad

Not

for

Reproduction

Instrucciones importantes de seguridad

GUARDE ESTAS INSTRUCCIONES - Este manual contiene

instrucciones importantes que se deben seguir durante

la instalación y el mantenimiento del generador y de

las baterías.

Símbolos sobre la seguridad y significados

Explosión

Gases Tóxicos

Peligro al Elevar Lea el Manual

Fuego

Partes en Movimiento Superficie Caliente

Presión ExplosivaArranque Automático

Descarga Eléctrica

Quemaduras Química

El fabricante no puede prever todas las posibles

circunstancias que pueden implicar riesgos. Por lo tanto, las

advertencias que aparecen en este manual y las etiquetas

y calcomanías adheridas a la unidad no incluyen todas las

posibilidades. Si aplica un procedimiento, método de trabajo

o técnica de operación no recomendada específicamente

por el fabricante, debe estar seguro de que se trata de una

práctica segura para usted y para otras personas. También

debe asegurarse de que el procedimiento, método de trabajo

o técnica de operación que elija, no haga que el generador

se torne inseguro.

ADVERTENCIA Los motores en funcionamiento emiten

monóxido de carbono, un gas tóxico, inodoro e incoloro.

La inhalación de monóxido de carbono puede provocar

lesiones graves, dolor de cabeza, fatiga, mareos, vómitos,

confusión, convulsiones, náuseas, desmayos o incluso la muerte.

• Haga funcionar este producto ÚNICAMENTE a la intemperie en una

zona en donde no se acumulen gases de escape mortales.

• Evite que los gases de escape entren por ventanas, puertas, tomas

de aire de ventilación, ventilaciones en plafones, entresuelos, puertas

de garaje abiertas u otras aberturas que permitan que entre o se

arrastre dentro de un edificio o estructura que pueda estar habitado.

• Los detectores del monóxido de carbono deben ser instalados y