Page 1

Safety Information ............. 2

Specifications

and Performance Claims ........ 3

About the Softener .......... 4-6

Before you Start ............... 7

Installation Requirements .....8-10

Installation Instructions .......11-15

Programming the Softener . . .16-20

SYSTEM

Care and Cleaning .............21

Routine Maintenance .......... 22

Before you call for Service . . 23-26

Exploded View/Parts List . . . 29-32

Warranty (U.S.) ............... 33

Warranty (Canada) ...........34

Systems tested and certified by NSF International

against NSF/ANSI Standard 44 for the chemical

reduction claims specified on page 3, and certified

to NSF/ANSI 372.

OWNER’S MANUAL

AND INSTALLATION

INSTRUCTIONS

Model GXSF30V

Write the model and

serial numbers here:

Model # _____________

Serial # _____________

To find these numbers,

lift the cover and look

on the rim below the

control panel.

Systems Tested and Certified by the Water Quality

Association against CSA B483.1.

R

C

If you have any questions or concerns when installing or maintaining

your water softener, call our toll free number at 800-952-5039 (US)

or 866-777-7627 (Canada), or visit www.geappliances.com. When you

call, please be prepared to provide the model and serial number of your

product. This information can be found on the rating decal located on

the rim under the salt cover.

USA

WATER SOFTENING

GE is a trademark of the General Electric Company. Manufactured under trademark license.

7350846 49-50282-9 04-17 GEA

Page 2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING

SAFETY PRECAUTIONS

For your safety, the information in this manual must be followed

WARNING

to minimize the risk of electric shock, property damage or

personal injury.

WARNING

A copper or galvanized cold water pipe may be

used to ground electrical outlets in the home.

Failure to maintain this ground path may result in

an electric shock hazard. If the cold water pipe

is used to ground electric outlets, please refer to

Installing the Ground Wire section before cutting

the pipe.

Check and comply with your state and local

codes. You must follow these guidelines.

Use care when handling the water softening

system. Do not turn upside down, drop, drag

or set on sharp protrusions.

Water softening systems using sodium

chloride (salt) for recharge add sodium to the

water.

Persons on sodium restricted diets should

consider the added sodium as part of their

overall intake. Potassium chloride can be

used as an alternative to sodium chloride in

your softener.

Use only lead-free solder and flux for all

sweat-solder connections, as required by

state and federal codes.

This water softening system must be properly

installed and located in accordance with the

installation instructions before it is used.

Keep the salt hole cover in place on the

softener unless servicing the unit or refilling

with salt.

In the state of California: You must turn

the Salt Efficiency Feature setting to ON.

This may initiate more frequent recharges.

However it will operate at 4,000 grains per

pound of salt or higher. To turn on the Salt

Efficiency Feature, follow the instructions in

the “Salt Saver” section of this manual

WARNING

with water that is microbiologically unsafe or of

unknown quality without adequate disinfection

before or after the system.

WARNING

unused parts and packaging material after

installation. Small parts remaining after the

installation could be a choke hazard.

The water softening system works on 24 volt-

electrical power only. Be sure to use

60 Hz

the included external power supply.

External power supply must be plugged into

an indoor 120 volt, grounded outlet only.

Use clean water softening salts only, at least

99.5% pure. NUGGET, PELLET or coarse

SOLAR salts are recommended. Do not use

rock, block, granulated or ice cream making

salts. These types of salts may contain dirt

and sediments that might mush or cake,

creating maintenance issues for the water

softener.

Avoid installing in direct sunlight. Excessive

heat may cause distortion or other damage to

non-metallic parts.

If installing the water softener outdoors, do

not locate where it will be exposed to wet

weather, direct sunlight, extreme hot or cold

temperatures, or other forms of abuse.

In the Commonwealth of Massachusetts,

Plumbing Code 248 CMR shall be adhered

to. Consult with your licensed plumber.

Do not use

Discard all

READ AND SAVE THESE INSTRUCTIONS

2

Page 3

Specifications and Performance Claims

This model is efficiency rated. The efficiency rating is valid only at the minimum stated salt dose. The softener has

a demand initiated regeneration (D.I.R) feature that complies with specific performance specifications intended to

minimize the amount of regenerant brine and water used in its operation.

The softener has a rated salt efficiency of not less than 4,000 grains of total hardness exchange per pound of salt

(based on sodium chloride), and shall not deliver more salt than its listed rating or be operated at a sustained maximum

service flow rate greater than its listed rating. This softener has been proven to deliver soft water for at least ten

continuous minutes at the rated service flow rate. The rated salt efficiency is measured by laboratory test described

in NSF/ANSI Standard 44. These tests represent the maximum possible efficiency that the system can achieve.

Operational efficiency is the actual efficiency after the system has been installed. It is typically less than the efficiency,

due to individual application factors including water hardness, water usage, and other contaminants that reduce the

softener’s capacity.

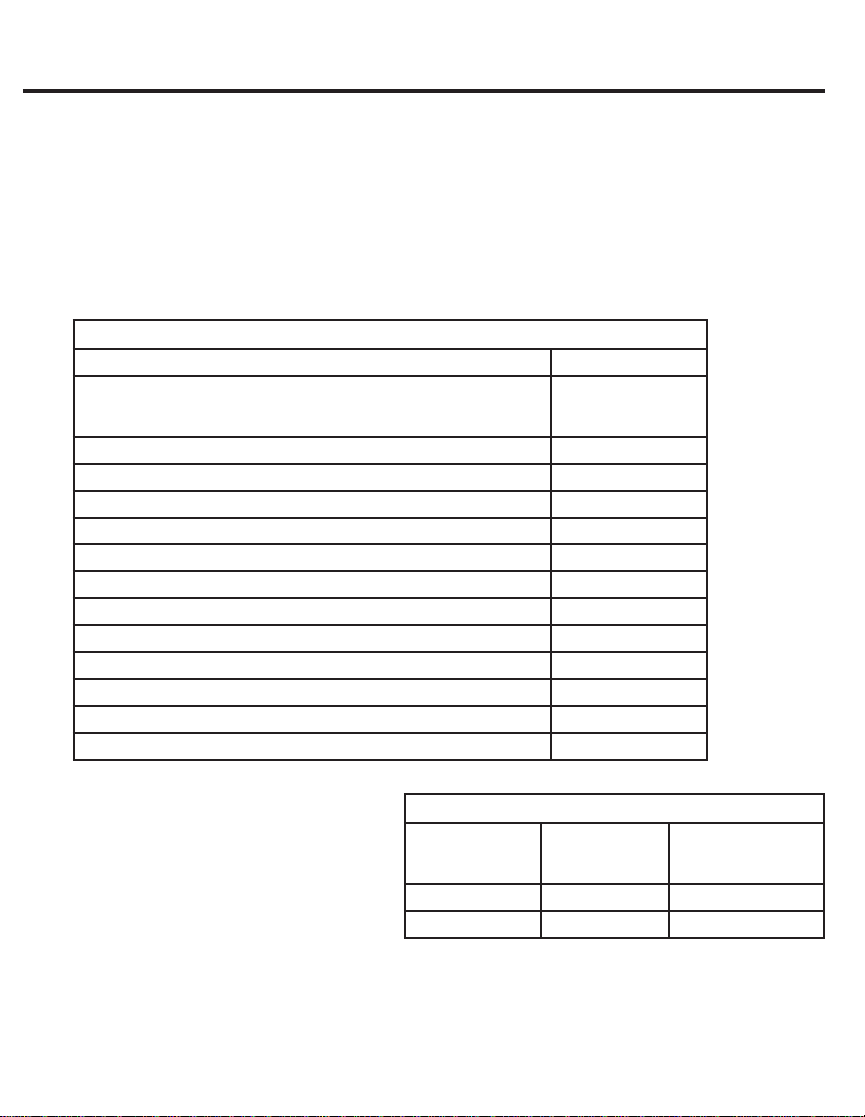

Specifications

Model GXSF30V

Rated Capacity* (Grains@ Salt Dose) 11,900 @ 2.5 lbs

Rated Efficiency** (Grains/Pound of Salt @ Minimum Salt Dose) 4,770 @ 2.5 lbs.

Water used during Regeneration (gallons/grains) 2.8 /1000

Total Water Used per Regeneration @ Maximum Salt Dose 35.5 gallons

Amount of High Capacity Ion Exchange Resin (lb/cu.ft.) 43/0.83

Resin Tank Nominal Size (in., dia. x height) 9 x 35

Service Flow Rate (gpm) 7.5

Pressure Drop at Rated Service Flow (psig) 13.4

Water Supply Maximum Hardness (gpg) 95

Water Supply Maximum Clear Water Iron (ppm)*** 8

Water Pressure Limits (minimum-maximum psi)**** 20-125

Water Temperature Limits (minimum-max. °F) 40-120

Maximum Flow Rate to Drain (gpm) 2.3

25,300 @ 7.9 lbs.

30,100 @ 13.3 lbs.

These systems conform to NSF/ANSI 44 for

the specific capacity claims as verified and

substantiated by test data.

* Testing was performed using pellet grade

sodium chloride as the regenerant salt.

** Efficiency rating is valid only at the lowest

stated salt dosage. These softeners were

efficiency rated according to NSF/ANSI 44.

*** Extent of iron removal may vary with

conditions. The capacity to reduce clear

water iron is substantiated by WQA test

data. State of Wisconsin requires additional

treatment if water supply contains greater than 5 ppm clear water iron. Refer to Cleaning Iron Out of the

Water Softening System section.

**** Canada working pressure limits: 1.4–7.0 kg/cm

Contaminant

Barium 10 ±10% mg/L 2.0 mg/L

Radium 226/228 25 pCi/L 5pCi/L

Test parameters include: pH = 7.5±0.5, flow rate = 7.5 gpm

and dynamic pressure = 35±5 psig

2

.

Performance Claims

Influent

Challenge

Level

able Product Water

Maximum Allow-

Level

3

Page 4

About the water softener system

SERVICE

When the water softening system is providing

soft water, it is called “Service.” During service,

hard water flows from the house main water

pipe into the water softening system. Inside

the water softening system resin tank is a bed

made up of thousands of tiny, plastic resin

beads. As hard water passes through the bed,

each bead attracts and holds the hard minerals.

This is called ion-exchanging. It is much like a

magnet attracting and holding metals. Water

without hard minerals (soft water) flows from

the water softening system and to the house

pipes.

AUTOMATIC HARD WATER BYPASS

DURING RECHARGE

During recharge the water softener is

automatically put in bypass mode allowing hard

water to be available to the home. Once the

softener is recharged water is directed back

through the softener to be conditioned.

After a period of time, the resin beads become

coated with hard minerals and they have to

be cleaned. This cleaning is called recharge.

Recharge is started at 2:00 AM (factory setting)

by the water softening system control, and

consists of five stages or cycles. These are

FILL, BRINING, BRINE RINSE, BACKWASH

and FAST RINSE.

However, you should avoid using HOT water

because the water heater will fill with the

hard water.

FILL

Salt dissolved in water is called brine. Brine is

needed to clean the hard minerals from resin

beads. To make the brine, water flows into the

salt storage area during the fill stage.

BRINING

During brining, brine travels from the salt

storage area into the resin tank. Brine is the

cleaning agent needed to remove hard minerals

from the resin beads. The hard minerals and

brine are discharged to the drain.

The nozzle and venturi create a suction to

move the brine, maintaining a very slow rate to

get the best resin cleaning with the least salt.

BRINE RINSE

After a pre-measured amount of brine is used,

the brine valve closes. Water continues to flow

in the same path as during brining, except for

the discontinued brine flow. Hard minerals and

brine flush from the resin tank to the drain.

BACKWASH

During backwash, water travels up through

the resin tank at a fast flow rate, flushing

accumulated iron, dirt and sediments

from the resin bed and to the drain.

FAST RINSE

Backwash is followed by a fast flow of water

down through the resin tank. The fast flow

flushes brine from the bottom of the tank,

and packs the resin bed.

After fast rinse, the water softening system

returns to soft water service.

4

Page 5

About the water softener system

NORMAL OPERATION, CONTROL

DISPLAYS

During normal operation, the present time of

day and AM or PM and DAYS TO EMPTY

show in the control display area.

FEATURE: OPTIONAL RECHARGE

CONTROLS

Sometimes, a manually started recharge may

be desired or needed. Two examples:

You have used more water than usual (house

guests, extra washing, etc.) and you may run

out of soft water before the next recharge.

The system ran out of salt.

Use one of the following features to start a

recharge immediately, or at the next preset

recharge start time.

FEATURE: MEMORY

If electrical power to the water softening system

is interrupted, the control display is blank, and the

blue indicator light is off, but the control keeps

correct time for 24 hours. When power is restored,

you have to reset the present time only if the

display and blue indicator light are flashing. All

other settings are maintained and never require

resetting unless a change is desired.

The system will automatically recharge at the

preset recharge time as needed.

RECHARGE TONIGHT

Touch (do not hold) the RECHARGE button.

RECHARGE TONIGHT flashes in the control

display area. A recharge will occur at the next

preset recharge start time. If you decide to

cancel this recharge, touch the same button

once more.

RECHARGE NOW

Press and hold the RECHARGE button until

RECHARGE NOW starts to flash in the control

display area. The water softening system

begins an immediate recharge and, when over

in about two hours, you will have a new supply

of soft water. Once started, you cannot cancel

this recharge.

If the time is flashing after a long power outage,

the water softening system continues to work

as it should to provide you with soft water.

However, recharge may occur at the wrong time

of day until you reset the control to the correct

time of day.

FEATURE/SERVICE: AUTOMATIC

ELECTRONIC DIAGNOSIS

The control computer has a self-diagnostic

function for the electrical system (except

input power and water meter). The computer

monitors the electronic components and circuits

for correct operation. If a malfunction occurs, an

error code appears in the control display.

5

Page 6

About the water softener system

WATER CONDITION INFORMATION

IRON

Iron in water can cause stains on clothing

and plumbing fixtures. It can negatively affect

the taste of food,drinking water, and other

beverages. Iron in water is measured in parts

per million (ppm). The total* ppm of iron, and

type or types*, is determined by chemical

analysis. Four different types of iron in water

are:

Ferrous (clear water) iron

Ferric (red water) iron

Bacterial and organically bound iron

Colloidal and inorganically bound iron

(ferrous or ferric)

Ferrous (clear water) iron is soluble and

dissolves in water. This water softener will

reduce moderate amounts of this type of iron

(see specifications).**Ferrous (clear water)

iron is usually detected by taking a sample of

water in a clear bottle or glass. Immediately

after taking, the sample is clear. As the water

sample stands, it gradually clouds and turns

slightly yellow or brown as air oxidizes the iron.

This usually occurs in 15 to 30 minutes.

When using the softener to reduce Ferrous

(clear water) iron, add 5 grains to the hardness

setting fore very 1 ppm of Ferrous (clear water)

iron. See “Set Water Hardness Number”

section.

Ferric (red water), and bacterial and organically

bound irons are insoluble. This water softener

will not remove ferric or bacterial iron. This

iron is visible immediately when drawn from a

faucet because it has oxidized before reaching

the home. It appears as small cloudy yellow,

orange, or reddish suspended particles. After

the water stands for a period of time,the

particles settle to the bottom of the container.

Generally these irons are removed from water

by filtration. Chlorination is also recommended

for bacterial iron.

Colloidal and inorganically bound iron is of ferric

or ferrous form that will not filter or exchange

out of water. This water softener will not remove

colloidal iron. In some instances, treatment

may improve colloidal iron water. Colloidal iron

water usually has a yellow appearance when

drawn. After standing for several hours, the

color persists and the iron does not settle,but

remains suspended in the water.

SEDIMENT

Sediment is fine, foreign material particles

suspended in water. This water softener will

not remove sediment. This material is most

often clay or silt. Extreme amounts of sediment

may give the water a cloudy appearance. A

sediment filter installed upstream of the water

softener normally corrects this situation.

* Water may contain one or more of the four

types of iron and any combination of these.

Total iron is the sum of the contents.

** Capacity to reduce clear water iron is

substantiated by WQA test data.

CHLORINE

S

oftener resins may degrade in the presence

of chlorine above 2 ppm. If you have chlorine

in excess of this amount, you may experience

reduced life of the resin. In these conditions,

you may wish to consider purchasing a GE

Appliances point-of-entry household filtration

system with a chlorine reducing filter.

6

Page 7

Before you start

BEFORE YOU START

The water softener requires a minimum water flow of 3 gallons per minute at the inlet. Maximum

allowable inlet water pressure is 125 psi. If daytime pressure is over 80 psi, nighttime pressure

may exceed the maximum. Use a pressure reducing valve if necessary (Adding a pressure

reducing valve may reduce the flow). If your home is equipped with a back flow preventer, an

expansion tank must be installed in accordance with local codes and laws.

The water softener uses a direct plug-in external power supply (included). Be sure to use the

included power supply and plug it into a nominal 120V, 60 cycle household outlet that is in a

dry location only, grounded and properly protected by an over current device such as a circuit

breaker or fuse.

Do not use this system to treat water that is microbiologically unsafe or of unknown quality without

adequate disinfection upstream or downstream of the system.

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION

Pliers

Screwdriver

Razor knife

Two adjustable wrenches

Teflon tape

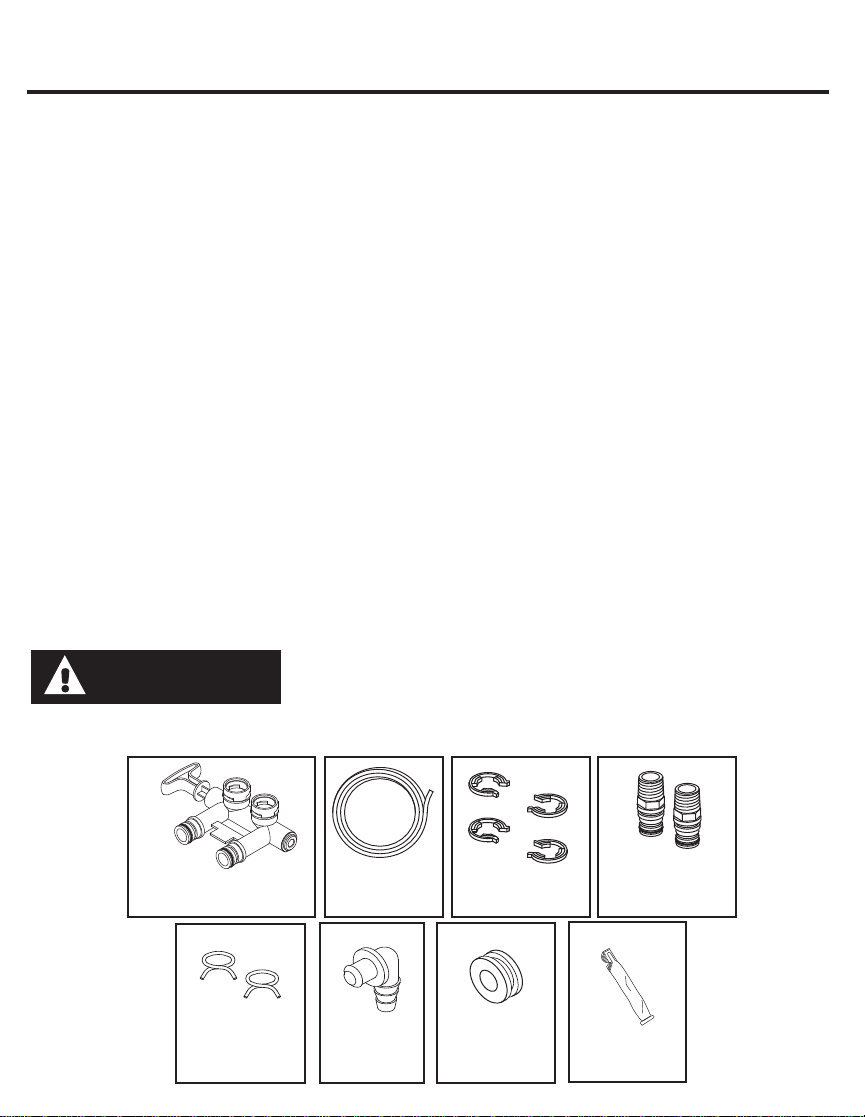

INSPECT SHIPMENT

Make sure all the parts shown below are present. Additional parts must be purchased to complete

the installation.

Also inspect and note any damage to the shipping carton.

Remove and discard (or recycle) all packing materials. To avoid loss of small parts, we suggest you keep

the small parts in the parts bag until you are ready to use them.

Thoroughly check the water softener for possible shipping damage and parts loss.

Discard all unused parts and packaging material after installation.

WARNING

Small parts remaining after the installation could be a choke hazard.

2 fittings to connect household plumbing to 1”

NPT threads on softening adaptors.

Additional installation parts may be required:

• UL-approved grounding clamps and

6-gauge copper grounding wire.

NOTE: Failure to comply with these installation instructions will void the product warranty,

and the installer will be responsible for any service, repair or damages caused thereby.

Bypass Valve Drain Hose Clips

Hose Clamps Overflow

Adapter

Grommet

Installation

Adaptors

Silicone

Grease

7

Page 8

Installation Requirements

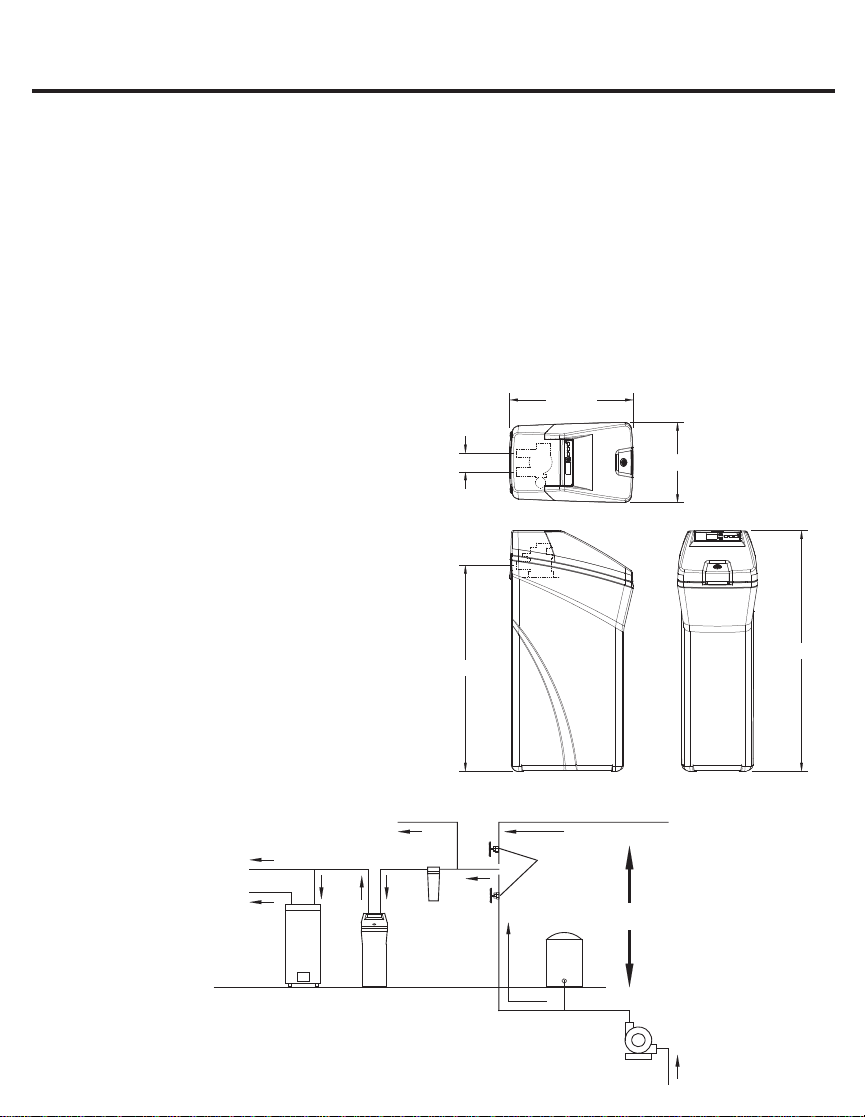

LOCATION REQUIREMENTS

Consider all of the following when selecting an

installation location for the water softener.

Do not locate the water softener where freezing

temperatures occur. Do not attempt to treat

water over 120ºF. Freezing temperatures or

hot water damage voids the warranty.

To condition all water in the home, install the

water softener close to the water supply inlet,

and upstream of all other plumbing connections,

except outside water pipes. Outside faucets

should remain on hard water to avoid wasting

conditioned water and salt.

A nearby drain is needed to carry away

regeneration discharge (drain) water. Use a

floor drain,laundry tub, sump, standpipe, or

DO NOT RUN HOT WATER THROUGH THE

SOFTENER. Temperature of water passing

through the softener must be less than 120° F.

Avoid installing in direct sunlight. Excessive sun

heat may cause distortion or other damage to

non-metallic parts.

When installing in an outside location you

must take steps necessary to assure the

softener, installation plumbing and wiring, are

protected from the elements, direct sunlight,

contamination, vandalism, insects, vermin, etc.

Do not install the softener where it would block

access to the water heater or access to the

main water shutoff.

DIMENSIONS

22-7/16"

other options(check your local codes). See

“Air Gap Requirements” and “Valve Drain

Requirements”sections.

The water softener uses a direct plug-in

external power supply (included). Be sure to

use the included power supply and plug it into

IN

3-3/8"

OUT

TOP VIEW

a nominal 120V, 60 cycle household outlet that

is in a dry location only, grounded and properly

protected by an over current device such as a

IN - OUT

circuit breaker or fuse.

Always install the water softener between

the water inlet and water heater. Any other

installed water conditioning equipment should

be installed between the water inlet and water

softener (See Figure below).

37"

If installing the water softener outdoors, do

not locate where it will be exposed to wet

weather, direct sunlight, extreme hot or cold

temperatures, or other forms of abuse.

SIDE VIEW FRONT VIEW

PROPER ORDER TO INSTALL WATER TREATMENT EQUIPMENT

Cold Water to House

Hot Water to House

Untreated Water to

Outside Faucets

Optional

Sediment

Filter

City Water Supply

Shut off

valve

Pressure

Tank

OR

14-7/16"

43-1/4"

Water

Heater

Water

Softener

Well Water Supply

Well

Pump

8

Page 9

Installation Requirements

PLUMBING CODES

All plumbing must be completed in accordance

with national, state and local plumbing codes.

In the state of Massachusetts: The

Commonwealth of Massachusetts plumbing

code 248-CMR shall be adhered to. A licensed

plumber shall be used for this installation.

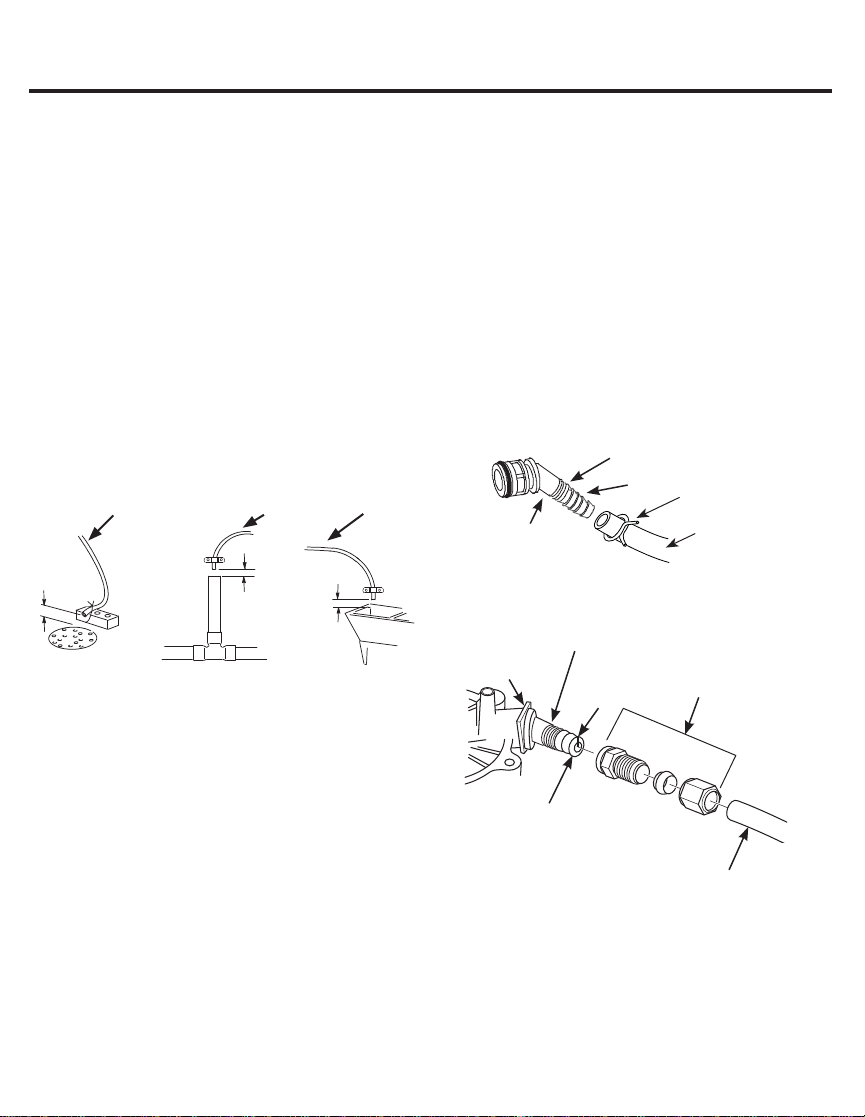

AIR GAP REQUIREMENTS

A drain is needed for regeneration water (See

Figure 1). A floor drain, close to the water

softener, is preferred. A laundry tub, standpipe,

etc. are other drain options. Secure valve

drain hose in place. Leave an air gap of 1-1/2”

between the end of the hose and the drain.

This gap is needed to prevent back flow of

sewer water into the water softener. Do not put

the end of the drain hose into the drain.

Drain

Hose

1-1/2”

air gap

FlOOR DRAIN STANDPIPE LAUNDRY TUB

Drain

Hose

1-1/2”

air gap

Drain

Hose

1-1/2”

air gap

Figure 1

VALVE DRAIN REQUIREMENTS

Using the flexible drain hose (included) (See

Figure 2), measure and cut to the length

needed. Flexible drain hose is not allowed in

all localities (check your plumbing codes). If

local codes do not allow use of a flexible drain

hose, a rigid valve drain run must be used.

Purchase a compression fitting (1/4 NPT x 1/2

in. minimum tube) and 1/2” tubing from your

local hardware store. Plumb a rigid drain as

needed (See Figure 3).

NOTE: Avoid drain hose runs longer than 30

feet. Avoid elevating the hose more than 8 feet

above the floor. Make the valve drain line as

short and direct as possible.

FLEXIBLE DRAIN LINE

1/4” NPT Thread

Barbs for 3/8Ǝ I.D. tubing

Hose clamp

Drain hose adapter

Drain hose

Figure 2

RIGID DRAIN LINE

1/4Ǝ NPT thread

Clip

Barbs

Compression fitting

137[Ǝ2'

tube (not provided)

Cut barbs from valve drain

elbow (pull clip and remove

drain valve elbow from valve)

Figure 3

9

ƎRXWVLGH

diameter copper

tube (not provided)

Page 10

Installation Requirements

INLET/OUTLET PLUMBING

REQUIREMENTS

Always install either a single bypass valve

(provided),as shown in Figure 4, or, if desired,

parts for a 3 valve bypass system (not included)

can be purchased and assembled, as shown in

Figure 5. Bypass valves allow you to turn off

water to the softener for maintenance if needed,

but still have water in house pipes.

Pipe fittings must be 1/2” minimum.

Use:

Copper pipe

Threaded pipe

PEX (Crosslinked Polyethylene) pipe

CPVC plastic pipe

Other pipe approved for use with potable

water

IMPORTANT: Do not solder with plumbing

attached to installation adaptors and single

bypass valve. Soldering heat will damage the

adaptors and valve.

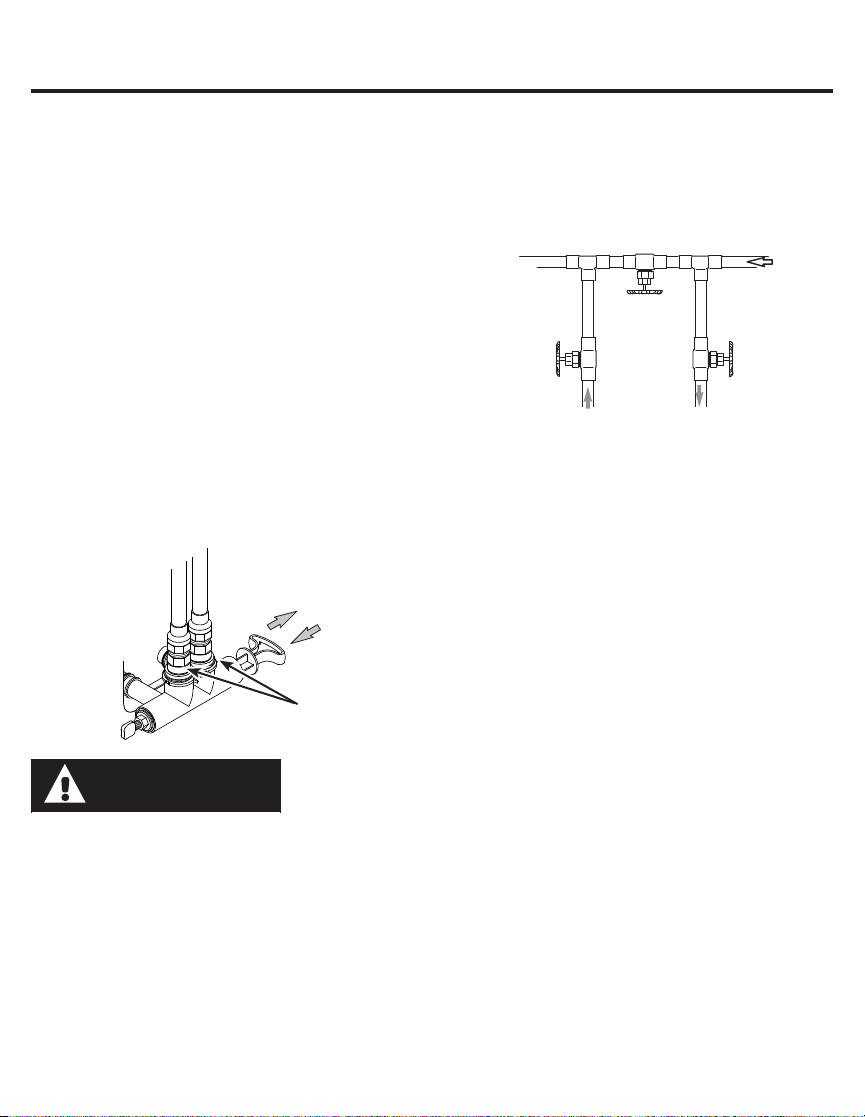

SINGLE BYPASS VALVE

Pull out for “Service”

(Soft water)

Push in for

“Bypass”

Installation

adaptors

Figure 4

3-VALVE BYPASS SYSTEM

For soft water service: Open the inlet and

outlet valves and close the bypass valve.

For bypass hard water: Close the inlet and

outlet valves and open the bypass valve.

3 VALVE BYPASS

Bypass

Valve

Outlet

Valve

From Water

Softener

To Water

Softener

Inlet

Valve

Figure 5

WARNING

A copper or galvanized cold water pipe may be

used to ground electrical outlets in the home.

Failure to maintain this ground path may result in

an electric shock hazard. If the cold water pipe

is used to ground electric outlets, please refer to

Installing the Ground Wire section before cutting

the pipe.

10

Page 11

Installation Instructions

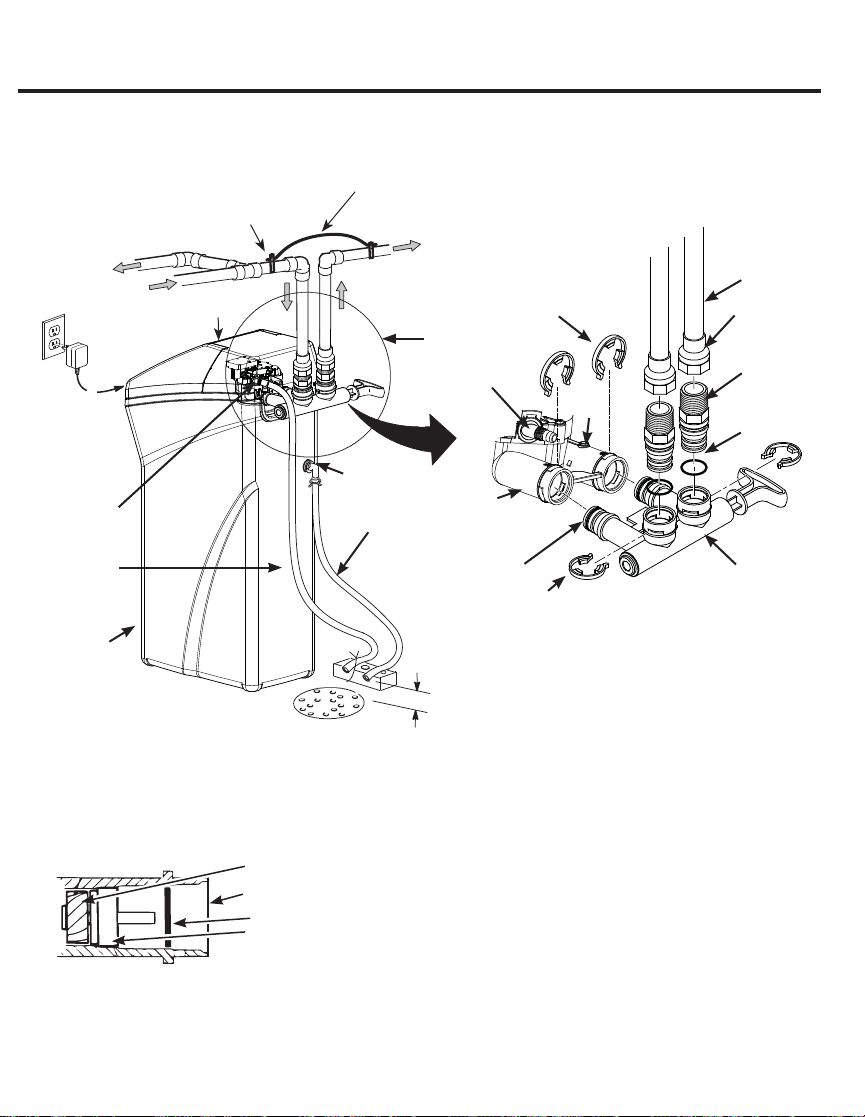

TYPICAL INSTALLATION

Hard Water

to Outside

Faucets

IncomingHard Water

Plug-in

Transformer

To

Controller

Drain Hose

Adapter

Valve Drain

Hose*

Brine Tank

(Salt Storage)

*Do not connect the water

softener valve drain hose

to the brine tank overflow

Clamp

(not included)

Top

Cover

Figure 6

Main Water Pipe

Overflow

Adapter

Floor Drain

Ground Wire

(not included)

Conditioned

Water

Bypass Valve

Assembly

Adapter

BrineTank

Overflow Hose*

Secure Valve Drain

Hose in place over

Floor Drain

Drain

Hose

Inlet

Lubricated

O-ring

1-1/2”

air gap

Pipe

Clips

Outlet

Clips

1” NPTF Sweat

Adaptor (not

included)

1” NPTM

Threaded

Adaptor

O-ring

Single By-

pass Valve

Figure 7

NOTE: See “Air Gap Requirements”

section.

• Remove plastic shipping plug and wire from valve outlet.

Turbine

Valve outlet

Plastic shipping plug

Turbine shaft and support

Figure 8

NOTE: Be sure the turbine and support are firmly in place

in the valve outlet. Blow into the valve port and observe the

turbine for free rotation.

11

Page 12

Installation Instructions

TURN OFF WATER SUPPLY

1. Close the main water supply valve, located

near the well pump or water meter.

2. Open all faucets to drain all water from

house pipes.

NOTE: Be sure not to drain water from the

water heater, as damage to the water heater

elements could result.

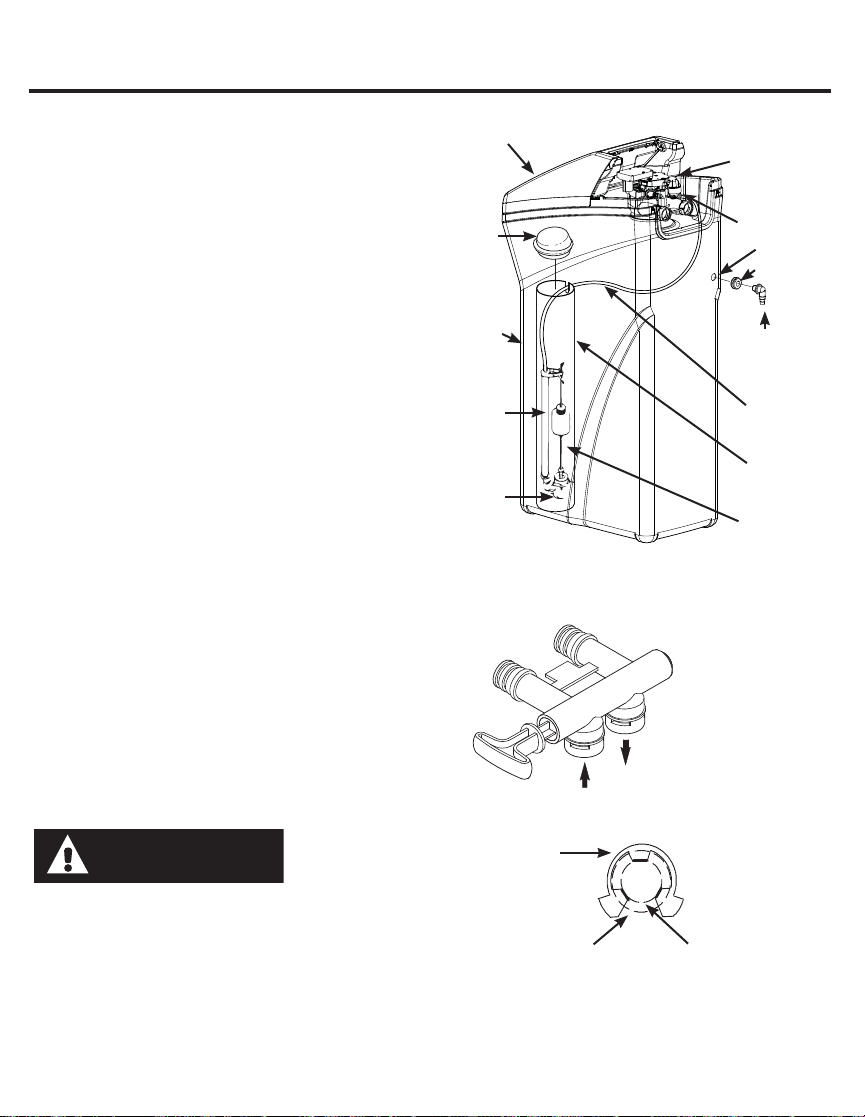

INSTALL THE BRINE TANK OVERFlOW

ADAPTER

Install the brine tank overflow grommet and

adapter in the 13/16” diameter hole in the back

of the salt storage tank sidewall, (see Figure 9).

NOTE: The brine tank overflow adapter accepts

either 1/2” or 3/8” I.D. hose.

INSTALL THE BYPASS VALVE

NOTE: For easier installation, remove the top

cover. Release 2 clips at rear of cover. Rotate

cover forward and lift up.

1. Visually check and remove any debris from

the water softener valve inlet and outlet

ports, (see Figure 7).

2. Make sure the turbine assembly spins freely

in the”out” port of the valve, (see Figure 8).

3. If not already done, put a light coating of

silicone grease (provided) on the single

bypass valve o-rings, (see Figure 7).

4. Push the single bypass valve into the

softener valve as far as it will go. Snap the

two large holding clips into place, from the

top down, (see Figure 7 and 10).

IMPORTANT: Be sure the clips snap firmly into

place so the single bypass valve will not pull

out.

MOVE THE WATER SOFTENER INTO

PLACE

WARNING

Excessive Weight Hazard

Use two or more people to move and install

water Softener Failure to do so can result in

back or other injury.

1. Move the water softener into the desired

location. Set it on a solid, level surface.

IMPORTANT: Do not place shims directly

under the salt storage tank to level the softener.

The weight of the tank, when full of water and

salt, may cause the tank to fracture at the shim.

Salt

Cover

Brinewell

Cover

Brine

Tank

Stand

Tube

Brine

Valve

Assembly

Nut - Ferrule

Float Stem

Figure 9

Note: Unit is shown with top cover

removed.

SINGLE BYPASS VALVE

If connecting to floor

level plumbing, install

the bypass valve turned

downward, as shown.

CORRECT ASSEMBLY

Clip

Outside diameter of

water softener valve

inlet & outlet

Outside diameter

of clip channel on

single bypass valve

Figure 10

NOTE: Be sure all 3 tabs of the clip go through the

matching holes on the water softener valve inlet or outlet, and fully into the channel on the single bypass valve.

Make sure that the tabs are fully seated.

12

Nozzle

Venturi

Assembly

Hole

Grommet

Brine Tank

Overflow

Adapter

Brine

Tubing

Brinewell

Page 13

Installation Instructions

COMPLETE INLET AND OUTLET PLUMBING

A copper or

WARNING

be used to ground electrical outlets in the home.

Failure to maintain this ground path may result in an

electric shock hazard. If the cold water pipe is used to

ground electric outlets, please refer to Installing the

Ground Wire section before cutting the pipe.

IMPORTANT: This water softener has a nonmetallic valve system. Installing it on metal

plumbing will break electrical continuity, which

may interrupt grounding for the home. You must

restore electrical continuity in your metal plumbing

system.

If you install a 3-valve bypass system (Figure 5),

electrical continuity will be maintained. If you

install the non-metallic bypass valve (Figure 11),

please refer to the Installing the Ground Wire

section before cutting the pipe.

galvanized cold

water pipe may

Figure 11

Measure, cut, and loosely assemble pipe and

fittings from the main water pipe to the inlet and

outlet ports of the water softener valve. Be sure to

keep fittings fully together, and pipes squared and

straight.

BE SURE INCOMING HARD WATER SUPPLY IS

DIRECTED TO THE SOFTENER VALVE INLET

PORT.

NOTE: Inlet and outlet are marked on the water

softener valve. Trace the water flow direction to

be sure hard water is to inlet.

IMPORTANT: Be sure to fit, align and support

all plumbing to prevent putting stress on the

water softener valve inlet and outlet. Stress from

misaligned or unsupported plumbing may cause

damage to the valve.

• If making a soldered copper installation, do all

sweat soldering before connecting pipes to the

NPT adapters and bypass valve. Torch heat will

damage plastic parts.

13

If solder is

WARNING

connection use only lead free solder and

flux to prevent lead poisoning.

• When turning threaded pipe fittings onto

plastic fittings, use care not to cross-thread.

• Use Teflon Tape on all external pipe threads.

Complete the inlet and outlet plumbing for the

type of pipe you will be using. Secure ground

clamp to metal pipes.

used to make

pipe

INSTALLING THE GROUND WIRE

NOTE: If your house plumbing is plastic, it

would not be used as a grounding path, and

this step should be skipped.

IMPORTANT: A copper or galvanized cold water

pipe is often used to ground electrical outlets

in the home. Grounding protects you from

electrical shock. The water softener may have

broken this ground path. To restore connection,

install a 12”-long, 6-gauge copper wire across and

tightly clamp using UL-approved 1/2”–1” bronze

grounding clamps at both ends as shown (Figure

12). Zinc clamps should not be used on copper

plumbing. Wire and clamps may be purchased

separately from your local hardware store.

1. Clean copper pipe and ends of wire with

emery paper. Bare wire is recommended. If

insulated wire is used, is should be stripped

3/4” at each end before cleaning with emery

paper.

2. Attach bronze clamps to pipe. Tighten

screws.

3. Attach to clamps as shown. Tighten screws.

Ground Wire

Clamp (2)

Figure 12

NOTE: If you are installing a sediment filter or

other item(s) into the plumbing system, along

with the water softener, be sure to restore

electrical continuity across all removed metal

pipe sections.

Page 14

Installation Instructions

INSTALL VALVE DRAIN HOSE

1. Measure, cut to needed length and connect

the 3/8”drain line (provided) to the water

softener valve drain fitting. Use a hose

clamp to hold the hose in place.

NOTE: Avoid drain hose runs longer than 30

feet. Avoid elevating the hose more than 8 feet

above the floor. Make the valve drain line as

short and direct as possible.

IMPORTANT: If codes require a rigid drain line

see“Valve Drain requirements” section.

2. Route the drain hose or copper tubing

to the floor drain or other suitable drain

point. Secure drain hose. This will prevent

“whipping’’ during regenerations. See “Air

Gap Requirements” section (Figure 1).

NOTE: The softener will not work if the water

cannot exit the drain hose during recharge.

INSTALL BRINE TANK (SALT

STORAGE) OVERFlOW HOSE

1. Measure, cut to needed length and connect

the 3/8”drain line (provided) to the salt

storage tank overflow elbow and secure in

place with a hose clamp.

2. Route the hose to the floor drain, or other

suitable drain point no higher than the drain

fitting on the salt storage tank (This is a

gravity drain). If the tank overfills with water,

the excess water flows to the drain point.

Cut the drain line to the desired length and

route it neatly out of the way.

IMPORTANT: For proper operation of the water

softener, do not connect the water softener valve

drain tubing to the salt storage tank overflow hose.

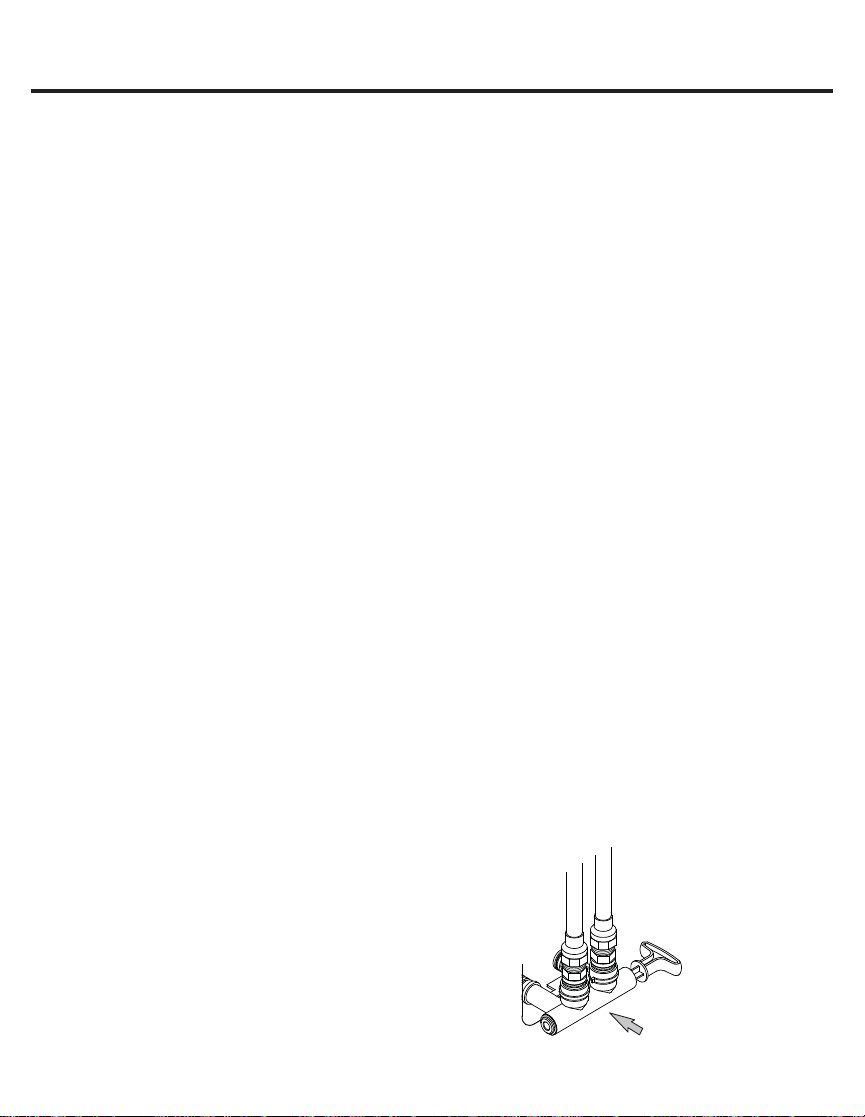

TEST FOR LEAKS

To prevent air pressure in the water softener

and plumbing system, complete the following

steps in order:

1. Fully open two or more softened cold water

faucets close to the water softener, located

down stream from the water softener.

2. Place the bypass valve (single or 3 valve)

into

the”bypass” position. See Figures 4 and 5.

3. Slowly open the main water supply valve.

Run water until there is a steady flow from

the opened faucets, with no air bubbles.

4. Place bypass valve(s) in “service” or soft

water position as follows:

• Single bypass valve (Figure 4): Slowly

move the valve stem toward “service,”

pausing several times to allow the water

softener to fill with water.

• 3 valve bypass (Figure 5): Fully close the

bypass valve and open the outlet valve.

Slowly open the inlet valve, pausing

several times to allow the water softener to

fill with water.

5. After about three minutes, open a hot water

faucet until there is a steady flow and there

are no air bubbles, then close this faucet.

6. Close all cold water faucets and check for

leaks at the plumbing connections that you

made.

7. Check for leaks around clips at softener’s

inlet and outlet. If a leak occurs at a clip,

depressurize the plumbing (turn off the water

supply and open faucets) before removing

clip. When removing clips at the softener’s

inlet or outlet, push the single bypass valve

body toward the softener (See Figure 12).

Improper removal may damage clips. Do not

reinstall damaged clips.

If removing

clips.....

14

Figure 12

....depressurize the

plumbing, then push

Bypass Valve body

toward softener

Page 15

Installation Instructions

ADD WATER AND SALT TO THE SALT

STORAGE TANK

WARNING

EXCESSIVE WEIGHT HAZARD:

Use two or more people to move and lift salt

bags. Failure to do so can result in back or

other injuries.

1. Using a container, add about three gallons

of clean water into the salt storage tank.

2. Add salt to the storage tank. Use nugget,

pellet or coarse solar salts with less than 1%

impurities.

PLUG IN THE WATER SOFTENER

1. Plug the water softener into an electrical

outlet that is not controlled by a switch.

2. Replace the top cover.

3. Replace the salt hole cover.

NOTE: The water heater is filled with hard

water and,as hot water is used, it will refill

with conditioned water. In a few days, the hot

water will be fully conditioned. To have fully

conditioned hot water immediately, wait until the

initial recharge is over. Then, drain the water

heater(following instructions for water heater)

until water runs cold.

WARNING

SANITIZE THE WATER SOFTENER /

SANITIZE AFTER SERVICE

1. Open salt hole cover, remove the brinewell

cover and pour about 3 oz. (6 tablespoons) of

household bleach into the softener brinewell.

Replace the brinewell cover.

2. Make sure the bypass valve(s) is in the

“service”(open) position.

3. Start a recharge (regeneration). See “Start a

Recharge”on Page 17.

4. After the recharge has completed, fully open

a cold water faucet, downstream from the

softener, and allow 50 gallons of water to pass

through the system. This should take at least

20 minutes. Close the faucet.

Discard all unused parts and packaging

material after installation. Small parts

remaining after the installation could be a

choke hazard.

15

Page 16

Programming the Water Softener

e

When the transformer is plugged into the

electrical outlet, a model code and test number

(example: J3.4 & F30) are shown in the

display. Then, “12:00 PM” begins to flash . An

arrow

face plate decal.

is displayed next to CLOCK on the

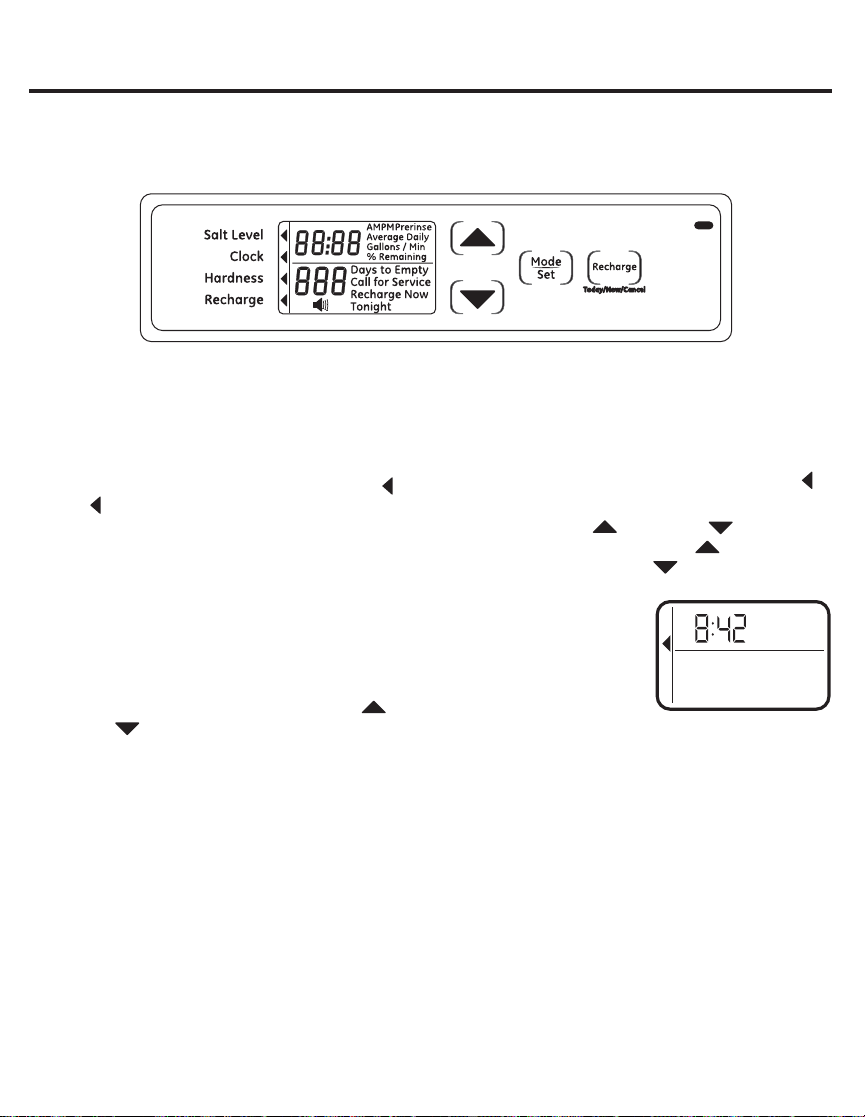

CONTROL OPERATION:

• CONTROL SETTINGS REQUIRED upon

initial installation and after an extended power

outage.

• Use the MODE/SET button to scroll arrow to

desired control function set.

• After the mode is selected use the UP

DOWN

the control.

• Press the MODE/SET button to accept

changes.

• A “beep” sounds while pressing buttons for

control programming. One beep signals a

change in the control display. Repeated

beeps mean the control will not accept a

change from the button you have pressed,

and you should select another button.

buttons to change the settings of

and

SET TIME OF DAY

1. Press MODE/SET button until the arrow

points to CLOCK.

2. Press the UP

to set the present time. UP

display ahead; DOWN

back. Be sure AM and PM is correct.

NOTE: Press buttons and quickly release

to slowly advance the display one number

at a time. Hold the buttons down for fast

advance.

3. When the correct time is shown in the

display, press MODE/SET to accept.

or DOWN buttons

sets the time

Salt Level

Clock

Hardness

Recharge

moves the

PM

16

Page 17

Programming the Water Softener

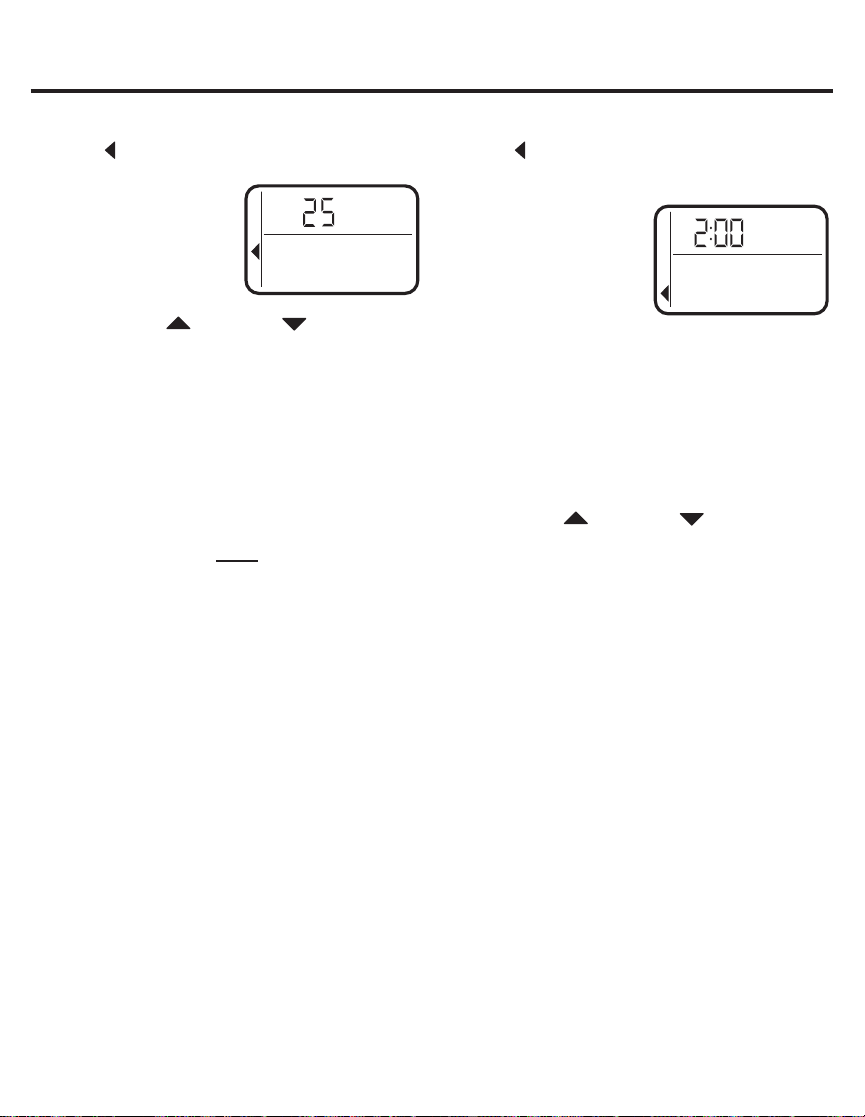

SET WATER HARDNESS NUMBER

1. Press the MODE/SET button until the

arrow

25 will appear in the display.

2. Press the UP

set your water hardness number.

NOTE: If your water supply contains iron,

compensate for it by adding to the water

hardness number. For example, assume

your water is 20 gpg hard and contains 2

ppm iron. Add 5 to the hardness number

for each 1 ppm or iron. In this example, you

would use 30 for your hardness number.

20 gpg hardness

2 ppm iron x 5 = 10 +10

(times) 30 HARDNESS NUMBER

3. When the display shows your water

hardness (in grains per gallon), press

MODE/SET to accept.

points to HARDNESS. A flashing

Salt Level

Clock

Hardness

Recharge

or DOWN buttons to

SET RECHARGE (STARTING) TIME

1. Press the MODE/SET button until the

arrow

NOTE: A flashing 2:00 AM (factory default)

should show in the display. This is a good

time for recharge to start (takes about 2

hours) in most households because water

is not in use. HARD WATER is bypassed to

house faucets during recharge.

If no change is needed, go to step 3. To

Change the recharge starting time, follow

step 2.

2. Press UP

3. Press the MODE/SET button to accept.

points to RECHARGE.

Salt Level

Clock

Hardness

Recharge

or DOWN

the desired recharge start time. Be sure

to observe the AM or PM as you did when

setting the time of day.

AM

button to set

You can get the grains per gallon (gpg)

hardness of your water supply from a

water analysis laboratory. If you are on

a municipal supply, call your local water

department. Or call Legend Technical

Services, an independent laboratory,

to request a water hardness test kit at

1.800.949.8220, Option 4. If your report

shows hardness in parts per million (ppm)

or milligrams per liter (mg/l), simply divide

by 17.1 to get the equivalent number of

grains per gallon.

17

Page 18

Programming the Water Softener

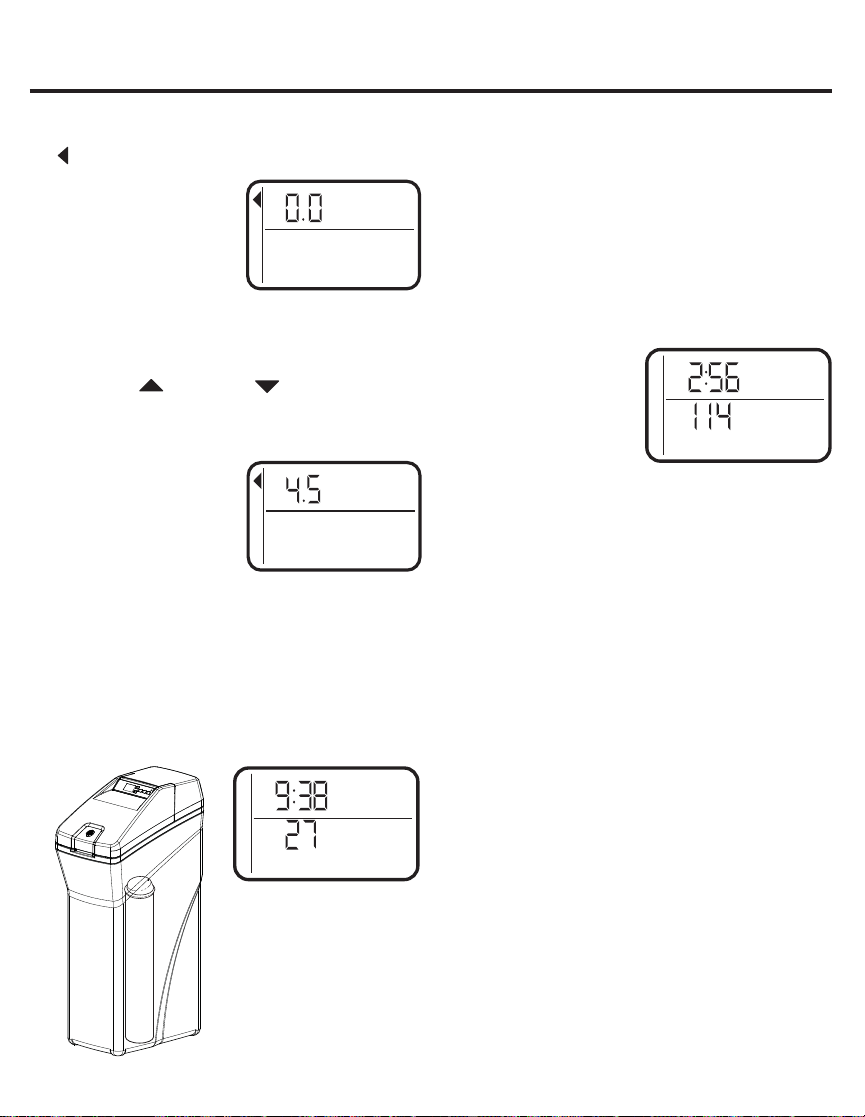

SET SALT LEVEL

1. Press the MODE/SET button until the arrow

points to SALT LEVEL.

Salt Level

Clock

Hardness

Recharge

2. Determine level of salt in brine tank using the

numbered scale on side of brine well, inside

brine tank (see Figure 13).

3. Press UP

or DOWN

SALT LEVEL to correspond to level on the

button to set the

numbered scale in brine tank.

Salt Level

Clock

Hardness

Recharge

NOTE: Each press of a button changes the

level by increments of 0.5 up to 8.0.

Lowering the salt level below zero turns the

SALT LEVEL indicator OFF.

4. Press the MODE/SET button to accept. The

display shows the present time of day and

DAYS TO EMPTY.

PM

Days to Empty

8

7

6

5

4

3

2

1

Figure 13

DAYS TO EMPTY

The words DAYS TO EMPTY and a number

are shown in the lower half of the display. This

information is shown in the normal run display.

This is to inform the user of the number of days

before the salt level in the brine tank reaches

Level 0. There will be salt left in the salt tank,

but it may not be sufficient to fully recharge

the system. Salt should be added at this time

to avoid hard water. The value is updated

daily and whenever the SALT LEVEL value is

changed.

Days to Empty

NOTE: For the first several weeks of operation,

the DAYS TO EMPTY may provide erratic

operation. For example, the blue indicator light

may flash, showing that more salt is required

when the actual salt level in the tank is well

above the Level 0. In some cases, the DAYS

TO EMPTY may even increase over a several

week period.

It takes a couple of months for the water

softener to learn your water usage pattern.

Once it does this, it will accurately determine

actual salt usage pattern. During this first

period, check salt level when blue indicator

light flashes. If the salt level in the tank is at

Level 1 or above, allow system to run. Be sure

to reset your salt level indicator each time you

add salt to the system.

START A RECHARGE

Press the RECHARGE button and hold for

three seconds, until “RECHARGE NOW”

begins to flash in the display, starting a

recharge. This recharge draws the sanitizing

bleach or brine

into and through the water

softener. Any air remaining in the water

softener is purged to the drain. During this

time periodically check for leaks.

NOTE: As with all other water system

applications, leaks may occur. Leaks may not

be immediately apparent. Recheck 24 hours

after first recharge cycle is complete.

18

AM

Page 19

Programming the Water Softener

OPTIONAL CONTROL SETTINGS

The controller display has several options and

features.

LOW SALT ALARM

The LOW SALT

ALARM, when

enabled, will sound

the beeper when the

DAYS TO EMPTY

value is 15 days or

less. To change this setting, press and hold

the MODE/SET button for 3 seconds or until

you hear a beep. ON (factory default) or OFF

will flash in the display. Press the UP

or DOWN buttons to toggle this feature

ON or OFF. Press the MODE/SET button to

accept, and the display will move to SALT

EFFICIENCY.

SALT EFFICIENCY

When the SALT

EFFICIENCY feature

is ON, the unit will

operate at a salt

efficiency of 4000

grains of hardness removed per pound of salt.

This mode of operation is the most efficient

setting for salt usage, because the system

will tend to recharge more often, with less salt

usage. Turning the feature OFF will tend to

lengthen the time between recharge cycles,

which will provide the most efficient usage of

water, but may use more salt. The degree of

difference between these two cycles is highly

dependent on the water usage and hardness at

a particular installation.

NOTE: California Regulations require this

feature to be ON for installations in California.

To access the Salt Efficiency, press and

hold the MODE/SET button for 3 seconds. The

System Diagnostics display will appear.

Press the MODE/SET button again and the

Salt Efficiency display will appear.

To change the setting, press the

or DOWN buttons to toggle the

UP

feature ON or OFF. Press the MODE/SET

button to accept.

e

RESETTING TO FACTORY DEFAULT

To reset the electronic controller to its factory

default for all settings (time, hardness, etc.):

1. Press the MODE/SET button and hold

until the display changes twice to show the

flashing mode code.

2. Press the UP button to display a flashing

“SoS”.

3. Press the MODE/SET button and the

electronic controller will restart.

4. Set the present time, hardness, etc, as

described in the Programming the Water

Softener section.

19

Page 20

Programming the Water Softener

POWER OUTAGE MEMORY

If electrical power to the water softener is

lost, “memory’’ built into the timer circuitry will

keep all settings for up to 24 hours. While the

power is out, the display is blank and the water

softener will not regenerate. When electrical

power is restored, the following will occur:

Reset the present time only if the display is

flashing. The HARDNESS and RECHARGE

TIME never require resetting unless a change

is desired. Even if the clock is incorrect after

a long power outage, the softener operates

as it should to keep your water soft. However,

regenerations may occur at the wrong time of

day until you reset the clock to the correct time

of day.

NOTE: If the water softener was regenerating

when power was lost, it will now finish the

cycle.

BLUE INDICATOR LIGHT

Steady blue light indicates that the unit is

working correctly. The light flashes when the

unit needs attention from the user.

• Light will also flash when power to until has

been interrupted. Check the PRESENT TIME

setting.

• Light flashes and DAYS TO EMPTY flashes check salt level and add salt as required.

• Light flashes and Err is in the display electrical problem with system (see page 25).

LOW SALT SIGNAL

When the DAYS TO EMPTY drops to 15, the

blue indicator light and DAYS TO EMPTY in

the display

will flash every second and the alarm will beep

every 30 seconds (from 8:00 AM to 8:00 PM),

to notify the user that the unit is running low

on salt. As soon as any button is pressed, the

alarm will stop beeping. The blue indicator light

and DAYS TO EMPTY will continue to flash.

Once salt is added to the brine tank and the

SALT LEVEL is reset, the DAYS TO EMPTY

will be reset.

ERROR SIGNALS

If there is an error code

detected, the blue

indicator light will flash

4 times every second,

the display will flash Err

and the alarm will beep

every 30 seconds (from 8:00 AM to 8:00 PM)

to signal that the softener requires service. The

alarm can be turned off by pressing any button,

but the blue indicator light and display will

continue to flash.

Disconnect the transformer from the wall

outlet momentarily, and plug it back in. The

normal display will appear. The motor may

run for several minutes, as the unit resets. If

the problem is not corrected, the error code

will reappear in 8 minutes. See the Before

you Call for Service section to assist in

troubleshooting the water softener.

Call for Service

20

Page 21

Care and Cleaning

CHECKING THE SALT STORAGE

LEVEL and REFILL

Brine (salt dissolved in water) is needed for

each and every recharge. The water for making

brine is metered into the salt storage area by

the water softening system valve and control.

However, you must keep the tank supplied

with salt.

ADDING SALT

Lift the salt hole cover and check the salt

storage level frequently. If the water softener

uses all the salt before you refill it, you will

experience hard water. Until you have

established a refilling routine, check the salt

every two or three weeks. Always add if less

than 1/4 full. Be sure the brinewell cover is on.

NOTE: if using potassium chloride (KCI), do

not fill above level 4 on the brinewell decal.

NOTE: In humid areas, it is best to keep the

salt storage level lower, and to refill more often

to avoid salt “bridging”.

Recommended Salt: Nugget, pellet or coarse

solar salts with less than 1% impurities.

Salt Not Recommended: Rock salt, high in

impurities, block, granulated table, ice melting,

ice cream making salts, etc.

CAUTION

Water softening salt with iron removing

additives:

Some salts may have an additive to help the

water softening system handle iron in the

water supply. Although this additive may

help to keep the water softening system

resin clean, it may also release corrosive

fumes that weaken and shorten the life of

some water softening system parts.

CLEANING IRON OUT OF THE WATER

SOFTENING SYSTEM

Your water softening system takes hardness

minerals (calcium and magnesium) out of

the water. Also, it can control some (see the

Specification Guidelines section) “clear water”

iron. With clear water iron, water from a faucet

is clear when first put into a glass. After 15 to

30 minutes, the water begins to cloud or turn

rust colored. A water softening system will not

remove any iron that makes the water cloudy

or rusty as it comes from the faucet (called red

water iron). To take red water iron out of water,

or over the maximum of clear water iron,

an iron filter or other equipment is needed.

GE Appliances recommends using Super Iron

®

to clean your resin bed if your iron content

Out

is high. Use Super Iron Out

bag of salt as preventative maintenance against

rust build up. Clean the bed at least every six

months, or more often if iron appears in the soft

water between cleanings.

IMPORTANT: It is important to mix the resin bed

cleaner with water (following the manufacturer’s

instructions), pour it into the brinewell (see

Figure 9) and recharge the softener immediately.

Do not pour the resin bed cleaner in with the

salt, as it will not be as effective in cleaning the

resin, and can cause damage to the softener if

it is left in the brine tank for an extended period

due to the corrosive gases that are formed.

®

with every 40lb.

21

Page 22

Routine Maintenance

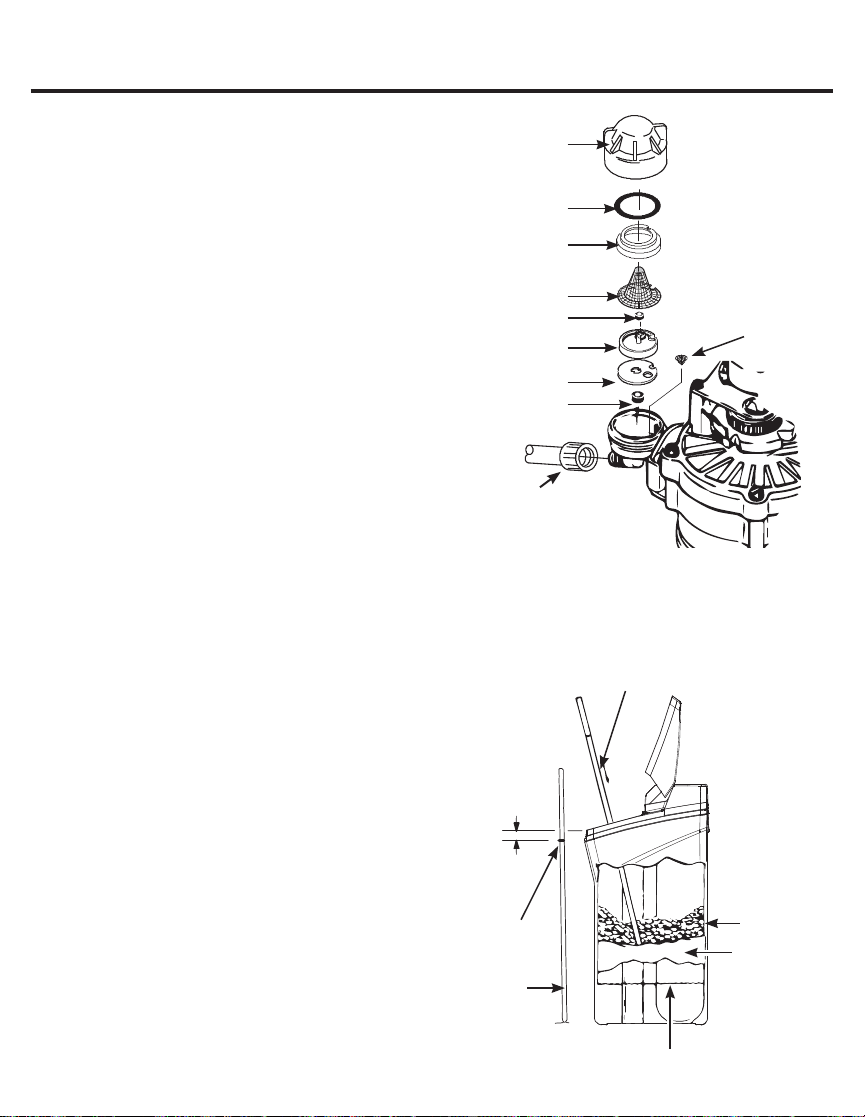

CLEANING THE NOZZLE AND VENTURI

ASSEMBLY

A clean nozzle and venturi is needed for the

water softening system to work properly. This

small unit makes the suction to move brine from the

salt storage area to the resin tank during recharge.

If it becomes plugged with sand, dirt, etc., the water

softening system will not work and you will get hard

water.

To get to the nozzle and venturi, remove the water

softening system top cover. Be sure the water

softening system is in service cycle (no water

pressure at nozzle and venturi). Then, while holding

the nozzle and venturi housing with one hand,

remove the cap. Lift out the screen support and

screen, then the nozzle and venturi. Wash and rinse

the parts in warm water until clean. If needed, use

a small brush to remove iron or dirt. Also check and

clean the gasket.

NOTE: Some models have a small flow plug located

in the nozzle and venturi, and/or a small cone

shaped screen in the housing. Be sure to check and

clean these parts, if your model is so equipped.

Carefully replace all parts in the correct order. Lightly

lubricate the o-ring seal with clean silicone grease

or petroleum jelly and place in position. Install and

tighten the cap, by hand only. Do not overtighten

the cap.

BREAKING A SALT BRIDGE

Sometimes, a hard crust or salt bridge forms in

the salt storage area. It is usually caused by high

humidity or the wrong kind of salt. When the salt

bridges, an empty space forms between the water

and salt. Then salt will not dissolve in the water to

make brine.

If the brine tank is full of salt, it is hard to tell if you

have a salt bridge. Salt is loose on top, but the

bridge is under it. The following is the best way to

check for a salt bridge.

Salt should be loose all the way to the bottom of the

tank. Take a broom handle or like tool, and carefully

push it down into the salt, working it up and down.

If the tool strikes a hard object (be sure it’s not the

bottom or sides of the tank), it’s most likely a salt

bridge. Carefully break the bridge with the tool. Do

not pound on the walls of the tank.

the salt bridge pour one gallon of warm water (not

hot) into the tank.

If the wrong kind of salt made the bridge, take it out.

Then fill the tank with nugget or pellet salt only. In

humid areas, it is best to fill with less salt, more often

to prevent a salt bridge from forming.

To help dissolve

22

Cap

O-ring seal

Screen

support

Screen

*Flow plug

Nozzle and

Venturi

Gasket

*Flow

plug

Ferrule Nut

IMPORTANT: Be sure small holes in the gasket

are centered directly over the small holes in the

nozzle and venturi housing.

* Install with numbered side up, concave side

down.

Push tool into salt

bridge to break

Ǝ±Ǝ

Pencil

mark

Broom

handle

Water level

Screen

Salt

Salt

bridge

Page 23

Before you call for service

Troubleshooting Tips

Save time and money! Review the chart on this page first and you may not

need to call for service.

NO SOFT WATER – Most Common Problems:

Check the following before calling for service:

Not enough salt—should be at least 1/3 full.

•

•

Bypass valve in “Bypass” position—handle should be in the “OUT” (service) position.

•

Hardness setting too low. Check hardness setting and adjust. Verify hardness of supply water—from local

water company, water test or call the GE Appliances Answer Center (800-952-5039 in US).

•

Salt Bridge—salt solidifies above water level so that brine water is not in contact with salt. See the

Breaking a Salt Bridge section.

Problem Possible Cause What to do

No soft water Faucet or fixture where sample

was taken not plumbed to soft

water. NOTE: Be sure sample is

from a faucet that does not mix soft

and hard water. For example, a single lever kitchen faucet, if the cold

side is plumbed to hard water.

No salt in the brine tank or salt

bridged

External power supply unplugged

at wall outlet or power cable to

softener not connected. Fuse

blown or circuit breaker popped

on circuit to electrical outlet.

Electrical outlet on a circuit that

can continuously be switched off

Manual bypass valve in bypass

position

Valve drain hose pinched,

plugged, elevated too high or

otherwise restricted

Nozzle and venturi dirty,

incorrectly assembled or

damaged

• To conserve salt, the installer may have isolated

some fixtures (outside faucets, toilets, etc.)

from soft water. From the outlet of the water

softening system, trace the water flow path, in

house plumbing. If soft water is not directed

to a faucet or fixture where wanted, consult a

plumber.

• Check for a salt bridge or, if the tank is empty,

refill with recommended salt. Press (for 3

seconds) the RECHARGE button to start an

immediate recharge and restore soft water

supply.

• Check for a loss of electrical power to the

water softening system, due to any of these

conditions and correct as needed. With the

power supply restored, observe the faceplate

time display and read Programming the

Control section. NOTE: the electrical outlet

for the softener should be live so it cannot be

accidentally switched off.

• Be sure the bypass valve stem is positioned

properly, with the handle in the OUT position.

• Any restriction in the drain hose may prevent

proper operation of the nozzle and venturi and

reduce or prevent brine draw during recharge..

• Refer to Cleaning the Nozzle and Venturi

Assembly instructions. With water pressure to

the water softening system off, take the nozzle

assembly apart. Inspect, clean and replace

as needed. Any foreign particle(s), scratches,

nicks, etc. in the passages can prevent

operation. Be sure holes in the gasket are

centred over holes in the housing.

23

Page 24

Before you call for service

Problem Possible Cause What to do

Water hard sometimes

Water feels

slippery after

installation of

water softener

Water Softener not

using any salt

Water is blue color

after water

softener was

installed

Water softener not

regenerating

Cloudiness on

glassware

(automatic

dishwashers)

Using hot water while the water

softening system is regenerating

Control HARDNESS number setting too low

Grains of hardness in your water

supply have increased

Absence of hardness minerals • This is normal. Hardness in water gives it the

Water softening system is a

“demand” unit

Possible salt bridge • See the Breaking a Salt Bridge section.

Possible plugged nozzle and

venturi

Acidic water in copper plumbing • Have the water tested at once.

Meter turbine stuck • See the Manually Initiated Electronics

Sensor wire not plugged into the

control

No power to unit • Check the circuit breaker or fuses.

Mechanical defect • Call for service.

Combination of soft water and

too much detergent

• Avoid using hot water during water softening

system recharge because the water heater

will refill with hard water. See Automatic Hard

Water Bypass During Recharge section.

• Press MODE/SET button until arrow points to

HARDNESS. Be sure the number shown is

the same as the actual grains per gallon hardness of your water supply. See Programming

the Control section if a change in setting is

needed.

• Water hardness can change over time, especially in well water. To check, have the water

tested by a water analysis laboratory or call

your local water department. Adjust the Hardness number setting as needed.

abrasive feel you may have been accustomed

to. The slippery feel is the clean feel of soft

water..

• Does not use much salt to regenerate - very

efficient.

• See the Cleaning the Nozzle and Venturi As-

sembly section.

Diagnostics section for troubleshooting

procedures .

• Call for service.

• See the Manually Initiated Electronics

Diagnostics section for troubleshooting

procedures .

• Call for service

• This is called etching and is permanent. To prevent this from happening, use less detergent

if you have soft water. Wash glassware in the

shortest cycle that will get them clean.

24

Page 25

Before you call for service

Problem Possible Cause What to do

Excessive/high

level of water in

brine tank

Salty tasting or

brown/yellow

colored water after

installation

Brown/yellow

colored water

Resin beads

showing up in

drinking water

Sounds you might

hear

Water has air

bubbles and is

cloudy

Blue light Flashing

When power

applied to the

system

If “DAYS TO

EMPTY” is

flashing

Valve drain hose pinched,

plugged, elevated too high or

otherwise restricted

Drain lines connected together • Separate drain lines.

Nozzle and venturi dirty,

incorrectly assembled or

damaged.

Unit not sanitized • Complete Sanitization Procedures.

Low water pressure Check pressure:

Restricted drain hose • Clean and reconnect hose.

Unit was idle for a period of time • Complete the Sanitization Procedures.

Cracked distributor

plumbed backwards

Running water from the unit into

a drain during recharge

Air in system after installation • Will go away after it runs for a while.

Control needs to be programmed

(a power outage may have

occurred)

Low salt level, less than 15 days • Fill with salt.

or unit

• A restriction in this drain hose may prevent

proper operation of the nozzle and venturi and

reduce or prevent brine draw during recharge.

• Refer to Cleaning the Nozzle and Venturi

Assembly instructions. With water pressure to

the water softening system off, take the nozzle

assembly apart. Inspect, clean and replace

as needed. Any foreign particle(s), scratches,

nicks, etc. in the passages can prevent

operation. Be sure holes in the gasket are

centred over holes in the housing

• At completion of recharge cycle (approx. 2

hours), run water from faucets to purge the

salty water.

• Drain height 8’ or less, pressure should be

minimum 20 psi.

• Drain height above 8’, pressure should be

minimum 50 psi.

• Check for kinks in drain line

• Call for service.

• This is normal.

• See the Programming the Control section.

• Reset salt level.

25

Page 26

Before you call for service

Problem Possible Cause What to do

Error Codes on

Control

If “Err” in display Electrical problem with system • Call for service.

Wiring may have worked loose in

the control

• Unplug external power supply.

• Remove control cover, release clips on side.

• Check for loose/incorrect wiring connections

to electronic board or switch. Reconnect as

required.

• Reassemble control cover.

• Plug in Transformer.

• Wait 8 minutes for Error Code to reappear.

• If error Code reappears, call for service.

2626

Page 27

Advanced troubleshooting for service

3.

AUTOMATIC ELECTRONIC

DIAGNOSTICS

This water softener has

a self-diagnostic function

for the electrical system

(except into power and/or

water meter). The water

softener monitors electronic

components and circuits

for correct operation. If

a malfunction occurs, an error code appears in the

display.

While an error code appears in the display, all buttons

are inoperable except the MODE/SET button. MODE/

SET remains operational so the service person can

perform the Manual Advanced Diagnostics, see below,

to further isolate the problem.

Call for Service

Figure 14

Procedure for removing error code from

display:

1. Unplug transformer from electrical outlet.

2. Correct problem.

3. Plug in transformer.

4. Wait 8 minutes. The error code will return if the

problem was not corrected.

MANUAL INITIATED ELECTRONIC

DIAGNOSTICS

Use the following procedures to advance the water

softener through the regeneration cycles to check

operation.

Lift off the Salt Hole Cover, remove the top cover by

unlocking the tabs in the back and rocking forward,

to observe cam and switch operation during valve

rotation.

1. Press and hold MODE/SET for 3 seconds until the

Set low salt alarm display appears, next press the

MODE/SET button two addition times until “000”

shows in the display, then release, see Figure 15.

2. The 3 digits indicated water meter operation as

follows: If you don’t get a reading on the display,

with faucet open, pull the sensor from the valve

outlet port. Pass a small magnet back and forth

in front of the

sensor. You

should get a

reading in the

display. If you

get a reading,

shut off water

supply, unhook

the in and

out plumbing

and check

the turbine for

binding.

Motor

Valve outlet

Position

switch

Sensor

housing

Turbine

Turbine

support

and shaft

Symbols in the display indicate POSITION switch

operation, see Figure 15

Switch is open

Water Meter

4.

Use RECHARGE button to manually advance

the valve into each cycle and check correct switch

operation. NOTE: Be sure water is in contact

with salt, and not separated by a salt bridge (see

Breaking a Salt Bridge section).

5. While in this diagnostic screen, the following

information is available and may be beneficial for

various reasons. This information is retained by

the computer from the first time electrical power is

applied to the electronic controller.

a. Press the UP button to display the

number of days this electronic control has had

electrical power applied.

b. Press the DOWN button to display the

number of regenerations initiated by the

electronic control since the code number was

entered.

6. Press and hold the MODE/SET button until the

mode code (F30 for GXSH30V) shows in the

display. This code identifies the softener mode. If

an incorrect model code is displayed, the softener

will operate on incorrect configurations data.

7. To change the code number, press the UP or

DOWN button until the correct code shows.

8. To return to the present time display, press the

MODE/SET button.

9. Press the MODE/SET button to return to the

present time display. If the code was changed,

make all the timer setting. NOTE: If the control

is left in a diagnostic display or a flashing display

when setting times or hardness, present time

automatically returns if a button is not pressed

within four minutes.

27

Switch is closed

Figure 15

Page 28

Advanced troubleshooting for service

Service: Manually Advance Recharge Check

NOTE: The control display must show a steady time

(not flashing).

1. Press the RECHARGE button and hold in for three

seconds. RECHARGE NOW begins to flash as

the water softening system enters the fill cycle

of recharge. Remove the brinewell cover and,

using a flashlight, observe fill water entering the

brine tank. If water does not enter the tank, look

for an obstructed nozzle, venturi, fill flow plug or

brine tubing. See Care and Cleaning of the Water

Softener System section.

2. After observing fill, press the RECHARGE button

to move the water softening system into brining.

A slow flow of water to the drain will begin.

Verify brine draw from the brine tank by shining

a flashlight into the brinewell and observing a

noticeable drop in the liquid level over an extended

period of time (15 to 20 minutes).

NOTE: Be sure a salt bridge is not preventing water

from contacting salt. See Care and cleaning of the

water softening system section.

If the water softening system does not draw brine,

check:

nozzle and/or venturi dirty or defective.

defective nozzle and venturi seal.

nozzle and venturi not seated properly

on gasket.

other inner valve defect (rotor seal, rotor and

disc, wave washer, etc.).

restricted drain (check drain fitting and hose).

NOTE: If water system pressure is low, an elevated

drain hose may cause back pressure, stopping brine

draw.

3. Again, press the RECHARGE button to move the

water softening system into backwash. Look for a

fast flow of water from the drain hose. A slow flow

indicates a plugged top distributor, backwash flow

plug or drain hose.

4. Press the RECHARGE button to move the water

softening system into fast rinse. Again look for a

fast drain flow. Allow the water softening system to

rinse for a few minutes to flush out any brine that

may remain in the resin tank from the brining cycle

test.

5. To return the water softening system to service,

press the RECHARGE button.

28

Page 29

Exploded View

11

4

12

17

16

19

2

146

13

5

23

20

22

999

8

7

6

29

3

7

8

56

56

24

5

23

10

30

9

26

2929

Page 30

Exploded View

124

105

141

140

138

136

103

132

117

109

110

111

112

113

114

116

115

118 120

Wear Strip

Seal

Cross-section

View

146

119

106

121

108

130

130

107

123

122

130

145

143

152

130

151

152

147

30

Page 31

Parts List

G

X

S

F

3

0

V

REF. NO. PART NO. PART DESCRIPTION (01)

0002 WS31X10051 BACK COVER, ELECTRONICS 1

0003 WS35X10001 O-RING SEAL KIT 1

0004 WS34X10020 DECAL, FACEPLATE 1

0005 WS07X10004 HOSE, DRAIN, 20 FT. 1

0007 WS14X10002 DISTRIBUTOR, TOP 1

0008 WS14X10005 DISTRIBUTOR, BOTTOM 1

0009

0010 WS32X10030 TANK, RESIN,

0011 WS31X10052 COVER, TOP 1

0012 WS34X10021 FACEPLATE 1

0013 WS21X10053 CONTROL 1

0016 WS26X10013

0017 WS31X10053 COVER, SALT HOLE,

WITH LABEL 1

0019 WS33X10010 RIM 1

0020

0022

0023

0024 WS32X10031 TANK, BRINE 1

0026

0029 WS15X10077 BRINE VALVE ASM. 1

0030 WS35X10063 FlOAT, STEM & GUIDE 1

0056

0103 WS21X10003 SWITCH 1

0105 WS02X10014 SCREW

0106 WS31X20060

0107 WS03X10010

0108 WS26X10002 ROTOR & DISC ASM. 1

0109

0110 WS03X10011 SEAL, O-RING

WS01X10002 RESIN, 1 CU. FT. 1

9 X 35 1

EXTERNAL POWER SUPPLY WITH

POWER CORD 1

WS31X10024 COVER, BRINEWELL 1

WS34X10025 BRINEWELL 1

WS02X10088 SCREW KIT, BRINE TANK 1

WS22X10063 OVERFlOW ADAPTER KIT 1

WS28X10078 TANK NECK CLAMP KIT 1

, #10 - 14 x 2” 5

COVER, VALVE 1

WASHER WAVE 1

WS19X10010 CAP 1

1.125 X 1.37 1

31

Page 32

Parts List

G

X

S

F

3

0

V

REF. NO. PART NO. PART DESCRIPTION (01)

0111 WS19X10005 SUPPORT SCREEN 1

0112 WS03X10013 SCREEN 1

0113

0114

0115

0116 WS22X10021 PLUG, FILL FlOW, .30 GPM 1

0117 WS03X10017

0118 WS15X10034 NOZZLE/VENTURI BODY 1

0119 WS03X10018 RETAINER 1

:6; 6($/25,1*Ǝ;Ǝ

0121 WS15X10010 BODY, VALVE 1

0122 WS03X10020 SPRING 1

0123 WS22X10022 PLUG, DRAIN SEAL 1

0124

0130 WS35X10005

0132

0136 WS26X10003 CAM & GEAR 1

0138 WS26X20061

0140 WS26X20062 MOTOR 1

0141 WS02X20063 6&5(:[Ǝ

0143 WS60X10013

0145 WS60X10004 CLIP 4

0146 WS28X10017

0147 WS19X10006 TURBINE & SUPPORT ASM.* 1

0151 WS15X10053 BYPASS VALVE ASM.* 1

0152 WS03X10025 SEAL, O-RING 4

0998

0999 49-50282-8 OWNER’S MANUAL 1

WS22X10036 FlOW PLUG, .15 GPM 1

WS08X10008 GASKET, NOZZLE/VENT 1

WS03X10073 SCREEN CONE 1

NUT FERRULE 1

WS15X10046 NOZZLE/VENTURI ASM. 1

WS22X10064 DRAIN HOSE ADAPTER KIT 1

WS35X10064 INSTALLATION KIT 1

SEAL KIT 1

MOTOR MOUNT 1

ADAPTER—NPT THREADED—STD VALVE

HARNESS WIRE, SENSOR ASSY 1

2

* Includes 2 each of REF. NO. 152 (O-RING)

32

Page 33

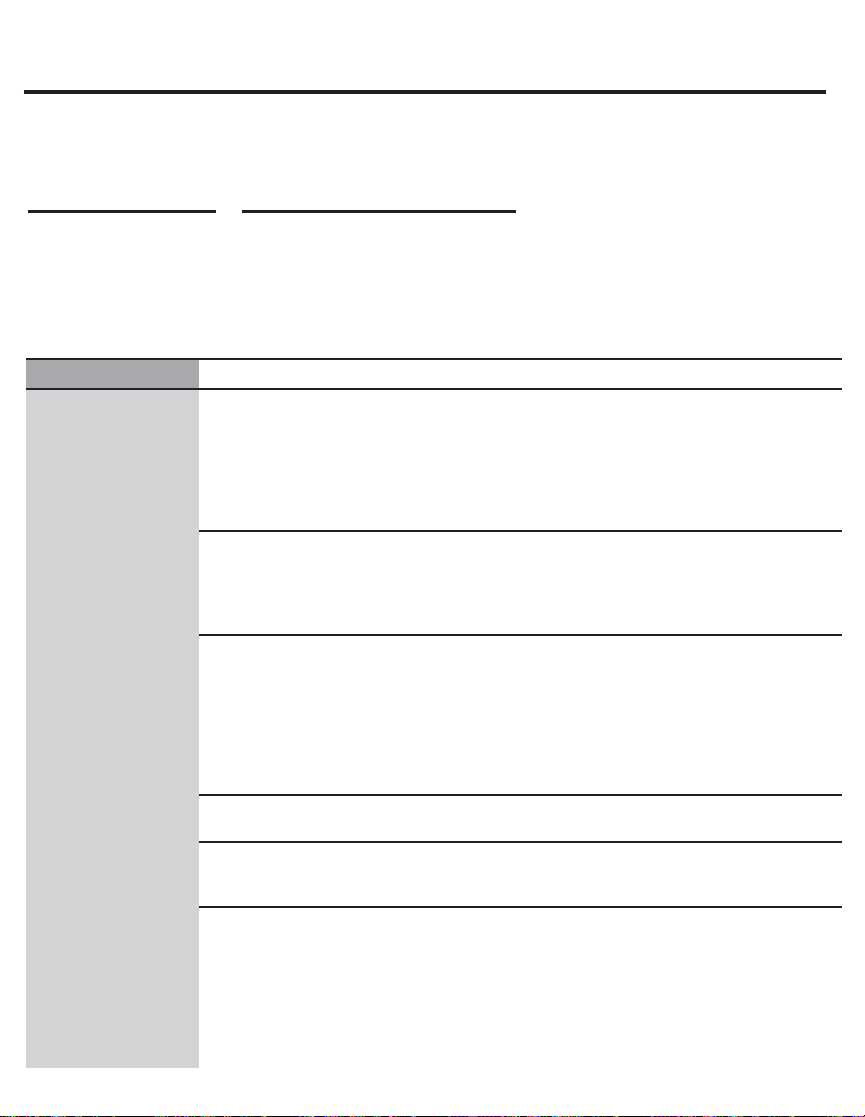

Water Softening System Warranty

All warranty service provided by our Factory Service Centers or an authorized technician. For service,

call toll free 1-800-952-5039. Please have serial number and model number availa ble when calling for

service.

For The Period Of:

One Year

From the date of the

original purchase

Three Years

From the date of the

original purchase

T en Years

From the date of the

original purchase

We Will Replace:

Any part of the Water Softening System which fails due to defect in

materials or workmanship. During this limited one-year warranty,

GE will also provide, free of charge, all labor and related service to

replace the defective part.

The electronic monitor, if it fails due to a defect in materials or

workmanship. During this three-year limited warranty, you will be

responsible for any labor or related service cost.

A replacement resin tank, if it fails due to defect in materials or

workmanship. During this ten-year limited warranty, you will be

responsible for any labor or related service costs.

(For Customers in the U.S.)

What Is Not Covered:

Service trips to your home to teach you

how to use the product.

Improper installation, delivery or

maintenance.