Page 1

la

d,

=

E

ho

tr'l

D

661

7J

Eur

-rA

<o

fi=

z

rI

o

F"."froToFACT*

FolJ"t

GENERAL

moDEr

INDUSTRIES

25()

o

Itt

z

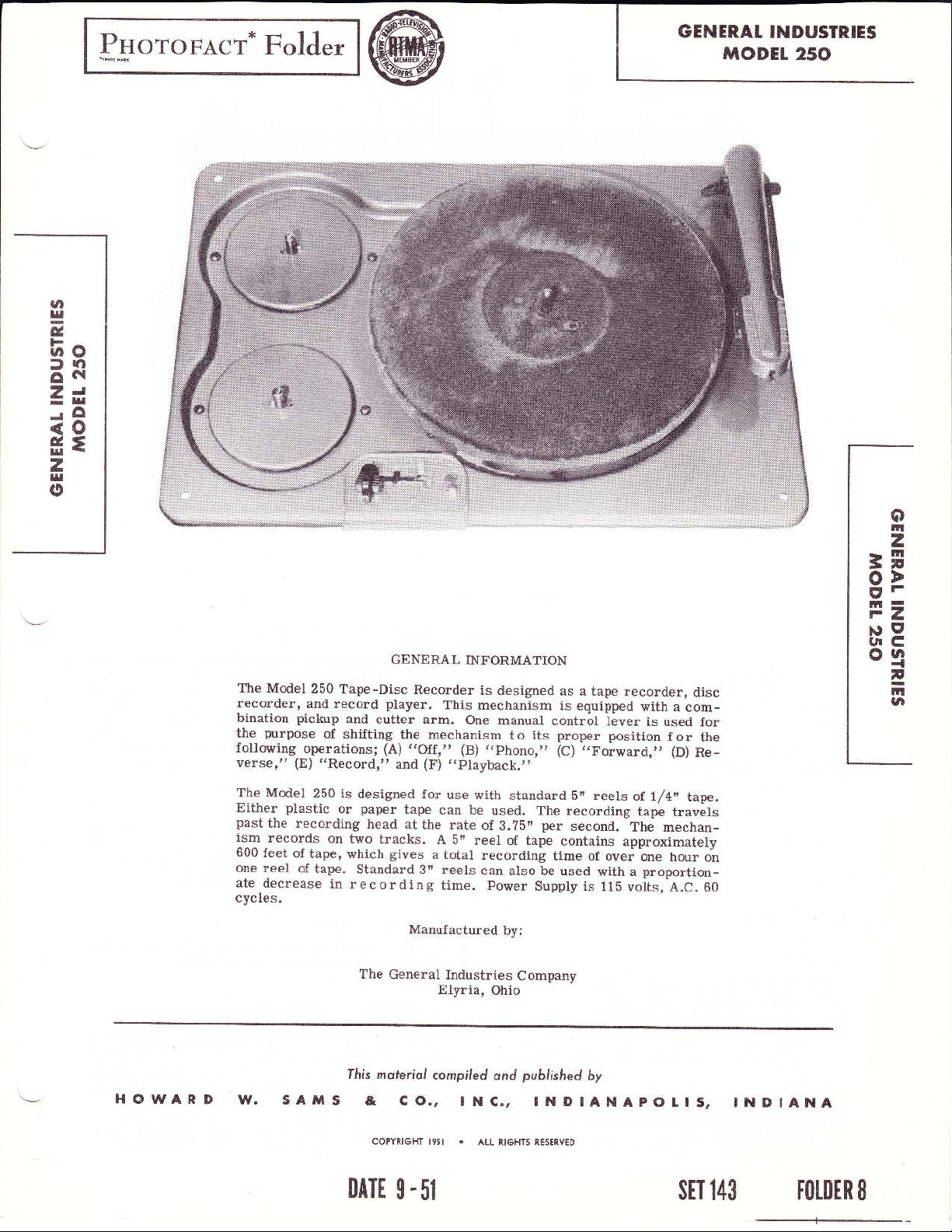

The Model

recorder,

bination

prrpose

the

following.

verse,"

The

Model

Either

past

ism

600

one

ate

cycles.

plastic

the recording

records

feet

of

reel

decrease

250

Tape-Disc

and

record

pickup

(E)

and

of

shifting

operations;

"Record,"

250 is

or

on

two

tape,

of

which

tape.

in

recording

GENERAL

player.

cutter

the

(A)

and

designed

paper

tape

head

at

tracks.

gives

Standard

The

General

INFORMATION

Recorder

arm.

mechanism

,,Off:,

(F)

for

the

a

3n

is

This

mechanism

One

,,phono,,,

(B)

,,playback.',

use

with

can

be

rate

of

A

bn

reel

total

recording

reels

can

time.

Manufactured

Industries

Elyria,

designed

manual

o its

t

standard

used.

3.?b"

of tape

also be

power

by:

Company

Ohio

as

a

is

equipped

control

proper

,,Forward,,'

(C)

br reels

The

recording

per

second.

contains

time

of

used

supply is

tape recorder,

with

lever

is

position

of.

tape

-The

approximately

ovei

one

proportion-

with

a

llb

voits,

a

used

f

o r

(D)

l/4"

travels

mechan-

hour

A.c.60

disc

com-

for

the

Re_

tape.

on

OD

=F

gr

m=

F1

xrEl

UtC

oa

{

2

TT

ta

HGWARD

l^f.

sAxl

fhis

5

0ATE

moferiol

&

COPYRIGHT

g

co.,

5l

compiled

I

NC., INDIANAPOIlS,

o

l95l

ALL

published

ond

RIGHTS RESERVED

by

sET

INDIANA

t43

t0rDtR

8

Page 2

OPERATING INSTRUCTIONS

Threading of

(a)

plastic

pan

(32)

sure

of

the reel.

making

of

the

approximately

around

the hub

taken

tape is

contact

ready

Recording

To record

ward,

with

then

safety

engagement

position.

When

contacts

only

recording

Place a reel

paper

or

with one

the magnetic

(b)

Place

sure

spindle.

(c)

Grasp the

t}te

turntable

of

the front reel.

up by

tightened, it

the rubber

for

operation.

-

on

slightly,

the

"Record"

pushed

forward

button

in

the

the recording

at the instant

head

Tape

-

(3n

base recording

of

slot

the empty

the

coating

that the slot

free

three feet of

and

the free end is

turning

the tape, move

the front reel

will

capstan

and then

slide under

to the right, until it is

position.

(42)

of

and,

pulled

is

the control knob

"Record"

tape and erases

just

(2?).

Only the lower

or 5"

diameter)

tape on the

reel

engaging

of

the tape faces the

reel

on the front

in

reel

the

end of the

engages the key

tape

tape. The

The slack in

clockwise.

the

(?4).

The recorder is

the control knob

The

at the same

position,

prior

control knob

f orward

(a2)

the

passing

to

time, the

in

track of the tape

of either

rear

reel

(31).

key

center

pan,

reel

and unwind

placed

is

tape

threaded into

the tape is

turntable

to

the

erase head

the lowertrack

When

(43)

aligned

(43)

record

permit

"Reeord"

over

and

now

for-

Be

full

(35)

the

half

one,

played

of the tape,

must be

back.

the

removed from the

transferred to the rear reel

that the slot

must

in

be

the tap€, as

with

recording in

the

-

tape

to the start of

position

o

t

control knob

The recorder

the Recorder

may be

to the

the

into

-

stopped

position

is

now rewinding.

at any

-

the tape to t}e start

on

"To

Rewind");

If both tracks

played

be

to

to remove

reel

the

the reels

pans,

as

described

control knob

will now operate

front reel,

reel engages

tfie

transferred

previously

the same

the recording,

marked

the reverse

point

marked

from

"Off."

of

that

recording

the

is,

if one track

have been recorded

the start,

and transfer

under

3'Playback"

to the

for

record

to

is

the

the

now

turned

pan,

key

front

and

which

pan,

to

described,

manner.

shift

"Reverse."

slot as far as

by shifting the

(see

only

it

will be

them to

"Record-

playback.

posi-

is recorded or

Whenthe rear reel is emptyand it isdesired

the upper

full

the

completely over, and

making

(31).

pan.

proceed

To Rewind

To rewind the

sure

The empty reel

Thread

the control knob

Push the

possible.

To Stop

The tape

control

is

Playback

Reurind

paragraph

has been recorded.

and the tape is

necessary

the

ing."

knob

opposite

Move

tion. The recorder

Page

2

Page 3

To

Repair

In case

to edit

tape.

adhesive

Scotch

coated,

splice

or a

the recording

without interference.

Fast-Forward

If

a recording

tape

the

To Play

play

To

tion

With

function

rear

tape,

tate

of

the

back

is

held

Cutting

To

the

or

Sp1ice

the

a recording,

tape

is

Do not use

material is

tape

should be

side of

should be

the recording

trimmed with a

knife, to bring

tape so

-

near

may

be speeded

('Forward"

Standard

?8

the

control

the

shift

reel

and

the

turntable.

pickup

needle

in

Disc

cut

home

playback

position.

RPM

control

lever

clutches.

the

only function

arm

is inserted

position

Recordings

recordings,

needle from

records,

knob

Tape

-

broken

accidentally,

4 splice may

medicated

not

suited

applied

the width of

pass

it

will

the end

up by

78

RPM

knob in

(a1)

of

moving

Records

it

is

(43)

in

the

depresses

This eliminates

the

playing

In

(4)

with

is

depressed;

in

the

needle

-

records,

it is

the cartridge

be

made

adhesive

to this

to

the reverse,

tape.

The edges of

small

the splice

the

the

tape is

the

-

only

necessary

,,phono,'

the

',phono"

both

the

performs

unit

a

pickup

thumb

screw.

necessary

is

or it

desired

with

tape

purpose.

pair

of

scissors,

various

to that of

contacts

desired,

control knob

to

position.

position,

the front

driving of

is

the rear

standard

cartridge

to remove

(6)

and insert

Scotch

as

the

The

or

un-

the

the

posi-

the

and

the

to ro-

portion

play-

(6)

and

a

blank on

the

ing

of

edge

tion

of the

right

the

the

This

follower

recording

the

to

tion. If

place

The drive

motor

ing

and

turn,

to the

shaft.

Operation

.off,t

When the control

the

knob,

(63),

standardS/8"

the turntable

turntable

disc.

the record.

of the

at which

pickup

side of

llp

through

Raise

recording

the recording

arm

the arm.

on

the

lock spring

holds

the

(83)

arm

is

tape,

being

move

the recording

the

control

MECHANICAL

mechanism

(61),

and

drives

drive

of

Position

which

the

the

pulley

the

mechanism

(51)

shift lever

is moved

shutting

off

recording

the hole

pickup

the

Place

the

by

lifting

rear

of

of

the

arm

arm

in

to

engage

done

the

control

knob

drives'both

through

drive

capstan

(60)

Control

knob

(41),

which

against

the

motor

stylus.

with

the record

provided

arm

and

recording

blank

at

the

is

to

on

The arm

the

is

in

inpludes

which is

(43)

the

the ear

follower

lock

bracket

a

raised position

the

some

knob

t o be

,.playback,,

the

FUNCTION

lead

from

the following:

the turntable"and

the

media

pulley

(6b).

(?4).

These

fastened

(4S)

Knob

is

in

is

fastened

pin

of

power.

place

move

stylus

approximate

start.

extending

should

be raised

arm

assembly

screw

source

,rphono,

to

the

made

from

of

drive

The

belts

,,Off',

the

t o the

the

switch

a recording

driving

in

the record-

it

to the

on

the

Raise

the rear

(82)

engages

causing

(?g).

other

the

position.

A

belts

turntable,

are

coupled

to the

position,

control

assembly

pin

edge

outer

loca-

to the

until

(80).

the

if

the

than

posi_

1ape,

single

re6l-

(b0)

in

motor

o

F

z

35

o>

gF

li=

F1

|\r9

lrr

of

C

oa

{

?

trl

UI

Page

3

Page 4

Page

4

Page 5

*r

<@

0a

}/o

hr

!>

k

d06

x2

EE

ltJ

:o

tn

E

)c

uJ

o-

III

cx

I

:

lrt

oa

xlI

tl

tn

2

C

-l

F1

Et=

gr

=Fo>

z

o

llt

Page 6

ttPhono"

With the control knob

shift lever

(63).

against the

which

ing

actuating

pin (40)

ord and

"Reverse

When the shift lever

position,

the front reel from the clutch assembly. The

engages

ism

For

reversed.

to

playback

The Fast Forward

to the

positions

(14), pressure pad

tape

jEecqA

When

"Playback"

Position

(a1)

is

-

moved

The switch actuator

pin,

switch

on

turns

(40)

lever

is actuated by spring

lever

by the shift

Playbaek"

and

Forward"

it

depresses

the clutch spring, thus

for

Fast Rewind.

Forward,

Fast

The Forward

1

over the

3

-3/4"

tape speed.

fact that when the shift

-

"Forward

gives

which

Pt"VnactL

""4

the control

position,

motor

the

(40)

is

lever

positions.

the

per

and

and spring

free

knob

tilting the

(a1)

movement

('Phono"

in

the

away from

lever

mercury

power.

pushed

away

(al)

when

Positions

is moved to the

the lift

position

lever

operating the

of the

speed

second

Rewind

-

(43)

the shift

normal recording

are accomplished due

lever

Reverse," the

(18)

to

is in

lever

position,

the switch

(40)

then

The switch

switch

(62).

from t h e switch

in

the

-

(58)

disengaging

reel

is

approximately

(41)

pinch

do not

reels.

either

"Record"

(al)

contacts

the

pin

moves

(63A)

actuat-

The switch

-Rec-

"Off

"Reverse"

pan

rear

mechan-

pans

are

is

in these

roller

contact

the

the

pressure

spring

(14)in

roller

capstan

part

of

recording

ing head

driving

recording tape firmly

part

is

(?4)

is,

acts

as

"wow"

tape.

Automatic

When

back"

ing

20

or

or

lever

tension

positionl

forward

in

such

automatically

Mechanism

broken.

pad

(21) (see

(74).

this assembly,

tape and is held

(2?).

capstan and the

of

the recording head.

in

turn, driven by

a f lywheel,

effect as

Shut Off

pinch

and

Figure 2).

firm

contact with the tape and the driving

pressure

The

is

This assures firm

against

thus minimizing any flutter or

a result of

-

the mechansim

position,

of

a manner

t.

the

(40)

the tape then

however, when

reel,

shift

are

moved clear of

the mercury switch

as to open

stopping

TROUBLES AND

Does Not Turn

Switch

actuating

roller assembly actuating

brings

This

(18),

pad

brought into

firmly

tape, as well a s

the

contact

against

contact

r€cording

The driving

the large turntable,

changing velocity of the

is

in the

"Record"

(41)

lever

holds

aII

the

the unit.

ADJUSTMENTS

On

and

the

switch

the switch

is wound

tape

permitted

is

motor circuit,

the

in

Position

'

spring

(62)

which

switch

pinch

the

is also

with the

the record-

between the

holding

gap,

which

capstan

which

or

"PIay-

actuat-

(63).

(

in the

on the

-

loose

the

The

.On"

to

thus

tip

or

Page

6

Page 7

(a)

Switch

to the

actuating

switch

actuating

actuating lever

switch to the

(62).

spring

Turntable Rotates

1. Mercury

direction.

switch bracket and reverse

Reel

Pans

Remove

(32)

Fail to

1. Lift levers

(a)

In the

pan

must be raised to the

the

clears

the front

clutch spiing

clear the lower end

by approximately 1f32" to

the lift lever

section of the

front reel

1/16n clearance is obtained.

(b)

In reverse, the

and the front

(69)

lever

above, leaving a clearance

NOTE: In the

"Record"

the lift levers

pan

reel

tact the clutch

Fails to Record or

1. Pressure

(a)

Checkthe screws thathold

spring

they are tight.

(18)

2. Pressure

"On"

in

"Off

switch

mercury switctr

Rotate

(58)

"Forward-Speed"

clutch

pan

must be

(49),

(58),

lever immediately

pan

shaft

pan

in

the same

(58)

shafts

so

springs

Playback Properly

pad

spring

to the mounting

pad

worn or missing.

spring

(40)

Position but will

its

and

must be connected

(40)

lever

may tilt the

position.

(63.{)

turned

(63A)

position (see

to Wind the

(69)

out of adjustment.

position,

so

mercury

Replace

not

from

Tape -

position

(48).

spring

and the lift lever

of the front reel

At the same

Lowered

contact the

to

1/16". To

bend the short unf

until a

rear reel

space

pan

of

is lowered

is raised. Adjust the

manner as described

of.1f32" to l/16.'

and

"Playback"

(69)

and

that both the

must elear

(48)

and

(18)

loose.

plate

pans

(a9).

-

pressure pad

the

(15)

that the

the

in wrong

clip of

Figure 3).

rear

the

so that

time,

(58)

must

pan

shaft

adjust

Iange d

under the

l/32"

lift

positions,

both

will

con-

to see if

allowlng

mounting

plate

ttRecordt'

the spring to slip

plate (15),

will not be

or

pivoted

t'Playbackt'

turn, the tape will not

stan and

lWowj'

lgftng

1. Follower

(?3) properly.

pickup

engage

pickup

it

to

arm

ment should

pickup

the

point

of engagement,it can be

bending

engages the

will

in

heavy,

result

the

and continuous

The

ufacture,

of time;

the follower arm

put

be

recording.

the

there

of the follower arm

lead screw

recorder

however, if the unit is used to

recording head.

Disc Reco"di"g

(83)

arm

When lifting the rear section

arm assembly, the

the lead screw

in

locks

be at a

arm locks. If

lead

screw too

on the

(?3)

raised

the

point

betwee\ tf 8"

it is

lead

screw,

If the engagement

possibllity

is

a

rather than moving along

pattern.

LUBRICATION

has been lubricated at time of

unit

which should be sufficient

or is subjected to extreme

be cleaned with carbon tetrachloride

should

as follows:

cated

t.

lubricate

(52),

To

and reel

pan

Remove the

end of the reel shaft,

(32)

and clutch springs

ine. Place

on the reel shaft and the

ing. Place

inthe

countersunk

next to the

the felt

60 oil.

SAE

the

clutch springs

"C"

or three drops of

two

five

porous

pads

on the clutch springs with

over

pinch

the

position.

be held against the cap-

not engaging

follower arm

before the rear

position.

necessary

accomplished byslightly

(83).

If the

tightly,

thus

grouping,

of

lifting up on

boss on the

the

roller mounting

inward

an

injecting

is

when

If

this

-

lead

screw

(83)

should

of the

engage-

This

lf 4 before

^nd

to adjust this

follower

excessive

which

the

"Wow"

threads

not sufficiently

in a smooth

great

recorder

the

and lubri-

off

the

SAE

of the

SAE

period

sheave

Saturate

for a Iong

heat or dust,

pan

reel

washer

or

six

portion

bronze bearing.

a

shaft, reel

(48-49):

(56)

and lift the reel

(48-a9)

inside

drops of

ofthe reel sheave

on the lower

in

is

of the

arm

load

is the

of

man-

extent

pan

mach-

10 oil

bear-

20 oil

o

m

z

=5o>

gF

!n=

F1

dE

ora

q

2

EI

gl

(a)

of adjustment, it may be

Remove the

Loosen

(1

7).

Set the

position.

Turn the adjusting

pressure

pad just

Then

wise

Replace the

(b)

If the

pad

and adjust

3.

Spring

(a)

If

the

broken

pressure pad

If the

pinch

the lock nut on

shift lever

pad

spring

contacts

turn the screw

and tighten

pressure pad

(21)

pressure pad

the

pinch

as above.

loose

or the mounting

is

worn some

corrected as follows:

cover

(tr1).

roller

the adjusting screw

(41)

in

the

"Rec

(1?)

screw

(18)

until

in

against

the

pressure

the recording head

ll2to3/4 turn clock-

lock

nut.

cover

(11).

spring

(19)

is

roller

is

missing, replace

broken.

or

actuating

screw

or is

ord"

the

(2?).

the

(21)

loose,

pad.

out

CAUTION:

Do not oversaturate the f elt

avoid overlubrication of all

much

oil may come

in

contact with the

parts,

Also

as too

rubber drive surfaces of the drive mech-

anism, causing

"Wow."

2. To lubricate the turntable drive wheel

(26):

shaft

thb

SAE

place

rubber

10

and

Move

the machine

drive

go.

it will

oil on the

(9).

Raise the

put

two or three

post

the

post.

Page

wheel

Plare

wherl

up

?

and

Remove

on its

(26)

one or

shaft.

Pivot

pickup

drops of SAE 20 oil on the

down

is

3.

arm

several times to equalize the oil on the

the turntable and

edge. Raise

in its

bearing as far as

two drops of

post (5)

its highest

to

and bushing

position

post.

Page 8

PARTS LIfiT

Ref .

No.

1

2

3

4

5

6

7

B

I

10

11

t2

13

L4

15

16

t1

1B

19

20

2l

22

23

24

25

26

27

28

29

30

31

32

33

33A

34

35

36

3?

38

Part

No.

64419

11509

1620?

25t49

25108

2 5113

12098

25168

25126

22903

25193

21914

21844

25186

251 91

30214

115?8

25182

12129

25t71

251 78

11598

25r32

25131

25t57

25049

251 16

22376

58?1

25034

25036

25039

25003

25147

25t61

25072

251

25't2t

2

5119

Description

Turntable

Set Screw

Lock

Nut

Tone

Arm

Pivot

Shaft

Pickup

Cartridge

Felt Washer

Tone Arm

Pinch RoIIer Cover

Mounting Screws

Pinch

Roller

Hairpin

Fiber Washer

Pinch

Roller

Pinch

Roller

Stud

Assembly

Spring

PIate

Pad Adjustment Screw

Felt

Felt Pressure Pad and

Spring

Screw

Shoulder Washer

Pressure Pad

Screw,

Recording Head

Tape

Guide

Rubber Bushing

Tape

Washer for Tape

Turntable Drive Wheel

Recording Head

Screw,

Sub-Chassis

Screw,

Sleeve

Assembly

Key

Lug used on

Platform

Disc

Plate

Platform

Base Plate

Tone Arm

Screw,

Head

Erase

18

Spring

Recording

Spring

Shoulder

Complete

Assembly

Cartridge

Mounting

Pivot Post

Shure

-

Screw

Bushing

Plate

Plate

Cover

Clip

Hub and Tire

Mounting Plate and

for Pinch

Roller

Mounting

Assembly

Actuating

used for Mounting

Post

used on

Post

Guide

Guide

Post

used to Mount Motor

used

to Mount

Bushing

Disc Plate

for

Reel Plafform

Reel

Assembly

used

on

Reel

Assembly

Rest

used for

Head

Mounting Erase

Clip used with

Head

Clip

Washer

P89R

ing

Spring

Ref .

No.

39

40

4l

42

43

44

45

46

41

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

63A

64

65

66

61

6B

69

?0

1t

72

?3

74

75

?6

77

?8

79

80

B1

82

83

Part

No.

22903

25122

25134

251 51

25r46

3119

14463

25176

25174

25029

25031

25019

2501 3

25031

2286r

25121

25091

25084

22903

25028

23235

25r24

2506?

25129

25054

25044

25119

2286t

25056

25084

25OBB

13823

21934

21933

25077

7534

9569

250?9

22903

25166

25102

25153

22376

25098

Description

Screw, used

Auxiliary

Switch Actuator

Function

for Mounting

Shaft Housing

Lever

Switch Lever

Safety Button

Control Knob

Lockwasher, used

Hex Nut

Keyed Washer

Washer

Clutch

Clutch

Reel

Plate

Plate

Drive Belt

on Control Knob

Assembly

Rear

Assembly

Front

Turntable Drive Belt

Reel Pan and

Clutch Drive

Sub-Chassis

Reel Shaft

Nut,

ttC"

used to

Washer

Mount

Sub-Chassis

Spring, used with LiJt Lever

LiJt

Lever

Screw,

used

to

Mount

Drive Pulley

Pulley

Drive

Motor

Spring, Switch

Shut-off Switch

(Iess

Mercury

Actuating

Assembly

Switch)

Mercury Switch

Drive Wheel

Bearing

Plate and

Assembly

Drive Pulley

Shoulder Washer

Hex Nut

Set Screw

LiJt Lever

Tri-Mount Stud, Lift

Lever Mounting

Lock

Nut for Lead Screw

End

Thrust Screw for Lead Screw

Lead

Screw and Gear

Turntable Shaft and

Lock

Screw

for Turntable

Assembly

Capstan

Shaft and Capstan

Lock

Nut

Auxiliary

Adjusting

Reinforcing

Arm

Lock

Shaft Housing

Screw, Shaft Housing

Plate

Lock Bracket

Arm

Nut,

Assembly

Bracket

Assembly

Lock Screw, Follower Arm

Follower Arm

Sheave

Loading...

Loading...