Page 1

General HP

40W

Printed In Malaysia

A38251614A

PD001216

Full Channel AM/FM

Amateur Mobile Transceiver

OWNER'S

MANUAL

Downloaded from www.cbradio.nl

Page 2

TABLE OF CONTENTS

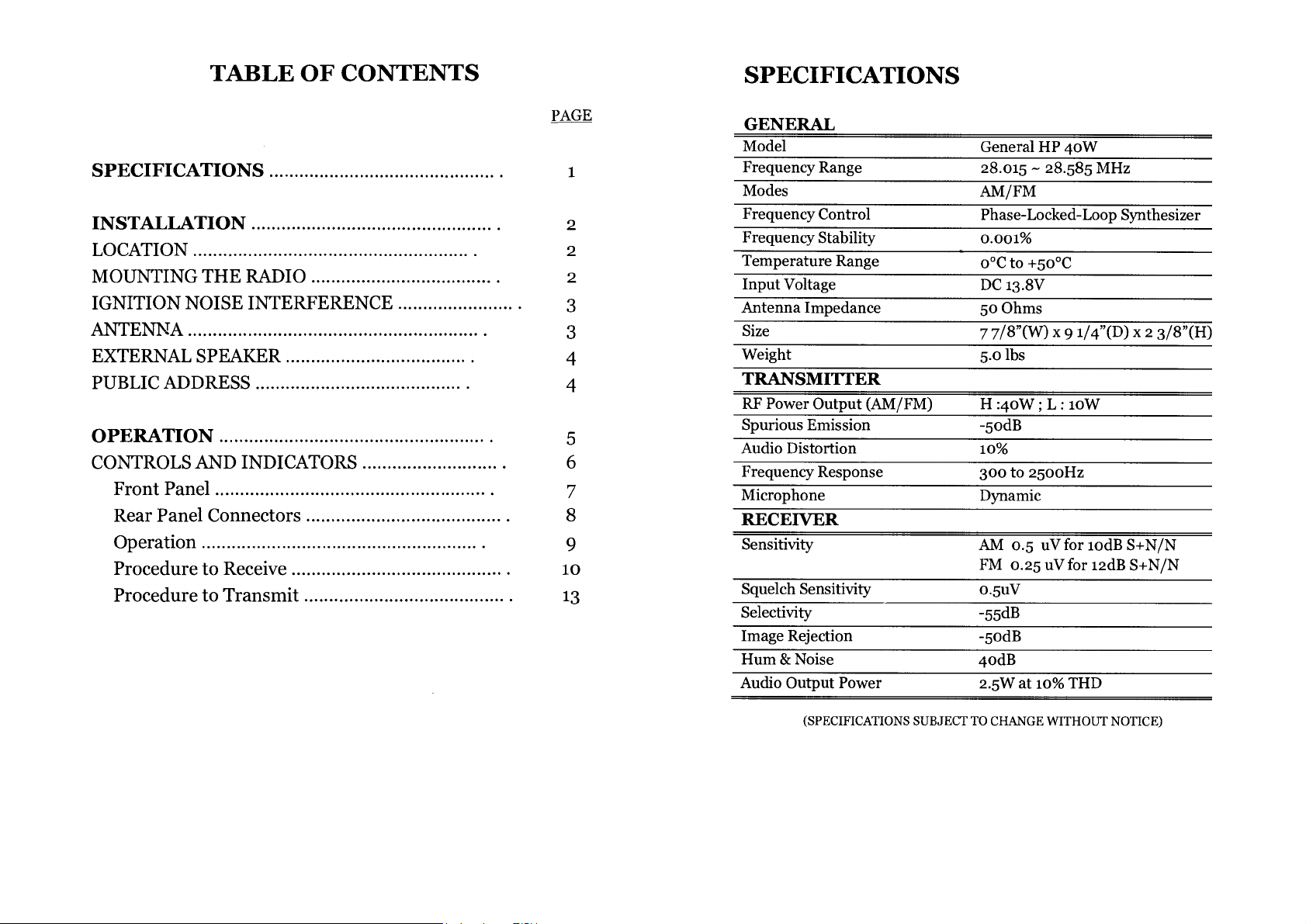

SPECIFICATIONS

SPECIFICATIONS

INSTALLATION

LOCATION

MOUNTING THE RADIO

IGNITION NOISE INTERFERENCE

ANTENNA

EXTERNAL SPEAKER

PUBLIC ADDRESS

OPERATION

CONTROLS AND INDICATORS

Front Panel

Rear Panel Connectors

Operation

Procedure to Receive

Procedure to Transmit

PAGE

1

2

2

2

3

3

4

4

5

6

7

8

9

10

13

GENERAL

Model

Frequency Range

Modes

Frequency Control

Frequency Stability

Temperature Range

Input Voltage

Antenna Impedance

Size

Weight

TRANSMITTER

RF Power Output (AM/FM)

Spurious Emission

Audio Distortion

Frequency Response

Microphone

RECEIVER

Sensitivity

Squelch Sensitivity

Selectivity

Image Rejection

Hum & Noise

Audio Output Power

General HP 40W

28.015 - 28.585 MHz

AM/FM

Phase-Locked-Loop Synthesizer

0.001%

o°C to +50°C

DC 13.8V

50 Ohms

7 7/8"(W) x 9 1/4"(D)

.olbs

H :40W; L: loW

-odB

10%

300 to 2500Hz

Dynamic

AM 0.5 uV for iodBS+N/N

FM 0.25 uVfor 12dB S+N/N

0.5uV

-odB

40dB

2.5W at io% THD

X

2 3/8"(H)

(SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE)

Page 3

INSTALLATION

LOCATION

Plan the location of the transceiver and microphone

bracket before starting the installation. Select a location

that is convenient for operation and does not interfere

with the drive or passengers in the automobiles, the

transceiver is usually mounted the dash panel with the

microphone bracket beside it.

MOUNTING THE RADIO

The transceiver is supplied with a universal mounting

bracket. When mounting the bracket and radio to your car,

make sure it is mechanically strong. Also provide a good

electrical connection to the chassis of the vehicle. Proceed

as follows to mount the transceiver:

1.

After you have determined the most convenient

location in your vehicle, hold the transceiver with

mounting bracket in the exact location desired. If

nothing will interfere with mounting it in the desired

position remove the mounting bolts. Before drilling the

holes, make sure nothing will interfere with the

installation of the mounting bolts.

2.

Connect the antenna cable plug to the standard

receptacle on the rear panel. Most transceiver antennas

are terminated with a type PL-259 plug and mate with

the receptacle.

Connect the red DC power input wire (with the fuse) to

3.

+13.8V

automobile installation,

from the accessory contact on the ignition switch. This

prevent the set being left on accidentally when the

driver leaves the car and also permits operating the

unit without the engine running. Locate the accessory

contact on most ignition switches by tracing the power

wire from the AM broadcast receiver in the car.

DC. This wire extends from the rear panel. In

+13.8V

DC is usually obtained

Connect the black lead to

4.

the chassis of the car. Any convenient location with

good electrical contact (remove paint) may be used.

Mount the microphone bracket on the right side of the

5.

transceiver, using two screws supplied. When

mounting in an automobile, place the bracket under

the dash so that microphone is readily accessible.

—13.8V

DC. This is usually

IGNITION NOISE INTERFERENCE

Use of a mobile receiver at low signal levels is normally

limited by the presence of electrical noise. The primary

source of noise in automobile installation is from the

generator and ignition system in the vehicle. Under most

operating conditions, when signal level is adequate, the

background noise does not present a serious problem.

Also, when extremely low level signals are being received,

the transceiver may be operated with vehicles engine

turned off. The unit requires very little current and

therefore will not significantly discharge the vehicle

battery.

Even though the transceiver has ANL and NB controls, in

some installation ignition interference may be high

enough to make good communications impossible. The

electrical noise may come from several sources. Many

possibilities exist, as variations between vehicles require

different solutions to reduce the noise.

ANTENNA

A vertically polarized, quarter-wavelength whip antenna

provides the most reliable operation and greatest range.

Shorter, loaded-type whip antennas are more attractive,

compact and adequate for applications where the

maximum possible distance is not required. Also, loaded

whips do not present the problems of high wind resistant

imposed by a full quarter-wavelength whip.

Page 4

Mobile whip antennas utilize the metal body of the

vehicle as a ground plane. When mounted at a corner of

the vehicle they are slightly directional, in the direction of

the body of the vehicle. For all practical purpose, however,

the radiation pattern is nondirectional. The slight

directional characteristic will be observed only at extreme

distances. A standard antenna connector (type So-239) is

provided on the transceiver for easy connection to a

standard PL-259 cable termination.

If the transceiver is not mounted on a meta' surface, it is

necessary to run a separate ground wire from the unit to

good metal electrical ground in the vehicle. When installed

in a boat, the transceiver will not operate at maximum

efficiency without a ground plate, unless the vessel has a

steel hull.

Before installing the transceiver in a boat, consult your

dealer for information regarding an adequate grounding

system and prevention of electrolysis between fittings in

the hull and water.

EXTERNAL SPEAKER

The external speaker jack (EXT SP.) on the rear panel is

used for remote receiver monitoring. The external speaker

should have 8 ohms impedance and be able to handle at

least

watts. When the external speaker is plugged in, the

4

internal speaker is disconnected.

PUBLIC ADDRESS

To use the transceiver as a public address system,

connect an external 8 Ohms speaker

watts minimum)

(4

to the PA SP jack located on the rear panel. Direct speaker

aay from the microphone to prevent acoustic feedback.

Physical separation or isolation of the microphone and

speaker is important when operating the PA at high output

level.

OPERATION

CONTROLS

Front Panel

GENEPAL HP 40W

1

.

MICROPHONE

microphone for voice source.

2.

ON/OFF VOLUME CONTROL

apply power to the radio and to set the desired

listening level.

SQUELCH CONTROL : This switch is used to

3.

eliminate background noise being heard through the

receiver which can be disturbing when no signal is

being received. To use this feature of your radio, gently

turn the switch fully counterclockwise and then turn

clockwise until the background noise is just eliminated.

Further clockwise rotation will increase the threshold

level so that only strong signals will be heard.

MIC GAIN CONTROL

4.

in the transmit and PA modes. This controls the gain to

the extent that full talk power is available several

inches away from the microphone. In the Public

AND

NBANL

ANL

OFF )

VOL-S-SO MIC GAN-- RF

INDICATORS

GAIN

PA FM AM

c

0

JACK

: Adjust the microphone gain

E-TDNE

Used to

: Turn clockwise to

connect

-4

-5-

Page 5

Address (PA) mode, the control functions as the

volume control.

14.DIMMER SWITCH :

tower the level of brightness of display.

This switch is used to select

RF GAIN CONTROL :

5.

the gain of the RF amplifier under strong signal

conditions.

MODE CONTROL :

6.

one of the following operating modes: PA/FM/AM.

BAND SELECTOR :

7.

user to select the desired band.

E-TONE CONTROL :

8.

effect and intervals of echo sound.

CHANNEL SELECTOR :

9.

select a desired transmit and receive channel.

to. FRONT PANEL METER:

allows the user to monitor signal strength and RF

output power level.

11.

NB/ANL/OFF SWITCH :

switch. Move the switch all the way up to activate the

Noise Blanker (NB) and Automatic Noise Limiter

(ANL). The Noise Blanker is very effective in

eliminating repetitive impulse noise such as ignition

interference. When the switch is moved to the middle

position, only the Automatic Noise Limiter is engaged.

Move the switch to the bottom position to turn off the

ANL and NB.

This control is used to reduce

This control allows you to select

This band selector allow the

This control is used for echo

This control is used to

The front pane' meter

This is a three position

15.TX/RX LED :

the transmit mode. The green indicates the units is in

the receive mode.

16.CHANNEL DISPLAY :

indicates the current selected channel.

The red LED indicates the units is in

This channel display

12.RF POWER HI/LO SWITCH :

to select the HI or LO transmitting power.

13.T.B./OFF SWITCH :

the sound feedback effects.

This switch is used to monitor

This switch is used

Page 6

Rear Panel Connectors

-

0

ANT

PA

SP

o

00

o

0

MADE IN MALA

SIA

0

/

ANTENNA

1.

with a PL-259 type plug.

PA.

2.

SP.

operating, you must first connect a PA speaker (8 ohms,

4W) to this jack.

POWER

3.

built-in fuse. The power cord provided with the radio

has a black and red wire. The black goes to negative

and the red goes to positive

This jack accepts 50 ohms coaxial cable

:

: This jack is used for PA operation. Before

This accepts 13.8V DC power cable with

:

EXISP

PROCEDURE TO RECEIVE AND TRANSMIT

A.

MICROPHONE

The receiver and transmitter are controlled by the push-to-talk

switch on the microphone. Press the switch and the transmitter

is activated, release switch to receive. When transmitting, hold

the microphone two inches from the mouth and speak clearly in

a normal voice. This transceiver comes complete with a low

impedance dynamic microphone.

B. PROCEDURE TO RECEIVE

1.

Be sure that power source, microphone and antenna are

connected to the proper connectors before going to the next

step.

Turn VOL knob clockwise to apply power to the radio.

2.

Set the VOL for a comfortable listening level.

3.

Set the MODE switch to the desired mode.

4.

Listen to the background noise from the speaker. Turn the SQ

5.

knob slowly clockwise until the noise just disappears. The SQ

is now properly adjusted. The receiver will remain quiet until a

not advance the control too far

signal is actually received.

Do

or some of weaker signals will not be heard.

EXT SP.

4.

This jack accepts 4 to 8 ohm,

:

external speaker. When the external speaker is

connected to this jack, the built-in speaker will be

disabled.

F.C.

5.

: This connector is used for an external frequency

counter that indicates the frequency of the selected

channel.

watts

5

Set the CHANNEL selector switch to the desired channel.

6.

7.

Set the

RF GAIN

control fully clockwise for maximum RF

gain.

C. PROCEDURE TO TANSMIT

1. Select the desired channel of transmission

2. Set the

MIC GAIN

control fully clockwise.

Page 7

3. If the channel is clear, depress the push-to-talk switch on the

microphone and speak in a normal voice.

ALTERNATE MICROPHONES AND INSTALLATION

For best results, the user should select a low-impedance

dynamic type microphone or a transistorized microphone.

Transistorized type microphones have low output impedance

characteristics. The microphones must be provided with a five-

lead cable. The audio conductor and its shielded lead comprise

two of the leads. The third lead is for receive control, the fourth

is for grounding and fifth is for transmit control.

The microphone should provide the functions shown in

schematic below.

If the microphone to be used is provided with precut leads,

they must be revised as follows.

Cut leads so that they extend 7/16" beyond the plastic

1.

insulating jacket of the microphone cable.

All leads should be cut to the same length. Strip the ends of

2.

each wire 1/8" and tin the exposed wire.

Before beginning the actual wiring, read carefully the circuit

and wiring information provided with the microphone you select.

Use the minimum heat required in soldering the connections.

Keep the exposed wire lengths to a minimum to avoid shorting

when the microphone plug is reassembled.

5 WIRE MIC CABLE

Pin Number

2

3

4

Fig. 1 Your transceiver microphone schematic.

Mic Cable Lead

Audio Shield

Audio Lead

Transmit Control

Receive Control

KNURLED RING

PIN RECEPTACLE

RETAINING SCREW

A. MICROPHONE CONNECTOR ASSEMBLY

,- WASHER

CABLE CLAMP

RETAINER SCREW(2)

0

E=

-

.0.

B. MICROPHONE CONNECTOR DISASSEMBLED FOR WIRING

Fig. 2 Microphone plug wiring

Page 8

To wire the microphone cable to the plug provided, proceed as

follows

1.

Remove the retaining screw.

Unscrew the housing from the pin receptacle body.

2.

Loosen the two cable clamp retainer screws.

3.

Feed the microphone cable through the housing, knurled ring

4.

and washer as shown Figure 2.

The wires must now be soldered to the pins as indicated in the

5.

above wiring tables. If a vise or clamping tool is available it

should be used to hold the pin receptacle body during the

soldering operation, so that both hands are free to perform the

soldering. If a vise or clamping tool is not available, the pin

receptacle body can be held in a stationary position by inserting

it into the microphone jack on the front panel. The numbers of

the microphone plug are shown in Fig. 3, as viewed from the

back of the plug. Before soldering the wire to the pins, pre-tin

the wire receptacle of each pin of the plug.

make sure that it is placed on the threaded portion of the pin

receptacle body before soldering.

7.

If the microphone jack is used to hold the pin receptacle

during soldering operation, best results are obtained when the

connections to pin 1 and 3 are made first and then the

connections to pins 2, 4 and

soldering and be careful to prevent excessive solder

accumulation on pins, which could cause a short between the

pin and the microphone plug housing.

When all soldering connections to the pins of the microphone

8.

are completed, push the knurled ring and the housing forward

and screw the housing onto the threaded portion of the pin

receptacle body. Note the location of the screw clearance

hole in the plug housing with respect to the threaded hole in

the pin receptacle body. When the housing is completely

threaded into the pin receptacle body, a final fraction of a

turn either clockwise or counterclockwise may be required to

align the screw hole with the threaded hole in the pin

receptacle body. When these are aligned, the retaining screw

is then screwed into place to secure the housing to the pin

receptacle body.

Use a minimum amount of

5.

The two cable clamp retainer screws should now be tightened

9.

to secure the housing to the microphone cord. If the cutting

directions have been carefully followed, the cable clamp

should secure to the insulation jacket of the microphone

cable.

10.

Fig. 3

6. Be sure that the housing and the knurled ring of Figure 2 are

Microphone plug pin numbers viewed from rear of pin

receptacle.

pushed back onto the microphone cable before starting to

solder. If the washer is not captive to the pin receptacle body,

-

12 -

and secure the microphone plug in the transceiver.

Upon completion of the microphone plug wiring, connect

-

13

-

Loading...

Loading...